Quantitative Prediction of Fractures in Shale Using the Lithology Combination Index

Abstract

:1. Introduction

2. Geologic Setting

3. Lithology Combination Index (LCI)

4. Data Preparation

4.1. Fracture Characterization of a Rock Slice

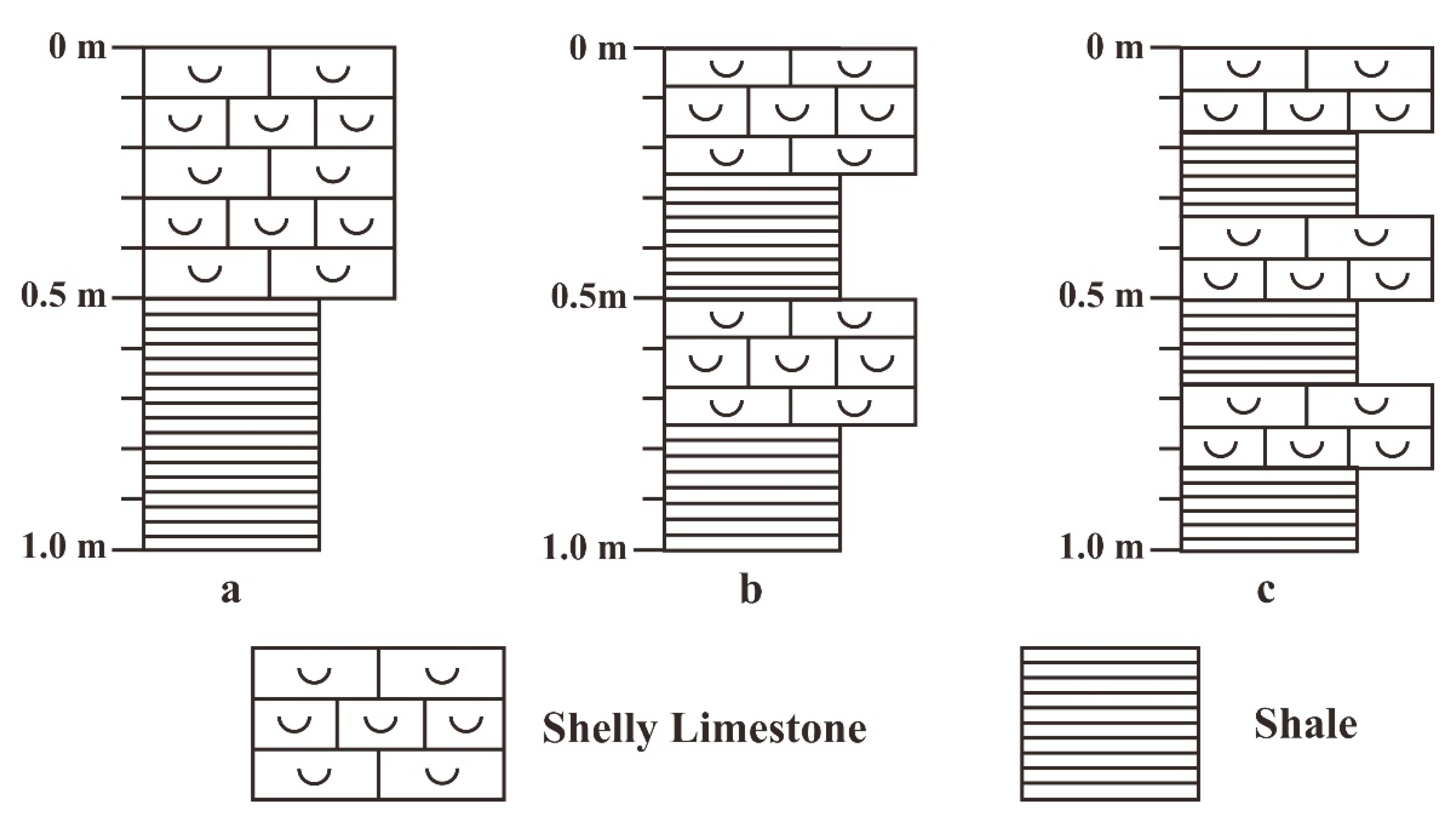

4.2. Acquisition of Lithology Parameters

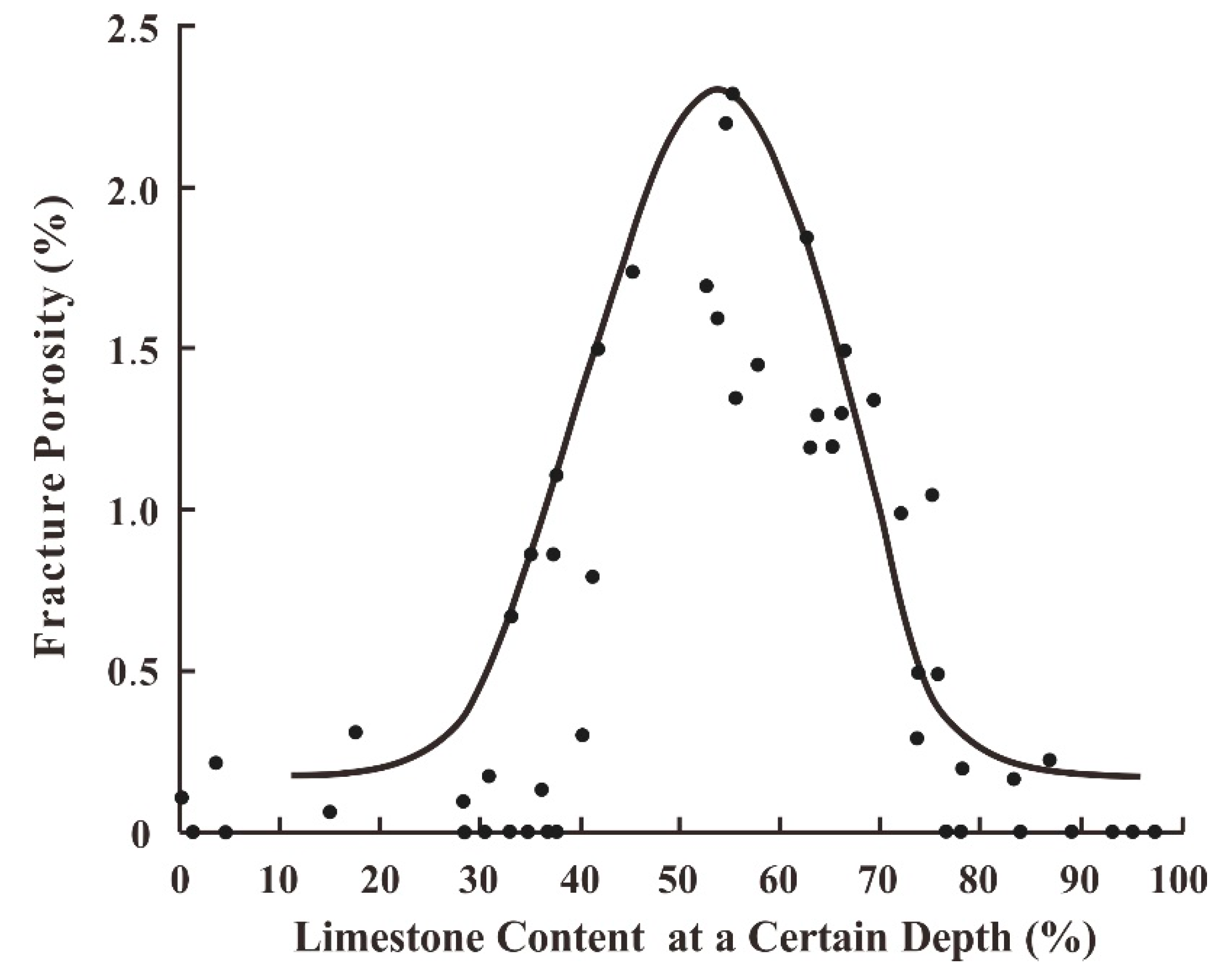

4.3. Relationship between Formation Lithology and Fractures

4.4. Relationship between the Number of Layers and Fracture

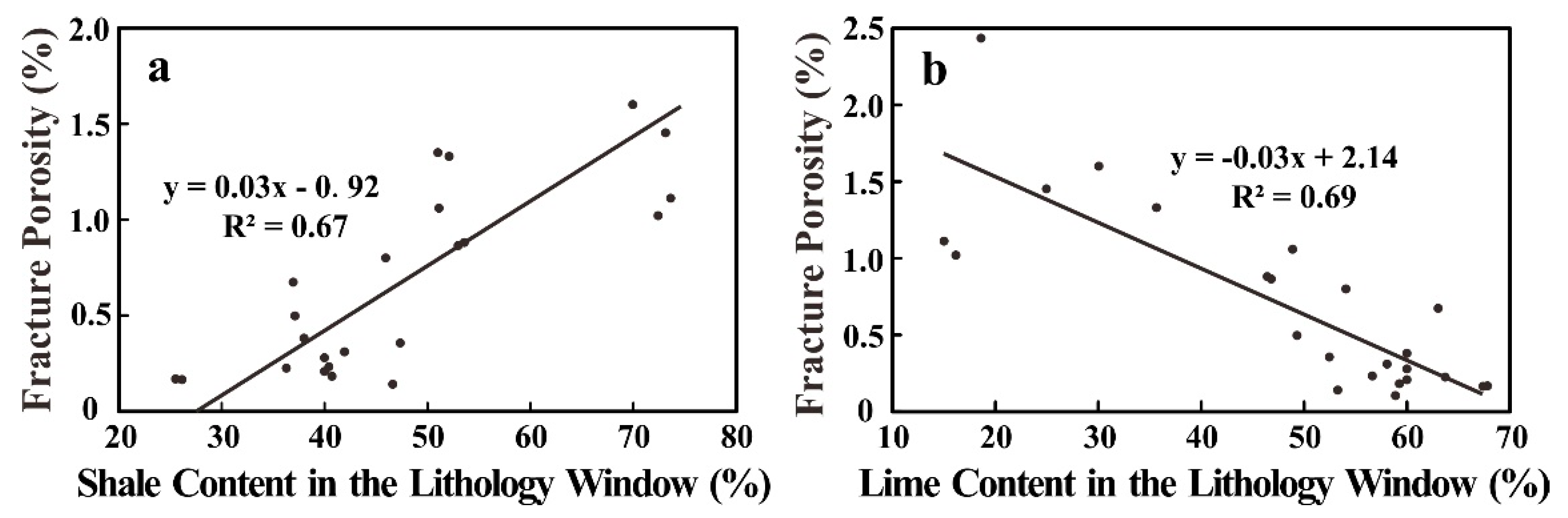

4.5. Relationship between Window Lithology and Fractures

5. Machine Learning

5.1. Data Processing

5.2. Model Selection

5.3. Parameter Adjustment and Optimization

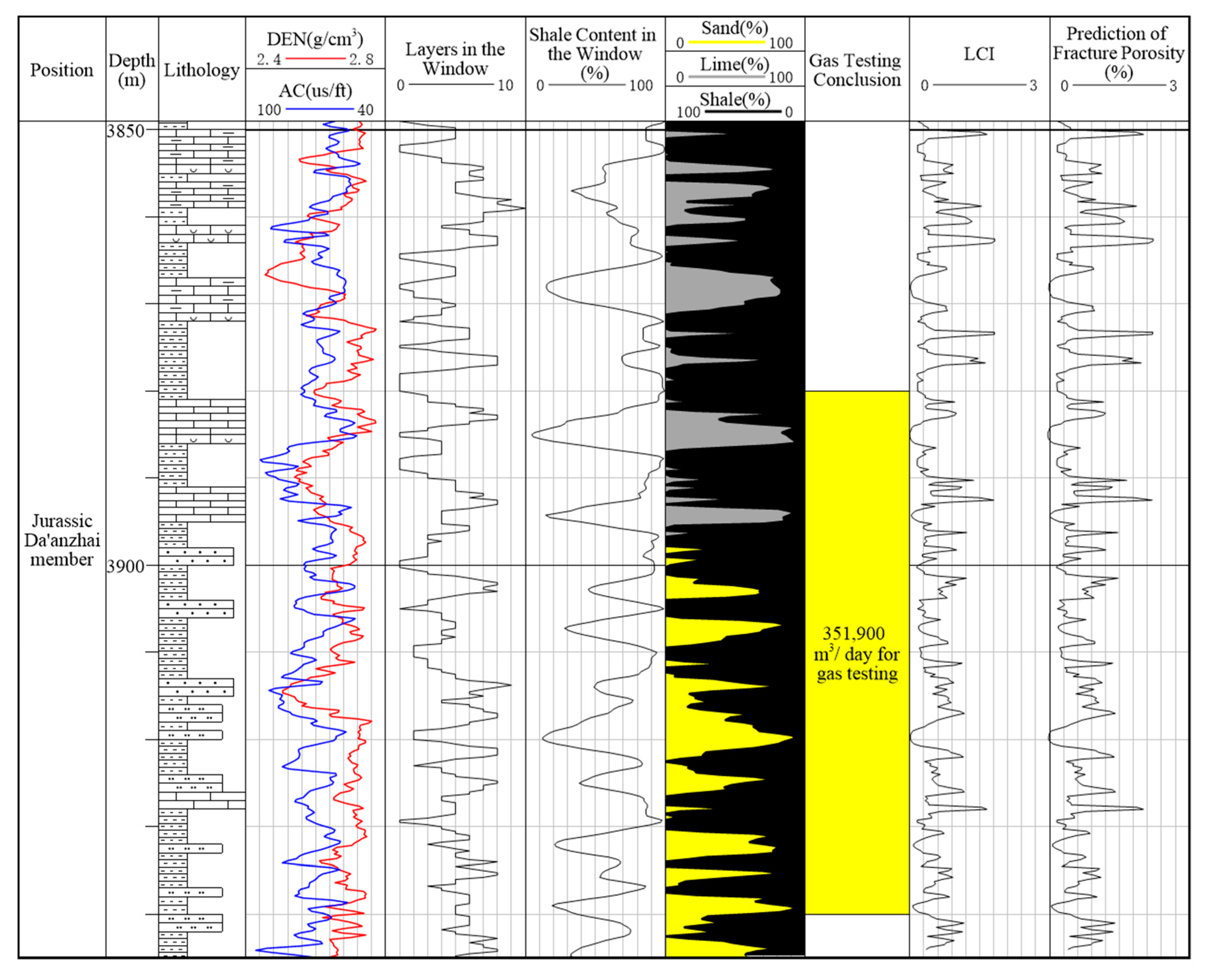

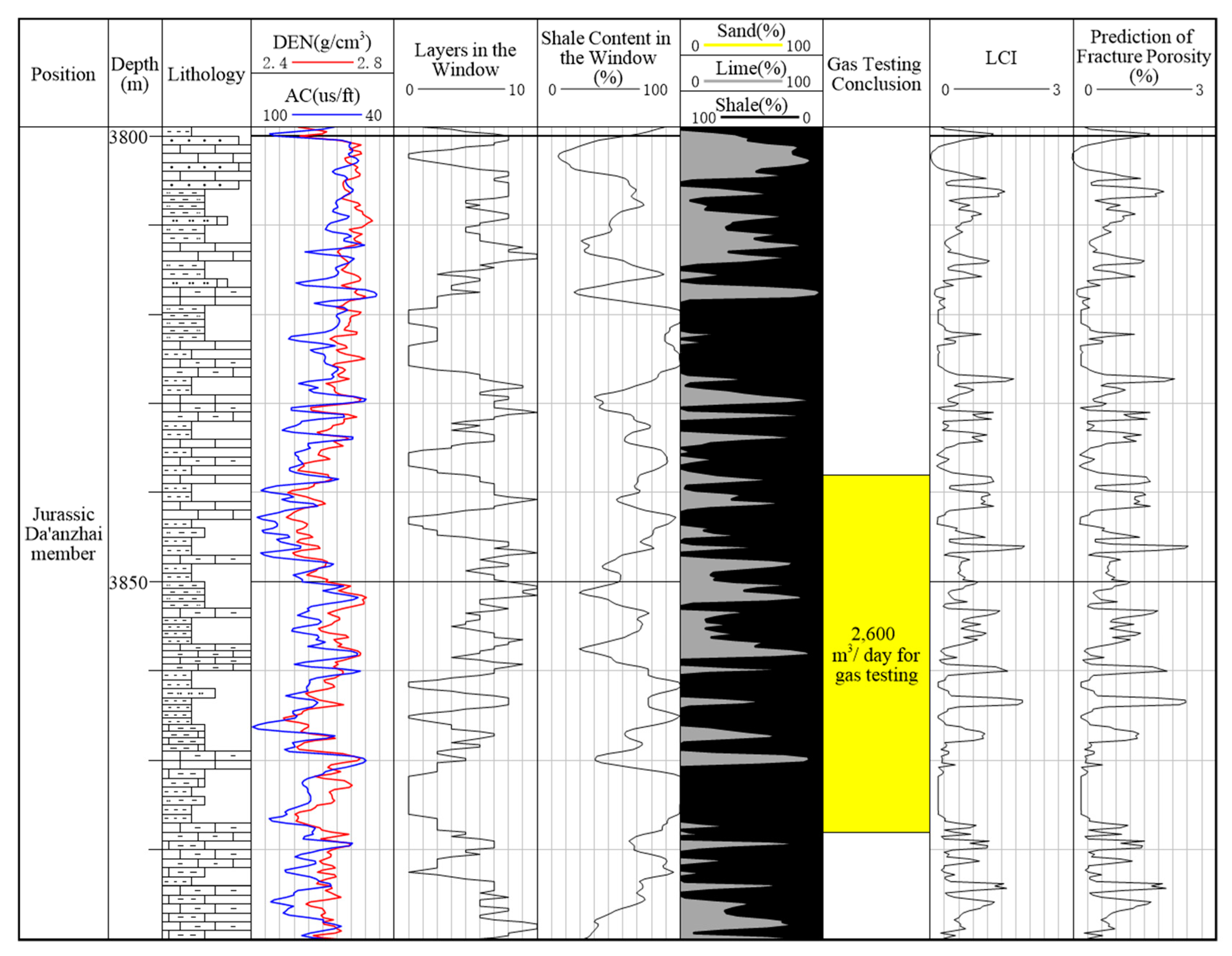

6. Characterization Prediction

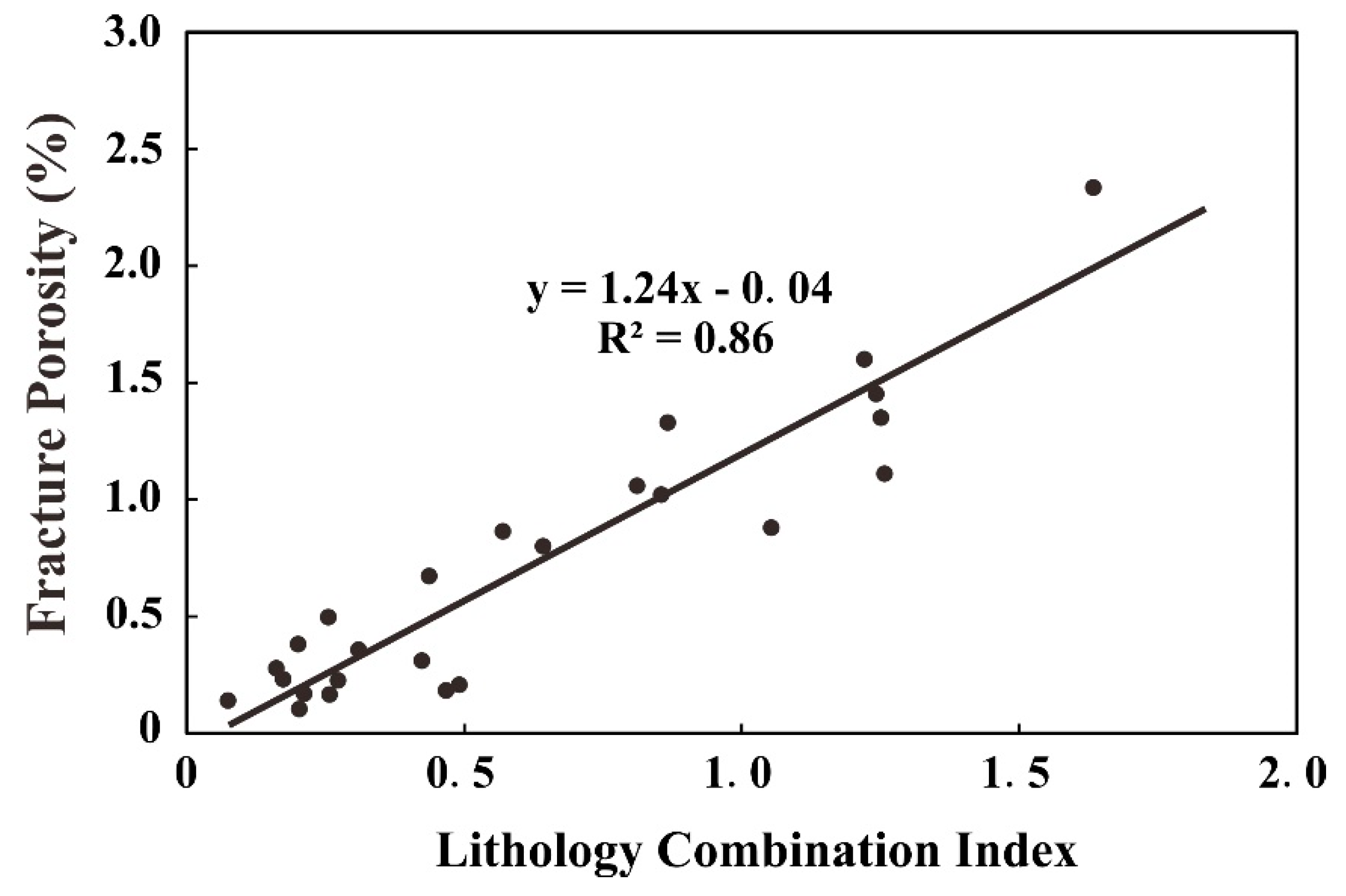

6.1. LCI Formula

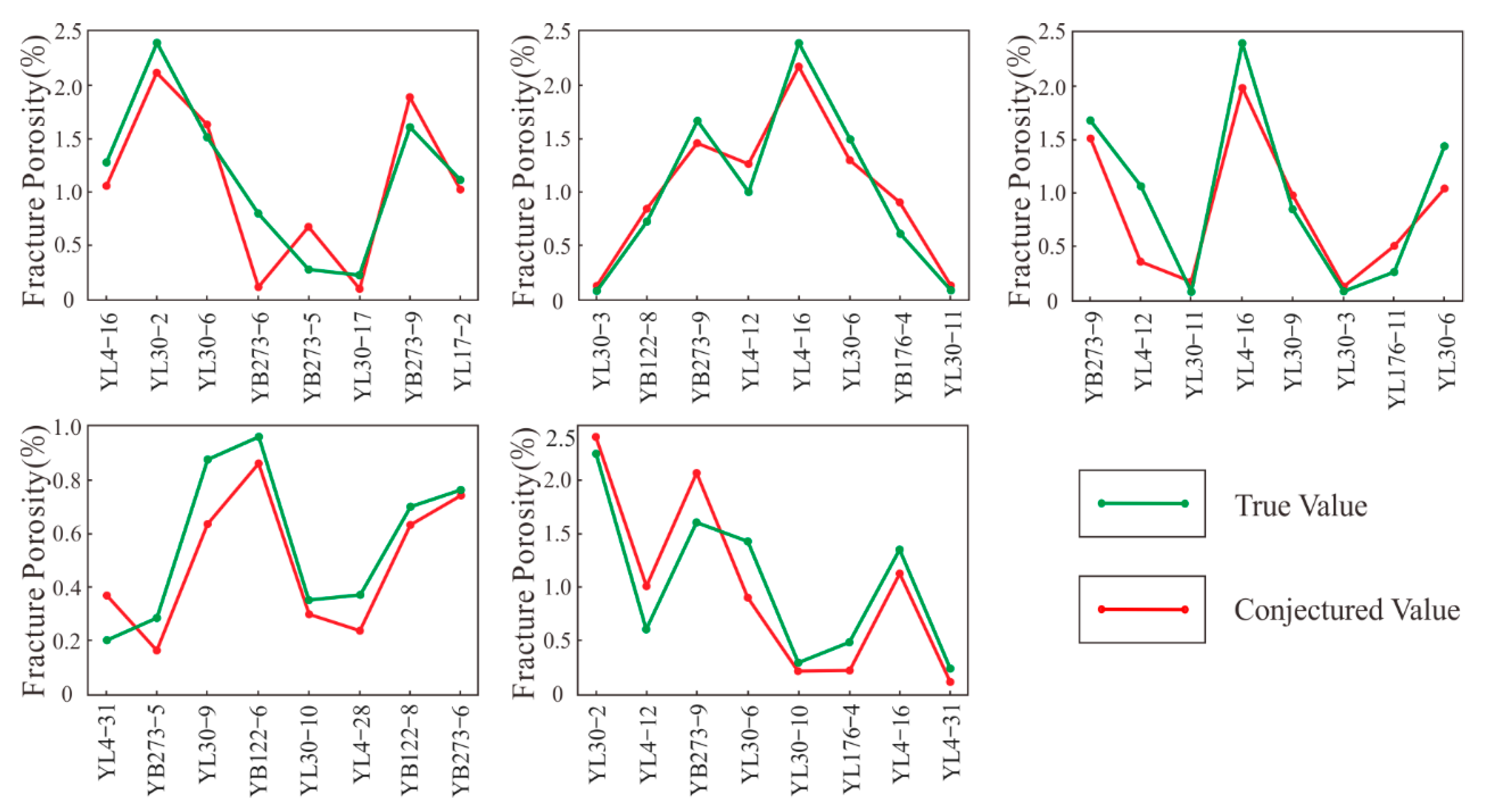

6.2. Fracture Predictions

7. Discussions

8. Conclusions

- (1)

- From a lithology combination perspective and the machine learning concept, we established a quantitative characterization model for the LCI and fracture development. The LCI quantifies the complex comprehensive influence that multiple factors have on fracture development, using several formulae to fit the composite function relationship with the fractures and some factors, which yields a quantitative characterization of the fractures. We established the quantitative characterization model of LCI and fracture development by defining this index, such that we can quantitatively predict fracture development.

- (2)

- After determining the LCI formula for a specific area, inputting the values of the various factors that affect the fractures in this area can simulate fracture development in the entire stratum. This method has been used to predict fractures in the Da’anzhai member of the Yuanba area, whose results show that the method is reliable. This method is also applicable in other regions, but the regional parameters must be adapted according to the actual conditions of the region.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- Engelder, T. Loading paths to joint propagation during a tectonic cycle: An example from the Appalachian Plateau, U.S.A. J. Struct. Geol. 1985, 7, 459–476. [Google Scholar] [CrossRef]

- Gale, J.F.W.; Laubach, S.E.; Olson, J.E. Natural fractures in shale: A review and new observations. Aapg Bull. 2014, 98, 2165–2216. [Google Scholar] [CrossRef]

- Gale, J.F.W.; Elliott, S.J.; Li, J.Z. Natural fracture characterization in the Wolfcamp Formation at the Hydraulic Fracture Test Site (HFTS), Midland basin, Texas. In Proceedings of the Unconventional Resources Technology Conference, Denver, CO, USA, 22–24 July 2019. [Google Scholar] [CrossRef]

- Laubach, S.E.; Lander, R.H.; Criscenti, L.J. The role of chemistry in fracture pattern development and opportunities to advance interpretations of geological materials. Rev. Geophys. 2019, 57, 1065–1111. [Google Scholar] [CrossRef] [Green Version]

- Huang, Q.; Angelier, J. Fracture spacing and its relation to bed thickness. Geol. Mag. 1989, 126, 355. [Google Scholar] [CrossRef]

- Ellis, M.A.; Laubach, S.E.; Eichhubl, P. Fracture development and diagenesis of Torridon Group Applecross Formation, near an Teallach, NW Scotland: Millennia of brittle deformation resilience? J. Geol. Soc. Lond. 2012, 169, 297–310. [Google Scholar] [CrossRef]

- Zeng, L.; Li, X. Fractures in sandstone reservoirs with ultra-low permeability: A case study of the Upper Triassic Yanchang Formation in the Odos Basin, China. Aapg. Bull. 2009, 93, 461–477. [Google Scholar] [CrossRef]

- Gale, J.F.W.; Lander, R.H.; Reed, R.M. Modeling fracture porosity evolution in dolostone. J. Struct. Geol. 2010, 32, 1201–1211. [Google Scholar] [CrossRef]

- Rickman, R.; Mullen, M.J.; Petre, J.E. A Practical Use of Shale Petrophysics for Stimulation Design Optimization: All Shale Plays Are Not Clones of the Barnett Shale. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 21–24 September 2008. [Google Scholar] [CrossRef] [Green Version]

- Wang, R.; Hu, Z.; Liu, J. Comparative analysis of characteristics and controlling factors of fractures in marine and continental shales: A case study of the Lower Cambrian in Cenggong area, northern Guizhou Province. Oil Gas. Geol. 2018. (In Chinese) [Google Scholar] [CrossRef]

- Wang, X.; Zhao, M.; Xiang, B. Carboniferous source rocks in the Ludong-Wucaiwan area, Junggar Basin, NW China. Pet. Explor. Dev. 2010, 37, 523–530. [Google Scholar] [CrossRef]

- Zhu, G.; Gu, L.; Su, J. Sedimentary association of alternated mudstones and tight sandstones in China’s oil and gas bearing basins and its natural gas accumulation. J. Asian Earth Sci. 2012, 50. [Google Scholar] [CrossRef]

- Yurewicz, D.A.; Bohacs, K.M.; Kendall, J. 2005. Controls on gas and water distribution, Mesaverde basin-centered gas play, Piceance basin, Colorado. Search Discov. 2005, 105–136. [Google Scholar] [CrossRef]

- Alpaydin, E. Introduction to Machine Learning; MIT Press: Cambridge, MA, USA, 2004. [Google Scholar] [CrossRef]

- Mayer-Schonberger, V.; Cukier, K. Big Data: A Revolution That Will Transform How We Live, Work, and Think; Houghton Mifflin Harcourt Publishing Company: New York, NY, USA, 2013. [Google Scholar] [CrossRef]

- Mulder, E.F.J.D.; Cheng, Q.; Agterberg, F. New and game-changing developments in geochemical exploration. Episodes 2016, 39, 70–71. [Google Scholar] [CrossRef] [Green Version]

- Ross, Z.E.; Men-Andrin, M.; Egill, H. 2018. P-wave arrival picking and first-motion polarity determination with deep learning. J. Geophys. Res. Solid Earth 2018. [Google Scholar] [CrossRef]

- Ouenes, A.; Richardson, S.; Weiss, W.W. Fractured Reservoir Characterization and Performance Forecasting Using Geomechanics and Artificial Intelligence. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 22–25 October 1995. [Google Scholar] [CrossRef]

- Ouenes, A. Practical application of fuzzy logic and neural networks to fractured reservoir characterization. Comput. Geosci. 2000, 26, 953–962. [Google Scholar] [CrossRef]

- Barman, I.; Ouenes, A.; Wang, M. Fractured Reservoir Characterization Using Streamline-Based Inverse Modeling and Artificial Intelligence Tools. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 1–4 October 2000. [Google Scholar] [CrossRef]

- Ozkaya, S.I. Using Probabilistic Decision Trees to Detect Fracture Corridors from Dynamic Data in Mature Oil Fields. Spe Reserv. Eval. Eng. 2008. [Google Scholar] [CrossRef]

- Lu, B. Shale Gas. Reservoir Evaluation of Da’anzhai Member in Ziliujing Formation of Lower Jurassic in Eastern Sichuan Basin; Chengdu University of Technology: Chengdu, China, 2015. (In Chinese) [Google Scholar]

- Wang, Y.; Tong, M.; Sun, Y. Reservoir characteristics of Da’anzhai shell limestone tight oil in Sichuan Basin. Acta Pet. Sin. 2019, 40, 42–55. (In Chinese) [Google Scholar]

- Zhou, X.; Liang, B. Characteristics and recognition of Lower Jurassic shell limestone in Yuanba Area of Sichuan Basin. J. Xi Pet. Univ. 2017, 32, 35–43. (In Chinese) [Google Scholar]

- Yan, X. The Sedimentary Facies Study of Lower Jurassic Da’anzhai Member in Fuling Area, Eastern Sichuan Basin; Chengdu University of Technology: Chengdu, China, 2015. (In Chinese) [Google Scholar]

- Zhou, G.; Xu, S.; Ran, X. Pore structure characteristics and control factors of shale in the Da’anzhai formation centrale of Sichuan Basin. J. Northwest. Univ. 2018, 48, 718–728. (In Chinese) [Google Scholar]

- Curtis, J.B. Fractured shale-gas systems. Aapg Bull. 2002, 86, 1921–1938. [Google Scholar] [CrossRef]

- Curtis, M.E.; Sondergeld, C.H.; Ambrose, R.J. Microstructural investigation of gas shales in two and three dimensions using nanometerscale resolution imaging. Aapg Bull. 2012, 96, 665–677. [Google Scholar] [CrossRef]

- Sun, W.; Li, W.; Dong, Z. A new approach to the characterization of shale pore structure. Lithol. Reserv. 2017, 29, 125–130. [Google Scholar] [CrossRef]

- Yuan, Y.; Rezaee, R.; Al-Khdheeawi, A.E. Impact of Composition on Pore Structure Properties in Shale: Implications for Micro-/Mesopore Volume and Surface Area Prediction. Energy Fuels 2019, 33, 9619–9628. [Google Scholar] [CrossRef]

- Yuan, Y.; Rezaee, R. Comparative Porosity and Pore Structure Assessment in Shales: Measurement Techniques, Influencing Factors and Implications for Reservoir Characterization. Energies 2019, 12, 2094. [Google Scholar] [CrossRef] [Green Version]

- Zheng, R.; He, L.; Liang, X. Formation condition of shale gas (oil) in the Lower Jurassic Da’anzhai member in the eastern Sichuan Basin. Nat. Gas. Ind. 2013, 33, 30–40. (In Chinese) [Google Scholar]

- Martin, J. A Geomechanical Approach to Evaluate Brittleness Using Well Logs: Mississippian Limestone, Northern Oklahoma. Master’s Thesis, The University of Texas at Arlington, Arlington, TX, USA, 2015. [Google Scholar]

- Zhao, L.; Wei, W.; Li, Y. The Application of the Multi-Mineral Model in a Block of Southern China. In Proceedings of the 75th EAGE Conference & Exhibition Incorporating SPE EUROPEC, London, UK, 13 June 2013. [Google Scholar] [CrossRef]

- Feng, R.; Wu, Y.; Tao, S. Sedimentary microfacies characteristics and their control on reservoirs in Da’anzhai Member, Lower Jurassic, Sichuan Basin. Pet. Geol. Exp. 2015, 37, 320–327. (In Chinese) [Google Scholar]

- Tan, M. Features and Model of Mixed Siliciclastic-Carbonate Sediments of Da’anzhai Member in Lower Jurassic Ziliujing Formation, Huilong Area, Sichuan Basin; Chengdu University of Technology: Chengdu, China, 2017. (In Chinese) [Google Scholar]

- Yuan, Y.; Rezaee, R.; Verrall, M. Pore characterization and clay bound water assessment in shale with a combination of NMR and low-pressure nitrogen gas adsorption. Int. J. Coal Geol. 2018, S0166516218302702. [Google Scholar] [CrossRef]

- Yuan, Y.; Rezaee, R. Fractal analysis of the pore structure for clay bound water and potential gas storage in shales based on NMR and N2 gas adsorption. J. Pet. Sci. Eng. 2019. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C. Spectrum of pore types and networks in mudrocks and a descriptive classification for matrix-related mudrock pores. AAPG Bull. 2012, 96, 1071–1098. [Google Scholar] [CrossRef] [Green Version]

- Vapnik, V.N.; Drucker, H.; Burges, J.C. Support. Vector Regression Machines. Advances in Neural Information Processing Systems 9; MIT Press: Cambridge, MA, USA, 1996; pp. 155–161. [Google Scholar] [CrossRef]

- Cherkassky, V.; Mulier, F. Statistical Learning Theory. Learning from Data: Concepts, Theory, and Methods, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2006; Volume 41, p. 3185. [Google Scholar] [CrossRef] [Green Version]

- Hsieh, W.W. Machine Learning Methods in the Environmental Sciences: Neural Networks and Kernels; Cambridge University Press: Cambridge, UK, 2009; pp. 157–169. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Yang, F. Classification of Gas-Rich Lithofacies in Continental Shale Formation Based on bi-Langmuir Model and SVM Methods. In Proceedings of the Society of Exploration Geophysicists SEG Technical Program Expanded Abstracts, Dallas, TX, USA, 16–21 October 2016; pp. 3518–3522. [Google Scholar] [CrossRef]

- Aryafar, A.; Moeini, H. Application of continuous restricted Boltzmann machine to detect multivariate anomalies from stream sediment geochemical data, Korit, East of Iran. J. Min. Environ. 2017, 8, 673–682. [Google Scholar] [CrossRef]

- Carranza, E.J.M.; Laborte, A.G. Random forest predictive modeling of mineral prospectivity with small number of prospects and data with missing values in Abra (Philippines). Comput. Geosci. 2015, 74, 60–70. [Google Scholar] [CrossRef]

- Tan, M.; Song, X.; Yang, X. Support-vector-regression machine technology for total organic carbon content prediction from wireline logs in organic shale: A comparative study. J. Nat. Gas. Sci. Eng. 2015, 26, 792–802. [Google Scholar] [CrossRef]

- Shi, G. Superiorities of Support Vector Machine in Fracture Prediction and Gassiness Evaluation. Pet. Explor. Dev. 2008, 35, 588–594. [Google Scholar] [CrossRef]

| Model | Shale Content at a Certain Depth | The Number of Layers | Shale Content in the Window | Reliability |

|---|---|---|---|---|

| Multi-linear regression | 0.19 | 1.12 | 1.53 | 0.48 |

| Decision-making tree | 0.02 | 0.01 | 0.96 | 0.46 |

| Support vector machine | 0.21 | 0.48 | 1.27 | 0.71 |

| K-nearest neighbor prediction | / | / | / | 0.39 |

| Random forest algorithm | 1.94 | 0.33 | 0.46 | 0.39 |

| Number | Shale Content at a Certain Depth | The Number of Layers | Shale Content in the Window | Reliability |

|---|---|---|---|---|

| The first time | 0.13 | 0.78 | 1.64 | 0.76 |

| The second time | 0.09 | 0.81 | 1.73 | 0.93 |

| The third time | 0.06 | 1.07 | 1.55 | 0.84 |

| The fourth time | 0.12 | 0.70 | 1.52 | 0.76 |

| The fifth time | 0.14 | 0.97 | 1.62 | 0.86 |

| Average value | 0.11 | 0.87 | 1.61 | 0.83 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Li, P.; Yuan, Y.; Liu, K.; Hao, J.; Zou, H. Quantitative Prediction of Fractures in Shale Using the Lithology Combination Index. Minerals 2020, 10, 569. https://doi.org/10.3390/min10060569

Zhang Z, Li P, Yuan Y, Liu K, Hao J, Zou H. Quantitative Prediction of Fractures in Shale Using the Lithology Combination Index. Minerals. 2020; 10(6):569. https://doi.org/10.3390/min10060569

Chicago/Turabian StyleZhang, Zhengchen, Pingping Li, Yujie Yuan, Kouqi Liu, Jingyu Hao, and Huayao Zou. 2020. "Quantitative Prediction of Fractures in Shale Using the Lithology Combination Index" Minerals 10, no. 6: 569. https://doi.org/10.3390/min10060569