Lens on Tropical Sericulture Development in Indonesia: Recent Status and Future Directions for Industry and Social Forestry

Abstract

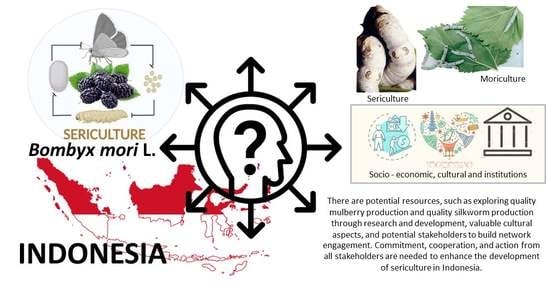

:Simple Summary

Abstract

1. Introduction

2. Examining Sericulture Development in Indonesia

2.1. Cultivation of Mulberry Plant (Moriculture)

2.2. Silkworm Rearing (Sericulture)

2.2.1. Silkworm Breeding

2.2.2. Silkworm Nursery

2.2.3. Silkworm Rearing

2.2.4. Pests and Diseases

2.3. Silkworm Products

2.3.1. Main Products

- Cocoons

- Silk Yarn

- Material Fabrics

2.3.2. Diversification Product

2.4. Social, Economic, Cultural, and Institutional Factors

2.4.1. Social, Economic, and Cultural Factors

2.4.2. Sericulture Development Policy

2.4.3. Institutional Factors

3. The Way Forward

3.1. Moriculture

- Enhance the commitment and compliance of all related stakeholders to apply standard operating procedures in cultivating mulberries (selection of suitable locations for mulberry cultivation, cultivation techniques, intensive rearing, appropriate fertilization, and preventive measures to anticipate plant pests and diseases).

- Superior mulberry seeds with high productivity that can be planted under various growing conditions. Indonesia, through the Ministry of Environment and Forestry, has initiated and produced a mulberry hybrid with productivity of 52.35 tons/ha/year [39].

- Integrating mulberry agroforestry with other plants to increase land productivity and mulberry production in Indonesia. Agroforestry that integrates mulberry plantations with agricultural crops provides multidimensional benefits, including the efficient use of land area, increased production and total leaf yield, improved nutrition, efficient use of light and water from the mulberry plant, and its inherent ability to combat pests and diseases [46]. Expanding the mulberry plantation to the potential of the Social Forestry areas of 5.03 million Ha [139].

- Managing mulberry blocks to ensure the continuity of mulberry production. A good field division will optimize feed production so that, in addition to optimal leaf quality and productivity, it can also increase the intensity of silkworm rearing per year. The separation of young and grown silkworms into different facilities with the different dedicated mulberry fields has the advantages of intensive maintenance, pest control, and feed productivity prediction, considering that young silkworms need one-month-old mulberry feed. In contrast, grown silkworms require two months old mulberry feed. Otherwise, it will cause losses due to separation, which will result in high maintenance operational costs and will require a wider allocation of the mulberry plantation area.

3.2. Silkworm Cultivation (Sericulture)

- Creation of silkworm breeding centers as silkworm egg producers with superior strains of silkworm eggs. The scheme for establishing a silkworm nursery center in collaboration with related stakeholders in Sukabumi can be an example to be implemented in other areas, especially in South Sulawesi.

- Develop superior silkworm hybrids. The Ministry of Environment and Forestry has initiated the distribution of the superior silkworm hybrid strains PS 01, which has 35–40 kg/box cocoon production. This strain can be developed more widely to increase the productivity of Indonesian sericulture.

- Enforcement in implementing SOP for silkworm rearing. The SOP for maintaining silkworms that are not carried out properly has an impact on the productivity of cocoons and yarns. Adherence to selecting a good and suitable location (effectiveness of feed sources and minimal air pollution), carrying out room and silkworm disinfection procedures, and paying attention to the timing and rearing procedures correctly will be steps to ensure optimal cocoons and yarns.

- The separation of young and grown silkworm farmers can increase productivity. Young silkworms require intensive care and are susceptible to disease. Productivity will increase if skilled farmers carry out the maintenance of young silkworms. Only then can the maintenance of grown silkworms be carried out by novice farmers. The advantages of this separation are the effective use of the rearing room, and the productivity is maintained because young silkworms are susceptible to disease, so they will only be kept by skilled farmers. Good cooperative arrangements can increase the intensity of maintenance. Disadvantages will arise if communication is established between young and grown silkworm farmers; high mobility is also required because of the distance between the two.

3.3. Products

3.4. Social, Economic, and Cultural Factors

- Build production networks and cooperate with stakeholders, facilitated by the government to ensure the sustainability of the production of superior eggs and the propagation of silkworm egg producers.

- Internalization of silkworm rearing (sericulture) through both formal and informal education involving various stakeholders, including business stakeholders, to maintain socio-cultural values and develop the value of silk entrepreneurship as part of the nation’s identity.

- Increasing the community’s capacity for silkworm rearing in terms of technical aspects, farm management, farmer group organization management, and improved access to markets. The yield of silk products is low due to a lack of assistance regarding proper rearing procedures. Efforts are needed to increase farmers’ adoption of good rearing standards by providing consistent, accessible, relevant, and practical information via more personal means of communication and coupling with stakeholders by a transdisciplinary approach, including social scientists, communication specialists, entrepreneurs, and marketing experts. The role of the Forest Management Unit/FMU, which is the implementation of management at the site level, needs to be more intensive for facilitating sericulture development.

3.5. Institutional Factors

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sparrow, R.; Dartanto, T.; Hartwig, R. Indonesia Under the New Normal: Challenges and the Way Ahead. Bull. Indones. Econ. Stud. 2020, 56, 269–299. [Google Scholar] [CrossRef]

- Halimatussadiah, A.; Cesarina, A.; Siregar, A.A.; Hanum, C.; Wisana, D.; Rahardi, F.; Bintara, H.; Rezki, J.F.; Husna, M.; Azar, M.S.; et al. Thinking Ahead: Indonesia’s Agenda on Sustainable Recovery from COVID-19 Pandemic; LPEM FEB UI dan BAPPENAS: Jakarta, Indonesia, 2020. [Google Scholar]

- United Nations. Ending Poverty. Available online: https://www.un.org/en/global-issues/ending-poverty (accessed on 15 November 2020).

- Golar, G.; Malik, A.; Muis, H.; Herman, A.; Nurudin, N.; Lukman, L. The social-economic impact of COVID-19 pandemic: Implications for potential forest degradation. Heliyon 2020, 6, e05354. [Google Scholar] [CrossRef] [PubMed]

- Djalante, R.; Lassa, J.; Setiamarga, D.; Sudjatma, A.; Indrawan, M.; Haryanto, B.; Mahfud, C.; Sinapoy, M.S.; Djalante, S.; Rafliana, I.; et al. Review and analysis of current responses to COVID-19 in Indonesia: Period of January to March 2020. Progress in Disaster Science 2020, 6, 100091. [Google Scholar] [CrossRef]

- Suryahadi, A.; Al Izzati, R.; Suryadarma, D. The Impact of COVID-19 Outbreak on Poverty: An Estimation for Indonesia (Draft); SMERU Working Paper; The SMERU Research Institute: Jakarta, Indonesia, 2020; pp. 1–20. [Google Scholar]

- FAO. The impact of disasters and crises on agriculture and food security: 2021; Food and Agriculture Organization of The United Nations: Rome, Italy, 2021. [Google Scholar]

- Cahyadi, H.S.; Newsome, D. The post COVID-19 tourism dilemma for geoparks in Indonesia. Int. J. Geoheritage Park. 2021, 9, 199–211. [Google Scholar] [CrossRef]

- Supriyanto, B. Cara Belajar Baru Petani Dalam Buku Salam Lima Jari; Direktorat Penyiapan Kawasan Perhutanan Sosial: Jakarta, Indonesia, 2020. [Google Scholar]

- Shackleton, C.; Delang, C.O.; Shackleton, S.; Shanley, P. Non-timber Forest Products: Concept and Definitions. In Non-Timber Forest Products in the Global Context; Shackleton, S., Shackleton, C., Shanley, P., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 3–21. [Google Scholar]

- Sardeshpande, M.; Shackleton, C. Wild Edible Fruits: A Systematic Review of an Under-Researched Multifunctional NTFP (Non-Timber Forest Product). Forests 2019, 10, 467. [Google Scholar] [CrossRef] [Green Version]

- Simangunsong, B.C.H.; Manurung, E.G.T.; Elias, E.; Hutagaol, M.P.; Tarigan, J.; Prabawa, S.B. Tangible economic value of non-timber forest products from peat swamp forest in Kampar, Indonesia. Biodiversitas 2020, 21, 5954–5960. [Google Scholar] [CrossRef]

- Wahyudi, W. Non-Timber Forest Product (Ntfp) Commodities Harvested and Marketed By Local People At the Local Markets in Manokwari—West Papua. Indones. J. For. Res. 2017, 4, 27–35. [Google Scholar] [CrossRef] [Green Version]

- Kartodihardjo, H.; Suwito. Survei dan Indeks Perhutanan Sosial: Jalan Menuju Kesejahteraan Rakyat dan Kelestarian Hutan; Katadata Insight Center: Jakarta, Indonesia, 2020. [Google Scholar]

- Barcelos, S.M.B.D.; Salvador, R.; Guedes, M.D.G.; de Francisco, A.C. Opportunities for improving the environmental profile of silk cocoon production under Brazilian conditions. Sustainability 2020, 12, 3214. [Google Scholar] [CrossRef] [Green Version]

- Agustarini, R.; Andadari, L.; Minarningsih; Dewi, R. Conservation and breeding of natural silkworm (Bombyx mori L.) in Indonesia. IOP Conf. Ser. Earth Environ. Sci. 2020, 533, 012004. [Google Scholar] [CrossRef]

- Kasi, E. Role of Women in Sericulture and Community Development. SAGE Open 2013, 3(3), 2158244013502984. [Google Scholar] [CrossRef]

- Hogeboom, R.J.; Hoekstra, A.Y. Water and land footprints and economic productivity as factors in local crop choice: The case of silk in Malawi. Water (Switzerland) 2017, 9, 802. [Google Scholar] [CrossRef] [Green Version]

- Harbi, J.; Nurrochmat, D.R.; Kusharto, C.M. Pengembangan Usaha Persuteraan Alam Kabupaten Wajo, Sulawesi Selatan. Risal. Kebijak. Pertan. Dan Lingkung. Rumusan Kaji. Strateg. Bid. Pertan. Dan Lingkung. 2015, 2, 128. [Google Scholar] [CrossRef] [Green Version]

- ISC. Global Silk Industry. Available online: https://inserco.org/en/statistics (accessed on 21 June 2021).

- Nuraeni, S. Gaps in the thread: Disease, production, and opportunity in the failing silk industry of south sulawesi. For. Soc. 2017, 1, 110–120. [Google Scholar] [CrossRef] [Green Version]

- Rusniati. Analisis Pengendalian Proses Produksi LIPA SABBE’ (Sarung Sutera) Sengkang di Kecamatan Tanasitolo Kabupaten Wajo; Universitas Muhammadiyah Makassar: Makassar, Indonesia, 2018. [Google Scholar]

- Minister of Forestry. Peraturan Menteri Kehutanan Republik Indonesia No.P.21/Menhut-II/2009 tentang Kriteria dan Indikator Penetapan Jenis Hasil Hutan Bukan Kayu Unggulan; Ministry of Environment and Forestry of The Republic of Indonesia: Jakarta, Indonesia, 2009.

- Mutiara, F.; Asnani, D. Strategi pengembangan agribisnis Ulat Sutera Pemakan Daun Singkong di Kabupaten Malang. J. Ilmu-Ilmu Peternak. 2017, 27, 24–38. [Google Scholar] [CrossRef] [Green Version]

- Tenriawaru, A.N.; Fudjaja, L.; Jamil, M.H.; Rukka, R.M.; Anisa, A.; Halil. Natural silk agroindustry in Wajo Regency. IOP Conf. Ser. Earth Environ. Sci. 2021, 807, 012037. [Google Scholar] [CrossRef]

- Hartati. Analisis Fenotip Ulat Sutera (bombyx mori L.) Hasil Persilangan Ras Jepang, Chna, dan Rumania; Global Research and Consulting Institute (Global-RCI): Makassar, Indonesia, 2015; pp. 21–23. [Google Scholar]

- Sadapotto, A. Proses Kebijakan Persuteraan Alam di Sulawesi Selatan. J. Parennial 2012, 8, 1–5. [Google Scholar]

- Nurjayanti, E.D. Budidaya Ulat Sutera Dan Produksi Benang Sutera Melalui Sistem Kemitraan Pada Pengusaha Sutera Alam (PSA) Regaloh Kabupaten Pati. Mediagro 2011, 7, 1–10. [Google Scholar]

- Zambrano-Gonzalez, G.; Ramirez-Gonzalez, G.; Almanza-P, M.I. The evolution of knowledge in sericultural research as observed through a science mapping approach. F1000Research 2017, 6, 2075. [Google Scholar] [CrossRef] [Green Version]

- Sathyanarayana, K.; Saratchandra, B. Carbon trading through afforestation programmes with host plants of tasar silkworm (Antheraea mylitta Drury) in private waste lands: A Value Add for Tribals; Council of Research and Experiments in Agriculture, Apiculture and Sericulture Unit of Bologna: Padua, Italy, 2013. [Google Scholar]

- Rohela, G.K.; Shukla, P.; Muttanna; Kumar, R.; Chowdhury, S.R. Mulberry (Morus spp.): An ideal plant for sustainable development. Trees For. People 2020, 2, 100011. [Google Scholar] [CrossRef]

- Deepa, K.B.; Vishaka, G.V.; Kumar, N. Mulberry as a avenue plant. J. Pharmacogn. Phytochem. 2020, 9(4S), 135–137. [Google Scholar]

- McNair, P.D. Reviving the Sericulture Industry. In Proceedings of the 5th BACSA International Conference “Sericulture for Multi Products—New Prospects for Development” SERIPRODEV, Bucharest, Romania, 11–15 April 2011. [Google Scholar]

- Tarigan, D.; Fauzi, A.M.; Suryani, A.; Kaomini, M.; Tarigan, D.; Fauzi, A.M.; Suryani, A.; Kaomini, M. Strategi pengembangan agroindustri sutera alam melalui pendekatan klaster a strategy for the development of silk agroindustry using cluster approach. J. Teknol. Ind. Pertan. 2019, 20, 39–47. [Google Scholar]

- Nursita, I.W. Perbandingan produktifitas ulat Sutra dari dua tempat pembibitan yang berbeda pada kondisi lingkungan pemeliharaan panas. J. Ilmu Peternak. 2011, 3, 10–17. [Google Scholar]

- Muin, N.; Suryanto, H.; Minarningsih. Ujicoba Hibrid Morus Khunpai dan Morus Indica Sebagai Pakan Ulat Sutera (Bombyx Mori. Linn). J. Penelit. Kehutan. Wallaceae 2015, 4, 137–145. [Google Scholar] [CrossRef] [Green Version]

- Pudjiono, S. Ulat Sutra; Badan Litbang dan Inovasi: Jakarta, Indonesia, 2015; pp. 42–59. [Google Scholar]

- Shantibala, T.; Lokeshwari, R.K.; Gusheinzed, W.; Agarwala, B.K. Documentation of Ethno-Entomophagy Practices in Ethnic Communities of Manipur, North-East India. Ancestral Knowledge in Agri-Allied Science of India; India Publishing Agency: New Delhi, India, 2013. [Google Scholar]

- Andadari, L. Pemilihan jenis hibrid ulat sutera yang optimal untuk dikembangkan di dataran tinggi dan/atau dataran rendah. J. Penelit. Hutan Tanam. 2016, 13, 13–21. [Google Scholar] [CrossRef] [Green Version]

- Sadapotto, A.; Palulungan, L.; Riwu, M.; Sahide, M.A.K.; Sirimorok, N.; Parenreng, S.M.; Salindeho, Y.M.; Yahya, A.F.; Mulyani, A.; Said, R.D.; et al. Laporan Kajian Final Rantai Nilai Komoditas Sutra Sulawesi Selatan; Bappelitbangda Provinsi Sumatera Selatan: Makassar, Indonesia, 2021. [Google Scholar]

- Muin, N.; Bisjoe, A.R.H. Budidaya Ulat Sutera Di Desa Sudu, Kecamatan Alla, Kabupaten Enrekang, Sulawesi Selatan. J. Penelit. Hutan Tanam. 2013, 10, 229–239. [Google Scholar] [CrossRef]

- Hadi, P.; Rustiono, D. Silkworm Agribusiness in Bejen Village Temanggung. Int. J. Agric. Innov. Res. 2015, 3, 1592–1594. [Google Scholar]

- Maturidy, A.F. Preferensi pelaku usaha dalam pengembangan persuteraan alam di Provinsi Sulawesi Selatan. J. Pasca Sarj. Univ. Hasanuddin 2011, 1–11. [Google Scholar]

- Isnan, W. Perception and Motivation of Farmers in the Development of Natural Silk Business in Soppeng Regency Sulawesi Selatan. J. Wasian 2019, 6, 1–10. [Google Scholar] [CrossRef]

- Sharma, A.; Krishna, V.; Kaur, P.; Rayal, R. Characterization and Screening of Various Mulberry Varieties Throgh Morpho-Biochemical Characteristics. J. Glob. Biosci. 2015, 4, 1186–1192. [Google Scholar]

- Mir, M.R.; Khan, I.L.; Baqual, M.F.; Banday, M.; Raja, R.; Khursheed, S. Mulberry-Based Agroforestry System: An Effective Way of Maintaining Livelihood Security and Climate Change Mitigation; Apple Academic Press: Palm Bay, FL, USA, 2019. [Google Scholar]

- Andadari, L.; Minarningsih; Dewi, R. The Effect of Mulberry Types on the Productivity of Cocoon of Two Bombyx mori L. Silkworm Hybrids. Widyariset 2017, 3, 119. [Google Scholar] [CrossRef] [Green Version]

- Sasmita, N.; Komara, L.L. Species Test of Morus alba and Morus cathayana in Indonesia. Adv. Biol. Sci. Res. 2021, 11, 246–252. [Google Scholar] [CrossRef]

- Daulay, N.S. Pengaruh Kualitas Daun Murbei Moruscathayana Terhadap Indeks Nutrisi Ulat Sutera Bombyx mori L. (Lepidoptera: Bombicidae); Repositori Institusi Universitas Sumatera Utara: Sumatera Utara, Indonesia, 2013. [Google Scholar]

- Triandi, A.; Mubin, N.; Nurulalia, L. Identification of Mulberry Pests and Its Natural Enemies at “Rumah Sutera Alam” Ciapus, West Java. Akta Agrosia 2021, 24, 9–18. [Google Scholar] [CrossRef]

- Sulthoni, A. Peranan Entomologi Hutan dan Tantangannya Menghadapi Pembangunan Hutan Tanaman Industri. Pidato Pengukuhan Guru Besar dalam Ilmu Hama Tanaman; Universitas Gadjah Mada: Yogyakarta, Indonesia, 1991. [Google Scholar]

- Pudjiono, S.; Na'iem, M. Pengaruh Pemberian Pakan Murbei Hibrid Terhadap Produktivitas dan Kualitas Kokon. J. Pemuliaan Tanam. Hutan 2007, 1, 81–87. [Google Scholar] [CrossRef] [Green Version]

- Singh, B.; Makkar, H.P.S. The Potential of Mulberry Foliage as Feed Supplement in India. In Proceedings of the FAO Electronic Conference on Mulberry for Animal Production (Morus I-L), Rome, Italy, August 2020; pp. 1–20. [Google Scholar]

- Yongkang, H. Mulberry cultivation and utilization in China. In Proceedings of the Electronic Conference, 2000. [Google Scholar]

- Doss, S.G.; Chakraborti, S.P.; Roychowdhuri, S.; Das, N.K.; Vijayan, K.; Ghosh, P.D. Development of mulberry varieties for sustainable growth and leaf yield in temperate and subtropical regions of India. Euphytica 2012, 185, 215–225. [Google Scholar] [CrossRef]

- Bhatia Narendra, K.; Yousuf, M.; Nautiyal, R. Yield Gap Analysis of Mulberry Sericulture in Northwest India. Int. J. Ind. Entomol. 2013, 27, 131–141. [Google Scholar] [CrossRef] [Green Version]

- Sori, W.; Gebreselassie, W. Evaluation of mulberry (Morus spp.) genotypes for growth, leaf yield and quality traits under Southwest Ethiopian condition. J. Agron. 2016, 15, 173–178. [Google Scholar] [CrossRef] [Green Version]

- Nursyamsi. Propagasi Tiga Varietas Murbei Melalui Teknik Kultur Jaringan. J. Penelit. Hutan Tanam. 2012, 9, 75–82. [Google Scholar] [CrossRef] [Green Version]

- Pudjiono, S.; Septina, S. Morfologi Tanaman Hibrid Murbei di Purwobinangun Yogyakarta. J. Pemuliaan Tanam. Hutan 2008, 2(1), 163–171. [Google Scholar] [CrossRef]

- Atmosoedarjo, S.; Kartasubrata, J.; Kaomini, M.; Saleh, W.; Murdoko, W. Sutera Alam Indonesia; Yayasan Sarana Wana Jaya: Jakarta, Indonesia, 2000. [Google Scholar]

- Andadari, L.; Pudjiono, S.; Suwandi; Rahmawati, T. Budidaya Murbei dan Ulat Sutra; Forda Press: Bogor, Indonesia, 2013. [Google Scholar]

- Santoso, B.; Budisantoso, H. Adaptasi Varietas Murbei Hasil Silangan. In Proceedings of the Prosiding Ekspose Hasil Penelitian dan Pengembangan Kehutanan Ujung Pandang, Makassar, Indonesia, 1999. [Google Scholar]

- Andadari, L.; Dewi, R.; Pudjiono, S. Adaptation Test of Five New Hybrid Mulberry to Improve Natural Silk Productivity. Widyariset 2016, 2(2), 96–105. [Google Scholar] [CrossRef] [Green Version]

- Pudjiono, S.; Andadari, L.; Darwo. Pemilihan Jenis Hibrid Murbei Untuk Dikembangkan Di Dataran Tinggi. J. Penelit. Hutan Tanam. 2016, 13, 133–138. [Google Scholar]

- Gupta, S.K.; Dubey, R.K. Impact of heavily polluted air and acid rain on mulberry silkworm and cocoon production of Bombyx mori Linn. Int. J. Fauna Biol. Stud. 2021, 8, 26–30. [Google Scholar] [CrossRef]

- Yulistiani, D. Tanaman murbei sebagai sumber protein hijauan pakan domba dan kambing. Wartazoa 2012, 22, 46–52. [Google Scholar]

- Mahadeva, A. Insect Pest Infestation, an Obstacle in Quality Mulberry Leaves Production. Asian J. Biol. Sci. 2018, 11, 41–52. [Google Scholar] [CrossRef]

- Prayudyaningsih, R.; Tikupadang, H.; Santoso, B. Hama Dan Penyakit Jenis Murbei Eksot Dan Tingkat Kehilangan Daunnya Pada Akhir Musim Kemarau. J. Penelit. Hutan dan Konserv. Alam 2006, 3, 429–435. [Google Scholar] [CrossRef]

- Dewi, R.; Andadari, L.; Maharani, K.E. Tinjauan Bioekologi dan Pengendalian Hama Kutu Kebul (Bemisia tabaci Genn.). In Proceedings of the Prodising Seminar Nasional PEI, Jatinangor, Bandng, 25–26 October 2017; pp. 40–45. [Google Scholar]

- Mukhopadhyay, S.K.; Trivedy, K. Intregated management and forecasting of insect pests of mulberry (Morus Alba L.) for Eastern and Northeastern regions of India. J. Environ. Sociobiol. 2016, 13, 137–145. [Google Scholar]

- Soliman, N.H.; Sherif, D.F.E. rovided for non-commercial research and education use. Not for reproduction, distribution or commercial use. Hepatoprotective Agents in Rats. Egypt. Acad. J. Biol. Sci. 2019, 11, 91–95. [Google Scholar]

- Maru, R.; Badwi, N.; Abbas, I.; Nurfadillah; Nur, M.M.; Basram, N.F. Opportunities and Challenges of SilkWorm Cultivation Development in Geography Perspectives. La Geogr. 2021, 19, 201–210. [Google Scholar]

- Shi, M.; Li, G.; Zheng, X.; Liu, F.; Zhao, S.; Cai, M.; Zhu, Y. Effects of dimethoate on the gonads and oxidative stress response in the silkworm, Bombyx mori. Acta Entomol. Sin. 2019, 62, 1186–1196. [Google Scholar]

- BPA. Laporan Bulanan. Pelaksana Harian Balai Persuteraan Alam (BPA), Kabupaten Soppeng; Balai Persuteraan Alam (BPA): Makassar, Indonesia, 2014. [Google Scholar]

- Fambayun, R.A.; Agustarini, R.; Andadari, L. Cultivation and Breeding Techniques for Increase Silk Productivity in Indonesia. IOP Conf. Ser. Earth Environ. Sci. 2022, 995, 012055. [Google Scholar] [CrossRef]

- Deni; Diba, F.; Tavita, G.E. Deni, Farah Diba, Gusti Eva Tavita. J. Hutan Lestari 2019, 7, 874–883. [Google Scholar]

- Andadari, L.; Kuntadi. Comparison of Chinese-Origin and Local Silkworm (L.) Hybrids in South Sulawesi. J. Penelit. Hutan Tanam. 2014, 11, 173–183. [Google Scholar] [CrossRef]

- Djabar, M.; Utiarahman, N. Kelayakan Usaha Budidaya Ulat Sutera (Bombix Mori L.) Berdasarkan Aspek Non Finanasial Kabupaten Boalemo. J. Penelit. Kehutan. Bonita 2019, 1, 15–22. [Google Scholar] [CrossRef]

- Syam, D. Analisis Pendapatan Pemelihara Ulat Sutera Pada Pemeliharaan Konvensional di Desa Sering, Kecamatan Donri-Donri, Kabupaten Sorong (Studi Kasus Kelompok Tani Batu Tungke’E); Universitas Hasanuddin: Makassar, Indonesia, 2017. [Google Scholar]

- Watanabe, H. Genetic resistance of the silkworm, Bombyx mori to viral diseases. Curr. Sci. 2002, 83, 439–446. [Google Scholar]

- Potrich, M.; Alves, L.F.A.; Brancalhão, R.C.; Dalcin, G. Entomopatógenos Associados a Lagartas De Bombyx Mori L. (Lepidoptera: Bombycidae) No Estado Do Paraná. Arq. Do Inst. Biológico 2007, 74, 363–367. [Google Scholar] [CrossRef]

- Nuraeni, S. Kuantitas dan kualitas produksi F1 ulat sutera (Bombyx mori L.) hasil persilangan antara Ras Rusia dengan Ras China; Fakultas Pertanian universitas Hasanuddin: Makassar, Indonesia, 1993. [Google Scholar]

- Budisantoso. Pengeringan Kokon dengan Alat Pengering Tenaga Matahari dan pengaruhnya Terhadap Kualitas Serat Sutra. Bul. Penelit. Kehutan. 2001, 7(1), 24–36. [Google Scholar]

- Kasip, M. Pembentukan Galur Baru Ulat Sutera (Bombyx mori L) Melalui Persilangan Ulat Sutera Bivoltin dan Polivoltin; IPB University: Bogor, Indonesia, 2001. [Google Scholar]

- Yuniati, D.; Suharti, S.; Widiarti, A.; Andadari, L.; Heryati, Y.; Agustarini, R. Business feasibility of several PS-01 hybrid silkworms (Bombix mori L.) cultivation scheme. IOP Conf. Ser. Earth Environ. Sci. 2021, 917, 012031. [Google Scholar] [CrossRef]

- Estetika, Y.; Endrawati, Y.C. Produktivitas Ulat Sutera (Bombyx mori L.) Ras BS-09 di Daerah Tropis. J. Ilmu Prod. Dan Teknol. Has. Peternak. 2018, 6, 104–112. [Google Scholar] [CrossRef]

- Minister of Forestry. Keputusan Menteri Kehutanan Republik Indonesia No. SK. 794/Menhut-II/2013 Tentang Pelepasan Bibit Ulat Sutera (Bombyx mori L.) Hibrid PS-01; Ministry of Environment and Forestry of The Republic of Indonesia: Jakarta, Indonesia, 2013.

- Ministry of Environment and Forestry. Decree of the Minister of Environment and Forestry of the Republic of Indonesia No: SK.300/Menlhk/Setjen/KUM.1/4/2019 Dated 24 April 2019; Ministry of Environment and Forestry of The Republic of Indonesia: Jakarta, Indonesia, 2019.

- Cholis, N. Studi Penampilan Produksi Ulat Sutera F1 Hibrid Hasil Persilangan RAS Jepang dan RAS Cina yang Berasal dari Pusat Pembibitan Soppeng dan Temanggung. J. Ternak Trop. 2014, 15, 72–76. [Google Scholar]

- Cholis, N. Studi tentang polimorfisme ulat sutera F1 hibrid hasil persilangan ras Jepang dan ras Cina yang berasal dari pusat pembibitan Soppeng dan Temanggung dengan menggunakan enzim restriksi Pst1 dan EcoR1. J. Ilmu-Ilmu Peternak. 2015, 25, 61–65. [Google Scholar] [CrossRef]

- Minister of Forestry. Keputusan Menteri Kehutanan Indonesia No. SK. 369/Menhut-II/2004 Tentang Pelepasan Bibit Ulat Sutera (Bombyx mori L.) Hibrid BS-08 dan BS-09; Ministry of Environment and Forestry of The Republic of Indonesia: Jakarta, Indonesia, 2004.

- Rahmathulla, V.K. Management of Climatic Factors for Successful Silkworm (Bombyx mori L.) Crop and Higher Silk Production: A Review. Psyche 2012, 11, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Mubarak, H. Produktivitas Ulat Sutera (Bombyx Mori L.) Candirotobs- 09dan Hibrid PS.01 Yang Diberi Pakandaun Murbei (Morus Multicaulis); Institut Pertanian Bogor: Bogor, Indonesia, 2017. [Google Scholar]

- Nuraeni, S.; Putranto, B. Aspek Biologis Ulat Sutera (Bombyx mori L.) dari Dua Sumber Bibit di Sulawesi Selatan. J. Perenn. 2007, 4, 10–17. [Google Scholar] [CrossRef] [Green Version]

- Sadapotto, A.; Kartodihardjo, H.; Triwidodo, H.; Darusman, D.; Sila, M. Penataan institusi untuk peningkatan kinerja persuteraan alam di Sulawesi Selatan. J. Forum Pascasarj. 2010, 33, 133–140. [Google Scholar]

- Andadari, L.; Minarningsih, S. The effect of feeding various species of mulberry (Morus spp.) on the growth of silkworm and quality of cocoon hybrid BS 09. IOP Conf. Ser. Earth Environ. Sci. 2021, 914, 012017. [Google Scholar] [CrossRef]

- San-Ming, W. Silkworm Egg Production; FAO: Rome, Italy, 1989; p. 64. [Google Scholar]

- Yuniati, D.; Widiarti, A.; Suharti, S. Pengembangan Persutraan Alam di Kabupaten Sukabumi. In Pembelajaran Dunia Riset untuk Pengembangan HHBK; Widiarti, A., Irma, Y., Minarningsih, A.R., Eds.; IPB Press: Bogor, Indonesia, 2020. [Google Scholar]

- Prihatin, J. Pemeliharaan dan Pengokonan Ulat Sutera Bombyx mori L. Menggunakan Seriframe Standar dan Seriframe Modifikasi. Bioedukasi 2009, 7, 31–38. [Google Scholar]

- Fauziyah, E.; Wijayanto, N. Strategi pengembangan usaha persuteraan alam di kabupaten sukabumi, propinsi jawa barat (Development Strategy of Striving Nature Silk in Kabupaten Sukabumi, Propinsi Jawa Barat). J. Manaj. Hutan Trop. 2007, 13, 59–77. [Google Scholar]

- Agustarini, R.; Andadari, L. Implementasi Persuteraan Alam dalam Mendukung Perhutanan Sosial. In Proceedings of the Prosiding Seminar Nasional Ekosistem Unggul Membangun Hutan Sebagai Ekosistem Unggul Berbasis Das: Jaminan Produksi, Pelestarian, dan Kesejahteraan, Yogyakarta, Indonesia, 23 August 2018; pp. 151–162. [Google Scholar]

- Ritter, C.; Jansen, J.; Roche, S.; Kelton, D.F.; Adams, C.L.; Orsel, K.; Erskine, R.J.; Benedictus, G.; Lam, T.; Barkema, H.W. Invited review: Determinants of farmers' adoption of management-based strategies for infectious disease prevention and control. J. Dairy Sci. 2017, 100, 3329–3347. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sarkhel, S.; Shrivastava, S.; Pouranik, M. The Effective Influence of Temperature on the Varied Characteristic of Silkworm: A Review. Asian J. Exp. Sci. 2017, 31, 31–37. [Google Scholar]

- Sakthivel, N.; Kumaresan, P.; Qadri, S.M.H.; Ravikumar, J.; Balakrishna, R. Adoption of integrated pest management practices in sericulture—A case study in Tamil Nadu. J. Biopestic. 2012, 5, 212–215. [Google Scholar]

- Sharma, A.; Sharma, P.; Thakur, J.; Murali, S.; Bali, K. Viral diseases of Mulberry Silkworm, Bombyx mori L. —A Review. 2020, 9, 415–423. [Google Scholar]

- Nuraeni, S.; Muin, N.; Sanusi, D. Respon Empat Ras Ulat Sutera Terhadap Bombyx mori Nuclear Polyhedrosis Virus (BmNPV). In Proceedings of the Prosiding Seminar Nasional Mikrobiologi Kesehatan dan Lingkungan, Makassar, Indonesia, 29 January 2015. [Google Scholar]

- Muin, N. Pengaruh Pakan Pada Resistensi Ulat Sutra (Bombyx mori L.) Terhadap Penyakit Grasserie; IPB University: Bogor, Indonesia, 2009. [Google Scholar]

- Guo-Ping, K.; Xi-Jie, G. Overview of silkworm pathology in China. Afr. J. Biotechnol. 2011, 10, 18046–18056. [Google Scholar] [CrossRef]

- Nuraeni, S.; Baharuddin. The adaptability of the commercial seeds of silkworm (Bombyx Mori L) on different altitude preservation. IOP Conf. Ser. Earth Environ. Sci. 2019, 270, 012034. [Google Scholar] [CrossRef]

- Antaranews. Ulat “Sinar” Diharapkan Penuhi Kebutuhan Benang Sutera Lokal; Antaranews: Jakarta, Indonesia, 2019. [Google Scholar]

- ASSIA. World Sericulture in Industry 4.0. In Proceedings of the ASEAN Country Member National Brief on Silk and Sericulture: Indonesia, Bangkok, Thailand, 28–29 July 2019. [Google Scholar]

- Hussain, M.; Khan, S.A.; Naeem, M.; Aqil, T.; Khursheed, R.; ul Mohsin, A. Evaluations of silkworm lines against variations in temperature and RH for various parameters of commercial cocoon production. Psyche 2011, 2011, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Gowda, B.N.; Reddy, N.M. Influence of different environmental conditions on cocoon parameters and their effects for reeling performance of bivoltine hybrids of silkworm, Bombyx mori L. Int. J. Indust. Entomol 2007, 14, 15–21. [Google Scholar]

- Mirhosseini, S.Z.; Nematollahian, S.; Ghanipoor, M.; Seidav, A. Comparison of Phenotypic and Genetic Performance of Local Silkworm Groups and Two Commercial Lines. Biol. Res. 2010, 43, 411–416. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.E. Silkworm Breeding. In Principle and Practices in Sericulture; NSERI: City, Korea, 1998. [Google Scholar]

- BPS. Data dan Informasi Kemiskinan 2005−2006, Buku 1: Provinsi [Poverty Data and Information 2005−2006, Book 1: Province]; BPS: Jakarta, Indonesia, 2007. [Google Scholar]

- Rochmawati, R. Kualitas Kokon Hasil Silangan Ulat Sutera (Bombyx mori L.) Ras Cina dengan Ras Jepang Secara Resiprocal; IPB University: Bogor, Indonesia, 2011. [Google Scholar]

- Sadapotto, A. Strategi Pengembangan Sutra Alam di Kabupaten Poliwali Mandar, Sulawesi Barat. In Proceedings of the Seminar Nasional MAPEKI XVII, Medan, Indonesia; 2014. [Google Scholar]

- Martinez-Mora, C.; Mrowiec, A.; Garcia-Vizcaino, E.M.; Alcaraz, A.; Cenis, J.L.; Nicolas, F.J. Fibroin and sericin from Bombyx mori silk stimulate cell migration through upregulation and phosphorylation of c-Jun. PLoS ONE 2012, 7, e42271. [Google Scholar] [CrossRef]

- Rockwood, D.N.; Preda, R.C.; Yucel, T.; Wang, X.; Lovett, M.L.; Kaplan, D.L. Materials fabrication from Bombyx mori silk fibroin. Nat. Protoc. 2011, 6, 1612–1631. [Google Scholar] [CrossRef] [Green Version]

- Battampara, P.; Nimisha Sathish, T.; Reddy, R.; Guna, V.; Nagananda, G.S.; Reddy, N.; Ramesha, B.S.; Maharaddi, V.H.; Rao, A.P.; Ravikumar, H.N.; et al. Properties of chitin and chitosan extracted from silkworm pupae and egg shells. Int. J. Biol. Macromol. 2020, 161, 1296–1304. [Google Scholar] [CrossRef] [PubMed]

- Lin, M.J.; Lu, M.C.; Chan, Y.C.; Huang, Y.F.; Chang, H.Y. An Insulin-like Growth Factor-1 Conjugated Bombyx mori Silk Fibroin Film for Diabetic Wound Healing: Fabrication, Physicochemical Property Characterization, and Dosage Optimization In Vitro and In Vivo. Pharmaceutics 2021, 13(9), 1459. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Y.; Jiang, Z.; Wang, J.; Xu, Z.; Meng, K.; Zhao, H. Poly(glyceryl sebacate)/silk fibroin small-diameter artificial blood vessels with good elasticity and compliance. Smart Mater. Med. 2021, 2, 74–86. [Google Scholar] [CrossRef]

- Veiga, A.; Castro, F.; Rocha, F.; Oliveira, A.L. Protein-Based Hydroxyapatite Materials: Tuning Composition toward Biomedical Applications. ACS Appl. Bio Mater. 2020, 3, 3441–3455. [Google Scholar] [CrossRef] [PubMed]

- Su, D.; Ding, S.; Shi, W.; Huang, X.; Jiang, L. Bombyx mori silk-based materials with implication in skin repair: Sericin versus regenerated silk fibroin. J. Biomater. Appl. 2019, 34, 36–46. [Google Scholar] [CrossRef]

- Ulfa, M.; Yahya, P.T.; Angriani, P.D.; Nur, A.A. Formulasi dan Uji Efektivitas Krim Limbah Air Kokon Ulat Sutera (Bombyx mori) Asal Kabupaten Soppeng sebagai Pelembab Kulit. J. Farm. UIN Alauddin Makassar 2020, 8, pagination. [Google Scholar] [CrossRef]

- Hwang, S.W.; Tao, H.; Kim, D.H.; Cheng, H.; Song, J.K.; Rill, E.; Brenckle, M.A.; Panilaitis, B.; Won, S.M.; Kim, Y.S.; et al. A physically transient form of silicon electronics. Science 2012, 337, 1640–1644. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.-H.; Viventi, J.; Amsden, J.J.; Xiao, J.; Vigeland, L.; Kim, Y.-S.; Blanco, J.A.; Panilaitis, B.; Frechette, E.S.; Contreras, D.; et al. Dissolvable films of silk fibroin for ultrathin conformal bio-integrated electronics. Nat. Mater. 2010, 9, 511–517. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aramwit, P.; Kanokpanont, S.; Nakpheng, T.; Srichana, T. The Effect of Sericin from Various Extraction Methods on Cell Viability and Collagen Production. Int. J. Mol. Sci. 2010, 11, 2200–2211. [Google Scholar] [CrossRef]

- Xiang, M.; Wang, Y.; Wu, J.; Guo, Y.; Wu, H.; Zhang, Y.; Liu, H. Natural Silk Cocoon Derived Nitrogen-doped Porous Carbon Nanosheets for High Performance Lithium-Sulfur Batteries. Electrochim. Acta 2017, 227, 7–16. [Google Scholar] [CrossRef]

- Ho, J.; Cao, C.; Idrees, F.; Ma, X. Hierarchical Porous Nitrogen-Doped Carbon Nanosheets Derived from Silk for Ultrahigh-Capacity Battery Anodes and Supercapacitors. ACS Nano Publ. 2015, 9, 2556–2564. [Google Scholar] [CrossRef]

- Iwang, B.; Sudirman. Peranan Pemerintah dalam Memajukan Perusahaan Sutera di Sulawesi Selatan, Indonesia. Southeast Asian Soc. Sci. Rev. 2020, 5, 103–132. [Google Scholar]

- Chanotra, S.; Bali, K.; Bali, R. Sericulture: An opportunity for the upliftment of rural livelihood. J. Entomol. Zool. Stud. 2019, 7, 1100–1103. [Google Scholar]

- Pratama, A.G.; Supratman, S.; Makkarennu, M. Examining forest economies: A case study of silk value chain analysis in Wajo District. For. Soc. 2019, 3, 22–33. [Google Scholar] [CrossRef]

- Dewangan, S.K.; Sahu, K.R.; Soni, S.K. Breaking of poverty through sericulture among the tribe- A Socio-Economic study of Dharamjaigarh block. Res. J. Recent Sci. 2012, 1, 371–374. [Google Scholar]

- Ibrahim, H. Pemberdayaan Pengrajin Ekonomi Kreatif Kerajinan Sutera Di Perdesaan Provinsi Sulawesi Selatan; IPB Press: Bogor, Indonesia, 2014. [Google Scholar]

- BPS. Sulawesi Selatan Dalam Angka 2020; Badan Pusat Statistik Provinsi Sulawesi Selatan: Makassar, Indonesia, 2020.

- Sari, R.P.; Holilulloh; Yanzi, A. Faktor-faktor Yang Mempengaruhi Pola Pikir Masyarakat Terhadap Pentingnya Pendidikan di Desa Cugung. J. Kult. Demokr. 2015, 3, pagination. [Google Scholar]

- goKUPS. Perhutanan Sosial dan Kemitraan Lingkungan. Available online: http://sinav.usahahutan.id/index.php/frontend/analisa/kups (accessed on 20 August 2022).

- Haruna, A.; Ridwan Sadapotto, A. Nilai Tambah Produk Persutraan Alam Dari Produk Intermediate Kokon ke Produk Akhir Benang di Kelurahan Walannae Kecamatan Sabbangparu Kabupaten Wajo. J. Eboni 2021, 3, 24–38. [Google Scholar]

- Muin, N.; Hayati, N. Penerapan Iptek Persuteraan Alam di Sulawesi Selatan [Laporan Hasil Penelitian]; Balai Penerapan Standarisasi Instrumen Kementrian Lingkungan Hidup dan Kehutanan: Makassar, Indonesia, 2017. [Google Scholar]

- Alam, A.M.K. Peran Perempuan pada Usaha Persuteraan Alam di Desa Pising Kecamatan Donri-Donri Kabupaten Soppeng; Universitas Hasanuddin: Makassar, Indonesia, 2016. [Google Scholar]

- Bukhari, R.; Kour, H.; Aziz, A. Women and the Indian Sericulture Industry. Int. J. Curr. Microbiol. Appl. Sci. 2019, 8, 857–871. [Google Scholar] [CrossRef]

- Geetha, G.S.; Indira, R. Silkworm Rearing by Rural Women in Karnataka: A Path to Empowerment. Indian J. Gend. Stud. 2011, 18, 89–102. [Google Scholar] [CrossRef]

- Hanum, F. Kajian dan Dinamika Gender; Instrans Publishing: Malang, Indonesia, 2018. [Google Scholar]

- Hubeis, A.V.S. Pemberdayaan Perempuan dari Masa Ke Masa; IPB Press: Bogor, Indonesia, 2010. [Google Scholar]

- Muin, N.; Bisjoe, A.R.H. Strengthening Gender Role in Managing Private Forests in South Konawe, South East Sulawesi Province. J. Penelit. Sos. Dan Ekon. Kehutan. 2019, 16, 127–135. [Google Scholar] [CrossRef] [Green Version]

- Harbi, J. Kajian teknis usaha persuteraan alam kelurahan walennae, kec. sabbangparu, kab. wajo, sulawesi selatan. J. Penelit. Ilmu-Ilmu Kehutan. 2016, 5, 45–53. [Google Scholar]

- Muhammad, S.; Dharmawan, A.; Unito, S.; Damanhuri, D. Kearifan Lokal dalam Sistem Sosial Ekonomi Masyarakat Penenun Bugis-Wajo. Mudra J. Seni Budaya 2013, 28(2), 129–142. [Google Scholar]

- Kumar, S.N. Strategies for Adoption of Appropriate Innovations and Technologies for the Development of Sericulture in SAARC Countries; SAARC Agriculture Center: Dhaka, Bangladesh, 2015. [Google Scholar]

- Anantanyu, S. Kelembagaan Petani: Peran Dan Strategi Pengembangan Kapasitasnya. SEPA 2011, 7, 102–109. [Google Scholar]

- Widiarti, A.; Andadari, L.; Suharti, S.; Heryati, Y.; Yuniati, D.; Agustarini, R. Partnership model for sericulture development to improve farmer's welfare (a case study at bina mandiri farmer group at Sukabumi Regency). IOP Conf. Ser. Earth Environ. Sci. 2021, 917, 012009. [Google Scholar] [CrossRef]

- Kanafi, R.R.; Ebadi, R.; Mirhosseini, S.Z.; Seidavi, A.R.; Zolfaghari, M.; Etebari, K. A review on nutritive effect of mulberry leaves enrichment with vitamins on economic traits and biological parameters of silkworm Bombyx mori L. Invertebr. Surviv. J. 2007, 4, 86–91. [Google Scholar]

| The Origin of the Cross | Leaf Production (ton/ha/year) |

|---|---|

| M. australis Poir x M. indica L. | 23.2 * |

| M. nigra L. x M. indica L. | 23 * |

| M. cathayana Hemsl. x M. amakusaguwa (Hybrid M. bombycis Koidz x M.s acidosa Griff.) | 52.35 ** |

| M. acidosa Griff.x M. latifolia Poir. | 35.42 ** |

| M. australis Poir x M. indica L. | 29.56 ** |

| Egg Type | Producer | Hatching Percentage (%) | Characteristics | Cocoon Quality | Filament Quality |

|---|---|---|---|---|---|

| C301 * | KSPA Soppeng and PPUS Candiroto | 81.65–81.95 |

|

|

|

| BS 09 ** | KSPA Soppeng dan PPUS Candiroto | >90 |

|

|

|

| PS 01 *** | Bina Mandiri Forest Farmers Group, Sukabumi | 90.74–96.99 |

|

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andadari, L.; Yuniati, D.; Supriyanto, B.; Murniati; Suharti, S.; Widarti, A.; Steven, E.; Sadapotto, A.; Winarno, B.; Minarningsih; et al. Lens on Tropical Sericulture Development in Indonesia: Recent Status and Future Directions for Industry and Social Forestry. Insects 2022, 13, 913. https://doi.org/10.3390/insects13100913

Andadari L, Yuniati D, Supriyanto B, Murniati, Suharti S, Widarti A, Steven E, Sadapotto A, Winarno B, Minarningsih, et al. Lens on Tropical Sericulture Development in Indonesia: Recent Status and Future Directions for Industry and Social Forestry. Insects. 2022; 13(10):913. https://doi.org/10.3390/insects13100913

Chicago/Turabian StyleAndadari, Lincah, Dhany Yuniati, Bambang Supriyanto, Murniati, Sri Suharti, Asmanah Widarti, Eden Steven, Andi Sadapotto, Bondan Winarno, Minarningsih, and et al. 2022. "Lens on Tropical Sericulture Development in Indonesia: Recent Status and Future Directions for Industry and Social Forestry" Insects 13, no. 10: 913. https://doi.org/10.3390/insects13100913