The Setup Design for Selective Laser Sintering of High-Temperature Polymer Materials with the Alignment Control System of Layer Deposition

Abstract

:1. Introduction

2. Equipment for Plastic Additive Manufacturing

2.1. Analysis of Analogue Equipment

2.2. Known Features of the SLS Process for Heat-Resistant PEEK

- (a)

- The heaters built into the platform and the changeable frame are heated up to a temperature of ~360 °С;

- (b)

- The protective gas (nitrogen) is pumped through the airtight chamber to obtain the required purity, and the entire SLS machine is held for two hours till uniform heating of all its elements in order to avoid their thermal deformation during operation;

- (c)

- The platform is lowered to the thickness of the first powder layer to be applied (usually ~120 μm);

- (d)

- The recoater (in the form of a double knife) moves to the left limit position under the splined shaft and the required powder batch is dosed to the recoater with the help of the splined shaft;

- (e)

- The recoater moves to the right limit position (shown in phantom) applying and leveling the first layer of powder on the platform during the movement;

- (f)

- The applied powder layer is heated up to ~385 °C with the help of upper heaters;

- (g)

- The platform is lowered to the thickness of the second powder layer to be applied (usually ~120 μm);

- (h)

- The recoater moves to the left limit position and with the help of the splined shaft and the powder delivery hopper applies in a similar way the second powder layer over the first layer on the platform, dropping excess powder into the powder collecting hopper;

- (i)

- The process of applying preliminary powder layers (about 50 layers in total) is carried out according to the c–h points without laser treatment. It is necessary for uniform heating of the machine together with the powder, and also for checking the correctness of the recoater knife position relative to the platform. During this stage, the heaters maintain the constant temperature (about 360 °C) of the whole powder volume;

- (j)

- The part manufacture begins when the recoater knife is set correctly relative to the platform;

- (k)

- The 51st layer of powder is applied over the 50 heated powder layers;

- (l)

- The 51st powder layer is heated to 385 °C with the help of upper heaters;

- (m)

- Powder is sintered with a laser beam in the individual zones of the applied layer depending on the shape of the part being manufactured;

- (n)

- Then, a new layer of powder is applied and the process is repeated until the part is completely manufactured;

- (o)

- After the whole part construction, it is cooled down very slowly (the cooling time is usually twice as long as the time of the part construction) together with the volume of the unsintered powder in the SLS machine in the changeable frame by means of heater control;

- (p)

- After complete cooling of the part together with the unsintered powder, the changeable frame is removed from the SLS machine and moved to the cleaning station where the part is cleaned from the unsintered powder.

3. Main Technical Characteristics and Requirements for the Developing Equipment

- i.

- the possibility of using the SLS technology for various types of the PEEK-based powders;

- ii.

- the workspace of 500 × 500 × 300 mm3 (length × width × height);

- iii.

- preheating of the applied powder layer to 385 °С with an accuracy ±2 °C (over the entire area of 500 × 500 mm2);

- iv.

- nitrogen protective atmosphere (nitrogen purity: up to 99.8%);

- v.

- the accuracy of the applied powder layer ±10 μm;

- vi.

- the capability to maintain controllable slow cooling of the entire volume of the manufactured part together with the unsintered powder from 385 °C to 20 °C;

- vii.

- the capability of automated control of the powder recoater alignment;

- viii.

- use of special materials for parts and assemblies under heating. For example, for springs whose alloys lose their mechanical properties during heating (spring alloys A 29 1060 ASTM, A 576 1060 ASTM, 5147 ASTM, 6150 ASTM, 9262 ASTM, etc., which are designed for operation at temperatures up to 400 °C);

- thermal deformation of the laser-optical unit of the installation, thermal aberrations, up to the destruction of protective glasses, lenses, mirrors, etc., at high temperatures;

- the property change in the optical elements of the laser-optical assembly of the installation due to heating. For example, it is changing the refractive index of the protective glass in a complex scanner lens (f-theta lens);

- the chamber sealing (most standard silicone seals and sealants really work at temperatures up to 300 °C);

- thermal insulation of the working chamber (space where the part is made from the remaining elements of the installation, for example, the precise drive of the vertical movement and alignment, the device for depositing the powder layers, the laser-optical unit, etc.);

- an interactive system for the thermal picture monitoring during the SLS process;

- the protection of electrical components (induction position sensors, contact sensors of emergency situations, electric wires, electrical connectors, etc.), used up to a temperature of 50–70 °С.

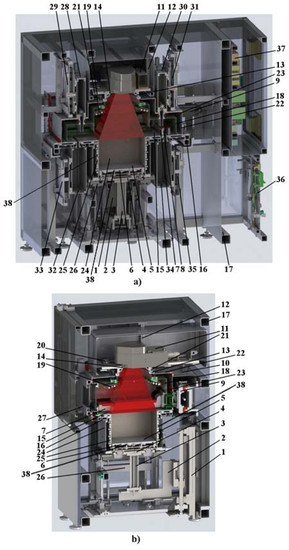

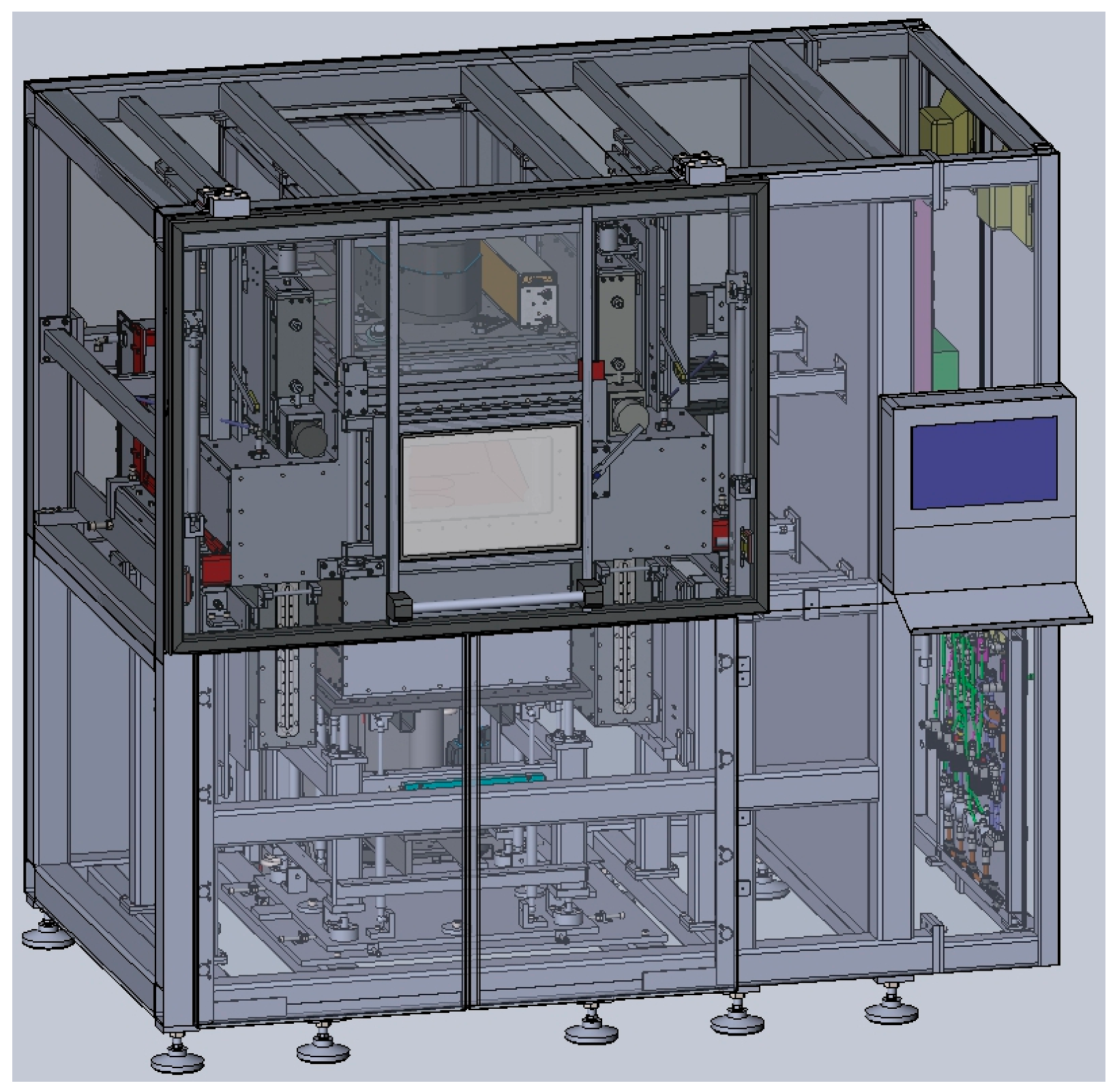

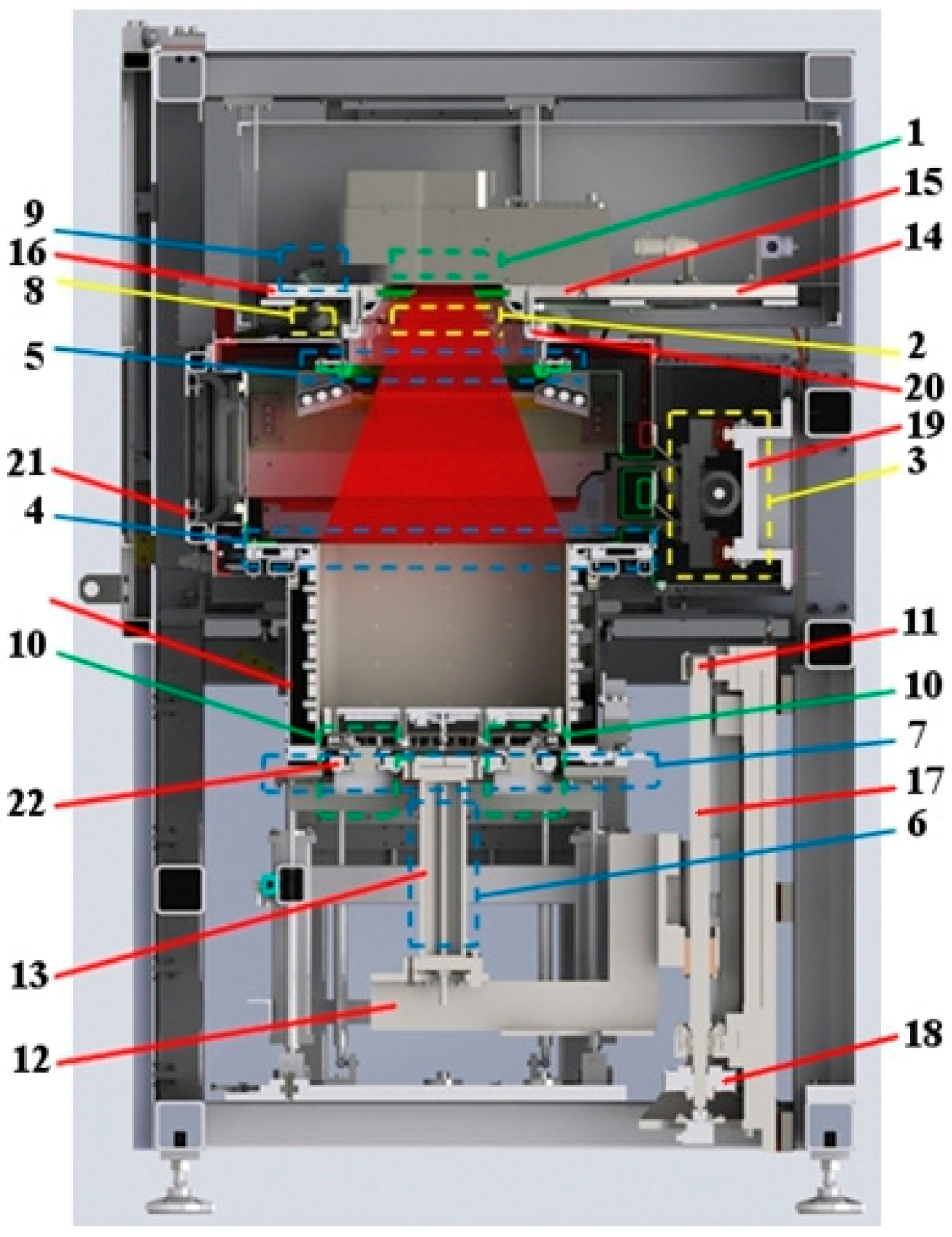

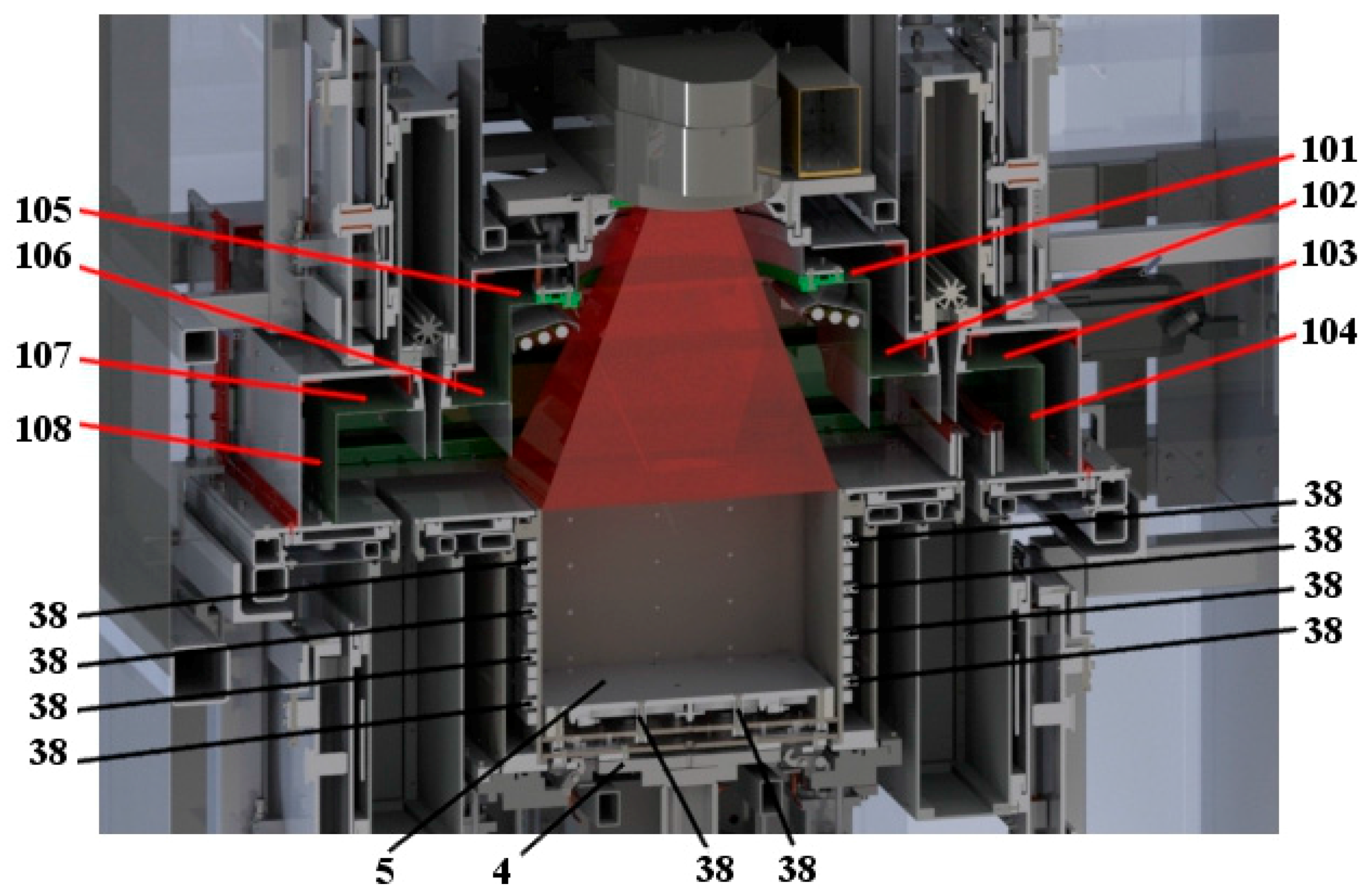

4. Design and Technological Solutions for the High-Temperature Plastic SLS Machine

- (1)

- in the nitrogen protective atmosphere (99.8% purity), it was necessary to pre-heat the applied powder layer to 385 °C, (due to the peak heating of the upper heaters to 2600 °С [38,39]), and also to support the entire volume of the manufactured part together with the unsintered powder at a temperature of 360 °C, with subsequent slow controllable cooling to 20 °C;

- (2)

- it was also necessary to maintain the accuracy of the deposited layer of powder at 120 ± 10 μm over the entire working area of 500 × 500 mm, and also to keep the focused laser spot and the accuracy of its positioning during laser processing.

- -

- vertical movement of the desktop is realized thanks to a ball screw rotated from the servomotor, which is a traditional solution for such nodes in a variety of SLS installations;

- -

- the horizontal movement of the powder layer’s delivering device is realized by means of a ball screw rotated from the servomotor. This fundamentally differentiates our equipment from those of other manufacturers, which often use a belt drive stretched between the two rollers to realize horizontal movement. However, the experience of operating the belt drive stretched between the rollers has shown its unreliability due to periodic clogging of the tension rollers with powder, which leads to frequent drive failures;

- -

- dosing of the necessary powder portions is realized thanks to splined shafts, rotated by stepping motors, which is a classic solution for modern SLS machines working with polymer powders;

- -

- for the prevention of emergency movements of the nodes, end position sensors are provided;

- -

- for precise tracking of the movement, the sensors of the coordinate control are applied.

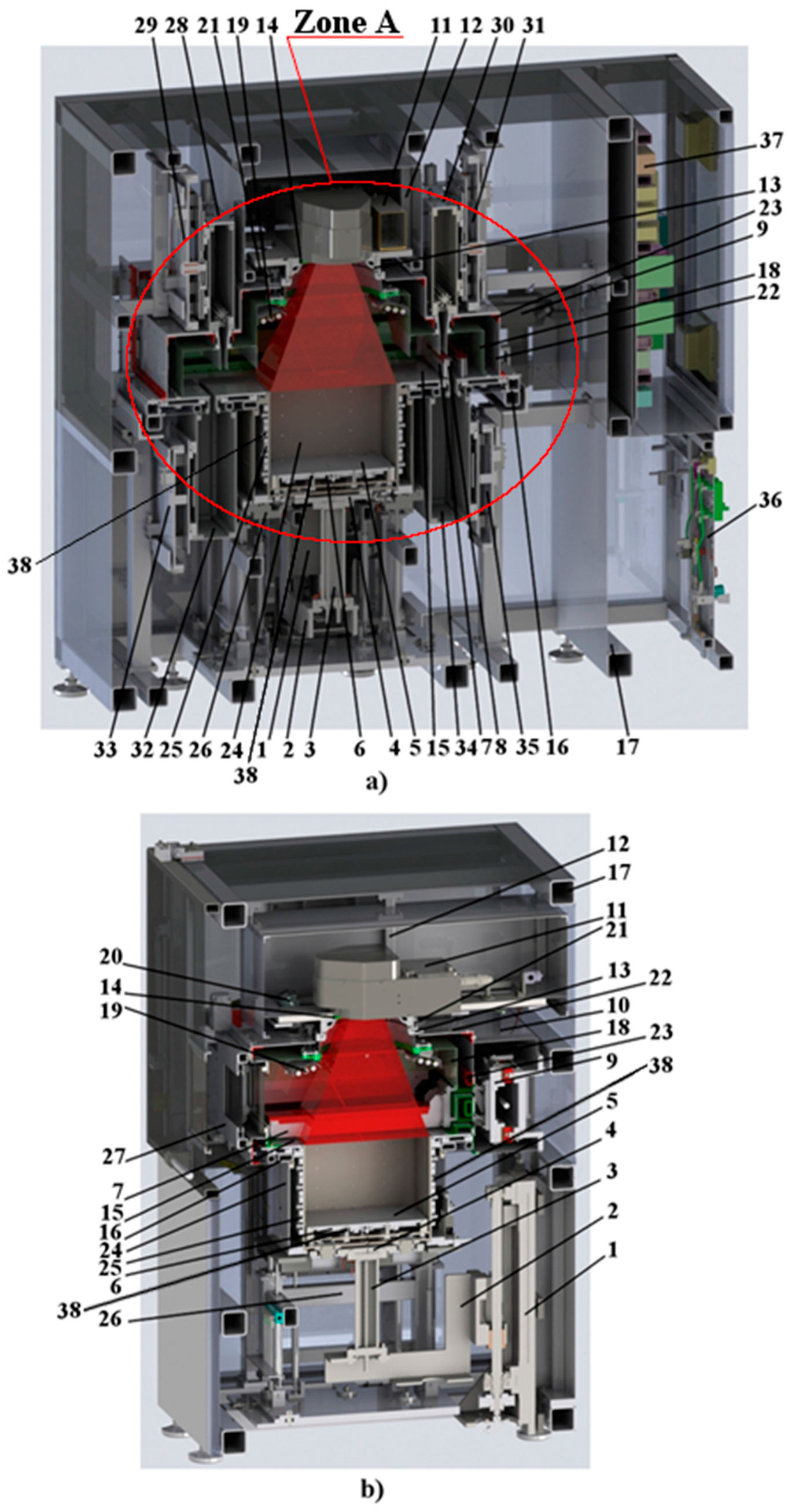

5. Adjustment Control System for Powdered Layer Delivery

- -

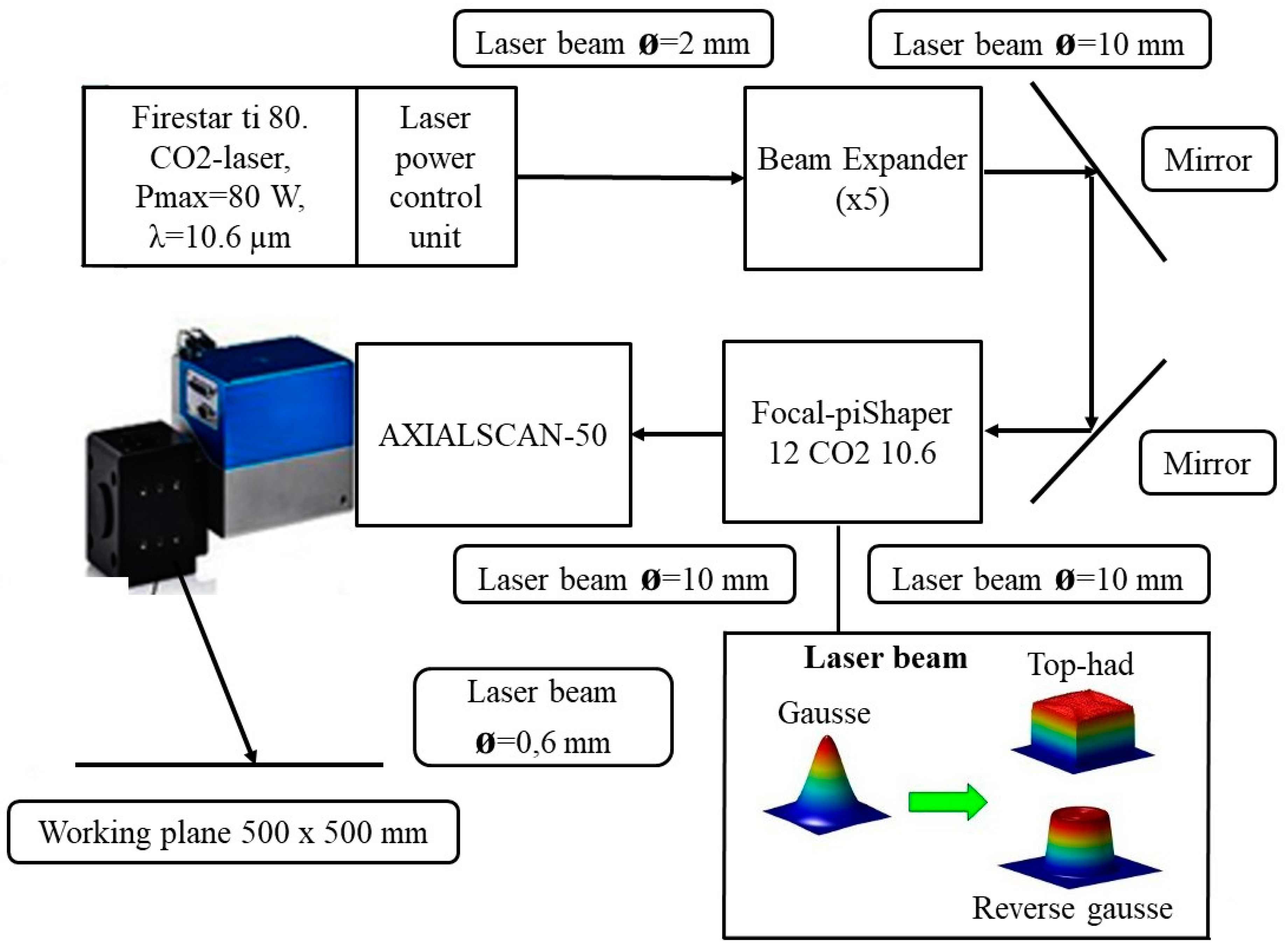

- CO2—Firestar ti-Series 80 laser (Synrad, Mukilteo, WA, USA) [43]. This laser provides a power control range from 5 W to 80 W management to the frequency modulation of laser influence;

- -

- laser Beam Expander x5 (Synrad, Mukilteo, WA, USA) [44] is necessary for matching the optical characteristics between the scanner and the laser beam due to changing the intensity distribution device of laser radiation;

- -

- the intensity distribution device—Focal-piShaper-12 CO2 10.6 (Ald Optics, Berlin, Germany) [45]. This technical solution fundamentally distinguishes the laser-optical node developed by us, from other manufacturers of the SLS equipment. The Focal-piShaper device allows changing the laser intensity distribution from “gauss” to “reverse gauss” or “top hat” shape, which by some results [36,37,38], can improve the component’s quality produced by the SLS method;

- -

- the AXIALSCAN-50 scanner (Raylase, Wessling, Germany) [46]. A striking feature of this scanner is the constant diameter of the focused laser beam along the entire large 500 × 500 mm field of scanning. It is maintained due to the joint interaction of the fixed focusing lens and the rapidly moving defocusing lens. This technical solution is fundamentally different from the classical use of a dual-axis scanner with an f-theta objective in the SLS equipment;

- -

- two CO2 mirrors are necessary to turn the direction of laser beam propagation by 180° in order to achieve the maximum compactness of the laser scanning system.

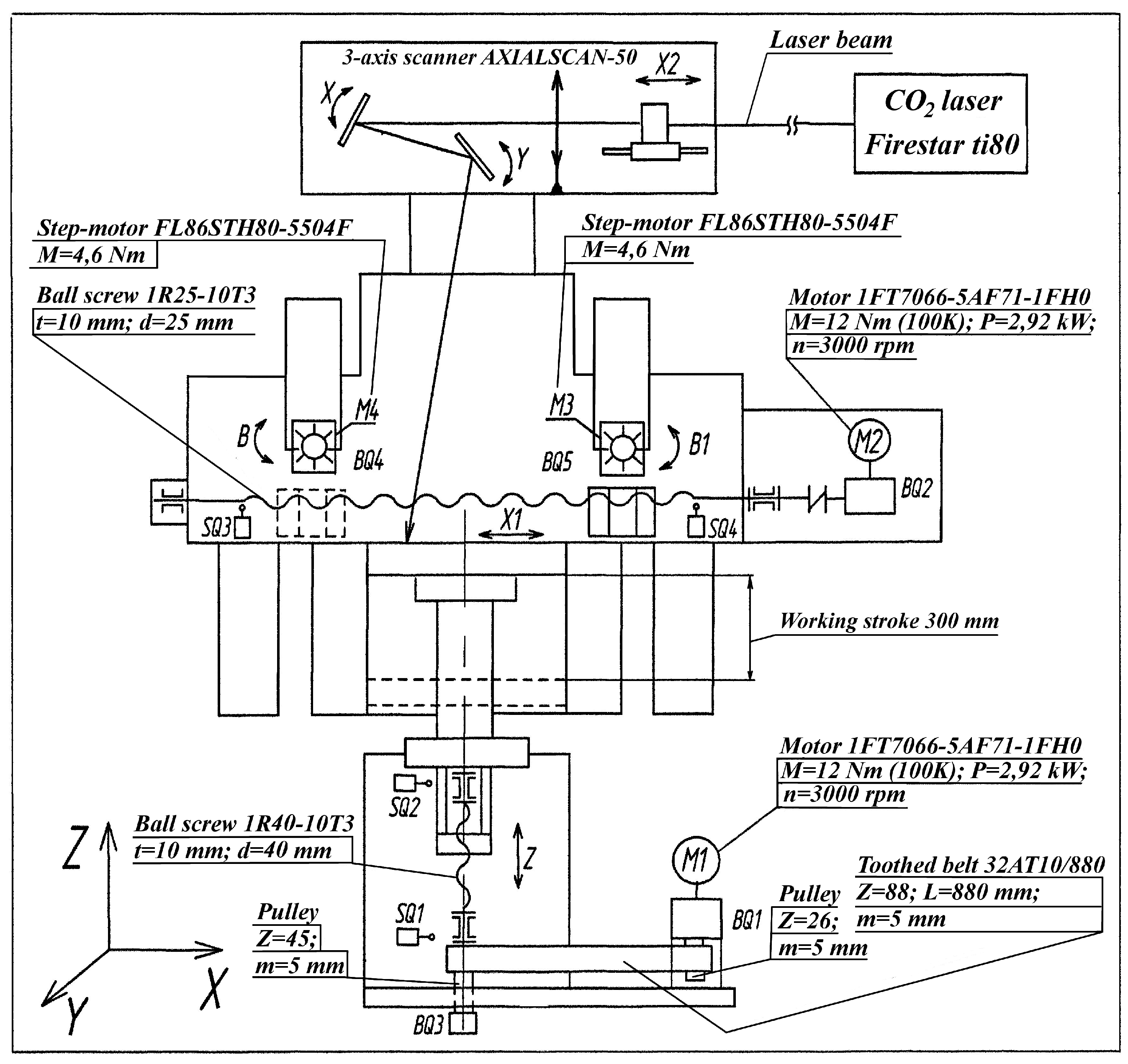

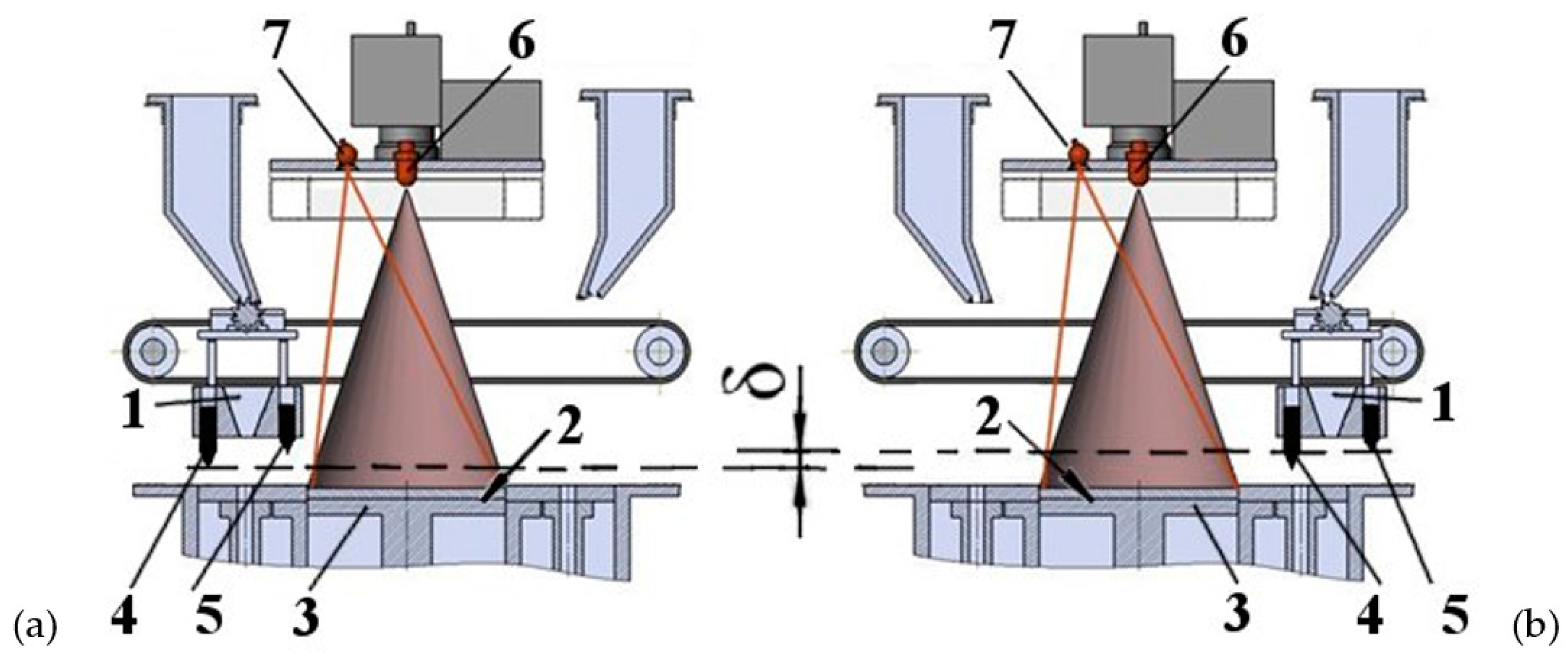

- (a)

- leveling of the double-knife recoater is set by the operator manually before starting the operation on the upper surface of the platform;

- (b)

- leveling of the double-knife recoater is always skewed relative to the platform top surface. While applying the powder layer from the left limit position (Figure 7a), the applied layer thickness is specified by knife 4;

- (c)

- while applying the powder layer from the right limit position (Figure 7b), the thickness of the applied layer is specified by knife 5, and therefore the difference of the thickness of the layers applied from the left limit position and the right limit position will be δ μm;

- (d)

- in case of proper adjustment of the heaters installed above the applied powder layer, they transfer an equal heat amount to each applied powder layer;

- (e)

- pyrometer mounted above the applied powder layer measures the heating of the applied powder layer and registers slight differences between the values of heating the powder layers applied from the left limit position and those applied from the right limit position due to the difference of thickness layers of the δ ~ 20 μm;

- (f)

- the sum of the heating values (integral heating) for the 25 layers of powder applied from the leftmost position will differ from the sum of the heat values for the 25 layers of powder deposited from the extreme right position due to the difference in layer thickness by the δ value;

- (g)

- Based on the difference in the integral heating for the powder layers applied from the extreme left and rightmost positions, the skewing degree of the leveling double knife relative to the upper surface of the platform can be unambiguously concluded;

- (h)

- the alignment control of the double knife according to the principles described above must be carried out before the 3D part building for the correctness verification of the operator adjustment, and also directly during the construction process.

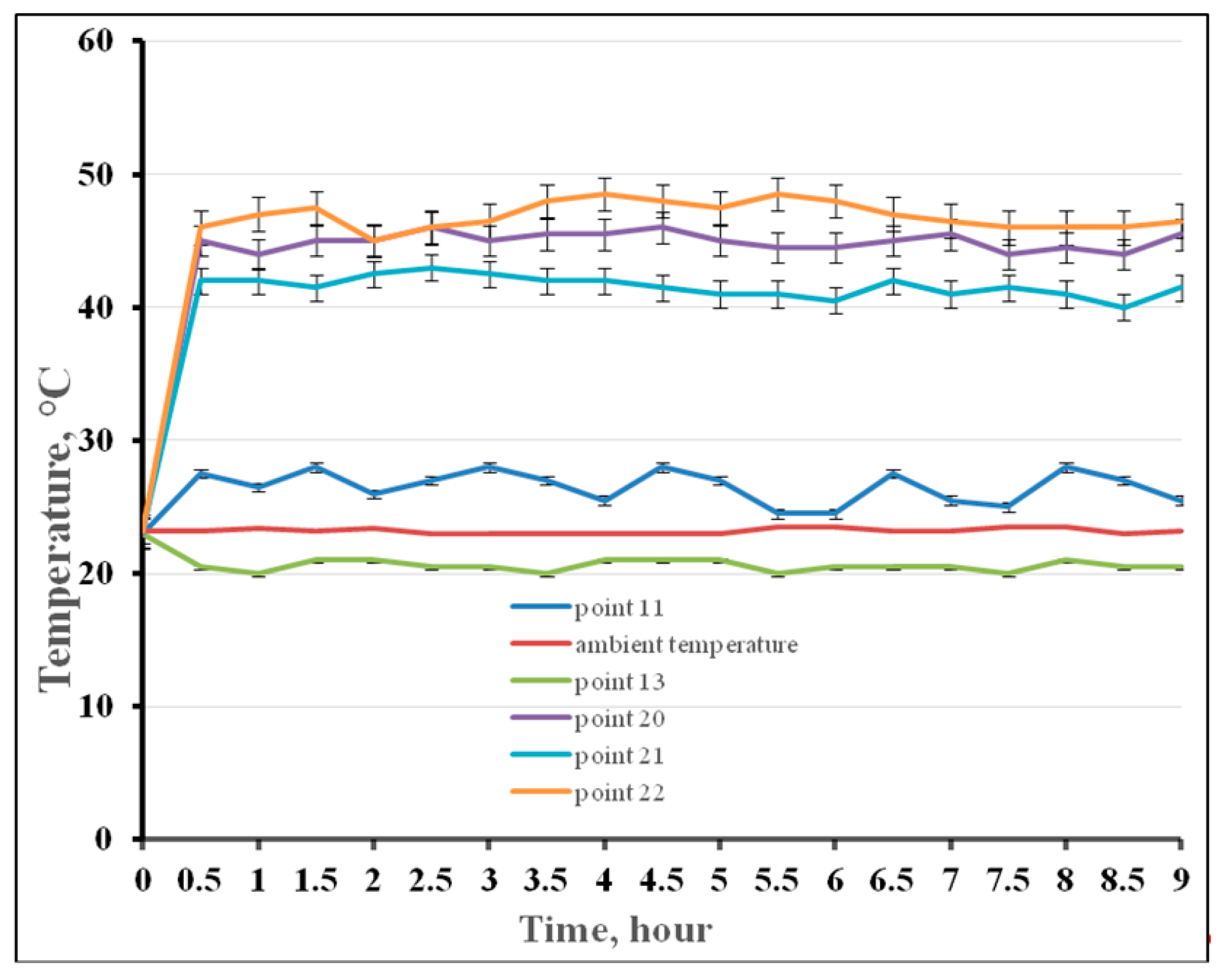

6. Experimental Implementation and Discussion

7. Conclusions

Acknowledgments

Author Contributions

Conflict of Interest

References

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies: Rapid Prototyping to Direct Digital Manufacturing; Springer: New York, NY, USA, 2010. [Google Scholar]

- Rundle, G.A. Revolution in the Making: 3D Printing, Robots and the Future; Affirm Press: South Melbourne, Australia, 2014. [Google Scholar]

- Shishkovsky, I.V. Laser Synthesis of Functional Mesostructures and 3D Parts; Fizmatlit Publ.: Moscow, Russia, 2009. [Google Scholar]

- Nazarov, A.P. Perspective of rapid prototyping via selective laser sintering/melting method. Vestnik MGTU Stankin 2011, 4, 46–51. [Google Scholar]

- Tarasova, T.V.; Nazarov, A.P. Investigation of the processes of modification of the surface layer and the manufacture of three-dimensional engineering components through selective laser melting. Vestnik MGTU Stankin 2013, 2, 17–21. [Google Scholar]

- Kinstlinger, I.S.; Bastian, A.; Paulsen, S.J.; Hwang, D.H.; Ta, A.H.; Yalacki, D.R.; Schmidt, T.; Miller, J.S. Open-Source Selective Laser Sintering (OpenSLS) of Nylon and Biocompatible Polycaprolactone. PLoS ONE 2016, 11, e0147399. [Google Scholar] [CrossRef] [PubMed]

- Van Hooreweder, B.; Moens, D.; Boonen, R.; Kruth, J.-P.; Sas, P. On the difference in material structure and fatigue properties of nylon specimens produced by injection molding and selective laser sintering. Polym. Test. 2013, 32, 972–981. [Google Scholar] [CrossRef]

- Nelson, J.S.; Xue, S.; Barlow, J.W.; Beaman, J.J.; Marcus, H.L.; Bourell, D.L. Model of Selective Laser Sintering of Bisphenol-A Polycarbonate. Ind. Chem. Eng. Res. 1993, 32, 2305–2317. [Google Scholar] [CrossRef]

- Berzins, M.; Childs, T.H.C.; Ryder, G.R. The Selective Laser Sintering of Polycarbonate. CIRP Ann. 1996, 45, 187–190. [Google Scholar] [CrossRef]

- Ivanova, A.M.; Kotova, S.P.; Kupriyanov, N.L.; Petrov, A.L.; Tarasova, E.Y.; Shishkovskii, I.V. Physical characteristics of selective laser sintering of metal-polymer powder composites. Quantum Electron. 1998, 28, 420–425. [Google Scholar] [CrossRef]

- Shishkovskii, I.V.; Kupriyanov, N.L. Thermal fields in metal-polymer powder compositions during laser treatment. High Temp. 1997, 35, 710–714. [Google Scholar]

- Ho, H.C.H.; Cheung, W.L.; Gibson, I. Morphology and Properties of Selective Laser Sintered Bisphenol A Polycarbonate. Ind. Eng. Chem. Res. 2003, 42, 1850–1862. [Google Scholar] [CrossRef]

- Goodridge, R.D.; Tuck, C.J.; Hague, R.J.M. Laser sintering of polyamides and other polymers. Prog. Mater. Sci. 2012, 57, 229–267. [Google Scholar] [CrossRef]

- Franco, A.; Lanzetta, M.; Romoli, L. Experimental analysis of selective laser sintering of polyamide powders: An energy perspective. J. Clean. Prod. 2010, 18, 1722–1730. [Google Scholar] [CrossRef]

- Goodridge, R.D.; Hague, R.J.M.; Tuck, C.J. Effect of long-term aging on the tensile properties of a polyamide 12 laser sintering material. Polym. Test. 2010, 29, 483–493. [Google Scholar] [CrossRef]

- Shishkovsky, I.V.; Juravleva, I.N. Kinetics of polycarbonate distraction during laser-assisted sintering. Int. J. Adv. Manuf. Technol. 2014, 72, 193–199. [Google Scholar] [CrossRef]

- Shishkovsky, I.; Nagulin, K.; Sherbakov, V. Study of biocompatible nano oxide ceramics, interstitial in polymer matrix during laser-assisted sintering. Int. J. Adv. Manuf. Technol. 2015, 78, 449–455. [Google Scholar] [CrossRef]

- Goodridge, R.D.; Hague, R.J.M.; Tuck, C.J. An empirical study into laser sintering of ultra-high molecular weight polyethylene (UHMWPE). J. Mater. Process. Technol. 2010, 210, 72–80. [Google Scholar] [CrossRef]

- Laureto, J.J.; Dessiatoun, S.V.; Ohadi, M.M.; Pearce, J.M. Open Source Laser Polymer Welding System: Design and Characterization of Linear Low-Density Polyethylene Multilayer Welds. Machines 2016, 4, 14. [Google Scholar] [CrossRef]

- Tarasova, E.; Juravleva, I.; Shishkovsky, I.; Ruzhechko, R. Layering laser-assisted sintering of functional graded porous PZT ceramoplasts. Phase Transit. Multinatl. J. 2013, 86, 1121–1129. [Google Scholar] [CrossRef]

- Volyansky, I.; Shishkovsky, I. Laser assisted 3D printing of functional graded structures from polymer covered nanocomposites. In New Trends in 3D Printing; Shishkovsky, I.V., Ed.; InTech Publ.: Rijeka, Croatia, 2016; Chapter 11; 268p. [Google Scholar]

- Serra, T.; Planell, J.A.; Navarro, M. High-resolution PLA-based composite scaffolds via 3-D printing technology. Acta Biomater. 2013, 9, 5521–5530. [Google Scholar] [CrossRef] [PubMed]

- Chia, H.N.; Wu, B.M. Recent advances in 3D printing of biomaterials. J. Biol. Eng. 2015, 9, 4. [Google Scholar] [CrossRef] [PubMed]

- Trachtenberg, J.E.; Mountziaris, P.M.; Miller, J.S.; Wettergreen, M.; Kasper, F.K.; Mikos, A.G. Open-source three-dimensional printing of biodegradable polymer scaffolds for tissue engineering. J. Biomed. Mater. Res. Part A 2014, 102, 4326–4335. [Google Scholar] [CrossRef]

- Laureto, J.; Tomasi, J.; King, J.A.; Pearce, J.M. Thermal properties of 3-D printed polylactic acid-metal composites. Prog. Addit. Manuf. 2017, 2, 57–71. [Google Scholar] [CrossRef]

- Wittbrodt, B.; Pearce, J.M. The effects of PLA color on material properties of 3-D printed components. Addit. Manuf. 2015, 8, 110–116. [Google Scholar] [CrossRef]

- EOS Plastic Materials for Additive Manufacturing. Available online: https://www.eos.info/material-p (accessed on 10 January 2018).

- Polyether Ether Ketone. Available online: https://en.wikipedia.org/wiki/Polyether_ether_ketone (accessed on 10 January 2018).

- VICTREX™ PEEK Polymers. Available online: https://www.victrex.com/~/media/datasheets/victrex_tds_450g.ashx (accessed on 10 January 2018).

- Berretta, S.; Evans, K.E.; Ghita, O. Processability of PEEK, a new polymer for High-Temperature Laser Sintering (HT-LS). Eur. Polym. J. 2015, 68, 243–266. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, M.; Pohle, D.; Rechtenwald, T. Selective Laser Sintering of PEEK. CIRP Ann. Manuf. Technol. 2007, 56, 205–208. [Google Scholar] [CrossRef]

- PEEK (Polyarylethe-Retherketone). Available online: http://www.bpf.co.uk/plastipedia/polymers/peek.aspx (accessed on 10 January 2018).

- EOS Systems and Equipment for Plastic Additive Manufacturing. Available online: https://www.eos.info/systems_solutions/plastic/systems_equipment (accessed on 10 January 2018).

- D Systems. Available online: https://www.3dsystems.com/3d-printers/plastic#selective-laser-sintering-printers-sls (accessed on 10 January 2018).

- EOS P 500—The Automation-Ready Manufacturing Platform for Laser Sintering of Plastic Parts on an Industrial Scale. Available online: https://www.eos.info/systems_solutions/eos-p-500 (accessed on 17 January 2018).

- Zhirnov, I.; Podrabinnik, P.; Okunkova, A.; Gusarov, V. Laser beam profiling: Experimental study of its influence on single-track formation by selective laser melting. Mech. Ind. 2015, 16, 709. [Google Scholar] [CrossRef]

- Gusarov, V.; Okunkova, A.; Peretyagin, P.; Zhirnov, I.; Podrabinnik, P. Means of Optical Diagnostics of Selective Laser Melting with Non-Gaussian Beams. Meas. Tech. 2015, 58, 872–877. [Google Scholar] [CrossRef]

- πShaper. Available online: http://www.pishaper.com/public.php (accessed on 10 January 2018).

- HEATRODSHOP. Available online: http://www.heatrodshop.com/product/qhs (accessed on 10 January 2018).

- Mir Nagreva. Available online: https://www.mirnagreva.ru/catalog/infrakrasnye_nagrevateli_obogrevateli_lampy/kvartsevye_nagrevateli/kvartsevye_galogenovye_izluchateli/ (accessed on 10 January 2018).

- Thermon. Available online: http://www.thermon.co.za/catalogue/heating-elements/flat-elements-box-heaters/thermon-fc-flat-heater-ceramic-insulation (accessed on 10 January 2018).

- Marion. Available online: http://elektroteni.ru/ploskie.html (accessed on 10 January 2018).

- Synrad. Available online: https://www.synrad.com/synrad/docroot/products/lasers/ti-series (accessed on 10 January 2018).

- Synrad. Available online: https://www.synrad.com/synrad/docroot/products/accessories/beam-expanders (accessed on 10 January 2018).

- πShaper. Available online: http://www.pishaper.com/shaper_for_co2.php (accessed on 10 January 2018).

- Raylase. Available online: https://www.raylase.de/en/products/3-axis-deflection-units/axialscan-50.html (accessed on 10 January 2018).

- Renishaw. Available online: http://www.renishaw.com/en/xl-80-laser-system--8268 (accessed on 30 January 2018).

- Shakhmurzova, K.T.; Kurdanova, Z.I.; Khashirova, S.Y.; Beev, A.A.; Ligidov, M.K.; Pahomov, S.I.; Mikitaev, A.K. Polyetherketones. Receiving, properties and application. News Higher Educ. Inst. Chem. Eng. Chem. 2015, 58, 3–11. [Google Scholar]

- Shakhmurzova, K.T.; Kurdanova, Z.I.; Jansitov, A.A.; Baikaziev, A.E.; Hashitova, S.U.; Pahomov, S.I.; Ligidov, M.K. Synthesis and Properties of Aromatic Polyester Resins with Cord Fragments. News Higher Educ. Inst. Chem. Eng. Chem. 2017, 60, 28–39. [Google Scholar] [CrossRef]

- Shishkovsky, I.V.; Morozov, Y.G.; Kuznetsov, M.V.; Parkin, I.P. Surface laser sintering of exothermic powder compositions: A thermal and SEM/EDX study. J. Therm. Anal. Calorimetery 2008, 92, 427–436. [Google Scholar] [CrossRef]

- Hasenauer-Hesse. Available online: http://www.hasenauer-hesser.de/fileadmin/dokumente_infos/datebblaetter/en/EOSPeek.pdf (accessed on 30 January 2018).

| Name of Item | Manufactured Samples | EOS Data [51] |

|---|---|---|

| Tensile modulus ASTM D638 | 3150 ± 150 MPa | 4250 ± 150 MPa |

| Tensile strength ASTM D638 | 70 ± 8 MPa | 90 ± 5 MPa |

| Elongation at break ASTM D638 | 2.5 ± 0.2% | 2.8 ± 0.2% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nazarov, A.; Skornyakov, I.; Shishkovsky, I. The Setup Design for Selective Laser Sintering of High-Temperature Polymer Materials with the Alignment Control System of Layer Deposition. Machines 2018, 6, 11. https://doi.org/10.3390/machines6010011

Nazarov A, Skornyakov I, Shishkovsky I. The Setup Design for Selective Laser Sintering of High-Temperature Polymer Materials with the Alignment Control System of Layer Deposition. Machines. 2018; 6(1):11. https://doi.org/10.3390/machines6010011

Chicago/Turabian StyleNazarov, Alexey, Innokentiy Skornyakov, and Igor Shishkovsky. 2018. "The Setup Design for Selective Laser Sintering of High-Temperature Polymer Materials with the Alignment Control System of Layer Deposition" Machines 6, no. 1: 11. https://doi.org/10.3390/machines6010011