Nanofluids Minimal Quantity Lubrication Machining: From Mechanisms to Application

Abstract

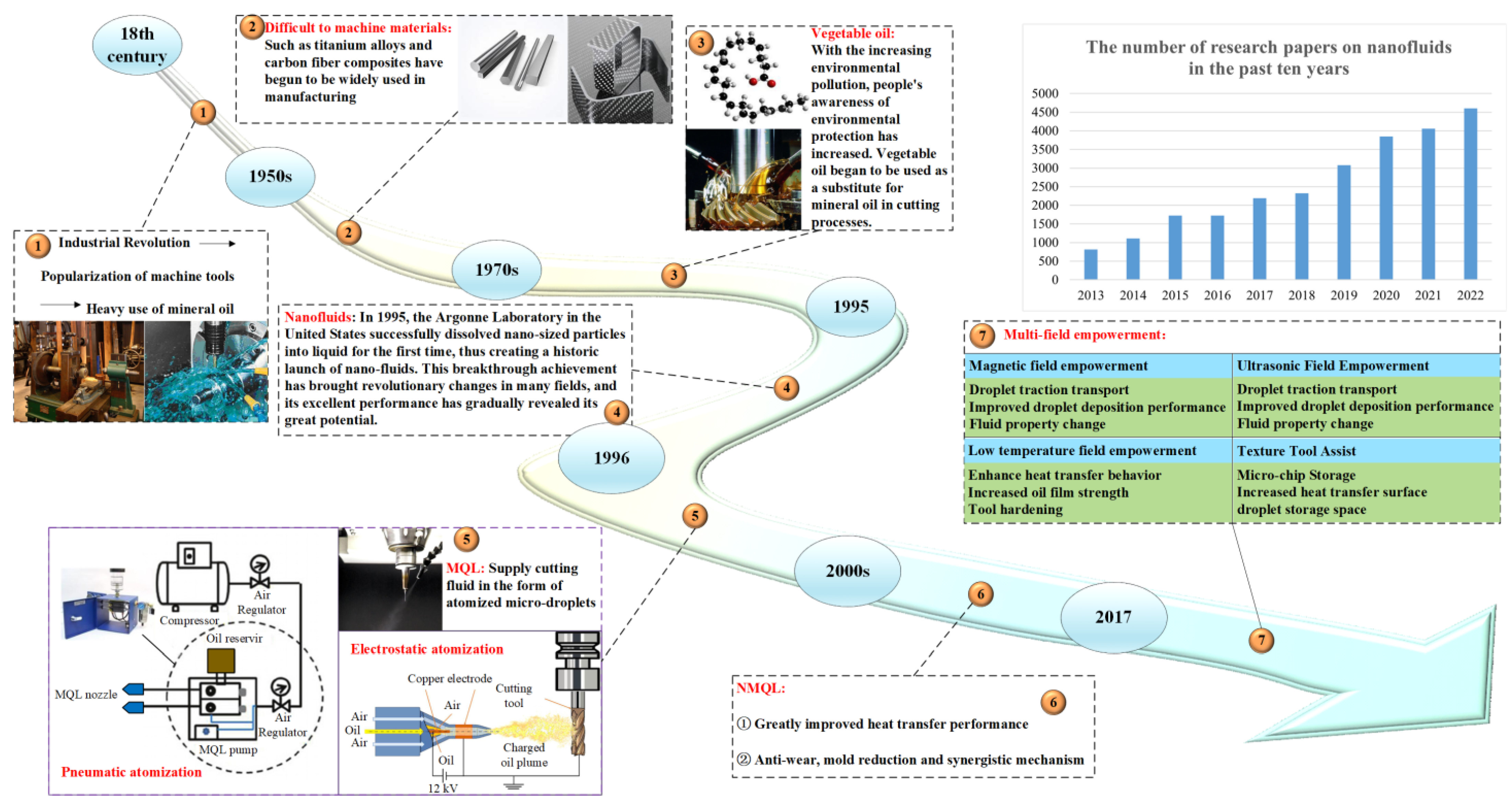

:1. Introduction

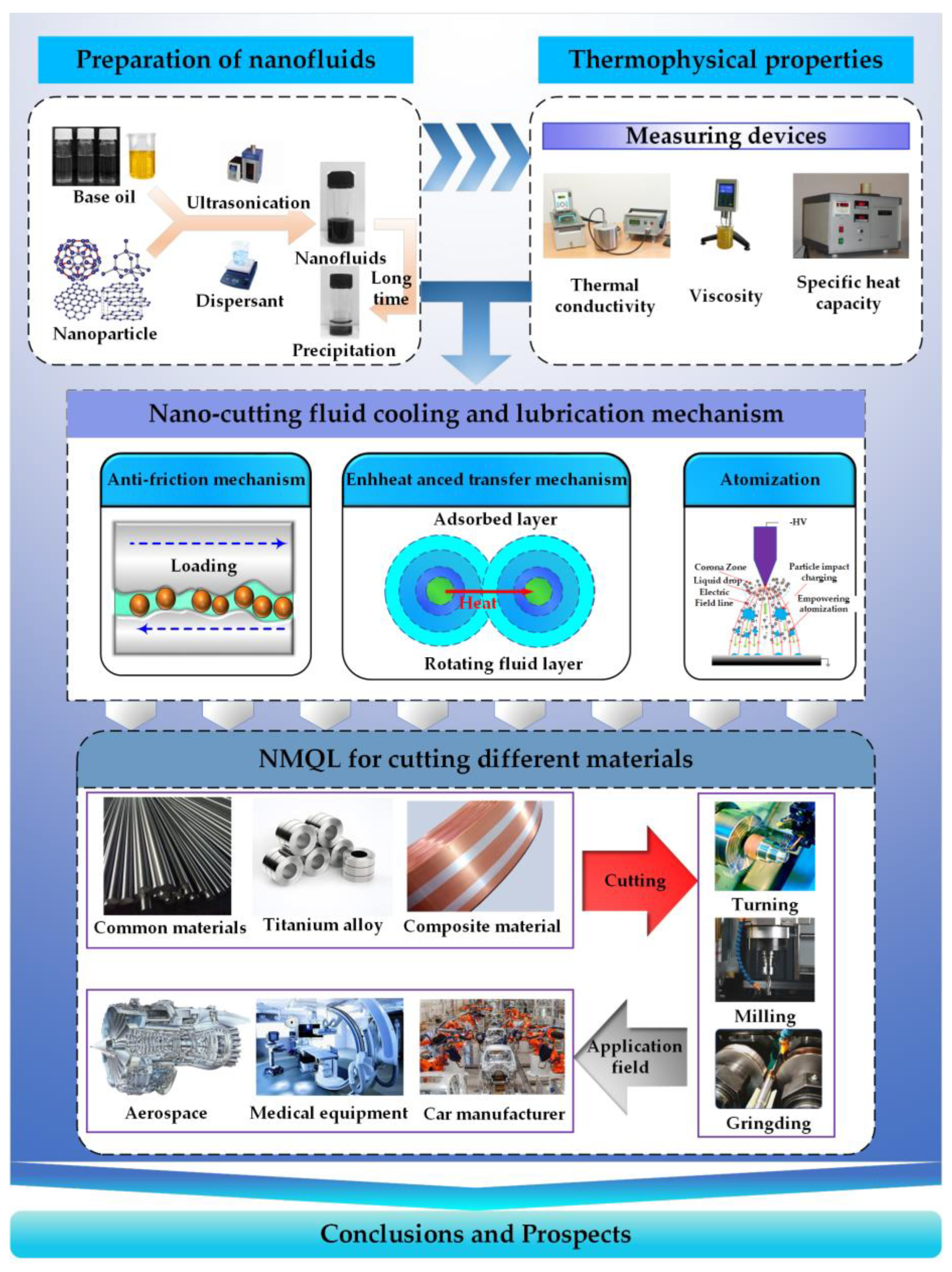

2. Preparation of Nanofluids

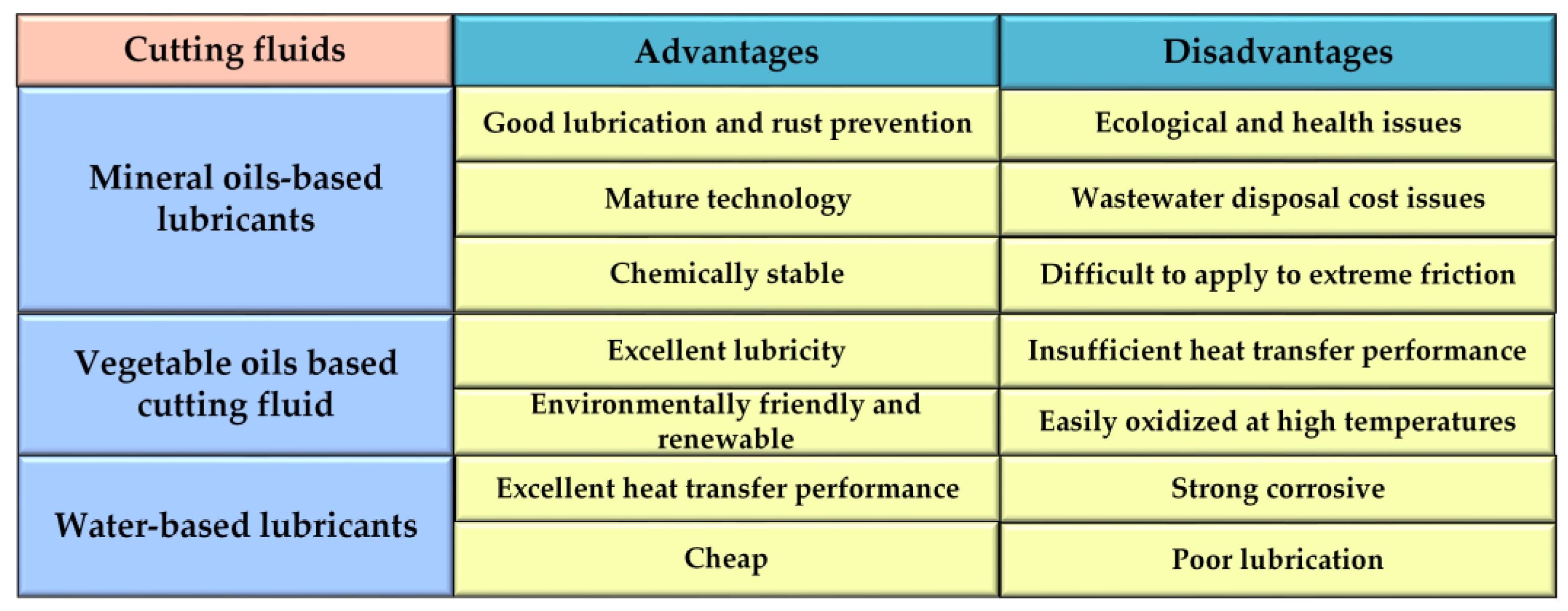

2.1. Base Fluid Selection

2.1.1. Vegetable-Based Oil

2.1.2. Water-Based Lubricants

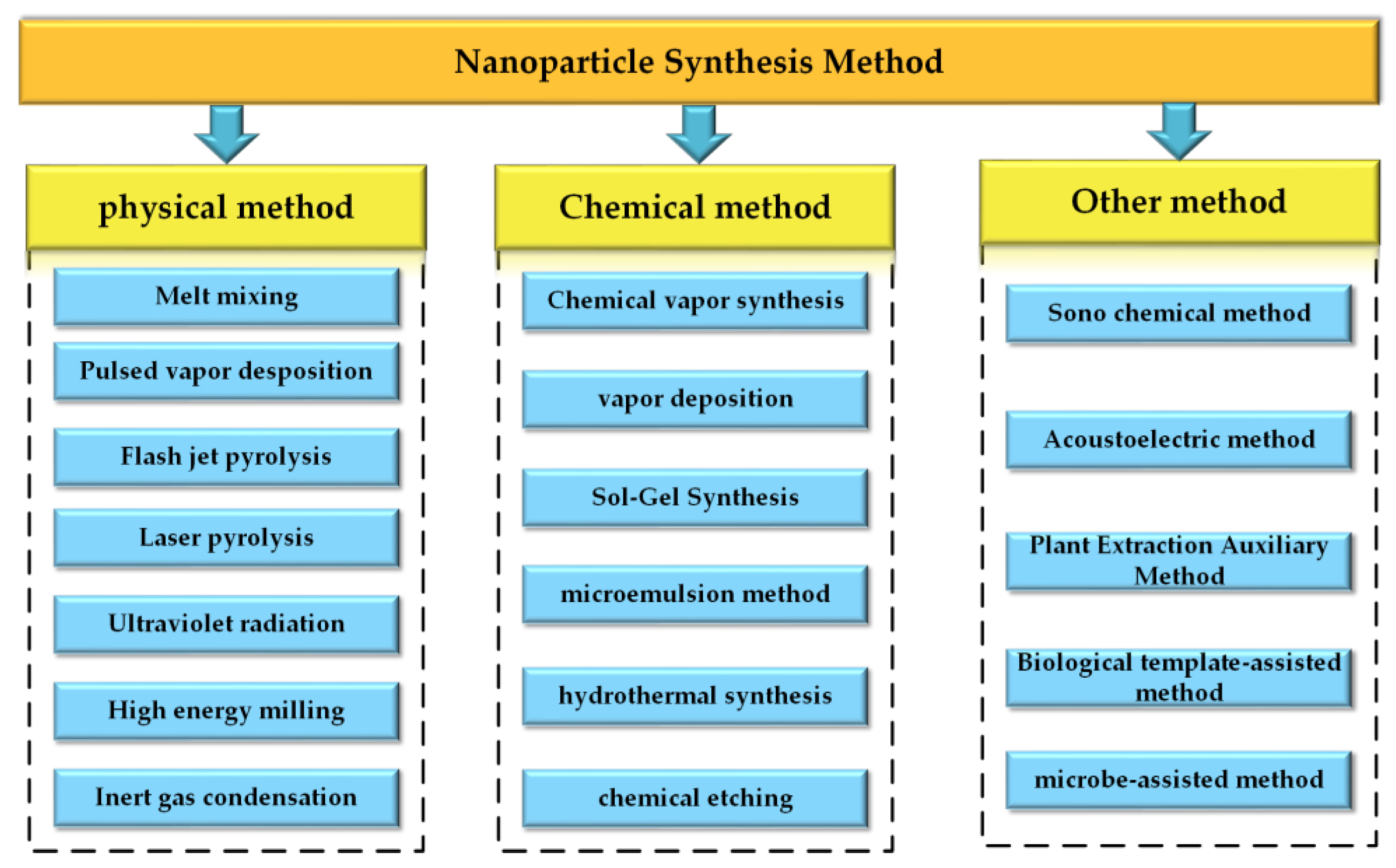

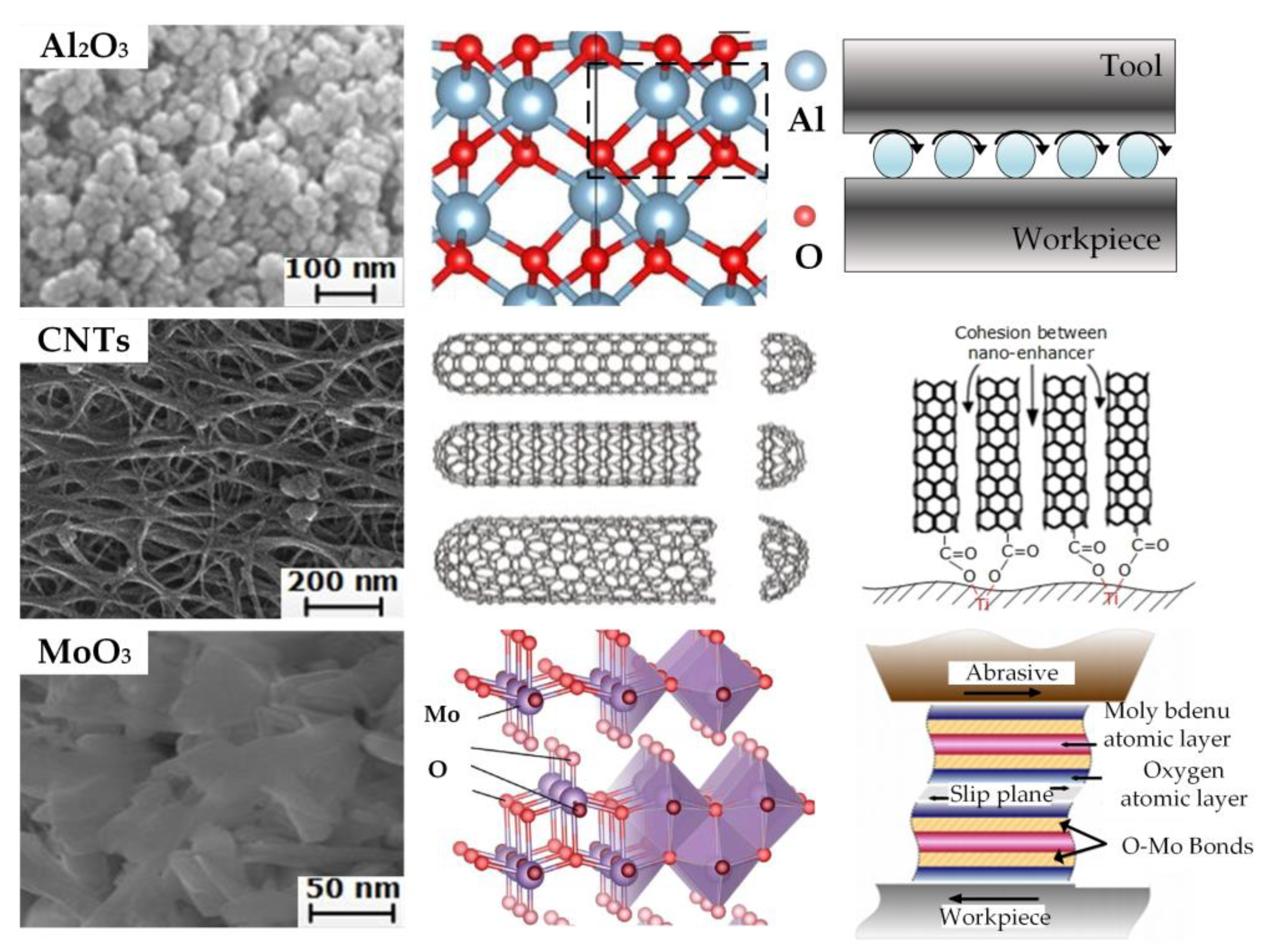

2.2. Nanoparticles

2.2.1. Type of Nanoparticle

2.2.2. Shape of Nanoparticles

2.3. The Preparation Method

2.3.1. One Step

2.3.2. Two Steps

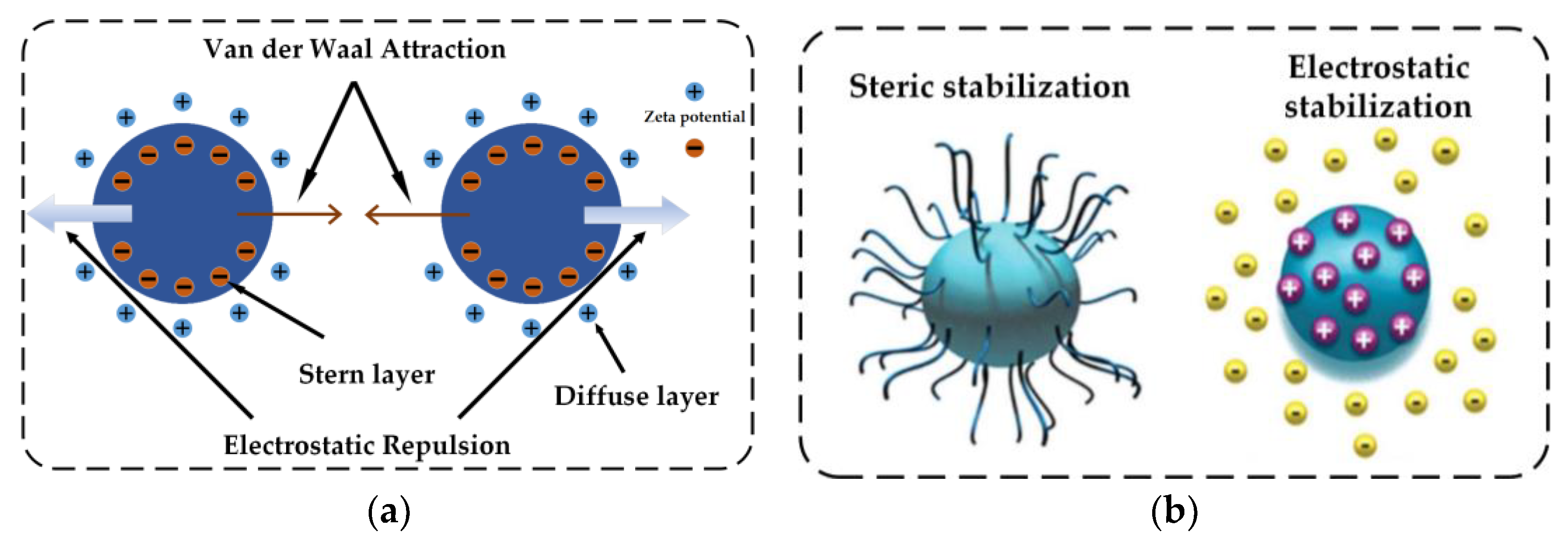

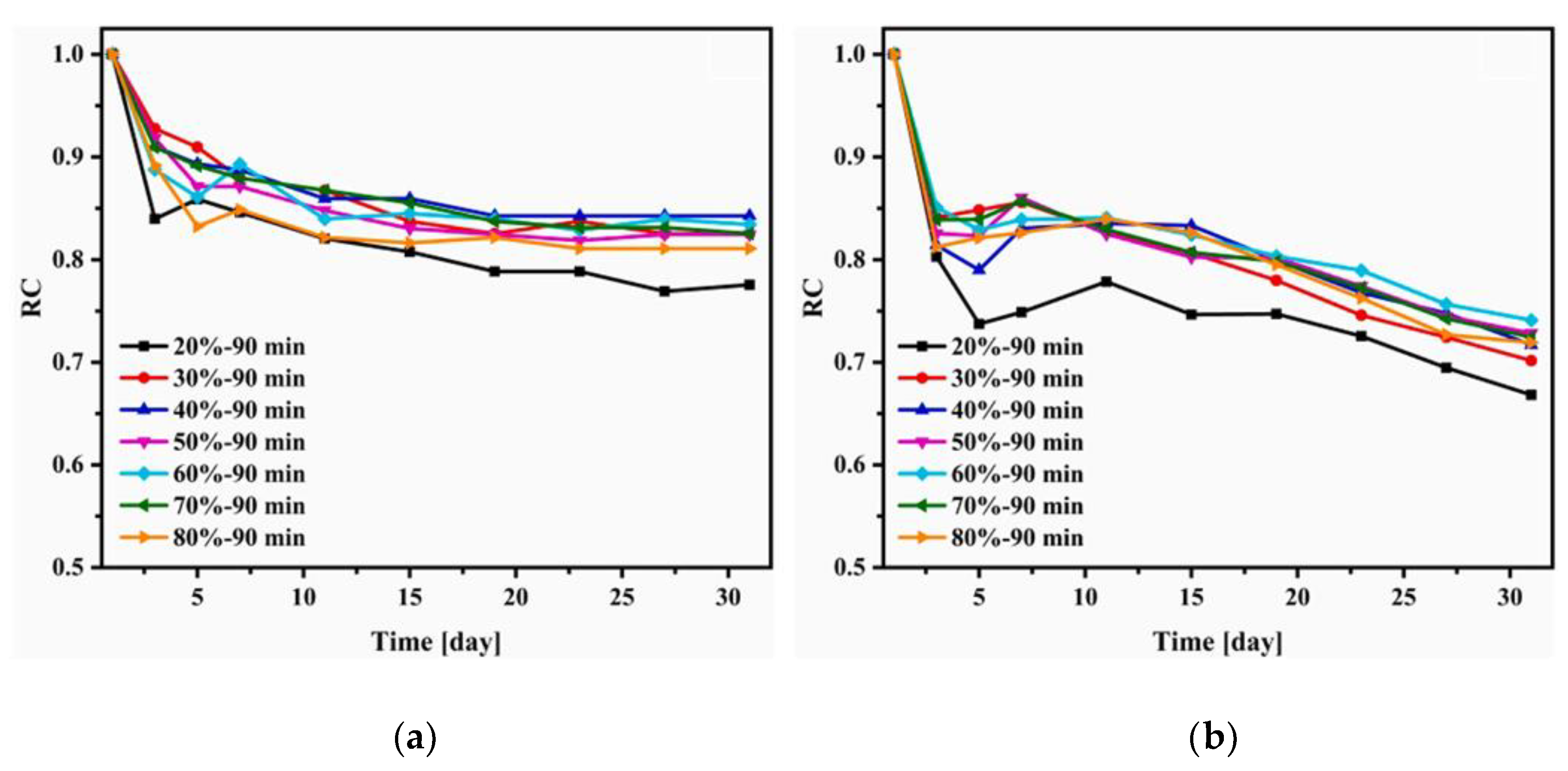

2.4. Stability of Nanofluids

2.4.1. Stability Mechanism

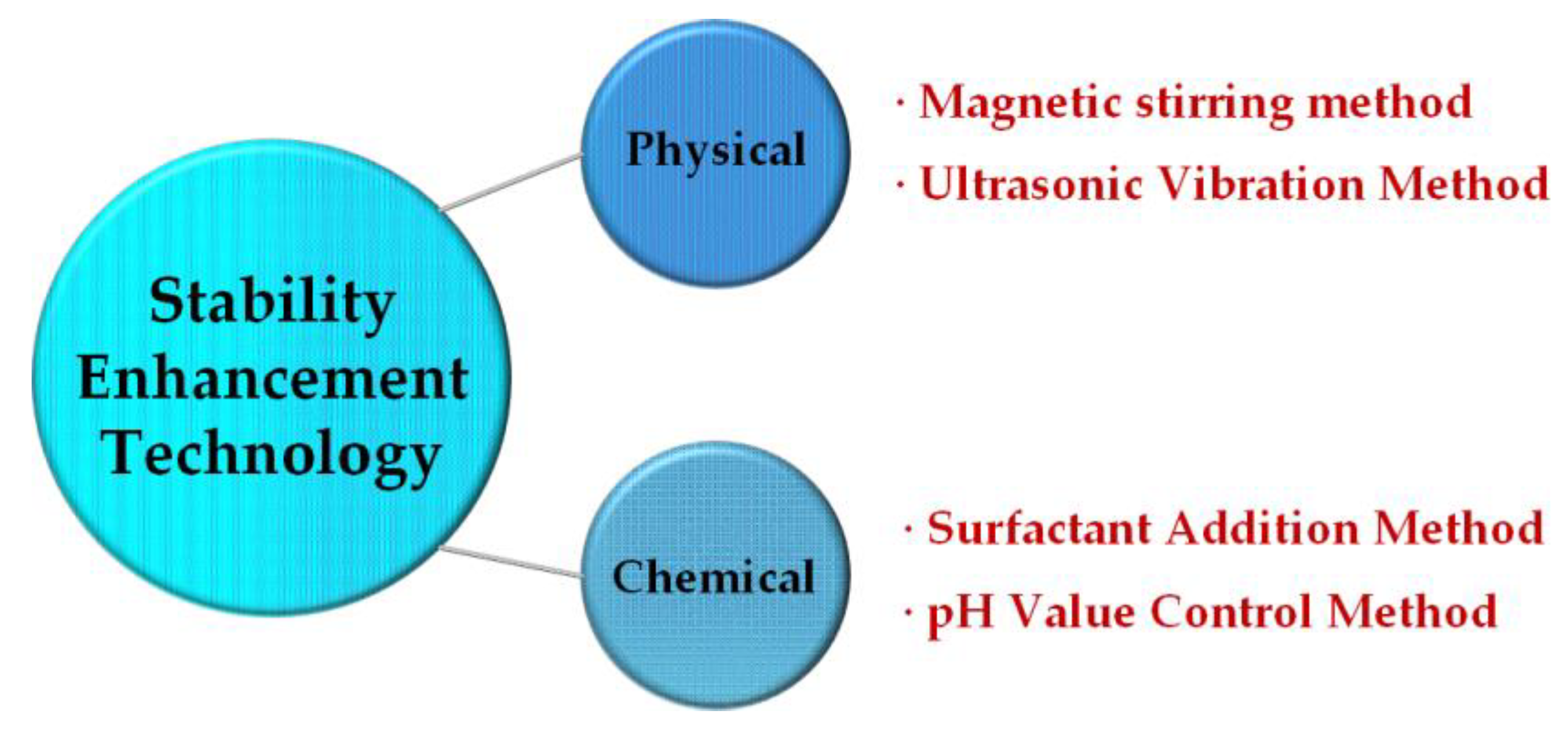

2.4.2. Stability Enhancement Technology

3. Thermophysical Properties of Nanofluids

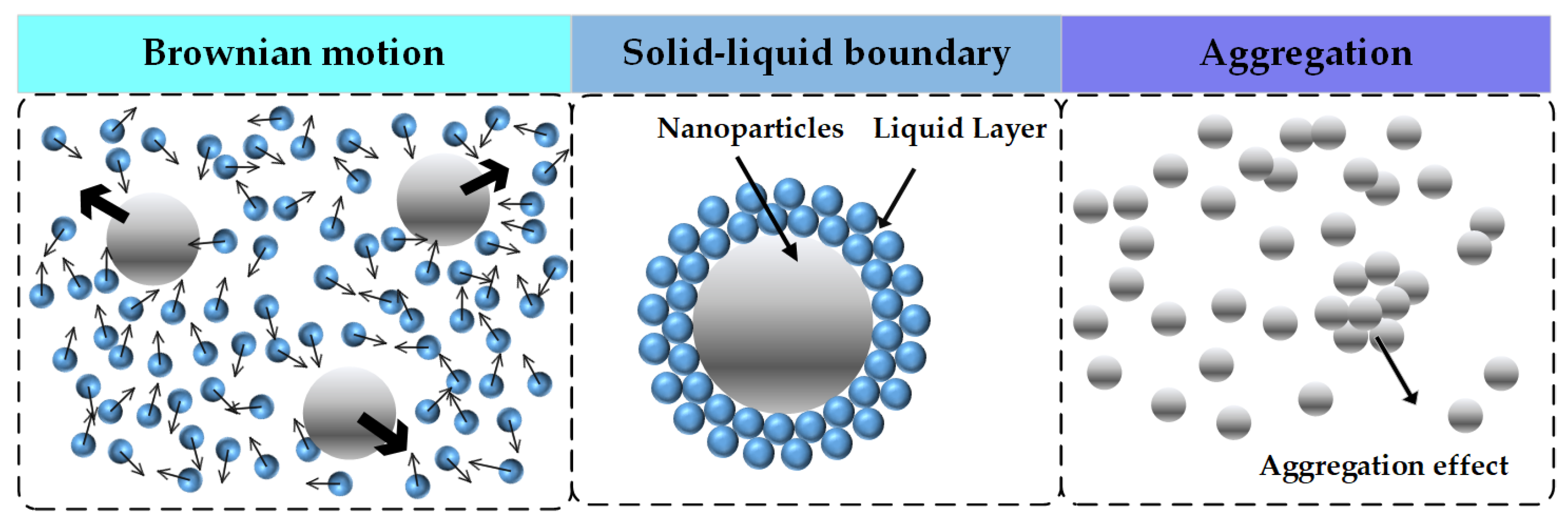

3.1. Thermal Conductivity

3.1.1. Influencing Factors

3.1.2. The Thermal Conductivity Model

3.2. Viscosity

3.2.1. Influencing Factors

3.2.2. The Viscosity Prediction Model

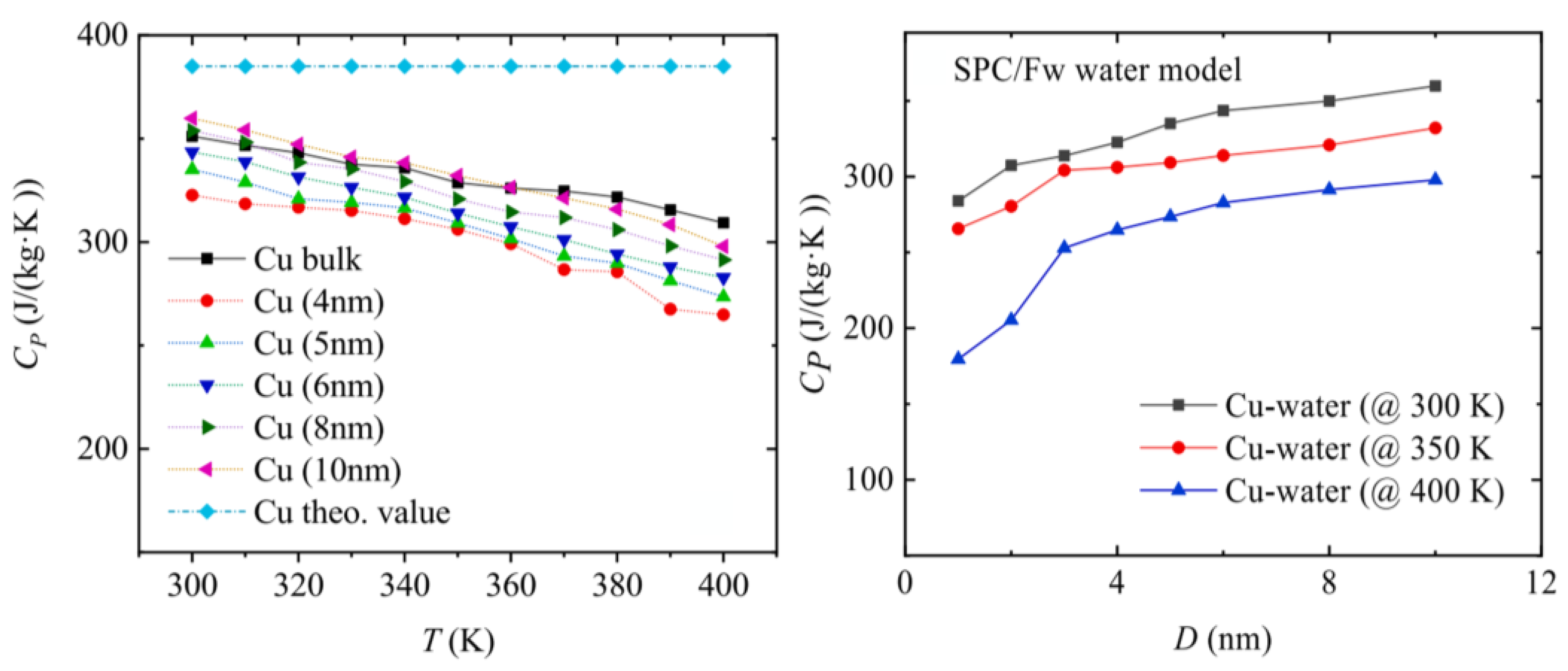

3.3. The Specific Heat Capacity

4. The Nano-Cutting Fluid Cooling and Lubrication Mechanism

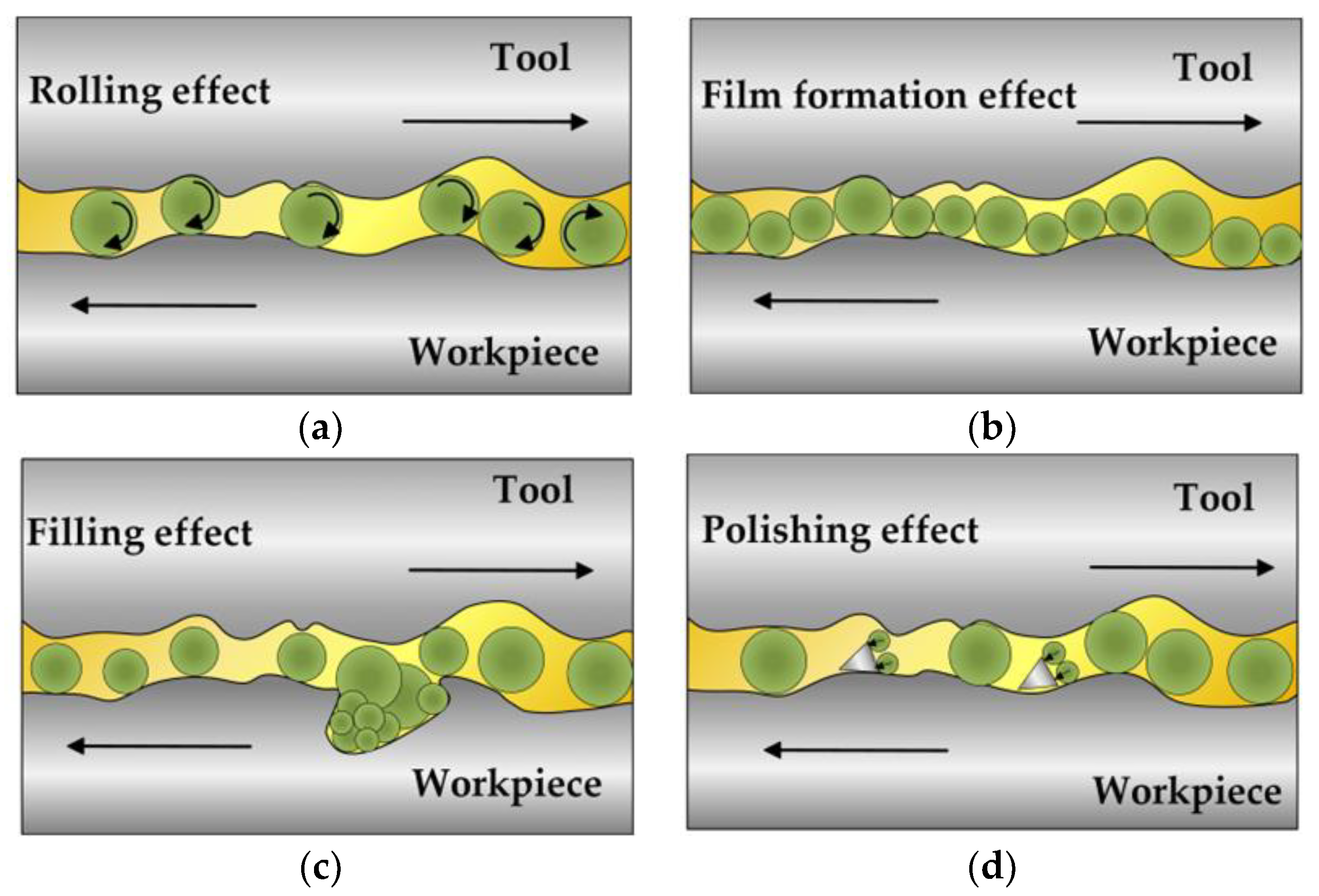

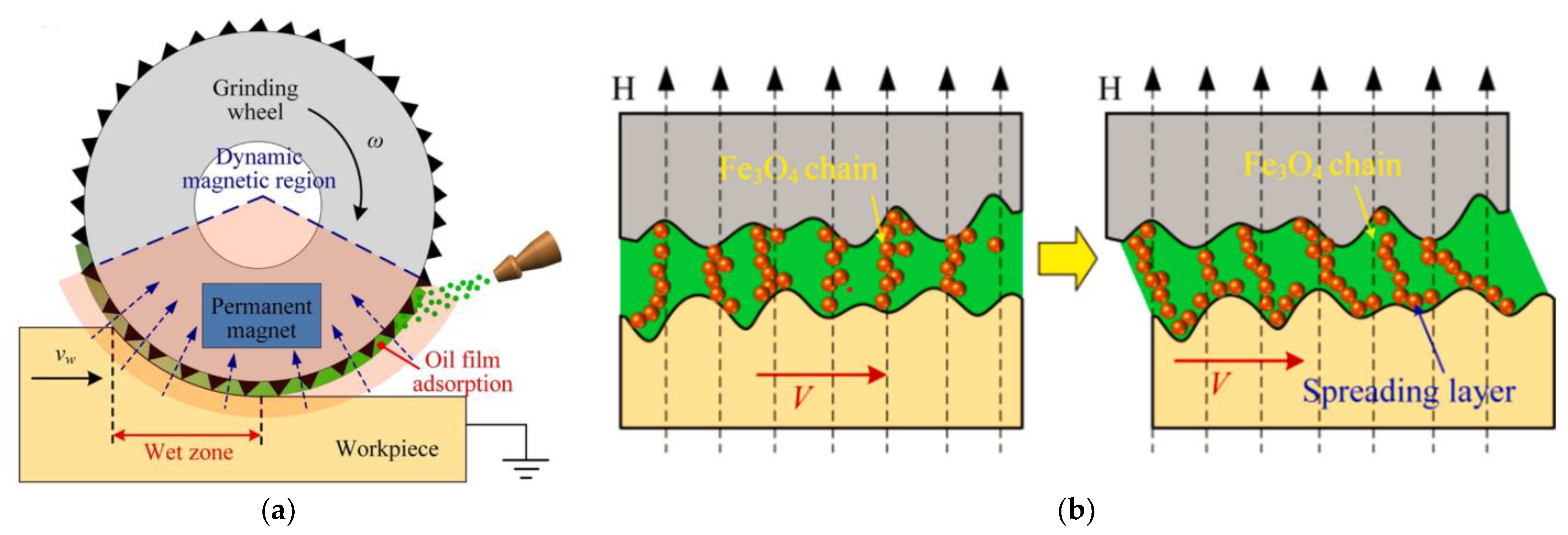

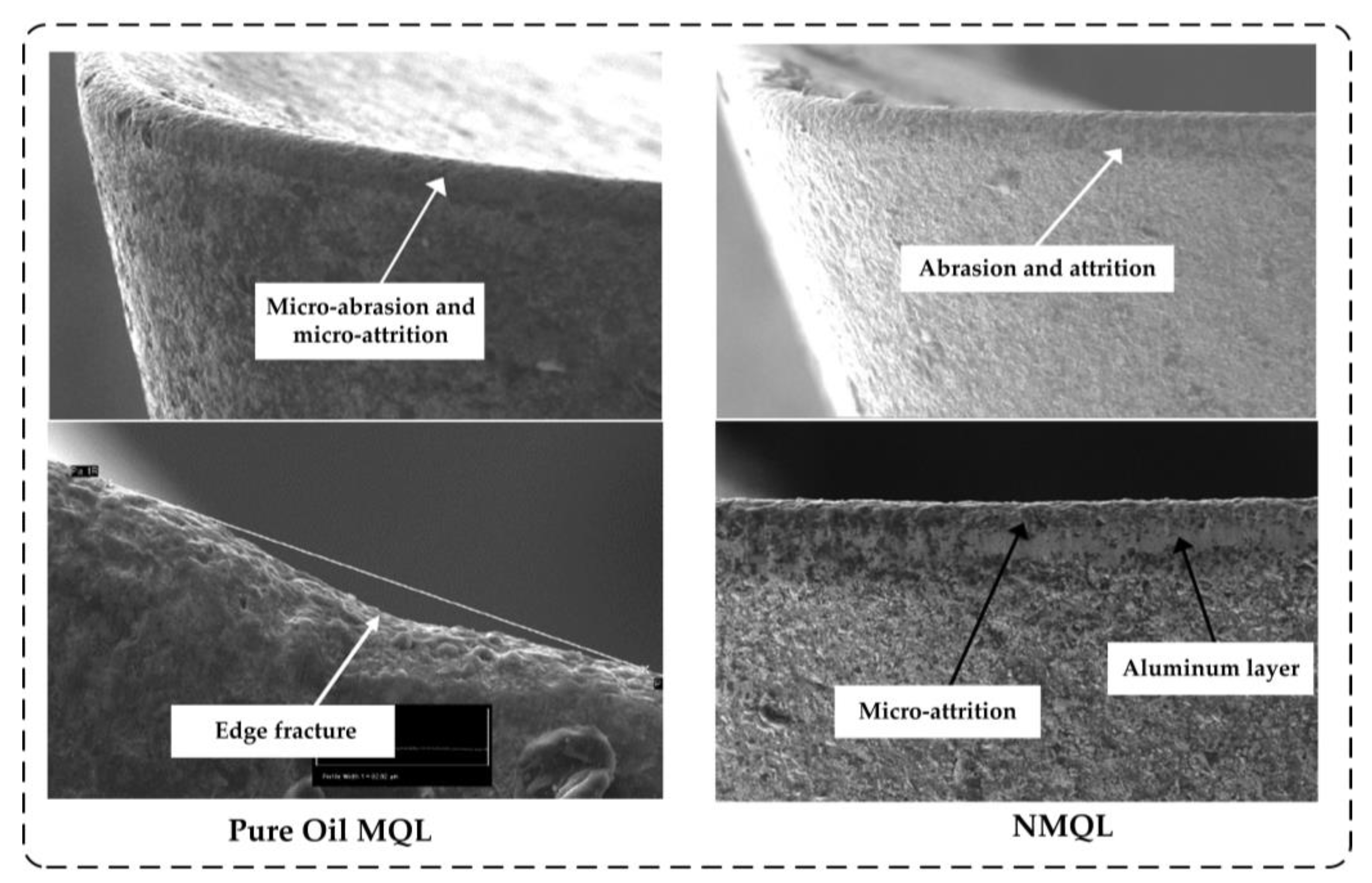

4.1. The Anti-Friction and Anti-Wear Mechanism

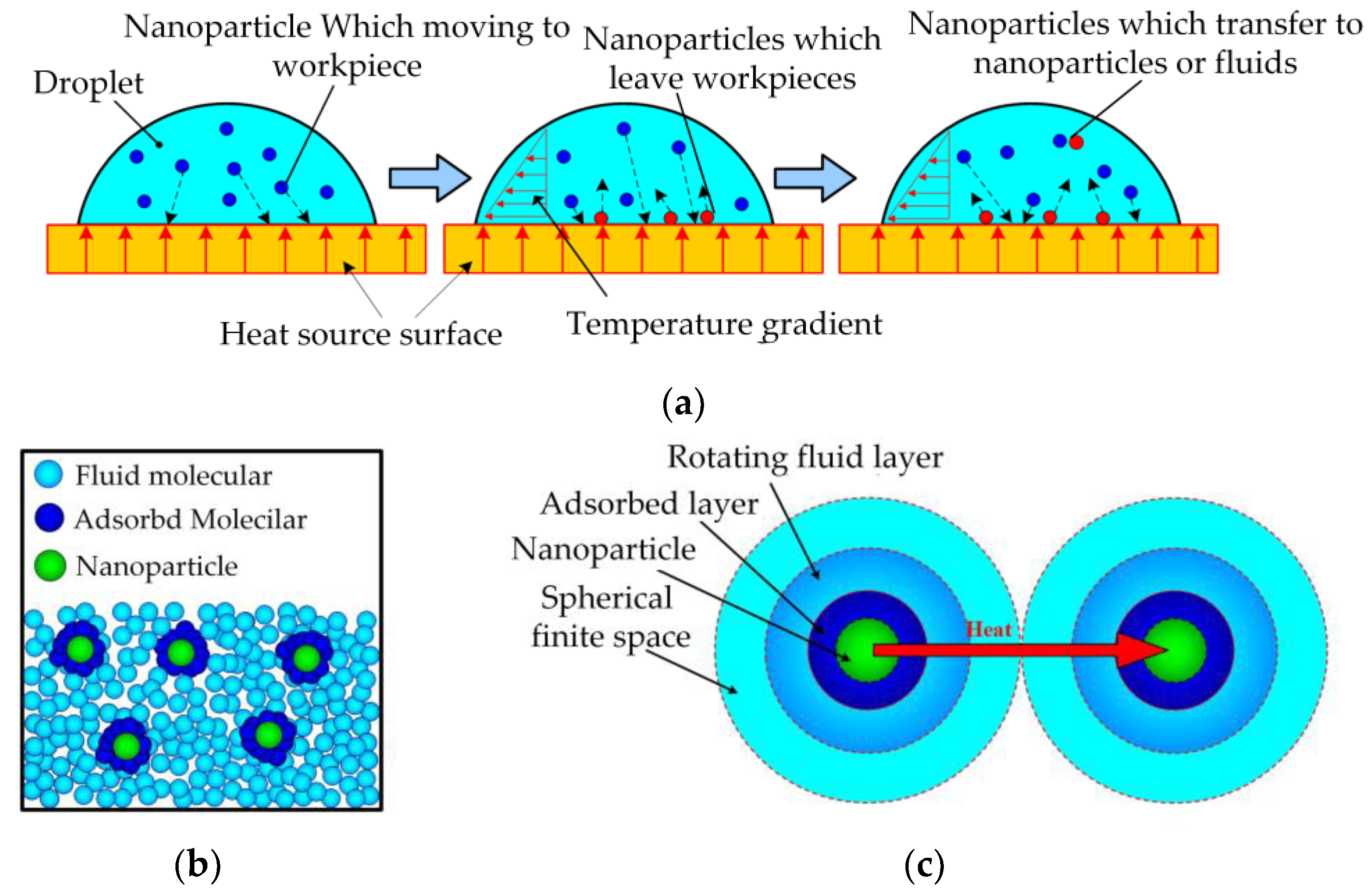

4.2. The Enhanced Heat Transfer Mechanism

4.3. The Atomization and Penetration Mechanism

4.4. Dialectical Perspectives

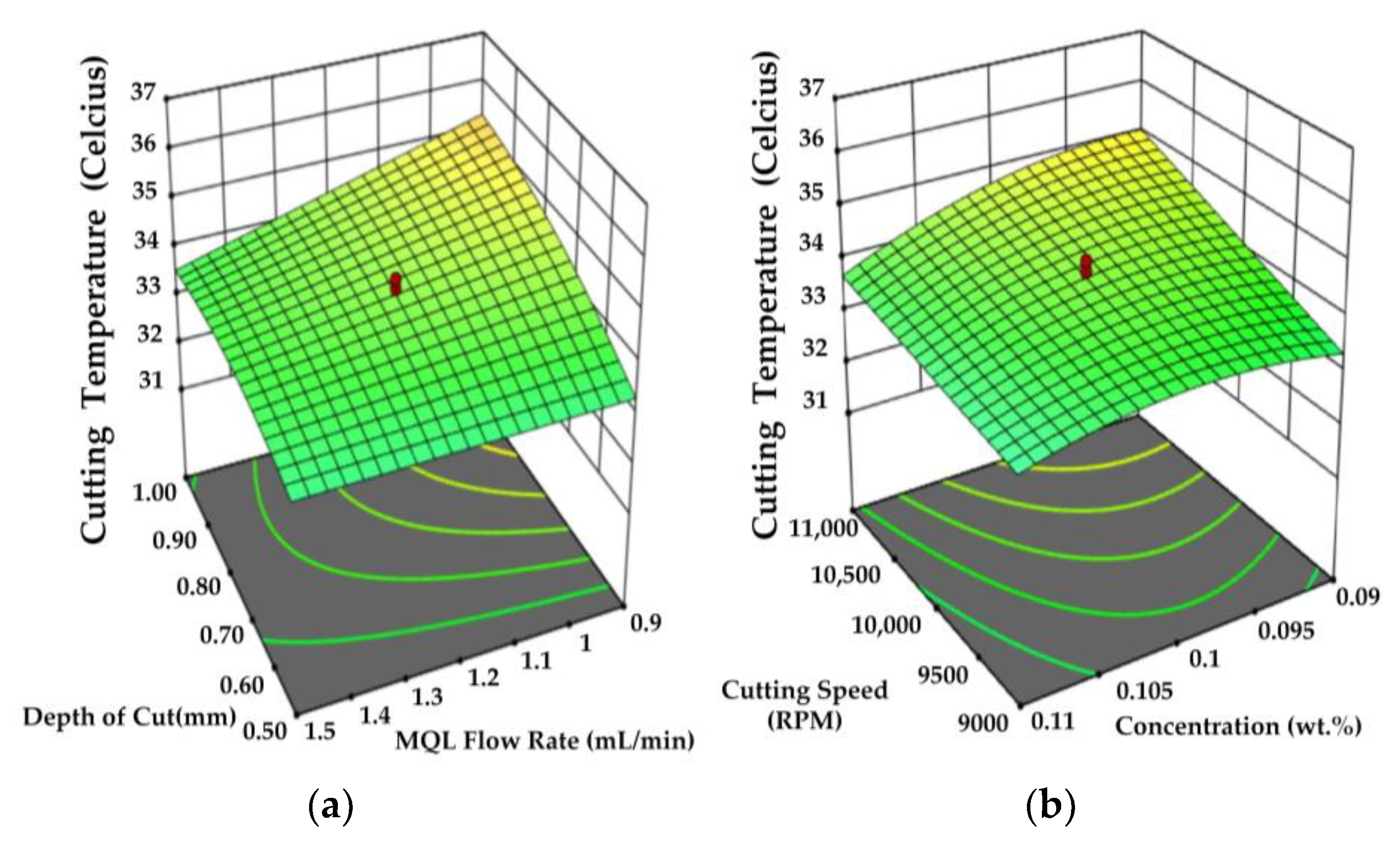

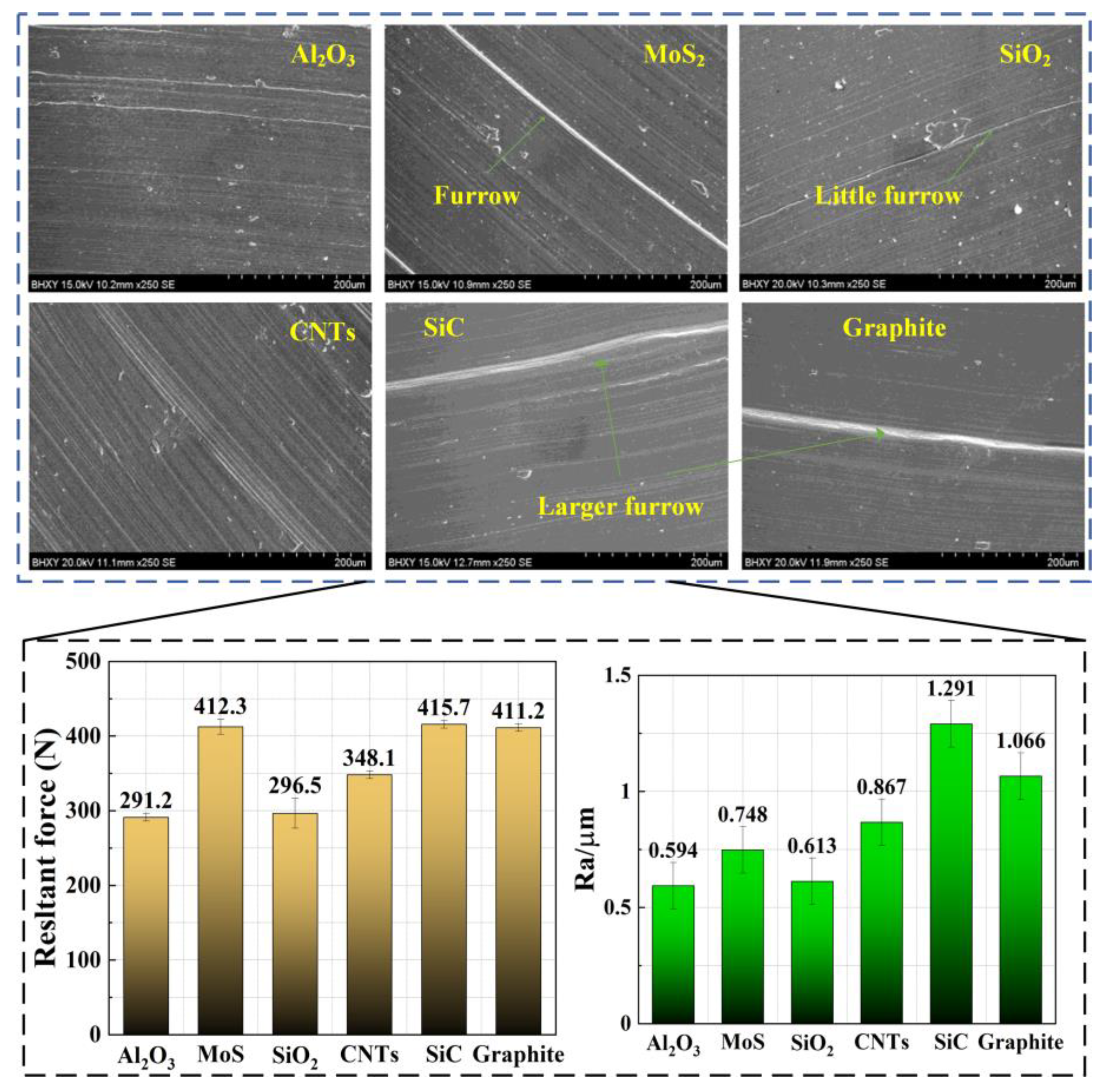

5. Evaluation of the Processing Performance of Different Materials

5.1. Common Materials

5.2. Difficult-to-Machine Materials

5.2.1. Titanium Alloys

5.2.2. Nickel-Based Alloys

5.2.3. Hardened Steel

5.3. Composite Material

5.4. Sustainability Assessment in NMQL

6. Conclusions and Prospects

6.1. Conclusions

- Nano-cutting fluid has excellent cooling and lubrication properties and can be used as an efficient cooling and lubricating medium under the development trend of cutting fluid reduction. Vegetable oil-based and water-based cutting fluids are ideal base fluids for nano-cutting fluids due to their high performance and environmental protection. Hybrid nano-cutting fluids can achieve further enhancement of nanofluid processing performance due to their physical synergistic effects. The dispersion stability of nano-cutting fluid is a key physical property that affects its physical properties and processing performance. The electrostatic stability and steric stability of nano-cutting fluid can be achieved by regulating the dynamic behavior of nanoparticles in the basic fluid through mechanical/chemical dispersion.

- The addition of nanoparticles increases the dynamic viscosity of the fluid, thereby improving the lubricating performance of the cutting fluid. Nanofluid has higher thermal conductivity and specific heat capacity. The addition of nanoparticles reduces the surface tension of the fluid, making it easier for the atomized droplets to penetrate into the capillary in the cutting area; the decrease in surface tension leads to a smaller contact angle, a larger spreading area of the droplet and easier rupture. Compared with dry cutting, the cutting force is reduced by 15–40% under NMQL conditions. The cutting temperature is reduced by 13–76%, and the surface roughness is increased by 10–45%.

- Compared with traditional lubricants, nanoparticles entirely transform the friction mechanism of the lubricant at the -tool–workpiece interface through rolling, filling, film-forming, and polishing effects. Simultaneously, through Brownian motion and heat channels, the heat transfer efficiency of the lubricant experiences a significant increase. The contributions of nanoparticles to reducing the cutting force, decreasing surface roughness, minimizing tool wear, and lowering cutting temperature are 8.6%, 19.2%, 26.8%, and 13.77%, respectively. The contribution of the base fluid is 72.86%, 22.5%, 46.6%, and 67%, respectively.

- Due to the differences in the structure and mode of action of nanoparticles, different particles have different emphasis on performance enhancement. For materials with poor thermal conductivity and sensitivity to heat accumulation, it is more appropriate to prepare nanofluids with excellent cooling properties, such as GR and MWCNTs. When dealing with high-hardness materials, ND nanofluids exhibit excellent polishing ability. After balancing the principles of performance enhancement and economic feasibility, affordable and durable nanoparticles such as and have been widely used. The infiltration and film formation process of droplets is affected by the surface tension and viscosity of nano-cutting fluid. In continuous cutting, nano-cutting fluids with a faster droplet migration speed should be preferred; in intermittent cutting, the droplet diffusion area and oil film should be optimized.

6.2. Prospects

- Due to structural variations in nanoparticles, nanofluids often exhibit enhanced performance in specific aspects. Blending nanofluids can compensate for these limitations, and through synergistic effects among particles, can further improve performance improvement effects. Seeking multifunctional nanofluid formulations is a key direction. The high-pressure assist provided by MQL systems overcomes the air barrier caused by the high-speed rotation of cutting tools. However, traditional pneumatic atomization is not stable; the dispersion of droplets into the air continues to pose a significant health risk. Electrostatic atomization, which employs electric field forces to constrain droplet dispersion, is a pivotal research direction for future atomization methods.

- Extensive and in-depth research should be carried out into multi-field empowering equipment including ultrasonic empowering, low-temperature empowering, magnetic field empowering and textured tool-assisted nano-fluid MQL cutting and grinding-, and the relationship between process parameters and optimal enabling parameters should be determined. Mapping relations: First, solve the problems of sensor connection of production equipment/production lines, collection, storage and construction of production data, and analysis and mining of production-related big data. Intelligent follow-up nozzles need to be applied on a large scale to achieve the optimal spray posture of the nozzle and online adjustment of process parameters. In addition, as a means of improving lubrication parameter control strategies, communication technology between machine tools and MQL supply systems also requires large-scale industrial applications.

- Due to machine tool operators’ insufficient understanding of the action rules of nano-cutting fluid, it is difficult to achieve precise control of processing parameters during the industrialization process. Therefore, there is an urgent need to establish a standardized public database, including workpiece materials, lubricating medium parameters (such as the chemical formula of the base fluid, nanoparticles/size/shape/concentration, supply flow rate, atomization pressure, nozzle distance and angle), cutting process parameters (cutting speed, feed and depth of cut) and machining performance evaluation (such as cutting forces, the cutting temperature, tool life and workpiece surface integrity). In addition, the mapping relationship between cutting parameters, lubricating medium parameters and evaluation indicators should be established. On this basis, an artificial intelligence software platform for recommending NMQL process parameters can be further built based on neural network algorithms.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| MQL | minimal quantity lubrication | C=C | carbon-carbon double bond |

| NMQL | nanofluid minimum quantity lubrication | specific heat capacity | |

| CFRP | carbon fiber-reinforced plastics | K | thermal conductivity |

| ND | nano-diamond | μ | viscosity |

| SWCNT | single-walled carbon nanotube | CCF | commercial cutting fluids |

| DWCNT | double-walled carbon nanotube | SME | spatially multiplexed exposure |

| MWCNT | multi-walled carbon nanotube | MMC | metal matrix composites |

| GR | graphene | EG | ethylene glycol |

| CNT | carbon nanotube | RC | relative concentration |

| DW | deionized water |

References

- Sen, B.; Mia, M.; Krolczyk, G.M.; Mandal, U.K.; Mondal, S.P. Eco-Friendly Cutting Fluids in Minimum Quantity Lubrication Assisted Machining: A Review on the Perception of Sustainable Manufacturing. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 249–280. [Google Scholar] [CrossRef]

- Tang, L.; Zhang, Y.; Li, C.; Zhou, Z.; Nie, X.; Chen, Y.; Cao, H.; Liu, B.; Zhang, N.; Said, Z.; et al. Biological Stability of Water-Based Cutting Fluids: Progress and Application. Chin. J. Mech. Eng. 2022, 35, 3. [Google Scholar] [CrossRef]

- Hosseini, S.F.; Emami, M.; Sadeghi, M.H. An Experimental Investigation on the Effects of Minimum Quantity Nano Lubricant Application in Grinding Process of Tungsten Carbide. J. Manuf. Process. 2018, 35, 244–253. [Google Scholar] [CrossRef]

- Dragičević, M. The Application of Alternative Techniques for Cooling, Flushing and Lubrication to Improve Efficiency of Machining Processes. Technol. Vjesn. 2018, 25, 1561–1568. [Google Scholar] [CrossRef]

- Sankaran Nair, S.; Prabhakaran Nair, K.; Rajendrakumar, P.K. Micro and Nanoparticles Blended Sesame Oil Bio-lubricant: Study of Its Tribological and Rheological Properties. Micro. Amp. Nano Lett. 2018, 13, 1743–1746. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, H.N.; Li, C.; Huang, C.; Ali, H.M.; Xu, X.; Mao, C.; Ding, W.; Cui, X.; Yang, M.; et al. Nano-Enhanced Biolubricant in Sustainable Manufacturing: From Processability to Mechanisms. Friction 2022, 10, 803–841. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, D.; Ye, Y.; Zhao, Y. Recent Advances in Multifunctional Fluorescent Probes for Viscosity and Analytes. Coord. Chem. Rev. 2022, 453, 214336. [Google Scholar] [CrossRef]

- Younes, H.; Mao, M.; Sohel Murshed, S.M.; Lou, D.; Hong, H.; Peterson, G.P. Nanofluids: Key Parameters to Enhance Thermal Conductivity and Its Applications. Appl. Therm. Eng. 2022, 207, 118202. [Google Scholar] [CrossRef]

- Mahian, O.; Bellos, E.; Markides, C.N.; Taylor, R.A.; Alagumalai, A.; Yang, L.; Qin, C.; Lee, B.J.; Ahmadi, G.; Safaei, M.R.; et al. Recent Advances in Using Nanofluids in Renewable Energy Systems and the Environmental Implications of Their Uptake. Nano Energy 2021, 86, 106069. [Google Scholar] [CrossRef]

- Said, Z.; Rahman, S.; Sharma, P.; Amine Hachicha, A.; Issa, S. Performance Characterization of a Solar-Powered Shell and Tube Heat Exchanger Utilizing MWCNTs/Water-Based Nanofluids: An Experimental, Numerical, and Artificial Intelligence Approach. Appl. Therm. Eng. 2022, 212, 118633. [Google Scholar] [CrossRef]

- Liu, M.; Li, C.; Zhang, Y.; Yang, M.; Gao, T.; Cui, X.; Wang, X.; Xu, W.; Zhou, Z.; Liu, B.; et al. Analysis of Grinding Mechanics and Improved Grinding Force Model Based on Randomized Grain Geometric Characteristics. Chin. J. Aeronaut. 2023, 36, 160–193. [Google Scholar] [CrossRef]

- Singh, H.; Sharma, V.S.; Singh, S.; Dogra, M. Nanofluids Assisted Environmental Friendly Lubricating Strategies for the Surface Grinding of Titanium Alloy: Ti6Al4V-ELI. J. Manuf. Process. 2019, 39, 241–249. [Google Scholar] [CrossRef]

- Lin, H.; Jian, Q.; Bai, X.; Li, D.; Huang, Z.; Huang, W.; Feng, S.; Cheng, Z. Recent Advances in Thermal Conductivity and Thermal Applications of Graphene and Its Derivatives Nanofluids. Appl. Therm. Eng. 2023, 218, 119176. [Google Scholar] [CrossRef]

- Masoudi, S.; Esfahani, M.J.; Jafarian, F.; Mirsoleimani, S.A. Comparison the Effect of MQL, Wet and Dry Turning on Surface Topography, Cylindricity Tolerance and Sustainability. Int. J. Precis. Eng. Manuf.-Green Technol. 2023, 10, 9–21. [Google Scholar] [CrossRef]

- Jia, D.; Li, C.; Liu, J.; Zhang, Y.; Yang, M.; Gao, T.; Said, Z.; Sharma, S. Prediction Model of Volume Average Diameter and Analysis of Atomization Characteristics in Electrostatic Atomization Minimum Quantity Lubrication. Friction 2023, 11, 2107–2131. [Google Scholar] [CrossRef]

- Liu, N.-M.; Chiang, K.-T.; Hung, C.-M. Modeling and Analyzing the Effects of Air-Cooled Turning on the Machinability of Ti–6Al–4V Titanium Alloy Using the Cold Air Gun Coolant System. Int. J. Adv. Manuf. Technol. 2013, 67, 1053–1066. [Google Scholar] [CrossRef]

- Hemmat Esfe, M.; Bahiraei, M.; Mir, A. Application of Conventional and Hybrid Nanofluids in Different Machining Processes: A Critical Review. Adv. Colloid Interface Sci. 2020, 282, 102199. [Google Scholar] [CrossRef]

- Molaie, M.M.; Akbari, J.; Movahhedy, M.R. Ultrasonic Assisted Grinding Process with Minimum Quantity Lubrication Using Oil-Based Nanofluids. J. Clean. Prod. 2016, 129, 212–222. [Google Scholar] [CrossRef]

- Lv, T.; Huang, S.; Hu, X.; Ma, Y.; Xu, X. Tribological and Machining Characteristics of a Minimum Quantity Lubrication (MQL) Technology Using GO/SiO2 Hybrid Nanoparticle Water-Based Lubricants as Cutting Fluids. Int. J. Adv. Manuf. Technol. 2018, 96, 2931–2942. [Google Scholar] [CrossRef]

- Kursus, M.; Liew, P.J.; Che Sidik, N.A.; Wang, J. Recent Progress on the Application of Nanofluids and Hybrid Nanofluids in Machining: A Comprehensive Review. Int. J. Adv. Manuf. Technol. 2022, 121, 1455–1481. [Google Scholar] [CrossRef]

- Akhtar, S.S. A Critical Review on Self-Lubricating Ceramic-Composite Cutting Tools. Ceram. Int. 2021, 47, 20745–20767. [Google Scholar] [CrossRef]

- Bai, X.; Jiang, J.; Li, C.; Dong, L.; Ali, H.M.; Sharma, S. Tribological Performance of Different Concentrations of Al2O3 Nanofluids on Minimum Quantity Lubrication Milling. Chin. J. Mech. Eng. 2023, 36, 11. [Google Scholar] [CrossRef]

- Xiong, Q.; Altnji, S.; Tayebi, T.; Izadi, M.; Hajjar, A.; Sundén, B.; Li, L.K.B. A Comprehensive Review on the Application of Hybrid Nanofluids in Solar Energy Collectors. Sustain. Energy Technol. Assess. 2021, 47, 101341. [Google Scholar] [CrossRef]

- Jamei, M.; Karbasi, M.; Mosharaf-Dehkordi, M.; Adewale Olumegbon, I.; Abualigah, L.; Said, Z.; Asadi, A. Estimating the Density of Hybrid Nanofluids for Thermal Energy Application: Application of Non-Parametric and Evolutionary Polynomial Regression Data-Intelligent Techniques. Measurement 2022, 189, 110524. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Y.; Cui, X.; Said, Z.; Sharma, S.; Liu, M.; Gao, T.; Zhou, Z.; Wang, X.; Li, C. Mechanical Behavior and Modeling of Grinding Force: A Comparative Analysis. J. Manuf. Process. 2023, 102, 921–954. [Google Scholar] [CrossRef]

- Wang, X.; Song, Y.; Li, C.; Zhang, Y.; Ali, H.M.; Sharma, S.; Li, R.; Yang, M.; Gao, T.; Liu, M.; et al. Nanofluids Application in Machining: A Comprehensive Review. Int. J. Adv. Manuf. Technol. 2023. [Google Scholar] [CrossRef]

- Philip, J. Magnetic Nanofluids (Ferrofluids): Recent Advances, Applications, Challenges, and Future Directions. Adv. Colloid Interface Sci. 2023, 311, 102810. [Google Scholar] [CrossRef]

- Mao, C.; Zhang, J.; Huang, Y.; Zou, H.; Huang, X.; Zhou, Z. Investigation on the Effect of Nanofluid Parameters on MQL Grinding. Mater. Manuf. Process. 2013, 28, 436–442. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Y. Experimental Study on Enhanced Heat Transfer and Flow Performance of Magnetic Nanofluids under Alternating Magnetic Field. Int. J. Therm. Sci. 2021, 164, 106897. [Google Scholar] [CrossRef]

- Lv, T.; Huang, S.; Liu, E.; Ma, Y.; Xu, X. Tribological and Machining Characteristics of an Electrostatic Minimum Quantity Lubrication (EMQL) Technology Using Graphene Nano-Lubricants as Cutting Fluids. J. Manuf. Process. 2018, 34, 225–237. [Google Scholar] [CrossRef]

- Aslan, A.; Salur, E.; Kuntoglu, M. Evaluation of the Role of Dry and MQL Regimes on Machining and Sustainability Index of Strenx 900 Steel. Lubricants 2022, 10, 301. [Google Scholar] [CrossRef]

- Mallick, R.; Kumar, R.; Panda, A.; Sahoo, A.K. Hard Turning Performance Investigation of AISI D2 Steel under a Dual Nozzle MQL Environment. Lubricants 2023, 11, 16. [Google Scholar] [CrossRef]

- Sun, H.; Shi, Y.; Zhao, P.; Long, G.; Li, C.; Wang, J.; Qiu, D.; Lu, C.; Ding, Y.; Liu, L.; et al. Effect of MQL condition on cutting performance of high-speed machining of GH4099 with ceramic end mills. Tribol. Int. 2023, 868, 161557. [Google Scholar] [CrossRef]

- Choi, S.U.S.; Eastman, J.A. Enhancing Thermal Conductivity of Fluids with Nanoparticles; Argonne National Lab. (ANL): Argonne, IL, USA, 1995. [Google Scholar]

- Simpson, S.; Schelfhout, A.; Golden, C.; Vafaei, S. Nanofluid Thermal Conductivity and Effective Parameters. Appl. Sci. 2018, 9, 87. [Google Scholar] [CrossRef]

- Choi, S.U.S.; Zhang, Z.G.; Yu, W.; Lockwood, F.E.; Grulke, E.A. Anomalous Thermal Conductivity Enhancement in Nanotube Suspensions. Appl. Phys. Lett. 2001, 79, 2252–2254. [Google Scholar] [CrossRef]

- Mehta, B.; Subhedar, D.; Panchal, H.; Said, Z. Synthesis, Stability, Thermophysical Properties and Heat Transfer Applications of Nanofluid—A Review. J. Mol. Liq. 2022, 364, 120034. [Google Scholar] [CrossRef]

- Jakhar, S.; Paliwal, M.K.; Purohit, N. Assessment of Alumina/Water Nanofluid in a Glazed Tube and Sheet Photovoltaic/Thermal System with Geothermal Cooling. J. Therm. Anal. Calorim. 2022, 147, 3901–3918. [Google Scholar] [CrossRef]

- Khan, A.M.; Jamil, M.; Mia, M.; He, N.; Zhao, W.; Gong, L. Sustainability-Based Performance Evaluation of Hybrid Nanofluid Assisted Machining. J. Clean. Prod. 2020, 257, 120541. [Google Scholar] [CrossRef]

- Diglio, G.; Roselli, C.; Sasso, M.; Jawali Channabasappa, U. Borehole Heat Exchanger with Nanofluids as Heat Carrier. Geothermics 2018, 72, 112–123. [Google Scholar] [CrossRef]

- Kim, H.J.; Lee, S.-H.; Lee, J.-H.; Jang, S.P. Effect of Particle Shape on Suspension Stability and Thermal Conductivities of Water-Based Bohemite Alumina Nanofluids. Energy 2015, 90, 1290–1297. [Google Scholar] [CrossRef]

- Said, Z.; Saidur, R.; Rahim, N.A. Energy and Exergy Analysis of a Flat Plate Solar Collector Using Different Sizes of Aluminium Oxide Based Nanofluid. J. Clean. Prod. 2016, 133, 518–530. [Google Scholar] [CrossRef]

- Apmann, K.; Fulmer, R.; Soto, A.; Vafaei, S. Thermal Conductivity and Viscosity: Review and Optimization of Effects of Nanoparticles. Materials 2021, 14, 1291. [Google Scholar] [CrossRef] [PubMed]

- Zenjanab, M.J.; Pedrammehr, S.; Qazani, M.R.C.; Shabgard, M.R. Influence of Cutting Fluid-Based CuO-Nanofluid with Boric Acid-Nanoparticles Additives on Machining Performances of AISI 4340 Tool Steel in High-Speed Turning Operation. Iran J. Sci. Technol.-Trans. Mech. Eng. 2022, 46, 335–345. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, M.; Li, C.; Li, R.; Said, Z.; Ali, H.M.; Sharma, S. Machinability of Ultrasonic Vibration-Assisted Micro-Grinding in Biological Bone Using Nano-lubricant. Front. Mech. Eng. 2023, 18, 1. [Google Scholar] [CrossRef]

- Yang, M.; Li, C.; Zhang, Y.; Jia, D.; Li, R.; Hou, Y.; Cao, H.; Wang, J. Predictive Model for Minimum Chip Thickness and Size Effect in Single Diamond Grain Grinding of Zirconia Ceramics under Different Lubricating Conditions. Ceram. Int. 2019, 45, 14908–14920. [Google Scholar] [CrossRef]

- Sher Akbar, N.; Maraj, E.N.; Noor, N.F.M.; Habib, M.B. Exact Solutions of an Unsteady Thermal Conductive Pressure Driven Peristaltic Transport with Temperature-Dependent Nanofluid Viscosity. Case Stud. Therm. Eng. 2022, 35, 102124. [Google Scholar] [CrossRef]

- Jamshed, W.; Eid, M.R.; Hussain, S.M.; Abderrahmane, A.; Safdar, R.; Younis, O.; Pasha, A.A. Physical Specifications of MHD Mixed Convective of Ostwald-de Waele Nanofluids in a Vented-Cavity with Inner Elliptic Cylinder. Int. Commun. Heat Mass Transf. 2022, 134, 106038. [Google Scholar] [CrossRef]

- Pasha, A.A.; Islam, N.; Jamshed, W.; Alam, M.I.; Jameel, A.G.A.; Juhany, K.A.; Alsulami, R. Statistical Analysis of Viscous Hybridized Nanofluid Flowing via Galerkin Finite Element Technique. Int. Commun. Heat Mass Transf. 2022, 137, 106244. [Google Scholar] [CrossRef]

- Sui, M.; Li, C.; Wu, W.; Yang, M.; Ali, H.M.; Zhang, Y.; Jia, D.; Hou, Y.; Li, R.; Cao, H. Temperature of Grinding Carbide With Castor Oil-Based MoS2 Nanofluid Minimum Quantity Lubrication. J. Therm. Sci. Eng. Appl. 2021, 13, 051001. [Google Scholar] [CrossRef]

- Zhou, S.; Wang, D.; Wu, S.; Gu, G.; Dong, G.; An, Q.; Guo, H.; Li, C. Minimum Quantity Lubrication Machining Nickel Base Alloy: A Comprehensive Review. Int. J. Adv. Manuf. Technol. 2023. [Google Scholar] [CrossRef]

- Revuru, R.S.; Posinasetti, N.R.; Ramana, V.V.S.N.; Amrita, M. Application of Cutting Fluids in Machining of Titanium Alloys-a Review. Int. J. Adv. Manuf. Technol. 2017, 91, 2477–2498. [Google Scholar] [CrossRef]

- Lawal, S.A.; Medupin, R.O.; Yoro, K.O.; Okoro, U.G.; Adedipe, O.; Abutu, J.; Tijani, J.O.; Abdulkareem, A.S.; Ukoba, K.; Ndaliman, M.B.; et al. Nanofluids and Their Application in Carbon Fibre Reinforced Plastics: A Review of Properties, Preparation, and Usage. Arab. J. Chem. 2023, 16, 104908. [Google Scholar] [CrossRef]

- Wang, X.M.; Li, C.; Zhang, Y.; Ali, H.M.; Sharma, S.; Li, R.; Yang, M.; Said, Z.; Liu, X. Tribology of Enhanced Turning Using Biolubricants: A Comparative Assessment. Tribol. Int. 2022, 174, 107766. [Google Scholar] [CrossRef]

- Ouni, M.; Ladhar, L.M.; Omri, M.; Jamshed, W.; Eid, M.R. Solar Water-Pump Thermal Analysis Utilizing Copper–Gold/Engine Oil Hybrid Nanofluid Flowing in Parabolic Trough Solar Collector: Thermal Case Study. Case Stud. Therm. Eng. 2022, 30, 101756. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Y.; Li, C.; Zhou, Z.; Nie, X.; Chen, Y.; Cao, H.; Liu, B.; Zhang, N.; Said, Z.; et al. Extreme Pressure and Antiwear Additives for Lubricant: Academic Insights and Perspectives. Int. J. Adv. Manuf. Technol. 2022, 120, 1–27. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Farshad, S.A.; Ebrahimpour, Z.; Said, Z. Recent Progress on Flat Plate Solar Collectors and Photovoltaic Systems in the Presence of Nanofluid: A Review. J. Clean. Prod. 2021, 293, 126119. [Google Scholar] [CrossRef]

- Wu, X.; Li, C.; Zhou, Z.; Nie, X.; Chen, Y.; Zhang, Y.; Cao, H.; Liu, B.; Zhang, N.; Said, Z.; et al. Circulating Purification of Cutting Fluid: An Overview. Int. J. Adv. Manuf. Technol. 2021, 117, 2565–2600. [Google Scholar] [CrossRef]

- Sun, H.; Shi, Y.; Zhao, P.; Long, G.; Li, C.; Wang, J.; Qiu, D.; Lu, C.; Ding, Y.; Liu, L.; et al. Effects of Polyethylene and Biodegradable Microplastics on Photosynthesis, Antioxidant Defense Systems, and Arsenic Accumulation in Maize (Zea Mays L.) Seedlings Grown in Arsenic-Contaminated Soils. Sci. Total Environ. 2023, 868, 161557. [Google Scholar] [CrossRef]

- Murshed, S.M.S.; Estellé, P. A State of the Art Review on Viscosity of Nanofluids. Renew. Sustain. Energy Rev. 2017, 76, 1134–1152. [Google Scholar] [CrossRef]

- Xu, W.; Li, C.; Zhang, Y.; Ali, H.M.; Sharma, S.; Li, R.; Yang, M.; Gao, T.; Liu, M.; Wang, X.; et al. Electrostatic Atomization Minimum Quantity Lubrication Machining: From Mechanism to Application. Int. J. Extreme Manuf. 2022, 4, 042003. [Google Scholar] [CrossRef]

- Khanna, N.; Agrawal, C.; Pimenov, D.Y.; Singla, A.K.; Machado, A.R.; Da Silva, L.R.R.; Gupta, M.K.; Sarikaya, M.; Krolczyk, G.M. Review on Design and Development of Cryogenic Machining Setups for Heat Resistant Alloys and Composites. J. Manuf. Process. 2021, 68, 398–422. [Google Scholar] [CrossRef]

- Sidik, N.A.C.; Mohammed, H.A.; Alawi, O.A.; Samion, S. A Review on Preparation Methods and Challenges of Nanofluids. Int. Commun. Heat Mass Transf. 2014, 54, 115–125. [Google Scholar] [CrossRef]

- Gajrani, K.K.; Ram, D.; Ravi Sankar, M. Biodegradation and Hard Machining Performance Comparison of Eco-Friendly Cutting Fluid and Mineral Oil Using Flood Cooling and Minimum Quantity Cutting Fluid Techniques. J. Clean. Prod. 2017, 165, 1420–1435. [Google Scholar] [CrossRef]

- Lanjewar, A.; Bhanvase, B.; Barai, D.; Chawhan, S.; Sonawane, S. Intensified Thermal Conductivity and Convective Heat Transfer of Ultrasonically Prepared CuO–Polyaniline Nanocomposite Based Nanofluids in Helical Coil Heat Exchanger. Period. Polytech. Chem. Eng. 2019, 64, 271–282. [Google Scholar] [CrossRef]

- Reeves, C.J.; Menezes, P.L.; Jen, T.-C.; Lovell, M.R. The Influence of Fatty Acids on Tribological and Thermal Properties of Natural Oils as Sustainable Biolubricants. Tribol. Int. 2015, 90, 123–134. [Google Scholar] [CrossRef]

- Li, B.; Li, C.; Zhang, Y.; Wang, Y.; Jia, D.; Yang, M. Grinding Temperature and Energy Ratio Coefficient in MQL Grinding of High-Temperature Nickel-Base Alloy by Using Different Vegetable Oils as Base Oil. Chin. J. Aeronaut. 2016, 29, 1084–1095. [Google Scholar] [CrossRef]

- Khan, M.M.A.; Mithu, M.A.H.; Dhar, N.R. Effects of Minimum Quantity Lubrication on Turning AISI 9310 Alloy Steel Using Vegetable Oil-Based Cutting Fluid. J. Mater. Process. Technol. 2009, 209, 5573–5583. [Google Scholar] [CrossRef]

- Gajrani, K.K.; Suvin, P.S.; Kailas, S.V.; Sankar, M.R. Hard Machining Performance of Indigenously Developed Green Cutting Fluid Using Flood Cooling and Minimum Quantity Cutting Fluid. J. Clean. Prod. 2019, 206, 108–123. [Google Scholar] [CrossRef]

- Jia, D.; Zhang, Y.; Li, C.; Yang, M.; Gao, T.; Said, Z.; Sharma, S. Lubrication-Enhanced Mechanisms of Titanium Alloy Grinding Using Lecithin Biolubricant. Tribol. Int. 2022, 169, 107461. [Google Scholar] [CrossRef]

- Zhang, X.; Li, C.; Zhou, Z.; Liu, B.; Zhang, Y.; Yang, M.; Gao, T.; Liu, M.; Zhang, N.; Said, Z.; et al. Vegetable Oil-Based Nano lubricants in Machining: From Physicochemical Properties to Application. Chin. J. Mech. Eng. 2023, 36, 76. [Google Scholar] [CrossRef]

- Sagraloff, N.; Dobler, A.; Tobie, T.; Stahl, K.; Ostrowski, J. Development of an Oil Free Water-Based Lubricant for Gear Applications. Lubricants 2019, 7, 33. [Google Scholar] [CrossRef]

- Rahman, M.H.; Warneke, H.; Webbert, H.; Rodriguez, J.; Austin, E.; Tokunaga, K.; Rajak, D.K.; Menezes, P.L. Water-Based Lubricants: Development, Properties, and Performances. Lubricants 2021, 9, 73. [Google Scholar] [CrossRef]

- Zou, Q.; Zhang, T.; Ma, T.; Tian, S.; Jia, X.; Jiang, Z. Effect of Water-Based SiO2 Nanofluid on Surface Wettability of Raw Coal. Energy 2022, 254, 124228. [Google Scholar] [CrossRef]

- Gu, Y.; Zhao, X.; Liu, Y.; Lv, Y. Preparation and Tribological Properties of Dual-Coated TiO2 Nanoparticles as Water-Based Lubricant Additives. J. Nanomater. 2014, 2014, e785680. [Google Scholar] [CrossRef]

- Cui, Y.; Ding, M.; Sui, T.; Zheng, W.; Qiao, G.; Yan, S.; Liu, X. Role of Nanoparticle Materials as Water-Based Lubricant Additives for Ceramics. Tribol. Int. 2020, 142, 105978. [Google Scholar] [CrossRef]

- Liu, C.; Guo, Y.; Wang, D. PEI-RGO Nanosheets as a Nano-additive for Enhancing the Tribological Properties of Water-Based Lubricants. Tribol. Int. 2019, 140, 105851. [Google Scholar] [CrossRef]

- Xie, H.; Dang, S.; Jiang, B.; Xiang, L.; Zhou, S.; Sheng, H.; Yang, T.; Pan, F. Tribological Performances of SiO2/Graphene Combinations as Water-Based Lubricant Additives for Magnesium Alloy Rolling. Appl. Surf. Sci. 2019, 475, 847–856. [Google Scholar] [CrossRef]

- Najiha, M.S.; Rahman, M.M.; Kadirgama, K. Performance of Water-Based TiO2 Nanofluid during the Minimum Quantity Lubrication Machining of Aluminium Alloy, AA6061-T6. J. Clean. Prod. 2016, 135, 1623–1636. [Google Scholar] [CrossRef]

- Babar, H.; Ali, H.M. Towards Hybrid Nanofluids: Preparation, Thermophysical Properties, Applications, and Challenges. J. Mol. Liq. 2019, 281, 598–633. [Google Scholar] [CrossRef]

- Duan, Z.; Li, C.; Ding, W.; Zhang, Y.; Yang, M.; Gao, T.; Cao, H.; Xu, X.; Wang, D.; Mao, C.; et al. Milling Force Model for Aviation Aluminum Alloy: Academic Insight and Perspective Analysis. Chin. J. Mech. Eng. 2021, 34, 18. [Google Scholar] [CrossRef]

- Liu, M.; Li, C.; Zhang, Y.; An, Q.; Yang, M.; Gao, T.; Mao, C.; Liu, B.; Cao, H.; Xu, X.; et al. Cryogenic Minimum Quantity Lubrication Machining: From Mechanism to Application. Front. Mech. Eng. 2021, 16, 649–697. [Google Scholar] [CrossRef]

- Ali, A.R.I.; Salam, B. A Review on Nanofluid: Preparation, Stability, Thermophysical Properties, Heat Transfer Characteristics and Application. SN Appl. Sci. 2020, 2, 1636. [Google Scholar] [CrossRef]

- Berrada, N.; Hamze, S.; Desforges, A.; Ghanbaja, J.; Gleize, J.; Maré, T.; Vigolo, B.; Estellé, P. Surface Tension of Functionalized MWCNT-Based Nanofluids in Water and Commercial Propylene-Glycol Mixture. J. Mol. Liq. 2019, 293, 111473. [Google Scholar] [CrossRef]

- Amani, P.; Vajravelu, K. Intelligent Modeling of Rheological and Thermophysical Properties of Green Covalently Functionalized Graphene Nanofluids Containing Nanoplatelets. Int. J. Heat Mass Transf. 2018, 120, 95–105. [Google Scholar] [CrossRef]

- Agunsoye, J.O.; Nwoji, C.U.; Aigbodion, V.S. Machining Performance of Oil-Based SiO2-Derived Rice Husk Ash Nanofluid for the Machining of Aluminum Alloy. Int. J. Adv. Manuf. Technol. 2021, 116, 1285–1295. [Google Scholar] [CrossRef]

- Mashali, F.; Languri, E.; Mirshekari, G.; Davidson, J.; Kerns, D. Nanodiamond Nanofluid Microstructural and Thermo-Electrical Characterization. Int. Commun. Heat Mass Transf. 2019, 101, 82–88. [Google Scholar] [CrossRef]

- Tong, Y.; Ding, Y.; Guo, W.; Wang, S.; Cho, H. Heat Transfer and Lubrication Performance of Palm Oil-Al2O3 Nanofluid Compared to Traditional Cutting Fluid. Scienceasia 2022, 48, 69–74. [Google Scholar] [CrossRef]

- Kumar, R.; Sahoo, A.K.; Mishra, P.C.; Das, R.K. Influence of Al2O3 and TiO2 Nanofluid on Hard Turning Performance. Int. J. Adv. Manuf. Technol. 2020, 106, 2265–2280. [Google Scholar] [CrossRef]

- Salimi-Yasar, H.; Heris, S.Z.; Shanbedi, M. Influence of Soluble Oil-Based TiO2 Nanofluid on Heat Transfer Performance of Cutting Fluid. Tribol. Int. 2017, 112, 147–154. [Google Scholar] [CrossRef]

- Edelbi, A.; Kumar, R.; Sahoo, A.K.; Pandey, A. Comparative Machining Performance Investigation of Dual-Nozzle MQL-Assisted ZnO and Al2O3 Nanofluids in Face Milling of Ti–3Al–2.5V Alloys. Arab. J. Sci. Eng. 2023, 48, 2969–2993. [Google Scholar] [CrossRef]

- Huang, W.T.; Wu, D.H.; Lin, S.P.; Chen, J.T. Robust Design of Using MWCNTs in Minimum Quantity Lubrication. AMM 2014, 670–671, 11–21. [Google Scholar] [CrossRef]

- Zhang, G.; Chen, H.; Xiao, G.; Yi, M.; Chen, Z.; Zhang, J.; Wang, G.; Xu, C. Effect of SiC Nanofluid Minimum Quantity Lubrication on the Performance of the Ceramic Tool in Cutting Hardened Steel. J. Manuf. Process. 2022, 84, 539–554. [Google Scholar] [CrossRef]

- Chen, L.; Yu, W.; Xie, H. Enhanced Thermal Conductivity of Nanofluids Containing Ag/MWNT Composites. Powder Technol. 2012, 231, 18–20. [Google Scholar] [CrossRef]

- Berger Bioucas, F.E.; Rausch, M.H.; Schmidt, J.; Bück, A.; Koller, T.M.; Fröba, A.P. Effective Thermal Conductivity of Nanofluids: Measurement and Prediction. Int. J. Thermophys. 2020, 41, 55. [Google Scholar] [CrossRef]

- Barewar, S.D.; Kotwani, A.; Chougule, S.S.; Unune, D.R. Investigating a Novel Ag/ZnO Based Hybrid Nanofluid for Sustainable Machining of Inconel 718 under Nanofluid Based Minimum Quantity Lubrication. J. Manuf. Process. 2021, 66, 313–324. [Google Scholar] [CrossRef]

- Sharma, A.K.; Singh, R.K.; Dixit, A.R.; Tiwari, A.K. Novel Uses of Alumina-MoS2 Hybrid Nanoparticle Enriched Cutting Fluid in Hard Turning of AISI 304 Steel. J. Manuf. Process. 2017, 30, 467–482. [Google Scholar] [CrossRef]

- Yang, M.; Kong, M.; Li, C.; Long, Y.; Zhang, Y.; Sharma, S.; Li, R.; Gao, T.; Liu, M.; Cui, X.; et al. Temperature field model in surface grinding: A comparative assessment. Int. J. Extreme Manuf. 2023, 5, 042011. [Google Scholar] [CrossRef]

- Cui, W.; Cao, Z.; Li, X.; Lu, L.; Ma, T.; Wang, Q. Experimental Investigation and Artificial Intelligent Estimation of Thermal Conductivity of Nanofluids with Different Nanoparticles Shapes. Powder Technol. 2022, 398, 117078. [Google Scholar] [CrossRef]

- Li, X.; Yuan, F.; Tian, W.; Dai, C.; Yang, X.; Wang, D.; Du, J.; Yu, W.; Yuan, H. Heat Transfer Enhancement of Nanofluids with Non-Spherical Nanoparticles: A Review. Appl. Sci. 2022, 12, 4767. [Google Scholar] [CrossRef]

- Sharma, A.K.; Katiyar, J.K.; Bhaumik, S.; Roy, S. Influence of Alumina/MWCNT Hybrid Nanoparticle Additives on Tribological Properties of Lubricants in Turning Operations. Friction 2019, 7, 153–168. [Google Scholar] [CrossRef]

- Albert, A.A.; Harris Samuel, D.G.; Parthasarathy, V. Review of Stability Enhanced Nanofluids Prepared by One-Step Methods—Heat Transfer Mechanism and Thermo-Physical Properties. Chem. Eng. Commun. 2022, 210, 1822–1852. [Google Scholar] [CrossRef]

- Zhu, H.; Lin, Y.; Yin, Y. A Novel One-Step Chemical Method for Preparation of Copper Nanofluids. J. Colloid Interface Sci. 2004, 277, 100–103. [Google Scholar] [CrossRef] [PubMed]

- Parsa, M.S.; Yazdani, A.; Aberoumand, H.; Farhadi, Y.; Ansari, A.; Aberoumand, S.; Karimi, N.; Afrand, M.; Cheraghian, G.; Muhammad Ali, H. A Critical Analysis on the Energy and Exergy Performance of Photovoltaic/Thermal (PV/T) System: The Role of Nanofluids Stability and Synthesizing Method. Sustain. Energy Technol. Assess. 2022, 51, 101887. [Google Scholar] [CrossRef]

- Ratnasari, D.; Widiyastuti, W.; Setyawan, H. One-Step Electrochemical Synthesis of Silica-Coated Magnetite Nanofluids. AIP Conf. Proc. 2022, 2470, 040009. [Google Scholar] [CrossRef]

- Yang, M.; Li, C.; Luo, L.; Li, R.; Long, Y. Predictive Model of Convective Heat Transfer Coefficient in Bone Micro-Grinding Using Nanofluid Aerosol Cooling. Int. Commun. Heat Mass Transf. 2021, 125, 105317. [Google Scholar] [CrossRef]

- Haque, A.K.M.M.; Kim, S.; Kim, J.; Noh, J.; Huh, S.; Choi, B.; Chung, H.; Jeong, H. Surface Modification of Graphene Nanoparticles by Acid Treatment and Grinding Process. J. Nanosci. Nanotechnol. 2018, 18, 645–650. [Google Scholar] [CrossRef]

- Bakthavatchalam, B.; Habib, K.; Saidur, R.; Saha, B.B.; Irshad, K. Comprehensive Study on Nanofluid and Ionanofluid for Heat Transfer Enhancement: A Review on Current and Future Perspective. J. Mol. Liq. 2020, 305, 112787. [Google Scholar] [CrossRef]

- Judran, H.K.; Al-Hasnawi, A.G.T.; Al Zubaidi, F.N.; Al-Maliki, W.A.K.; Alobaid, F.; Epple, B. A High Thermal Conductivity of MgO-H2O Nanofluid Prepared by Two-Step Technique. Appl. Sci. 2022, 12, 2655. [Google Scholar] [CrossRef]

- Sharma, B.; Sharma, S.K.; Gupta, S.M.; Kumar, A. Modified Two-Step Method to Prepare Long-Term Stable CNT Nanofluids for Heat Transfer Applications. Arab. J. Sci. Eng. 2018, 43, 6155–6163. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, W.; Tang, L.; Li, C.; Liang, X.; Xu, S.; Said, Z.; Sharma, S.; Chen, Y.; Liu, B.; et al. Abrasive water jet tool passivation: From mechanism to application. J. Adv. Manuf. Sci. Technol. 2022, 3, 2022018. [Google Scholar] [CrossRef]

- Missana, T.; Adell, A. On the Applicability of DLVO Theory to the Prediction of Clay Colloids Stability. J. Colloid Interface Sci. 2000, 230, 150–156. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, S.; Panigrahi, P.K. Stability of Nanofluid: A Review. Appl. Therm. Eng. 2020, 174, 115259. [Google Scholar] [CrossRef]

- Dey, D.; Kumar, P.; Samantaray, S. A Review of Nanofluid Preparation, Stability, and Thermo-Physical Properties. Heat Transf. —Asian Res. 2017, 46, 1413–1442. [Google Scholar] [CrossRef]

- Ali, N.; Teixeira, J.A.; Addali, A. A Review on Nanofluids: Fabrication, Stability, and Thermophysical Properties. J. Nanomater. 2018, 2018, 6978130. [Google Scholar] [CrossRef]

- He, Y.T.; Wan, J.; Tokunaga, T. Kinetic Stability of Hematite Nanoparticles: The Effect of Particle Sizes. J. Nanopart. Res. 2008, 10, 321–332. [Google Scholar] [CrossRef]

- Li, D.; Hong, B.; Fang, W.; Guo, Y.; Lin, R. Preparation of Well-Dispersed Silver Nanoparticles for Oil-Based Nanofluids. Ind. Eng. Chem. Res. 2010, 49, 1697–1702. [Google Scholar] [CrossRef]

- Chakraborty, S.; Sengupta, I.; Sarkar, I.; Pal, S.K.; Chakraborty, S. Effect of Surfactant on Thermo-Physical Properties and Spray Cooling Heat Transfer Performance of Cu-Zn-Al LDH Nanofluid. Appl. Clay Sci. 2019, 168, 43–55. [Google Scholar] [CrossRef]

- Hong, K.S.; Hong, T.-K.; Yang, H.-S. Thermal Conductivity of Fe Nanofluids Depending on the Cluster Size of Nanoparticles. Appl. Phys. Lett. 2006, 88, 031901. [Google Scholar] [CrossRef]

- Liu, M.; Li, C.; Zhang, Y.; Yang, M.; Gao, T.; Cui, X.; Wang, X.; Li, H.; Said, Z.; Li, R.; et al. Analysis of Grain Tribology and Improved Grinding Temperature Model Based on Discrete Heat Source. Tribol. Int. 2023, 180, 108196. [Google Scholar] [CrossRef]

- Baek, S.; Shin, D.; Kim, G.; Lee, A.; Noh, J.; Choi, B.; Huh, S.; Jeong, H.; Sung, Y. Influence of Amphoteric and Anionic Surfactants on Stability, Surface Tension, and Thermal Conductivity of Al2O3/Water Nanofluids. Case Stud. Therm. Eng. 2021, 25, 100995. [Google Scholar] [CrossRef]

- Zheng, N.; Wang, L.; Sun, Z. The Effects of Ultrasonication Power and Time on the Dispersion Stability of Few-Layer Graphene Nanofluids under the Constant Ultrasonic Energy Consumption Condition. Ultrason. Sonochem. 2021, 80, 105816. [Google Scholar] [CrossRef] [PubMed]

- Tavakkoli, O.; Kamyab, H.; Shariati, M.; Mohamed, A.M.; Junin, R. Effect of Nanoparticles on the Performance of Polymer/Surfactant Flooding for Enhanced Oil Recovery: A Review. Fuel 2022, 312, 122867. [Google Scholar] [CrossRef]

- Seyhan, M.; Kucharczyk, W.; Yarar, U.E.; Rickard, K.; Rende, D.; Baysal, N.; Bucak, S.; Ozisik, R. Interfacial Surfactant Competition and Its Impact on Poly(Ethylene Oxide)/Au and Poly(Ethylene Oxide)/Ag Nanocomposite Properties. NSA 2017, 10, 69–77. [Google Scholar] [CrossRef] [PubMed]

- Tiwari, A.K.; Pandya, N.S.; Said, Z.; Oztop, H.F.; Abu-Hamdeh, N. 4S Consideration (Synthesis, Sonication, Surfactant, Stability) for the Thermal Conductivity of CeO2 with MWCNT and Water Based Hybrid Nanofluid: An Experimental Assessment. Colloid Surf. A-Physicochem. Eng. Asp. 2021, 610, 125918. [Google Scholar] [CrossRef]

- Said, Z.; Sundar, L.S.; Tiwari, A.K.; Ali, H.M.; Sheikholeslami, M.; Bellos, E.; Babar, H. Recent Advances on the Fundamental Physical Phenomena behind Stability, Dynamic Motion, Thermophysical Properties, Heat Transport, Applications, and Challenges of Nanofluids. Phys. Rep. 2022, 946, 1–94. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, Y.; Zhao, Q.; Jiang, J.; Liu, G.; Li, C. Tribological Mechanism of Carbon Group Nanofluids on Grinding Interface under Minimum Quantity Lubrication Based on Molecular Dynamic Simulation. Front. Mech. Eng. 2023, 18, 17. [Google Scholar] [CrossRef]

- Liu, D.; Liu, H.; Zhou, Z.; Chen, Y.; Liu, B.; Zhang, N.; Li, C. Design and Analysis of Flexible Fixture for Aluminum Alloy Hub. Tool Eng. 2022, 56, 75–82. [Google Scholar] [CrossRef]

- Agarwal, S.; Sacheti, N.C.; Chandran, P.; Bhadauria, B.S.; Singh, A.K. Non-Linear Convective Transport in a Binary Nanofluid Saturated Porous Layer. Transp. Porous Med. 2012, 93, 29–49. [Google Scholar] [CrossRef]

- Aberoumand, S.; Jafarimoghaddam, A. Tungsten (III) Oxide (WO3)—Silver/Transformer Oil Hybrid Nanofluid: Preparation, Stability, Thermal Conductivity and Dielectric Strength. Alex. Eng. J. 2018, 57, 169–174. [Google Scholar] [CrossRef]

- Li, B.; Li, C.; Zhang, Y.; Wang, Y.; Yang, M.; Jia, D.; Zhang, N.; Wu, Q. Effect of the Physical Properties of Different Vegetable Oil-Based Nanofluids on MQLC Grinding Temperature of Ni-Based Alloy. Int. J. Adv. Manuf. Technol. 2017, 89, 3459–3474. [Google Scholar] [CrossRef]

- Alirezaie, A.; Hajmohammad, M.H.; Ahangar, M.R.H.; Hemmat Esfe, M. Price-Performance Evaluation of Thermal Conductivity Enhancement of Nanofluids with Different Particle Sizes. Appl. Therm. Eng. 2018, 128, 373–380. [Google Scholar] [CrossRef]

- Choi, J.; Zhang, Y. Numerical Simulation of Laminar Forced Convection Heat Transfer of Al2O3–Water Nanofluid in a Pipe with Return Bend. Int. J. Therm. Sci. 2012, 55, 90–102. [Google Scholar] [CrossRef]

- Ambreen, T.; Kim, M.-H. Influence of Particle Size on the Effective Thermal Conductivity of Nanofluids: A Critical Review. Appl. Energy 2020, 264, 114684. [Google Scholar] [CrossRef]

- Mahbubul, I.M.; Fadhilah, S.A.; Saidur, R.; Leong, K.Y.; Amalina, M.A. Thermophysical Properties and Heat Transfer Performance of Al2O3/R-134a Nanorefrigerants. Int. J. Heat Mass Transf. 2013, 57, 100–108. [Google Scholar] [CrossRef]

- Bindu, M.V.; Joselin Herbert, G.M. Thermal Conductivity and Viscosity of Al2O3-ZnO-MWCNT-EG Ternary Nanofluid. Int. J. Energy Res. 2022, 46, 17478–17496. [Google Scholar] [CrossRef]

- Suganthi, K.S.; Rajan, K.S. Temperature Induced Changes in ZnO-Water Nanofluid: Zeta Potential, Size Distribution and Viscosity Profiles. Int. J. Heat Mass Transf. 2012, 55, 7969–7980. [Google Scholar] [CrossRef]

- Huminic, A.; Huminic, G.; Fleaca, C.; Dumitrache, F.; Morjan, I. Thermal Conductivity, Viscosity and Surface Tension of Nanofluids Based on FeC Nanoparticles. Powder Technol. 2015, 284, 78–84. [Google Scholar] [CrossRef]

- Das, A.; Patel, S.K.; Biswal, B.B.; Sahoo, N.; Pradhan, A. Performance Evaluation of Various Cutting Fluids Using MQL Technique in Hard Turning of AISI 4340 Alloy Steel. Measurement 2020, 150, 107079. [Google Scholar] [CrossRef]

- Khairul, M.A.; Shah, K.; Doroodchi, E.; Azizian, R.; Moghtaderi, B. Effects of Surfactant on Stability and Thermo-Physical Properties of Metal Oxide Nanofluids. Int. J. Heat Mass Transf. 2016, 98, 778–787. [Google Scholar] [CrossRef]

- Michael, M.; Zagabathuni, A.; Ghosh, S.; Pabi, S.K. Thermo-Physical Properties of Pure Ethylene Glycol and Water–Ethylene Glycol Mixture-Based Boron Nitride Nanofluids. J. Therm. Anal. Calorim. 2019, 137, 369–380. [Google Scholar] [CrossRef]

- Maxwell, J. A Treatise on Electeicity and Magnetism; Oxford University Press: Cambridge, UK, 1881. [Google Scholar]

- Hamilton, R.L.; Crosser, O.K. Thermal Conductivity of Heterogeneous Two-Component Systems. Ind. Eng. Chem. Fund. 1962, 1, 187–191. [Google Scholar] [CrossRef]

- Bruggeman, D.A.G. Berechnung verschiedener physikalischer Konstanten von heterogenen Substanzen. I. Dielektrizitätskonstanten und Leitfähigkeiten der Mischkörper aus isotropen Substanzen. Ann. Phys. 1935, 416, 636–664. [Google Scholar] [CrossRef]

- Keblinski, P.; Phillpot, S.R.; Choi, S.U.S.; Eastman, J.A. Mechanisms of Heat Flow in Suspensions of Nano-Sized Particles (Nanofluids). Int. J. Heat Mass Transf. 2002, 45, 855–863. [Google Scholar] [CrossRef]

- Evans, W.; Prasher, R.; Fish, J.; Meakin, P.; Phelan, P.; Keblinski, P. Effect of Aggregation and Interfacial Thermal Resistance on Thermal Conductivity of Nanocomposites and Colloidal Nanofluids. Int. J. Heat Mass Transf. 2008, 51, 1431–1438. [Google Scholar] [CrossRef]

- Yu, W.; Choi, S.U.S. The Role of Interfacial Layers in the Enhanced Thermal Conductivity of Nanofluids: A Renovated Hamilton–Crosser Model. J. Nanoparticle Res. 2004, 6, 355–361. [Google Scholar] [CrossRef]

- Yu, W.; Choi, S.U.S. The Role of Interfacial Layers in the Enhanced Thermal Conductivity of Nanofluids: A Renovated Maxwell Model. J. Nanoparticle Res. 2003, 5, 167–171. [Google Scholar] [CrossRef]

- Xuan, Y.; Li, Q.; Hu, W. Aggregation Structure and Thermal Conductivity of Nanofluids. AIChE J. 2003, 49, 1038–1043. [Google Scholar] [CrossRef]

- Dambatta, Y.S.; Li, C.; Yang, M.; Li, B.; Gao, T.; Liu, M.; Cui, X.; Wang, X.; Zhang, Y.; Said, Z.; et al. Grinding with Minimum Quantity Lubrication: A Comparative Assessment. Int. J. Adv. Manuf. Technol. 2023, 128, 955–1014. [Google Scholar] [CrossRef]

- Pordanjani, A.H.; Aghakhani, S.; Afrand, M.; Sharifpur, M.; Meyer, J.P.; Xu, H.; Ali, H.M.; Karimi, N.; Cheraghian, G. Nanofluids: Physical Phenomena, Applications in Thermal Systems and the Environment Effects-a Critical Review. J. Clean. Prod. 2021, 320, 128573. [Google Scholar] [CrossRef]

- Minakov, A.V.; Rudyak, V.Y.; Pryazhnikov, M.I. Systematic Experimental Study of the Viscosity of Nanofluids. Heat Transf. Eng. 2021, 42, 1024–1040. [Google Scholar] [CrossRef]

- Hu, X.; Yin, D.; Chen, X.; Xiang, G. Experimental Investigation and Mechanism Analysis: Effect of Nanoparticle Size on Viscosity of Nanofluids. J. Mol. Liq. 2020, 314, 113604. [Google Scholar] [CrossRef]

- Ferrouillat, S.; Bontemps, A.; Poncelet, O.; Soriano, O.; Gruss, J.-A. Influence of Nanoparticle Shape Factor on Convective Heat Transfer and Energetic Performance of Water-Based SiO2 and ZnO Nanofluids. Appl. Therm. Eng. 2013, 51, 839–851. [Google Scholar] [CrossRef]

- Koca, H.D.; Doganay, S.; Turgut, A.; Tavman, I.H.; Saidur, R.; Mahbubul, I.M. Effect of Particle Size on the Viscosity of Nanofluids: A Review. Renew. Sustain. Energy Rev. 2018, 82, 1664–1674. [Google Scholar] [CrossRef]

- Jabbari, F.; Rajabpour, A.; Saedodin, S. Viscosity of Carbon Nanotube/Water Nanofluid: Equilibrium Molecular Dynamics. J. Therm. Anal. Calorim. 2019, 135, 1787–1796. [Google Scholar] [CrossRef]

- Iyahraja, S.; Rajadurai, J.S.; Sivakumar, M.; Lenin, N.N. Investigation on Silver-Water Nanofluid for Development of New Viscosity Correlation. Bull. Chem. Soc. Eth. 2022, 37, 505–514. [Google Scholar] [CrossRef]

- Albert, E. A New Determination of Molecular Dimensions. Annln. Phys. 1906, 19, 289–306. [Google Scholar]

- Brinkman, H.C. The Viscosity of Concentrated Suspensions and Solutions. J. Chem. Phys. 2004, 20, 571. [Google Scholar] [CrossRef]

- Batchelor, G.K. The Effect of Brownian Motion on the Bulk Stress in a Suspension of Spherical Particles. J. Fluid Mech. 1977, 83, 97–117. [Google Scholar] [CrossRef]

- Brenner, H.; Condiff, D.W. Transport Mechanics in Systems of Orientable Particles. IV. Convective Transport. J. Colloid Interface Sci. 1974, 47, 199–264. [Google Scholar] [CrossRef]

- De Noni, A., Jr.; Garcia, D.E.; Hotza, D. A Modified Model for the Viscosity of Ceramic Suspensions. Ceram. Int. 2002, 28, 731–735. [Google Scholar] [CrossRef]

- Tseng, W.J.; Lin, K.-C. Rheology and Colloidal Structure of Aqueous TiO2 Nanoparticle Suspensions. Mater. Sci. Eng. A 2003, 355, 186–192. [Google Scholar] [CrossRef]

- Murshed, S.M.S.; Santos, F.J.V.; de Castro, C.A.N. Investigations of Viscosity of Silicone Oil-Based Semiconductor Nanofluids. J. Nanofluids 2013, 2, 261–266. [Google Scholar] [CrossRef]

- Ragulkumar, E.; Palani, G.; Sambath, P.; Chamkha, A.J. Dissipative MHD Free Convective Nanofluid Flow Past a Vertical Cone under Radiative Chemical Reaction with Mass Flux. Sci. Rep. 2023, 13, 2878. [Google Scholar] [CrossRef] [PubMed]

- Noraldeen, S.F.M.; Jin, L.; Zhou, L. Size, Interface and Temperature Effects on Specific Heat Capacities of Cu-Water Nanofluid and Cu Nanoparticle: A Molecular Analysis. Therm. Sci. Eng. Prog. 2022, 27, 101157. [Google Scholar] [CrossRef]

- Buongiorno, J. Convective Transport in Nanofluids. J. Heat Transf. 2006, 128, 240–250. [Google Scholar] [CrossRef]

- Alammar, K.; Hu, L. Laminar Flow and Heat Transfer Characteristics of Nanoparticle Colloidal Dispersions in Water. Heat Mass Transf. 2010, 46, 541–546. [Google Scholar] [CrossRef]

- Seawram, S.; Nimmanterdwong, P.; Sema, T.; Piemjaiswang, R.; Chalermsinsuwan, B. Specific Heat Capacity Prediction of Hybrid Nanofluid Using Artificial Neural Network and Its Heat Transfer Application. Energy Rep. 2022, 8, 8–15. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, Y.; Hu, S.; Ji, H.; Yang, J. Research on Lubrication Mechanism with Fluid–Solid Coupling of Port Plate Pair in Swash Plate Axial Piston Pump. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 234, 515–527. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, M.; Jin, L.; Li, L.; Mo, Y.; Su, G.; Li, X.; Zhu, H.; Tian, Y. Recent Advances in Friction and Lubrication of Graphene and Other 2D Materials: Mechanisms and Applications. Friction 2019, 7, 199–216. [Google Scholar] [CrossRef]

- Pan, S.; Jin, K.; Wang, T.; Zhang, Z.; Zheng, L.; Umehara, N. Metal Matrix Nanocomposites in Tribology: Manufacturing, Performance, and Mechanisms. Friction 2022, 10, 1596–1634. [Google Scholar] [CrossRef]

- He, Y.; Wang, L.; Wu, T.; Wu, Z.; Chen, Y.; Yin, K. Facile Fabrication of Hierarchical Textures for Substrate-Independent and Durable Superhydrophobic Surfaces. Nanoscale 2022, 14, 9392–9400. [Google Scholar] [CrossRef] [PubMed]

- Erdemir, A.; Ramirez, G.; Eryilmaz, O.L.; Narayanan, B.; Liao, Y.; Kamath, G.; Sankaranarayanan, S.K.R.S. Carbon-Based Tribofilms from Lubricating Oils. Nature 2016, 536, 67–71. [Google Scholar] [CrossRef] [PubMed]

- Naresh Babu, M.; Anandan, V.; Muthukrishnan, N. Analysis of EN24 Steel in Turning Process with Copper Nanofluids under Minimum Quantity Lubrication. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 101. [Google Scholar] [CrossRef]

- Pal, A.; Chatha, S.S.; Sidhu, H.S. Experimental Investigation on the Performance of MQL Drilling of AISI 321 Stainless Steel Using Nano-Graphene Enhanced Vegetable-Oil-Based Cutting Fluid. Tribol. Int. 2020, 151, 106508. [Google Scholar] [CrossRef]

- Anandan, V.; Naresh Babu, M.; Muthukrishnan, N.; Dinesh Babu, M. Performance of Silver Nanofluids with Minimum Quantity Lubrication in Turning on Titanium: A Phase to Green Manufacturing. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 198. [Google Scholar] [CrossRef]

- Rapeti, P.; Pasam, V.K.; Rao Gurram, K.M.; Revuru, R.S. Performance Evaluation of Vegetable Oil Based Nano Cutting Fluids in Machining Using Grey Relational Analysis-A Step towards Sustainable Manufacturing. J. Clean. Prod. 2018, 172, 2862–2875. [Google Scholar] [CrossRef]

- Yi, S.; Li, G.; Ding, S.; Mo, J. Performance and Mechanisms of Graphene Oxide Suspended Cutting Fluid in the Drilling of Titanium Alloy Ti-6Al-4V. J. Manuf. Process. 2017, 29, 182–193. [Google Scholar] [CrossRef]

- Malladi, A.; Saravanan, R.; Gnanavel, C.; Rajesh, S.; Sekar, C.B.; Nagarathi, D.K. Taguchi Based Parameter Optimization for Cutting Force Reduction in SAE 1045 Steel Machining with Nanofluid. Mater. Today Proc. 2022, 62, 1325–1329. [Google Scholar] [CrossRef]

- Pashmforoush, F.; Delir Bagherinia, R. Influence of Water-Based Copper Nanofluid on Wheel Loading and Surface Roughness during Grinding of Inconel 738 Superalloy. J. Clean. Prod. 2018, 178, 363–372. [Google Scholar] [CrossRef]

- Khajehzadeh, M.; Moradpour, J.; Razfar, M.R. Influence of Nano lubricant Particles’ Size on Flank Wear in Hard Turning. Mater. Manuf. Process. 2019, 34, 494–501. [Google Scholar] [CrossRef]

- Tiara, A.M.; Chakraborty, S.; Sarkar, I.; Pal, S.K.; Chakraborty, S. Effect of Alumina Nanofluid Jet on the Enhancement of Heat Transfer from a Steel Plate. Heat Mass Transf. 2017, 53, 2187–2197. [Google Scholar] [CrossRef]

- Singh, R.K.; Sharma, A.K.; Bishwajeet; Mandal, V.; Gaurav, K.; Sharma, A.; Kumar, A.; Dixit, A.R.; Mandal, A.; Das, A.K. Effect of Multi-Walled Carbon Nanotubes Based Nanofluid on Surface Roughness and Cutting Temperature in Turning Operation Using Minimum Quantity Lubrication. IOP Conf. Ser. Mater. Sci. Eng. 2018, 377, 012017. [Google Scholar] [CrossRef]

- Safiei, W.; Rahman, M.M.; Yusoff, A.R.; Arifin, M.N.; Tasnim, W. Effects of SiO2-Al2O3-ZrO2 Tri-Hybrid Nanofluids on Surface Roughness and Cutting Temperature in End Milling Process of Aluminum Alloy 6061-T6 Using Uncoated and Coated Cutting Inserts with Minimal Quantity Lubricant Method. Arab. J. Sci. Eng. 2021, 46, 7699–7718. [Google Scholar] [CrossRef]

- Shuang, Y.; John, M.; Songlin, D. Experimental Investigation on the Performance and Mechanism of Graphene Oxide Nanofluids in Turning Ti-6Al-4V. J. Manuf. Process. 2019, 43, 164–174. [Google Scholar] [CrossRef]

- Li, M.; Yu, T.; Zhang, R.; Yang, L.; Li, H.; Wang, W. MQL Milling of TC4 Alloy by Dispersing Graphene into Vegetable Oil-Based Cutting Fluid. Int. J. Adv. Manuf. Technol. 2018, 99, 1735–1753. [Google Scholar] [CrossRef]

- Zetty Akhtar, A.M.; Rahman, M.M.; Kadirgama, K.; Maleque, M.A. Effect of TiO2 and Al2O3-Ethylene Glycol-Based Nanofluids on Cutting Temperature and Surface Roughness during Turning Process of AISI 1018. IOP Conf. Ser. Mater. Sci. Eng. 2020, 736, 052033. [Google Scholar] [CrossRef]

- Hoang, A.T. Combustion Behavior, Performance and Emission Characteristics of Diesel Engine Fuelled with Biodiesel Containing Cerium Oxide Nanoparticles: A Review. Fuel Process. Technol. 2021, 218, 106840. [Google Scholar] [CrossRef]

- Han, C.; Fang, Q.; Shi, Y.; Tor, S.B.; Chua, C.K.; Zhou, K. Recent Advances on High-Entropy Alloys for 3D Printing. Adv. Mater. 2020, 32, 1903855. [Google Scholar] [CrossRef]

- Moghaddam, A.O.; Shaburova, N.A.; Samodurova, M.N.; Abdollahzadeh, A.; Trofimov, E.A. Additive Manufacturing of High Entropy Alloys: A Practical Review. J. Mater. Sci. Technol. 2021, 77, 131–162. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, C.; Yang, M.; Jia, D.; Wang, Y.; Li, B.; Hou, Y.; Zhang, N.; Wu, Q. Experimental Evaluation of Cooling Performance by Friction Coefficient and Specific Friction Energy in Nanofluid Minimum Quantity Lubrication Grinding with Different Types. J. Clean. Prod. 2016, 139, 685–705. [Google Scholar] [CrossRef]

- Shi, L.; Hu, Y.; He, Y. Magneto controllable Convective Heat Transfer of Nanofluid through a Straight Tube. Appl. Therm. Eng. 2019, 162, 114220. [Google Scholar] [CrossRef]

- Zhang, K.; Li, Z.; Wang, S.; Wang, P.; Zhang, Y.; Guo, X. Study on the Cooling and Lubrication Mechanism of Magnetic Field-Assisted Fe3O4@CNTs Nanofluid in Micro-Textured Tool Cutting. J. Manuf. Process. 2023, 85, 556–568. [Google Scholar] [CrossRef]

- Jiao, A.Y.; Quan, H.J.; Li, Z.Z.; Chen, Y. Study of Magnetic Abrasive Finishing in Seal Ring Groove Surface Operations. Int. J. Adv. Manuf. Technol. 2016, 85, 1195–1205. [Google Scholar] [CrossRef]

- Zhang, L.; Guo, X.; Zhang, K.; Wu, Y.; Huang, Q. Enhancing Cutting Performance of Uncoated Cemented Carbide Tools by Joint-Use of Magnetic Nanofluids and Micro-Texture under Magnetic Field. J. Mater. Process. Technol. 2020, 284, 116764. [Google Scholar] [CrossRef]

- Cui, X.; Li, C.; Yang, M.; Liu, M.; Gao, T.; Wang, X.; Said, Z.; Sharma, S.; Zhang, Y. Enhanced Grindability and Mechanism in the Magnetic Traction Nano lubricant Grinding of Ti-6Al-4V. Tribol. Int. 2023, 186, 108603. [Google Scholar] [CrossRef]

- Ngoc, T.B.; Duc, T.M.; Tuan, N.M.; Hoang, V.L.; Long, T.T. Machinability Assessment of Hybrid Nano Cutting Oil for Minimum Quantity Lubrication (MQL) in Hard Turning of 90CrSi Steel. Lubricants 2023, 11, 54. [Google Scholar] [CrossRef]

- Singh, V.; Sharma, A.K.; Sahu, R.K.; Katiyar, J.K. Novel Application of Graphite-Talc Hybrid Nanoparticle Enriched Cutting Fluid in Turning Operation. J. Manuf. Process. 2021, 62, 378–387. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, C.; Jia, D.; Li, B.; Wang, Y.; Yang, M.; Hou, Y.; Zhang, X. Experimental Study on the Effect of Nanoparticle Concentration on the Lubricating Property of Nanofluids for MQL Grinding of Ni-Based Alloy. J. Mater. Process. Technol. 2016, 232, 100–115. [Google Scholar] [CrossRef]

- Li, M.; Yu, T.; Zhang, R.; Yang, L.; Ma, Z.; Li, B.; Wang, X.; Wang, W.; Zhao, J. Experimental Evaluation of an Eco-Friendly Grinding Process Combining Minimum Quantity Lubrication and Graphene-Enhanced Plant-Oil-Based Cutting Fluid. J. Clean. Prod. 2020, 244, 118747. [Google Scholar] [CrossRef]

- Singh, R.K.; Sharma, A.K.; Dixit, A.R.; Tiwari, A.K.; Pramanik, A.; Mandal, A. Performance Evaluation of Alumina-Graphene Hybrid Nano-Cutting Fluid in Hard Turning. J. Clean. Prod. 2017, 162, 830–845. [Google Scholar] [CrossRef]

- Said, Z.; Arora, S.; Farooq, S.; Sundar, L.S.; Li, C.; Allouhi, A. Recent Advances on Improved Optical, Thermal, and Radiative Characteristics of Plasmonic Nanofluids: Academic Insights and Perspectives. Sol. Energy Mater. Sol. Cells 2022, 236, 111504. [Google Scholar] [CrossRef]

- Baldin, V.; Rosa Ribeiro Da Silva, L.; Houck, C.F.; Gelamo, R.V.; Machado, Á.R. Effect of Graphene Addition in Cutting Fluids Applied by MQL in End Milling of AISI 1045 Steel. Lubricants 2021, 9, 70. [Google Scholar] [CrossRef]

- Abbas, A.T.; Benyahia, F.; El Rayes, M.M.; Pruncu, C.; Taha, M.A.; Hegab, H. Towards Optimization of Machining Performance and Sustainability Aspects When Turning AISI 1045 Steel under Different Cooling and Lubrication Strategies. Materials 2019, 12, 3023. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.T.; Chou, F.; Tsai, J.T.; Chou, J.H. Application of Graphene Nanofluid/Ultrasonic Atomization MQL System in Micromilling and Development of Optimal Predictive Model for SKH-9 High-Speed Steel Using Fuzzy-Logic-Based Multi-Objective Design. Int. J. Fuzzy Syst. 2020, 22, 2101–2118. [Google Scholar] [CrossRef]

- Ni, J.; Cui, Z.; Wu, C.; Sun, J.; Zhou, J. Evaluation of MQL Broaching AISI 1045 Steel with Sesame Oil Containing Nano-Particles under Best Concentration. J. Clean. Prod. 2021, 320, 128888. [Google Scholar] [CrossRef]

- Strange, L.E.; Shutthanandan, V.; Song, M.; Bowden, M.; Miller, Q.R.S.; Prabhakaran, R.; Shimskey, R.; Joshi, V.V. Multimodal Analysis and Characterization of the Boehmite Layer Formed on AA6061 before and after Alkaline Etching. J. Mater. Res. Technol. JMRT 2022, 21, 1274–1281. [Google Scholar] [CrossRef]

- Deyab, M.A.; Abd El-Rehim, S.S.; Hassan, H.H.; Shaltot, A.M. Impact of Rare Earth Compounds on Corrosion of Aluminum Alloy (AA6061) in the Marine Water Environment. J. Alloys Compd. 2020, 820, 153428. [Google Scholar] [CrossRef]

- Najiha, M.S.; Rahman, M.M.; Yusoff, A.R. Flank Wear Characterization in Aluminum Alloy (6061 T6) With Nanofluid Minimum Quantity Lubrication Environment Using an Uncoated Carbide Tool. J. Manuf. Sci. Eng.-Trans. ASME 2015, 137, 061004. [Google Scholar] [CrossRef]

- Niknam, S.A.; Jalali, A. Effects of Lubricants and Flow Rates on the Surface Roughness and Chip Thickness When MQL Turning of Aero-Engine Aluminum Alloys 6061-T6 and 7076-T6. Int. J. Adv. Manuf. Technol. 2020, 110, 2015–2022. [Google Scholar] [CrossRef]

- Gardner, L. Stability and Design of Stainless Steel Structures-Review and Outlook. Thin-Walled Struct. 2019, 141, 208–216. [Google Scholar] [CrossRef]

- Hua, J.; Wang, F.; Xiang, Y.; Yang, Z.; Xue, X.; Huang, L.; Wang, N. Mechanical Properties of Stainless-Clad Bimetallic Steel Bars Exposed to Elevated Temperatures. Fire Saf. J. 2022, 127, 103521. [Google Scholar] [CrossRef]

- Ondin, O.; Kivak, T.; Sarikaya, M.; Yildirim, C.V. Investigation of the Influence of MWCNTs Mixed Nanofluid on the Machinability Characteristics of PH 13-8 Mo Stainless Steel. Tribol. Int. 2020, 148, 106323. [Google Scholar] [CrossRef]

- Akincioğlu, S.; Şirin, Ş. Evaluation of the Tribological Performance of the Green HBN Nanofluid on the Friction Characteristics of AISI 316L Stainless Steel. Ind. Lubr. Tribol. 2021, 73, 1176–1186. [Google Scholar] [CrossRef]

- Ukamanal, M.; Chandra Mishra, P.; Kumar Sahoo, A. Temperature Distribution during AISI 316 Steel Turning under TiO2-Water Based Nanofluid Spray Environments. Mater. Today Proc. 2018, 5, 20741–20749. [Google Scholar] [CrossRef]

- Saatci, E.; Yapan, Y.F.; Uysal, M.U.; Uysal, A. Orthogonal Turning of AISI 310S Austenitic Stainless Steel under Hybrid Nanofluid-Assisted MQL and a Sustainability Optimization Using NSGA-II and TOPSIS. Sustain. Mater. Technol. 2023, 36, e00628. [Google Scholar] [CrossRef]

- Pal, A.; Chatha, S.S.; Singh, K. Performance Evaluation of Minimum Quantity Lubrication Technique in Grinding of AISI 202 Stainless Steel Using Nano-MoS2 with Vegetable-Based Cutting Fluid. Int. J. Adv. Manuf. Technol. 2020, 110, 125–137. [Google Scholar] [CrossRef]

- Maruda, R.W.; Arkusz, K.; Szczotkarz, N.; Wojciechowski, S.; Nieslony, P.; Krolczyk, G.M. Analysis of Size and Con-centration of Nanoparticles Contained in Cutting Fluid during Turning of 316L Steel in Minimum Quantity Lubrication Conditions. J. Manuf. Process. 2023, 87, 106–122. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, X.; Kang, X.; Yi, H.; Wang, Q.; Cao, H. Energy Field-Assisted High-Speed Dry Milling Green Machining Technology for Difficult-to-Machine Metal Materials. Front. Mech. Eng. 2023, 18, 28. [Google Scholar] [CrossRef]

- Cui, X.; Li, C.; Zhang, Y.; Ding, W.; An, Q.; Liu, B.; Li, H.N.; Said, Z.; Sharma, S.; Li, R.; et al. Comparative Assessment of Force, Temperature, and Wheel Wear in Sustainable Grinding Aerospace Alloy Using Biolubricant. Front. Mech. Eng. 2023, 18, 3. [Google Scholar] [CrossRef]

- Kaur, M.; Singh, K. Review on Titanium and Titanium Based Alloys as Biomaterials for Orthopaedic Applications. Mater. Sci. Eng. C-Mater. Biol. Appl. 2019, 102, 844–862. [Google Scholar] [CrossRef]

- Liang, X.; Liu, Z.; Wang, B. State-of-the-Art of Surface Integrity Induced by Tool Wear Effects in Machining Process of Titanium and Nickel Alloys: A Review. Measurement 2019, 132, 150–181. [Google Scholar] [CrossRef]

- Gupta, M.K.; Song, Q.; Liu, Z.; Sarikaya, M.; Jamil, M.; Mia, M.; Khanna, N.; Krolczyk, G.M. Experimental Characterisation of the Performance of Hybrid Cryo-Lubrication Assisted Turning of Ti–6Al–4V Alloy. Tribol. Int. 2021, 153, 106582. [Google Scholar] [CrossRef]

- Zhou, C.; Guo, X.; Zhang, K.; Cheng, L.; Wu, Y. The Coupling Effect of Micro-Groove Textures and Nanofluids on Cutting Performance of Uncoated Cemented Carbide Tools in Milling Ti-6Al-4V. J. Mater. Process. Technol. 2019, 271, 36–45. [Google Scholar] [CrossRef]

- Bai, X.; Li, C.; Dong, L.; Yin, Q. Experimental Evaluation of the Lubrication Performances of Different Nanofluids for Minimum Quantity Lubrication (MQL) in Milling Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2019, 101, 2621–2632. [Google Scholar] [CrossRef]

- Gaurav, G.; Sharma, A.; Dangayach, G.S.; Meena, M.L. Assessment of Jojoba as a Pure and Nano-Fluid Base Oil in Minimum Quantity Lubrication (MQL) Hard-Turning of Ti–6Al–4V: A Step towards Sustainable Machining. J. Clean. Prod. 2020, 272, 122553. [Google Scholar] [CrossRef]

- Huang, B.; Li, C.; Zhang, Y.; Ding, W.; Yang, M.; Yang, Y.; Zhai, H.; Xu, X.; Wang, D.; Debnath, S.; et al. Advances in Fabrication of Ceramic Corundum Abrasives Based on Sol–Gel Process. Chin. J. Aeronaut. 2021, 34, 1–17. [Google Scholar] [CrossRef]

- Sen, B.; Mia, M.; Gupta, M.K.; Rahman, M.A.; Mandal, U.K.; Mondal, S.P. Influence of Al2O3 and Palm Oil-Mixed Nano-Fluid on Machining Performances of Inconel-690: IF-THEN Rules-Based FIS Model in Eco-Benign Milling. Int. J. Adv. Manuf. Technol. 2019, 103, 3389–3403. [Google Scholar] [CrossRef]

- Venkatesan, K.; Mathew, A.T.; Devendiran, S.; Ghazaly, N.M.; Sanjith, S.; Raghul, R. Machinability Study and Multi-Response Optimization of Cutting Force, Surface Roughness and Tool Wear on CNC Turned Inconel 617 Superalloy Using Al2O3 Nanofluids in Coconut Oil. Procedia Manuf. 2019, 30, 396–403. [Google Scholar] [CrossRef]

- Şirin, Ş.; Sarıkaya, M.; Yıldırım, Ç.V.; Kıvak, T. Machinability Performance of Nickel Alloy X-750 with SiAlON Ceramic Cutting Tool under Dry, MQL and HBN Mixed Nanofluid-MQL. Tribol. Int. 2021, 153, 106673. [Google Scholar] [CrossRef]

- Zhang, X.; Li, C.; Zhang, Y.; Wang, Y.; Li, B.; Yang, M.; Guo, S.; Liu, G.; Zhang, N. Lubricating Property of MQL Grinding of Al2O3/SiC Mixed Nanofluid with Different Particle Sizes and Microtopography Analysis by Cross-Correlation. Precis. Eng. 2017, 47, 532–545. [Google Scholar] [CrossRef]

- Kuntoglu, M.; Aslan, A.; Pimenov, D.Y.; Usca, U.A.; Salur, E.; Gupta, M.K.; Mikolajczyk, T.; Giasin, K.; Kaplonek, W.; Sharma, S. A Review of Indirect Tool Condition Monitoring Systems and Decision-Making Methods in Turning: Critical Analysis and Trends. Sensors 2021, 21, 108. [Google Scholar] [CrossRef] [PubMed]

- Elbah, M.; Laouici, H.; Benlahmidi, S.; Nouioua, M.; Yallese, M.A. Comparative Assessment of Machining Environments (Dry, Wet and MQL) in Hard Turning of AISI 4140 Steel with CC6050 Tools. Int. J. Adv. Manuf. Technol. 2019, 105, 2581–2597. [Google Scholar] [CrossRef]

- Roy, S.; Ghosh, A. High-Speed Turning of AISI 4140 Steel by Multi-Layered TiN Top-Coated Insert with Minimum Quantity Lubrication Technology and Assessment of near Tool-Tip Temperature Using Infrared Thermography. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 228, 1058–1067. [Google Scholar] [CrossRef]

- Sayuti, M.; Sarhan, A.A.D.; Salem, F. Novel Uses of SiO2 Nano-Lubrication System in Hard Turning Process of Hardened Steel AISI4140 for Less Tool Wear, Surface Roughness and Oil Consumption. J. Clean. Prod. 2014, 67, 265–276. [Google Scholar] [CrossRef]

- Gürbüz, H.; Gönülaçar, Y.E.; Baday, Ş. Effect of MQL Flow Rate on Machinability of AISI 4140 Steel. Mach. Sci. Technol. 2020, 24, 663–687. [Google Scholar] [CrossRef]

- Gürbüz, H.; Gönülaçar, Y.E. Experimental and Statistical Investigation of the Effects of MQL, Dry and Wet Machining on Machinability and Sustainability in Turning of AISI 4140 Steel. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2022, 236, 1808–1823. [Google Scholar] [CrossRef]

- Muthuvel, S.; Naresh Babu, M.; Muthukrishnan, N. Copper Nanofluids under Minimum Quantity Lubrication during Drilling of AISI 4140 Steel. Aust. J. Mech. Eng. 2020, 18, S151–S164. [Google Scholar] [CrossRef]

- Khajehzaden, M.; Moradpour, J.; Razfar, R.M. Influence of Nanofluids Application on Contact Length during Hard Turning. Mater. Manuf. Process. 2019, 34, 30–38. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Kumar, R.; Pruncu, C.I. Recent Progress of Reinforcement Materials: A Comprehensive Overview of Composite Materials. J. Mater. Res. Technol.-JMRT 2019, 8, 6354–6374. [Google Scholar] [CrossRef]

- More, C.V.; Alsayed, Z.; Badawi, M.S.; Thabet, A.A.; Pawar, P.P. Polymeric Composite Materials for Radiation Shielding: A Review. Environ. Chem. Lett. 2021, 19, 2057–2090. [Google Scholar] [CrossRef]

- Xia, Y.; He, Y.; Zhang, F.; Liu, Y.; Leng, J. A Review of Shape Memory Polymers and Composites: Mechanisms, Materials, and Applications. Adv. Mater. 2021, 33, 2000713. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wang, H.; Zhang, H.; Yang, L. Comprehensive Performance Evaluation of Ti3C2 MXene/TiN Composite Nanofluids for Photo Thermal Conversion. Appl. Therm. Eng. 2023, 228, 120486. [Google Scholar] [CrossRef]

- M’Saoubi, R.; Axinte, D.; Soo, S.L.; Nobel, C.; Attia, H.; Kappmeyer, G.; Engin, S.; Sim, W.-M. High Performance Cutting of Advanced Aerospace Alloys and Composite Materials. CIRP Ann. 2015, 64, 557–580. [Google Scholar] [CrossRef]

- Gemi, L.; Alsdudi, M.; Aksoylu, C.; Yazman, S.; Ozkilic, Y.O.; Arslan, M.H. Optimum Amount of CFRP for Strengthening Shear Deficient Reinforced Concrete Beams. Steel Compos. Struct. 2022, 43, 735–757. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C.; Wang, Y. Mechanical Performance Evolution and Life Prediction of Prestressed CFRP Plate Exposed to Hygrothermal and Freeze-Thaw Environments. Compos. Struct. 2022, 293, 115719. [Google Scholar] [CrossRef]

- Sun, G.; Chen, D.; Zhu, G.; Li, Q. Lightweight Hybrid Materials and Structures for Energy Absorption: A State-of-the-Art Review and Outlook. Thin-Walled Struct. 2022, 172, 108760. [Google Scholar] [CrossRef]

- Cococcetta, N.M.; Pearl, D.; Jahan, M.P.; Ma, J. Investigating Surface Finish, Burr Formation, and Tool Wear during Machining of 3D Printed Carbon Fiber Reinforced Polymer Composite. J. Manuf. Process. 2020, 56, 1304–1316. [Google Scholar] [CrossRef]

- Gao, T.; Zhang, Y.; Li, C.; Wang, Y.; Chen, Y.; An, Q.; Zhang, S.; Li, H.N.; Cao, H.; Ali, H.M.; et al. Fiber-Reinforced Composites in Milling and Grinding: Machining Bottlenecks and Advanced Strategies. Front. Mech. Eng. 2022, 17, 24. [Google Scholar] [CrossRef]

- Pradana, Y.R.; Leresawan, A.A.; Ashar, A.A.; Aminnudin, A.; Sari, N.P.; Permanasari, A.A.; Suprayitno, S. The Role of TiO2/Water Nanofluids for Cooling Medium on the Carbon Fiber-Reinforced Polymer End Milling Operation. AIP Conf. Proc. 2023, 2687, 050004. [Google Scholar] [CrossRef]

- Qu, S.; Gong, Y.; Yang, Y.; Wang, W.; Liang, C.; Han, B. An Investigation of Carbon Nanofluid Minimum Quantity Lubrication for Grinding Unidirectional Carbon Fibre-Reinforced Ceramic Matrix Composites. J. Clean. Prod. 2020, 249, 119353. [Google Scholar] [CrossRef]

- Qu, S.; Yao, P.; Gong, Y.; Chu, D.; Yang, Y.; Li, C.; Wang, Z.; Zhang, X.; Hou, Y. Environmentally Friendly Grinding of C/SiCs Using Carbon Nanofluid Minimum Quantity Lubrication Technology. J. Clean. Prod. 2022, 366, 132898. [Google Scholar] [CrossRef]

- Mughal, K.; Mughal, M.P.; Farooq, M.U.; Anwar, S.; Ammarullah, M.I. Using Nano-Fluids Minimum Quantity Lubrication (NF-MQL) to Improve Tool Wear Characteristics for Efficient Machining of CFRP/Ti6Al4V Aeronautical Structural Composite. Processes 2023, 11, 1540. [Google Scholar] [CrossRef]

- Li, X.; Song, Q.; Liu, W.; Rao, H.; Xu, S.; Li, L. Protection of Nonpermanent Faults on DC Overhead Lines in MMC-Based HVDC Systems. IEEE Trans. Power Deliv. 2013, 28, 483–490. [Google Scholar] [CrossRef]

- Bhushan, R.K. Optimization of Cutting Parameters for Minimizing Power Consumption and Maximizing Tool Life during Machining of Al Alloy SiC Particle Composites. J. Clean. Prod. 2013, 39, 242–254. [Google Scholar] [CrossRef]

- Davim, J.P.; Sreejith, P.S.; Silva, J. Some Studies about Machining of MMC’s by MQL(Minimum Quantity of Lubricant) Conditions. Adv. Compos. Lett. 2009, 18, 21–23. [Google Scholar] [CrossRef]

- James, S.; Annamalai, A. Machinability Study of Developed Composite AA6061-ZrO2 and Analysis of Influence of MQL. Metals 2018, 8, 472. [Google Scholar] [CrossRef]

- Kilickap, E. Effect of Cutting Environment and Heat Treatment on the Surface Roughness of Drilled Al/SiC MMC. Mater. Test. 2016, 58, 357–361. [Google Scholar] [CrossRef]

- Vishwas, C.J.; Gajanan, M.N.; Sachin, B.; Abhinaba, R.; Puneet, N.P.; Anjan, B.N.; Vinayak, N.K. Study on Surface Roughness in Minimum Quantity Lubrication Turning of Al-6082/SiC Metal Matrix Composites. AMM 2019, 895, 127–133. [Google Scholar] [CrossRef]

- Nandakumar, A.; Rajmohan, T.; Vijayabhaskar, S. Experimental Evaluation of the Lubrication Performance in MQL Grinding of Nano SiC Reinforced Al Matrix Composites. Silicon 2019, 11, 2987–2999. [Google Scholar] [CrossRef]

- Chakma, P.; Bhadra, D.; Dhar, N.R. Modeling and Optimization of the Control Parameters in Machining of Aluminum Metal Matrix Nanocomposite under CNT Induced Nanofluid. Mater. Today Proc. 2022, 54, 866–872. [Google Scholar] [CrossRef]

- Sujith, S.V.; Mulik, R.S. Surface Integrity and Flank Wear Response Under Pure Coconut Oil-Al2O3 Nano Minimum Quantity Lubrication Turning of Al-7079/7 wt.%-TiC In Situ Metal Matrix Composites. J. Tribol. 2021, 144, 051701. [Google Scholar] [CrossRef]

- Deiab, I.; Raza, S.W.; Pervaiz, S. Analysis of Lubrication Strategies for Sustainable Machining during Turning of Titanium Ti-6Al-4V Alloy. Procedia CIRP 2014, 17, 766–771. [Google Scholar] [CrossRef]

- Khan, A.M.; Gupta, M.K.; Hegab, H.; Jamil, M.; Mia, M.; He, N.; Song, Q.; Liu, Z.; Pruncu, C.I. Energy-Based Cost Integrated Modelling and Sustainability Assessment of Al-GnP Hybrid Nanofluid Assisted Turning of AISI52100 Steel. J. Clean. Prod. 2020, 257, 120502. [Google Scholar] [CrossRef]

- Ic, Y.T.; Saraloğlu Güler, E.; Cabbaroğlu, C.; Dilan Yüksel, E.; Maide Sağlam, H. Optimisation of Cutting Parameters for Minimizing Carbon Emission and Maximising Cutting Quality in Turning Process. Int. J. Prod. Res. 2018, 56, 4035–4055. [Google Scholar] [CrossRef]

- Yi, Q.; Li, C.; Tang, Y.; Chen, X. Multi-Objective Parameter Optimization of CNC Machining for Low Carbon Manufacturing. J. Clean. Prod. 2015, 95, 256–264. [Google Scholar] [CrossRef]

- Singh, G.; Aggarwal, V.; Singh, S.; Singh, B.; Sharma, S.; Singh, J.; Li, C.; Królczyk, G.; Kumar, A.; Eldin, S.M. Performance Investigations for Sustainability Assessment of Hastelloy C-276 under Different Machining Environments. Heliyon 2023, 9, e13933. [Google Scholar] [CrossRef]

- Padhan, S.; Dash, L.; Behera, S.K.; Das, S.R. Modeling and Optimization of Power Consumption for Economic Analysis, Energy-Saving Carbon Footprint Analysis, and Sustainability Assessment in Finish Hard Turning Under Graphene Nanoparticle–Assisted Minimum Quantity Lubrication. Process. Integr. Optim. Sustain. 2020, 4, 445–463. [Google Scholar] [CrossRef]

- Priarone, P.C.; Robiglio, M.; Settineri, L. On the Concurrent Optimization of Environmental and Economic Targets for Machining. J. Clean. Prod. 2018, 190, 630–644. [Google Scholar] [CrossRef]

| Researchers | Nanoparticles | Work Condition | Effect |

|---|---|---|---|

| Gu et al. [75] | Milling 235 steel | -water nano-lubricant processing. | |

| Cui et al. [76] | Tribological experiments on ceramic materials | forms a more uniform protective film in water, and the tribological performance is better. | |

| Liu et al. [77] | Graphene (GR) | Steel ball-–plate friction test | Compared with pure deionized water lubricant, the friction coefficient and wear rate were reduced by 54.6% and 45.0%, respectively, by adding GR. |

| Xie et al. [78] | /GR | Rolled magnesium alloy sheet | prevents assembly between GR layers. |

| Najiha et al. [79] | Milling AISI D2 tool steel | Nano-lubricant reduces workpiece adhesion and improves tool life. |

| Researchers | Nanoparticles/ Based Fluids | Processing Conditions | Effect |

|---|---|---|---|

| Agunsoye et al. [86] | /RHA | Turning Aluminum Alloy | Nano-cutting fluid contributed 92.96%, 88.59%, and 93.40% in reducing cutting force, flank wear, and improving surface finish. |

| Tong et al. [88] | /Palm oil | Milling | -palm oil nanofluid exhibited the best heat transfer and lubrication properties at a concentration of 1.0 vol% and a particle size of 20 nm. |

| Kumar et al. [89] | / Deionized water (DW) | Turning AISI D2 | , the cutting temperature is 9.7% lower, and Ra is 14.3% lower. |

| Hamid et al. [90] | /Soluble oil | Rotary drilling | -soluble oil nanofluid decreased the operational temperature of drilling procedure. |

| Edelbi et al. [91] | /LRT-30 oil | Milling of Ti-3Al-2.5V | nanofluids, the cutting temperature and surface roughness of ZnO nanofluid are 1% and 2% lower, respectively. |

| Huang et al. [92] | MWCNTs/Cutting oil | Milling AISI P21 and 1050 | MWCNTs significantly reduce the cutting temperature. 9% improvement in surface roughness. |

| Zhang et al. [93] | SiC/Rapeseed oil | Turning 40Cr | NMQL reduces wear by 55.1%, cutting temperature by 41.5% and surface roughness by 19.2%. |

| Type | Nanofluids | Shape |

|---|---|---|

| Metal oxide nanoparticles | spherical | |

| spherical | ||

| spherical | ||

| threadiness | ||

| threadiness | ||

| threadiness | ||

| threadiness | ||

| stratiform | ||

| Non-metallic nanoparticles | SiC | spherical |

| ND | spherical | |

| CNTs | threadiness | |

| GR | stratiform | |

| HBN | stratiform | |

| stratiform |

| Process Method | Advantage | Shortcoming |

|---|---|---|

| One-step method | Less agglomeration, high stability | —— |

| No storage, drying steps required | Excessive deposition of residual reactants | |

| No oxidize | For low-vapor-pressure base fluids only | |

| No redistributable requirements | Cannot be mass-produced | |

| No transport required | —— | |

| Two-step method | Easy and cheap to make | Rapid condensation/Rapid settling |

| —— | Requires surfactant or functionalization treatment | |

| Suitable for oxide nanoparticles | High surface energy, increased self-weight |

| Classification | Surfactant | |

|---|---|---|

| An ionic surfactant | Sodium dodecyl sulfate | SDS |

| Sodium dodecylbenzene sulphonate | SDBS | |

| Ammonium lauryl sulfate | ALS | |

| Potassium lauryl sulfate | PLS | |

| Cationic surfactant | Cetrimonium chloride | CTAC |

| Cetyl trimethyl ammonium bromide | CTAB | |

| Non-ionic surfactant | Tween-20 | |

| Tween-80 | ||

| Span-80 | ||

| Polyvinyl pyrrolidone | PVP | |

| Triton X-100 | ||

| Oleyl amine | ||

| Amphoteric surfactant | Lecithin | |

| Hydroxysultaine |

| Researchers | Nanofluids | Variable | Effect |

|---|---|---|---|

| Aberoumand et al. [85] | - glycerol | Concentration | As the concentration increases, the thermal conductivity first increases and then decreases, and there is an optimal concentration that maximizes the thermal conductivity. |

| Seyhan et al. [124] | Ag- water/EG/ n-ethane | Surfactant, base fluid | The gum arabic surfactant did not affect the thermal conductivity of ethylene glycol and ethane, but decreased the thermal conductivity of water-based nanofluids. |

| Agarwal et al. [129] | - water/EG | Base fluid | The thermal conductivity of water is higher than that of ethylene glycol, and the nanofluid prepared from water has a higher thermal conductivity. |

| Alirezaie et al. [132] | MgO/Fe | Particle size | Both nanofluids exhibit the highest thermal conductivity at the smallest particle size. |

| Choi et al. [133] | -water | Particle size | The three particle sizes were 150 nm, 47 nm and 11 nm, and it was concluded that the increase in particle size decreased the thermal conductivity. |

| Mahbubul et al. [135] | -R14a | Temperature | As the temperature increases, the thermal conductivity increases. |

| Huminic et al. [138] | FeC-water | Surfactant | The addition of surfactants did not have a large effect on the thermal conductivity. |

| Researchers | Nanofluids | Variable | Effect |

|---|---|---|---|

| Bindu et al. [142] | -ZnO-MWCNT-EG | Temperature | The viscosity at 70 °C was only approximately half of that at 40 °C, highlighting a substantial downward trend. |

| Minakov et al. [152] | More than 30 kinds | Particle size | Viscosity increases as nanoparticle size decreases. |

| Hu et al. [153] | /ZnO | Particle size | As the particle size decreases, the viscosity also decreases. |

| Ferrouillat et al. [154] | /ZnO | Particle shape | The impact of particle shape and size on nanofluid viscosity presents conflicting influences. |

| Jabbari et al. [156] | SWCNT-water | Temperature | As the nanofluid’s temperature decreased, its viscosity increased. |

| lyahraja et al. [157] | Ag nanofluid | Temperature | Temperature and viscosity have a non-linear positive correlation. |

| Researchers | Nano-Cutting Fluid | Characterization Parameters | Effect |

|---|---|---|---|

| Rapeti et al. [173] | NPI-coconut oil | Flank wear | The contributions of base fluid and nanoparticles to reducing flank wear are 46.6% and 26.18%, respectively. |