The Influence of Micro-Heterogeneity on Water Injection Development in Low-Permeability Sandstone Oil Reservoirs

Abstract

:1. Introduction

2. Geological Background

2.1. General Geological Situation of the Ordos Basin

2.2. Selection of the Target Area

2.3. Genesis of the YW Low-Permeability Reservoir

3. Materials and Methods

3.1. Rock Samples and Fluids

3.2. Experimental Apparatus and Testing Methods

3.2.1. Measurement of Porosity and Permeability

3.2.2. Cast Thin Sections and Scanning Electron Microscopy Observation

3.2.3. X-ray Diffraction of Whole Rocks and X-ray Diffraction of Clay Analysis

3.2.4. Particle Size Image Analysis

3.2.5. High-Pressure Mercury Intrusion Experiment

3.2.6. Relative Permeability and a Water-Driving Oil Experiment

3.2.7. Wettability Test Experiment

4. Results and Discussion

4.1. Analysis of Micro-Heterogeneity Characteristics of Reservoirs

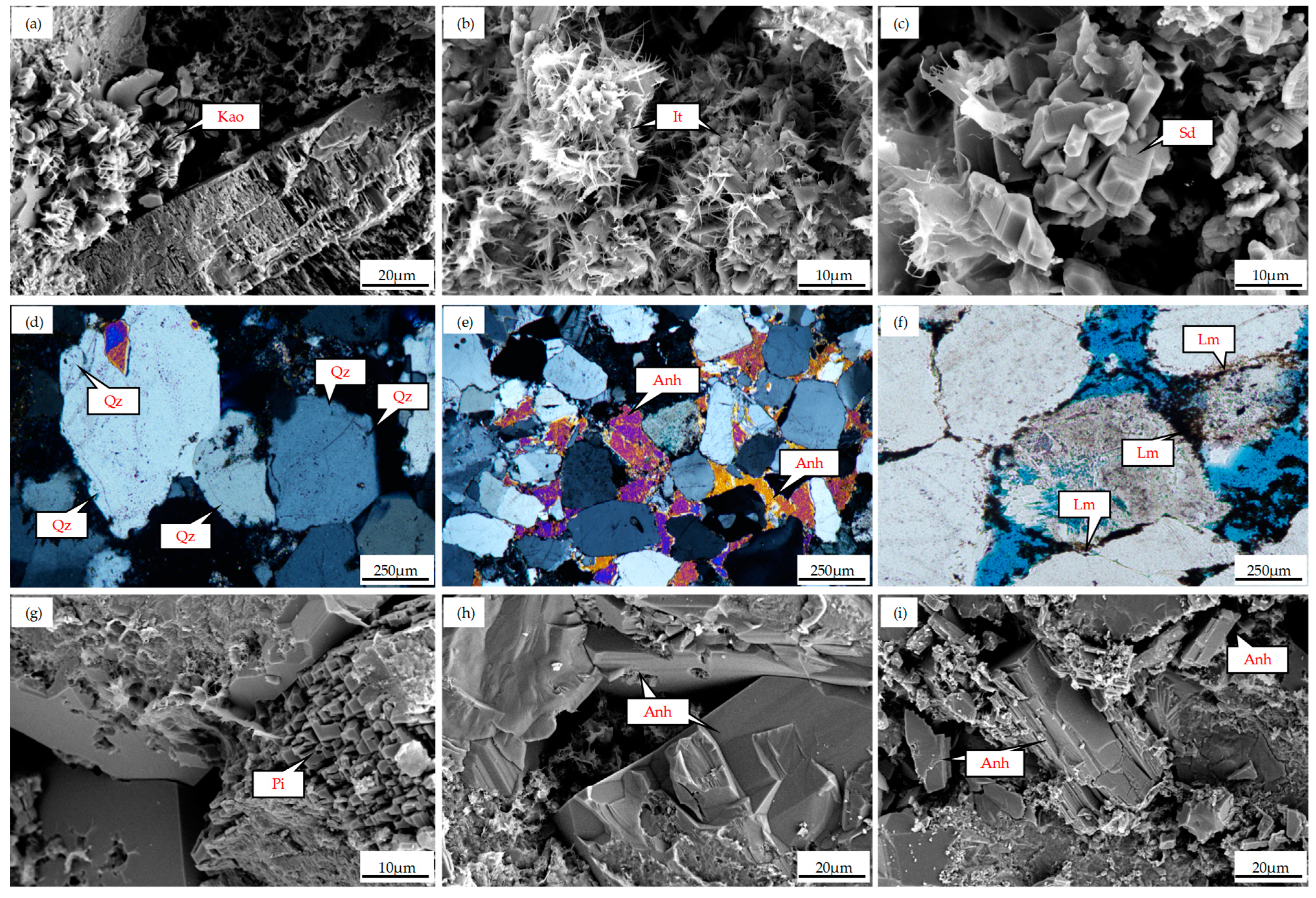

4.1.1. Interstitial Material Heterogeneity

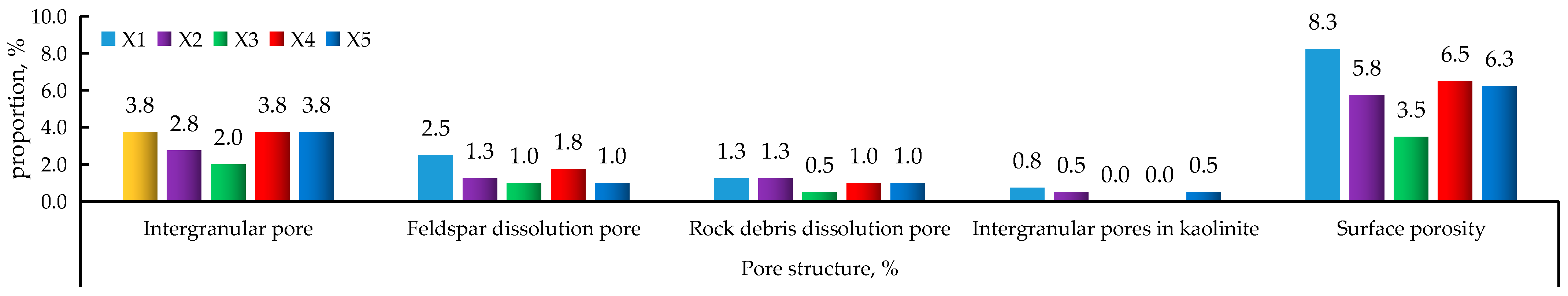

4.1.2. Pore Heterogeneity

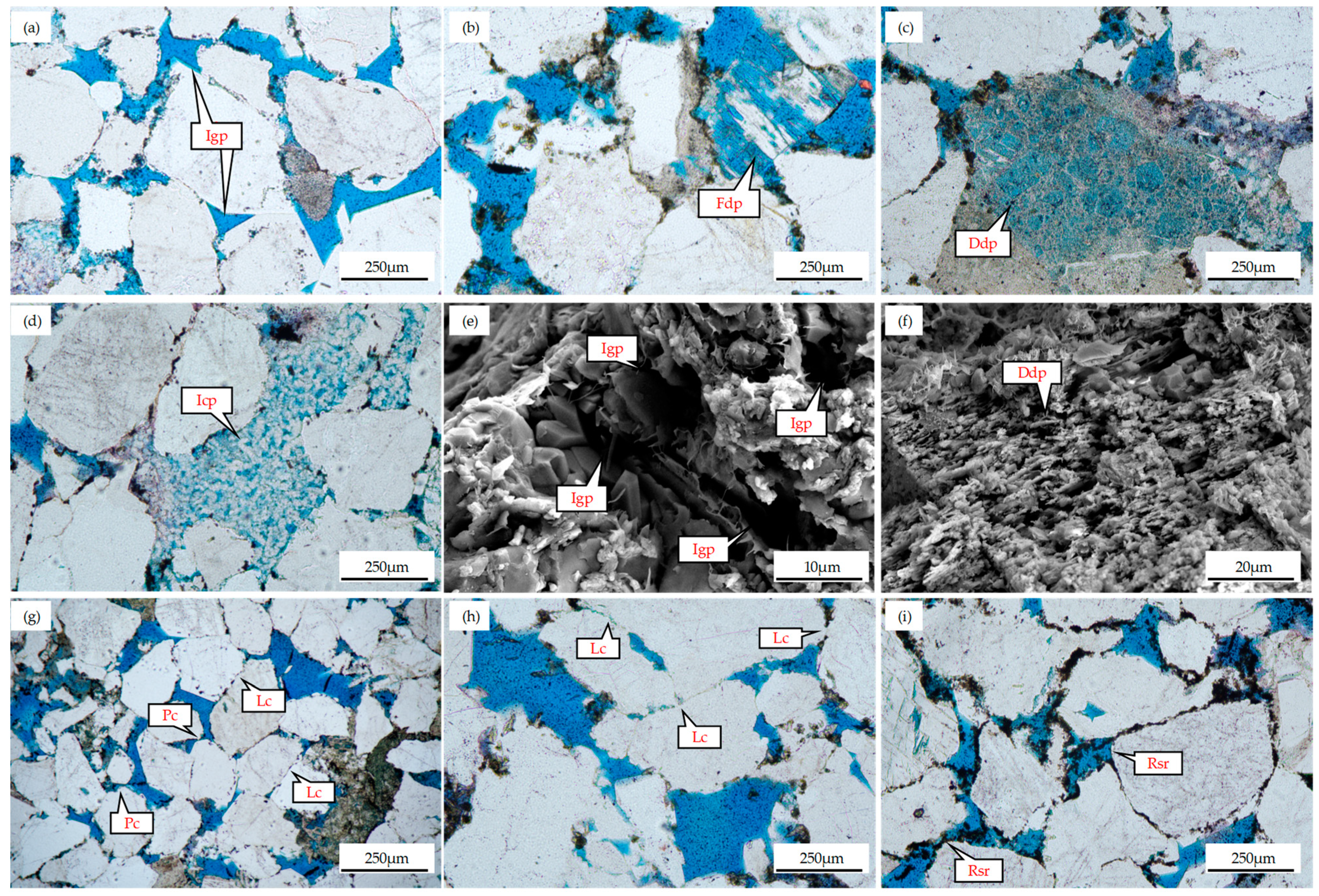

- Qualitative Evaluation of Pore Heterogeneity

- Quantitative Evaluation of Pore Heterogeneity

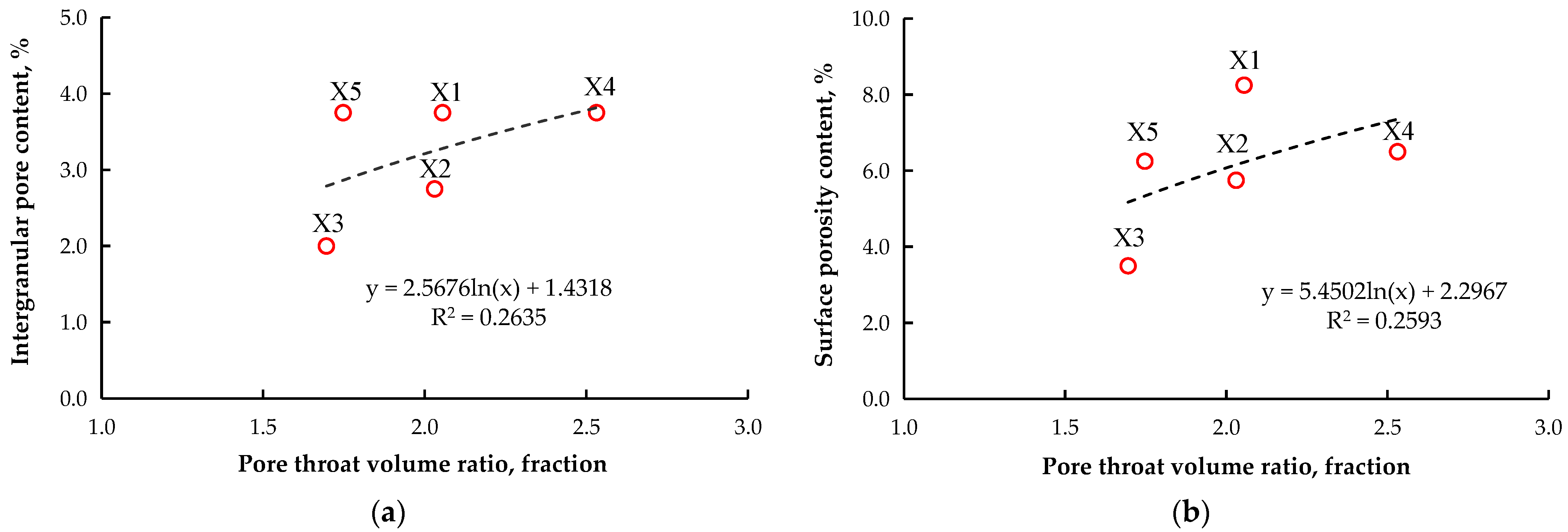

- The Relationship between Pore Structure and Pore Heterogeneity

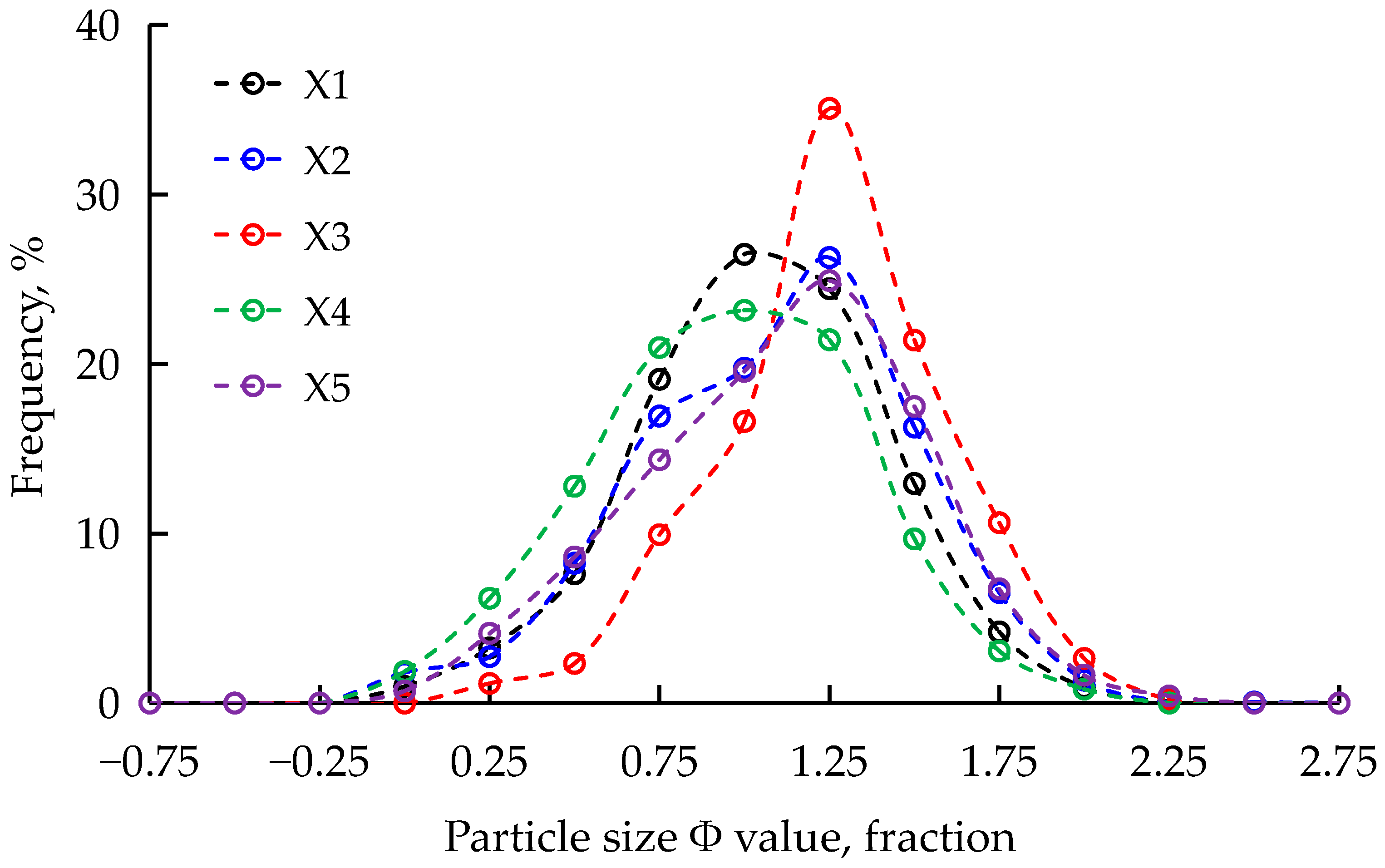

4.1.3. Particle Heterogeneity

4.2. Analysis of the Impact of Micro-Heterogeneity on Reservoir Water Injection Development

4.2.1. The Relationship between Micro-Heterogeneity and Relative Permeability

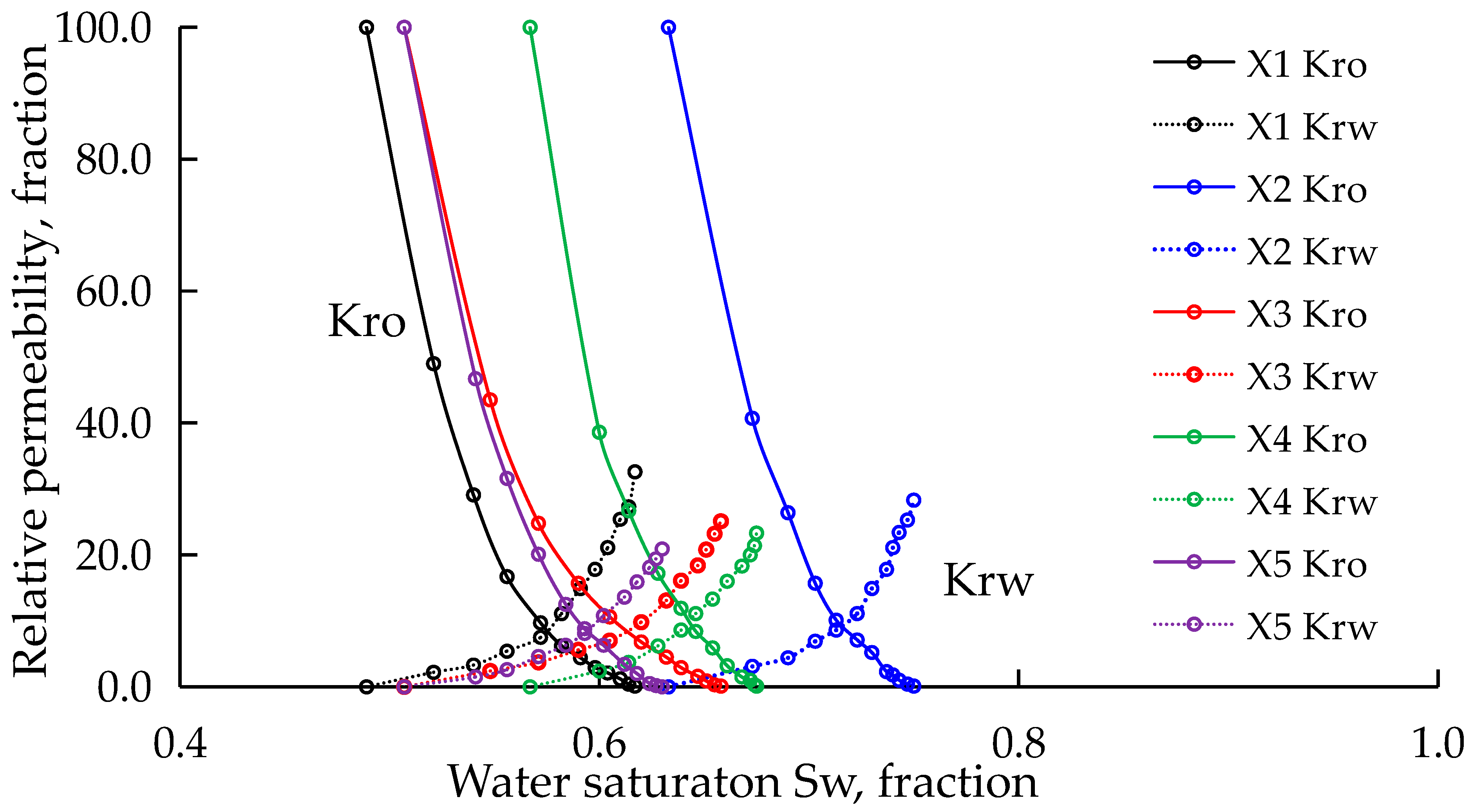

- Analysis of Experimental Data on Relative Permeability

- Analysis of the Characteristics of the Relative Permeability Curve

- Analysis of the Relationship between Reservoir Physical Properties and Relative Permeability

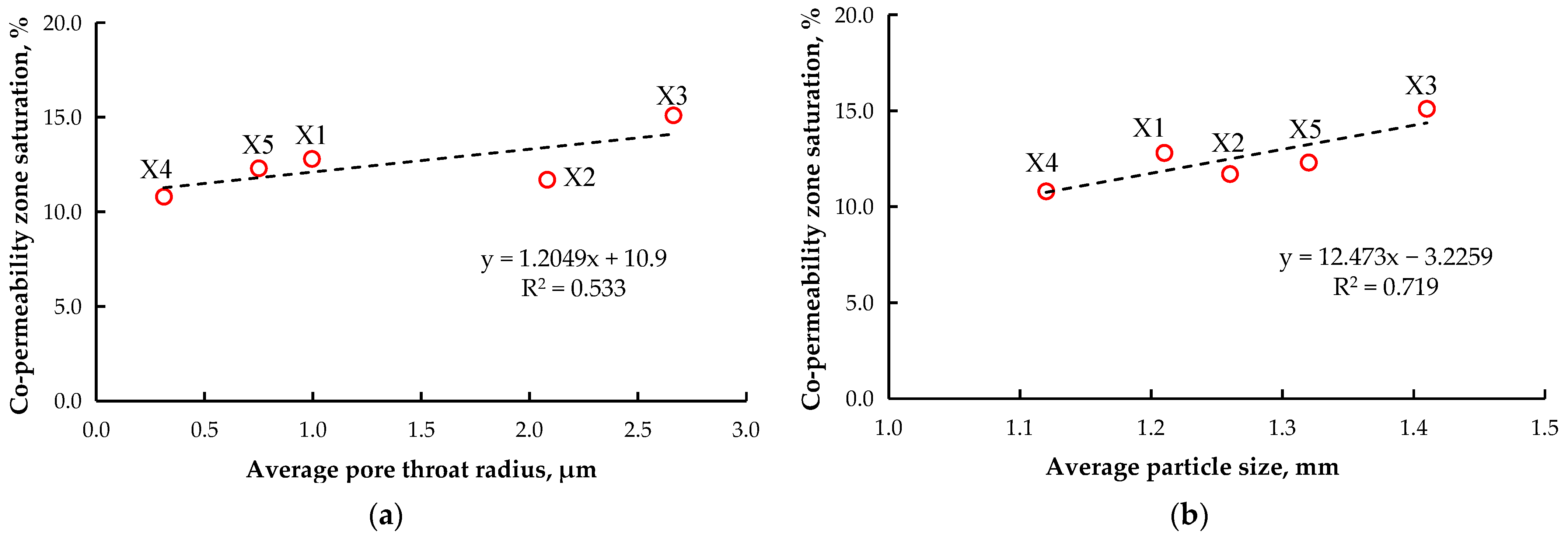

- The Relationship between Micro-Heterogeneity and Relative Permeability

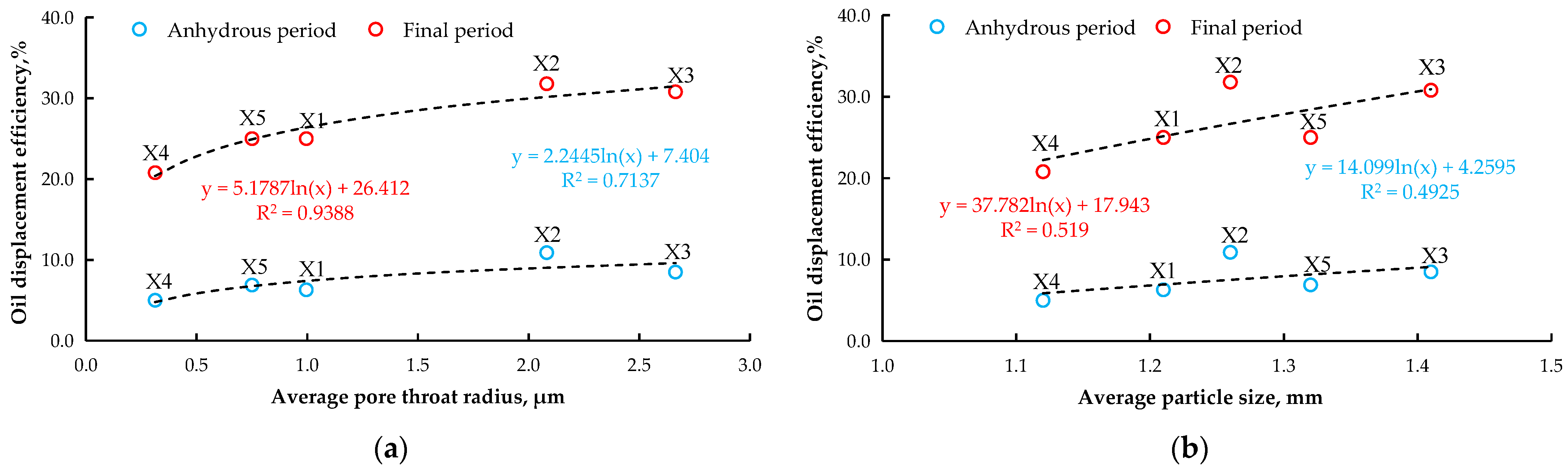

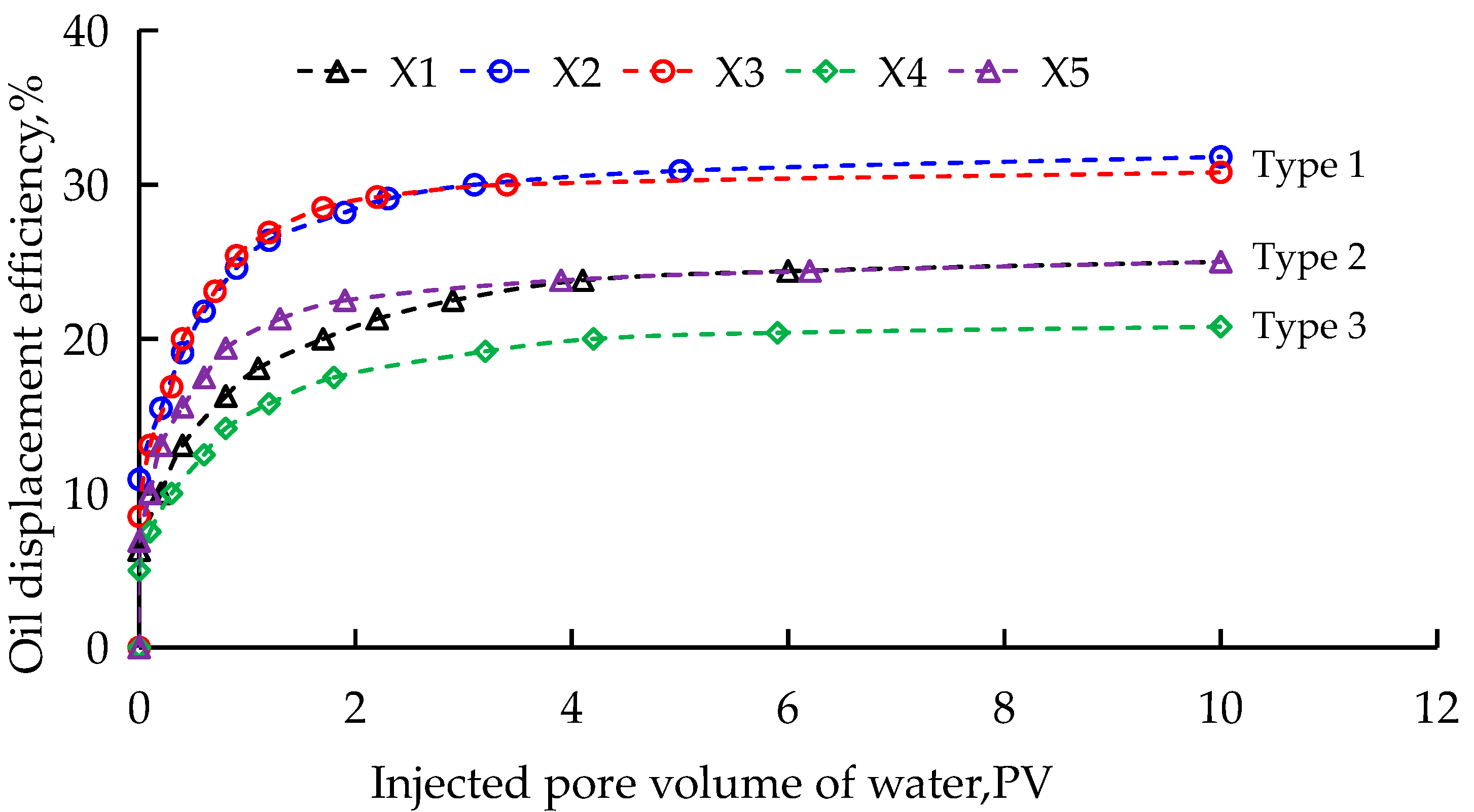

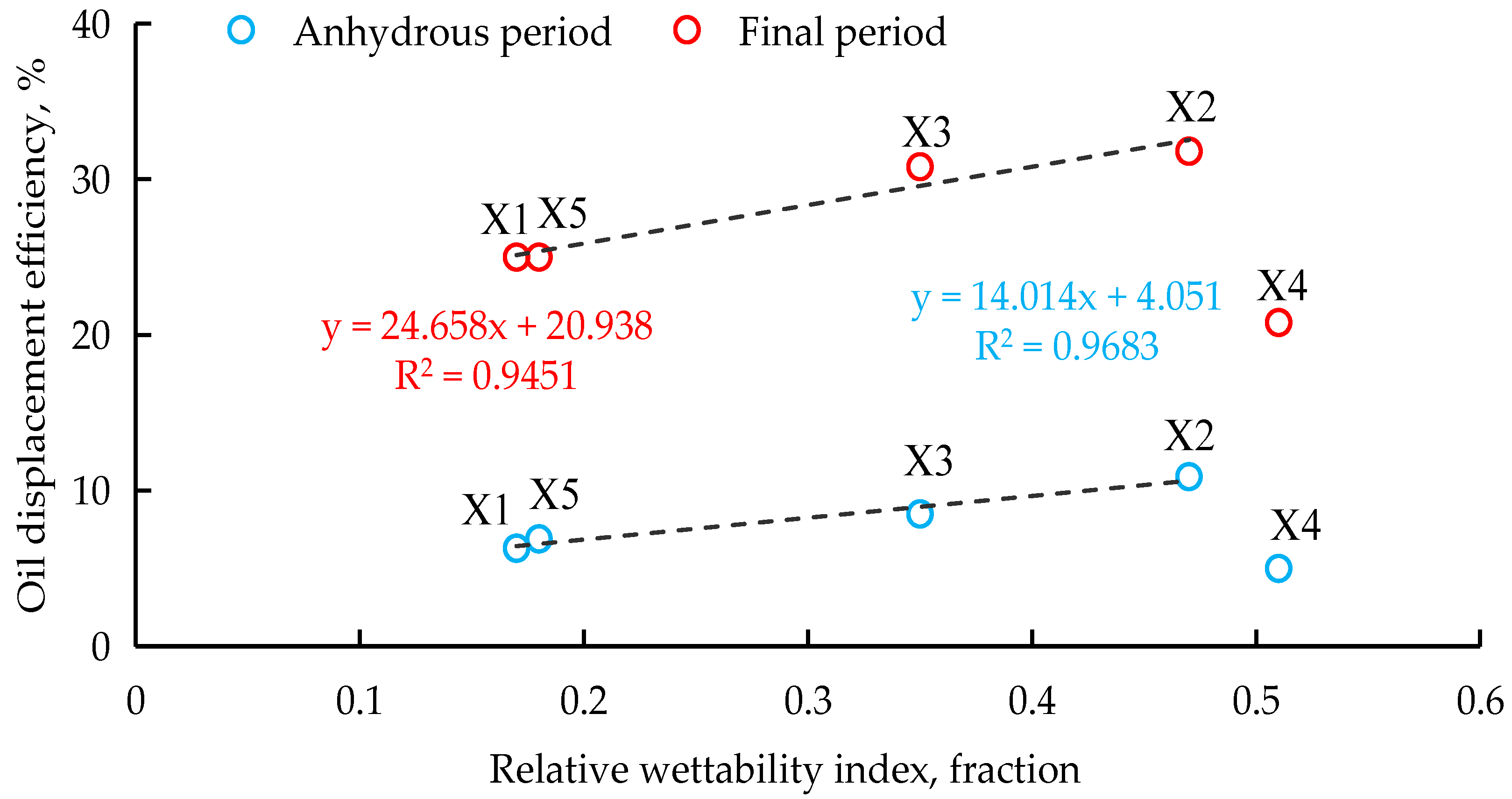

4.2.2. The Relationship between Micro-Heterogeneity and Oil Displacement Efficiency

4.2.3. The Relationship between Micro-Heterogeneity and Wettability

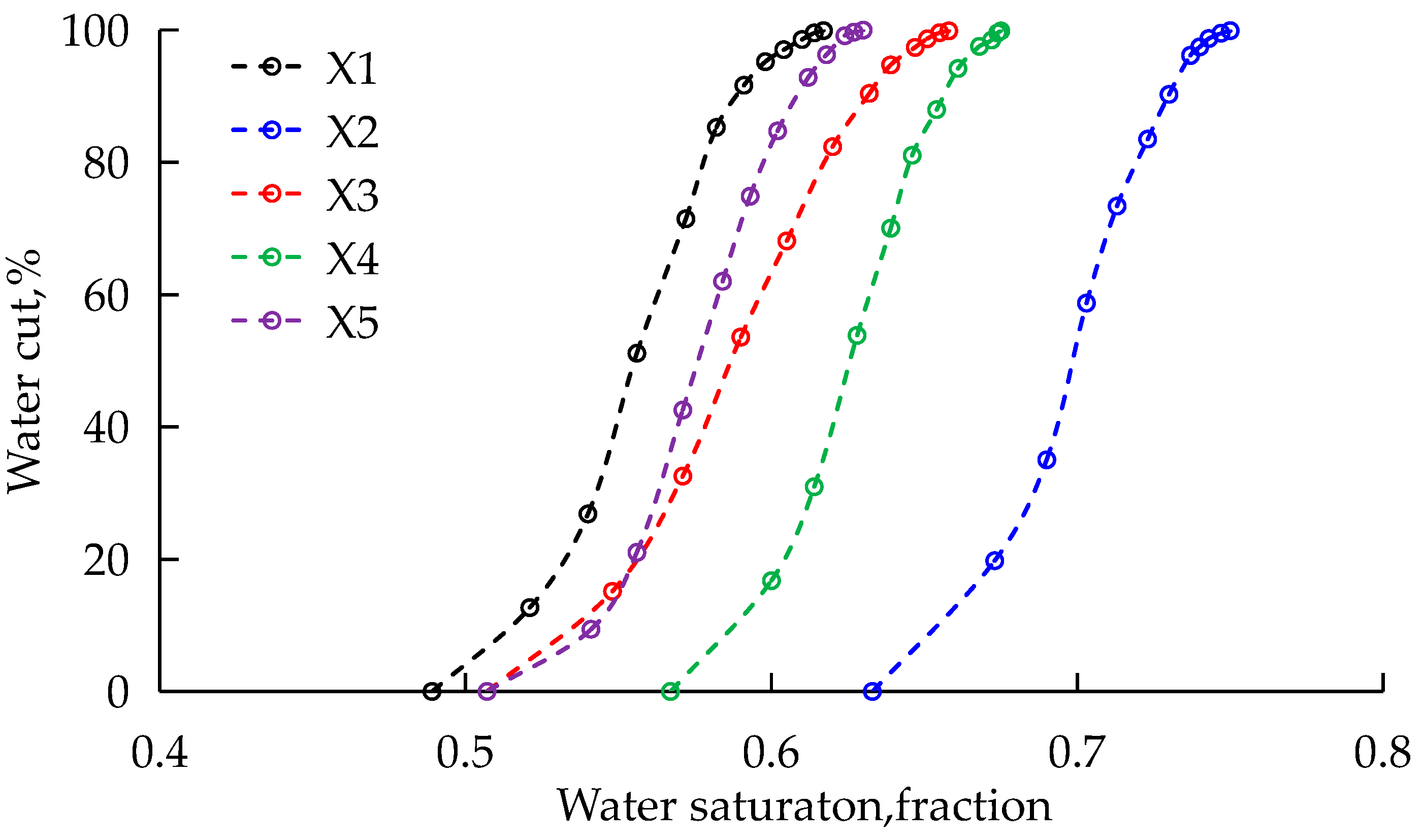

4.2.4. The Relationship between Micro-Heterogeneity and the Water Cut Change Law

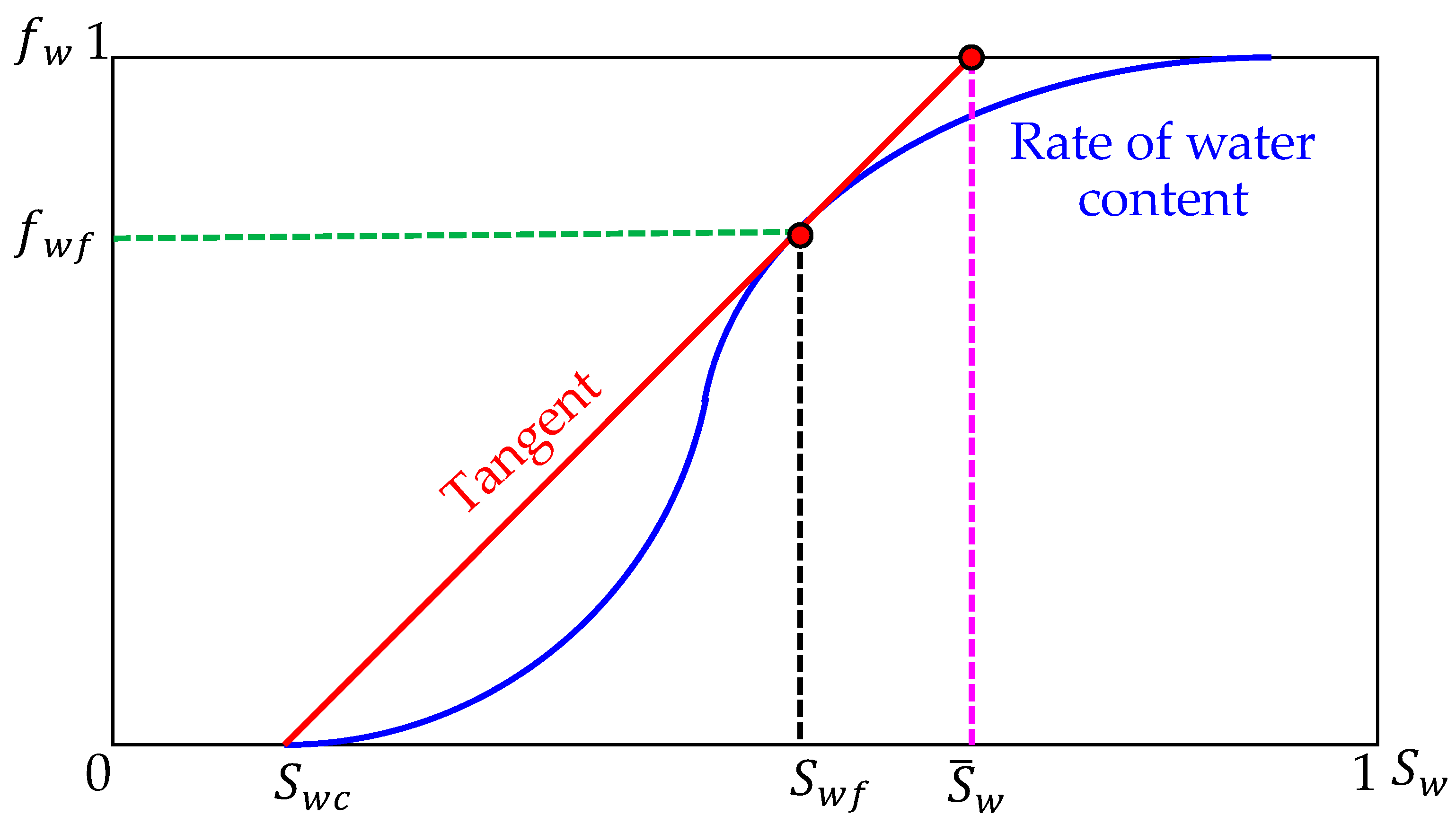

- Relationship between the Water Cut, Waterflood Front, and Water Saturation

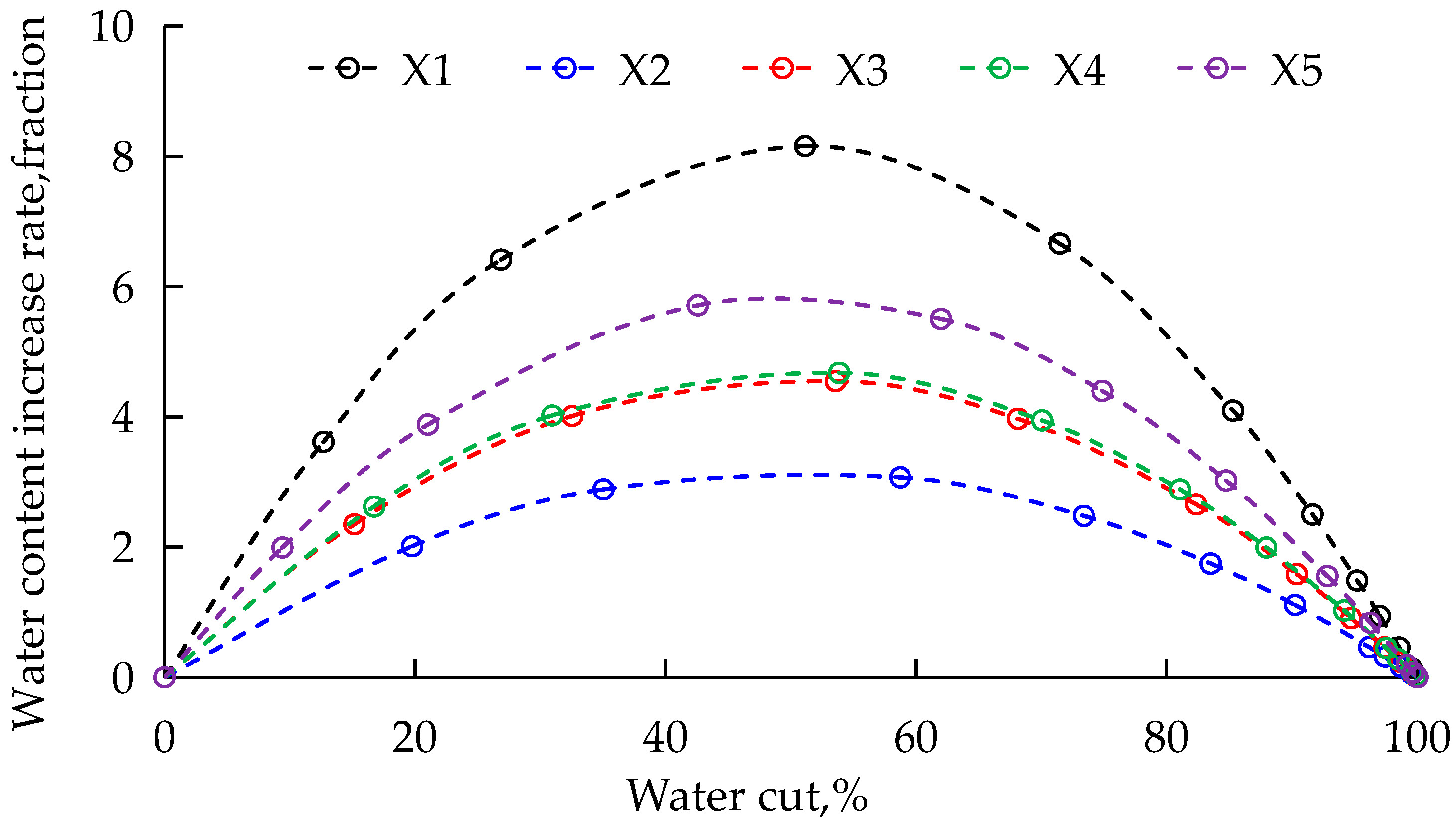

- Relationship between the Water Cut, Water Saturation, and the Water Cut Increase Rate

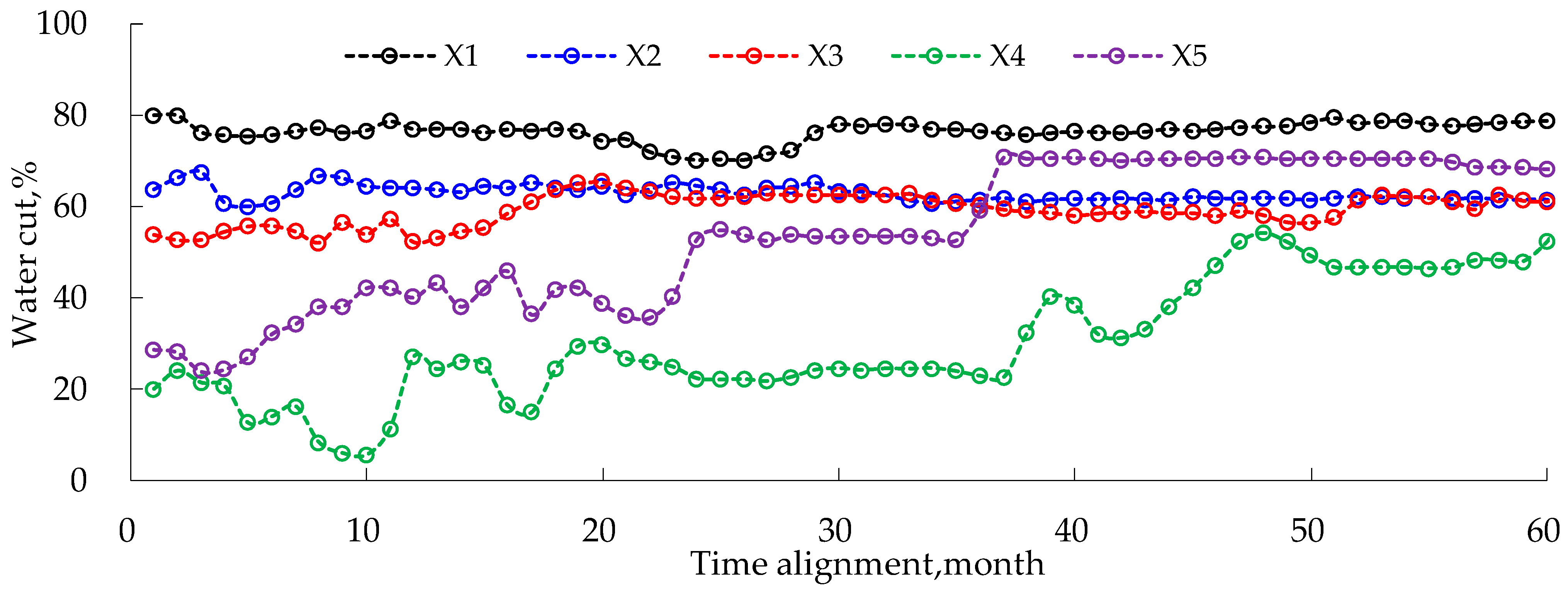

4.2.5. Production Dynamic Verification

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, Z.B.; Fu, L.; Chen, X.J.; Zhang, T.; Xie, Y.H.; Wang, H.B. Quantitative Evaluation Method for Micro Heterogeneity of Tight Sandstone: A case study of Chang-6 reservoir of Yanchang Formation in Huaqing area, Ordos Basin. ACTA Sedimentol. Sin. 2021, 39, 1086–1099. [Google Scholar] [CrossRef]

- Pettijohn, F.J.; Potter, P.E.; Siever, R. Sand and Sand-Stone; Springer: Berlin, Germany, 1973; pp. 550–554. [Google Scholar]

- Haldorsen, H.H. Reservoir Characterisation Procedures for Numerical Simulation; University of Texas at Austin: Austin, TX, USA, 1983. [Google Scholar]

- Weber, K.J. How heterogeneity affects oil recovery. In Reservoir Characterization; Academic Press: Orlando, FL, USA, 1986; pp. 487–543. [Google Scholar]

- Aigner, T.; Heinz, J.; Hornung, J.; Asprion, U. A hierarchical process-approach to reservoir heterogeneity: Examples from outcrop analogues. Bull. Cent. Rech. Explor. Prod. 1999, 22, 531. [Google Scholar] [CrossRef]

- Qiu, Y.N. Developments in reservoir sedimentology of continental clastic rocks in China. Acta Sedimentol. Sin. 1992, 10, 16–24. [Google Scholar]

- Wang, S.Q. A Heterogeneous Model Describing the Heterogeneity of the Production Reservoir in Shuanghe Oil Field. Pet. Expolor. Dev. 1987, 01, 61–69. [Google Scholar]

- Lai, J.; Wang, G.; Wang, Z.; Chen, J.; Pang, X.; Wang, S.; Zhou, Z.; He, Z.; Qin, Z.; Fan, X. A review on pore structure characterization in tight sandstones. Earth-Sci. Rev. 2018, 177, 436–457. [Google Scholar] [CrossRef]

- Chen, Z.K.; Yu, X.H.; Li, S.L. Sedimentary Microfacies and Heterogeneity in Fault Block Reservoir Shu266, Shuguang Oilfield, Bohai Gulf Basin. J. Geomech. 2006, 12, 91–95. [Google Scholar]

- Dong, L.F.; Zhang, D.X. Method of Indoor Experiment and Its Monitoring on Water Flooding in Micro Heterogeneity Reservoir. Sci. Technol. Eng. 2018, 18, 190–194. [Google Scholar]

- Fan, C.W.; Cao, J.J.; Luo, J.L.; Li, S.S.; Wu, S.J.; Dai, L.; Hou, J.X.; Mao, Q.R. Heterogeneity and influencing factors of marine gravity flow tight sandstone under abnormally high pressure: A case study from the Miocene Huangliu Formation reservoirs in LD10 area, Yinggehai Basin, South China Sea. Pet. Explor. Dev. 2021, 48, 1048–1062. [Google Scholar] [CrossRef]

- Nan, F.C.; Lin, L.B.; Yu, Y.; Chen, Z.B.; Mu, S.C.; Wang, H.B.; Ji, G.H.; Ma, J.M. Application of backward elimination procedure in evaluation of microscopic reservoir heterogeneity in Chang 6 Member, Ordos Basin. Oil Gas Geol. 2022, 43, 1155–1166. [Google Scholar]

- Sun, S.W.; Shu, L.S.; Zeng, Y.W.; Cao, J.; Feng, Z.Q. Porosity–permeability and textural heterogeneity of reservoir sandstones from the Lower Cretaceous Putaohua Member of Yaojia Formation, Weixing Oilfield, Songliao Basin, Northeast China. Mar. Pet. Geol. 2007, 24, 109–127. [Google Scholar] [CrossRef]

- Jiang, Z.; Mao, Z.; Shi, Y.; Wang, D. Multifractal Characteristics and Classification of Tight Sandstone Reservoirs: A Case Study from the Triassic Yanchang Formation, Ordos Basin, China. Energies 2018, 11, 2242. [Google Scholar] [CrossRef]

- Guo, Q.; Dong, M.C.; Mao, H.B.; Ju, J.T. Micro-Scale Pore-Throat Heterogeneity of Tight Oil Sandstone Reservoirs and Its Influence on Fluid Occurrence State. Front. Earth Sci. 2022, 10, 959796. [Google Scholar] [CrossRef]

- Guo, Y.H.; Zhao, D.F. Analysis of micro-scale heterogeneity characteristics in marine shale gas reservoir. J. China Univ. Min. Technol. 2015, 44, 300–307. [Google Scholar] [CrossRef]

- Feng, X.; Peng, X.; Li, L.X.; Yang, X.F.; Wang, J.; Li, Q.; Zhang, C.; Deng, H. Influence of reservoir heterogeneity on water invasion differentiation in carbonate gas reservoirs. Nat. Gas Ind. 2018, 38, 67–75. [Google Scholar] [CrossRef]

- Ma, Y.; Li, W.H.; Liu, C.Y. Microscopic characteristics of water flooding and the affecting factors of low-permeability sandstone reservoir in Zhidan area, Ordos Basin, China. Energy Explor. Exploit. 2015, 33, 145–156. [Google Scholar] [CrossRef]

- Zhong, X.Y.; Zhu, Y.S.; Jiao, T.; Qi, Z.; Luo, J.H.; Xie, Y.H.; Liu, L.Y. Microscopic pore throat structures and water flooding in heterogeneous low-permeability sandstone reservoirs: A case study of the Jurassic Yan’an Formation in the Huanjiang area, Ordos Basin, Northern China. JAESc 2021, 219, 104903. [Google Scholar] [CrossRef]

- Sun, P.K.; Xu, H.M.; Zhu, H.Q.; Jia, L.B.; Hu, X.N.; Fang, H.J.; Jiang, H.Q.; Xu, Z.H.; Jiang, T.W.; Jiang, X.; et al. Investigation of pore-type heterogeneity and its control on microscopic remaining oil distribution in deeply buried marine clastic reservoirs. Mar. Pet. Geol. 2021, 123, 104750. [Google Scholar] [CrossRef]

- Li, P.; Zheng, M.; Bi, H.; Wu, S.T.; Wang, X.R. Pore throat structure and fractal characteristics of tight oil sandstone: A case study in the Ordos Basin, China. J. Pet. Sci. Eng. 2017, 149, 665–674. [Google Scholar] [CrossRef]

- Xiao, P.F.; Leng, X.Y.; Xiao, H.M.; Sun, L.H.; Zhang, H.Q.; Mei, S.S.; Zhang, H.Y. Investigation effect of wettability and heterogeneity in water flooding and on microscopic residual oil distribution in tight sandstone cores with NMR technique. Open Phys. 2017, 15, 544–550. [Google Scholar] [CrossRef]

- Li, P.; Sun, W.; Wu, B.; Gao, Y.; Du, K. Occurrence characteristics and influential factors of movable fluids in pores with different structures of Chang 63 reservoir, Huaqing Oilfield, Ordos Basin, China. Mar. Pet. Geol. 2018, 97, 480–492. [Google Scholar] [CrossRef]

- Gao, Y.L.; Li, P.; Li, T. Influence of different pore structure types on the occurrence features of movable fluid in Chang-10 reservoir in Wuqi–Ansai Oilfield. J. Pet. Explor. Prod. Technol. 2021, 11, 1609–1620. [Google Scholar] [CrossRef]

- Zhang, F.; Jiang, Z.; Sun, W.; Zhang, X.; Zhu, L.; Li, X.; Zhao, W. Effect of Microscopic Pore-Throat Heterogeneity on Gas-Phase Percolation Capacity of Tight Sandstone Reservoirs. Energy Fuels 2020, 34, 12399–12416. [Google Scholar] [CrossRef]

- Yang, Y.B.; Xiao, W.L.; Zheng, L.L.; Lei, Q.H.; Qin, C.Z.; He, Y.A.; Liu, S.S.; Li, M.; Li, Y.M.; Zhao, J.Z.; et al. Pore throat structure heterogeneity and its effect on gas-phase seepage capacity in tight sandstone reservoirs: A case study from the Triassic Yanchang Formation, Ordos Basin. Pet. Sci. 2023, 28, 14211–14232. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, Z.; Zhou, S.; Luo, Y.; Liu, X.; Zhang, Y.; Lin, W.; Xiao, Q.; Niu, Z. Research on Characterization and Heterogeneity of Microscopic Pore Throat Structures in Tight Oil Reservoirs. ACS Omega 2021, 6, 24672–24682. [Google Scholar] [CrossRef] [PubMed]

- Tong, Q.; He, D.B.; Xia, Z.H.; Huang, J.X.; Di, K.X.; Xu, F.; Guo, S.W. Influence of Reservoir Pore-Throat Structure Heterogeneity on Water-Flooding Seepage: A Case Study of Yanchang Formation in Ordos Basin. Minerals 2022, 12, 1243. [Google Scholar] [CrossRef]

- Wang, L.; Lv, D.; Hower, J.C.; Zhang, Z.; Raji, M.; Tang, J.; Liu, Y.; Gao, J. Geochemical characteristics and paleoclimate implication of Middle Jurassic coal in the Ordos Basin, China. Ore Geol. Rev. 2022, 144, 104848. [Google Scholar] [CrossRef]

- Cui, J.; Li, S.; Mao, Z. Oil-bearing heterogeneity and threshold of tight sandstone reservoirs: A case study on Triassic Chang7 member, Ordos Basin. Mar. Pet. Geol. 2019, 104, 180–189. [Google Scholar] [CrossRef]

- Ding, F.; Shi, C.Q.; Zhang, P.H. Characteristics of the Braided River Deposits in the Tenth Member of Jurassic Yan’an Formation From Jiyuan Area in the Western Ordos Basin, China. Pet. Sci. Technol. 2013, 31, 2422–2430. [Google Scholar] [CrossRef]

- He, Z.X. Ordos Basin Evolution and Petroleum; Petroleun Industry Press: Beijing, China, 2003. [Google Scholar]

- Zhao, Y.D.; Qi, Y.L.; Luo, A.X.; Cheng, D.X.; Li, J.H.; Huang, J.X. Application of Fluid Inclusions and Dating of Authigenic Illite in Reconstruction Jurassic Reservoirs Hydrocarbon Filling History, Ordos Basin. J. Jilin Univ. Earth Sci. Ed. 2016, 46, 1637–1648. [Google Scholar] [CrossRef]

- He, J.X.; Duan, Y.; Zhang, X.L.; Wu, B.X.; Xu, L.; Xia, J. Stratigraphic Correlation and Sedimentary Microfacies of Yan 9 Subsection of Yan′an Formation in Linzhen Area, Ordos Basin. Nat. Gas Geosci. 2012, 23, 291–298. [Google Scholar]

- Shi, Z.Q.; Han, Y.L.; Zhao, J.X.; Yang, Y.; Ji, X.L. Depositional System and Paleogeographic Evolution of the Middle Jurassic Yan’anian Stage in the Central and Southern Ordos Basin. Acta Geosicientia Sin. 2003, 24, 49–54. [Google Scholar]

- Zeng, D.; Li, S. Types and Characteristics of Low Permeability Sandstone Peservoirs in China. Acta Pet. Sin. 1994, 15, 38. [Google Scholar]

- Xu, Z.; Zhang, X.; Wu, S.; Zhao, Y. Genesis of the low-permeability reservoir bed of upper Triassic Xujiahe Formation in Xinchang gas field, western Sichuan Depression. Pet. Sci. 2008, 5, 230–237. [Google Scholar] [CrossRef]

- Wang, S.; Yang, X.; Lu, Y.; Su, P.; Liu, D.; Meng, L.; Wang, Q.; Li, L.; Radwan, A.E. Densification mechanism of deep low-permeability sandstone reservoir in deltaic depositional setting and its implications for resource development: A case study of the Paleogene reservoirs in Gaoshangpu area of Nanpu sag, China. Front. Earth Sci. 2022, 10, 996167. [Google Scholar] [CrossRef]

- Liu, Z.; Wu, S.; Xu, Z.; Guo, R.; Liu, Z.; Liu, J.; Jia, C.; Xu, Z. Impact of coal evolution on formation of tight sandstone reservoirs: A case study in the Daniudi gas field, Ordos Basin, China. Energy Explor. Exploit. 2023, 41, 1576–1602. [Google Scholar] [CrossRef]

- Shuai, Y.; Zhang, S.; Gao, Y.; Lu, H.; Chen, J.; Mi, J.; Liu, J.; Hu, G. Effect and quantitative evaluation of CO2 derived from organic matter in coal on the formation of tight sandstone reservoirs. Sci. China Earth Sci. 2013, 56, 756–762. [Google Scholar] [CrossRef]

- Pu, Y.; Li, S.; Tang, D.; Chen, S. Effect of Magmatic Intrusion on In Situ Stress Distribution in Deep Coal Measure Strata: A Case Study in Linxing Block, Eastern Margin of Ordos Basin, China. Nat. Resour. Res. 2022, 31, 2919–2942. [Google Scholar] [CrossRef]

- Sun, J.; Dong, X.; Wang, J.; Schmitt, D.R.; Xu, C.; Mohammed, T.; Chen, D. Measurement of total porosity for gas shales by gas injection porosimetry (GIP) method. Fuel 2016, 186, 694–707. [Google Scholar] [CrossRef]

- Rui-Lan, L.; Lin-Song, C.; Hua-Yin, Z.; Jian-Fei, L.; Hui, R. Problems on the Study of Slippage Effect in Low-Permeability Gas Reservoirs. Nat. Gas Ind. 2007, 27, 92–94. [Google Scholar]

- Zhu, G.Y.; Liu, X.G.; Li, S.T. A Study of Slippage Effect of Gas Percolation in Low Permeability Gas Pools. Nat. Gas Ind. 2007, 27, 44–47. [Google Scholar]

- Huang, H.; Sun, Y.; Chang, X.; Wu, Z.; Li, M.; Qu, S. Experimental Investigation of Pore Characteristics and Permeability in Coal-Measure Sandstones in Jixi Basin, China. Energies 2022, 15, 5898. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, S.; Liang, F.; Huang, Z.; Li, W.; Yan, W.; Guo, W. Reservoir Space Characterization of Ordovician Wulalike Formation in Northwestern Ordos Basin, China. Processes 2023, 11, 2791. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, F.; Liu, D.; Zhao, L.; Zhang, X.; Lin, J.; Dong, H.; Zhao, S.; Liu, X.; Zan, M. Modes of Occurrence of Critical Metal Elements (Li, REEs and Other Critical Elements) in Low-Grade Bauxite from Southern Shanxi Province, China. Minerals 2022, 12, 990. [Google Scholar] [CrossRef]

- Zhi, J.; Zhang, R.; Qu, G.; Jiang, N. Experimental Study on Stimulation of Horizontal Wells Filled with Film-Coated Gravel in Deep-Sea Bottom-Water Gas Reservoirs. ACS Omega 2022, 7, 9024–9032. [Google Scholar] [CrossRef]

- Li, H.; Yang, Z.; Zhou, T.; Li, H.j.; Liu, W.; Guo, H.; Dai, Y.; Luo, Y.; Zhang, Y. Analysis on the mechanism of the enforced imbibition effect of tight oil reservoir by the activated water. Energy Rep. 2023, 10, 3158–3165. [Google Scholar] [CrossRef]

- Xiong, J.Y.; Guan, P.; Han, D.K.; Zhang, W.T.; Wang, J.Y.; Luo, M.; Li, D.L. Diagenesis of anhedritite in the Cretaceous reservoir and its influence on the hydrocarbon distribution in southeast Jianghan Basin. Pet. Explor. Dev. 2007, 34, 39–42. [Google Scholar] [CrossRef]

- Li, D. The Development of the Low Permeability Sandstone Oil Field; Publishing House of Oil Industry: Beijing, China, 1997. [Google Scholar]

- Xue, T.Q. Investigation on Characteristics of Granulometric Distribution of Sediments in Low-permeability Sandstone Reservoir. Acta Sedimentol. Sin. 2006, 3, 414–418. [Google Scholar]

- Li, C.; Liu, M.; Guo, B. Classification of tight sandstone reservoirs based on NMR logging. Appl. Geophys. 2020, 16, 549–558. [Google Scholar] [CrossRef]

- Ding, Y.; Gao, Y.; Meng, Z.; Narengerile; Huang, X. Particle Size Characteristics of Wind Erosion Surface Soil in the Desert Steppe. Soils 2016, 48, 803–812. [Google Scholar] [CrossRef]

- Folk, R.L.; Ward, W.C. Brazos River bar: A study in the significance of grain size parameters. J. Sediment. Res. 1957, 27, 3–26. [Google Scholar] [CrossRef]

- Folk, R.L. A Review of Grain-Size Parameters. Sedimentology 1966, 6, 73–93. [Google Scholar] [CrossRef]

- Li, S.; Feng, Q.; Zhang, X.; Yu, C.; Huang, Y. A new water flooding characteristic curve at ultra-high water cut stage. J. Pet. Explor. Prod. Technol. 2022, 13, 101–110. [Google Scholar] [CrossRef]

- Lisha, Q.; Zhibin, J.; Xiaowei, W.; Jie, W.; Chuanchuan, Q.; Liu, H. Seepage Characteristics of a Low Permeability Sandstone Reservoir in Mobei Oilfield, Junggar Basin. Lithosphere 2021, 2021, 6944088. [Google Scholar] [CrossRef]

- Lv, C.Y. Experimental study on oil-water relative permeability under natural reservoir conditions. Pet. Explor. Dev. 2003, 30, 102–104. [Google Scholar] [CrossRef]

- Sun, H.; Yao, J.; Zhao, Y. Water displacement characteristics at the high water-cut stage based on microscopic experiments and simulations. Simulation 2019, 97, 155–166. [Google Scholar] [CrossRef]

- Zhou, S.; Zhou, Y.; Shi, J.; Zhu, Y.; Xiao, W.; Zhang, R. Micropore structure and water driving characteristics of tight sandstone reservoirs in Ordos Basin. J. Pet. Explor. Prod. Technol. 2021, 12, 601–612. [Google Scholar] [CrossRef]

- Aghaeifar, Z.; Strand, S.; Puntervold, T. Significance of Capillary Forces during Low-Rate Waterflooding. Energy Fuels 2019, 33, 3989–3997. [Google Scholar] [CrossRef]

- Jia, K.; Zeng, J.; Wang, X.; Li, B.; Gao, X.; Wang, K. Wettability of Tight Sandstone Reservoir and Its Impacts on the Oil Migration and Accumulation: A Case Study of Shahejie Formation in Dongying Depression, Bohai Bay Basin. Energies 2022, 15, 4267. [Google Scholar] [CrossRef]

- Henry, W.J. A Simplified Method for Computing Oil Recovery by Gas or Water Drive. J. Pet. Technol. 1952, 4, 91–98. [Google Scholar] [CrossRef]

- Zhao, F.; Shen, R.; Gao, S.S.; Xu, G. Application and Calculation Method of Waterflood Front in Low Permeability Reservoir. J. Jpn. Pet. Inst. 2014, 57, 271–275. [Google Scholar] [CrossRef]

- Wang, C.; Sun, Z.; Sun, Q.; Zhang, L.; Zhang, X. Comprehensive evaluation of waterflooding front in low-permeability reservoir. Energy Sci. Eng. 2021, 9, 1394–1408. [Google Scholar] [CrossRef]

| No. | Textural Maturity | Cementitious Contact Type | |||

|---|---|---|---|---|---|

| Sorting | Psephicity | Cementation Type | Support Type | Contact Method | |

| X1 | Medium | Sub-round, sub-angular | Pore-type | Particle | Point–line contact |

| X2 | Well | Sub-round, sub-angular | Pore-type | Particle | Point–line contact |

| X3 | Well | Sub-round | Pore-type | Particle | Point–line contact |

| X4 | Medium | Sub-round, sub-angular | Pore-type | Particle | Line contact |

| X5 | Well | Sub-round, sub-angular | Pore-type | Particle | Point–line contact |

| No. | Permeability /mD | Intergranular Pore/% | Surface Porosity/% | Maximum Mercury Saturation/% | Residual Mercury Saturation/% | Pore Throat Volume Ratio | Displacement Pressure/MPa |

|---|---|---|---|---|---|---|---|

| X1 | 34.0 | 3.75 | 8.25 | 94.1 | 63.3 | 2.06 | 0.33 |

| X2 | 16.9 | 2.75 | 5.75 | 90.1 | 60.4 | 2.03 | 0.12 |

| X3 | 1.91 | 2.00 | 3.50 | 95.7 | 60.2 | 1.70 | 0.08 |

| X4 | 15.1 | 3.75 | 6.50 | 83.7 | 60.0 | 2.53 | 1.38 |

| X5 | 11.4 | 3.75 | 6.25 | 91.3 | 58.1 | 1.75 | 0.39 |

| No. | Depth /m | Lithology | Very Coarse Sand/% | Coarse Sand/% | Medium Sand/% | Fine Sand/% | Average Particle Size/mm | Standard Deviation | Skewness | Kurtosis |

|---|---|---|---|---|---|---|---|---|---|---|

| −1 < Φ ≤ 0 | 0 < Φ ≤ 1 | 1 < Φ ≤ 2 | 2 < Φ ≤ 4 | |||||||

| X1 | 2300.3 | Medium-grained sandstone | 0.0 | 24.7 | 74.7 | 0.7 | 1.21 | 0.34 | −0.09 | 1.01 |

| X2 | 2298.3 | Medium-grained sandstone | 0.9 | 22.5 | 75.0 | 1.6 | 1.26 | 0.38 | −0.83 | 1.02 |

| X3 | 2340.5 | Medium-grained sandstone | 0.0 | 13.9 | 84.2 | 1.8 | 1.41 | 0.32 | −0.17 | 1.13 |

| X4 | 2370.6 | Arenaceous medium-grained sandstone | 0.0 | 30.7 | 68.7 | 0.6 | 1.12 | 0.36 | −0.43 | 0.93 |

| X5 | 2263.9 | Medium-grained sandstone | 0.8 | 23.6 | 74.0 | 1.6 | 1.32 | 0.37 | −0.12 | 0.97 |

| Avg | 0.3 | 23.1 | 75.3 | 1.3 | 1.26 | 0.35 | −0.19 | 1.02 |

| No. | Porosity /% | Permeability /mD | With Irreducible Water (Wwc) | At Isotonic Point (Aip) | With Residual Oil (Wor) | Water Saturation in Oil–Water Co-Permeability Zone/% | |||

|---|---|---|---|---|---|---|---|---|---|

| Oil Phase Permeability /mD | Water Saturation /% | Oil–Water Co-Permeability /mD | Water Saturation /% | Water Phase Permeability /mD | Water Saturation /% | ||||

| X1 | 15.4 | 34.0 | 6.82 | 48.9 | 0.086 | 57.5 | 2.220 | 61.7 | 12.8 |

| X2 | 14.8 | 16.9 | 3.44 | 63.3 | 0.093 | 71.6 | 0.974 | 75.0 | 11.7 |

| X3 | 13.1 | 1.91 | 1.51 | 50.7 | 0.085 | 61.3 | 0.378 | 65.8 | 15.1 |

| X4 | 13.3 | 15.1 | 3.49 | 56.7 | 0.099 | 64.3 | 0.811 | 67.5 | 10.8 |

| X5 | 15.9 | 11.4 | 2.83 | 50.7 | 0.084 | 59.4 | 0.591 | 63.0 | 12.3 |

| Avg | 14.5 | 15.9 | 3.62 | 54.1 | 0.089 | 62.8 | 0.990 | 66.6 | 12.5 |

| No. | Permeability /mD | Water Wettability Index | Oil Wettability Index | Relative Wettability Index | Wettability Assessment | Anhydrous Period Oil Displacement Efficiency/% | Final Oil Displacement Efficiency/% |

|---|---|---|---|---|---|---|---|

| X1 | 34.0 | 0.50 | 0.33 | 0.17 | Slightly water-wet | 6.3 | 25.0 |

| X2 | 16.9 | 0.67 | 0.20 | 0.47 | Water-wet | 10.9 | 31.8 |

| X3 | 1.91 | 0.60 | 0.25 | 0.35 | Water-wet | 8.5 | 30.8 |

| X4 | 15.1 | 0.63 | 0.12 | 0.51 | Water-wet | 5.0 | 20.8 |

| X5 | 11.4 | 0.43 | 0.25 | 0.18 | Slightly water-wet | 6.9 | 25.0 |

| No. | Waterflood Front/% | Water Saturation/% | Water Saturation Difference/% | |||||

|---|---|---|---|---|---|---|---|---|

| Water Saturation | Water Current | When Irreducible Water | When Isotonic Point | When Residual Oil | When Waterflood Front and Irreducible Water | When Waterflood Front and Isotonic Point | When Residual Oil and Waterflood Front | |

| X1 | 58.2 | 85.3 | 48.9 | 57.5 | 61.7 | 9.3 | 0.7 | 3.5 |

| X2 | 72.3 | 83.5 | 63.3 | 71.6 | 75.0 | 9.0 | 0.7 | 2.7 |

| X3 | 62.0 | 82.3 | 50.7 | 61.3 | 65.8 | 11.3 | 0.7 | 3.8 |

| X4 | 64.6 | 81.0 | 56.7 | 64.3 | 67.5 | 7.9 | 0.3 | 2.9 |

| X5 | 60.2 | 84.7 | 50.7 | 59.4 | 63.0 | 9.5 | 0.8 | 2.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Qu, Z.; Wang, M.; Ran, W. The Influence of Micro-Heterogeneity on Water Injection Development in Low-Permeability Sandstone Oil Reservoirs. Minerals 2023, 13, 1533. https://doi.org/10.3390/min13121533

Li M, Qu Z, Wang M, Ran W. The Influence of Micro-Heterogeneity on Water Injection Development in Low-Permeability Sandstone Oil Reservoirs. Minerals. 2023; 13(12):1533. https://doi.org/10.3390/min13121533

Chicago/Turabian StyleLi, Mao, Zhan Qu, Mu Wang, and Wang Ran. 2023. "The Influence of Micro-Heterogeneity on Water Injection Development in Low-Permeability Sandstone Oil Reservoirs" Minerals 13, no. 12: 1533. https://doi.org/10.3390/min13121533