A Study of Respirable Silica in Underground Coal Mines: Particle Characteristics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Available RCMD Samples

2.2. Silica Particle Surface Analysis

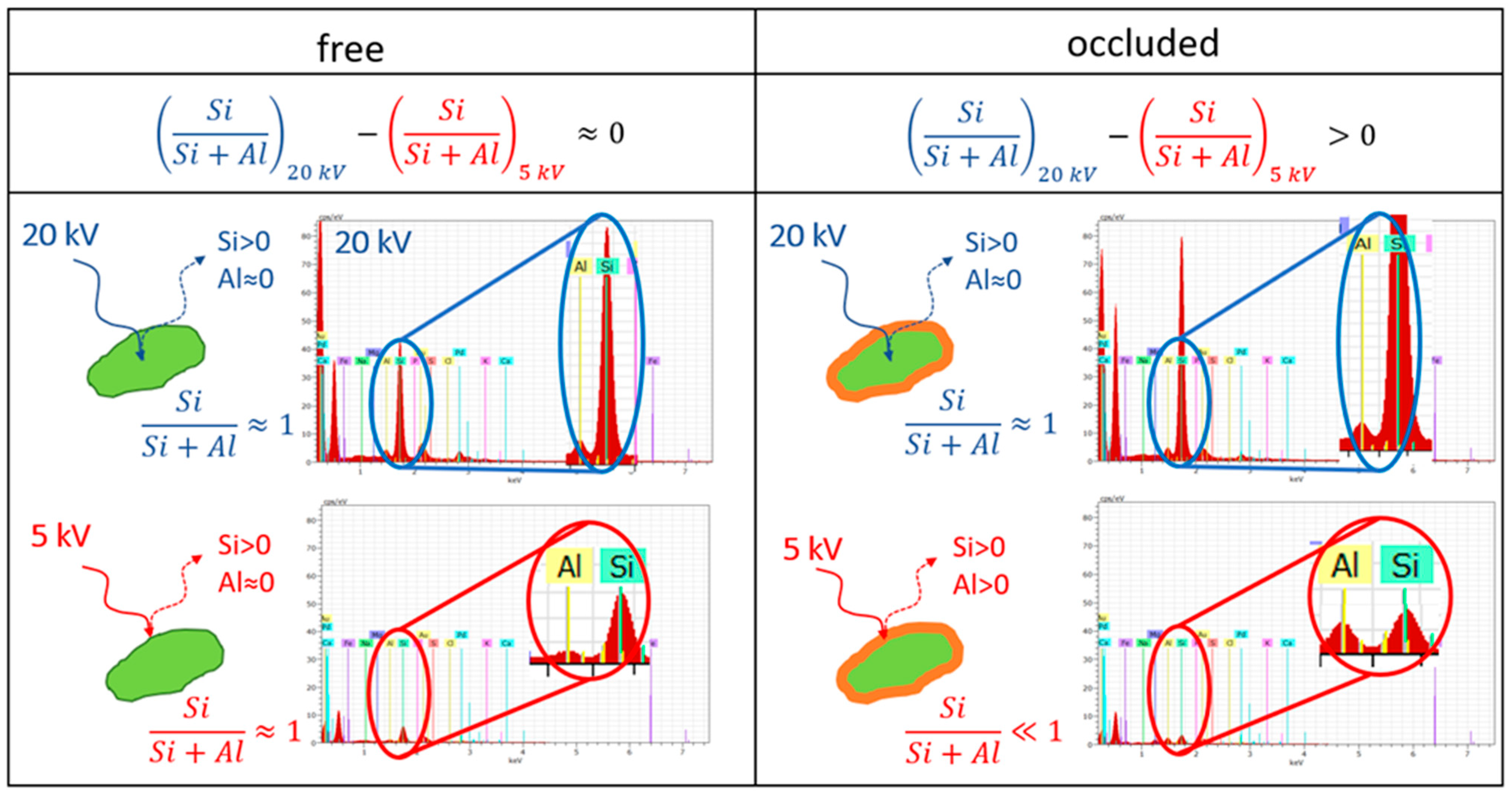

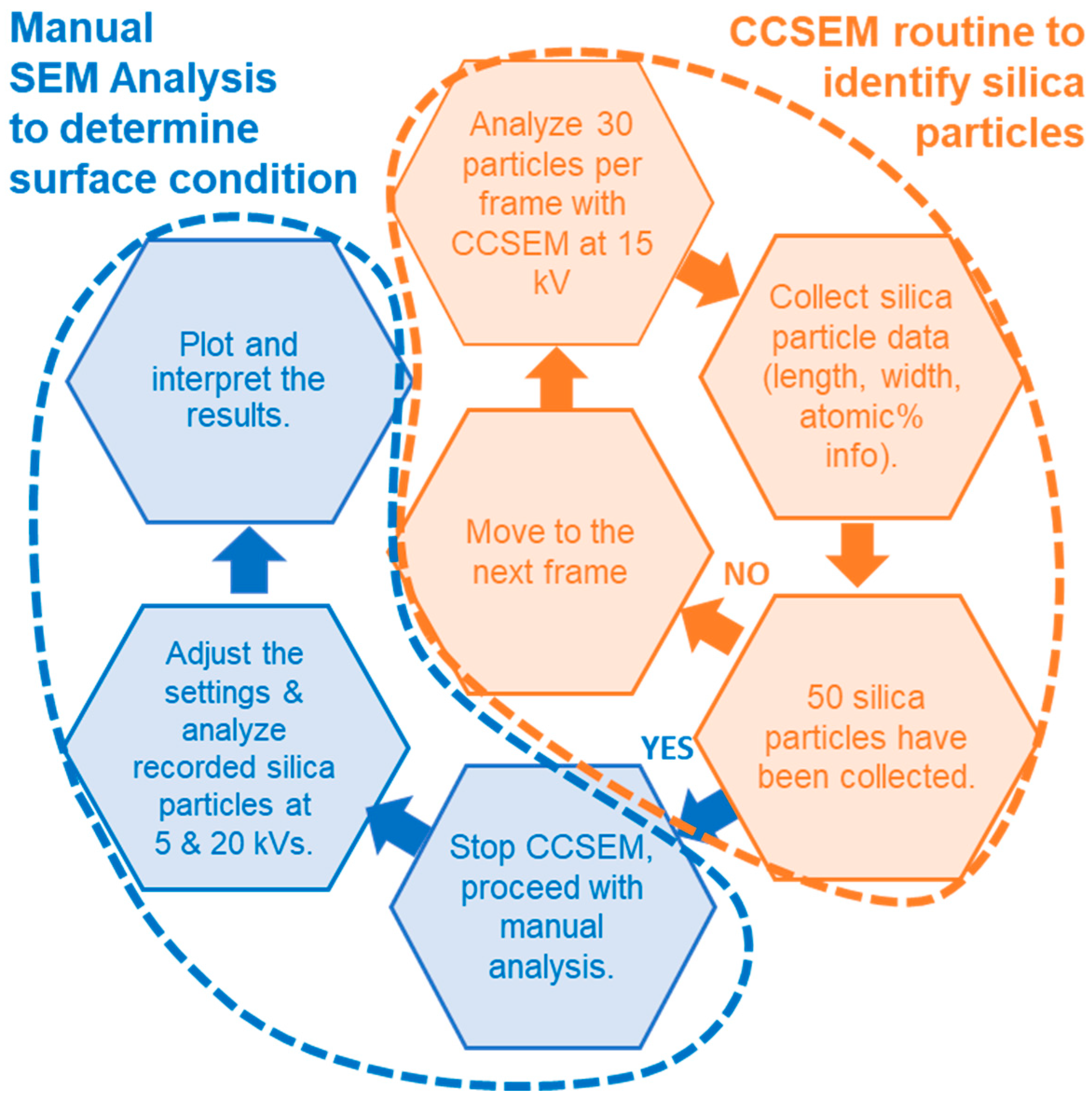

2.2.1. Particle Identification and Dual-Voltage Analysis

2.2.2. Reference Material Selection

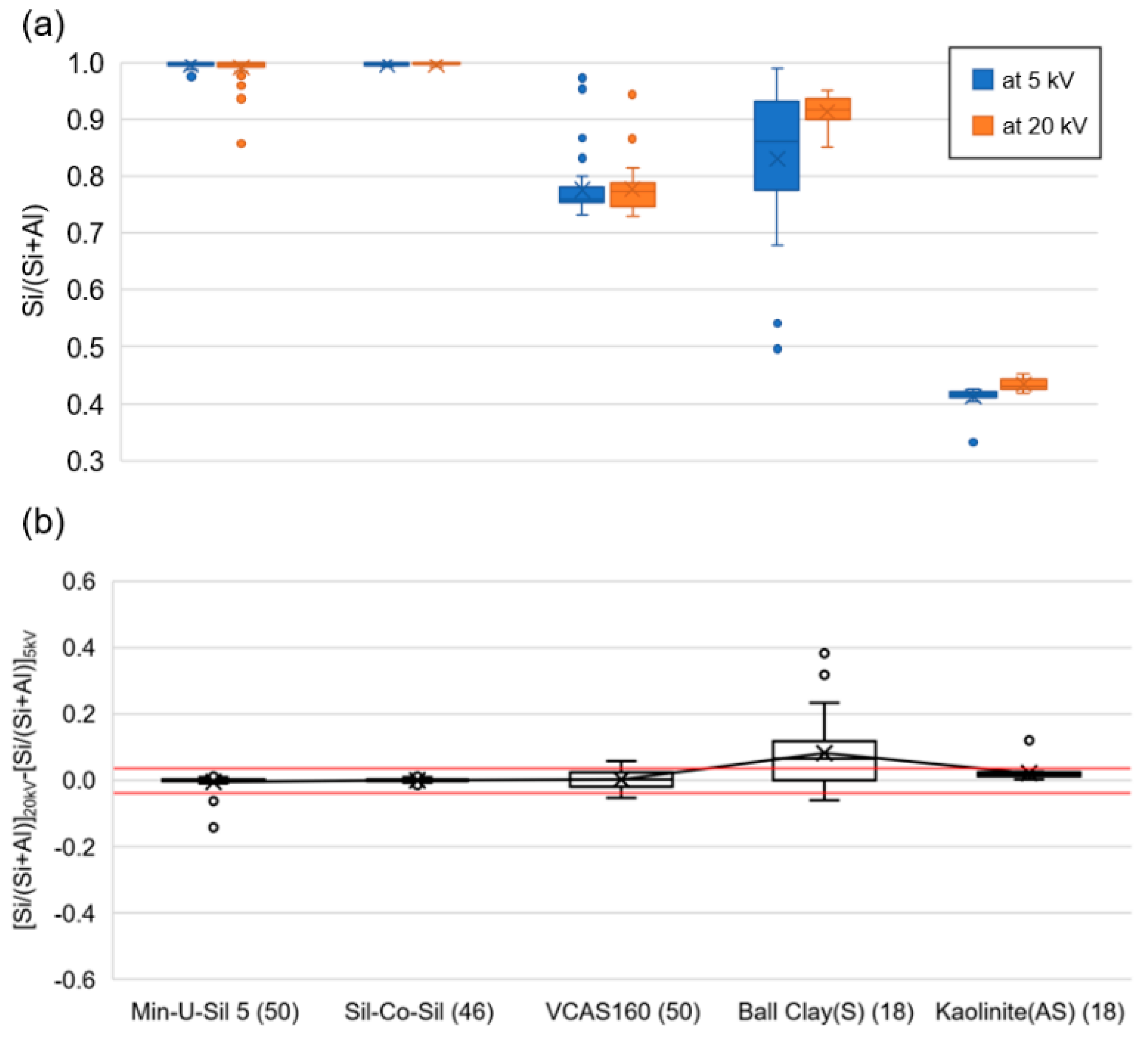

2.2.3. Classification Criteria for Free Silica

2.3. Silica Particle Size Analysis

2.3.1. Data from Silica Particle Surface Analysis

2.3.2. Pre-Existing Data

3. Results and Discussion

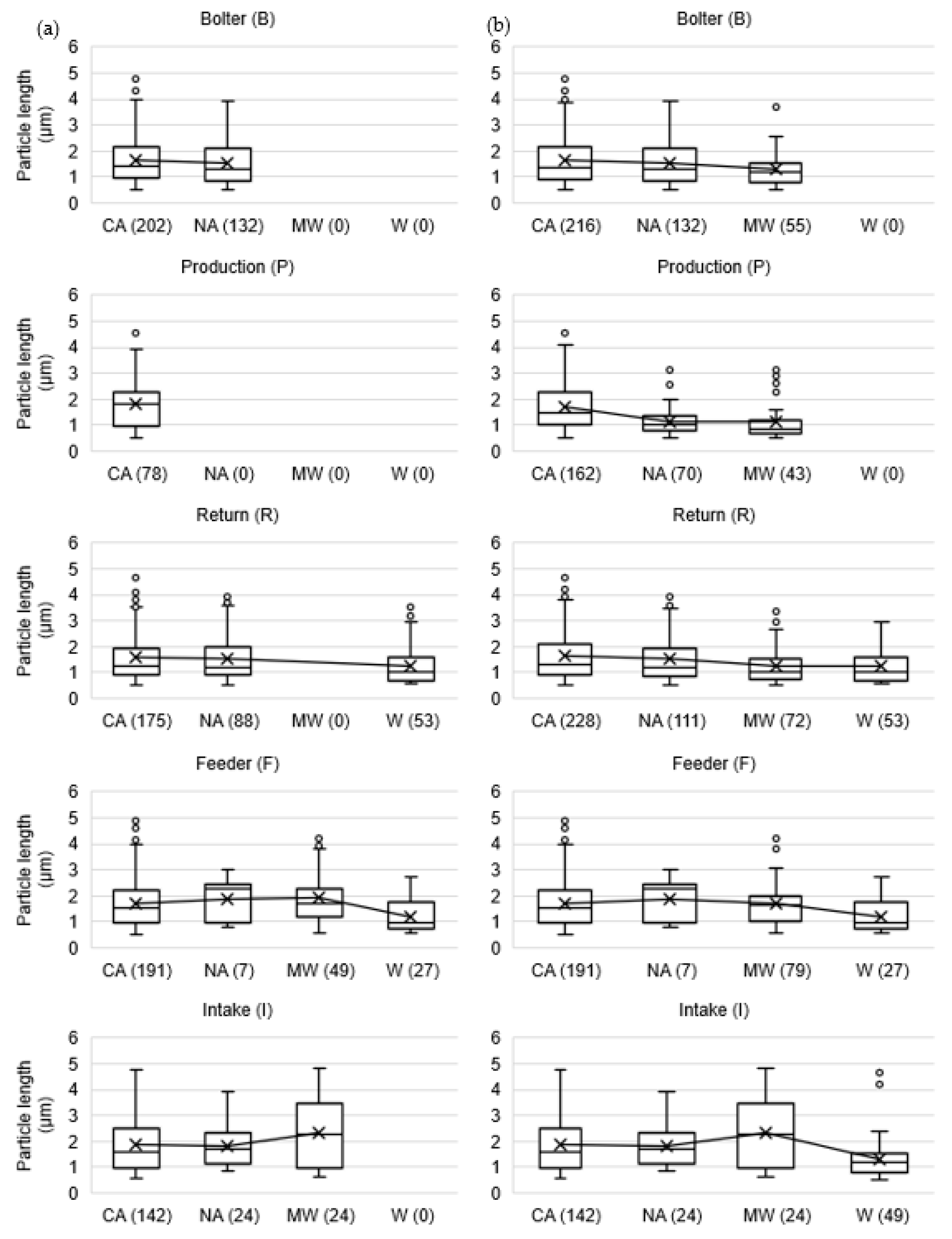

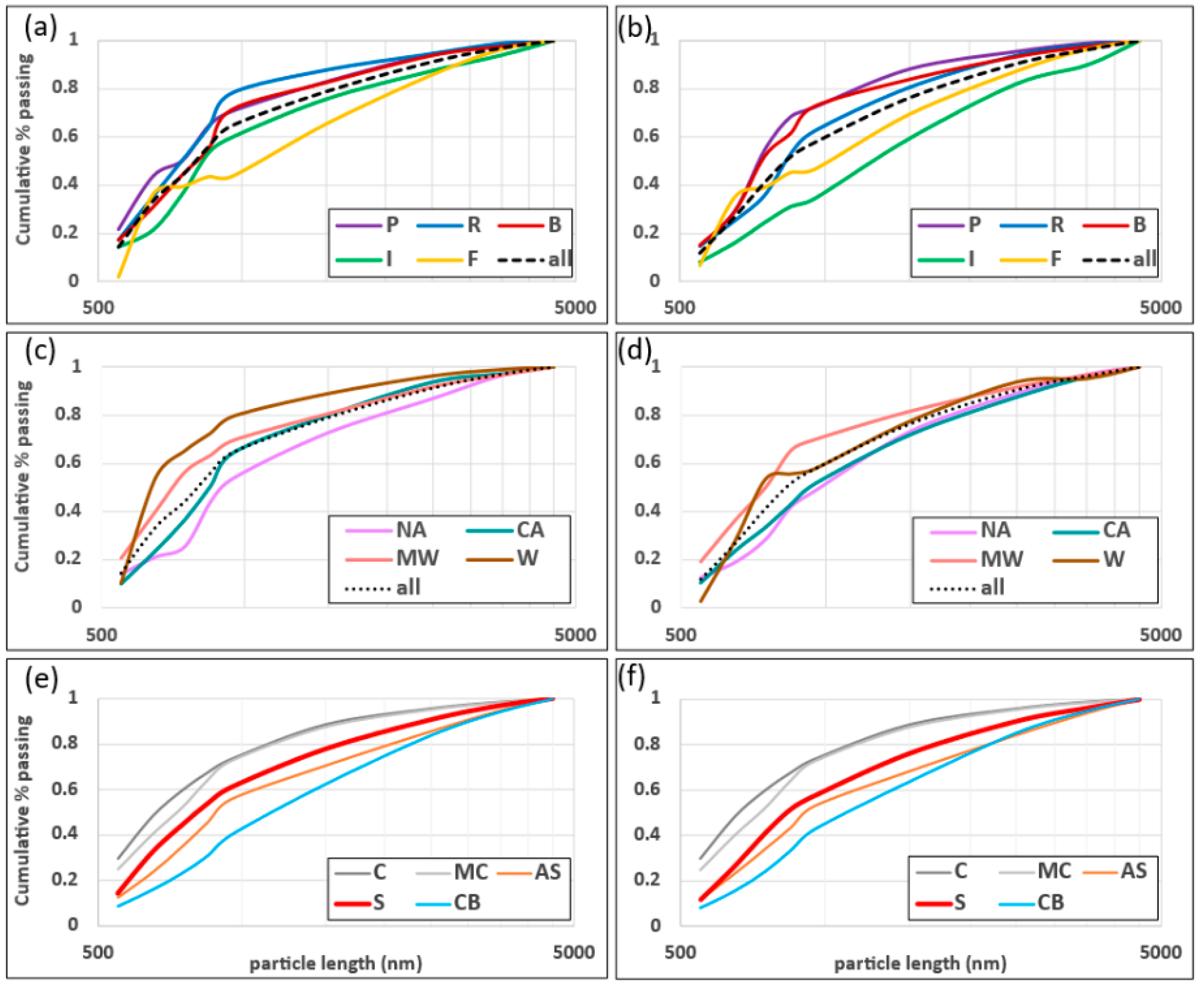

3.1. Silica Particle Size

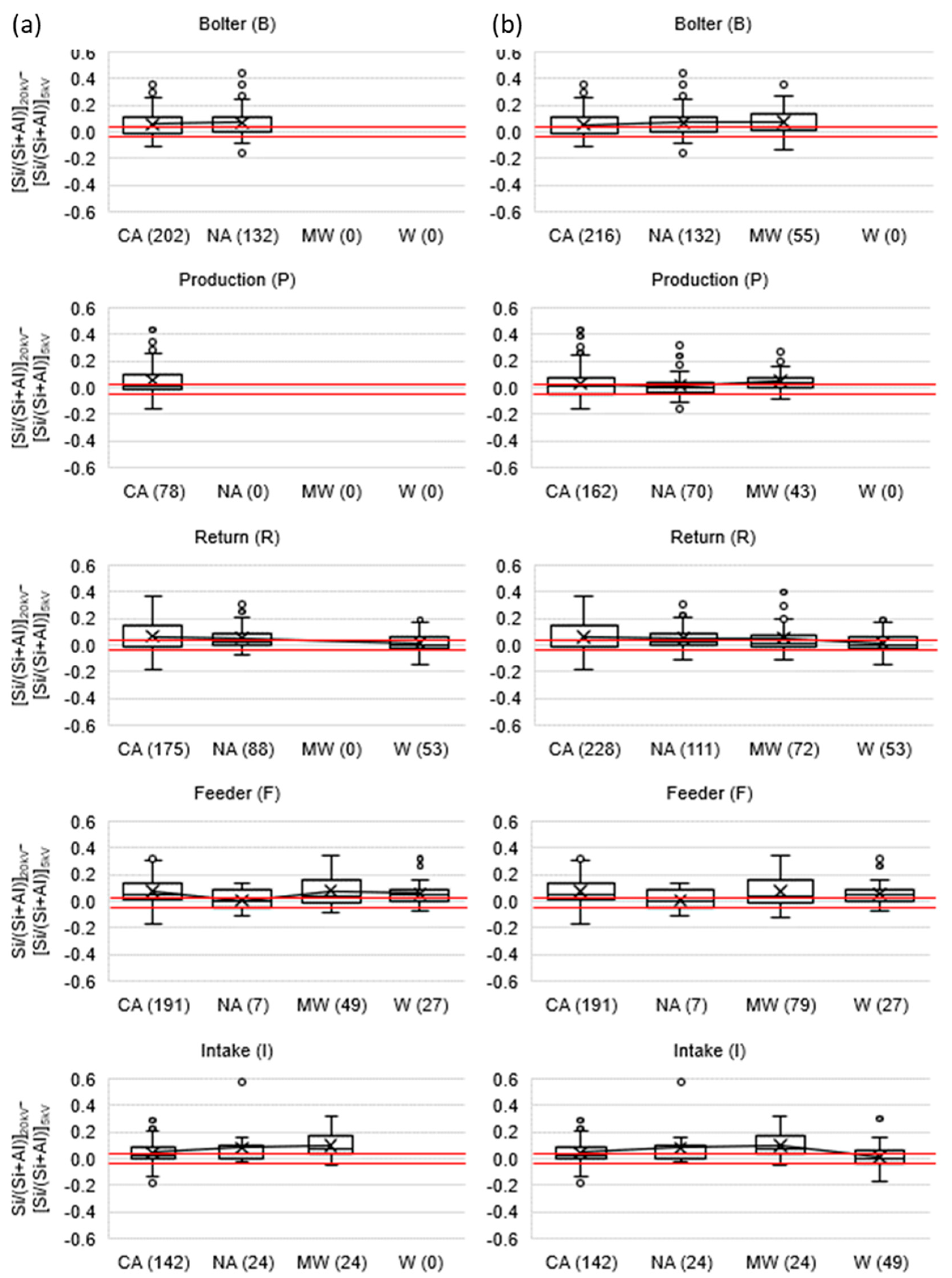

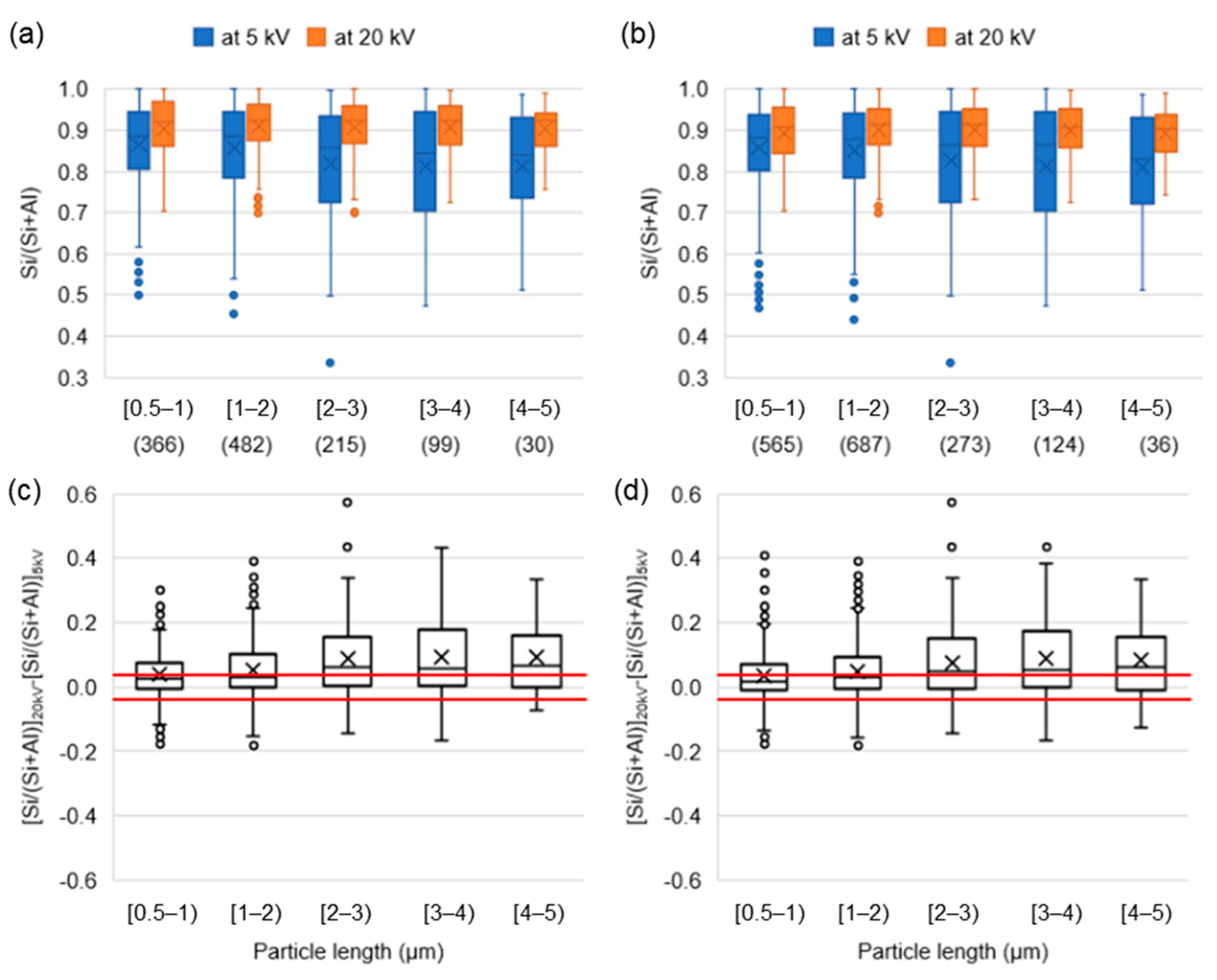

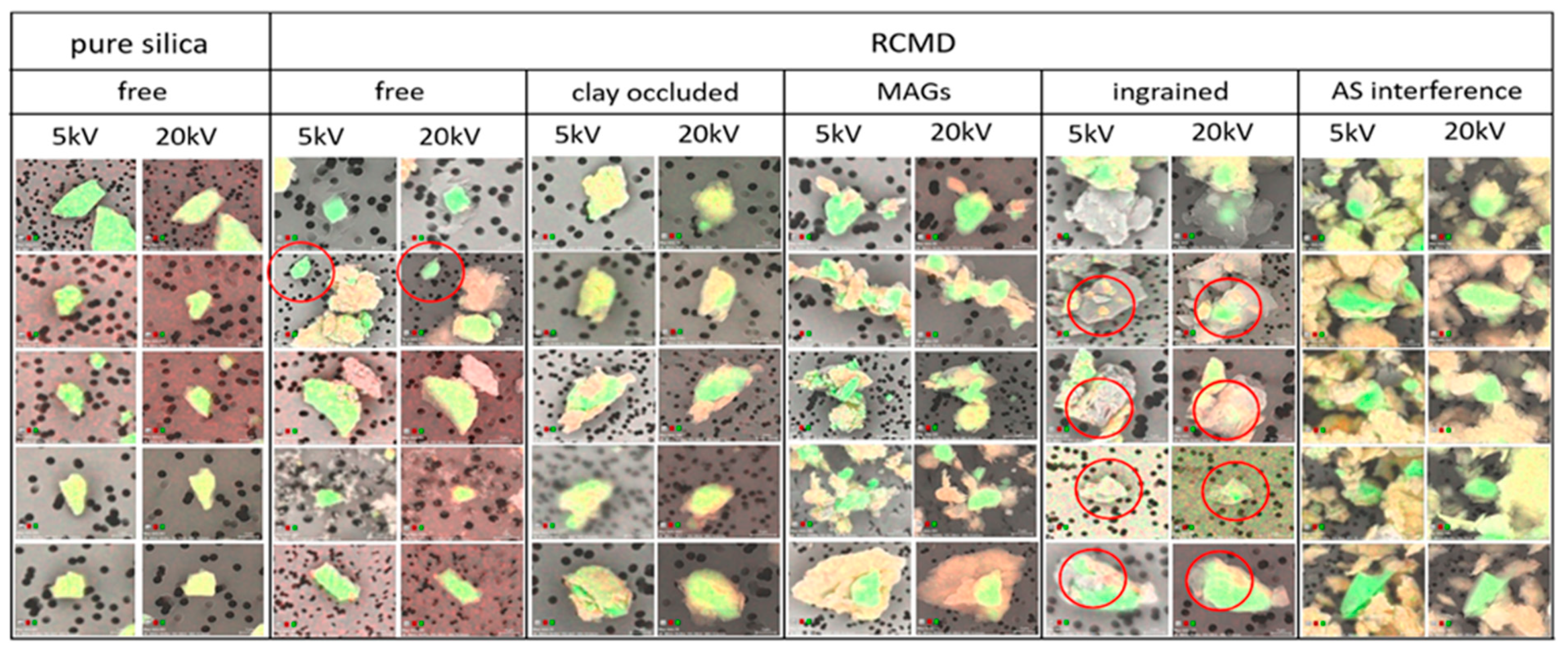

3.2. Silica Particle Surface Condition

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hall, N.B.; Blackley, D.J.; Halldin, C.N.; Laney, A.S. Current review of pneumoconiosis among US coal miners. Curr. Environ. Health Rep. 2019, 6, 137–147. [Google Scholar] [CrossRef] [PubMed]

- Antao, V.C.D.S.; Petsonk, E.L.; Sokolow, L.; Wolfe, A.L.; Pinheiro, G.A.; Hale, J.M.; Attfield, M.D. Rapidly progressive coal workers’ pneumoconiosis in the United States: Geographic clustering and other factors. Occup. Environ. Med. 2005, 62, 670–674. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Laney, A.S.; Weissman, D.N. Respiratory diseases caused by coal mine dust. J. Occup. Environ. Med. 2014, 56, S18–S22. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hall, N.B.; Blackley, D.J.; Halldin, C.N.; Laney, A.S. Continued increase in prevalence of r-type opacities among underground coal miners in the USA. Occup. Environ. Med. 2019, 76, 479–481. [Google Scholar] [CrossRef] [Green Version]

- Laney, A.S.; Petsonk, E.L.; Attfield, M.D. Pneumoconiosis among underground bituminous coal miners in the United States: Is silicosis becoming more frequent? Occup. Environ. Med. 2010, 67, 652–656. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cohen, R.A.; Petsonk, E.L.; Rose, C.; Young, B.; Regier, M.; Najmuddin, A.; Abraham, J.L.; Churg, A.; Green, F.H.Y. Lung Pathology in U.S. Coal Workers with Rapidly Progressive Pneumoconiosis Implicates Silica and Silicates. Am. J. Respir. Crit. Care Med. 2016, 193, 673–680. [Google Scholar] [CrossRef] [Green Version]

- Cohen, R.A.; Rose, C.S.; Go, L.H.T.; Zell-Baran, L.M.; Almberg, K.S.; Sarver, E.A.; Lowers, H.A. Pathology and mineralogy demonstrate respirable crystalline silica is a major cause of severe pneumoconiosis in U.S. coal miners. Ann. Am. Thorac. Soc. 2022, 19, 1469–1478. [Google Scholar] [CrossRef]

- Jelic, T.M.; Estelilla, O.C.; Sawyer-Kaplan, P.R.; Plata, M.J.; Powers, J.T.; Emmett, M.; Kuenstner, J.T. Coal mine dust desquamative chronic interstitial pneumonia: A precursor of dust-related diffuse fibrosis and of emphysema. Int. J. Occup. Environ. Med. 2017, 8, 153–165. [Google Scholar] [CrossRef] [Green Version]

- National Academies of Sciences, Engineering, and Medicine. Monitoring and Sampling Approaches to Assess Underground Coal Mine Dust Exposures; The National Academies Press: Washington, DC, USA, 2018. [Google Scholar] [CrossRef]

- Agioutanti, E.; Keles, C.; Sarver, E. A thermogravimetric analysis application to determine coal, carbonate, and non-carbonate minerals mass fractions in respirable mine dust. J. Occup. Environ. Hyg. 2020, 17, 47–58. [Google Scholar] [CrossRef]

- Doney, B.C.; Blackley, D.; Hale, J.M.; Halldin, C.; Kurth, L.; Syamlal, G.; Laney, A.S. Respirable coal mine dust in underground mines, United States, 1982-2017. Am. J. Ind. Med. 2019, 62, 478–485. [Google Scholar] [CrossRef]

- Mischler, S.E.; Cauda, E.G.; Di Giuseppe, M.; McWilliams, L.J.; Croix, C.S.; Sun, M.; Franks, J.; Ortiz, L.A. Differential activation of RAW 264.7 macrophages by size-segregated crystalline silica. J. Occup. Med. Toxicol. 2016, 11, 57. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ohyama, M.; Tachi, H.; Minejima, C.; Kameda, T. Comparing the role of silica particle size with mineral fiber geometry in the release of superoxide from rat alveolar macrophages. J. Toxicol. Sci. 2014, 39, 551–559. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wiessner, J.H.; Mandel, N.S.; Sohnle, P.G.; Mandel, G.S. Effect of particle size on quartz-induced hemolysis and on lung-inflammation and fibrosis. Exp. Lung Res. 1989, 15, 801–812. [Google Scholar] [CrossRef]

- Goldstein, B.; Webster, I. Intratracheal injection into rats of size-graded silica particles. Br. J. Ind. Med. 1966, 23, 71–74. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- IARC. Silica, Some Silicates, Coal Dust and Para-Aramid Fibrils. In Monographs on the Evaluation of Carcinogenic Risks to Humans; IARC: Lyon, France, 1997; Volume 68. [Google Scholar]

- Vallyathan, V.; Shi, X.L.; Dalal, N.S.; Irr, W.; Castranova, V. Generation of free radicals from freshly fractured silica dust. Potential role in acute silica-induced lung injury. Am. Rev. Respir. Dis. 1988, 138, 1213–1219. [Google Scholar] [CrossRef] [PubMed]

- Meldrum, M.; Howden, P. Crystalline silica: Variability in fibrogenic potency. Ann. Occup. Hyg. 2002, 46, 27–30. [Google Scholar] [CrossRef]

- Leung, C.C.; Yu, I.T.S.; Chen, W. Silicosis. Lancet 2012, 379, 2008–2018. [Google Scholar] [CrossRef]

- Hoy, R.F.; Chambers, D.C. Silica-related diseases in the modern world. Allergy 2020, 75, 2805–2817. [Google Scholar] [CrossRef] [Green Version]

- Hamilton, R.F., Jr.; Thakur, S.A.; Holian, A. Silica binding and toxicity in alveolar macrophages. Free Radic. Biol. Med. 2008, 44, 1246–1258. [Google Scholar] [CrossRef]

- Borm, P.J.A.; Fowler, P.; Kirkland, D. An updated review of the genotoxicity of respirable crystalline silica. Part Fibre. Toxicol. 2018, 15, 23. [Google Scholar] [CrossRef] [Green Version]

- Greenberg, M.I.; Waksman, J.; Curtis, J. Silicosis: A Review. Dis Mon. 2007, 53, 394–416. [Google Scholar] [CrossRef] [PubMed]

- Page, S.J. Comparison of coal mine dust size distributions and calibration standards for crystalline silica analysis. Am. Ind. Hyg. Assoc. J. 2003, 64, 30–39. [Google Scholar] [CrossRef] [PubMed]

- Chubb, L.; Cauda, E. Characterizing particle size distributions of crystalline silica in gold mine dust. Aerosol. Air Qual. Res. 2017, 17, 24–33. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chisholm, W.P.; Lee, T.; Chirila, M. Determination of crystalline silica in dust at low concentrations by low-temperature infrared spectrometry. Annu. Book ASTM Stand Sect. 11 Water Environ. Technol. 2013, 2013, 1–11. [Google Scholar] [CrossRef]

- Sarver, E.; Keles, C.; Rezaee, M. Beyond conventional metrics: Comprehensive characterization of respirable coal mine dust. Int. J. Coal Geol. 2019, 207, 84–95. [Google Scholar] [CrossRef]

- Sarver, E.; Keles, C.; Rezaee, M. Characteristics of respirable dust in eight Appalachian coal mines: A dataset including particle size and mineralogy distributions, and metal and trace element mass concentrations. Data Br. 2019, 25, 104032. [Google Scholar] [CrossRef]

- Rendall, R.E.G.; Goldstein, B.; Coetzee, F.S.J. Importance of particle size in the development of silicosis. Suid Afr. J. Sci. 1988, 84, 125–128. [Google Scholar]

- Monteiller, C.; Tran, L.; MacNee, W.; Faux, S.; Jones, A.; Miller, B.; Donaldson, K. The pro-inflammatory effects of low-toxicity low-solubility particles, nanoparticles and fine particles, on epithelial cells in vitro: The role of surface area. Occup. Environ. Med. 2007, 64, 609–615. [Google Scholar] [CrossRef] [Green Version]

- Gwinn, M.R.; Leonard, S.S.; Sargent, L.M.; Lowry, D.T.; McKinstry, K.; Meighan, T.; Reynolds, S.H.; Kashon, M.; Castranova, V.; Vallyathan, V. The role of p53 in silica-induced cellular and molecular responses associated with carcinogenesis. J. Toxicol. Environ. Health A 2009, 72, 1509–1519. [Google Scholar] [CrossRef]

- Vallyathan, V.; Kang, J.H.; Van Dyke, K.; Dalal, N.S.; Castranova, V. Response of alveolar macrophages to in vitro exposure to freshly fractured versus aged silica dust: The ability of Prosil 28, an organosilane material, to coat silica and reduce its biological reactivity. J. Toxicol. Environ. Health 1991, 33, 303–315. [Google Scholar] [CrossRef]

- Castranova, V.; Pailes, W.H.; Dalal, N.S.; Miles, P.R.; Bowman, L.; Vallyathan, V.; Pack, D.; Weber, K.C.; Hubbs, A.; Schwegler-Berry, D.; et al. Enhanced pulmonary response to the inhalation of freshly fractured silica as compared with aged dust exposure. Appl. Occup. Environ. Hyg. 1996, 11, 937–947. [Google Scholar] [CrossRef]

- Vallyathan, V.; Castranova, V.; Pack, D.; Leonard, S.; Shumaker, J.; Hubbs, A.F.; Shoemaker, D.A.; Ramsey, D.M.; Pretty, J.R.; McLaurin, J.L.; et al. Freshly fractured quartz inhalation leads to enhanced lung injury and inflammation. Potential role of free radicals. Am. J. Respir. Crit. Care Med. 1995, 152, 1003–1009. [Google Scholar] [CrossRef] [PubMed]

- Gothe, C.J.; Lidstrom, L.; Swensson, A. Influence of mode of disintegration on the fibrogenetic power of quartz particles. Med. Lav. 1971, 62, 375–377. [Google Scholar]

- Fubini, B. Surface chemistry and quartz hazard. Ann. Occ. Hyg. 1998, 42, 521–530. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Hnizdo, E.; Chen, J.Q.; Attfield, M.D.; Gao, P.; Hearl, F.; Lu, J.; Wallace, W.E. Risk of silicosis in cohorts of Chinese tin and tungsten miners and pottery workers (I): An epidemiological study. Am. J. Ind. Med. 2005, 48, 1–9. [Google Scholar] [CrossRef]

- Creutzenberg, O.; Hansen, T.; Ernst, H.; Muhle, H.; Oberdörster, G.; Hamilton, R. Toxicity of a quartz with occluded surfaces in a 90-day intratracheal instillation study in rats. Inhal. Toxicol. 2008, 20, 995–1008. [Google Scholar] [CrossRef]

- Stone, V.; Jones, R.; Rollo, K.; Duffin, R.; Donaldson, K.; Brown, D.M. Effect of coal mine dust and clay extracts on the biological activity of the quartz surface. Toxicol. Lett. 2004, 149, 255–259. [Google Scholar] [CrossRef]

- Ziemann, C.; Harrison, P.T.; Bellmann, B.; Brown, R.C.; Zoitos, B.K.; Class, P. Lack of marked cyto- and genotoxicity of cristobalite in devitrified (heated) alkaline earth silicate wools in short-term assays with cultured primary rat alveolar macrophages. Inhal. Toxicol. 2014, 26, 113–127. [Google Scholar] [CrossRef]

- Mestres, G.; Espanol, M.; Xia, W.; Tenje, M.; Ott, M. Evaluation of biocompatibility and release of reactive oxygen species of aluminum oxide-coated materials. ACS Omega 2016, 1, 706–713. [Google Scholar] [CrossRef] [Green Version]

- Ziemann, C.; Escrig, A.; Bonvicini, G.; Ibáñez, M.J.; Monfort, E.; Salomoni, A.; Creutzenberg, O. Organosilane-based coating of quartz species from the traditional ceramics industry: Evidence of hazard reduction using in vitro and in vivo tests. Ann. Work Expo. Health 2017, 61, 468–480. [Google Scholar] [CrossRef] [Green Version]

- Duffin, R.; Gilmour, P.S.; Schins, R.P.F.; Clouter, A.; Guy, K.; Brown, D.M.; MacNee, W.; Borm, P.J.; Donaldson, K.; Stone, V. Aluminum lactate treatment of DQ12 quartz inhibits its ability to cause inflammation, chemokine expression, and nuclear factor-κB activation. Toxicol. Appl. Pharmacol. 2001, 176, 10–17. [Google Scholar] [CrossRef] [PubMed]

- Walton, W.H.; Dodgson, J.; Hadden, G.G.; Jacobsen, M. The effect of quartz and other non-coal dusts in coal workers’ pneumoconiosis. In Inhaled Particles IV; Walton, W.H., Ed.; Unwin Brothers Ltd.: Surrey, UK, 1977; Volume 2, pp. 669–689. [Google Scholar]

- Harrison, J.C.; Brower, P.S.; Attfield, M.D.; Doak, C.B.; Keane, M.J.; Grayson, R.L.; Wallace, W.E. Surface composition of respirable silica particles in a set of US anthracite and bituminous coal mine dusts. J. Aerosol. Sci. 1997, 28, 689–696. [Google Scholar] [CrossRef]

- Wallace, W.E.; Harrison, J.C.; Grayson, R.L.; Keane, M.J.; Bolsaitis, P.; Kennedy, R.D.; Wearden, A.Q.; Attfield, M.D. Aluminosilicate surface contamination of respirable quartz particles from coal mine dusts and from clay works dusts. Ann. Occup. Hyg. 1994, 38, 439–445. [Google Scholar] [CrossRef]

- Wallace, W.E.; Chen, J.; Harrison, J.; Hnizdo, V.; Chen, W.; Nelson, J.; Chisholm, W.; Hnizdo, E.; Keane, M.J.; Miller, W.E. Respirable silica particle occlusion by alumino-silicate: Surface properties of dusts with disease risk anomalies. Med. Lav. 2002, 93, S66–S67. [Google Scholar]

- Frost, L.; Keles, C.; Sarver, E. A preliminary investigation of respirable silica particle surfaces in central Appalachian coal mine dust. In Proceedings of the 17th North American Mine Ventilation Symposium, Montreal, QC, Canada, 1 May 2019. [Google Scholar]

- Keles, C.; Pokhrel, N.; Sarver, E. A study of respirable silica in underground coal mines: Sources. Minerals 2022, 12, 1115. [Google Scholar] [CrossRef]

- Code of Federal Regulations (CFR). Mineral Resources. In Mandatory Safety Standards-Underground Coal Mines; Office of the Federal Register: Washington, DC, USA, 1969. [Google Scholar]

- Sarver, E.; Keles, C.; Afrouz, S.G. Particle size and mineralogy distributions in respirable dust samples from 25 US underground coal mines. Int. J. Coal Geol. 2021, 247, 103851. [Google Scholar] [CrossRef]

- Keles, C.; Taborda, M.J.; Sarver, E. Updating “Characteristics of respirable dust in eight Appalachian coal mines: A dataset including particle size and mineralogy distributions, and metal and trace element mass concentrations” with expanded data to cover a total of 25 US mines. Data Br. 2022, 42, 108125. [Google Scholar] [CrossRef]

- Goldstein, J.I.; Newbury, D.E.; Echlin, P.; Joy, D.C.; Lyman, C.E.; Lifshin, E.; Sawyer, L.; Michael, J.R. Procedures for elimination of charging in nonconducting specimens. In Scanning Electron Microscopy and X-Ray Microanalysis, 3rd ed.; Goldstein, J.I., Newbury, D.E., Eds.; Springer: New York, NY, USA, 2003; pp. 647–673. [Google Scholar]

- Harrison, J.; Chen, J.Q.; Miller, W.; Chen, W.; Hnizdo, E.; Lu, J.; Chisholm, W.; Keane, M.; Gao, P.; Wallace, W. Risk of silicosis in cohorts of chinese tin and tungsten miners and pottery workers (II): Workplace-specific silica particle surface composition. Am. J. Ind. Med. 2005, 48, 10–15. [Google Scholar] [CrossRef]

- Wallace, W.E.; Harrison, J.; Keane, M.J.; Bolsaitis, P.; Eppelsheimer, D.; Poston, J.; Page, S.J. Clay occlusion of respirable quartz particles detected by low voltage scanning electron microscopy–X-ray analysis. Ann. Occup. Hyg. 1990, 34, 195–204. [Google Scholar] [CrossRef]

- Wallace, W.E.; Keane, M.J. Differential Surface Composition Analysis by Multiple-Voltage Electron Beam X-ray Spectrometry. US Patent 5,210,414, 11 May 1993. [Google Scholar]

- Hnizdo, V.; Wallace, W.E. Monte Carlo analysis of the detection of clay occlusion of respirable quartz particles using multiple voltage scanning electron microscopy. Scanning 2002, 24, 264–269. [Google Scholar] [CrossRef]

- Pokhrel, N.; Agioutanti, E.; Keles, C.; Afrouz, S.; Sarver, E. Comparison of respirable coal mine dust constituents estimated using FTIR, TGA, and SEM-EDX. MMEX 2022, 39, 291–300. [Google Scholar] [CrossRef]

- Gonzalez, J.; Keles, C.; Sarver, E. On the occurrence and persistence of coal-mineral microagglomerates in respirable coal mine dust. MMEX 2022, 39, 271–282. [Google Scholar] [CrossRef]

| Mine | Mine | MSHA | State 2 | Mining | Coal | Mining | Roof | Sampling Location 5 | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| reg. 1 | District | Method 3 | Ht. (m) | Ht. (m) | Strata 4 | B | P | R | F | I | Total | ||

| 10 | CA | 5 | KY | CM | 1–1.2 | 1.8–1.9 | Sh/Sn | 2 | 0 | 1 | 2 | 1 | 6 |

| 11 | CA | 5 | VA | CM | 0.8 | 1.2–1.3 | Sh | 1 | 1 | 1 | 1 | 0 | 4 |

| 12 | CA | 5 | VA | CM | 0.8–1.5 | 1.9–2.0 | Sh/Sn | 1 | 1 | 1 | 0 | 1 | 4 |

| 13 | CA | 5 | VA | LW | 1.5–1.8 | 1.8–2.0 | Sn/Sh | 0 | 0 | 1 | 1 | 2 | 4 |

| 14 | CA | 5 | VA | CM | 0.6–0.9 | 1.5–1.9 | Sh | 1 | 0 | 0 | 1 | 1 | 3 |

| 15 | CA | 4 | WV | CM | 0.9–1.2 | 2 | Sh | 1 | 1 | 1 | 0 | 0 | 3 |

| 16 | NA | 3 | WV | CM | 2.7 | 2.1 | Sh | 1 | 1 | 1 | 1 | 0 | 4 |

| 17 | NA | 3 | WV | LW | 1.5–1.8 | 2.0–2.3 | Sh | 1 | 1 | 2 | 0 | 2 | 6 |

| 18 | NA | 3 | WV | CM | 0.7–0.8 | 1.5–1.8 | Sh | 1 | 1 | 1 | 1 | 1 | 5 |

| 19 | MW | 8 | IL | CM | 1.8–2.0 | 1.9–2.3 | Sh/Lm | 1 | 1 | 2 | 1 | 1 | 6 |

| 20 | MW | 8 | IL | CM | 1.8–1.9 | 1.8–2.0 | Sh/Lm | 1 | 0 | 0 | 2 | 1 | 4 |

| 21 | CA | 12 | WV | CM | 0.8–1.0 | 2 | Sh/Sn | 1 | 0 | 1 | 1 | 1 | 4 |

| 22 | CA | 12 | WV | CM | 0.8 | 1.4 | Sh | 0 | 1 | 0 | 1 | 0 | 2 |

| 23 | W | 9 | CO | LW | 6.1 | 4.3 | Sh | 0 | 0 | 0 | 0 | 0 | 0 |

| 24 | W | 9 | CO | LW | 1.8 | 2.1–2.4 | Sh/Sn | 0 | 0 | 1 | 1 | 1 | 3 |

| B | P | R | F | I | Total | ||||||||

| Total | 12 | 8 | 13 | 13 | 12 | 58 | |||||||

| Mine Region 1 | Sampling Location 2 | Total | PLD 3 < 0.035 | PLD > 0.035 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| n 4 | RCS 5 | n | RCS | Mean PLD (#/µm2) | Mean Length (µm) | Mean Change in Si/(Si + Al) 6 | n | RCS | Mean PLD (#/µm 2) | Mean Length (µm) | Mean Change in Si/(Si + Al) | ||

| CA | B | 7 | 216 | 6 | 202 | 0.017 | 1.6 | 0.056 | 1 | 14 | 0.051 | 1.5 | 0.013 * |

| P | 4 | 162 | 2 | 78 | 0.021 | 1.8 | 0.053 | 2 | 84 | 0.039 | 1.6 | 0.008 * | |

| R | 6 | 228 | 4 | 175 | 0.022 | 1.6 | 0.065 | 2 | 53 | 0.039 | 1.8 | 0.044 | |

| F | 7 | 191 | 7 | 191 | 0.018 | 1.7 | 0.071 | 0 | 0 | - | - | - | |

| I | 6 | 142 | 6 | 142 | 0.014 | 1.8 | 0.045 | 0 | 0 | - | - | - | |

| NA | B | 3 | 132 | 3 | 132 | 0.011 | 1.5 | 0.070 | 0 | 0 | - | - | - |

| P | 3 | 70 | 0 | 0 | - | - | - | 3 | 70 | 0.043 | 1.1 | 0.016 * | |

| R | 4 | 111 | 3 | 88 | 0.021 | 1.5 | 0.054 | 1 | 23 | 0.056 | 1.4 | 0.014 * | |

| F | 2 | 7 | 2 | 7 | 0.006 | 1.9 | 0.005 * | 0 | 0 | - | - | - | |

| I | 3 | 24 | 3 | 24 | 0.004 | 1.8 | 0.081 | 0 | 0 | - | - | - | |

| MW | B | 2 | 55 | 0 | 0 | - | - | - | 2 | 55 | 0.047 | 1.3 | 0.071 |

| P | 1 | 43 | 0 | 0 | - | - | - | 1 | 43 | 0.038 | 1.1 | 0.048 | |

| R | 2 | 72 | 0 | 0 | - | - | - | 2 | 72 | 0.044 | 1.3 | 0.052 | |

| F | 3 | 79 | 2 | 49 | 0.021 | 1.9 | 0.079 | 1 | 30 | 0.049 | 1.4 | 0.066 | |

| I | 2 | 24 | 2 | 24 | 0.005 | 2.3 | 0.098 | 0 | 0 | - | - | - | |

| W | B | 0 | 0 | 0 | 0 | - | - | - | 0 | 0 | - | - | - |

| P | 0 | 0 | 0 | 0 | - | - | - | 0 | 0 | - | - | - | |

| R | 1 | 53 | 1 | 53 | 0.032 | 1.2 | 0.014 * | 0 | 0 | - | - | - | |

| F | 1 | 27 | 1 | 27 | 0.015 | 1.2 | 0.056 | 0 | 0 | - | - | - | |

| I | 1 | 49 | 0 | 0 | - | - | - | 1 | 49 | 0.051 | 1.3 | 0.009 * | |

| all Samples | B | 12 | 403 | 9 | 334 | 0.015 | 1.6 | 0.062 | 3 | 69 | 0.048 | 1.3 | 0.059 |

| P | 8 | 275 | 2 | 78 | 0.021 | 1.8 | 0.053 | 6 | 197 | 0.040 | 1.3 | 0.020 * | |

| R | 13 | 464 | 8 | 316 | 0.023 | 1.5 | 0.053 | 5 | 148 | 0.044 | 1.5 | 0.044 | |

| F | 13 | 304 | 12 | 274 | 0.018 | 1.7 | 0.069 | 1 | 30 | 0.049 | 1.4 | 0.066 | |

| I | 12 | 239 | 11 | 190 | 0.012 | 1.9 | 0.057 | 1 | 49 | 0.051 | 1.3 | 0.009 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Keles, C.; Sarver, E. A Study of Respirable Silica in Underground Coal Mines: Particle Characteristics. Minerals 2022, 12, 1555. https://doi.org/10.3390/min12121555

Keles C, Sarver E. A Study of Respirable Silica in Underground Coal Mines: Particle Characteristics. Minerals. 2022; 12(12):1555. https://doi.org/10.3390/min12121555

Chicago/Turabian StyleKeles, Cigdem, and Emily Sarver. 2022. "A Study of Respirable Silica in Underground Coal Mines: Particle Characteristics" Minerals 12, no. 12: 1555. https://doi.org/10.3390/min12121555