1. Introduction

More than 80 percent of the consumptive water use in the United States, which is the water lost to the environment, goes to irrigated agriculture [

1]. The Mississippi River Valley alluvial aquifer of the Delta is used by agriculture in Arkansas, Missouri, Mississippi, and Louisiana, and irrigated acreage has more than doubled from 1982 to 2007 [

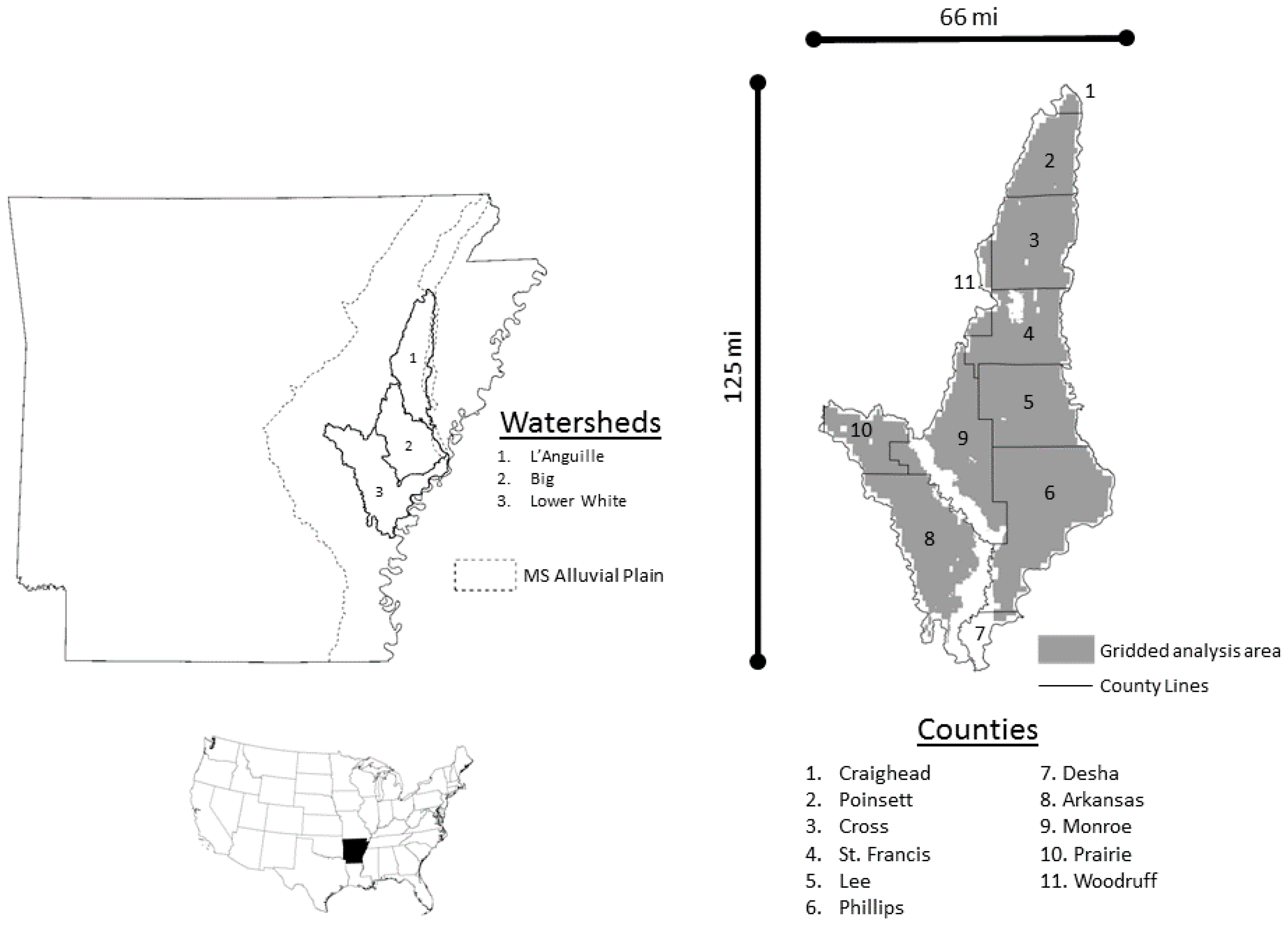

1]. Critical groundwater areas in the Delta region of eastern Arkansas continue to experience decline as groundwater demand outpaces recharge. Demand for groundwater constitutes 81% of the total water demand in the East Arkansas Region (

Figure 1), and a groundwater gap of over seven million acre-feet is projected for 2050 [

2]. A declining aquifer raises the cost of pumping groundwater and risks the future profitability of agriculture, the dominant industry in the region. These risks are amplified by prospects of long-term drought and climate uncertainty. Additional benefits to society of a greater aquifer volume include the avoidance of subsidence, less seepage of surface water from riparian areas vital to wildlife, and less pumping of underlying aquifers used for drinking water in towns. There is a need to move toward sustainable levels of groundwater withdrawal.

Precision agriculture provides the potential to enhance irrigation efficiency through site-specific variable-rate irrigation management of crops. Irrigation efficiency is defined as the ratio of applied water that is beneficially used for crop growth to the total amount of applied water [

3]. The irrecoverable fraction of applied water includes runoff from a geographic area, evaporation, and plant evapotranspiration [

3,

4]. Some fraction of applied irrigation water is recoverable, re-entering the aquifer in the future as deep percolation [

3,

4]. Field-level spatial variability in soil characteristics results in spatial variability of irrigation efficiency and can lead to over- or under- application of water under uniform application conditions. In most cases, a farmer will tend to over-apply to account for uneven distribution of water in the field and maximize yield [

5]. Mapping the variability of appropriate field conditions using remote monitoring methods can allow a farmer to apply variable-rate irrigation management and maintain yields while decreasing water use and groundwater pumping [

6,

7,

8,

9].

Precision agriculture adoption is one means by which farmers can limit the over-application of crop production inputs such as irrigation water and nutrients by using technology to inform site-specific management according to spatially localized conditions [

8,

10,

11]. The spatial information technologies that have enabled precision agriculture include global positioning systems, geographic information systems, remote sensing, and variable-rate application technologies [

12]. Precision agriculture involves combining the functions of these technologies to help with decision-making about crop and soil management in specific field locations [

13].

For the purposes of managing variable irrigation rates, two different paradigms of monitoring field-level spatial variability have emerged and proved effective: one based on monitoring soil properties and the other on monitoring plant conditions [

6,

14,

15]. Hedley and Yule [

6] demonstrated the potential to reduce irrigation water use by using soil–water balance to inform variable-rate irrigation of pre-mapped management zones at two sites in New Zealand. Stone et al. [

16] demonstrated the potential of similar methods in the humid Eastern U.S. Soil-based methods are thought to be superior because they more directly measure water-related stress as a function of plant available water content, whereas it can be more difficult with plant-based methods to separate the effect of the soil moisture property from that of other possible stresses such as nutrient deficiency [

17,

18]. Soil water measurements using soil moisture sensors, however, are only accurate for a small area, and soil water content is highly variable spatially and temporally [

19]. There is evidence that relative spatial variability of soil water content is persistent over time, further indicating the feasibility of variable-rate irrigation based on management zones [

20,

21].

Networks of remote soil moisture sensors have shown the ability to effectively inform variable-rate irrigation and contribute to improvements in irrigation efficiency [

6,

8,

11,

15,

18]. Though the soil moisture sensors themselves perform in-situ measurement of soil properties, these networks of sensors are monitored wirelessly by either an automated system or a user physically removed from the measurement site. In the past, installation of enough soil moisture sensors to capture soil variability has proven costly for farmers and has limited technology adoption [

22,

23]. This technology is getting better and more affordable at the same time that unmanned aerial vehicles are also becoming more economical for the purposes of plant-based remote sensing. Unmanned aircraft can deliver a variety of sensing devices including visual, multispectral, and thermal to monitor different aspects of plant health. There is even potential in the future for these vehicles to serve as the medium by which important production inputs such as seed, fertilizer, and chemical are applied [

24]. Though unmanned aerial vehicles have not been commonly used in agriculture to this point, the Department of Transit and Federal Aviation Administration have recently enacted a clear regulatory framework for small unmanned aerial aircraft, and many expect this to spur more widespread adoption in commercial uses such as agriculture [

25,

26].

We compare the two remote monitoring methods, soil moisture sensors and unmanned aerial vehicles, for cost-effectiveness and net return per acre-foot of aquifer retention by modeling crop production and groundwater use across a spatially-explicit farm landscape in the Delta region of eastern Arkansas. The model evaluates the optimal crop mix and irrigation practices to maximize farm returns across the gridded farm landscape. Spatial variation in crop yields, aquifer thickness, and the costs of groundwater pumping all influence the spatial-dynamic path of optimal management [

27]. The effectiveness of the remote monitoring methods for enhancing profitability and decreased pumping depends on these spatial variations.

The area for the application of our model encompasses three eight-digit hydrologic unit code (HUC) watersheds overlying the Mississippi River Valley alluvial aquifer where groundwater levels are critical (

Figure 1). Eight-digit HUCs define the drainage area of a sub-basin of a river [

28]. In addition to remote monitoring and variable-rate irrigation, we allow for the construction of on-farm reservoirs and tail-water recovery systems to help reduce pumping costs and promote recharge of the underlying aquifer. The impacts of remote monitoring and variable-rate irrigation are evaluated with and without the presence of reservoirs on the landscape. There are also ranges of potential costs and irrigation efficiencies associated with these remote monitoring methods, and the implications of these for investment in the technologies is considered. In addition, the effectiveness of policies that encourage the adoption of the remote monitoring for improved water management and aquifer retention is compared to typical fee and quantity policies for conservation. We describe the model for the dynamics of land cover, water use, and profit maximization in

Section 2. Data for crop land and model parameters are presented in

Section 3.

Section 4 discusses results and sensitivity analyses. We conclude with a discussion of major findings and future research needs.

3. Results

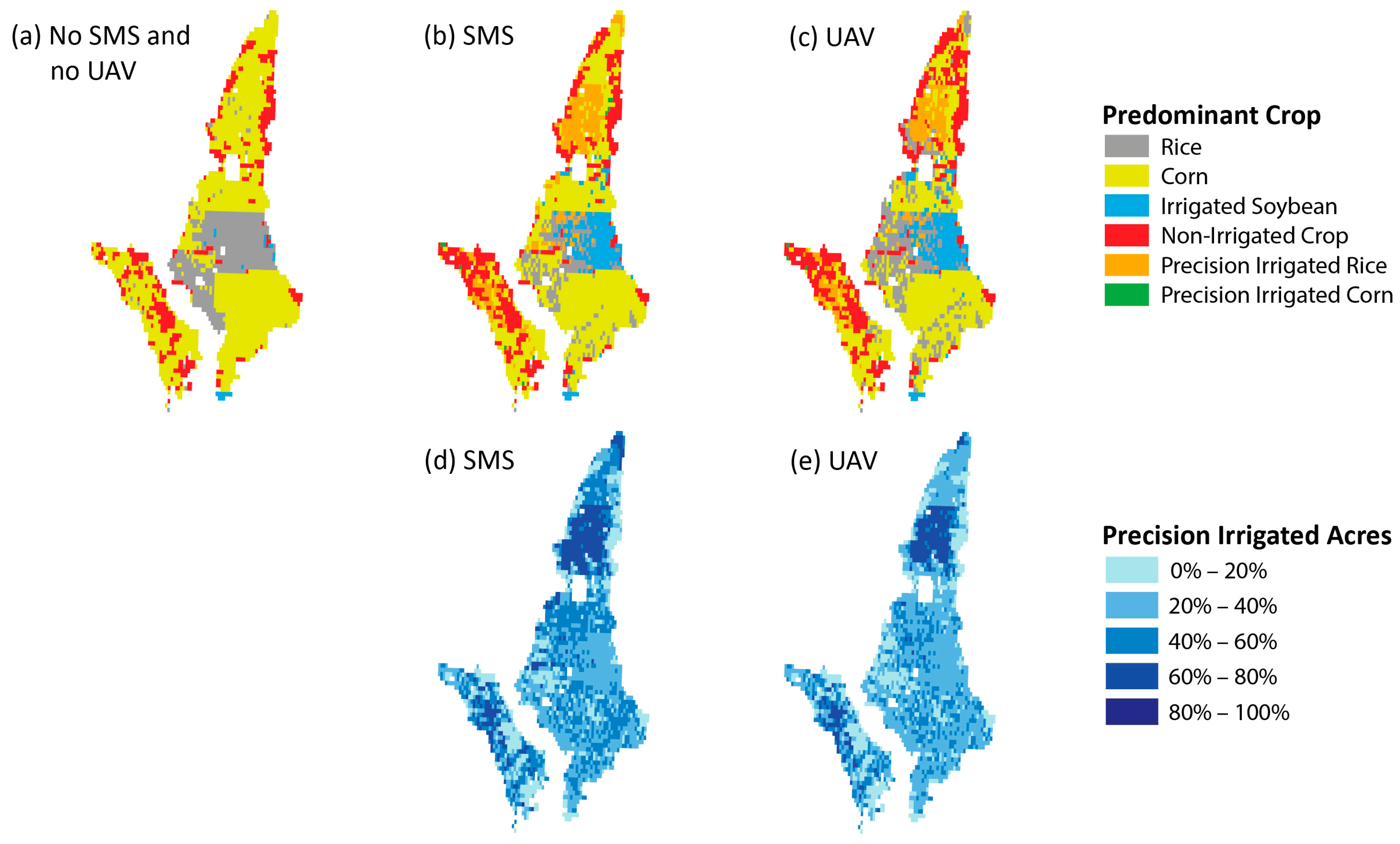

Table 4 indicates the results of the baseline model without precision irrigation or reservoirs. The relative prices over the last 5 years make rice and corn the predominant crops on the landscape at the end of the study period (

Figure 2a), and both are irrigation intensive crops. This makes the aquifer decline from 76 million acre-feet to 48.2 million acre-feet in 2045, and the 30-year farm net returns are $5.22 billion. We compare these results with a landscape where farms adopt soil moisture sensors or unmanned aerial vehicles to reduce the costly application of irrigation water. The use of soil moisture sensors increases the amount of land in rice from 305 thousand acres to 343 thousand acres, and most of the rice acreage adopts soil moisture sensors to mitigate irrigation costs (

Figure 2b). The increase in rice acreage is accompanied by a decline in corn, cotton, soybean, and non-irrigated sorghum acres. Although rice acreage expands, the soil moisture sensors mean less well pumping, and the aquifer in the final period is close to 48.7 million acre-feet.

Figure 2d,e depicts the extent of precision irrigation adoption under each scenario.

The use of unmanned aerial vehicles increases rice acreage to only 316 thousand acres because of the lower irrigation efficiency compared to soil moisture sensors, and much of the rice remains in conventional irrigation. There is a slight decline in the acres of corn, cotton, double crop soybean, and non-irrigated sorghum compared to the baseline (

Figure 2c). The final aquifer volume is 48.6 million acre-feet, slightly lower than the 48.7 million acre-feet with the soil moisture sensors, but higher than the 48.2 million acre-feet baseline. The soil moisture sensors have greater net returns per acre-foot conserved than the unmanned aerial vehicles, $9.09 per acre-foot versus $7.69 per acre-foot, because high-value rice acreage increases more with the soil sensors. The soil moisture sensor technology is more expensive per acre, though, and this makes it a less cost-effective solution for aquifer retention than the unmanned aerial vehicles. The positive net returns indicate that both farmers and conservationists gain from the technologies. Though the utility of unmanned aerial vehicles for precision management through mapping crop water stress has been demonstrated [

57,

58,

59,

60,

61], and plant-based monitoring of water stress to automate variable-rate irrigation has shown the ability to improve irrigation water use [

14], systematic and multidisciplinary research is still necessary to verify and quantify improvements from managing crop inputs based on images from unmanned aerial vehicles [

61,

65].

The presence of on-farm reservoirs and tail-water recovery increases the land in rice and corn compared to the baseline, and the non-irrigated sorghum is nearly gone. When the soil moisture sensors are adopted on the landscape rice increases to 390 thousand acres, corn falls to 672 thousand acres, and the acres in both non-irrigated crop and in reservoirs falls. The aquifer level in the final period rises to 50.4 million acre-feet from 50.2 million acre-feet without the soil moisture sensors. If unmanned aerial vehicles are adopted on the landscape with reservoirs, then the rice acres rise slightly to 357 thousand acres, and the corn acres fall to 678 thousand acres. The acres in reservoirs and non-irrigated sorghum are virtually unchanged from the landscape with reservoirs but without the unmanned aerial vehicles. The aquifer volume increased slightly over the baseline with 50.3 million acre-feet in the final period.

The net returns per acre-foot are higher for the precision irrigation when reservoirs are used on the landscape. This is because more crops use irrigation when reservoirs provide surface water. The farm returns to irrigation that is more efficient and the aquifer retention are magnified by precision irrigation when more of the landscape is using irrigation than before. The net returns per acre are $62 per acre-foot for the soil moisture sensors and $31 per acre-foot for the unmanned aerial vehicles. Looking only at cost-effectiveness for an acre-foot of aquifer retention, though, the unmanned aerial vehicles are preferred since the technology is somewhat less expensive.

The cost and irrigation efficiency of the soil moisture sensors and unmanned aerial vehicles is not known with certainty. We use a low and high-end range for the cost and irrigation efficiency of the precision irrigation technologies to see how crop choice, well pumping, and the farm net returns are affected in

Table 5. For the soil moisture sensors, rice expands to 452 thousand acres for the low cost/high irrigation efficiency scenario while the high cost/low irrigation efficiency scenario has rice expand to just 331 thousand acres. The large expansion of rice in the low cost/high irrigation efficiency scenario makes corn and other crop acreage fall compared to the baseline, and even though more irrigation intensive rice is grown, the well pumping falls to 1422 thousand acre-feet in the final period because the soil moisture sensors increase irrigation efficiency. The crop mix in the high cost/low irrigation efficiency scenario for the soil moisture sensors is largely the same as the landscape without the soil moisture sensors. The well pumping, though, does fall from the baseline to 1433 thousand acre-feet in the final period because of soil moisture sensor adoption.

These crop and water use changes on the landscape from the soil moisture sensor use make the 30-year farm net returns edge up slightly with the high cost/low irrigation efficiency scenario and go up substantially to $5.40 billion in the low cost/high irrigation efficiency scenario. The aquifer rises to 50.2 million acre-feet in the low cost/high irrigation efficiency scenario and to just 48.6 million acre-feet in the high cost/low irrigation efficiency scenario. The net-benefit assessment indicates $90 per acre-foot if the soil moisture sensors are low cost and high efficiency, and a modest $8.57 per acre-foot for high cost and low efficiency sensors. This means there is a wide range of potential net returns to an optimized landscape allowing the use of soil moisture sensors, but implementation that more closely approximates the low cost/high irrigation efficiency scenario can generate substantial gains to both farmers and the aquifer. The use of unmanned aerial vehicles makes the rice acreage expand to 430 thousand acres in the low cost/high irrigation efficiency scenario but fall slightly to 304 thousand acres in the high cost/low irrigation efficiency scenario. The low cost/high irrigation efficiency scenario for unmanned aerial vehicles has 1338 thousand acre-feet of well pumping in the final period because the unmanned aerial vehicles allow for a reduction in water use even as rice acres expand. There are 1437 thousand acre-feet of well pumping in the final period for the high cost/low efficiency scenario, only slightly below the baseline, because there is limited adoption of the unmanned aerial vehicles when the irrigation efficiency is low. The aquifer rises to 49.7 million acre-feet and 30-year farm net returns rise to $5.3 billion in the low cost/high efficiency scenario; however, the aquifer rises to only 48.4 million acre-feet and $5.2 billion in 30-year farm net returns for the high cost/low irrigation efficiency scenario. The wide range in the net returns per acre-foot for the low and high-end scenarios, from $70 to $5.55 per acre-foot, for the unmanned aerial vehicles indicates, as for the soil sensors, that improving the efficiency of the technology is valuable for profitability and aquifer retention.

The use of cost-share assistance to encourage precision irrigation, shown in

Table 6, improves farm net returns over 30 years and increases the volume of the aquifer, but the subsidy represents a loss of government revenue that the taxpayer must bear. The policies result in a loss of economic value to society because the rise in farm net returns is less than the loss in government revenue. However, these polices allow more of the aquifer to be retained. The groundwater conservation cost per acre-foot for the study period is found by dividing the economic cost to society of the policy by the acre-feet of the aquifer conserved. The soil moisture sensors are more irrigation-efficient and only slightly more expensive than the unmanned aerial vehicles, and this makes the $59 groundwater conservation cost per acre-foot for the cost-share on the soil moisture sensors less than the $67 cost per acre-foot for the unmanned aerial vehicles. The cost-share policies are both expensive, however, compared to the groundwater conservation cost associated with policies such as a cap on groundwater use ($12/acre-foot) or a fee on groundwater use ($1.6 acre-foot). Policies that target groundwater use directly through a cap or tax appear more cost-effective at groundwater conservation than the policies that offer a cost-share on irrigation technology for crops such as cotton and soybeans that are not especially irrigation intensive.

4. Discussion

Our results support the conclusion that remote monitoring to inform variable-rate irrigation practices is an increasingly viable alternative for reducing groundwater depletion through precision agriculture. We demonstrate that remote monitoring to inform variable-rate irrigation can improve irrigation efficiency modestly enough to conserve aquifer volumes, reduce pumping costs, and increase net returns by still allowing for more production of profitable but water-intensive rice. Furthermore, our results indicate the potential of remote monitoring and variable-rate irrigation to provide benefits in tandem with other complimentary practices such as the use of the on-farm reservoirs.

The uncertainty around the cost and water-use efficiency of the remote sensing techniques suggest that the net-returns per acre-foot of aquifer retention could be significantly larger or a little lower than the baseline costs and water use efficiencies for the precision irrigation techniques suggest. As the costs of the sensors fall and the efficiencies continue to improve, then the net returns per acre-foot of conserved aquifer promise to become substantially larger. As an important reminder, our model makes the simplifying assumption that all reduction in applied water due to improved irrigation efficiency saves irrecoverable fractions of applied irrigation water. While the overwhelming proportion of annual recharge to the alluvial aquifer is the result of precipitation and surface water flux [

37], precision irrigation scenarios may overestimate the aquifer volume by failing to account for decreased levels of deep percolation over the long term.

A cost-share policy to encourage more adoption of the sensing technologies appears to incur greater costs on society than either a regulatory cap of groundwater use or tax on groundwater use. Leaving aside issues surrounding an equitable share of the conservation burden across the agricultural producers and the rest of society, the most efficient approach to conservation is through directly targeting the overused resource with a cap or a tax.

The evaluation of benefits and costs here between soil moisture sensors and unmanned aerial vehicles only considers increased performance in irrigation efficiency with respect to soil-based versus plant-based monitoring regimes. We do not consider other benefits of variable-rate irrigation or other applications of remote monitoring which might present other benefits. Another implication of targeted spatial application of irrigation is that nutrient and sediment runoff is minimized, improving the quality of surface waters [

66]. In addition, it may be possible to monitor a range of other plant conditions with unmanned aerial vehicles at little additional cost that are not able to be measured by wireless soil moisture sensors [

24]. Explicit spatial management of other crop conditions might even allow farmers to realize more fully the benefits of high spatial resolution monitoring. For instance, producers may be able to improve the efficiency of nutrient application and uptake in a way that both lowers costs and increases yield. Although many farms may already have spatial soil information, we do not know how many have this information or how many use any form of precision agriculture. To be conservative in the adoption rates of this technology, we attribute all the costs of this spatial soil information to the soil sensors. To the extent most farmers already have this information, the soil moisture sensors will be more profitable than we have indicated.

The soil sensor technologies resemble a constant return to scale technology more than other irrigation equipment like center pivots or on-farm reservoirs. This is because soil sensors only have a particular spatial radius where they are effective. However, the unmanned aerial vehicle technologies do exhibit economies of scale, and the unquestionable improvement in these technologies is likely to further increase consolidation in the farming sector. The average farm size in the region has risen from 750 acres in 2002 to 820 acres in 2012 [

35]. Improved sensing technologies are likely to augment this trend.

As costs associated with unmanned aerial vehicles or their services decrease and monitoring applications increase, the aircraft are likely to surpass soil moisture sensors in terms of both cost-effectiveness of aquifer savings and net returns. Given that the most attractive policy alternative among the farming community also comes at the greatest cost to society, it may be that widespread implementation of one of these practices depends on a continued drop in costs. Future work should continue to explore the role of precision technology and high-resolution monitoring in agriculture by giving needed attention to adapting best practices to region-specific constraints. Toward this goal, it will be important to continue to characterize the benefits and costs of these applications under different environmental and economic conditions.