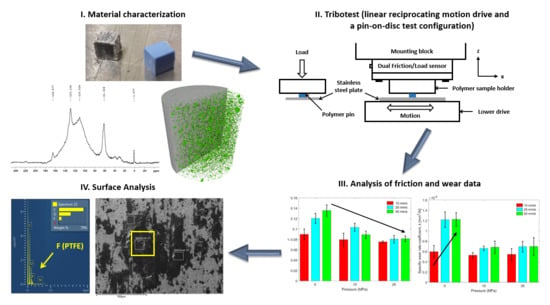

In the following section, results from material characterization, tribological characterization and surface analysis are presented and discussed. Thorough material characterization of the bearing materials has been conducted in order to study the microstructure and the composition of the materials. Tribological characterization has been carried out in order to investigate the influence of sliding speed and pressure on the friction and wear behavior of the bearing materials. In order to investigate and explain the tribological behavior, surface analysis of the polymer pins and the wear tracks formed on the counter surface during the sliding tests have been performed.

3.3. Surface Analysis

In order to investigate the observed decrease of COF with increased pressure as well as increase of specific wear rate coefficient at higher sliding speed, counter surfaces from tests performed with three different operating conditions were selected for further surface analysis based on findings from the tribological characterization. The selected operating conditions for both bearing materials were 9 MPa at 10 mm/s, 9 MPa at 40 mm/s and 28 MPa at 40 mm/s.

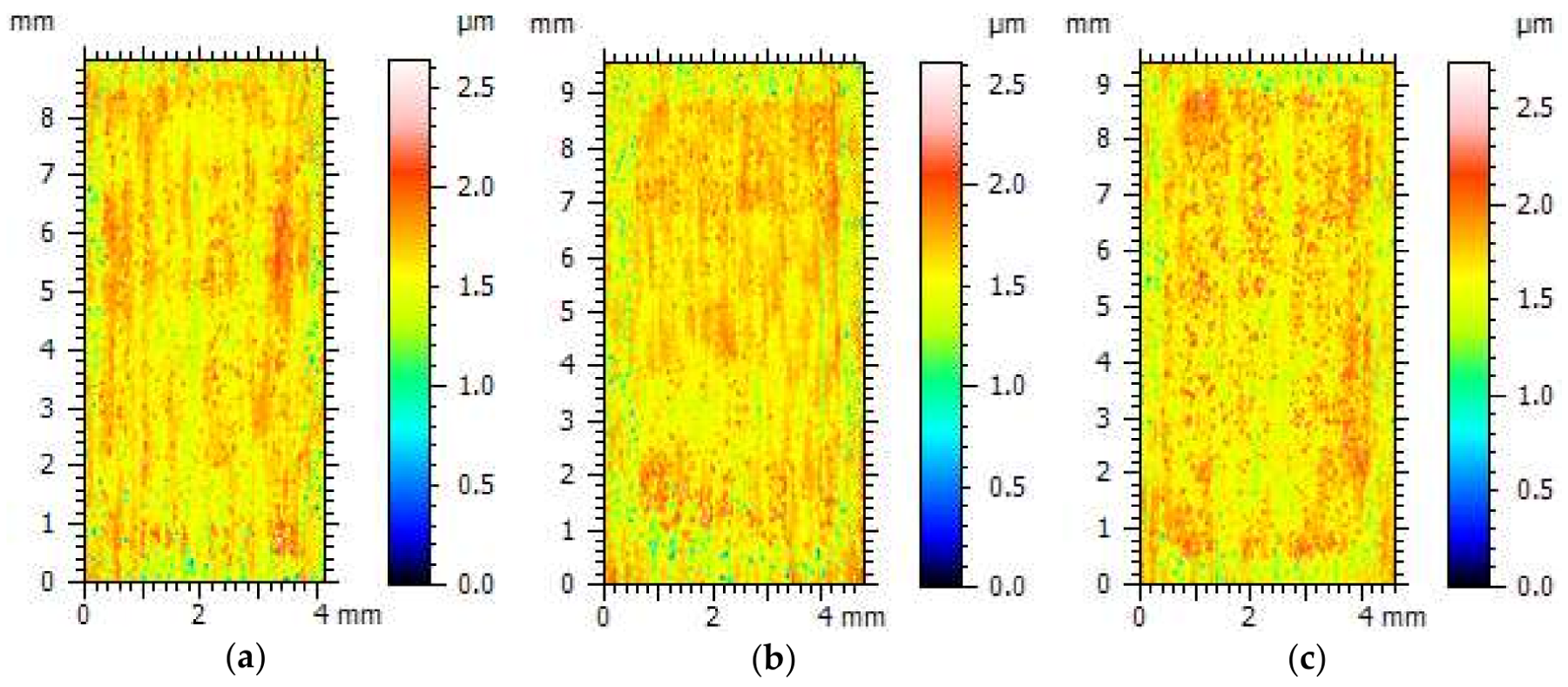

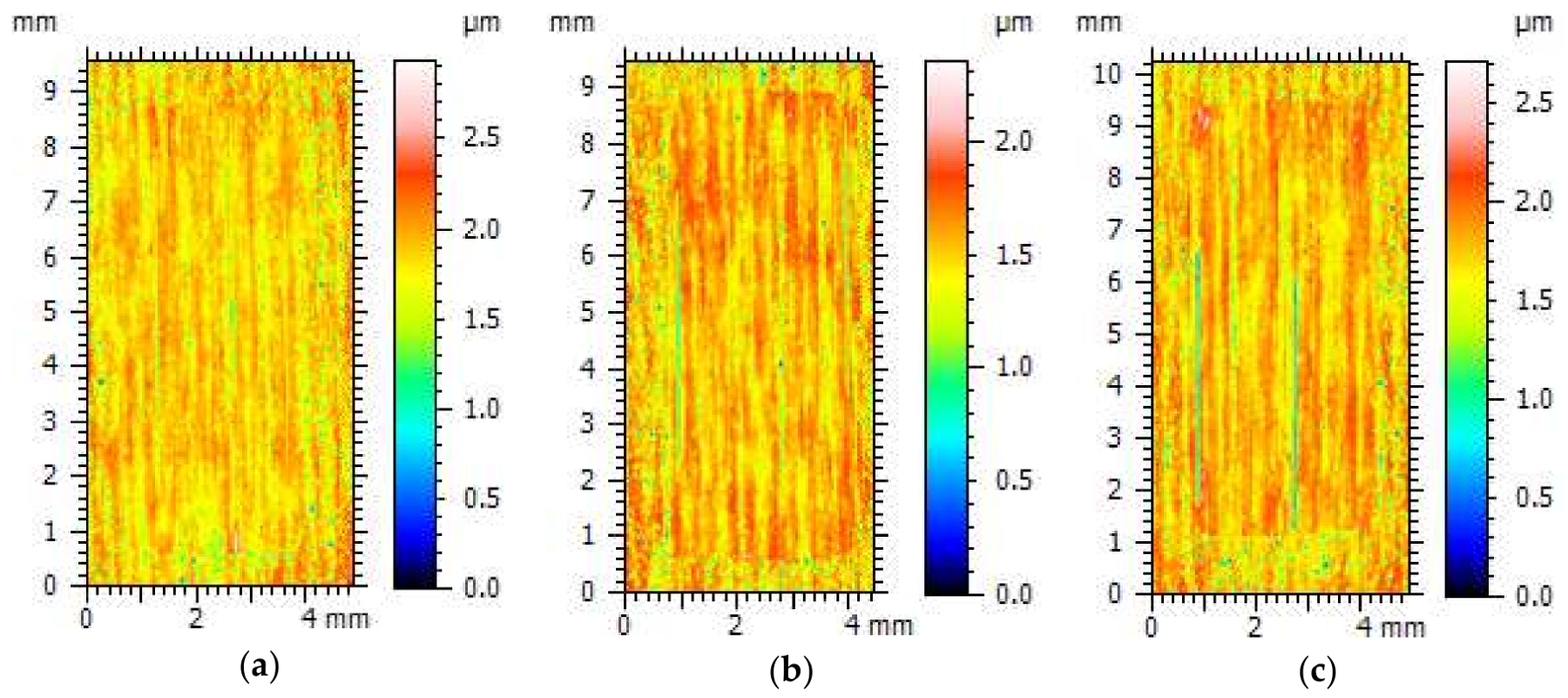

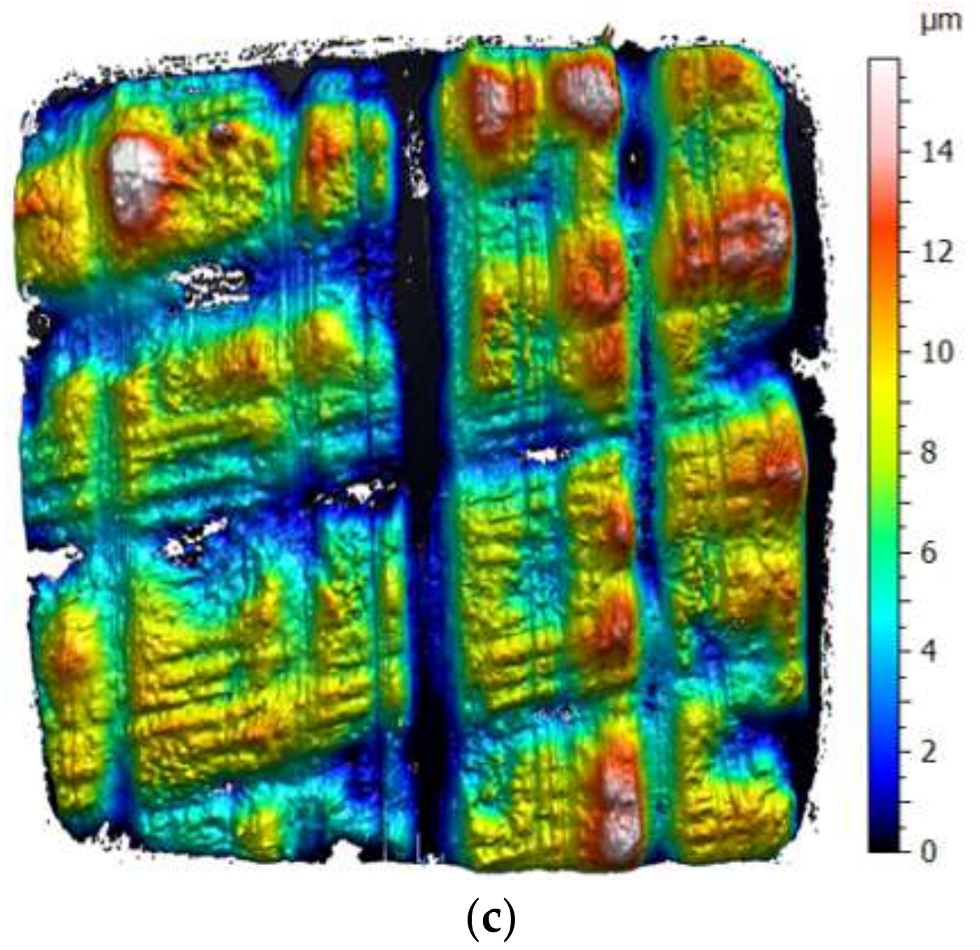

Surface topography of the wear tracks formed on the stainless steel counter surfaces during sliding tests, as measured by optical interferometer (Zygo), are presented in

Figure 13 for ThorPlas and

Figure 14 for Orkot. It should be noted that, as polymers are partially reflective materials, the measurements on transferred layers occasionally introduces artifacts manifested as spikes in the surface roughness measurements. These spikes have been filtered out using a threshold operator in order to truncate the peaks that mask other findings. As these artifacts may induce an error in calculation of the transferred material volume, no further quantitative analysis of the transferred layers has been performed.

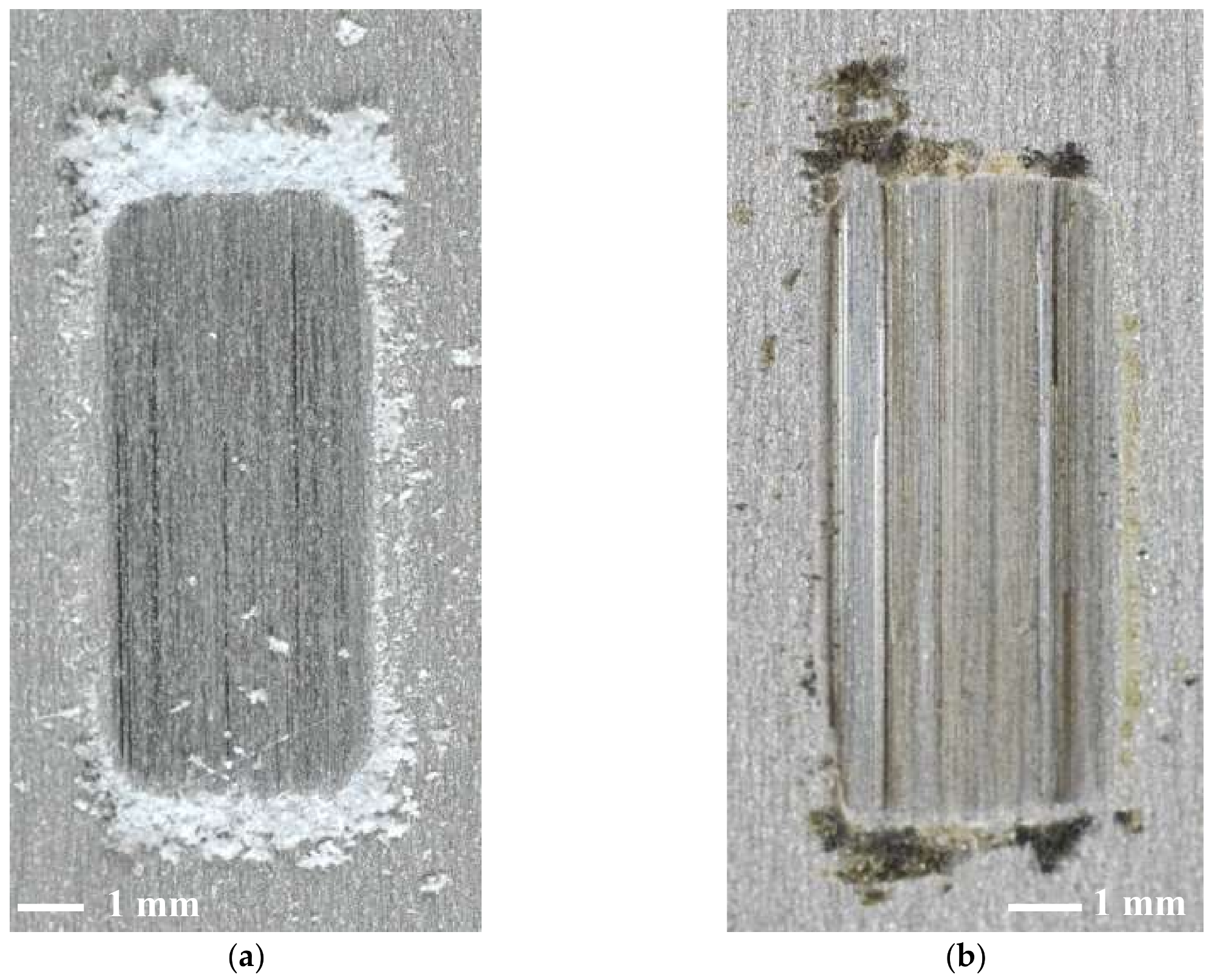

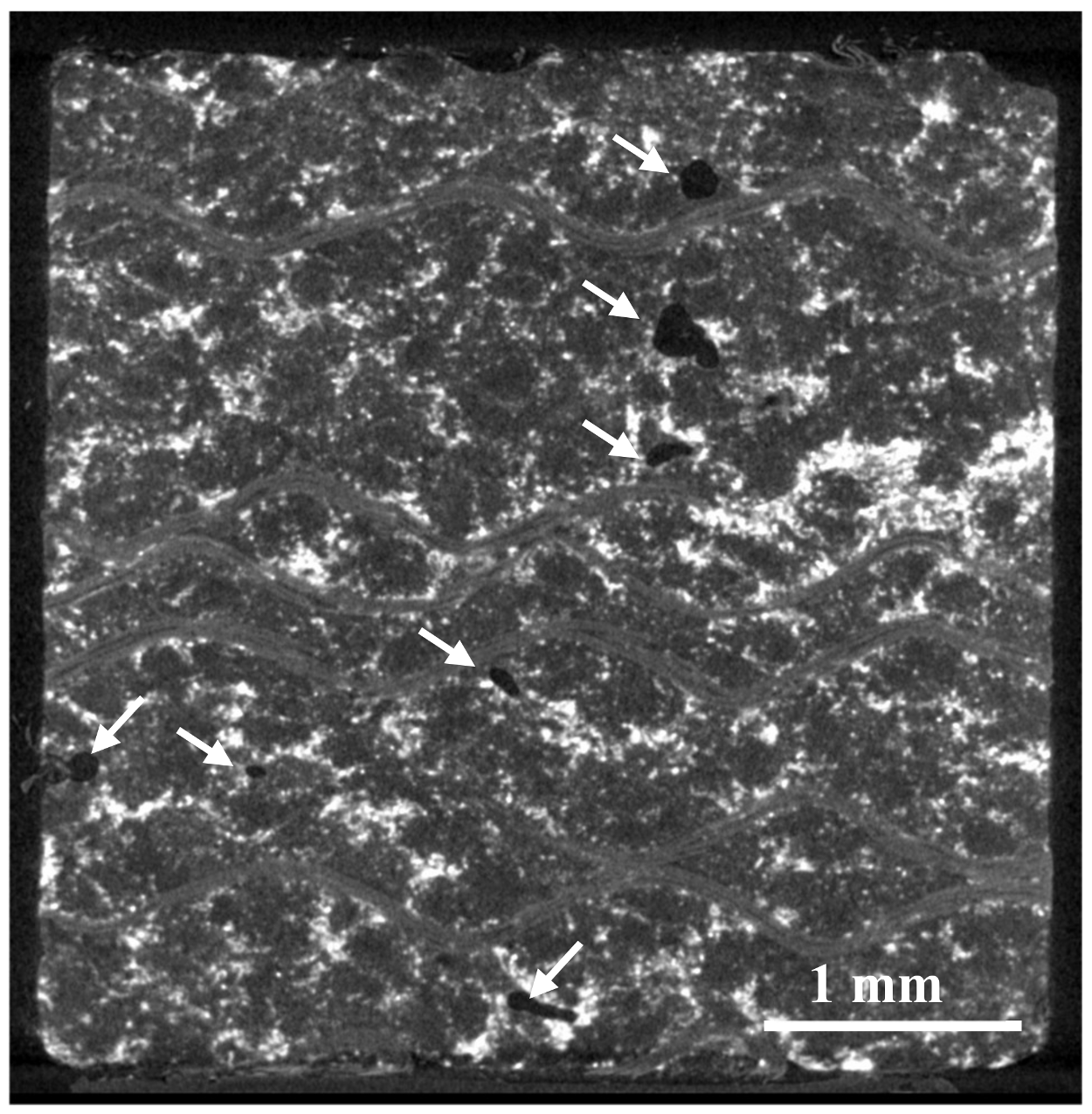

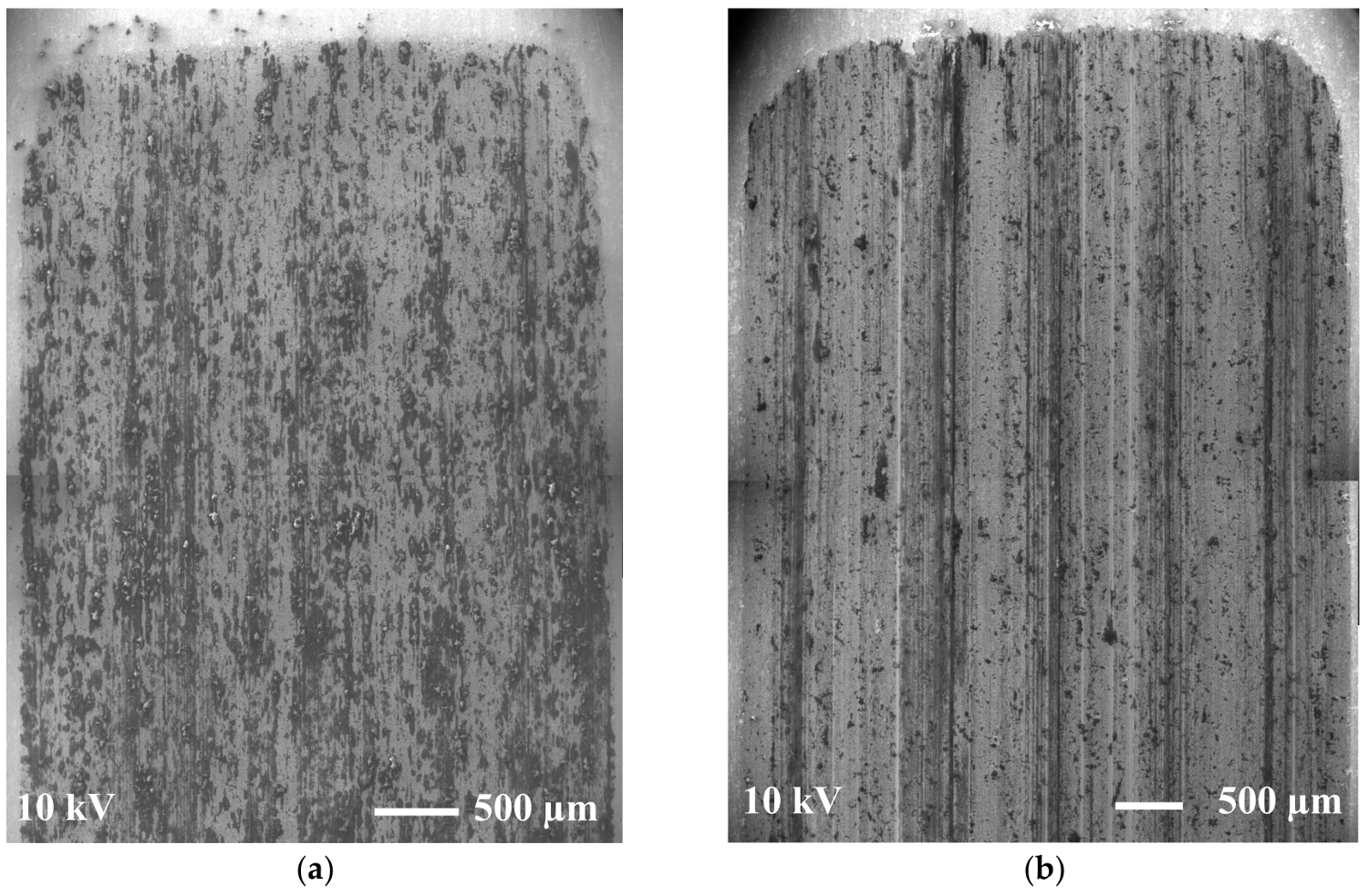

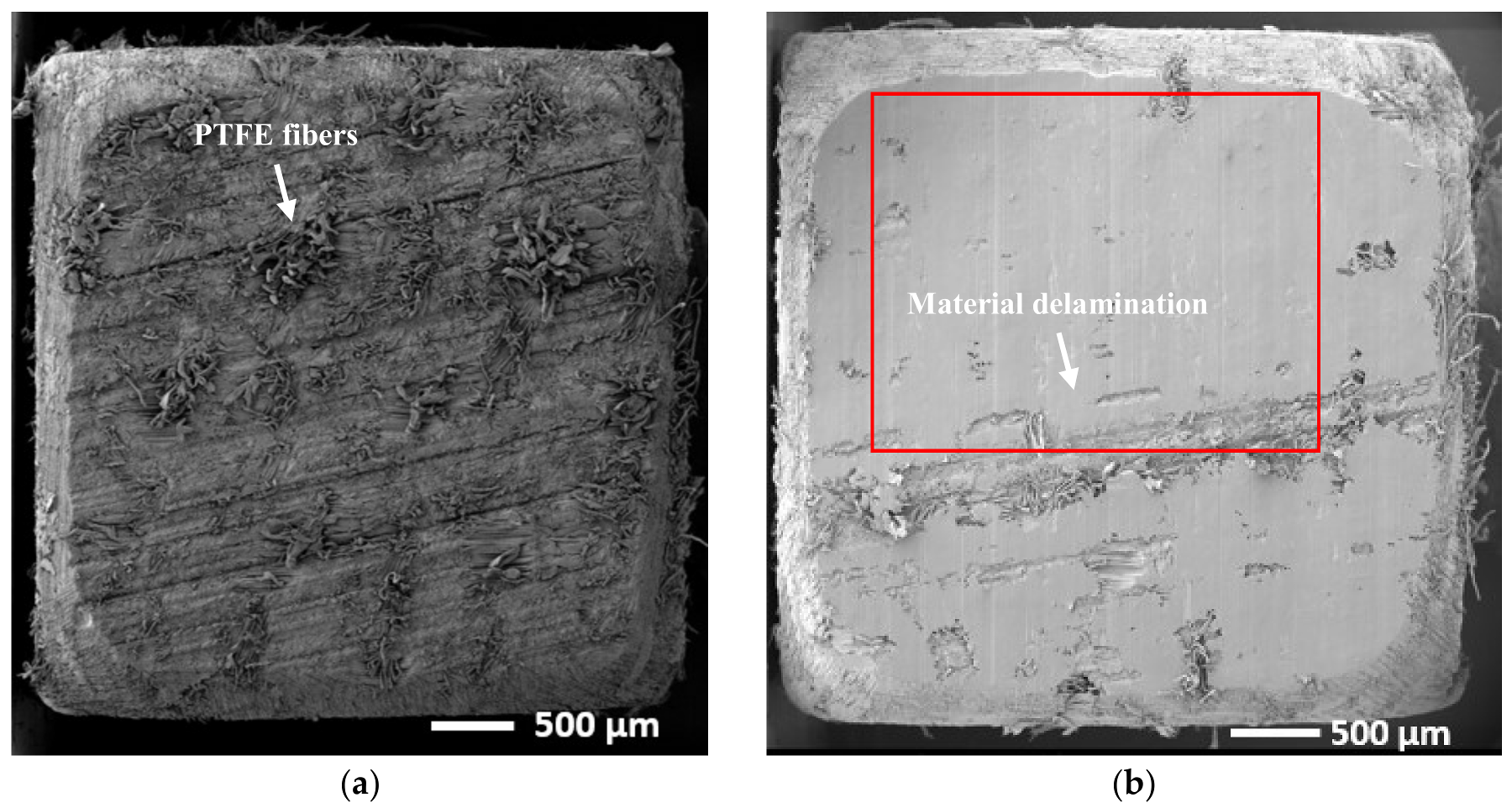

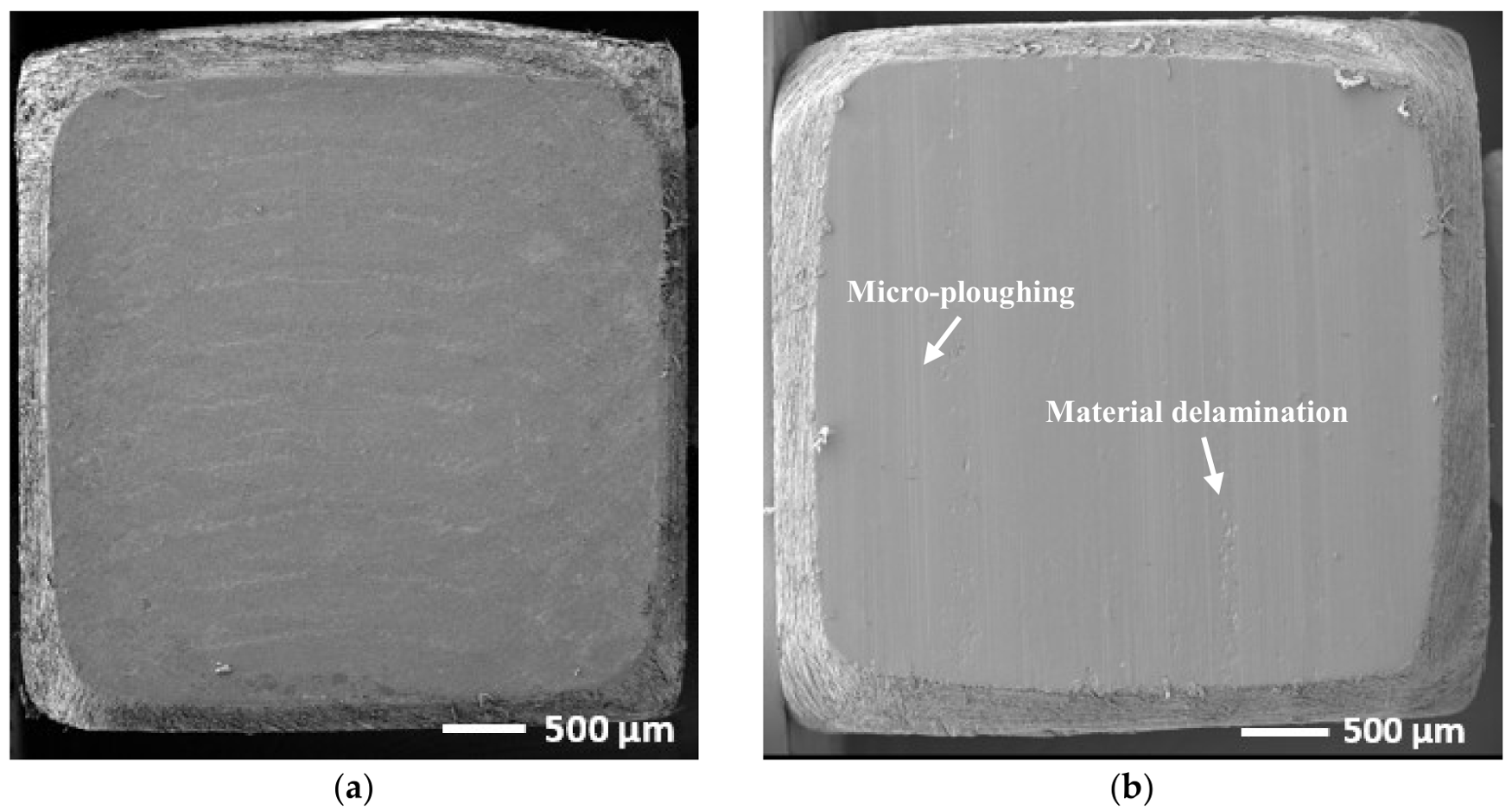

Stitched SEM micrographs of the wear tracks are shown in

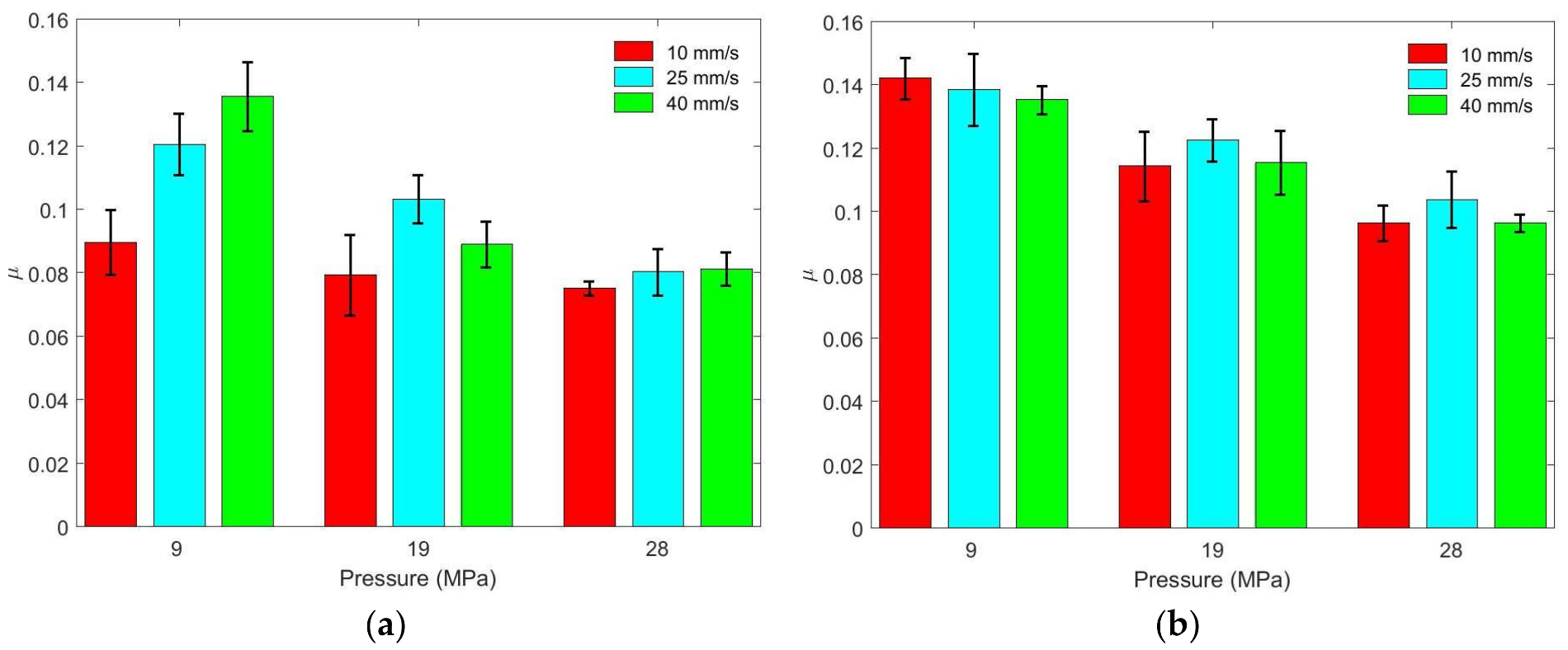

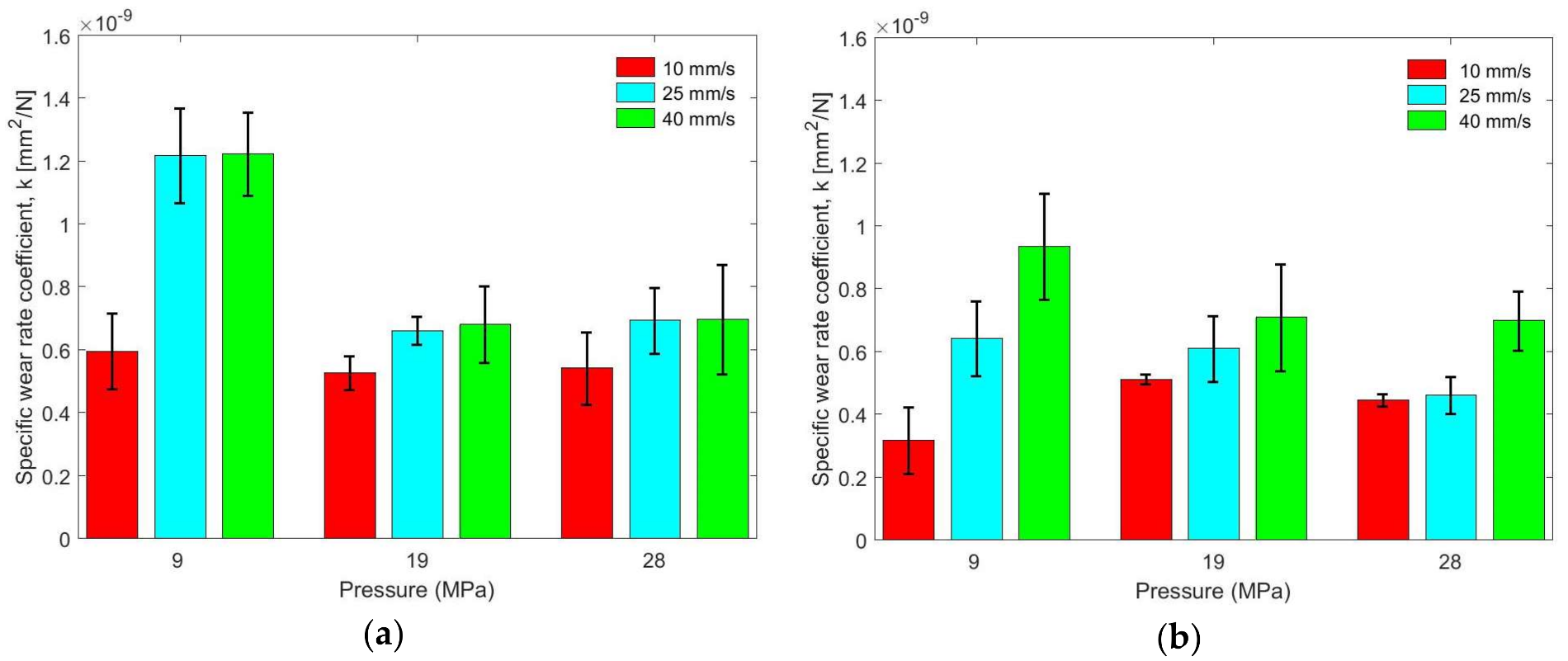

Figure 15. The darker areas in the images correspond to the transferred polymer layers. It can be seen that less material transfer occurs for tests performed with Orkot than with ThorPlas. This finding is consistent with the lower specific wear rate coefficients observed for Orkot during the tribological characterization (

Figure 12). In addition, a lower amount of deposited material in the transfer layer can explain the overall higher COF for tests performed with Orkot material (see

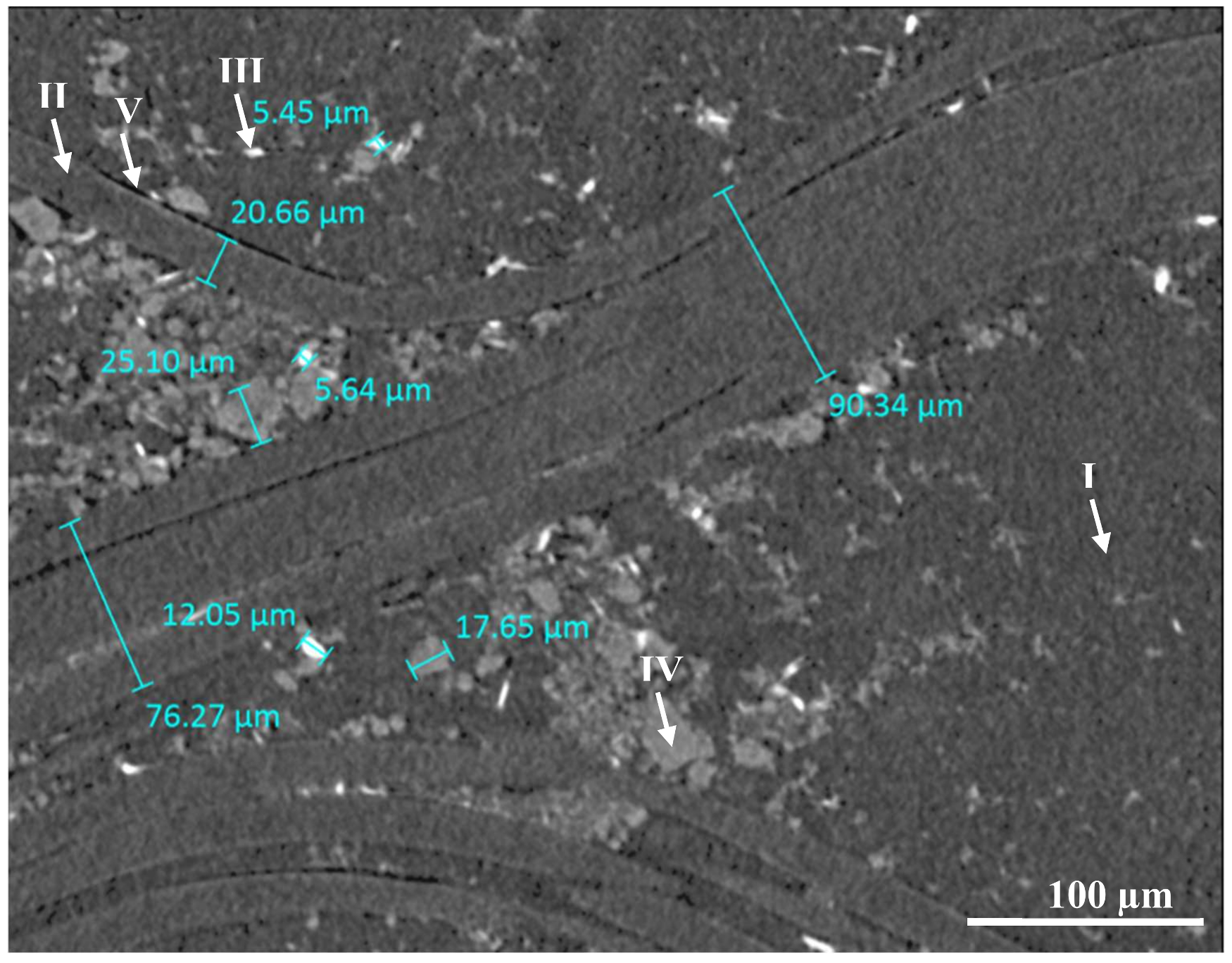

Figure 11). Furthermore, the surface topography reveals deep groves in the wear tracks formed during sliding tests with Orkot material, indicating that the counter surface are subjected to an extensive abrasive wear, contributing to a higher COF. It can be seen that the grooves grow deeper when the sliding speed and pressure are increased. These groves are believed to be caused by polyester fibers used as reinforcement (warp) in the material. Comparing SEM micrographs of the wear tracks (

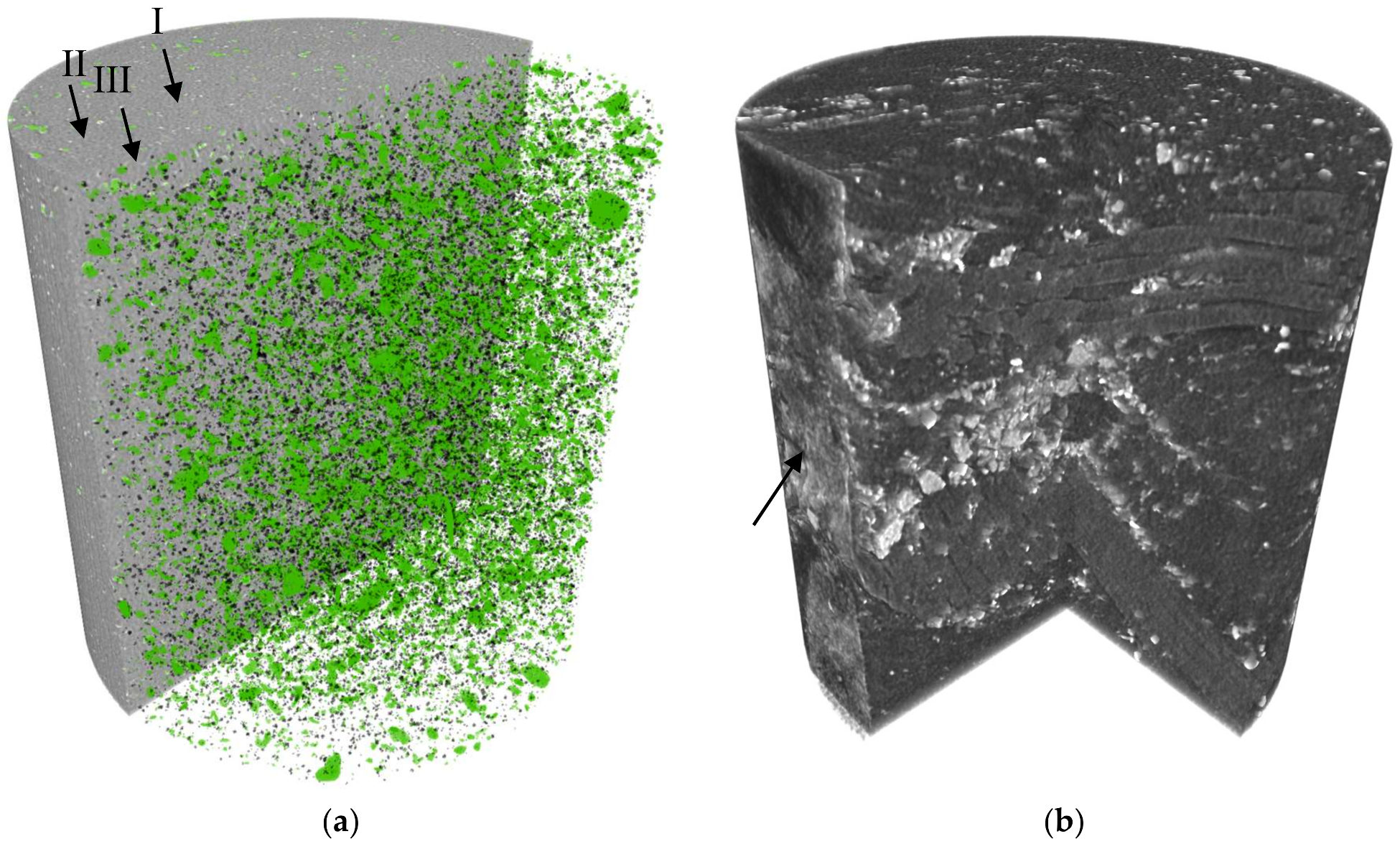

Figure 15) at higher magnifications with the tomographic reconstruction of Orkot (

Figure 6), it can be observed that the width of the groves is consistent with the width of the fibers.

From surface topography (

Figure 13 and

Figure 14) and SEM micrographs (

Figure 15) of the wear tracks, it can be seen that the transferred layers are less prominent for operating conditions characterized by low sliding speed and low nominal pressure. Comparing wear tracks for the two different pressures (9 and 28 MPa) at the same sliding speed (40 mm/s), it appears that more polymer material is transferred to the stainless steel at the lower pressure. Moreover, the transferred layers are more uniformly distributed than under other operating conditions, where more uneven, lumpy deposition can be seen. Therefore, it is unclear why the higher pressure gives rise to a lower COF.

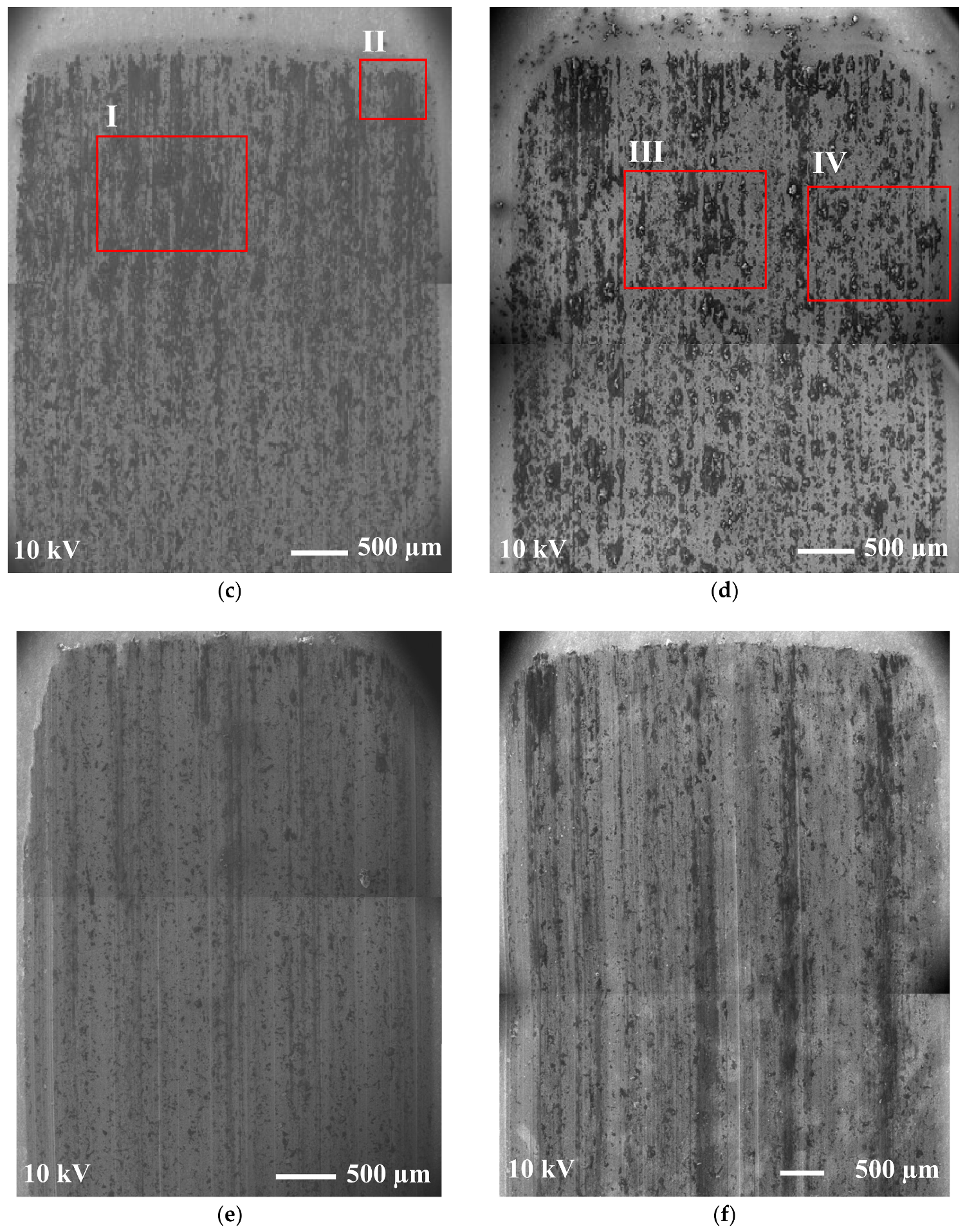

In order to study this behavior further, EDS analysis of the transferred layers was performed in several locations for each wear track. Four of the selected ROIs for ThorPlas are marked in

Figure 15. The corresponding SEM micrographs at higher magnifications for the ROI are presented in

Figure 16. For each area, EDS spectra are presented for two locations providing typical elemental content in the region. In

Table 6, obtained EDS spectra are presented for areas corresponding to the lower pressure and in

Table 7 to the higher pressure.

Comparing the elemental content for the two pressures, it can be observed that the transferred layers formed at the higher pressure contain higher amounts of the solid lubricants elements (fluorine and silicon) aiding lower COF. It should be mentioned that some locations for the wear tracks contained as much as 14.4 wt % fluorine and 3.8 wt % silicon. Similar findings were observed while studying the transferred layers deposited in tests performed with Orkot, indicating that, at higher pressures, solid lubricants were squeezed from the bulk of polymer at greater rates, depositing on the counter surface and contributing to lower friction observed. The mechanism bears similarities with a wet sponge: the harder it squeezed, the more water gets out.

This effect may also explain the wear increase caused by insufficient lubrication at higher sliding speeds and lower pressures.

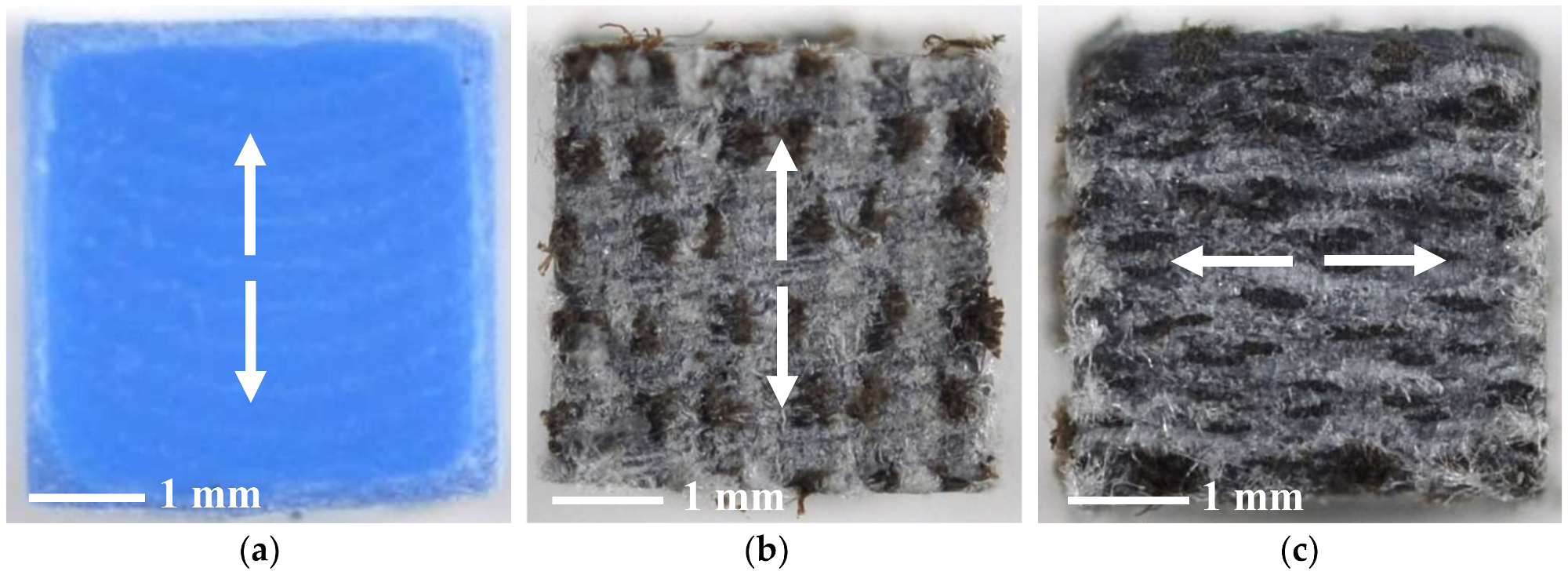

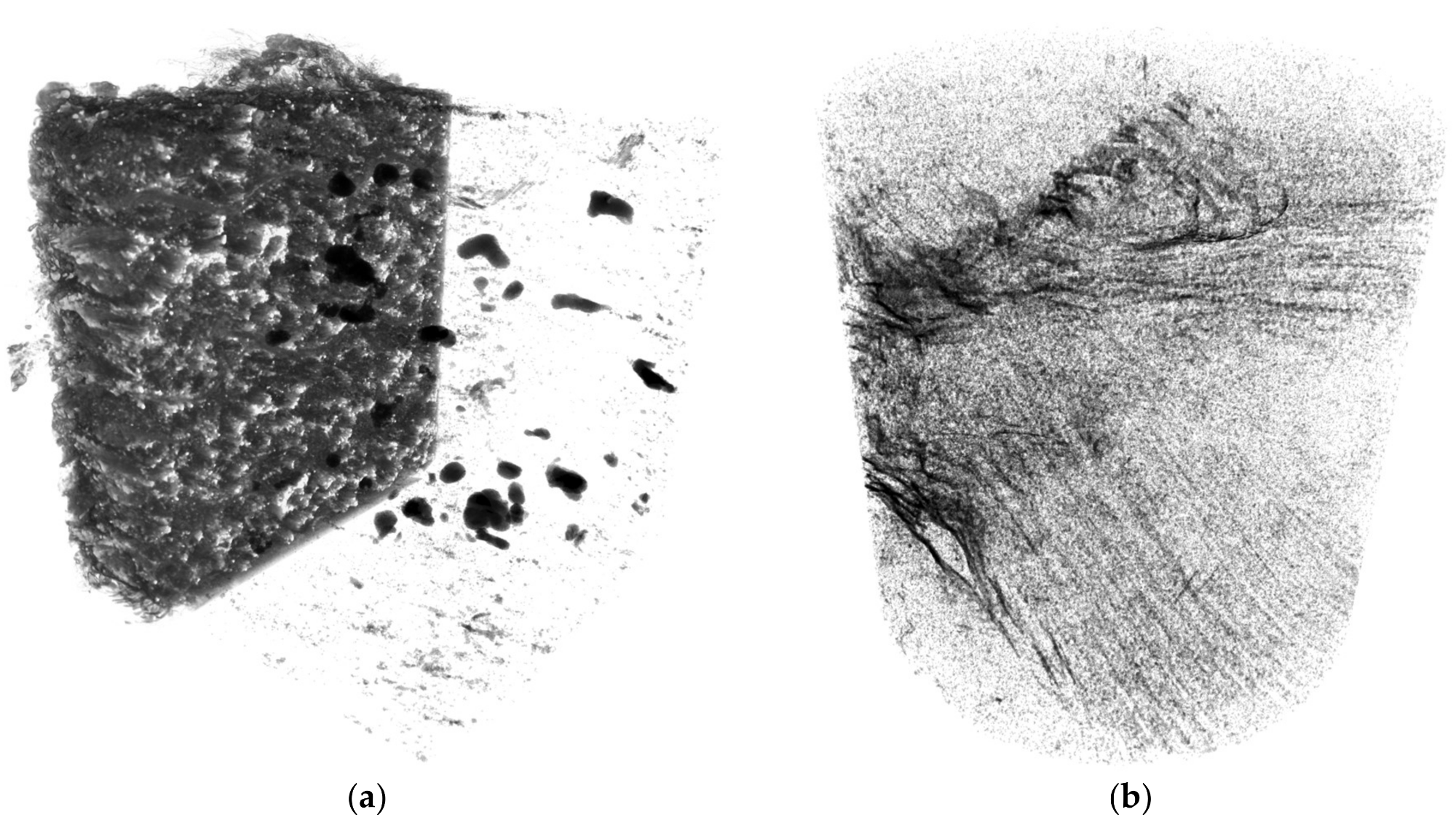

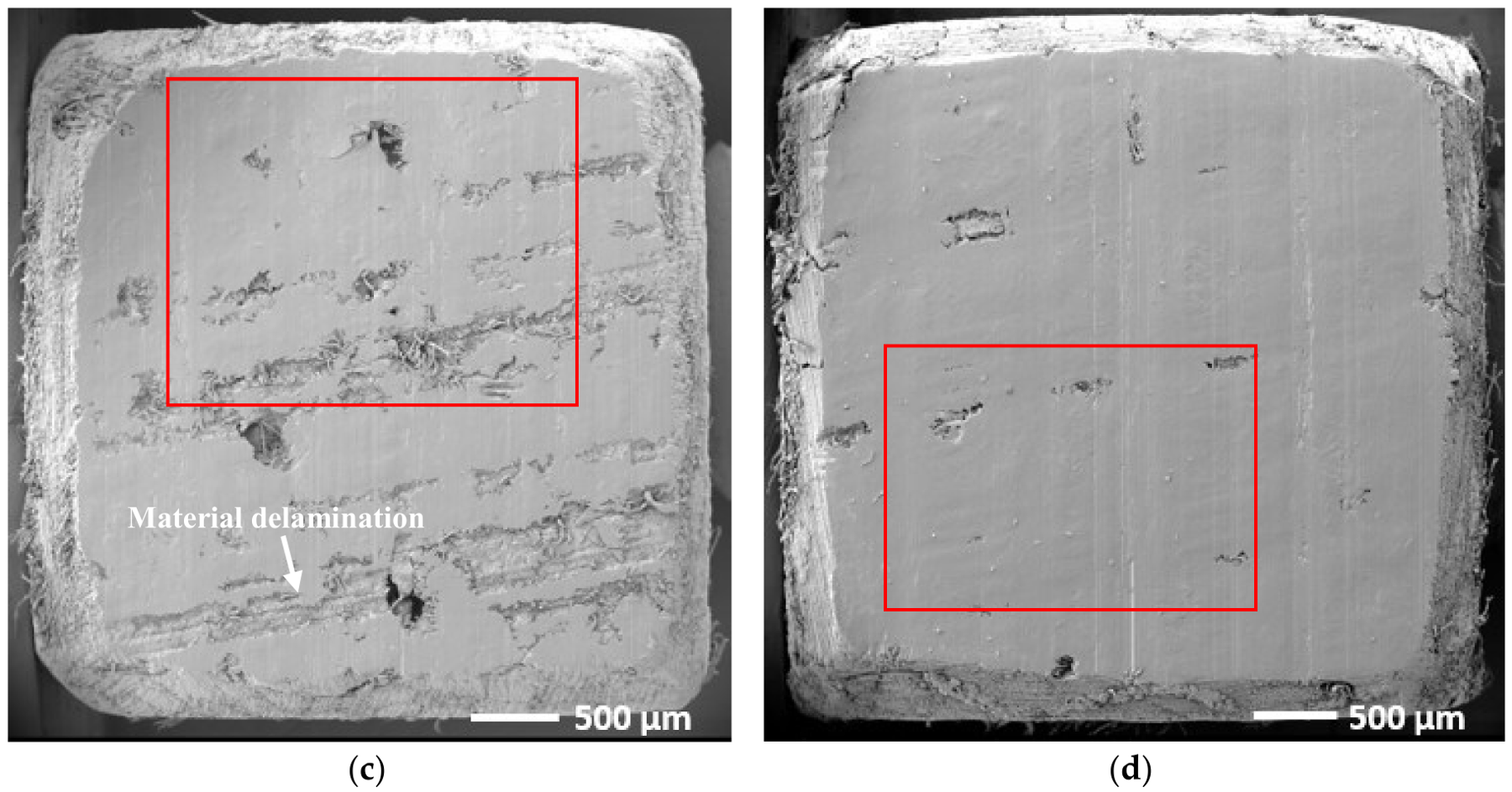

Surface analyses were also performed on the worn polymer pins that have caused the wear tracks on the counter surface shown in

Figure 15. Surface topography of worn Orkot polymer pins, after sputtering, is presented in

Figure 17 with the higher areas reflecting the PTFE weft. The corresponding SEM micrographs are presented in

Figure 18. In addition, a SEM micrograph of an unworn surface is shown in

Figure 18a, where the PTFE fibers (weft) protruding the surface can be clearly seen. Several attempts were made to measure surface topography of the unworn surface. However, because of the nature of the material, too much of the light was scattered. Moreover, regions of the worn polymer surfaces subjected to larger losses of material of the deposited material resulted in missing data points for the surface topography measurements seen as white areas in

Figure 17.

Surface topography and SEM micrographs of the polymer pins show that less material wear occurs at higher contact pressure. At low pressures, a higher rate of material delamination from the surface can be observed. Comparing pin surfaces worn at the two different sliding speeds (10 at 40 mm/s) and the same nominal pressure (9 MPa), it appears that the wear is more severe at the higher sliding speed, with significant losses of material observed from wider areas. Moreover, deeper valleys between the PTFE weft are formed at higher sliding speed, confirming higher wear of the warp. This is consistent with the higher specific wear rate coefficient observed for higher sliding speeds, as shown in

Figure 12.

An explanation for the higher wear of the polymer pins at low pressure is the poorer lubrication between the pin and the material deposited on the stainless steel counter surface (transferred layers formed on the wear track,

Table 6). Higher sliding speed leads to higher temperature in the contact zone, making the pin material softer and easier to shear. This causes more wear at low pressures when the lubrication is insufficient.

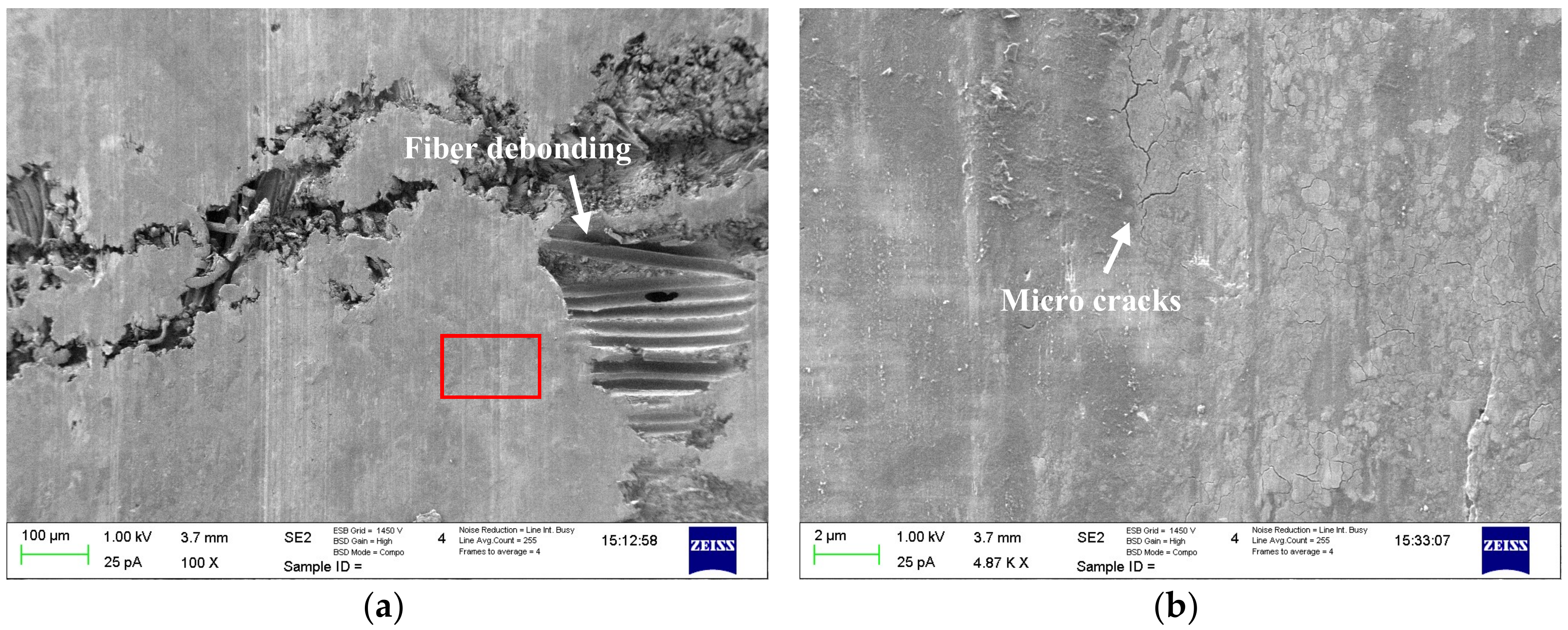

Studying the material delamination, clear traces of fiber debonding from the polymer matrix can be observed, as illustrated in

Figure 19. Furthermore, micro cracks can form on the surface, potentially causing delamination of material and exposure of unprotected fibers that can be peeled off by shear during the sliding motion.

A following explanation for the material delamination can be proposed: PTFE requires a certain amount of energy to be released from the fiber and deposited on the running faces to form a low shear layer. A micro-scale stiffness variances of the matrix components (various E-moduli and some porosity/voids that can be seen in

Figure 6 and

Figure 8) can cause the deposited PTFE to shear or break off at certain areas. Because of these variations, there might be vibration of different amplitudes that could aid with detaching of the deposited material.

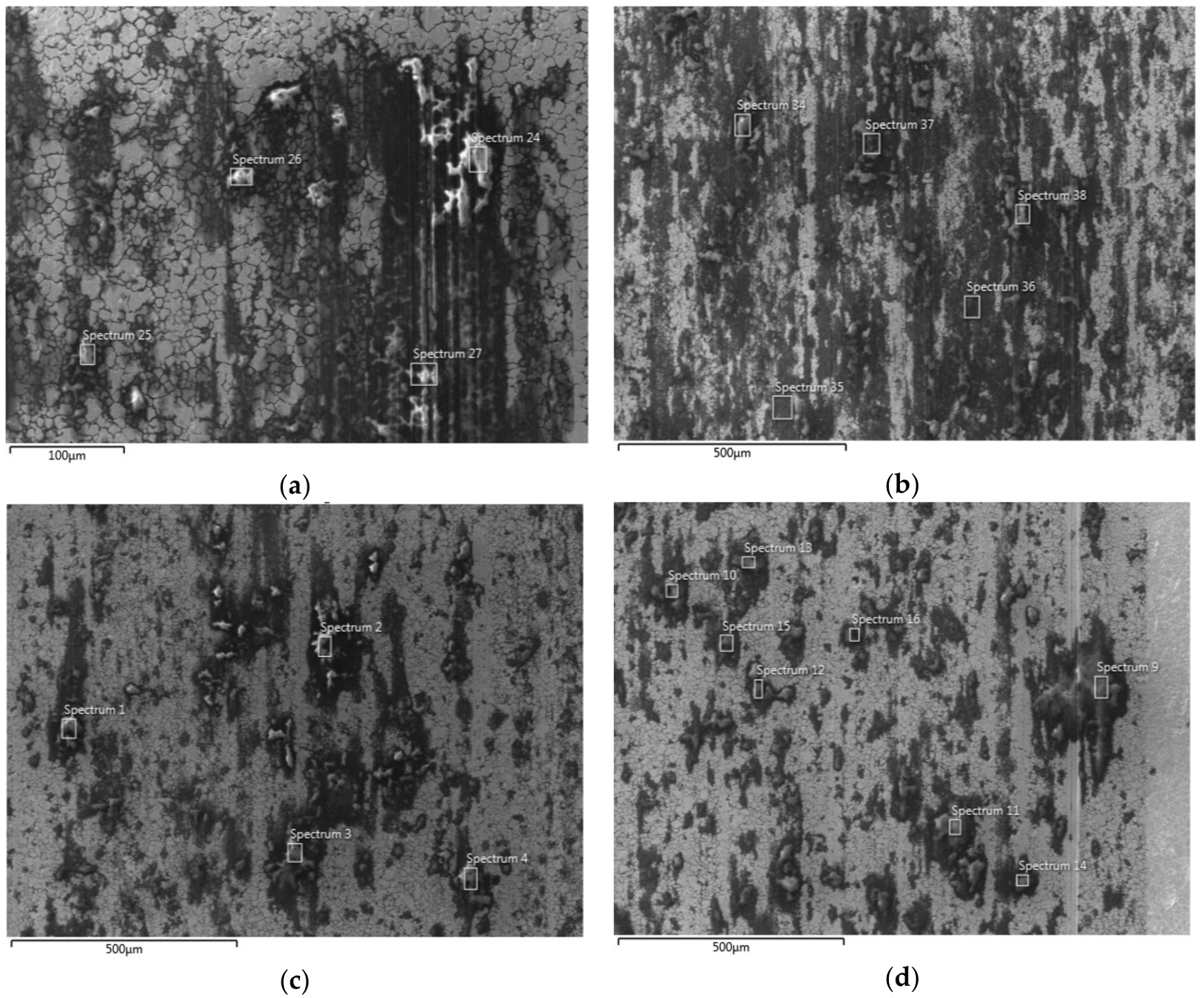

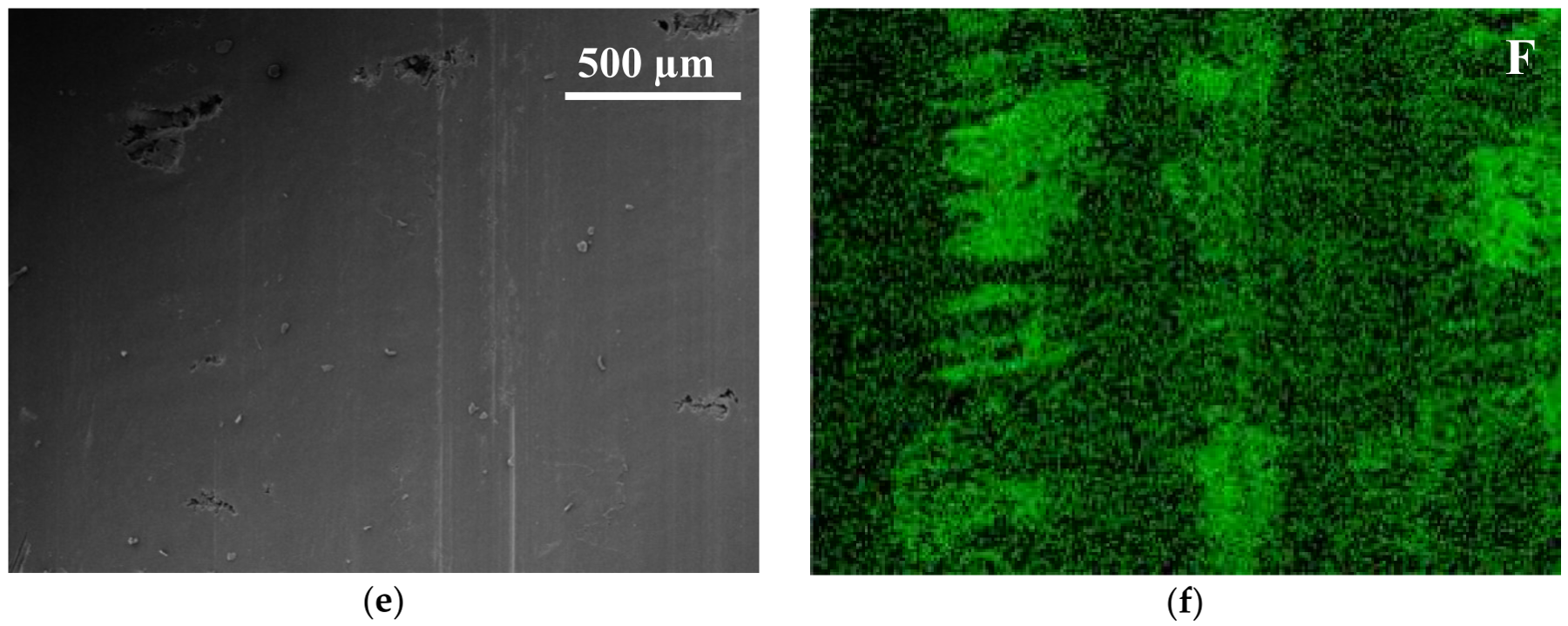

Additional surface analysis on the polymer pins was performed by EDS compositional mapping of the regions marked in

Figure 18. SEM micrographs of the ROI at higher magnifications and corresponding compositional maps of fluorine are presented in

Figure 20. The EDS spectra of the compositional maps are shown in

Table 8. Comparing the elemental content for the different operating conditions, higher fluorine concentrations can be observed for the sliding experiments done at higher pressure. Moreover, from the compositional maps for the same conditions it appears that the fluorine is smeared out in the sliding direction, contributing to better lubrication (as the solid lubricant cover a larger area) and thus to less wear of the surface. This may explain the lower COF observed at higher pressures (

Figure 11) and less polymer wear (

Figure 17).

Surface analysis was also performed on the worn and an unworn ThorPlas polymer pins that have caused the wear tracks on counter surface shown in

Figure 15. Surface topography of ThorPlas polymer pins, after sputtering, are presented in

Figure 21 and the corresponding SEM micrographs are shown in

Figure 22. Surface topography of the unworn surface (

Figure 21a) shows traces from manufacturing (milling) of the polymer pin. These traces can also be observed in the image of the polymer pin presented in

Figure 1a. Surface topography of the worn polymer pins shows no such traces and it can be concluded that the milling rests were removed during the sliding test.

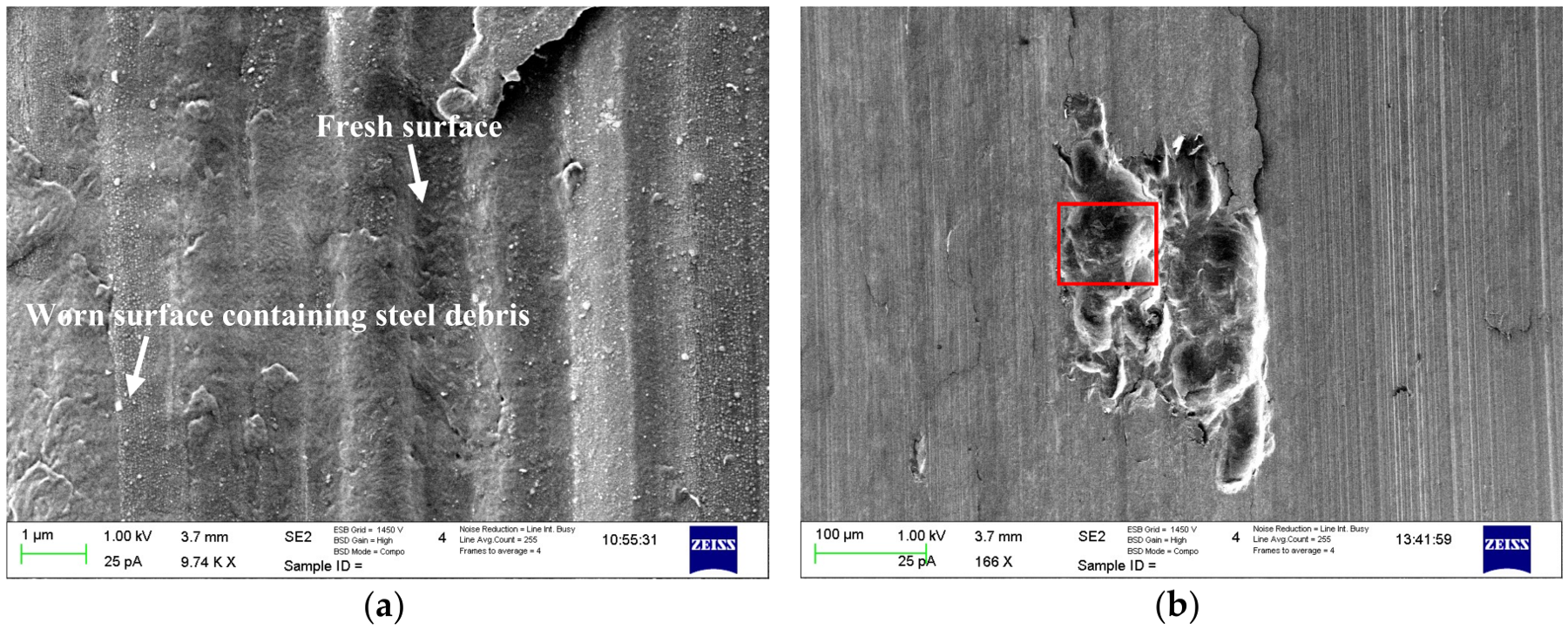

For low sliding speed and low nominal pressure (10 mm/s and 9 MPa,

Figure 21b), two broad valleys are formed in the surface topography, indicating that these regions experienced higher wear than the rest of the surface. Furthermore, on the sides of these valleys, higher peaks are seen indicating accumulation of adhered material on the surface. It appears as if a part of the removed material excavated from the valleys has been ploughing up to the sides and adhered to the surrounding regions. Such formation can be seen even better in

Figure 23a, showing the surface of an unsputtered polymer pin at higher magnification. In the SEM micrograph, traces of micro-ploughing are clearly visible alongside with fresh (unaffected) polymer surface and worn (exposed) surface containing nano-particles of steel debris. Thus, the surface is subjected to an on-going evolution process during the reciprocating sliding, where the part of worn surface is removed due to micro-ploughing and new fresh surface forms.

At the same nominal pressure (9 MPa), higher sliding speed (40 mm/s) results in more homogeneous surface wear, except for smaller regions in the middle, which are subjected to more severe wear (

Figure 21c). It seems that the material becomes softer when the sliding speed and hence temperature in the contact is increased, resulting in a smaller area for the fresh material to re-deposit. Furthermore, close scrutiny of surface topography reveals that, along the abrasive wear tracks formed in the sliding direction, the dominant wear mechanism is adhesive wear in the small contacts. All these mechanisms together contribute to a higher COF and specific wear rate coefficient than observed at lower sliding speed.

The surface in the experiment with the same sliding speed but under higher nominal pressure (28 MPa at 40 mm/s) has been subjected to less wear than under other operating conditions tested (

Figure 21d). A deeper valley has formed in the central region, reflecting significantly higher wear than the rest of the surface. Higher peaks can be seen in the regions surrounding the valley, made of the material removed from the valley and re-deposited in these regions during the reciprocating sliding. Less wear of the surface is consistent with the higher concentration of the solid lubricants measured in the transferred layers (

Table 7), providing a lower COF and less shear of the polymer, i.e., smaller specific wear rate coefficient, observed in the tribological characterization (

Figure 11 and

Figure 12, respectively).

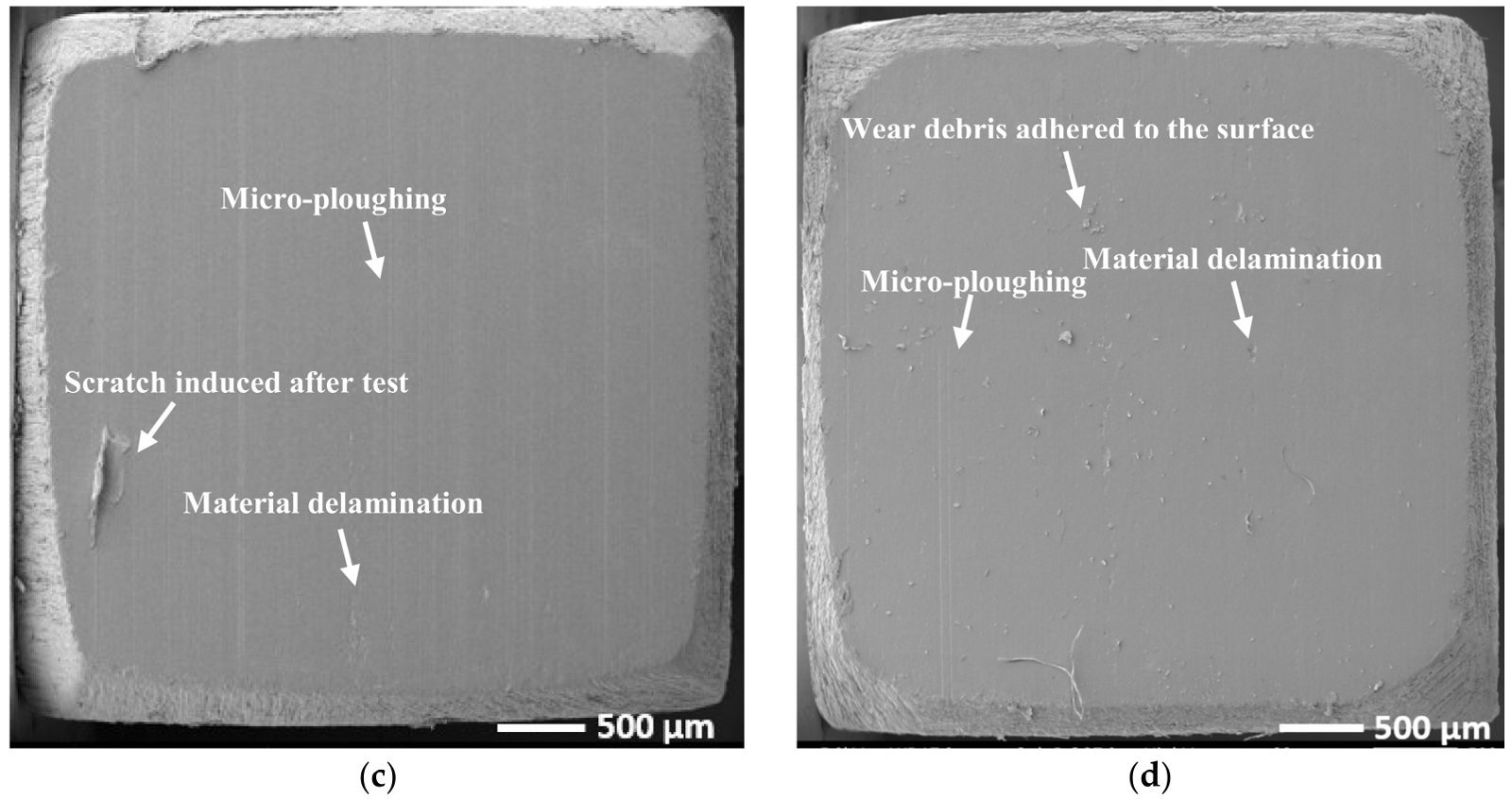

Worn polymer pin surfaces show traces of micro-ploughing and material delamination, visible in SEM micrographs (

Figure 22). It appears that these effects are less prominent for the higher pressure operating condition.

Figure 23b shows an example of a surface region subjected to material delamination, revealing a fresh polymer surface. At higher magnification, it can be seen that the polymer matrix contains two distinct phases (

Figure 24a). The lighter grey phase is consistent with the spherically shaped particles seen in the 3D visualization of material microstructure, from XMT reconstruction (

Figure 5a).

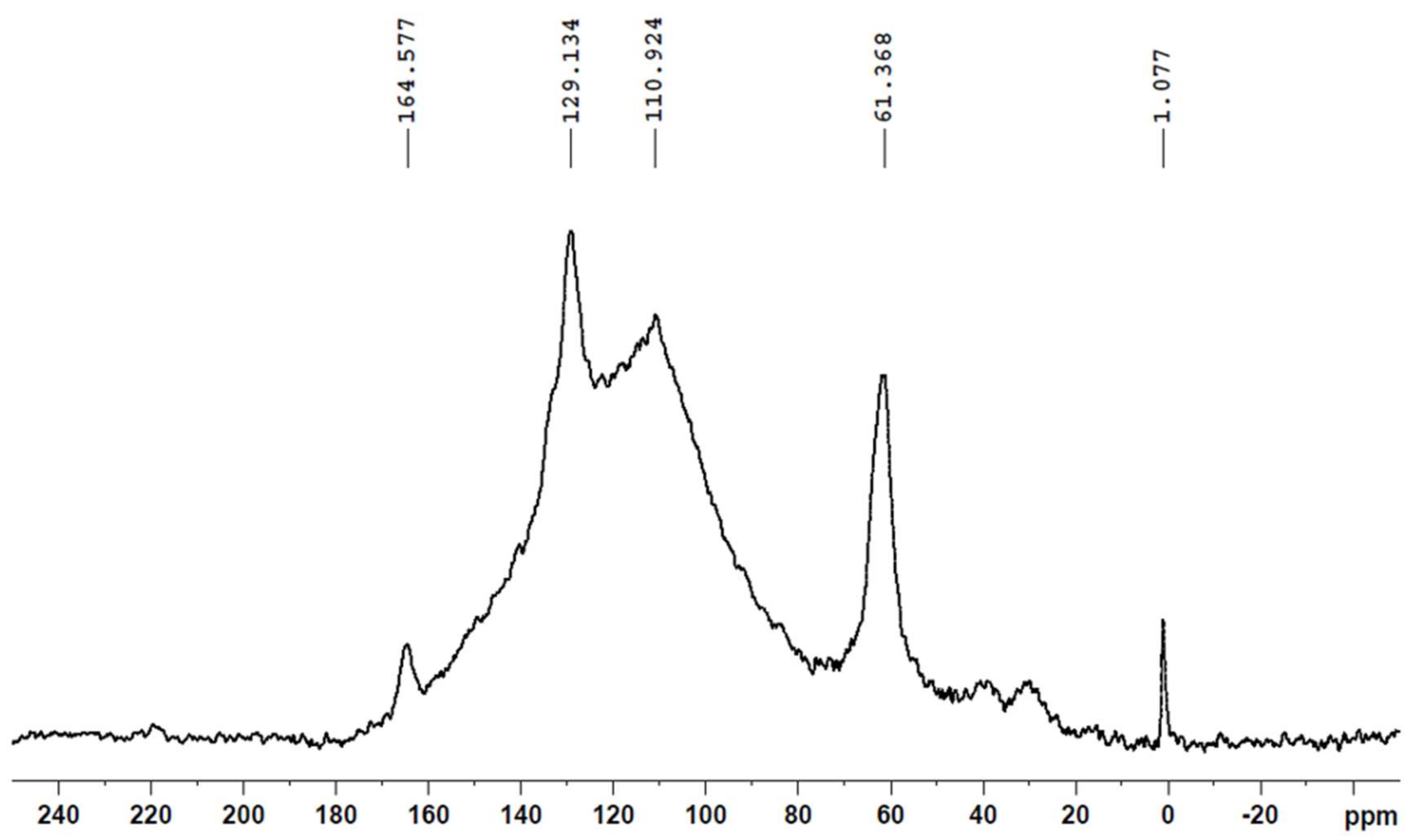

EDS compositional maps of the region (

Figure 24) reveal that the light grey phase has a high concentration of fluorine, suggesting that the spherically shaped particles is made of PTFE, as detected by NMR spectroscopic measurements (

Figure 10). Furthermore, traces of Si were also detected in the region, which is consistent with NMR results and ICP-SFMS elemental analysis (

Table 4). Both F and Si were detected in the transferred layers deposited on the stainless steel counter surface (

Figure 16), indicating that they serve as a solid lubricant in the material.