Using Chemically Enhanced Primary Treatment (CEPT) as a Pretreatment Option for Anaerobic Digestate from Cattle Manure Digestion System

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental

2.2. Wastewater Characteristics

2.3. Sampling and Analytical Methods

2.4. Experimental Procedure

3. Results

3.1. Effect of Conditions and Dosages on CEPT’s Efficiencies

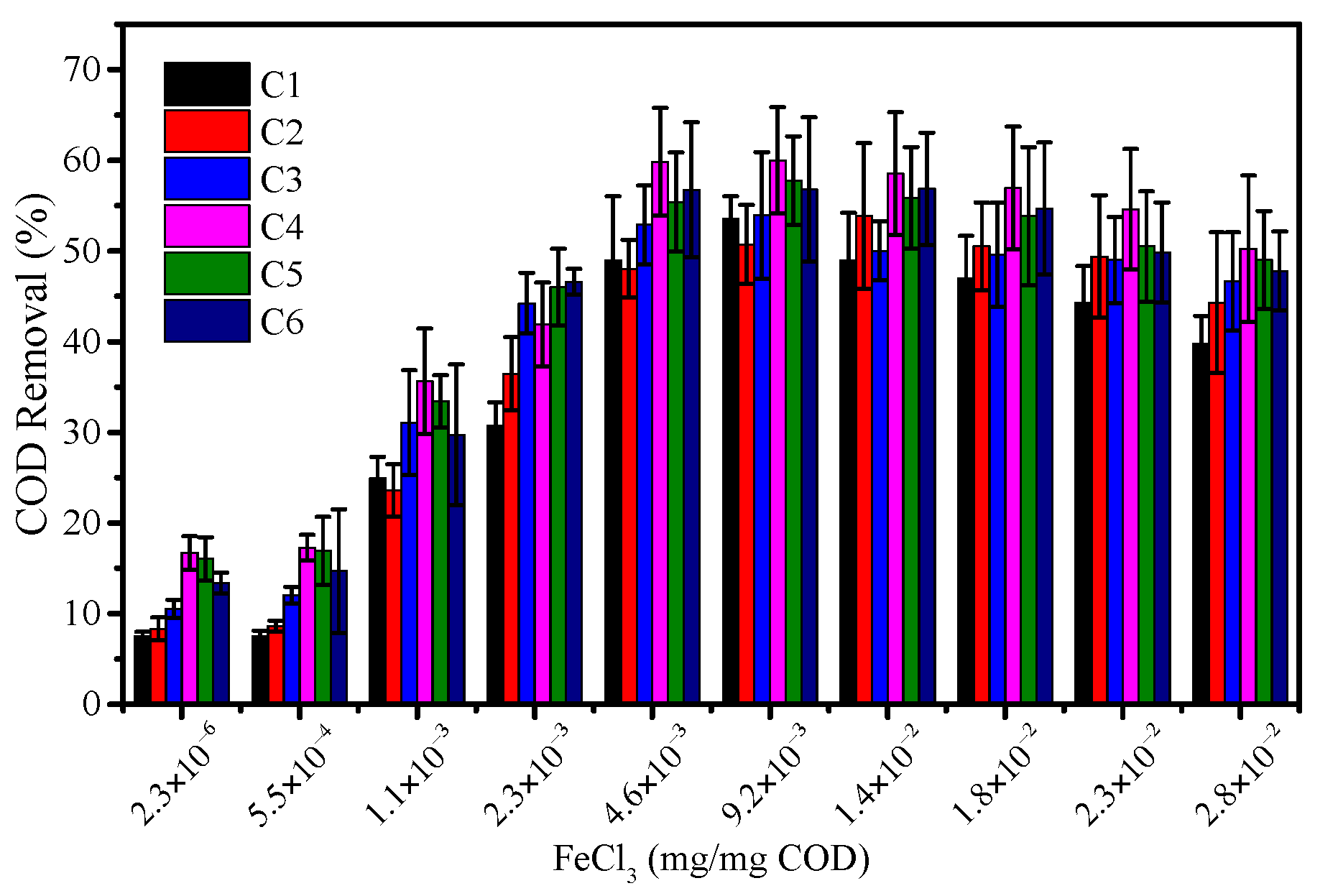

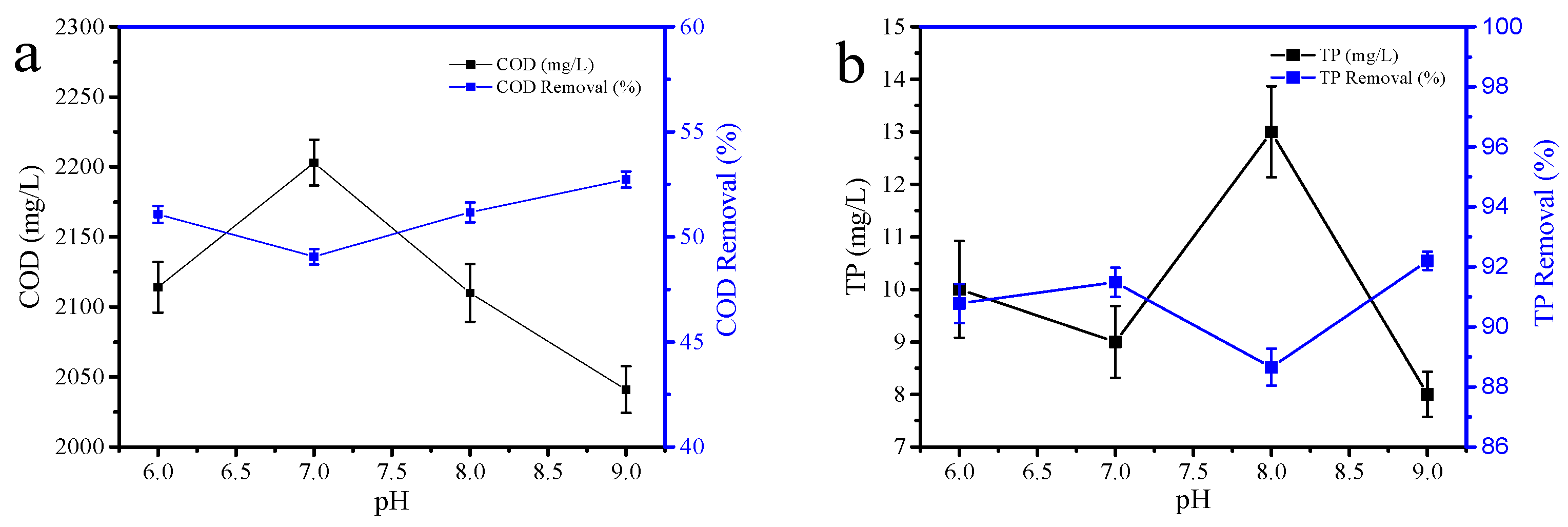

3.1.1. COD Removal

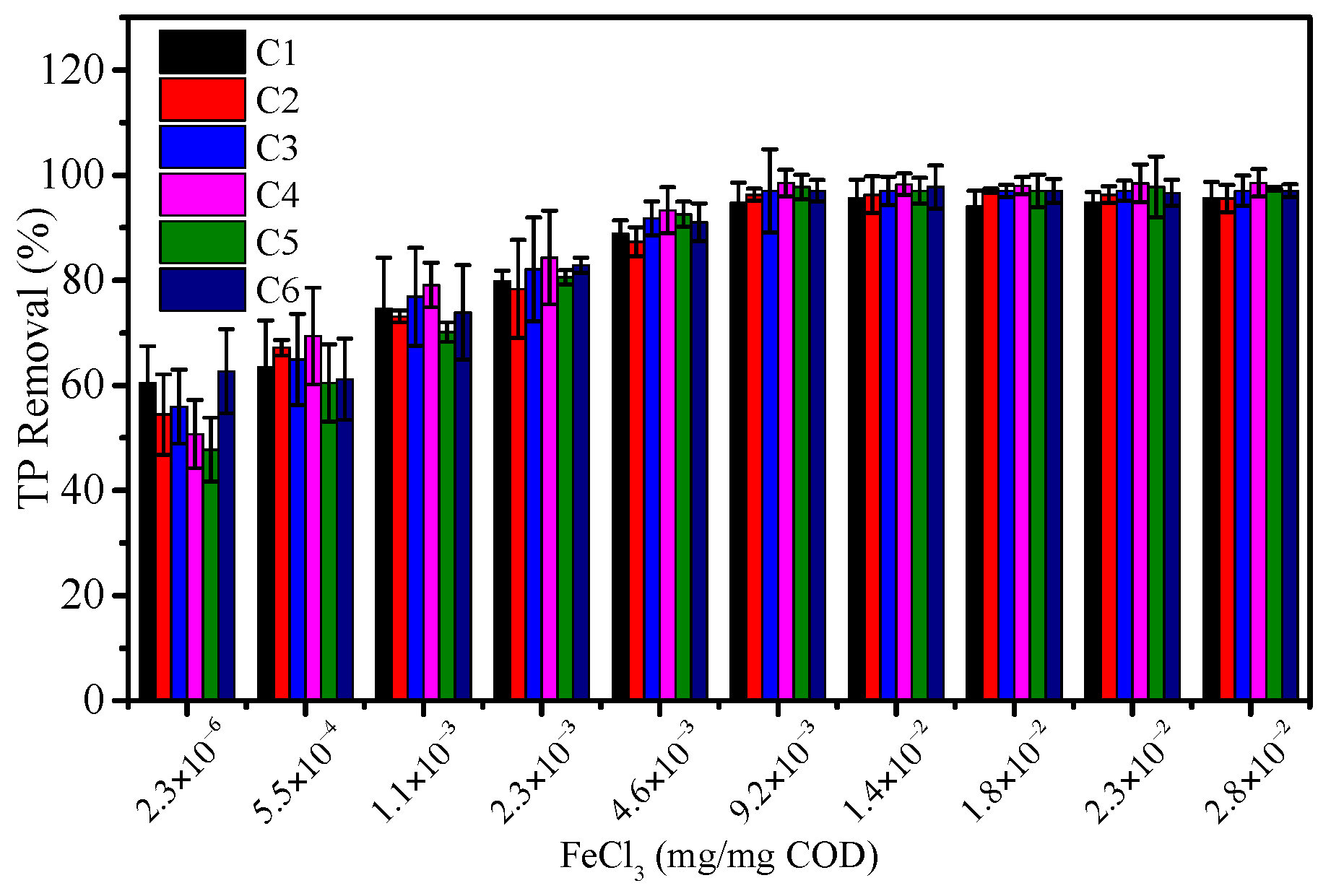

3.1.2. TP Removal

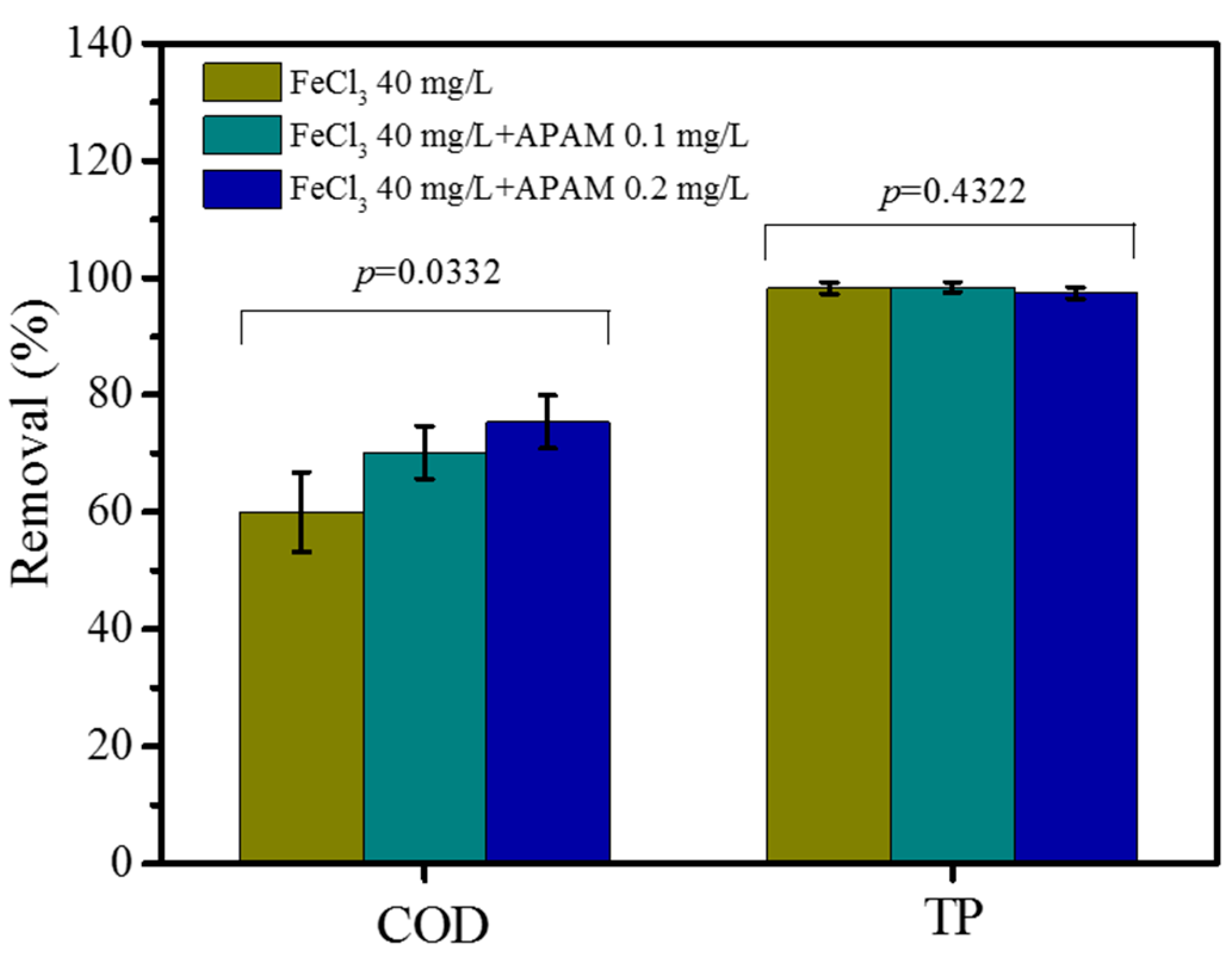

3.2. Efficiencies of Combined Use of FeCl3 and APAM in CEPT

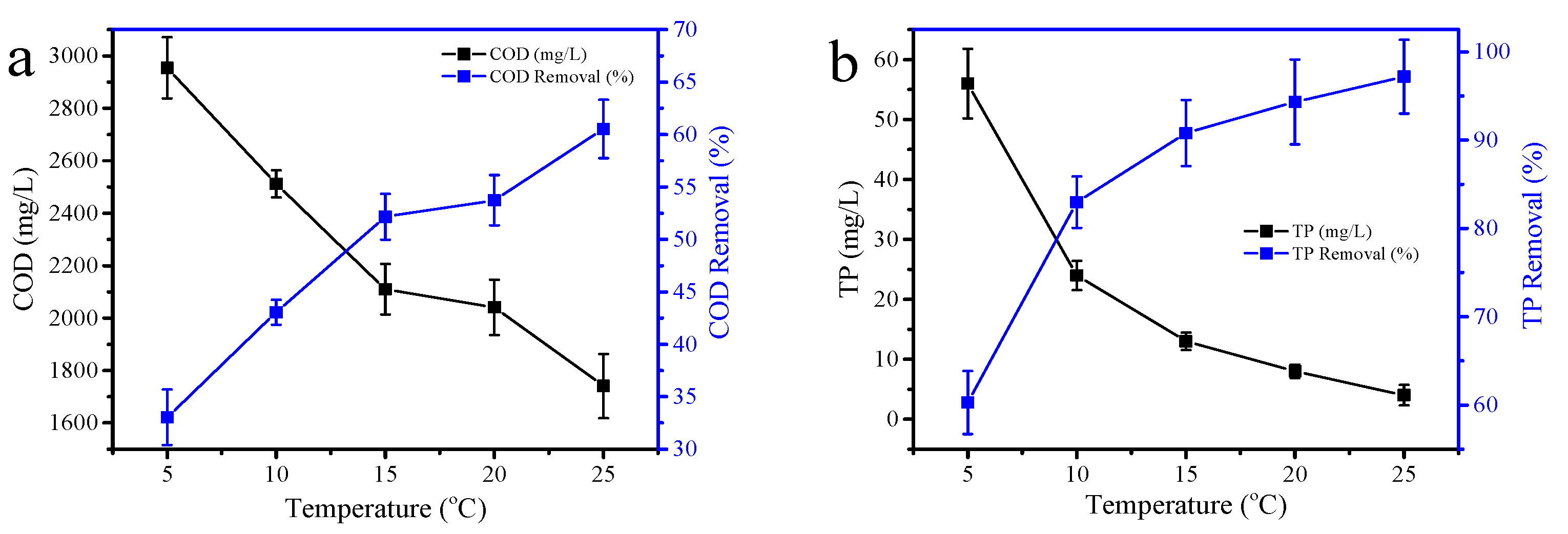

3.3. Factors Influencing CEPT’s Efficiencies

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bacenetti, J.; Negri, M.; Fiala, M.; González-García, S. Anaerobic digestion of different feedstocks: Impact on energetic and environmental balances of biogas process. Sci. Total Environ. 2013, 463, 541–551. [Google Scholar] [CrossRef] [PubMed]

- Yılmaz, S.; Selim, H. A review on the methods for biomass to energy conversion systems design. Renew. Sustain. Energy Rev. 2013, 25, 420–430. [Google Scholar] [CrossRef]

- Batstone, D.J.; Virdis, B. The role of anaerobic digestion in the emerging energy economy. Curr. Opin. Biotechnol. 2014, 27, 142–149. [Google Scholar] [CrossRef] [PubMed]

- Weiland, P. Biogas production: Current state and perspectives. Appl. Microbiol. Biotechnol. 2010, 85, 849–860. [Google Scholar] [CrossRef] [PubMed]

- Massé, D.; Masse, L.; Xia, Y.; Gilbert, Y. Potential of low-temperature anaerobic digestion to address current environmental concerns on swine production. J. Anim. Sci. 2010, 88, E112–E120. [Google Scholar] [CrossRef] [PubMed]

- Nasir, I.M.; Mohd Ghazi, T.I.; Omar, R. Anaerobic digestion technology in livestock manure treatment for biogas production: A review. Eng. Life Sci. 2012, 12, 258–269. [Google Scholar] [CrossRef]

- Rajagopal, R.; Massé, D.I.; Singh, G. A critical review on inhibition of anaerobic digestion process by excess ammonia. Bioresour. Technol. 2013, 143, 632–641. [Google Scholar] [CrossRef] [PubMed]

- Appels, L.; Lauwers, J.; Degrève, J.; Helsen, L.; Lievens, B.; Willems, K.; Van Impe, J.; Dewil, R. Anaerobic digestion in global bio-energy production: Potential and research challenges. Renew. Sustain. Energy Rev. 2011, 15, 4295–4301. [Google Scholar] [CrossRef]

- Buffiere, P.; Delgadillo Mirquez, L.; Steyer, J.P.; Bernet, N.; Delgenes, J.P. Anaerobic digestion of solid wastes needs research to face an increasing industrial success. Int. J. Chem. React. Eng. 2008, 6. [Google Scholar] [CrossRef]

- Clements, L.; Salter, A.; Banks, C.; Poppy, G. The usability of digestate in organic farming. Water Sci. Technol. 2012, 66, 1864–1870. [Google Scholar] [CrossRef] [PubMed]

- Bonetta, S.; Bonetta, S.; Ferretti, E.; Fezia, G.; Gilli, G.; Carraro, E. Agricultural reuse of the digestate from anaerobic co-digestion of organic waste: Microbiological contamination, metal hazards and fertilizing performance. Water Air Soil Pollut. 2014, 225, 2046. [Google Scholar] [CrossRef]

- Nkoa, R. Agricultural benefits and environmental risks of soil fertilization with anaerobic digestates: A review. Agron. Sustain. Dev. 2014, 34, 473–492. [Google Scholar] [CrossRef]

- Golkowska, K.; Vázquez-Rowe, I.; Lebuf, V.; Accoe, F.; Koster, D. Assessing the treatment costs and the fertilizing value of the output products in digestate treatment systems. Water Sci. Technol. 2014, 69, 656–662. [Google Scholar] [CrossRef] [PubMed]

- Rehl, T.; Müller, J. Life cycle assessment of biogas digestate processing technologies. Resour. Conserv. Recycl. 2011, 56, 92–104. [Google Scholar] [CrossRef]

- Fuchs, W.; Drosg, B. Assessment of the state of the art of technologies for the processing of digestate residue from anaerobic digesters. Water Sci. Technol. 2013, 67, 1984–1993. [Google Scholar] [CrossRef] [PubMed]

- Gong, W.; Li, W.; Liang, H. Application of A/O-MBR for treatment of digestate from anaerobic digestion of cow manure. J. Chem. Technol. Biotechnol. 2010, 85, 1334–1339. [Google Scholar] [CrossRef]

- Wellinger, A.; Murphy, J.D.; Baxter, D. The Biogas Handbook: Science, Production and Applications; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Gong, H.; Yan, Z.; Liang, K.; Jin, Z.; Wang, K. Concentrating process of liquid digestate by disk tube-reverse osmosis system. Desalination 2013, 326, 30–36. [Google Scholar] [CrossRef]

- Holloway, R.W.; Childress, A.E.; Dennett, K.E.; Cath, T.Y. Forward osmosis for concentration of anaerobic digester centrate. Water Res. 2007, 41, 4005–4014. [Google Scholar] [CrossRef] [PubMed]

- Carney, K.; Rodgers, M.; Lawlor, P.; Zhan, X. Treatment of separated piggery anaerobic digestate liquid using woodchip biofilters. Environ. Technol. 2013, 34, 663–670. [Google Scholar] [CrossRef] [PubMed]

- Comino, E.; Riggio, V.A.; Rosso, M. Constructed wetland treatment of agricultural effluent from an anaerobic digester. Ecol. Eng. 2013, 54, 165–172. [Google Scholar] [CrossRef]

- Magrí, A.; Béline, F.; Dabert, P. Feasibility and interest of the anammox process as treatment alternative for anaerobic digester supernatants in manure processing—An overview. J. Environ. Manag. 2013, 131, 170–184. [Google Scholar] [CrossRef] [PubMed]

- Libhaber, M.; Jaramillo, A.O. Sustainable Treatment and Reuse of Municipal Wastewater; Iwa Publishing: London, UK, 2012. [Google Scholar]

- Li, Y.; Tang, F.; Zhao, Q.; Hu, K. Domestic wastewater treatment with cept-wetlands process. Int. J. Environ. Pollut. 2011, 45, 186–196. [Google Scholar] [CrossRef]

- Pelendridou, K.; Michailides, M.K.; Zagklis, D.P.; Tekerlekopoulou, A.G.; Paraskeva, C.A.; Vayenas, D.V. Treatment of olive mill wastewater using a coagulation-flocculation process either as a single step or as post-treatment after aerobic biological treatment. J. Chem. Technol. Biotechnol. 2014, 89, 1866–1874. [Google Scholar] [CrossRef]

- Wang, H.; Li, F.; Keller, A.A.; Xu, R. Chemically enhanced primary treatment (CEPT) for removal of carbon and nutrients from municipal wastewater treatment plants: A case study of shanghai. Water Sci. Technol. 2009, 60, 1803–1809. [Google Scholar] [CrossRef] [PubMed]

- Xu, G.; Yan, Z.; Wang, Y.; Wang, N. Recycle of alum recovered from water treatment sludge in chemically enhanced primary treatment. J. Hazard. Mater. 2009, 161, 663–669. [Google Scholar] [CrossRef] [PubMed]

- Driscoll, C.T.; Letterman, R.D. Factors regulating residual aluminium concentrations in treated waters. Environmetrics 1995, 6, 287–305. [Google Scholar] [CrossRef]

- Sieliechi, J.M.; Kayem, G.J.; Sandu, I. Effect of water treatment residuals (aluminum and iron ions) on human health and drinking water distribution systems. Int. J. Conserv. Sci. 2010, 1, 175–182. [Google Scholar]

- Association, A.P.H.; Association, A.W.W.; Federation, W.P.C.; Federation, W.E. Standard Methods for the Examination of Water and Wastewater: Including Bottom Sediments and Sludges; American Public Health Association: Washington, DC, USA, 1971; Volume 13. [Google Scholar]

- Aguilar, M.; Saez, J.; Lloréns, M.; Soler, A.; Ortuno, J.; Meseguer, V.; Fuentes, A. Improvement of coagulation-flocculation process using anionic polyacrylamide as coagulant aid. Chemosphere 2005, 58, 47–56. [Google Scholar] [CrossRef] [PubMed]

- Haydar, S.; Aziz, J.A. Coagulation-flocculation studies of tannery wastewater using combination of alum with cationic and anionic polymers. J. Hazard. Mater. 2009, 168, 1035–1040. [Google Scholar] [CrossRef] [PubMed]

- Wong, S.; Teng, T.; Ahmad, A.; Zuhairi, A.; Najafpour, G. Treatment of pulp and paper mill wastewater by polyacrylamide (PAM) in polymer induced flocculation. J. Hazard. Mater. 2006, 135, 378–388. [Google Scholar] [CrossRef] [PubMed]

- Mahmoud, E. Chemically enhanced primary treatment of textile industrial effluents. Pol. J. Environ. Stud. 2009, 18, 651–655. [Google Scholar]

| Parameter | Average Value | Minimum Value | Maximum Value |

|---|---|---|---|

| pH | 7.31 | 7.03 | 7.78 |

| COD (mg/L) | 4352 | 2687 | 5088 |

| TP (mg/L) | 132 | 107 | 158 |

| Condition | C1 | C2 | C3 | C4 | C5 | C6 |

|---|---|---|---|---|---|---|

| Rapid mixing (r/min) | 300 | 200 | 300 | 200 | 300 | 200 |

| Slow stirring (r/min) | 30 | 30 | 40 | 40 | 50 | 50 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, W.; Luo, L.; Li, W.; Luo, X.; Liang, H.; Ngo, H.H.; Guo, W. Using Chemically Enhanced Primary Treatment (CEPT) as a Pretreatment Option for Anaerobic Digestate from Cattle Manure Digestion System. Water 2017, 9, 487. https://doi.org/10.3390/w9070487

Gong W, Luo L, Li W, Luo X, Liang H, Ngo HH, Guo W. Using Chemically Enhanced Primary Treatment (CEPT) as a Pretreatment Option for Anaerobic Digestate from Cattle Manure Digestion System. Water. 2017; 9(7):487. https://doi.org/10.3390/w9070487

Chicago/Turabian StyleGong, Weijia, Lina Luo, Wenzhe Li, Xinsheng Luo, Heng Liang, Huu Hao Ngo, and Wenshan Guo. 2017. "Using Chemically Enhanced Primary Treatment (CEPT) as a Pretreatment Option for Anaerobic Digestate from Cattle Manure Digestion System" Water 9, no. 7: 487. https://doi.org/10.3390/w9070487