A Laboratory Study on the Filtration and Clogging of the Sand-Bottom Ash Mixture for Stormwater Infiltration Filter Media

Abstract

:1. Introduction

2. Materials and Methods

2.1. Filter Media and Properties

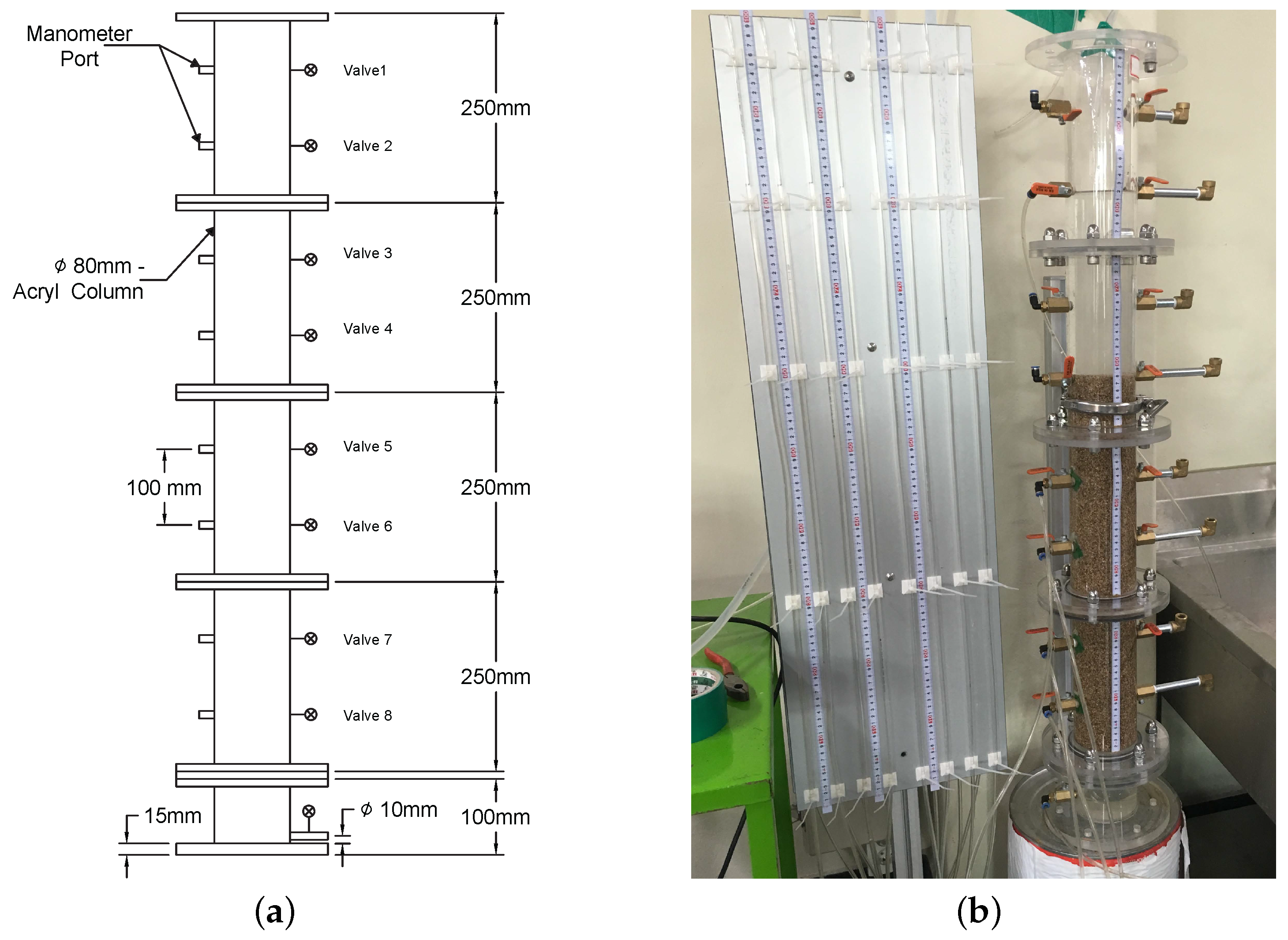

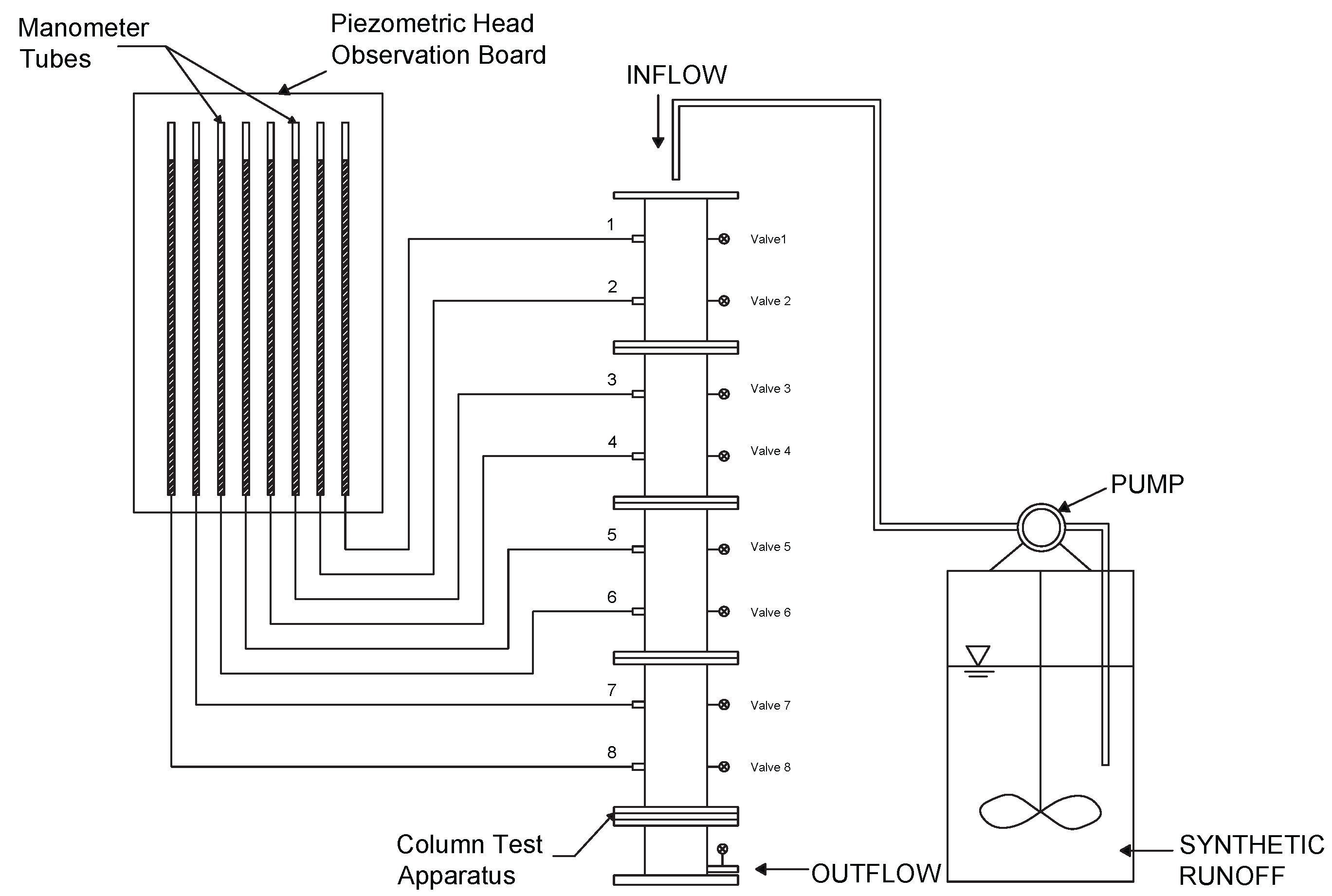

2.2. Improvised 1-Dimensional Column Infiltration Apparatus

2.3. Experiment Methods

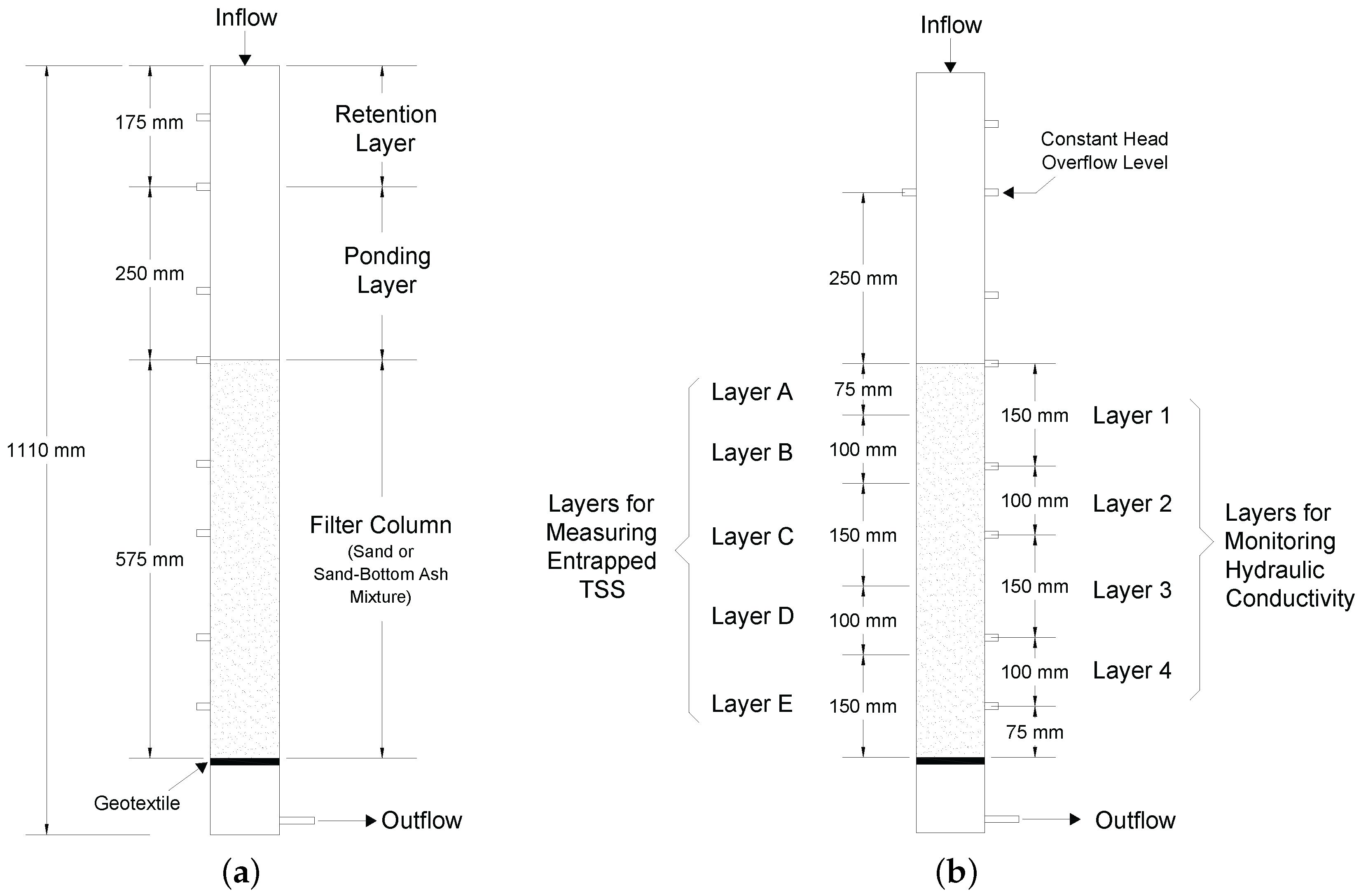

2.3.1. Filter Columns and Synthetic Stormwater

2.3.2. Infiltration Experiments

2.4. Measurement and Analysis

3. Results and Discussion

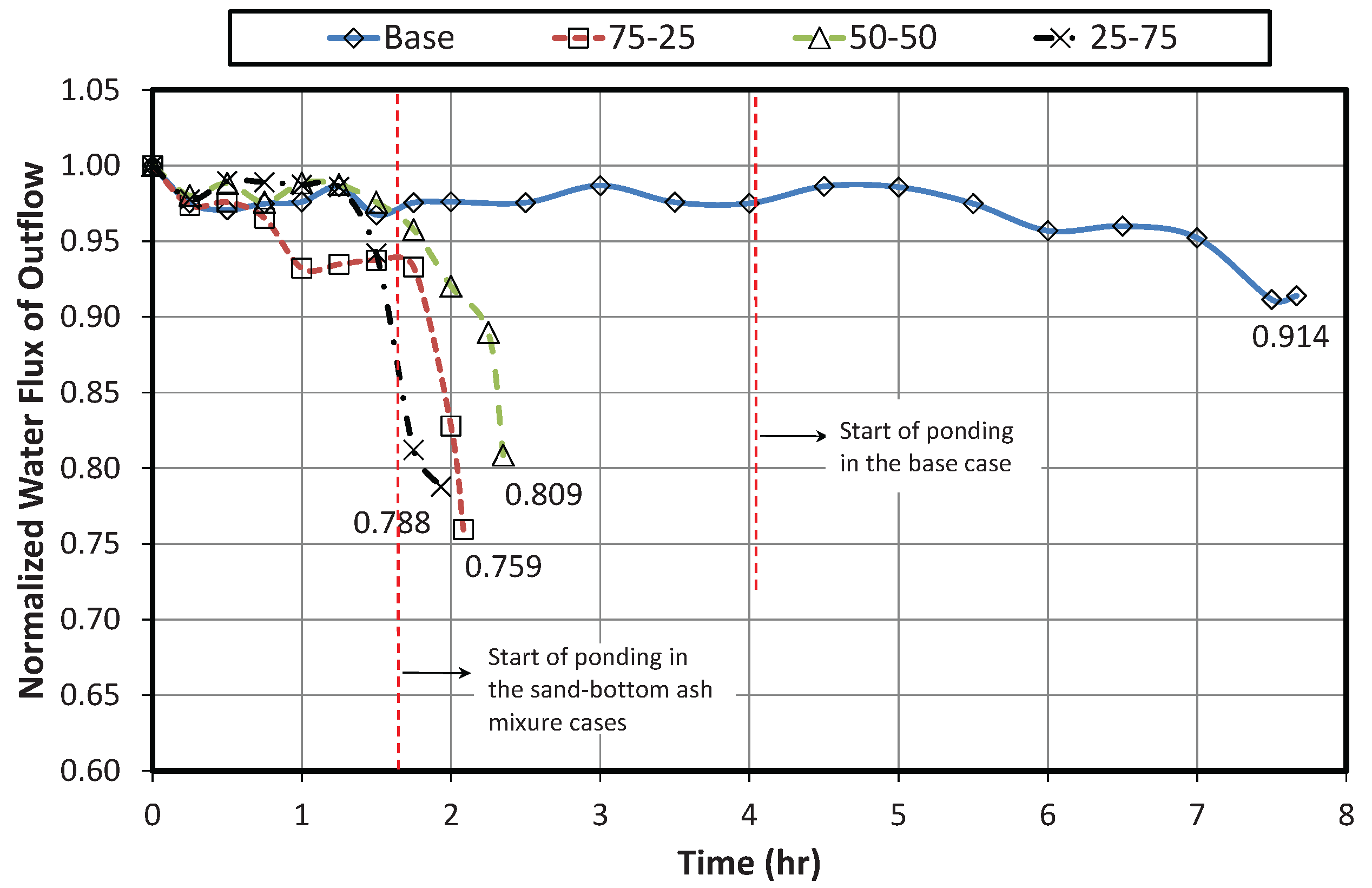

3.1. Varying Head Flow Condition

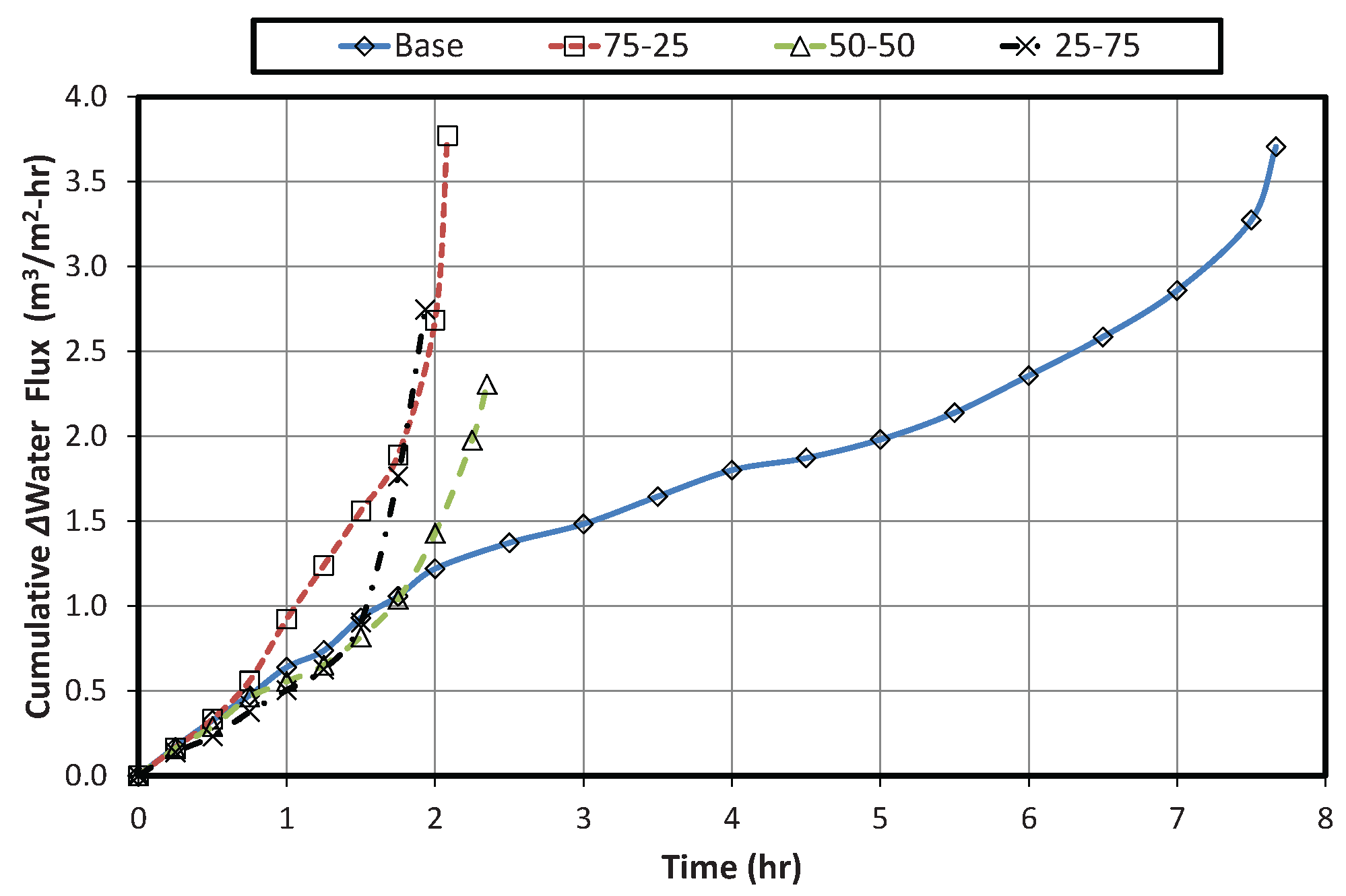

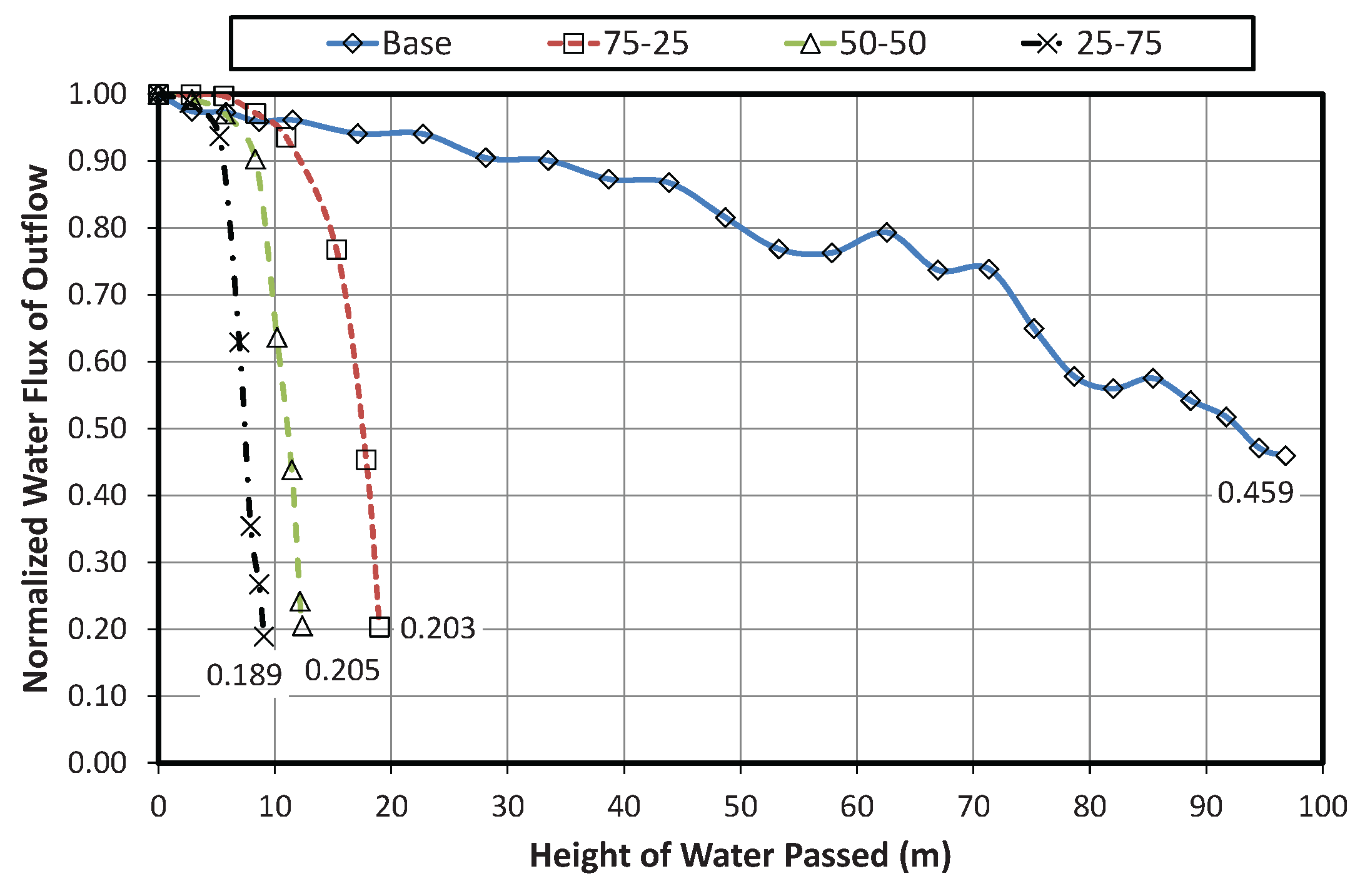

3.1.1. Clogging Characteristics

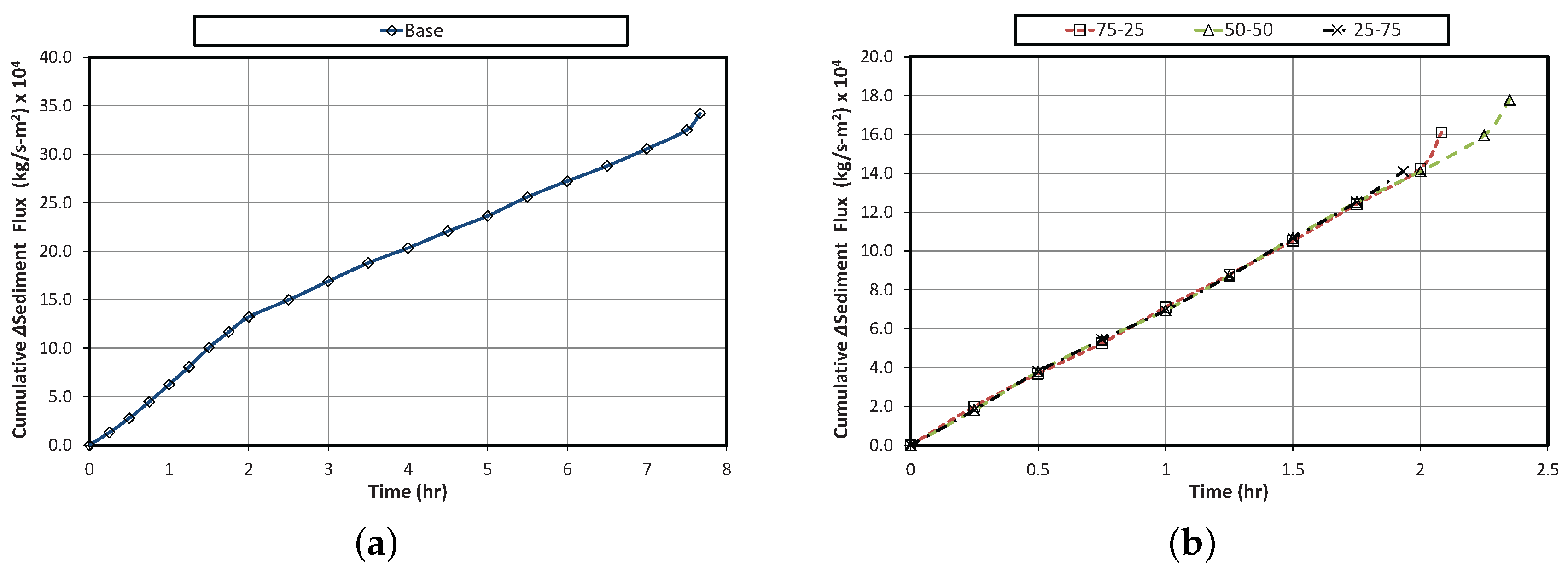

3.1.2. Trapped Sediments in Filter Column

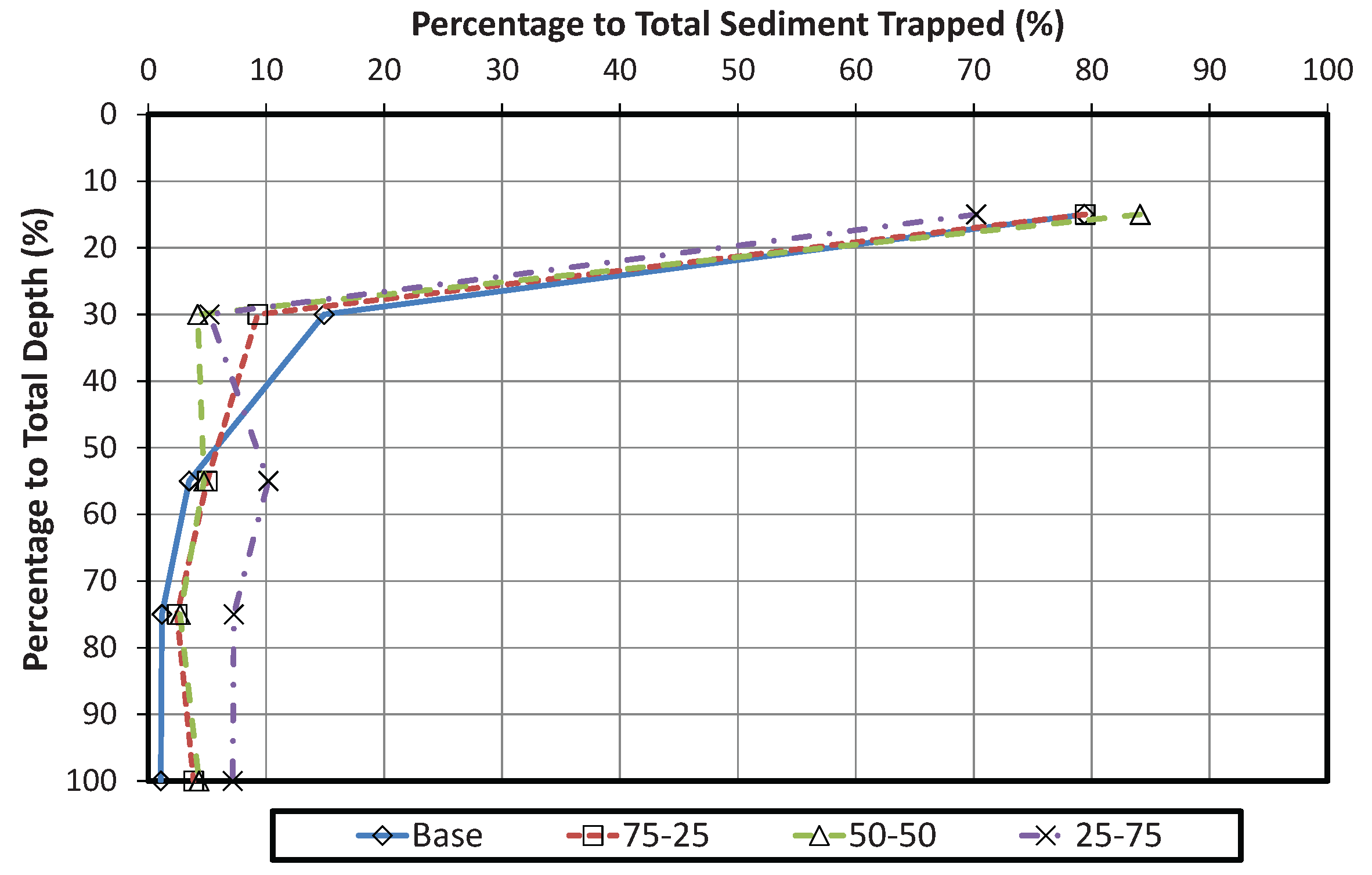

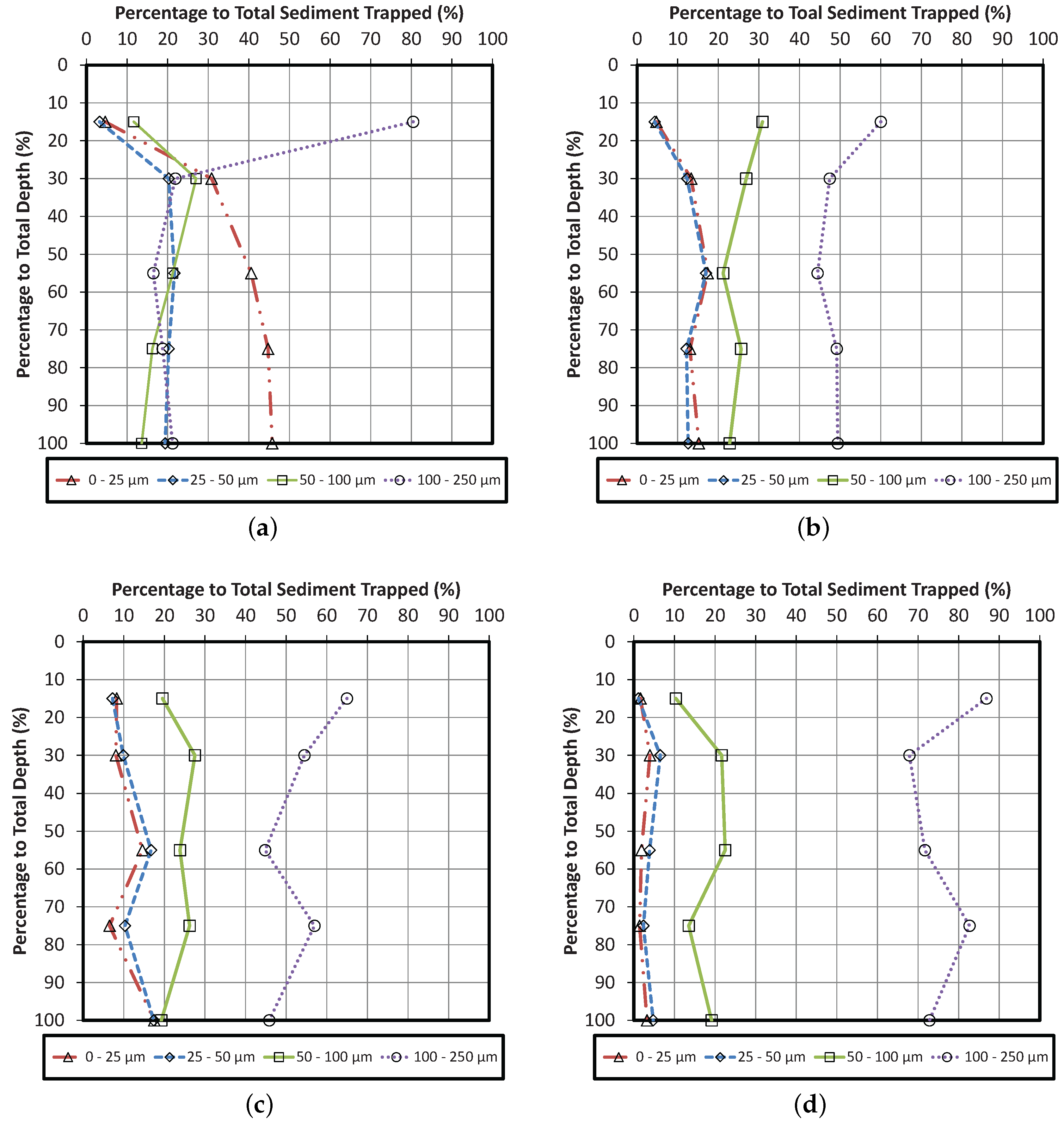

3.1.3. Influence of Sediment Particle Size on Clogging

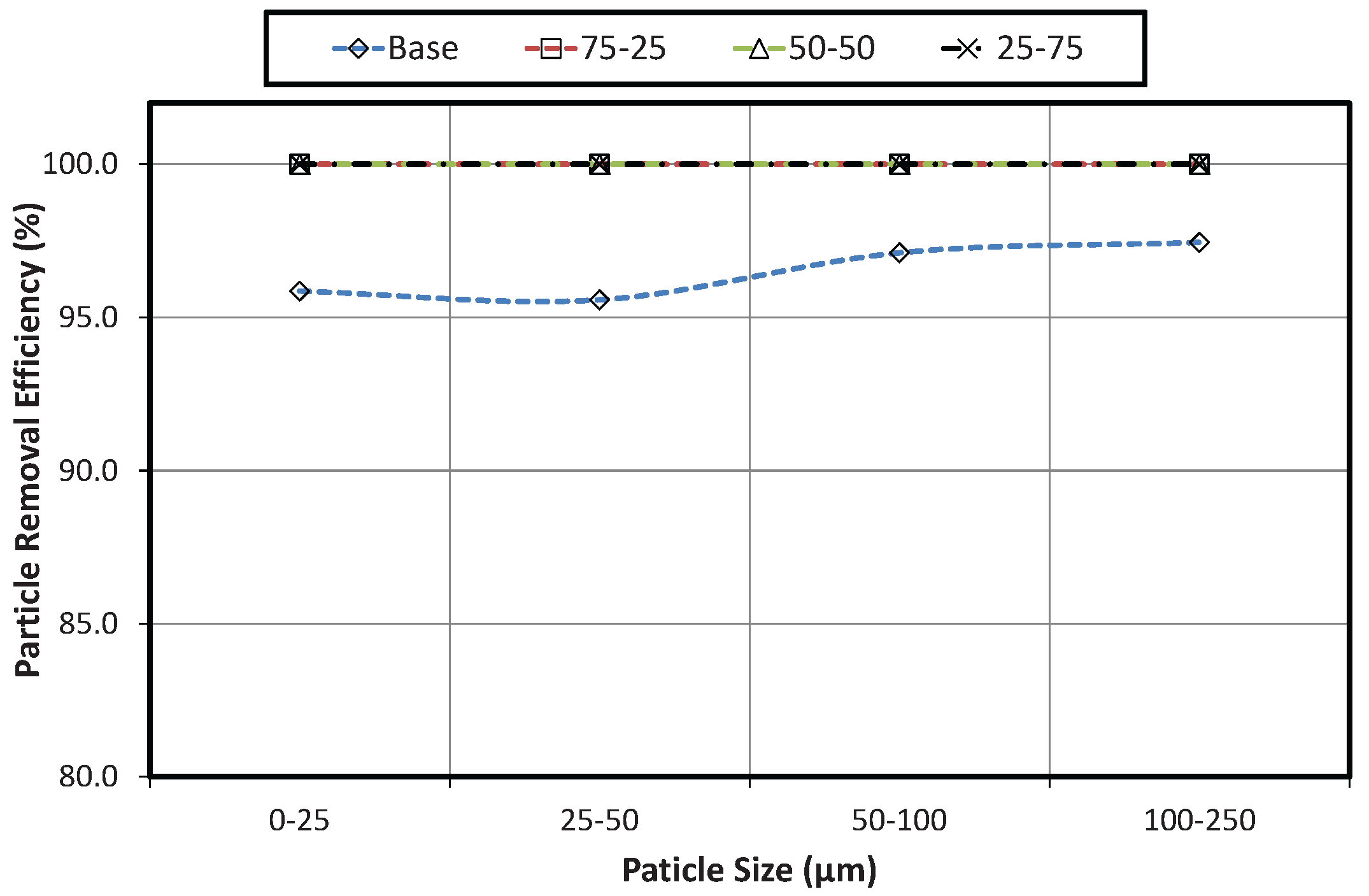

3.1.4. Sediment Removal Efficiency

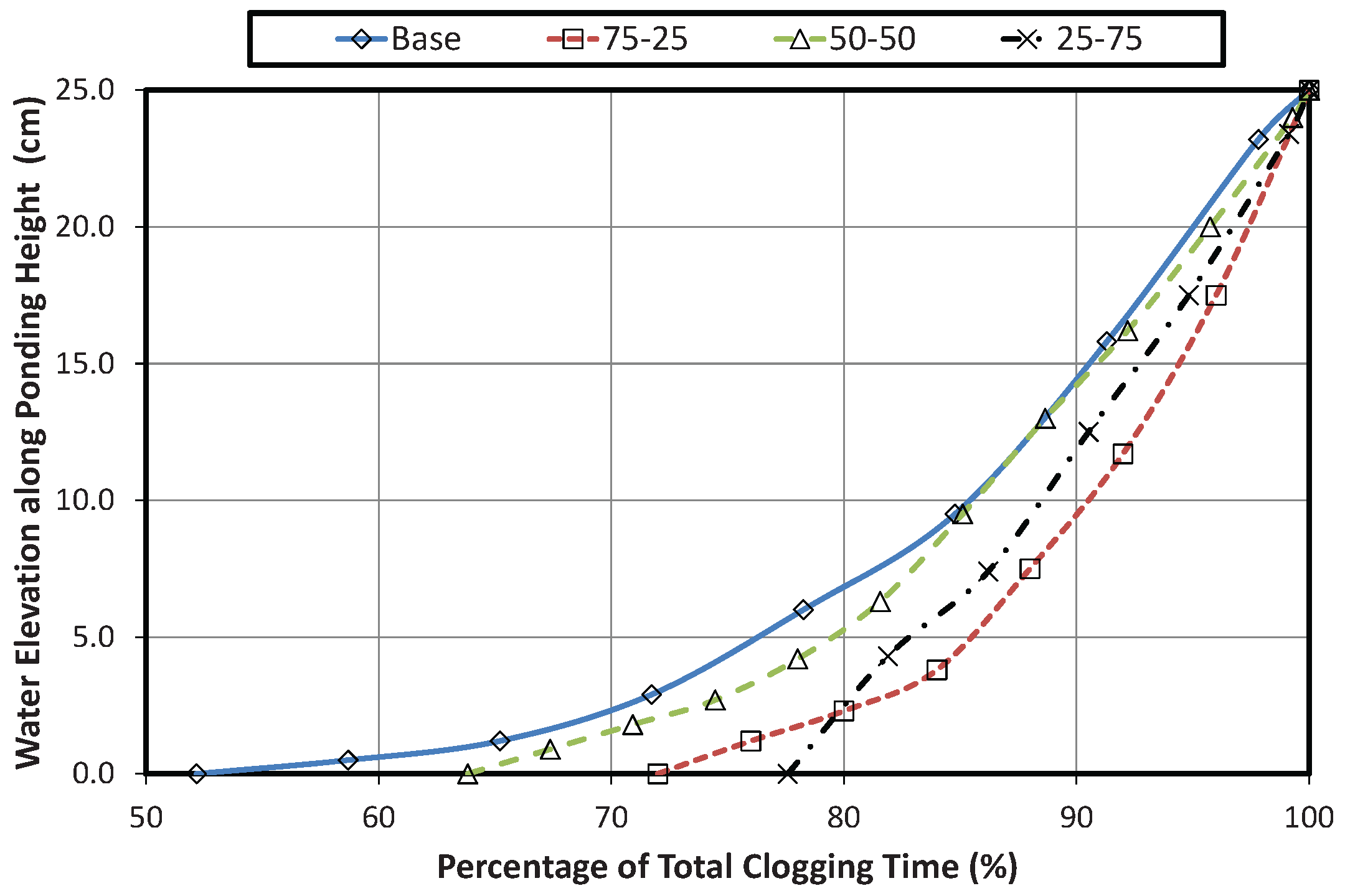

3.1.5. Increase in Water Elevation at the Column Ponding Section

3.2. Constant Head Flow Condition

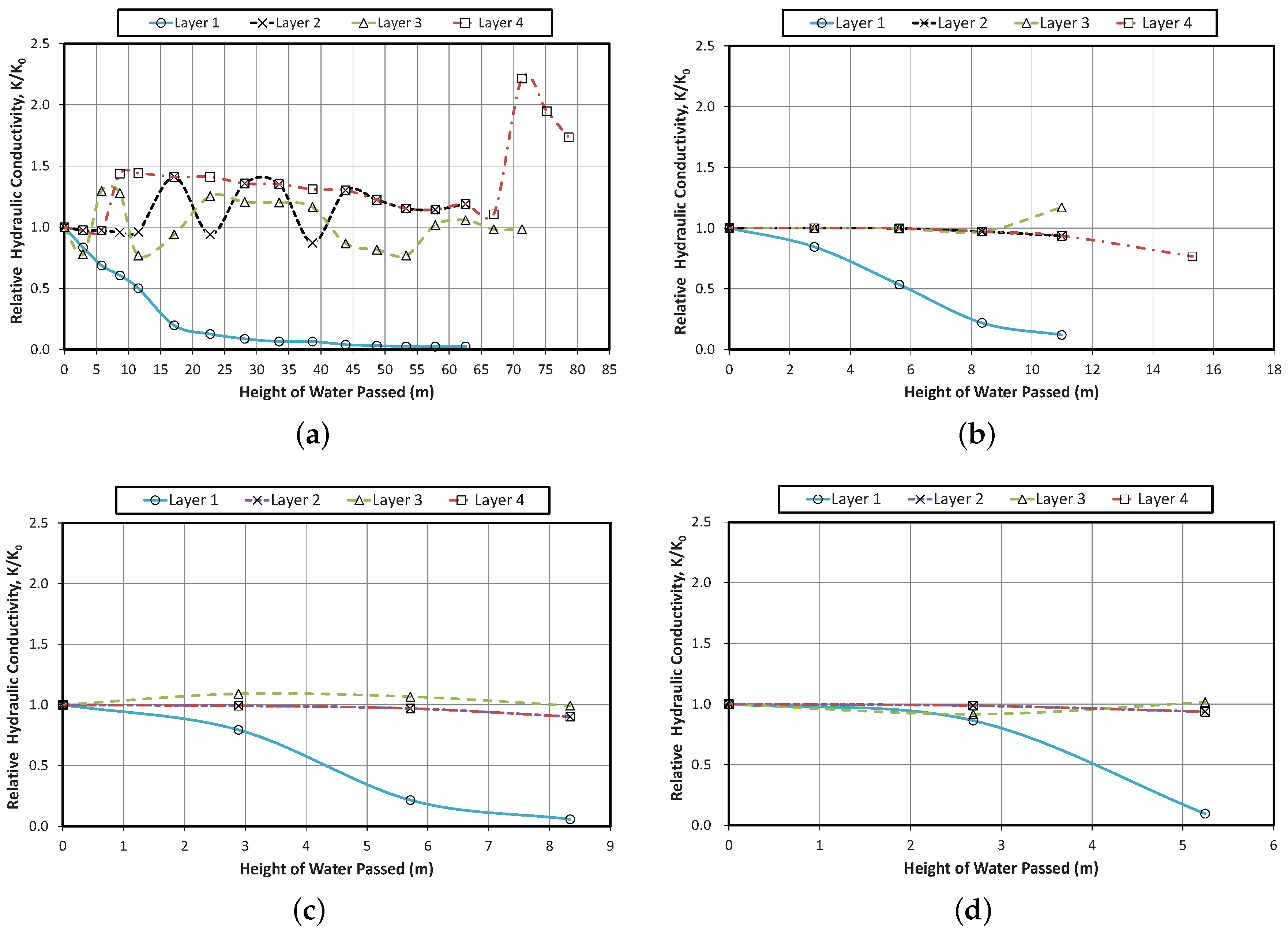

3.2.1. Clogging Characteristics and Hydraulic Conductivity Reduction

3.2.2. Trapped Sediments in Filter Column

3.2.3. Influence of Sediment Particle Size on Clogging

3.2.4. Sediment Removal Efficiency

4. Conclusions

Varying head condition

- Premature clogging prevailed in all performed column experiments wherein the base case experienced the least amount of reduction in hydraulic conductivity.

- The fraction amount of bottom ash used as filter media greatly affects the possibility of clogging. The sand-bottom ash mixing ratio of 50-50, 75-25, and 25-75 were the sequence order that induces a more clogged and shorter filter life span.

- Similar with previous study [21], a “cake-like” layer, which was mostly made up of 100–250 m sediment particle size, was found to form at the upper 15% of the filter media depth regardless of media configuration being used.

- Seepage forces under varying head flow induced particle breakage, most likely on bottom ash filter media, which increased the amount of sediment particles of size less than 250 m present along the filter media depth. An increase in bottom ash fraction used as filter media had resulted in an increase in amount of accumulated sediments found at the deeper depths of the filter column.

- All sand-bottom ash filter media gave 100 % particle removal efficiency in all sediment particle size range; whereas, single sand layer exhibited a particle removal efficiency range values of 87%–93%.

Constant head condition

- The clogging state prevailed in all the sand-bottom ash cases wherein it was identified that the clogging time experienced by the system was inversely proportional to the fraction of bottom ash present as filter media. The base case was the only configuration that reached the target amount of water to be treated.

- The accumulation of sediments created a “cake-like” layer that was found to form at the upper 15% of filter depth regardless of filter media mix. The said formed layer was found to be responsible for the overall reduction in hydraulic conductivity.

- Hydraulic conductivity reduction and fluctuation of all cases were mainly directed to the formation of clogging layer, and the rearrangement and re-entrainment of filter media.

- Seepage forces brought by constant head flow induced a noticeable amount of particle breakage on bottom ash filter media that resulted in an increase in amount of 100–250 m sediment present along its filter media depth. The increase in amount of accumulated sediments found at the deeper depth of the filter column was directly proportional to the amount of bottom ash presented as filter media; however the observed increase in accumulated sediments was less as compared with the obtained results from varying head flow clogging experiment.

- Sediment removal efficiency in all particle sizes improved with reference to its performance during varying head flow test.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Corbett, C.W.; Wahl, M.; Porter, D.E.; Edwards, D.; Moise, C. Nonpoint source runoff modeling. A comparison of a forested watershed and an urban watershed on the South Carolina coast. J. Exp. Mar. Biol. Ecol. 1997, 213, 133–149. [Google Scholar] [CrossRef]

- Paul, M.J.; Meyer, J.L. Streams in the urban landscape. Ann. Rev. Ecol. Syst. 2001, 32, 333–365. [Google Scholar] [CrossRef]

- US Environmental Protection Agency. National Water Quality Inventory: Report to Congress; Technical Report; US Environmental Protection Agency: Washington, DC, USA, 2002.

- Yong, C.; McCarthy, D.; Deletic, A. Predicting physical clogging of porous and permeable pavements. J. Hydrol. 2013, 481, 48–55. [Google Scholar] [CrossRef]

- Li, H.; Davis, A.P. Urban particle capture in bioretention media. II: Theory and model development. J. Environ. Eng. 2008, 134, 419–432. [Google Scholar] [CrossRef]

- Langergraber, G.; Haberl, R.; Laber, J.; Pressl, A. Evaluation of substrate clogging processes in vertical flow constructed wetlands. Water Sci. Technol. 2003, 48, 25–34. [Google Scholar] [PubMed]

- Bouwer, H. Artificial recharge of groundwater: Hydrogeology and engineering. Hydrogeol. J. 2002, 10, 121–142. [Google Scholar] [CrossRef]

- Dillon, P.; Hickinbotham, M.; Pavelic, P. Review of Internation Experience in Injecting Water into Aquifers for Storage and Reuse; Water Down Under 94: Groundwater Papers; reprints of Papers; Institution of Engineers: Barton, Australia, 1994; pp. 13–19. [Google Scholar]

- Hatt, B.E.; Fletcher, T.D.; Deletic, A. Treatment performance of gravel filter media: Implications for design and application of stormwater infiltration systems. Water Res. 2007, 41, 2513–2524. [Google Scholar] [CrossRef] [PubMed]

- Rinck-Pfeiffer, S.; Ragusa, S.; Sztajnbok, P.; Vandevelde, T. Interrelationships between biological, chemical, and physical processes as an analog to clogging in aquifer storage and recovery (ASR) wells. Water Res. 2000, 34, 2110–2118. [Google Scholar] [CrossRef]

- Knowles, P.; Dotro, G.; Nivala, J.; García, J. Clogging in subsurface-flow treatment wetlands: Occurrence and contributing factors. Ecol. Eng. 2011, 37, 99–112. [Google Scholar] [CrossRef]

- Page, D.; Miotlinski, K.; Dillon, P.; Taylor, R.; Wakelin, S.; Levett, K.; Barry, K.; Pavelic, P. Water quality requirements for sustaining aquifer storage and recovery operations in a low permeability fractured rock aquifer. J. Environ. Manag. 2011, 92, 2410–2418. [Google Scholar] [CrossRef] [PubMed]

- Page, D.; Vanderzalm, J.; Miotlinski, K.; Barry, K.; Dillon, P.; Lawrie, K.; Brodie, R.S. Determining treatment requirements for turbid river water to avoid clogging of aquifer storage and recovery wells in siliceous alluvium. Water Res. 2014, 66, 99–110. [Google Scholar] [CrossRef] [PubMed]

- Blazejewski, R.; Murat-Blazejewska, S. Soil clogging phenomena in constructed wetlands with subsurface flow. Water Sci. Technol. 1997, 35, 183–188. [Google Scholar] [CrossRef]

- Winter, K.J.; Goetz, D. The impact of sewage composition on the soil clogging phenomena of vertical flow constructued wetlands. Water Sci. Technol. 2003, 48, 9–14. [Google Scholar] [PubMed]

- Larmet, H.; Delolme, C.; Bedell, J. Bacteria and heavy metals concomitant transfer in an infiltration basin: Columns study under realistic hydrodynamical conditions. In Proceedings of the NOVATECH 2007: 6th International Conference on Sustainable Techniques and Strategies in Urban Water Management, Lyon, France, 25–28 June 2007; pp. 615–622.

- Le Coustumer, S.; Fletcher, T.D.; Deletic, A.; Barraud, S.; Poelsma, P. The influence of design parameters on clogging of stormwater biofilters: A large-scale column study. Water Res. 2012, 46, 6743–6752. [Google Scholar] [CrossRef] [PubMed]

- Kandra, H.S.; McCarthy, D.; Fletcher, T.D.; Deletic, A. Assessment of clogging phenomena in granular filter media used for stormwater treatment. J. Hydrol. 2014, 512, 518–527. [Google Scholar] [CrossRef]

- Treumann, S.; Torkzaban, S.; Bradford, S.A.; Visalakshan, R.M.; Page, D. An explanation for differences in the process of colloid adsorption in batch and column studies. J. Contam. Hydrol. 2014, 164, 219–229. [Google Scholar] [CrossRef] [PubMed]

- Kandra, H.S.; Deletic, A.; McCarthy, D. Assessment of Impact of Filter Design Variables on Clogging in Stormwater Filters. Water Resour. Manag. 2014, 28, 1873–1885. [Google Scholar] [CrossRef]

- Segismundo, E.Q.; Lee, B.S.; Kim, L.H.; Hong, K.B. Evaluation of the impact of filter media depth in filtration performance and clogging formation of a stormwater sand filter. J. Korean Soc. Water Environ. 2016, 32, 36–45. [Google Scholar] [CrossRef]

- Reddi, L.N.; Ming, X.; Hajra, M.G.; Lee, I.M. Permeability reduction of soil filters due to physical clogging. J. Geotech. Geoenviron. Eng. 2000, 126, 236–246. [Google Scholar] [CrossRef]

- Siriwardene, N.R.; Deletic, A.; Fletcher, T.D. Clogging of stormwater gravel infiltration systems and filters: Insights from a laboratory study. Water Res. 2007, 41, 1433–1440. [Google Scholar] [CrossRef] [PubMed]

- Kandra, H.S.; Callaghan, J.; Deletic, A.; Mccarthy, D.T. Biological clogging in storm water filters. J. Environ. Eng. 2014, 141. [Google Scholar] [CrossRef]

- Mercado, J.M.R.; Maniquiz-Redillas, M.C.; Kim, L.H. Laboratory study on the clogging potential of a hybrid best management practice. Desalin. Water Treat. 2015, 53, 3126–3133. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency. Wastewater Technology Fact Sheet: Intermittent Sand Filters; Technical Report; U.S. Environmental Protection Agency: Washington, DC, USA, 1999.

- Clark, S.; Pitt, R. Stormwater Treatment at Critical Areas: Evaluation of Filtration Media; Technical Report; U.S. Environmental Protection Agency: Cincinnati, OH, USA, 1999.

- Gorme, J.B.; Maniquiz-Redillas, M.C.; Kim, L.H. Development of a stormwater treatment system using bottom ash as filter media. Desalin. Water Treat. 2015, 53, 3118–3125. [Google Scholar] [CrossRef]

- Shim, Y.S.; Kim, Y.K.; Kong, S.H.; Rhee, S.W.; Lee, W.K. The adsorption characteristics of heavy metals by various particle sizes of MSWI bottom ash. Waste Manag. 2003, 23, 851–857. [Google Scholar] [CrossRef]

- ASTM D2487-06—Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System); ASTM International: West Conshohocken, PA, USA, 2006.

- ASTM D422-63—Standard Test Method for Particle-Size Analysis of Soils; ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM D854-14—Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer; ASTM International: West Conshohocken, PA, USA, 2014.

- Huisman, L.; Wood, W. Slow Sand Filtration; World Health Organization: Geneva, Switzerland, 1974; p. 122. [Google Scholar]

- Duncan, H.P. Urban Stormwater Quality: A Statistical Overview (Report 99/3); Technical Report; Cooperative Research Centre for Catchment Hydrology: Melbourne, Australia, 1999. [Google Scholar]

- Morganti, L. Sodium Hypochlorite Generation for Household Water Disinfection: A Case Study in Nepal. Master’s Thesis, MIT Department of Civil and Environmental Engineering, Boston, MA, USA, 2002. [Google Scholar]

- Maniquiz, M.C.; Lee, S.; Kim, L.H. Multiple linear regression models of urban runoff pollutant load and event mean concentration considering rainfall variables. J. Environ. Sci. 2010, 22, 946–952. [Google Scholar] [CrossRef]

- Greenberg, A.; Clesceri, L.; Eaton, A. Standard Methods for the Examination of Water and Wastewater, 18th ed.; American Public Health Association (APHA): Washington, DC, USA, 1992. [Google Scholar]

- Weber-Shirk, M.; Dick, R. Physical-chemical mechanisms in slow sand filters. J. Am. Water Works Assoc. 1997, 89, 87–100. [Google Scholar]

- Wang, Z.; Du, X.; Yang, Y.; Ye, X. Surface clogging process modeling of suspended solids during urban stormwater aquifer recharge. J. Environ. Sci. (China) 2012, 24, 1418–1424. [Google Scholar] [CrossRef]

- Hua, G.F.; Zhu, W.; Zhao, L.F.; Huang, J.Y. Clogging pattern in vertical-flow constructed wetlands: Insight from a laboratory study. J. Hazard. Mater. 2010, 180, 668–674. [Google Scholar] [CrossRef] [PubMed]

- Roger, S.; Montrejaud-Vignoles, M.; Andral, M.C.; Herremans, L.; Fortune, J.P. Mineral, physical and chemical analysis of the solid matter carried by motorway runoff water. Water Res. 1998, 32, 1119–1125. [Google Scholar] [CrossRef]

- Vaze, J.; Chiew, F.H.S. Nutrient loads associated with different sediment sizes in urban stormwater and surface pollutants. J. Environ. Eng. 2004, 130, 391–396. [Google Scholar] [CrossRef]

- Bian, B.; Zhu, W. Particle size distribution and pollutants in road-deposited sediments in different areas of Zhenjiang, China. Environ. Geochem. Health 2009, 31, 511–520. [Google Scholar] [CrossRef] [PubMed]

| Filter Media | Classification of Filter Column | Mix Ratio (Sand:Bottom Ash) | Particle Size Range (mm) | G | C | C | Porosity |

|---|---|---|---|---|---|---|---|

| Sand a | Base | - | 2.00–4.75 | 2.64 | 1.60 | 0.96 | 0.509 |

| Bottom Ash b | - | - | 0.85–2.00 | 2.14 | 1.29 | 0.97 | - |

| Sand- | 25:75 Mix | 25:75 | 0.85–4.75 | - | 1.58 | 1.12 | 0.676 |

| Bottom Ash | 50:50 Mix | 50:50 | 0.85–4.75 | - | 1.37 | 1.05 | 0.632 |

| Mix | 75:25 Mix | 75:25 | 0.85–4.75 | - | 1.39 | 0.89 | 0.577 |

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Segismundo, E.Q.; Kim, L.-H.; Jeong, S.-M.; Lee, B.-S. A Laboratory Study on the Filtration and Clogging of the Sand-Bottom Ash Mixture for Stormwater Infiltration Filter Media. Water 2017, 9, 32. https://doi.org/10.3390/w9010032

Segismundo EQ, Kim L-H, Jeong S-M, Lee B-S. A Laboratory Study on the Filtration and Clogging of the Sand-Bottom Ash Mixture for Stormwater Infiltration Filter Media. Water. 2017; 9(1):32. https://doi.org/10.3390/w9010032

Chicago/Turabian StyleSegismundo, Ezequiel Q., Lee-Hyung Kim, Sang-Man Jeong, and Byung-Sik Lee. 2017. "A Laboratory Study on the Filtration and Clogging of the Sand-Bottom Ash Mixture for Stormwater Infiltration Filter Media" Water 9, no. 1: 32. https://doi.org/10.3390/w9010032