Microstructural and Mechanical Response of NiTi Lattice 3D Structure Produced by Selective Laser Melting

Abstract

:1. Introduction

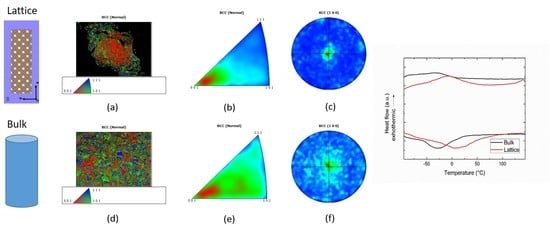

2. Experimental

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tang, Y.; Zhao, Y.F. A survey of the design methods for additive manufacturing to improve functional performance. Rapid Prototyp. J. 2016, 22, 569–590. [Google Scholar] [CrossRef]

- Otsuka, K.; Wayman, C.M. Shape Memory Materials; Cambridge Univ. Press: Cambridge, UK, 1998. [Google Scholar]

- Otsuka, K.; Ren, X. Physical Metallurgy of Ti-Ni based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Van Humbeeck, J. Non medical applications of shape memory alloys. Mater. Sci. Eng. A 1999, 273, 134–148. [Google Scholar] [CrossRef]

- Duerig, T.; Pelton, A.; Stöckel, D. An overview of nitinol medical applications. Mater. Sci. Eng. A 1999, 273, 149–160. [Google Scholar] [CrossRef]

- Elahinia, M.; Shayesteh Moghaddam, N.; Taheri Andani, M.; Amerinatanzi, A.; Bimber, B.A.; Hamilton, R.F. Fabrication of NiTi through additive manufacturing: A review. Prog. Mater. Sci. 2016, 83, 630–663. [Google Scholar] [CrossRef] [Green Version]

- Saedi, S.; Moghaddam, N.S.; Amerinatanzi, A.; Elahinia, M.; Karaca, H.E. On the effects of selective laser melting process parameters on microstructure and thermomechanical response of Ni-rich NiTi. Acta Mater. 2018, 14, 552–560. [Google Scholar] [CrossRef]

- Speirs, M.; Wang, X.; van Baelen, S.; Ahadi, A.; Dadbakhsh, S.; Kruth, J.P.; Van Humbeck, J. On the Transformation Behavior of NiTi Shape-Memory Alloy Produced by SLM. Shape Mem. Superelasticity 2016, 2, 310. [Google Scholar] [CrossRef] [Green Version]

- Dadbakhsh, S.; Speirs, M.; Van Humbeck, J.; Kruth, J.P. Laser additive manufacturing of bulk and porous shape memory NiTi alloys: From processes to potential biomedical applications. MRS Bull. 2016, 41, 765–774. [Google Scholar] [CrossRef] [Green Version]

- Andani, M.T.; Saedi, S.; Turabi, A.S.; Karamooz, M.R.; Haberland, C.; Karaca, H.E.; Elahinia, M. Mechanical and Shape Memory properties of porous Ni50.1Ti49.9 alloys manufactured by selective laser melting. J. Mech. Behav. Biomed. Mater. 2017, 68, 224–231. [Google Scholar] [CrossRef] [PubMed]

- Fiocchi, J.; Biffi, C.A.; Scaccabarozzi, D.; Saggin, B.; Tuissi, A. Enhancement of the Damping Behavior of Ti6Al4V Alloy through the Use of Trabecular Structure Produced by Selective Laser Melting. Adv. Eng. Mater. 2019. [Google Scholar] [CrossRef]

- Demir, A.G.; Previtali, B. Additive manufacturing of cardiovascular CoCr stents by selective laser melting. Mater. Des. 2017, 119, 338–350. [Google Scholar] [CrossRef] [Green Version]

- Funakubo, H. Shape Memory Alloys; Gordon and Breach Science Publishers: Amsterdam, The Netherlands, 1987. [Google Scholar]

- Nishida, M.; Wayman, C.; Honma, T. Precipitation processes in near-equiatomic TiNi shape memory alloys. Metall. Trans. A 1986, 17, 1505–1515. [Google Scholar] [CrossRef]

- Mahmoudi, M.; Tapia, G.; Franco, B.; Ma, J.; Arroyave, R.; Karaman, I.; Elwany, A. On the printability and transformation behavior of nickel-titanium shape memory alloys fabricated using laser powder-bed fusion additive manufacturing. J. Manuf. Process. 2018, 35, 672–680. [Google Scholar] [CrossRef]

- Bormann, T.; Muller, B.; Schinhammer, M.; Kessler, A.; Thalmann, P.; de Wild, M. Microstructure of selective laser melted nickel-titanium. Mater. Charact. 2014, 94, 189–202. [Google Scholar] [CrossRef]

- Biffi, C.A.; Fiocchi, J.; Bassani, P.; Tuissi, A. Selective Laser Melting of NiTi Shape Memory Alloy: Processability, microstructure and superelasticity. Shape Mem. Superelasticity 2020. Under consideration. [Google Scholar]

- Biffi, C.A.; Fiocchi, J.; Ferrario, E.; Fornaci, A.; Riccio, M.; Romeo, M.; Tuissi, A. Effects of the scanning strategy on the microstructure and mechanical properties of a TiAl6V4 alloy produced by electron beam additive manufacturing. Int. J. Adv. Manuf. Technol. 2020, 1–12. [Google Scholar] [CrossRef]

- Fiocchi, J.; Biffi, C.A.; Tuissi, A. Selective laser melting of high-strength primary AlSi9Cu3 alloy: Processability, microstructure, and mechanical properties. Mater. Des. 2020. [Google Scholar] [CrossRef]

- Shiva, S.; Palani, I.A.; Mishra, S.K.; Paul, C.P.; Kukreja, L.M. Investigation on the influence of composition in the development of Ni-Ti shape memory alloy using laser based additive manufacturing. Opt. Laser Technol. 2015, 69, 44–51. [Google Scholar] [CrossRef]

- Ashby, M.F.; Evans, A.G.; Fleck, N.A.; Gibson, L.J.; Hutchinson, J.W. Metal Foams: A Design Guide, Butterworth-Heinemann; United States of America: Boston, MA, USA, 2000.

| Parameters | Values |

|---|---|

| Power | 75 W |

| Exposure time | 75 μs |

| Atmosphere | Argon |

| Layer thickness | 30 μm |

| Hatch distance | 50 μm |

| Point distance | 50 μm |

| Laser spot size | 65 μm |

| Sample: | As (°C) | Ap (°C) | Af (°C) | HM→A (J/g) | Ms (°C) | Mp (°C) | Mf (°C) | HA→M (J/g) |

|---|---|---|---|---|---|---|---|---|

| Lattice | −47 | 9 | 76 | 10.5 | 44 | −5 | −52 | 7.5 |

| Bulk | −61 | −22 | 30 | 5.4 | 11 | −28 | −86 | 4.0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biffi, C.A.; Bassani, P.; Fiocchi, J.; Tuissi, A. Microstructural and Mechanical Response of NiTi Lattice 3D Structure Produced by Selective Laser Melting. Metals 2020, 10, 814. https://doi.org/10.3390/met10060814

Biffi CA, Bassani P, Fiocchi J, Tuissi A. Microstructural and Mechanical Response of NiTi Lattice 3D Structure Produced by Selective Laser Melting. Metals. 2020; 10(6):814. https://doi.org/10.3390/met10060814

Chicago/Turabian StyleBiffi, Carlo Alberto, Paola Bassani, Jacopo Fiocchi, and Ausonio Tuissi. 2020. "Microstructural and Mechanical Response of NiTi Lattice 3D Structure Produced by Selective Laser Melting" Metals 10, no. 6: 814. https://doi.org/10.3390/met10060814