A Paris-Edinburgh Cell for High-Pressure and High-Temperature Structure Studies on Silicate Liquids Using Monochromatic Synchrotron Radiation

Abstract

:1. Introduction

2. Experimental Setup

2.1. The Paris-Edinburgh Press

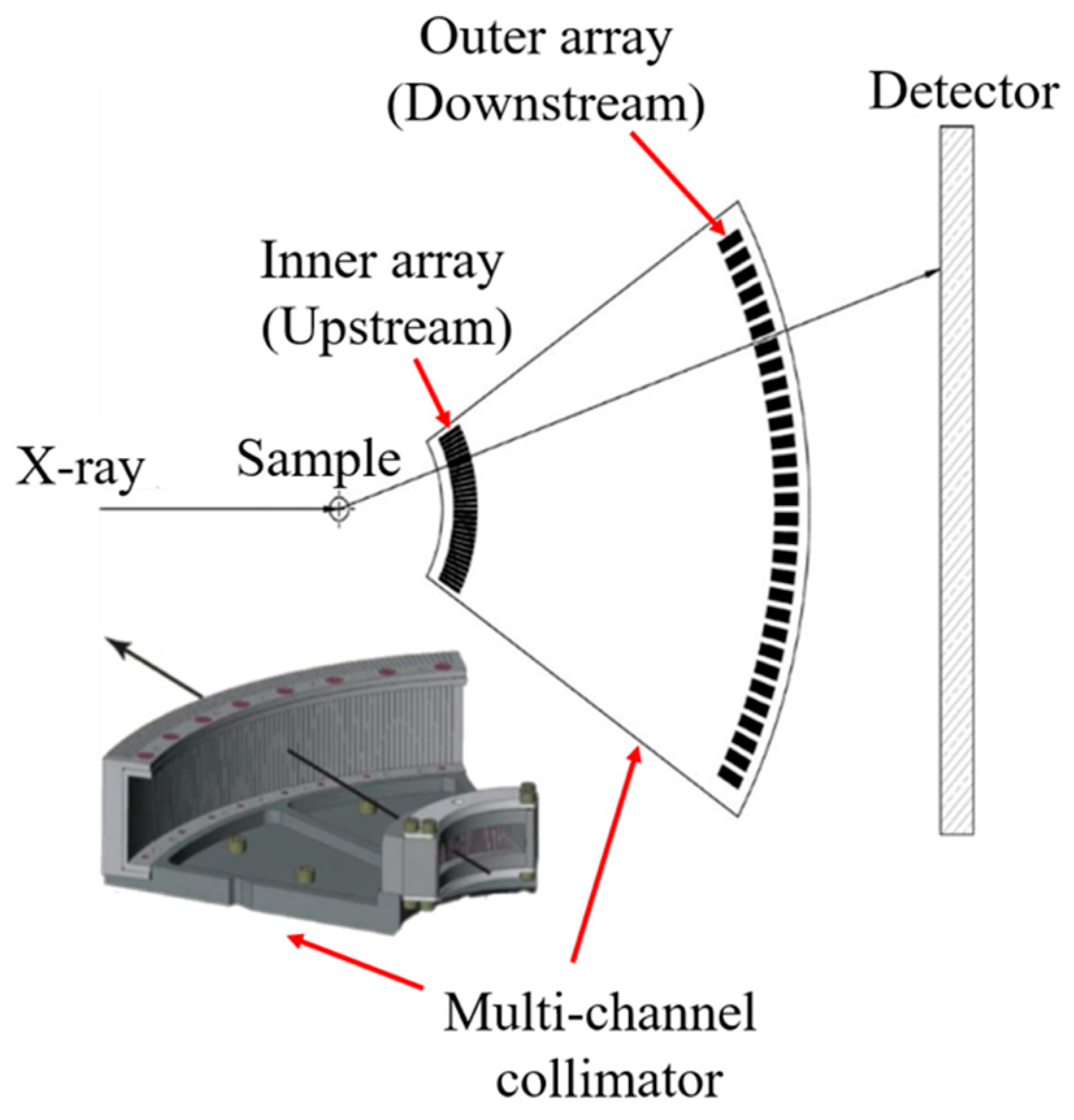

2.2. The Multi-Channel Collimator

2.3. The Detector

3. Sample Environment and Preparation

3.1. The Paris-Edinburgh Cell Assembly

3.2. Sample Preparation

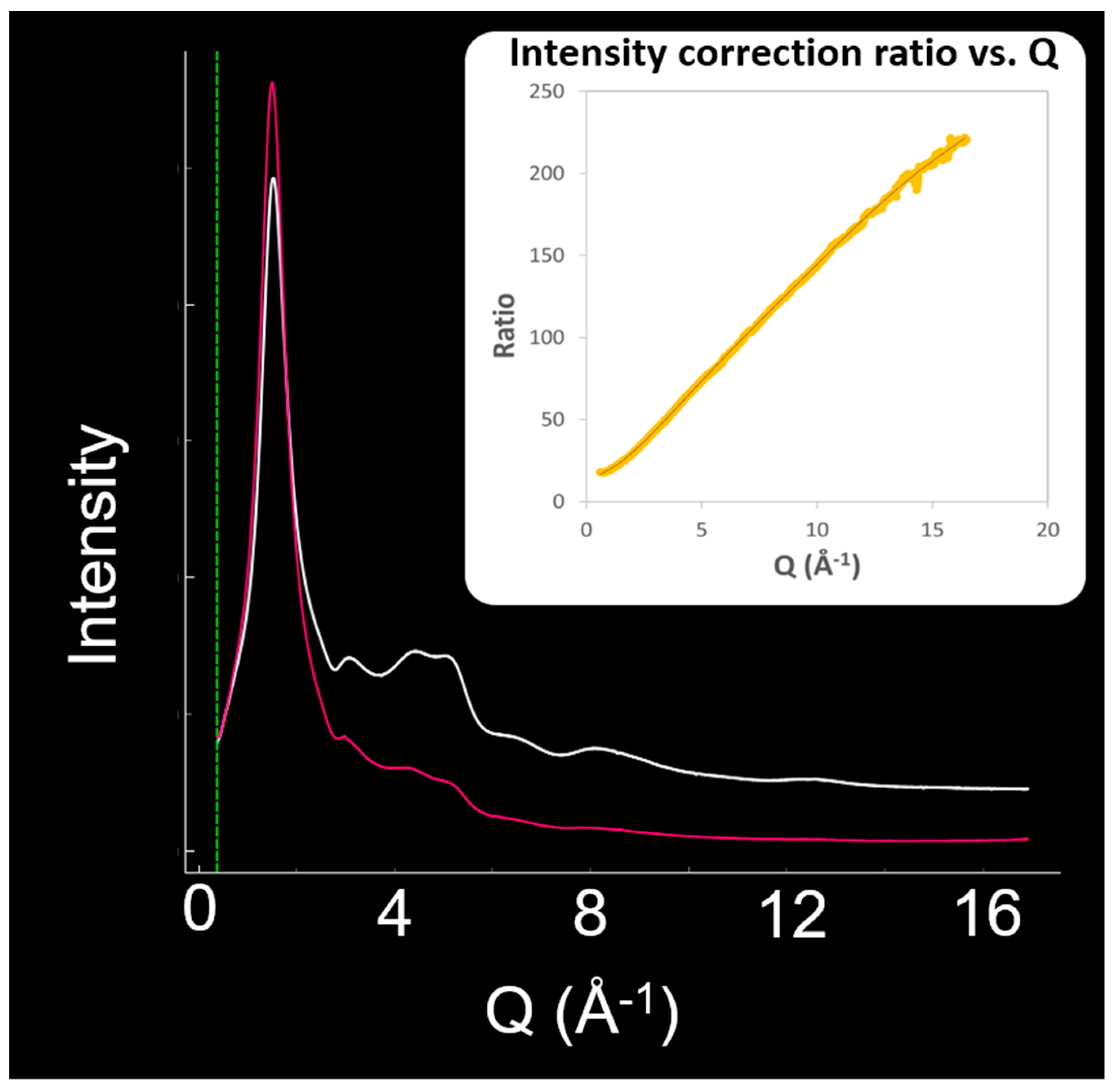

4. Data Collection and Analysis

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Funamori, N.; Yamamoto, S.; Yagi, T.; Kikegawa, T. Exploratory studies of silicate melt structure at high pressures and temperatures by in situ X-ray diffraction. J. Geophys. Res. 2004, 109, B03203. [Google Scholar] [CrossRef]

- McMillan, P. Structural studies of silicate glasses and melts—Applications and limitations of Raman spectroscopy. Am. Mineral. 1984, 69, 622–644. [Google Scholar]

- Stebbins, J.F.; Ellsworth, S.E. Temperature effects on structure and dynamics in borate and borosilicate liquids: High-resolution and high-temperature NMR results. J. Am. Ceram. Soc. 1996, 79, 2247–2256. [Google Scholar] [CrossRef]

- Angeli, F.; Villian, O.; Schuller, S.; Charpentier, T.; de Ligny, D.; Bressel, L.; Wondraczek, L. Effect of temperature and thermal history on borosilicate glass structure. Phys. Rev. B 2012, 85, 054110. [Google Scholar] [CrossRef]

- Susman, S.; Volin, K.J.; Price, D.L.; Grimsditch, M.; Rino, J.P.; Kalia, R.K.; Vashishta, P.; Gwanmesia, G.; Wang, Y.; Liebermann, R.C. Intermediate-range order in permanently densified vitreous SiO2: A neuton-diffraction and molecular-dynamics study. Phys. Rev. B 1991, 43, 1194–1197. [Google Scholar] [CrossRef]

- Zha, C.S.; Mao, H.K.; Hemley, R.J.; Duffy, T.S. Elasticity measurement and equation of state of MgO to 60 GPa. EOS. Trans. AGU 1997, 78, F752. [Google Scholar]

- Xu, M.; Jing, Z.; Chantel, J.; Jiang, P.; Yu, T.; Wang, Y. Ultrasonic velocity of diopside liquid at high pressure and temperature: Constraints on velocity reduction in the upper mantle due to partial melts. J. Geophys. Res. Sol. Earth 2018, 123, 8676–8690. [Google Scholar] [CrossRef]

- Jing, Z.; Karato, S. A new approach to the equation of state of silicate melts: An application of the theory of hard sphere mixtures. Geochim. Cosmochim. Acta 2011, 75, 6780–6802. [Google Scholar] [CrossRef]

- Wilding, M.C.; Benmore, C.J.; Weber, J.K.R. In situ diffraction studies of magnesium silicate liquids. J. Mater. Sci. 2008, 43, 4707–4713. [Google Scholar] [CrossRef]

- Inoue, K.; Asada, T. Cubic anvil X-ray diffraction press up to 100 kbar and 1000 °C. Jpn. J. Appl. Phys. 1973, 12, 1786–1793. [Google Scholar] [CrossRef]

- Tsuji, K.; Yaoita, K.; Imai, M.; Shimomura, O.; Kikegawa, T. Measurements of X-ray diffraction for liquid metals under high pressure. Rev. Sci. Instrum. 1989, 60, 2425–2428. [Google Scholar] [CrossRef]

- Yamada, A.; Wang, Y.; Inoue, T.; Yang, W.; Park, C.; Yu, T.; Shen, G. High-pressure X-ray diffraction studies on the structure of liquid silicate using a Paris-Edinburgh type large volume press. Rev. Sci. Instrum. 2011, 82, 015103–015107. [Google Scholar] [CrossRef] [PubMed]

- Mezouar, M.; Faure, P.; Crichton, W.; Rambert, N.; Sitaud, N.; Bauchau, S.; Blattmann, G. Multichannel collimator for structural investigation of liquids and amorphous materials at high pressures and temperautures. Rev. Sci. Instrum. 2002, 73, 3570–3574. [Google Scholar] [CrossRef]

- Morard, G.; Mezouar, M.; Bauchau, S.; Alvarez-Murga, M.; Hodeau, J.L.; Garbarino, G. High efficiency multichannel collimator for structural studies of liquids and low-Z materials at high pressures and temperatures. Rev. Sci. Instrum. 2011, 82, 023904. [Google Scholar] [CrossRef]

- Besson, J.M.; Nelmes, R.J.; Hamel, G.; Loveday, J.S.; Weill, G.; Hull, S. Neutron powder diffraction above 10 GPa. Phys. B Condens. Matter 1992, 180, 907–910. [Google Scholar] [CrossRef]

- Klotz, S.; Besson, J.M.; Hammel, G.; Nelmes, R.J.; Loveday, J.S.; Marshall, W.G. High pressure neutron diffraction using the Paris-Edinburgh cell: Experimental possibilities and future prospects. High Press. Res. 1996, 14, 249–255. [Google Scholar] [CrossRef]

- Rivers, M.L.; Duffy, T.S.; Wang, Y.; Eng, P.J.; Sutton, S.R.; Shen, G. A new facility for high-pressure research at the Advanced Photon Source. In Properties of Earth and Planetary Materials at High Pressure and Temperature; Manghnani, M.H., Yagi, T., Eds.; AGU: Washington, DC, USA, 1998; pp. 79–88. [Google Scholar]

- Kono, Y.; Park, C.; Kenney-Benson, C.; Shen, G.; Wang, Y. Toward comprehensive studies of liquids at high pressures and high temperatures: Combined structure, elastic wave velocity, and viscosity measurements in the Paris-Edinburgh cell. Phys. Earth Planet. Int. 2014, 228, 269–280. [Google Scholar] [CrossRef]

- Yu, T.; Wang, Y.; Rivers, M.L. Imaging in 3D under pressure: A decade of high-pressure X-ray microtomography development at GSECARS. Prog. Earth Planet. Sci. 2016, 3, 17. [Google Scholar] [CrossRef]

- Brönnimann, C.; Trüb, P. Hybrid pixel photon counting X-ray detectors for synchrotron radiation. In Synchrotron Light Sources and Free-Electron Lasers; Jaeschke, E., Khan, S., Schneider, J., Hastings, J., Eds.; Springer: Cham, Switzerland, 2016; pp. 995–1027. [Google Scholar]

- Dewaele, A.; Fiquet, G.; Andrault, D.; Hausermann, D. P-V-T equation of state of periclase from synchrotron radiation measurements. J. Geophys. Res. 2000, 105, 2869–2877. [Google Scholar] [CrossRef]

- Prescher, C.; Prakapenka, V.B. DIOPTAS: A program for reduction of two-dimensional X-ray diffraction data and data exploration. High Press. Res. 2015, 35, 223–230. [Google Scholar] [CrossRef]

- Prescher, C. Glassure: An API and GUI program for analyzing angular dispersive total X-ray diffraction data. Zenodo 2017, 2017. [Google Scholar] [CrossRef]

- Wagner, C.N.J. Direct methods for the determination of atomic-scale structure of amorphous solids (X-ray, electron, and neutron scattering). J. Non Cryst. Solids 1978, 31, 1–40. [Google Scholar] [CrossRef]

- Parise, J.B.; Antao, S.M.; Michel, F.M.; Martin, C.D.; Chupas, P.J.; Shastri, S.D.; Lee, P.L. Quantitative high-pressure pair distribution function analysis. J. Synchrotron Radiat. 2005, 12, 554–559. [Google Scholar] [CrossRef] [PubMed]

- Lorch, E. Neutron diffraction by Germania, silica and radiation-damaged silica glasses. J. Phys. C Solid State Phys. 1969, 2, 229–237. [Google Scholar] [CrossRef]

- Eggert, J.H.; Weck, G.; Loubeyre, P.; Mezouar, M. Quantitative structure factor and density measurements of high-pressrure fluids in diamond anvil cells by X-ray diffraction: Argon and water. Phys. Rev. B 2002, 65, 174105. [Google Scholar] [CrossRef]

- Misawa, M.; Price, D.L.; Suzuki, K. Short-range structure of alkali disilicate glasses by pulsed neutron total scattering. J. Non Cryst. Solids 1980, 37, 85–97. [Google Scholar] [CrossRef]

- Smith, W.; Greaves, G.N.; Gillan, M.J. Computer simulation of sodium disilicate glass. J. Chem. Phys. 1995, 103, 3031. [Google Scholar] [CrossRef]

- Huang, C.; Cormack, A.N. The structure of sodium silicate glass. J. Chem. Phys. 1990, 93, 8180–8186. [Google Scholar] [CrossRef]

| Atomic Bond Lengths | This Study | Neutron Scattering [28] | MD Simulation [29] | MD Simulation [30] |

|---|---|---|---|---|

| Si–O | 1.61 ± 0.01 | 1.63 | 1.7 | 1.61 |

| Na–O | 2.20 ± 0.04 | - | 2.3 | 2.42 |

| O–O | 2.60 ± 0.02 | 2.66 | 2.6 | 2.62 |

| Si–Si | 3.14 ± 0.01 | - | 3.1 | 3.16 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, T.; Prescher, C.; Ryu, Y.J.; Shi, F.; Greenberg, E.; Prakapenka, V.; Eng, P.; Stubbs, J.; Kono, Y.; Shen, G.; et al. A Paris-Edinburgh Cell for High-Pressure and High-Temperature Structure Studies on Silicate Liquids Using Monochromatic Synchrotron Radiation. Minerals 2019, 9, 715. https://doi.org/10.3390/min9110715

Yu T, Prescher C, Ryu YJ, Shi F, Greenberg E, Prakapenka V, Eng P, Stubbs J, Kono Y, Shen G, et al. A Paris-Edinburgh Cell for High-Pressure and High-Temperature Structure Studies on Silicate Liquids Using Monochromatic Synchrotron Radiation. Minerals. 2019; 9(11):715. https://doi.org/10.3390/min9110715

Chicago/Turabian StyleYu, Tony, Clemens Prescher, Young Jay Ryu, Feng Shi, Eran Greenberg, Vitali Prakapenka, Peter Eng, Joanne Stubbs, Yoshio Kono, Guoyin Shen, and et al. 2019. "A Paris-Edinburgh Cell for High-Pressure and High-Temperature Structure Studies on Silicate Liquids Using Monochromatic Synchrotron Radiation" Minerals 9, no. 11: 715. https://doi.org/10.3390/min9110715