Obtaining Excellent Mechanical Properties in an Ultrahigh-Strength Stainless Bearing Steel via Solution Treatment

Abstract

:1. Introduction

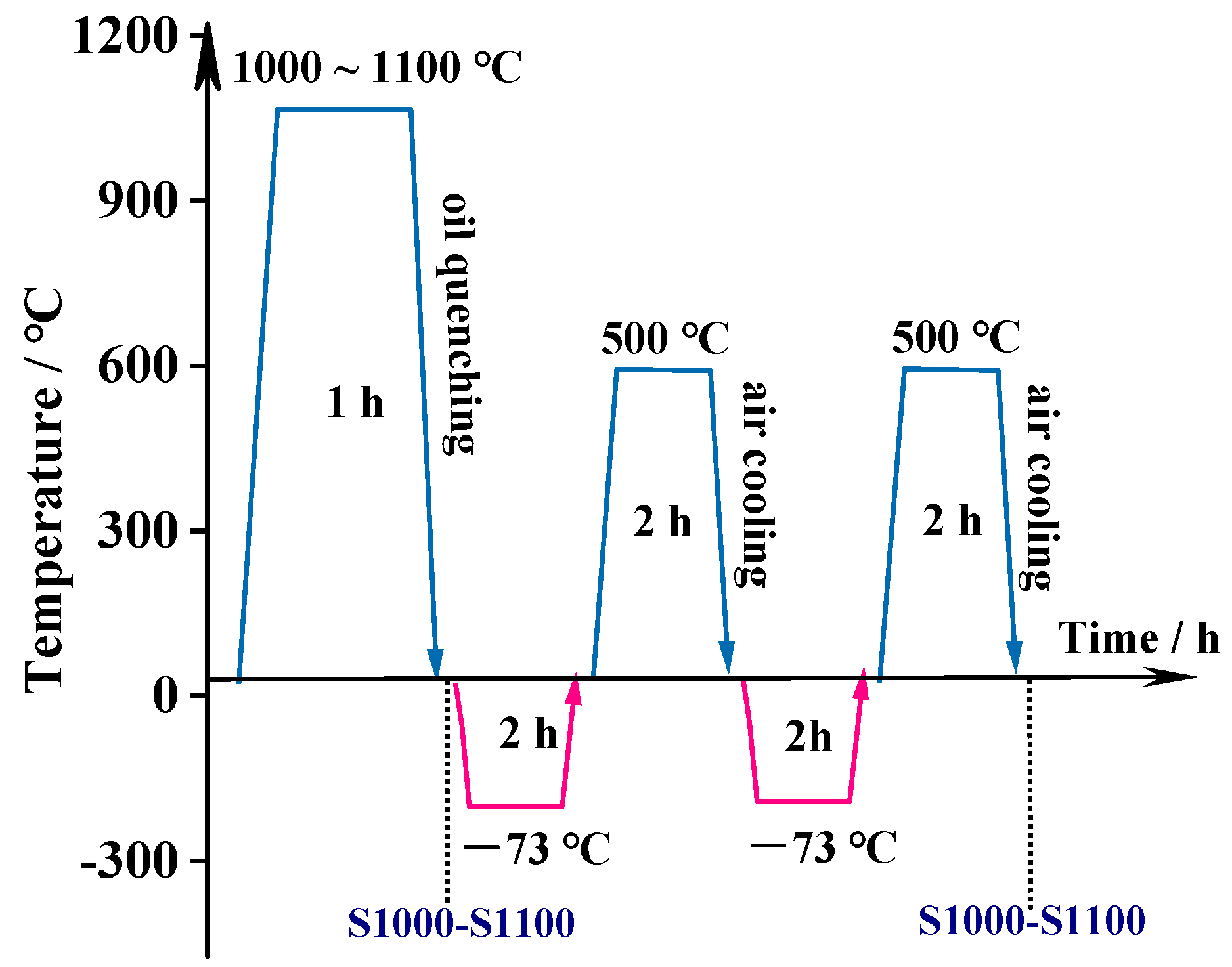

2. Materials and Methods

3. Results

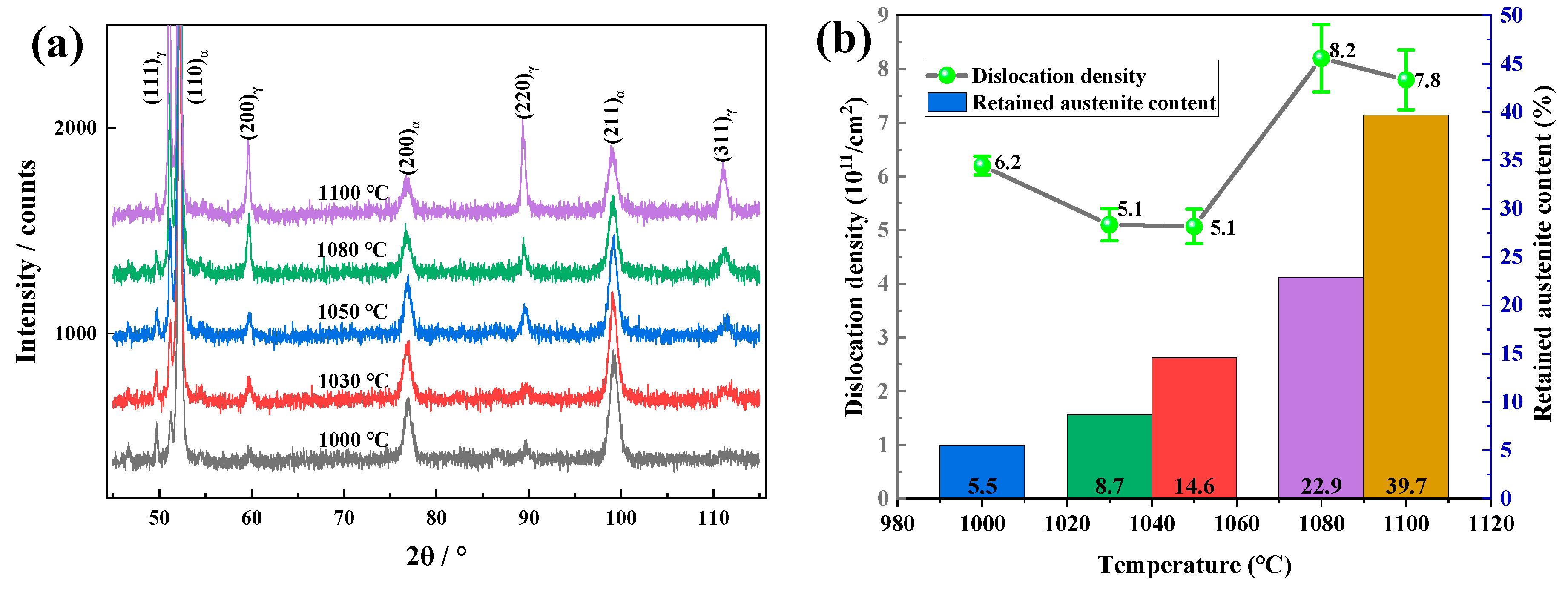

3.1. Retained Austenite Content and Dislocation Density

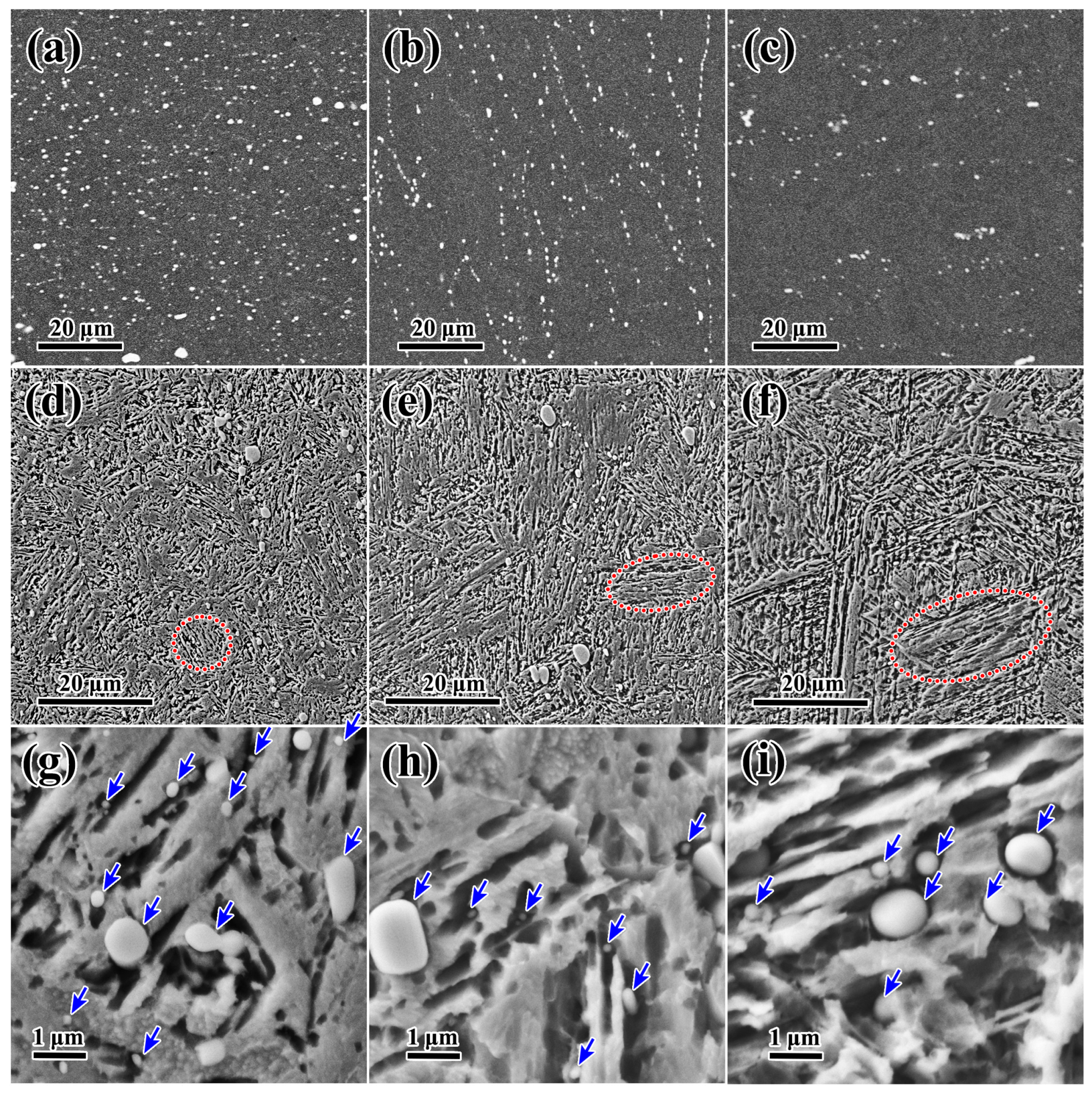

3.2. SEM Microstructure

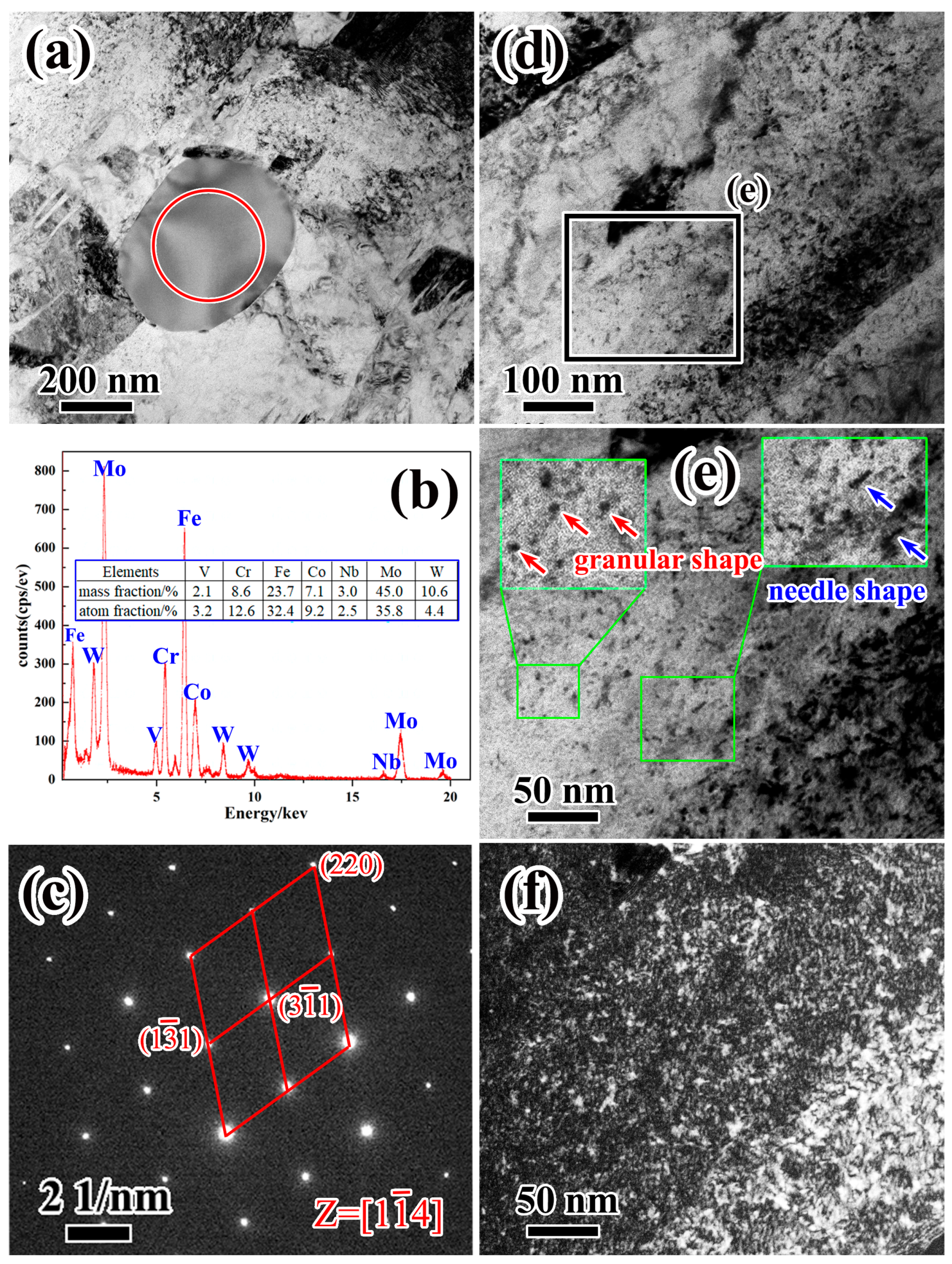

3.3. Precipitation and Retained Austenite

3.4. Mechanical Properties

4. Discussion

4.1. Mechanical Properties of the Developed Ultrahigh-Strength Steels and Bearing Steels

4.2. Strengthening and Toughening Mechanism

5. Conclusions

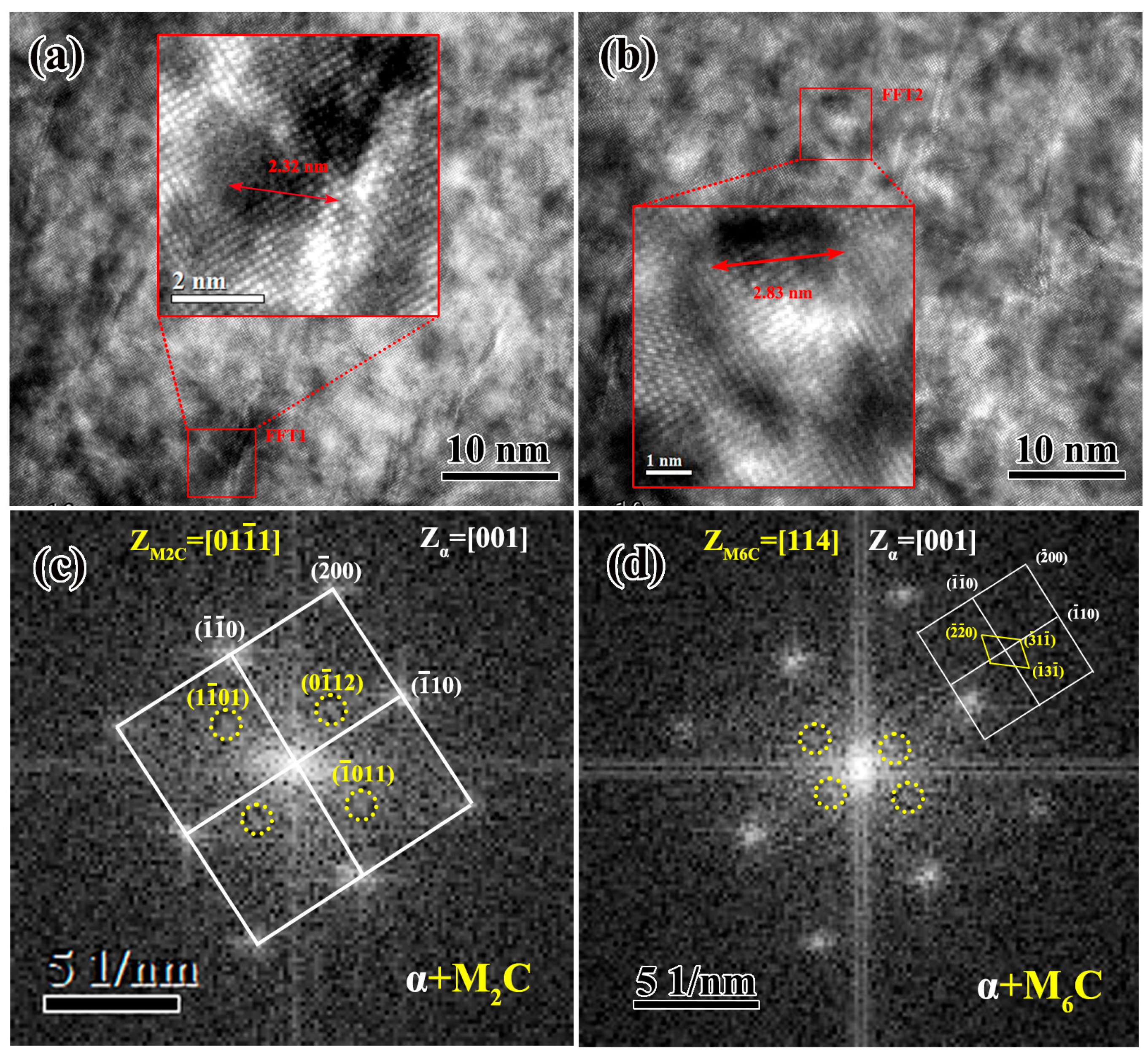

- With an increasing solid solution temperature, the retained austenite content increases to as high as 39.7% at a solution temperature of 1100 °C and the dislocation density reaches a peak value of 8.2 × 1011 cm−2 at a solution temperature of 1080 °C. TEM and HRTEM analyses reveal that the microstructure of samples tempered at 500 °C have a high density of tangled dislocations, together with film austenite with a thickness of 0.2~0.3 nm, and nanoprecipitates of M2C and M6C carbides, where both types of precipitate retain coherence with the martensite matrix. M2C carbides are present in a needle shape, with a width of 2~3 nm, and follow a [01 - 11]M2C∥[001]α-and (0 - 112)M2C∥(−110)α-orientation relationship with the martensitic matrix. M6C carbides are present with a spheroidal shape with a diameter of 2~3 nm, and follow a [114]M6C∥[001]α- and (−31 - 1)M6C∥(−110)α-orientation relationship with the martensitic matrix.

- Tensile strength and Rockwell hardness both increase gradually with increasing solid solution temperature up to 1080 °C, reaching peak values of 1830 MPa and 51.4 HRC, respectively, and then decrease rapidly with a further increase in solution temperature. Yield strength decreases linearly (to 1372 MPa) with increasing solution temperatures to up to 1080 °C, and then descends rapidly to 1033 MPa at higher solution temperatures. The representative toughness indexes of elongation, section shrinkage, and impact absorbed energy all increase with increasing solution temperature to reach maximum values. Excellent values of the strong plastic product, representing a combination of strength and toughness, are achieved after tempering at 1080 °C (33.9 GPa·%) and 1100 °C (37.0 GPa·%), both of which are far higher than the temperatures for any other ultrahigh-strength steel or bearing steel ever reported.

- The super-high strength and toughness of the newly developed steel is mainly attributed to the TRIP effect, promoted by a high retained austenite content, and to strong dislocation strengthening caused by a high dislocation density. The dislocation strengthening contribution is estimated as 1014.9 MPa in the sample tempered at 1080 °C, exceeding 50% of the total strength. The high dislocation density in the heat-treated samples is mainly attributed to the synergistic effect of cobalt addition and to the nanoprecipitation of M2C and M6C carbides.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Trivedi, H.K.; Forster, N.H.; Rosado, L. Rolling contact fatigue evaluation of advanced bearing steels with and without the oil anti-wear additive tricresyl phosphate. Tribol. Lett. 2011, 41, 597–605. [Google Scholar] [CrossRef]

- Wang, F.F.; Li, Q.S.; Zheng, L.J.; Zhang, F.X.; Zhang, H. Microstructure and corrosion characterization of Cr film on carburized CSS-42L aerospace bearing steel by filtered cathodic vacuum arc deposition. Coatings 2018, 8, 313. [Google Scholar] [CrossRef]

- Yin, L.C.; Ma, X.X.; Tang, G.Z.; Fu, Z.Y.; Yang, S.X.; Wang, T.J.; Wang, L.Q.; Li, L.H. Characterization of carburized 14Cr14Co13Mo4 stainless steel by low pressure carburizing. Surf. Coat. Technol. 2019, 358, 654–660. [Google Scholar] [CrossRef]

- Tomasello, C.M.; Burrier, H.I.; Knepper, R.A.; Balliett, S.; Maloney, J.L. Progress in the evaluation of CSS-42L(TM): A high performance bearing alloy. In Bearing Steel Technology; Beswick, J.M., Ed.; American Society for Testing and Materials (ASTM) International: West Conshohocken, PA, USA, 2002; pp. 375–385. [Google Scholar] [CrossRef]

- Bhadeshia, H. Steels for bearings. Prog. Mater. Sci. 2012, 57, 268–435. [Google Scholar] [CrossRef]

- Guan, J.; Wang, L.; Zhang, Z.; Shi, X.; Ma, X. Fatigue crack nucleation and propagation at clustered metallic carbides in M50 bearing steel. Tribol. Int. 2018, 119, 165–174. [Google Scholar] [CrossRef]

- Nygaard, J.R.; Rawson, M.; Danson, P.; Bhadeshia, H. Bearing steel microstructures after aircraft gas turbine engine service. Mater. Sci. Technol. 2014, 30, 1911–1918. [Google Scholar] [CrossRef]

- Wang, F.F.; Zhang, F.X.; Zheng, L.J.; Zhang, H. Structure and corrosion properties of Cr coating deposited on aerospace bearing steel. Appl. Surf. Sci. 2017, 423, 695–703. [Google Scholar] [CrossRef]

- Forster, N.H.; Rosado, L.; Ogden, W.P.; Trivedi, H.K. Rolling Contact Fatigue Life and Spall Propagation Characteristics of AISI M50, M50NiL, and AISI 52100, Part III: Metallurgical Examination. Tribol. Trans. 2010, 53, 52–59. [Google Scholar] [CrossRef]

- Maloney, J.L.; Tomasello, C.M. Case Carburized Stainless Steel Alloy for High Temperature Applications. U.S. Patent 5,424,028, 13 June 1995. [Google Scholar]

- Burrier, H.I.; Milam, L.; Tomasello, C.M.; Balliett, S.A.; Maloney, J.L.; Ogden, W.P. Development of CSS-42LTM, a high performance carburizing stainless steel for high temperature aerospace applications. In Proceedings of the Symposium on Bearing Steels: Into the 21st Century ASTM Committee A-1 on Steel, New Orleans, LA, USA, 19–21 November 1996; ASTM: Ann Arbor, MI, USA, 1998. [Google Scholar]

- Yu, F.; Chen, X.P.; Xu, H.F.; Dong, H.; Weng, Y.Q.; Cao, W.Q. Current status of metallurgical quality and fatigue performance of rolling bearing steel and development direction of high-end bearing steel. Acta Metall. Sin. 2020, 56, 513–522. [Google Scholar] [CrossRef]

- Gobber, F.S.; Bidulská, J.; Fais, A.; Bidulský, R.; Grande, M.A. Innovative Densification Process of a Fe-Cr-C Powder Metallurgy Steel. Metals 2021, 11, 665. [Google Scholar] [CrossRef]

- Yang, K.; Niu, M.C.; Tian, J.L.; Wang, W. Research and development of maraging stainless steel used for new generation landing gear. Acta Metall. Sin. 2018, 54, 1567–1585. [Google Scholar] [CrossRef]

- Luo, H.W.; Shen, G.H. Progress and perspective of ultra-high strength steels having high toughness. Acta Metall. Sin. 2020, 56, 494–512. [Google Scholar] [CrossRef]

- Pioszak, G.L.; Gangloff, R.P. Hydrogen environment assisted cracking of modern ultra-high strength martensitic steels. Metall. Mater. Trans. A 2017, 48A, 4025–4045. [Google Scholar] [CrossRef]

- Dini, G.; Ueji, R.; Najafizadeh, A.; Monir-Vaghefi, S.M. Flow stress analysis of TWIP steel via the XRD measurement of dislocation density. Mater. Sci. Eng. A 2010, 527, 2759–2763. [Google Scholar] [CrossRef]

- Liu, T.; Cao, Z.; Wang, H.; Wu, G.; Jin, J.; Cao, W. A new 2.4GPa extra-high strength steel with good ductility and high toughness designed by synergistic strengthening of nano-particles and high-density dislocations. Scr. Mater. 2020, 178, 285–289. [Google Scholar] [CrossRef]

- Liu, Z.B.; Zhang, B.N.; Sha, G.; Jin, S.B.; Yang, Z.Y.; Liang, J.X.; Tian, Z.L. Effect of cobalt on precipitation in Fe-Cr-Co-Mo-Ni-C stainless steels. Mater. Lett. 2021, 289, 129439. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Zhan, D.P.; Qi, X.W.; Jiang, Z.H.; Zhang, H.S. The role of twins during the aging process of secondary hardening ultrahigh-strength steel. Mater. Lett. 2019, 244, 83–87. [Google Scholar] [CrossRef]

- Machmeier, P.; Matuszewski, T.; Jones, R.; Ayer, R. Effect of chromium additions on the mechanical and physical properties and microstructure of Fe-Co-Ni-Cr-Mo-C ultra-high strength steel: Part I. J. Mater. Eng. Perform. 1997, 6, 279–288. [Google Scholar] [CrossRef]

- Lü, X.Y.; Wu, Z.W.; He, X.; Li, J.; Li, S.H.; Yang, M.S.; Zhao, K.Y. Effect of deep cryogenic treatment on martensitic lath refinement and nano-twins formation of low carbon bearing steel. J. Iron Steel Res. Int. 2020, 27, 105–113. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Zhan, D.P.; Qi, X.W.; Jiang, Z.H. Austenite and precipitation in secondary-hardening ultra-high-strength stainless steel. Mater. Charact. 2018, 144, 393–399. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, Z.B.; Liang, J.X.; Yang, Z.Y.; Sheng, G.M. Elucidating the role of secondary cryogenic treatment on mechanical properties of a martensitic ultra-high strength stainless steel. Mater. Charact. 2021, 178, 111277. [Google Scholar] [CrossRef]

- Seo, J.Y.; Park, S.K.; Kwon, H.; Cho, K.S. Influence of Carbide Modifications on the Mechanical Properties of Ultra-High-Strength Stainless Steels. Metall. Mater. Trans. A 2017, 48A, 4477–4485. [Google Scholar] [CrossRef]

- Yuan, X.H.; Zheng, S.J.; Yang, M.S.; Zhao, K.Y. Carbide precipitation and microstructure refinement of Cr-Co-Mo-Ni bearing steel during hot deformation. J. Cent. South. Univ. 2015, 22, 3265–3274. [Google Scholar] [CrossRef]

- Dyson, D.J.; Keown, S.R. A study of precipitation in a 12 percent Cr-Co-Mo steel. Acta Metall. 1969, 17, 1095–1107. [Google Scholar] [CrossRef]

- Lu, L.; Hou, L.G.; Zhang, J.X.; Wang, H.B.; Cui, H.; Huang, J.F.; Zhang, Y.A.; Zhang, J.S. Improved the microstructures and properties of M3:2 high-speed steel by spray forming and niobium alloying. Mater. Charact. 2016, 117, 1–8. [Google Scholar] [CrossRef]

- Zhang, C.; Su, J.; Liang, J.X.; Liu, Z.B.; Ge, Q.L. Research development of precipitation behavior of ultra high strength stainless steels. Iron Steel 2018, 53, 48–61. [Google Scholar] [CrossRef]

- Li, X.; Lin, F.J.; Du, S.M.; Wu, C.C. Comparative analysis of high performance bearing steels. Heat Treat. Met. 2021, 46, 14–20. [Google Scholar] [CrossRef]

- Liu, Z.B.; Liang, J.X.; Su, J.; Wang, X.H.; Sun, Y.Q.; Wng, C.J.; Yang, Z.Y. Research and application progress in ultra-high strength stainless steel. Acta Metall. Sin. 2020, 56, 549–557. [Google Scholar] [CrossRef]

- Zheng, K.; Cao, W.Q.; Yu, F.; Wang, C.Y.; Zhong, Z.Q.; Xu, H.F. The research status and progress of high temperature stainless carburized bearing steel. Iron Steel 2022, 57, 125–136. [Google Scholar] [CrossRef]

- Yu, X.; Shen, X.; Wang, S.; Su, Y.; Zhao, W.; Wei, Y. Effect of quenching and tempering treatment on microstructure and mechanical properties of CSS-42L bearing steel. J. Mater. Eng. Perform. 2022, 31, 5458–5466. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Zhan, D.P.; Qi, X.W.; Jiang, Z.H. Effect of tempering temperature on the microstructure and properties of ultrahigh-strength stainless steel. J. Mater. Sci. Technol. 2019, 35, 1240–1249. [Google Scholar] [CrossRef]

- Shi, J.; Sun, X.; Wang, M.; Hui, W.; Dong, H.; Cao, W. Enhanced work-hardening behavior and mechanical properties in ultrafine-grained steels with large-fractioned metastable austenite. Scr. Mater. 2010, 63, 815–818. [Google Scholar] [CrossRef]

- Bordone, M.; Monsalve, A.; Ipiña, J.P. Fracture toughness of High-Manganese steels with TWIP/TRIP effects. Eng. Fract. Mech. 2022, 275, 108837. [Google Scholar] [CrossRef]

- Niu, G.; Tang, Q.; Zurob, H.S.; Wu, H.; Xu, L.; Gong, N. Strong and ductile steel via high dislocation density and heterogeneous nano/ultrafine grains. Mater. Sci. Eng. A 2019, 759, 1–10. [Google Scholar] [CrossRef]

- Xiao, M.G.; Lü, X.Y.; Li, D.H.; Li, S.H.; Zhao, K.Y.; Yang, M.S. Carbides precipitation and their evolution of Cr15Co10Mo5-alloyed heat-resistant bearing steel after tempering at different temperatures. J. Iron Steel Res. Int. 2019, 26, 1096–1105. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Zhan, D.P.; Qi, X.W.; Jiang, Z.H. Effect of solid-solution temperature on the microstructure and properties of ultra-high-strength ferrium S53 steel. Mater. Sci. Eng. A 2018, 730, 41–49. [Google Scholar] [CrossRef]

- Yasnikov, I.S.; Kaneko, Y.; Uchida, M.; Vinogradov, A. The grain size effect on strain hardening and necking instability revisited from the dislocation density evolution approach. Mater. Sci. Eng. A 2022, 831, 142330. [Google Scholar] [CrossRef]

- Speich, G.R.; Dabkowski, D.S.; Porter, L.F. Strength and toughness of Fe-10Ni alloys containing C, Cr, Mo, and Co. Metall. Trans. 1973, 4, 303–315. [Google Scholar] [CrossRef]

| Sample | Yield Strength (Rp0.2)/MPa | Ultimate Tensile Strength (Rm)/MPa | Elongation (A)/% | Section Shrinkage (Z)/% | Impact Absorbed Energy (Aku)/J |

|---|---|---|---|---|---|

| T1000 | 1530 ± 1 | 1778 ± 2 | 15.3 ± 0.2 | 48.5 ± 0.5 | 37.0 |

| T1030 | 1493 ± 8 | 1803 ± 7 | 16.0 ± 0.5 | 51.0 ± 0.0 | 41.7 |

| T1050 | 1444 ± 1 | 1822 ± 0 | 15.5 ± 0.5 | 52.5 ± 0.5 | 44.6 |

| T1080 | 1372 ± 1 | 1830 ± 1 | 18.5 ± 0.0 | 56.0 ± 1.0 | 52.3 |

| T1100 | 1033 ± 17 | 1806 ± 4 | 20.5 ± 0.5 | 59.5 ± 0.5 | 86.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, K.; Zhong, Z.; Wang, H.; Xu, H.; Yu, F.; Wang, C.; Wu, G.; Liang, J.; Godfrey, A.; Cao, W. Obtaining Excellent Mechanical Properties in an Ultrahigh-Strength Stainless Bearing Steel via Solution Treatment. Metals 2023, 13, 1824. https://doi.org/10.3390/met13111824

Zheng K, Zhong Z, Wang H, Xu H, Yu F, Wang C, Wu G, Liang J, Godfrey A, Cao W. Obtaining Excellent Mechanical Properties in an Ultrahigh-Strength Stainless Bearing Steel via Solution Treatment. Metals. 2023; 13(11):1824. https://doi.org/10.3390/met13111824

Chicago/Turabian StyleZheng, Kai, Zhenqian Zhong, Hui Wang, Haifeng Xu, Feng Yu, Cunyu Wang, Guilin Wu, Jianxiong Liang, Andy Godfrey, and Wenquan Cao. 2023. "Obtaining Excellent Mechanical Properties in an Ultrahigh-Strength Stainless Bearing Steel via Solution Treatment" Metals 13, no. 11: 1824. https://doi.org/10.3390/met13111824