The Activation and Evolution of Twinning during Bending of Friction Stir Welded AZ31 Magnesium Alloys

Abstract

:1. Introduction

2. Materials and Experimental Procedures

3. Results and Discussion

3.1. Original Microstructure of FSWed AZ31 Mg Alloy Joint

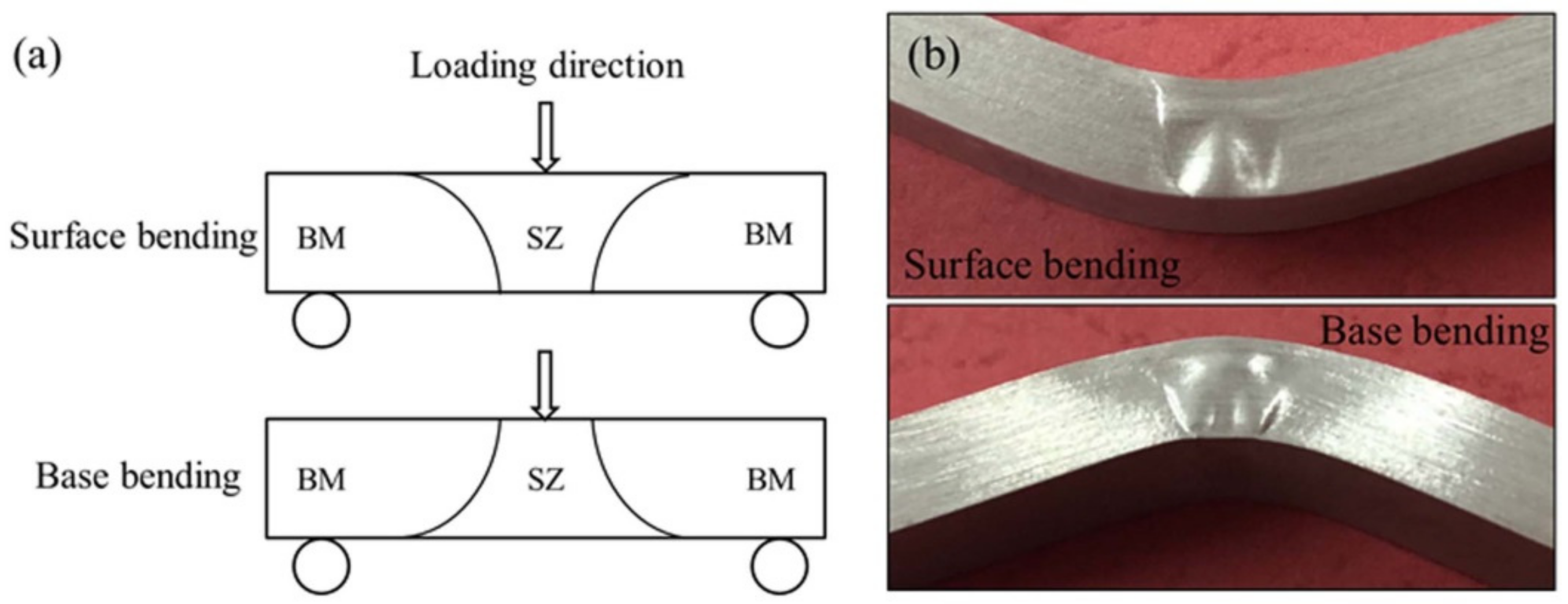

3.2. Bending Behavior of Surface Test Sample and Base Test Sample

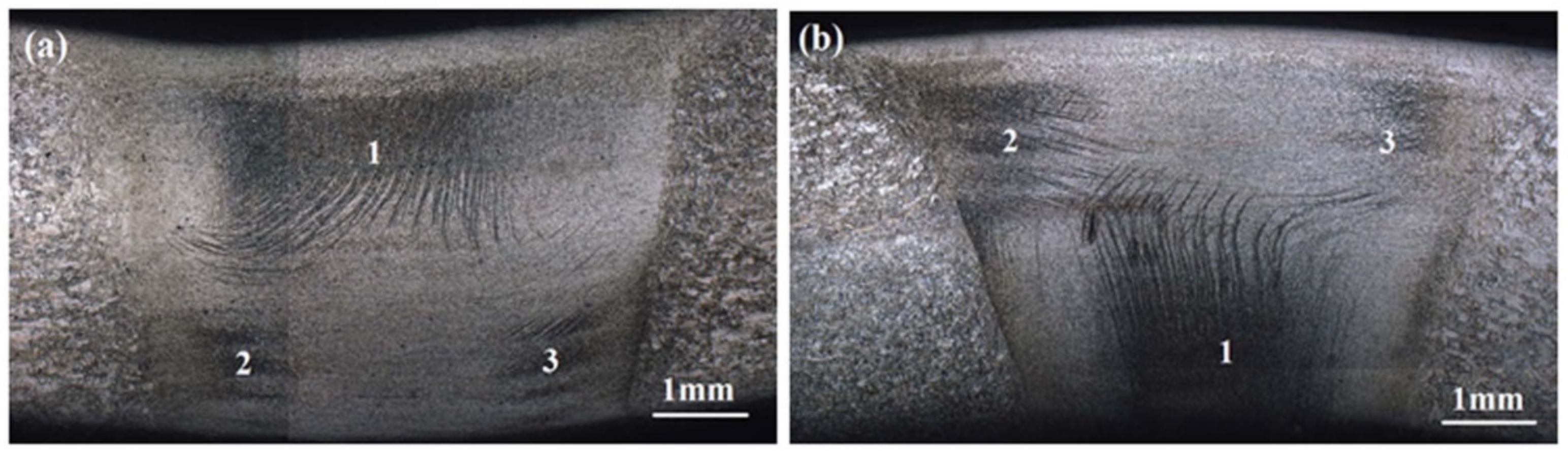

3.3. Microstructure Evolution of Surface Test Sample and Base Test Sample

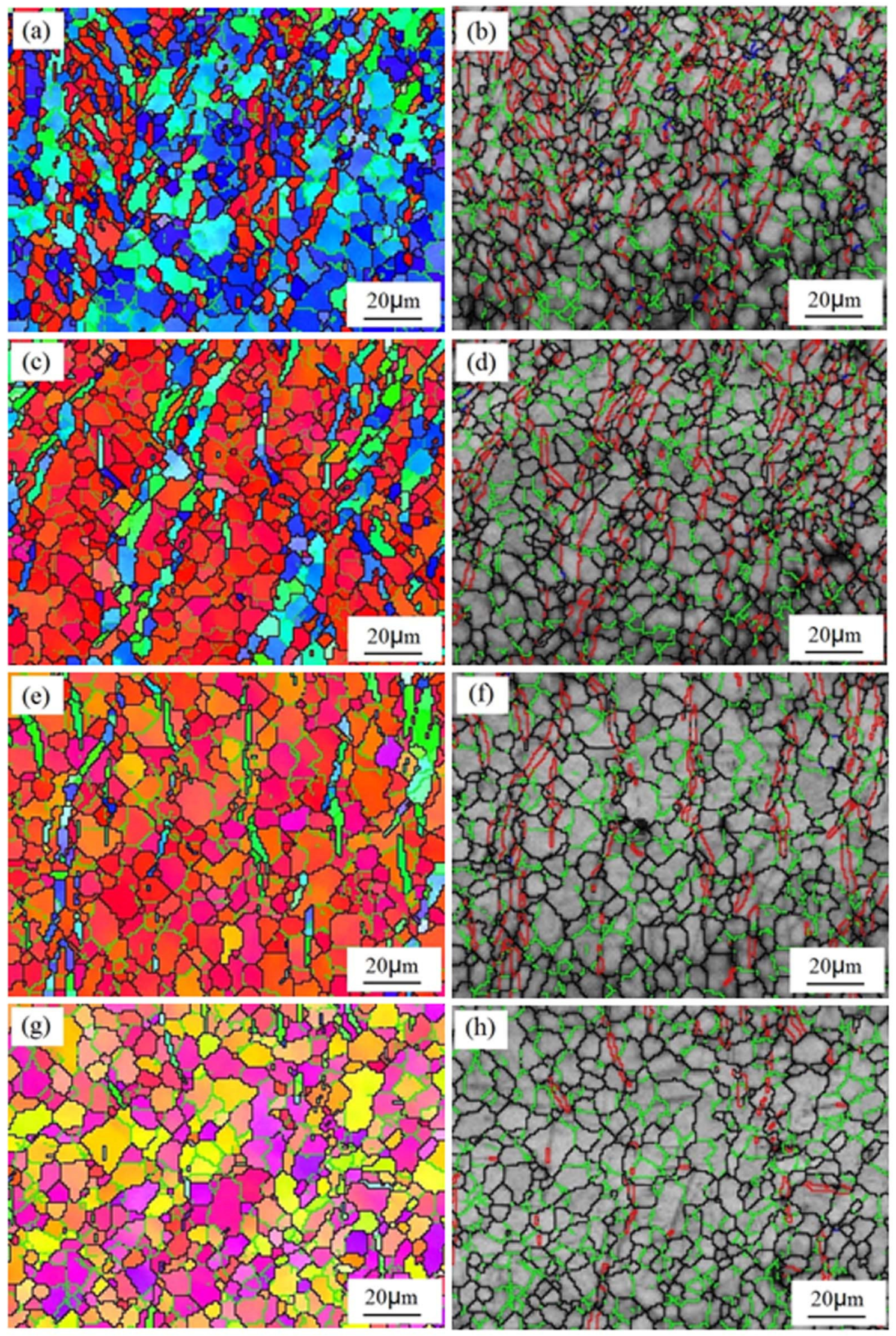

3.4. Twinning Mechanism during Bending Process

4. Conclusions

- (1)

- The stir zone had the smallest average grain size with ~7.0 μm and the strongest (0001) basal texture with c-axis parallel to welding direction. Then, the average grain sizes were 8.4 μm and 9.2 μm in the left and right transition zones of the weld, respectively. Meanwhile, the intensity of (0001) basal texture decreased and c-axis became parallel to transverse direction of weld.

- (2)

- The FSWed AZ31 Mg alloy joint exhibited different deformation behavior under different stress states. The stress-strain curve appeared as power-law shape during tension and work hardening shape during compression. However, the stress-strain curve during bending is different and macrographs for face and base bending indicated severe strain localization during bending.

- (3)

- Three concave regions formed during face and base bending, which was attributed to texture and stress distribution in the weld. In those regions, the grains had favorable orientation with c-axis parallel to the direction of tensile stress and abundant twins were activated and developed.

- (4)

- During three-point bending, two twinning mechanisms were activated—that is, ~56° {} contraction twin and ~86° {} expansion twin, in which {} twinning was the main plastic deformation mechanism and the number of twins was proportional to stress intensity. The twinning resulted in lattice rotation of about 86° around <> direction and changed orientation distribution of original crystal.

Author Contributions

Funding

Conflicts of Interest

References

- Kim, D.G.; Lee, K.M.; Lee, J.S.; Yoon, Y.O.; Son, H.T. Evolution of microstructures and textures in magnesium az31 alloys deformed by normal and cross-roll rolling. Mater. Lett. 2012, 75, 122–125. [Google Scholar] [CrossRef]

- Pollock, T.M. Weight loss with magnesium alloys. Science 2012, 328, 986–987. [Google Scholar] [CrossRef]

- Yasi, J.A.; Hector, L.G.; Trinkle, D.R. First-principles data for solid-solution strengthening of magnesium: From geometry and chemistry to properties. Acta Mater. 2010, 58, 5704–5713. [Google Scholar] [CrossRef] [Green Version]

- Yasi, J.A.; Hector, L.G.; Trinkle, D.R. Prediction of thermal cross-slip stress in magnesium alloys from direct first principles data. Acta Mater. 2011, 59, 5652–5660. [Google Scholar] [CrossRef] [Green Version]

- Templeman, Y.; Ben, H.G.; Meshi, L. Friction stir welded AM50 and AZ31 Mg alloys: Microstructural evolution and improved corrosion resistance. Mater. Charact. 2017, 126, 86–95. [Google Scholar] [CrossRef]

- Commin, L.; Dumont, M. Friction stir welding of az31 magnesium alloy rolled sheets: Influence of processing parameters. Acta Mater. 2009, 57, 326–334. [Google Scholar] [CrossRef] [Green Version]

- Chowdhury, S.M.; Chen, D.L.; Bhole, S.D.; Cao, X.; Powidajko, E.; Weckman, D.C.; Zhou, Y. Tensile properties and strain-hardening behavior of double-sided arc welded and friction stir welded az31b magnesium alloy. Mater. Sci. Eng. A 2010, 527, 2951–2961. [Google Scholar] [CrossRef]

- Chang, C.I.; Du, X.H.; Huang, J.C. Producing nanograined microstructure in Mg–Al–Zn alloy by two-step friction stir processing. Scr. Mater. 2008, 59, 356–359. [Google Scholar] [CrossRef]

- Yang, J.; Ni, D.R.; Xiao, B.L.; Ma, Z.Y. Non-uniform deformation in a friction stir welded Mg–Al–Zn joint during stress fatigue. Int. J. Fatigue 2014, 59, 9–13. [Google Scholar] [CrossRef]

- Liu, D.; Xin, R.; Xiao, Y.; Zhou, Z.; Liu, Q. Strain localization in friction stir welded magnesium alloy during tension and compression deformation. Mater. Sci. Eng. A 2014, 609, 88–91. [Google Scholar] [CrossRef]

- Xin, R.; Liu, D.; Li, B.; Sun, L.; Zhou, Z.; Liu, Q. Mechanisms of fracture and inhomogeneous deformation on transverse tensile test of friction-stir-processed az31 mg alloy. Mater. Sci. Eng. A 2013, 565, 333–341. [Google Scholar] [CrossRef]

- Liu, D.; Xin, R.; Li, Z.; Liu, Z.; Zheng, X.; Liu, Q. The activation of twinning and texture evolution during bending of friction stir welded magnesium alloys. Mater. Sci. Eng. A 2015, 646, 145–153. [Google Scholar] [CrossRef]

- Mcclelland, Z.; Li, B.; Horstemeyer, S.J.; Brauer, S.; Adedoyin, A.A.; Hector, L.G. Geometrically necessary twins in bending of a magnesium alloy. Mater. Sci. Eng. A 2015, 645, 298–305. [Google Scholar] [CrossRef]

- Hong, S.G.; Park, S.H.; Lee, C.S. Role of 10–12 twinning characteristics in the deformation behavior of a polycrystalline magnesium alloy. Acta Mater. 2010, 58, 5873–5885. [Google Scholar] [CrossRef]

- Wonsiewicz, B.C.; Backofen, W.A. Plasticity of magnesium crystals. Trans. AIME 1967, 239, 1422–1431. [Google Scholar]

- Kelley, E.W.; Hosford, J.W.F. Deformation characteristics of textured magnesium. Trans. AIME 1968, 242, 654–661. [Google Scholar]

- Knezevic, M.; Levinson, A.; Harris, R.; Mishra, R.K. Deformation twinning in AZ31: Influence on strain hardening and texture evolution. Acta Mater. 2010, 58, 6230–6242. [Google Scholar] [CrossRef]

- Christian, J.W.; Mahajan, S. Deformation twinning. Prog. Mater. Sci. 1995, 39, 1–157. [Google Scholar] [CrossRef]

- Han, T.; Huang, G.; Wang, Y. Enhanced mechanical properties of AZ31 magnesium alloy sheets by continuous bending process after V-bending. Prog. Nat. Sci. Mater. Int. 2016, 26, 97–102. [Google Scholar] [CrossRef] [Green Version]

- Huang, G.; Wang, L.; Zhang, H.; Wang, Y.; Shi, Z.; Pan, F. Evolution of neutral layer and microstructure of AZ31b magnesium alloy sheet during bending. Mater. Lett. 2013, 98, 47–50. [Google Scholar] [CrossRef]

- Park, S.H.C.; Sato, Y.S.; Kokawa, H. Effect of micro-texture on fracture location in friction stir weld of Mg alloy AZ61 during tensile test. Scr. Mater. 2003, 49, 161–166. [Google Scholar] [CrossRef]

- Park, S.H.C.; Sato, Y.S.; Kokawa, H. Basal plane texture and flow pattern in friction stir weld of a magnesium alloy. Metall. Mater. Trans. A 2003, 34, 987–994. [Google Scholar] [CrossRef]

- Wang, L.; Huang, G.; Zhang, H.; Wang, Y.; Yin, L. Evolution of springback and neutral layer of az31b magnesium alloy v-bending under warm forming conditions. J. Mater. Process. Technol. 2013, 213, 844–850. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, W.; Chen, W. Effect of initial texture on the bending behavior, microstructure and texture evolution of ZK60 magnesium alloy during the bending process. J. Alloys Compd. 2018, 737, 505–514. [Google Scholar] [CrossRef]

- Baird, J.C.; Li, B.; Parast, S.Y.; Horstemeyer, S.J.; Localized Hector, S.L., Jr.; Wang, P.T.; Horstemeyer, M.F. Localized twin bands in sheet bending of a magnesium alloy. Scr. Mater. 2012, 67, 471–474. [Google Scholar] [CrossRef]

- Mujika, F. On the difference between flexural moduli obtained by three-point and four-point bending tests. Polym. Test. 2006, 25, 214–220. [Google Scholar] [CrossRef]

| Gains | P1 | T1 | P2 |

|---|---|---|---|

| Φ1(deg) | 57.7 | 122.0 | 56.9 |

| Φ(deg) | 152.2 | 84.1 | 154.5 |

| Φ2(deg) | 25.7 | 8.8 | 25.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, F.; Li, Y.; Zheng, J. The Activation and Evolution of Twinning during Bending of Friction Stir Welded AZ31 Magnesium Alloys. Metals 2020, 10, 139. https://doi.org/10.3390/met10010139

Qin F, Li Y, Zheng J. The Activation and Evolution of Twinning during Bending of Friction Stir Welded AZ31 Magnesium Alloys. Metals. 2020; 10(1):139. https://doi.org/10.3390/met10010139

Chicago/Turabian StyleQin, Fengming, Yajie Li, and Jianjun Zheng. 2020. "The Activation and Evolution of Twinning during Bending of Friction Stir Welded AZ31 Magnesium Alloys" Metals 10, no. 1: 139. https://doi.org/10.3390/met10010139