Grade Distribution Modeling within the Bauxite Seams of the Wachangping Mine, China, Using a Multi-Step Interpolation Algorithm

Abstract

:1. Introduction

2. Methodology

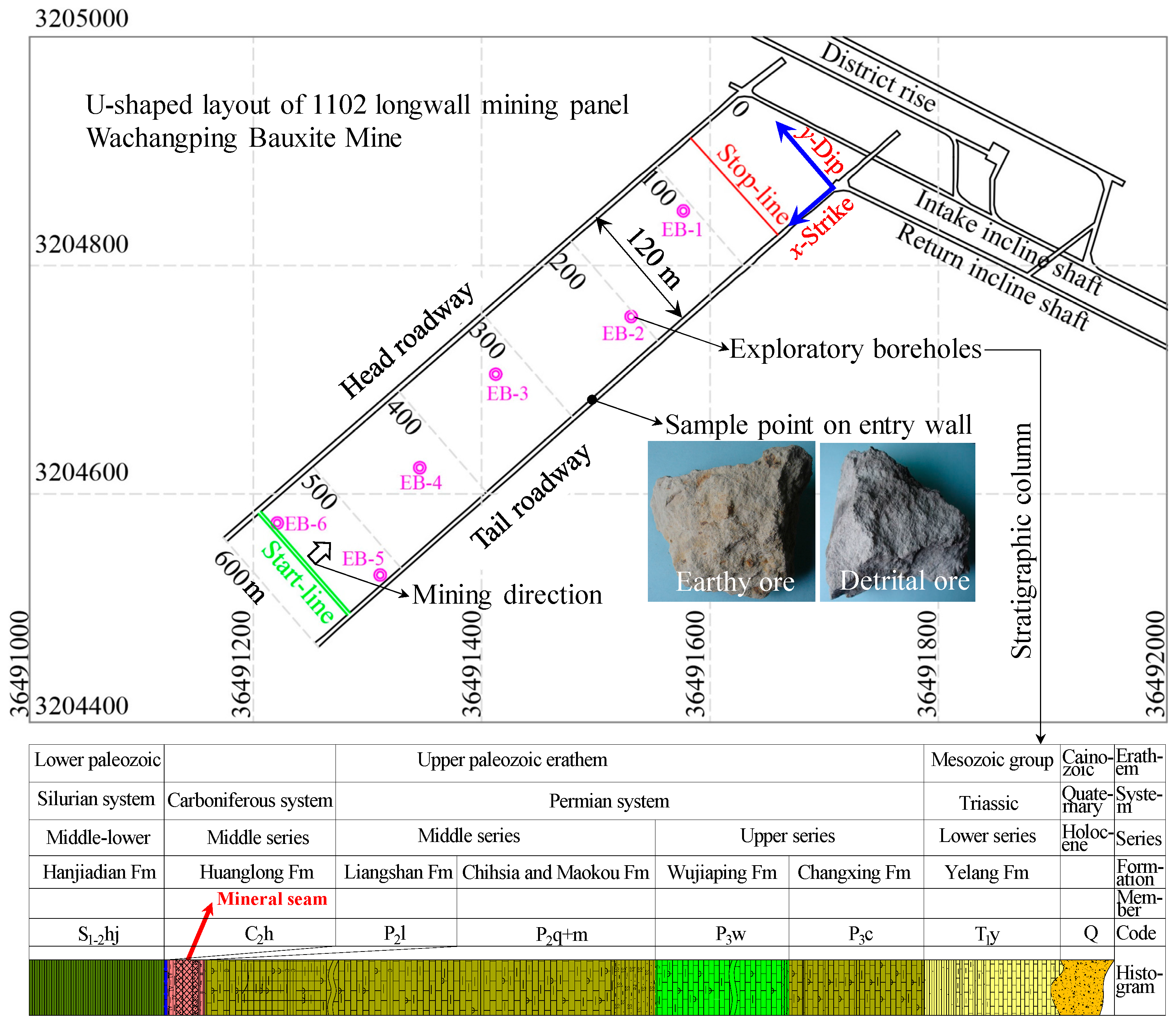

3. Scattered Grade Data

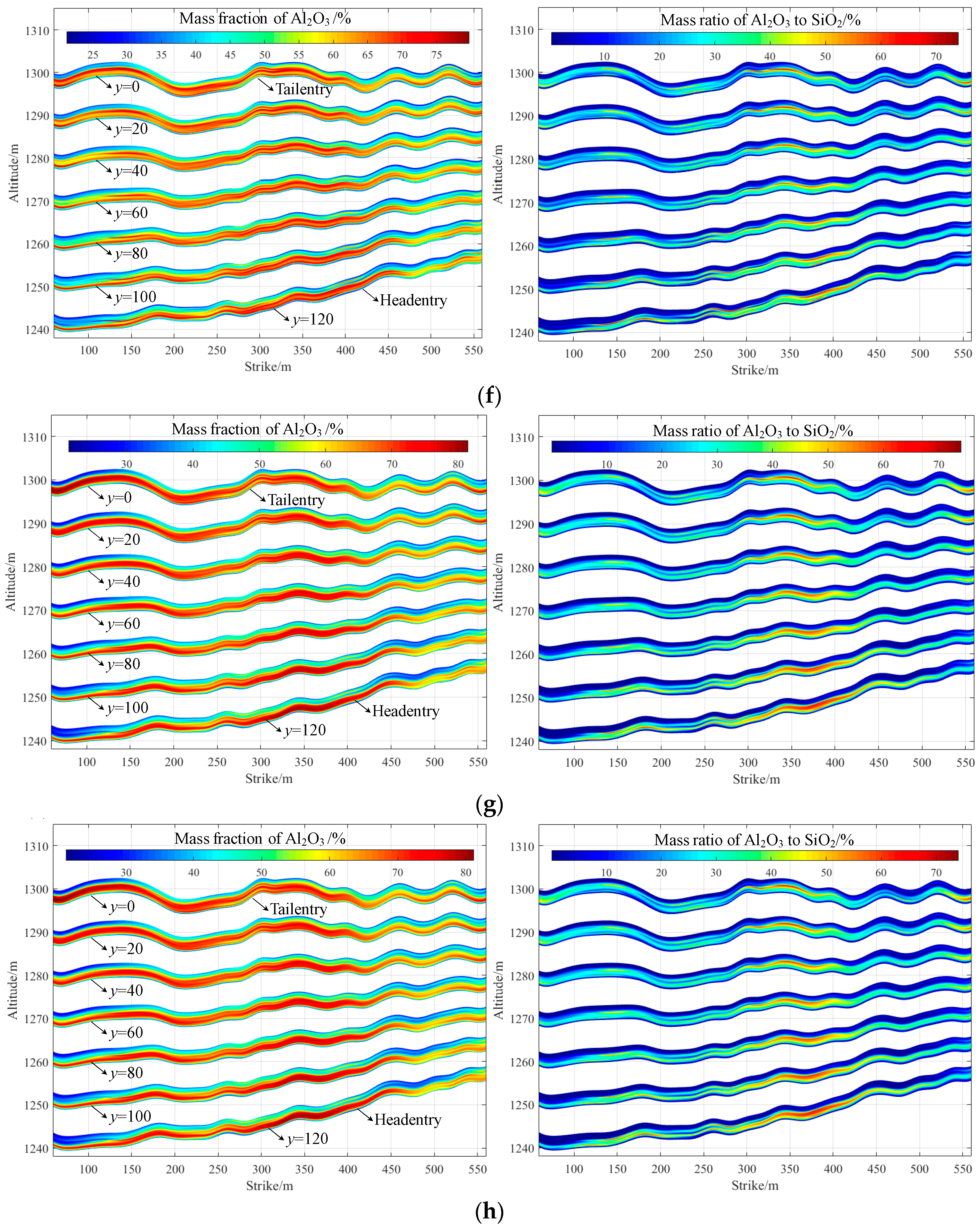

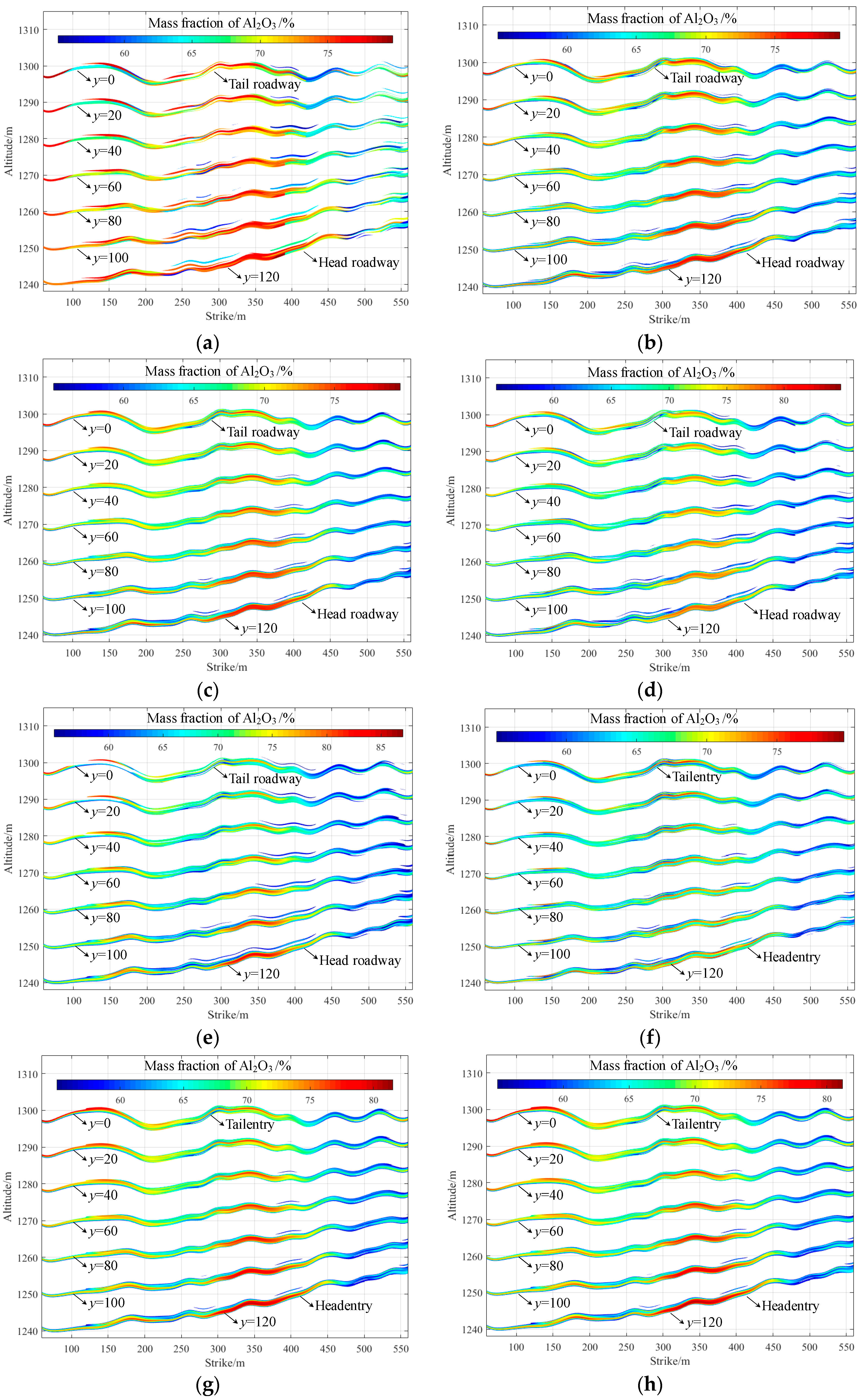

4. Grade Distribution Model

5. Results and Discussion

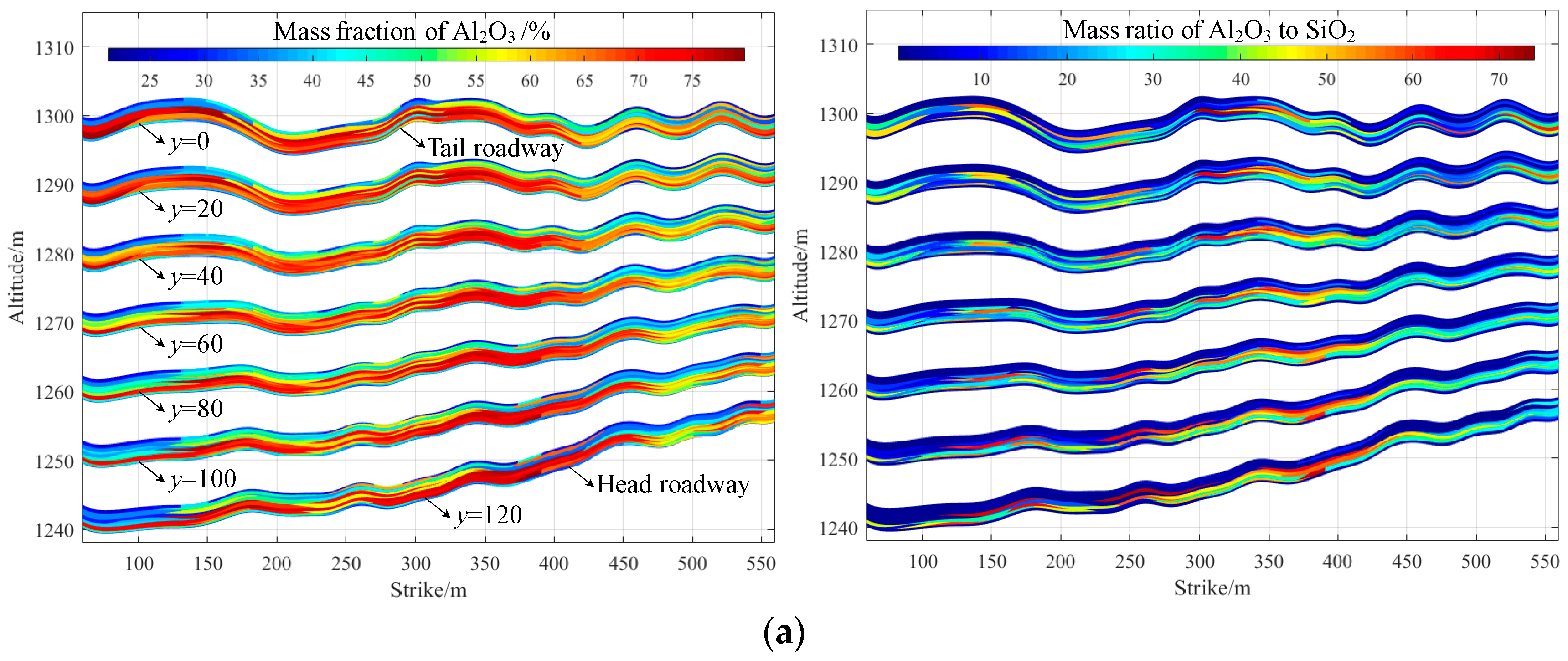

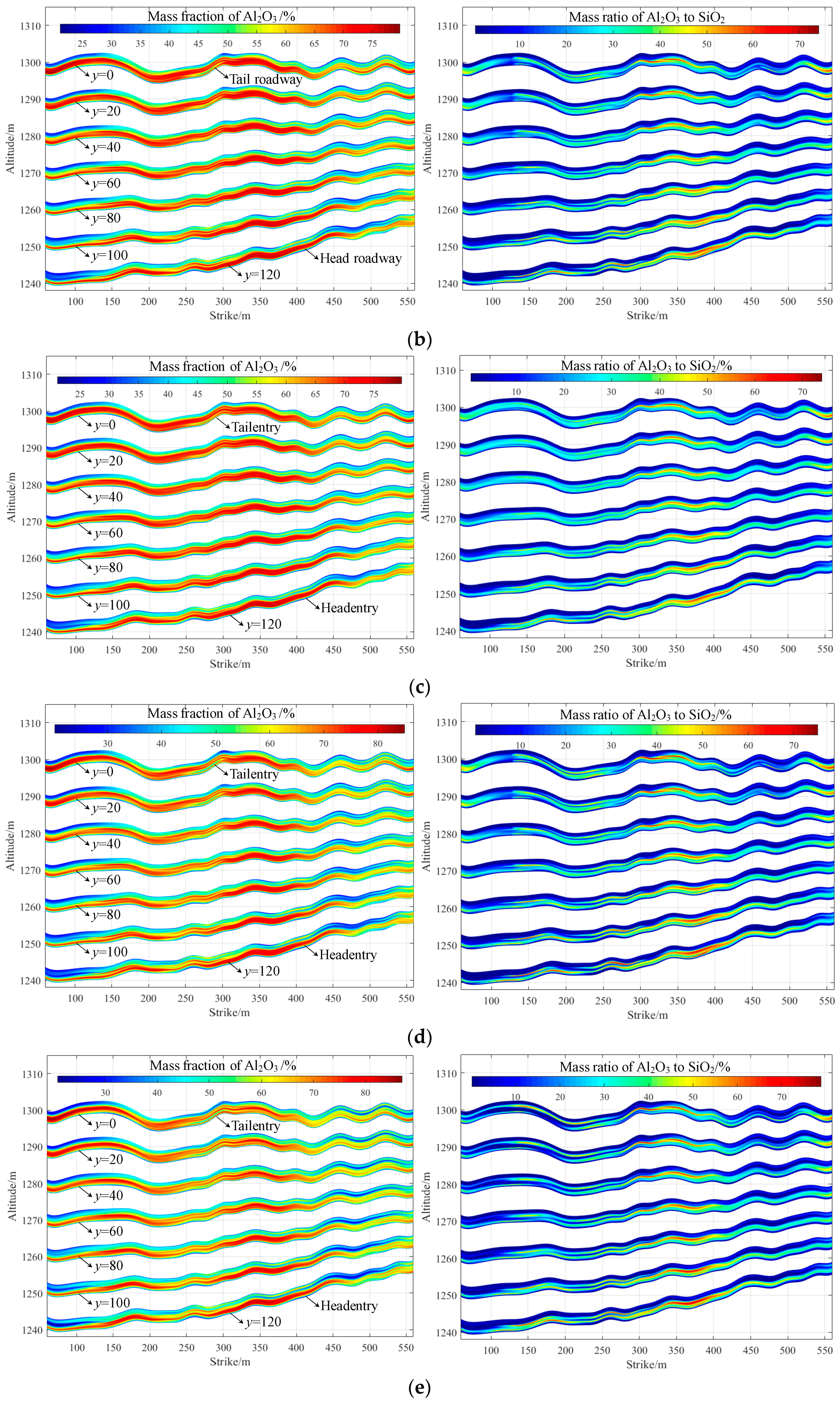

5.1. Comparison of Interpolation Methods

5.2. Confirmation by Exploratory Boreholes

5.3. Optimum Model

6. Conclusions

- (1)

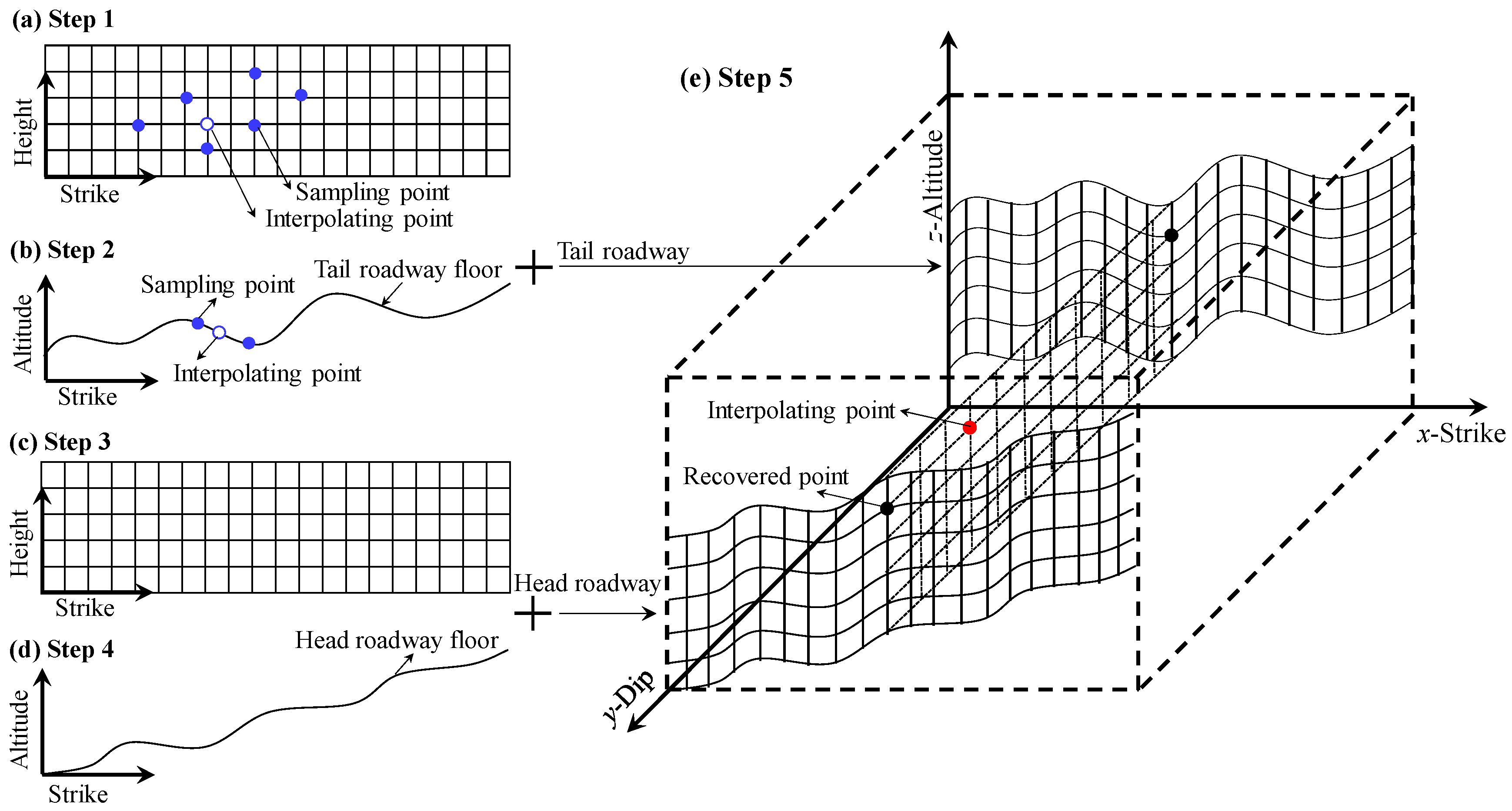

- A multi-step interpolation algorithm was proposed to establish the grade distribution model of the mineralized seams in three dimensions. For a longwall mining panel with a U-shaped layout, where the tail and head roadways at both sides of the panel will be excavated beforehand, a five-step interpolation procedure was established. Firstly, the sample data with large variations and irregular distributions measured in the tail roadway were mapped into the nodes of a regular rectangular mesh grid and then used to estimate the over-sampled node data by conventional interpolation methods. Secondly, using a biharmonic spline method, the interpolated curve of the floor altitude of the tail roadway was established to recover interpolation data into the original frame. Thirdly, similar to the first step, the grade distribution data on the head roadway wall were interpolated. Fourthly, similar to the second step, the interpolation data were recovered by interpolated floor altitudes of the head roadway. Finally, the 3D distribution data between roadways were interpolated by a linear method.

- (2)

- During the first and the third steps, the nearest neighbor, linear, natural neighbor, cubic, biharmonic spline, IDW, SK, and OK interpolations were used to select which one is optimal for smooth and exact interpolations of the mineralized seams. A comparison of the differences between interpolated and sampled data—and between the field data from exploratory boreholes and corresponding interpolated data—showed that the stabilities of the interpolation curves decrease sequentially from natural neighbor, OK, SK, IDW, linear, cubic, and biharmonic spline, to the nearest neighbor methods. The multi-step interpolation using the natural neighbor method has an optimal stability and a minimal difference with the grade distribution in three dimensions. It seems that the natural neighbor interpolation has some predominant characteristics to be more physically realistic in the data interpolation.

- (3)

- Using the multi-step interpolation in which the natural neighbor method was selected to estimate the grade data distributed on the roadway wall, the ore reserve was estimated at 97,576 m3 with a mass fraction of Al2O3, marked as Wa, of 61.68% and a mass ratio of Al2O3 to SiO2, marked as Wa/s, of 27.72. Subsequently, compared with the field data measured by the six exploratory boreholes, mean absolute errors, the root mean squared errors, and relative standard deviations of errors between interpolated and measured grade data are 2.544, 2.674, and 32.37% of Wa; and 1.761, 1.974, and 67.37% of Wa/s, respectively. On the whole, these differences are small relative to other methods.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mortensen, M.E. Geometric Modeling; John Wiley & Sons Inc.: New York, NY, USA, 1985. [Google Scholar]

- Calcagno, P.; Chilès, J.P.; Courrioux, G.; Guillen, A. Geological modelling from field data and geological knowledge Part I: Modelling method coupling 3D potential-field interpolation and geological rules. Phys. Earth Planet. Inter. 2008, 171, 147–157. [Google Scholar] [CrossRef]

- Bascetin, A.; Tuylu, S.; Nieto, A. Influence of the ore block model estimation on the determination of the mining cutoff grade policy for sustainable mine production. Environ. Earth Sci. 2011, 64, 1409–1418. [Google Scholar] [CrossRef]

- Franke, R. Scattered data interpolation: Tests of some methods. Math. Comput. 1982, 38, 181–200. [Google Scholar]

- Myers, D.E. Spatial interpolation: An overview. Geoderma 1994, 62, 17–28. [Google Scholar] [CrossRef]

- Goovaerts, P. Geostatistics for Natural Resources Evaluation; Oxford University Press: New York, NY, USA, 1997. [Google Scholar]

- Sinclair, A.J.; Blackwell, G.H. Applied Mineral Inventory Estimation; Cambridge University Press: Cambridge, UK, 2002. [Google Scholar]

- Abzalov, M. Applied Mining Geology; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Deutsch, C.V. Geostatistical Reservoir Modeling; Oxford University Press: New York, NY, USA, 2002. [Google Scholar]

- Zawadzki, J.; Fabijańczyk, P. Geostatistical evaluation of lead and zinc concentration in soils of an old mining area with complex land management. Int. J. Environ. Sci. Technol. 2013, 10, 729–742. [Google Scholar] [CrossRef]

- Zawadzki, J.; Szuszkiewicz, M.; Fabijańczyk, P.; Magiera, T. Geostatistical discrimination between different sources of soil pollutants using a magneto-geochemical data set. Chemosphere 2016, 164, 668–676. [Google Scholar] [CrossRef] [PubMed]

- Abramov, O.; Mcewen, A.S. An evaluation of interpolation methods for Mars Orbiter Laser Altimeter (MOLA) data. Int. J. Remote Sens. 2004, 25, 669–676. [Google Scholar] [CrossRef]

- Sidik, N.A.C.; Attarzadeh, M.R.N. The use of cubic interpolation method for transient hydrodynamics of solid particles. Int. J. Eng. Sci. 2012, 51, 90–103. [Google Scholar]

- Mahmoudabadi, H.; Izadi, M.; Menhaj, M.B. A hybrid method for grade estimation using genetic algorithm and neural networks. Comput. Geosci. 2009, 13, 91–101. [Google Scholar] [CrossRef]

- Tutmez, B. An uncertainty oriented fuzzy methodology for grade estimation. Comput. Geosci. 2007, 33, 280–288. [Google Scholar] [CrossRef]

- Gligorić, M.; Gligorić, Z.; Beljić, Č.; Torbica, S.; Štrbac Savić, S.; Nedeljković Ostojić, J. Multi-attribute technological modeling of coal deposits based on the fuzzy TOPSIS and C-mean clustering algorithms. Energies 2016, 9, 1059. [Google Scholar] [CrossRef]

- Samanta, B.; Bandopadhyay, S. Construction of a radial basis function network using an evolutionary algorithm for grade estimation in a placer gold deposit. Comput. Geosci. 2009, 35, 1592–1602. [Google Scholar] [CrossRef]

- Smirnoff, A.; Boisvert, E.; Paradis, S.J. Support vector machine for 3D modelling from sparse geological information of various origins. Comput. Geosci. 2008, 34, 127–143. [Google Scholar] [CrossRef]

- Wang, Q.; Deng, J.; Liu, H.; Wang, Y.; Sun, X.; Wan, L. Fractal models for estimating local reserves with different mineralization qualities and spatial variations. J. Geochem. Explor. 2011, 108, 196–208. [Google Scholar] [CrossRef]

- Sambridge, M.; Braun, J.; Mcqueen, H. Geophysical parametrization and interpolation of irregular data using natural neighbours. Geophys. J. Int. 1995, 122, 837–857. [Google Scholar] [CrossRef]

- Peng, S.S. Longwall Mining, 2nd ed.; Society for Mining, Metallurgy, and Exploration, Inc. (SME): Englewood, CO, USA, 2006; pp. 1–20. [Google Scholar]

- Karacan, C.Ö. Analysis of gob gas venthole production performances for strata gas control in longwall mining. Int. J. Rock Mech. Min. Sci. 2015, 79, 9–18. [Google Scholar] [CrossRef]

- Islavath, S.R.; Deb, D.; Kumar, H. Numerical analysis of a longwall mining cycle and development of a composite longwall index. Int. J. Rock Mech. Min. Sci. 2016, 89, 43–54. [Google Scholar] [CrossRef]

- Wang, S.; Li, X.; Wang, D. Mining-induced void distribution and application in the hydro-thermal investigation and control of an underground coal fire: A case study. Process Saf. Environ. Prot. 2016, 102, 734–756. [Google Scholar] [CrossRef]

- Wang, S.; Li, X.; Wang, D. Void fraction distribution in overburden disturbed by longwall mining of coal. Environ. Earth Sci. 2016, 75, 151. [Google Scholar] [CrossRef]

- Wang, S.; Li, X. Dynamic Distribution of Longwall Mining-Induced Voids in Overlying Strata of a Coalbed. Int. J. Geomech. 2016, 17. [Google Scholar] [CrossRef]

- Wang, S.F.; Li, X.B.; Wang, S.Y.; Li, Q.Y.; Chen, C.; Feng, F.; Chen, Y. Three-dimensional orebody modelling and intellectualized longwall mining for stratiform bauxite deposits. Trans. Nonferr. Met. Soc. China 2016, 26, 2724–2730. [Google Scholar] [CrossRef]

- Wang, S.; Li, X.; Du, K. Grade distribution and orebody demarcation of bauxite seam based on coupled Interpolation. Arab. J. Sci. Eng. 2017. [Google Scholar] [CrossRef]

- Math Works. Matlab User Manual Version R2016b; Math Works: Natick, MA, USA, 2016. [Google Scholar]

- Susanto, F.; de Souz, P.; He, J. Spatiotemporal interpolation for environmental modelling. Sensors 2016, 16, 1245. [Google Scholar] [CrossRef] [PubMed]

- Burrough, P.A.; McDonnell, R.A. Principles of Geographical Information Systems; Oxford University Press: New York, NY, USA, 1998. [Google Scholar]

- Sandwell, D.T. Biharmonic spline interpolation of GEOS-3 and SEASAT altimeter data. Geophys. Res. Lett. 1987, 14, 139–142. [Google Scholar] [CrossRef]

- Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China (AQSIQ). National Standard of the People’s Republic of China: Bauxite; Standard Press of China: Beijing, China, 2009.

| Method | Bauxite Seam Volume/m3 | Ore Reserve/m3 | In-Situ Average Grade of Bauxite Seam | Average Grade of Bauxite Orebody Applying Industrial Constrains | Assessment of Difference Ratio Between Interpolation Data and Sample Data Dis/% | Time Consuming/s | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wa/% (SD) | Wa/s (SD) | Wa/% (SD) | Wa/s (SD) | Mean | Max | Min | |||||||

| Wa | Wa/s | Wa | Wa/s | Wa | Wa/s | ||||||||

| Nearest | 189,260 | 97,750 | 54.80 (15.53) | 17.89 (18.94) | 63.73 (7.54) | 29.20 (17.18) | 18.48 | 45.24 | 0 | 0 | 0 | 0 | 76.2 |

| Linear | 189,260 | 96,192 | 54.84 (13.28) | 17.52 (14.98) | 61.78 (7.08) | 27.18 (11.84) | 18.58 | 42.19 | −0.12 | 0 | 0 | 0.09 | 80.4 |

| Natural | 189,260 | 97,576 | 54.88 (13.11) | 18.02 (14.48) | 61.68 (6.85) | 27.72 (10.27) | 17.67 | 35.92 | −0.15 | 0 | 0 | 0.09 | 81.4 |

| Cubic | 189,260 | 98,151 | 55.32 (13.82) | 17.57 (16.01) | 62.34 (7.59) | 27.30 (13.34) | 19.6 | 42.67 | 6.44 | 1.74 | −4.34 | −50.9 | 76.2 |

| Biharmonic | 189,260 | 99,763 | 56.32 (13.94) | 17.38 (16.59) | 62.78 (7.97) | 26.97 (14.59) | 21.76 | 41.14 | 9.03 | 6.59 | −1.41 | −51.4 | 78.1 |

| IDW | 189,260 | 93,348 | 53.15 (12.93) | 17.40 (14.31) | 60.74 (6.17) | 27.44 (10.79) | 14.92 | 41.27 | 0 | 0 | 0.05 | 0 | 153.3 |

| SK | 189,260 | 100,750 | 55.34 (14.11) | 18.28 (15.87) | 62.88 (7.19) | 28.52 (11.77) | 19.65 | 48.37 | 2.21 | 0 | 0 | −58.3 | 2161.7 |

| [E: 11.22] | [E: 11.71] | ||||||||||||

| [EV: 2.04] | [EV: 0.97] | ||||||||||||

| OK | 189,260 | 100,630 | 55.28 (14.12) | 18.24 (15.89) | 62.85 (7.16) | 28.52 (11.78) | 19.53 | 48.04 | 1.78 | 0 | 0 | −51.2 | 2601.5 |

| [E: 11.23] | [E: 11.73] | ||||||||||||

| [EV: 2.05] | [EV: 0.97] | ||||||||||||

| Position | I and F | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nearest | Linear | Natural | Cubic | Biharmonic | IDW | SK | OK | Nearest | Linear | Natural | Cubic | Biharmonic | IDW | SK | OK | |

| EB-1 (107, 72) |  |  |  |  |  |  |  |  | −10.88 | −7.78 | −6.24 | −7.03 | −1.37 | −9.43 | −4.81 | −5.01 |

| −42.00 | −33.35 | −19.11 | −36.21 | −40.46 | −23.00 | −15.59 | −15.98 | |||||||||

| EB-2 (204, 32) |  |  |  |  |  |  |  |  | 5.08 | 3.65 | 3.36 | 5.22 | 6.38 | −0.28 | 4.01 | 3.89 |

| −18.48 | −9.39 | −12.29 | −5.80 | −23.49 | −22.21 | −18.14 | −18.33 | |||||||||

| EB-3 (326, 72) |  |  |  |  |  |  |  |  | 6.22 | 6.72 | 5.03 | 8.32 | 7.94 | 0.58 | 6.73 | 6.66 |

| −10.13 | −5.38 | −5.71 | −6.88 | −5.94 | -12.09 | 1.36 | 1.27 | |||||||||

| EB-4 (430, 54) |  |  |  |  |  |  |  |  | 3.16 | 5.31 | 5.92 | 5.76 | 8.81 | 1.49 | 7.01 | 6.93 |

| 1.65 | 7.82 | 11.31 | 3.48 | 11.80 | 10.08 | 16.36 | 16.14 | |||||||||

| EB-5 (518, 5) |  |  |  |  |  |  |  |  | 3.37 | 2.41 | 1.95 | 3.64 | 3.28 | 0.29 | 2.17 | 2.07 |

| 2.97 | −3.56 | −1.90 | −4.91 | −13.78 | −2.86 | −4.86 | −5.28 | |||||||||

| EB-6 (556, 99) |  |  |  |  |  |  |  |  | 6.23 | 8.46 | 6.21 | 10.61 | 11.29 | 2.81 | 7.18 | 7.08 |

| 4.48 | 8.95 | 9.36 | 11.31 | 13.59 | 1.72 | 6.74 | 6.24 | |||||||||

| All | Evaluation index | Nearest | Linear | Natural | Cubic | Biharmonic | IDW | SK | OK | |||||||

| 3.125 | 3.050 | 2.544 | 3.612 | 3.464 | 1.310 | 2.832 | 2.808 | |||||||||

| 2.412 | 1.993 | 1.761 | 2.005 | 3.193 | 2.218 | 1.826 | 1.832 | |||||||||

| 3.424 | 3.258 | 2.674 | 3.807 | 3.877 | 2.165 | 2.989 | 2.966 | |||||||||

| 3.377 | 2.579 | 1.974 | 2.733 | 3.710 | 2.716 | 2.157 | 2.171 | |||||||||

| 44.74% | 37.54% | 32.37% | 33.22% | 50.23% | 131.5% | 33.78% | 34.06% | |||||||||

| 102.4% | 97.74% | 67.37% | 122.47% | 59.81% | 138.3% | 83.58% | 54.15% | |||||||||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Li, X. Grade Distribution Modeling within the Bauxite Seams of the Wachangping Mine, China, Using a Multi-Step Interpolation Algorithm. Minerals 2017, 7, 71. https://doi.org/10.3390/min7050071

Wang S, Li X. Grade Distribution Modeling within the Bauxite Seams of the Wachangping Mine, China, Using a Multi-Step Interpolation Algorithm. Minerals. 2017; 7(5):71. https://doi.org/10.3390/min7050071

Chicago/Turabian StyleWang, Shaofeng, and Xibing Li. 2017. "Grade Distribution Modeling within the Bauxite Seams of the Wachangping Mine, China, Using a Multi-Step Interpolation Algorithm" Minerals 7, no. 5: 71. https://doi.org/10.3390/min7050071