The Influence of Centerline Segregation on Impact Toughness in Welding Heat-Affected Zone of X70 Pipeline Steel

Abstract

1. Introduction

2. Experimental Materials and Methods

3. Experimental Results and Analyses

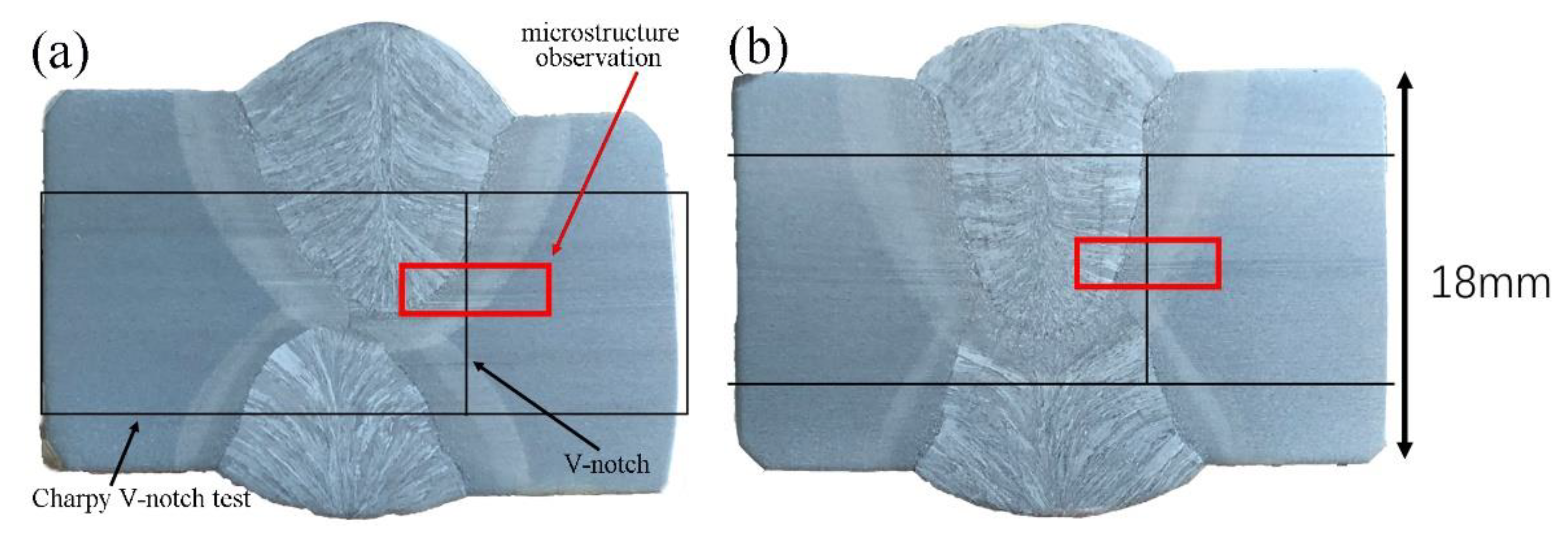

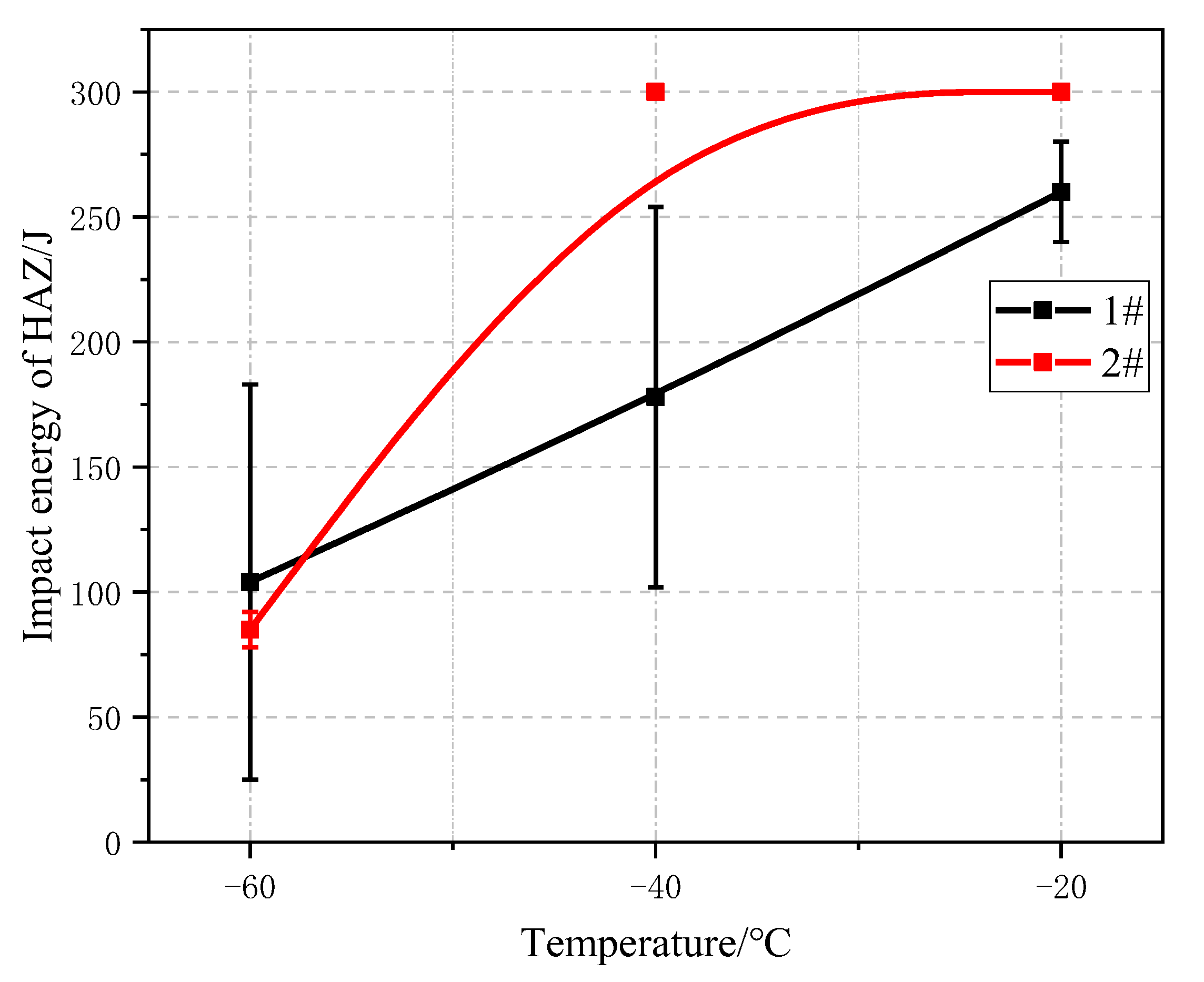

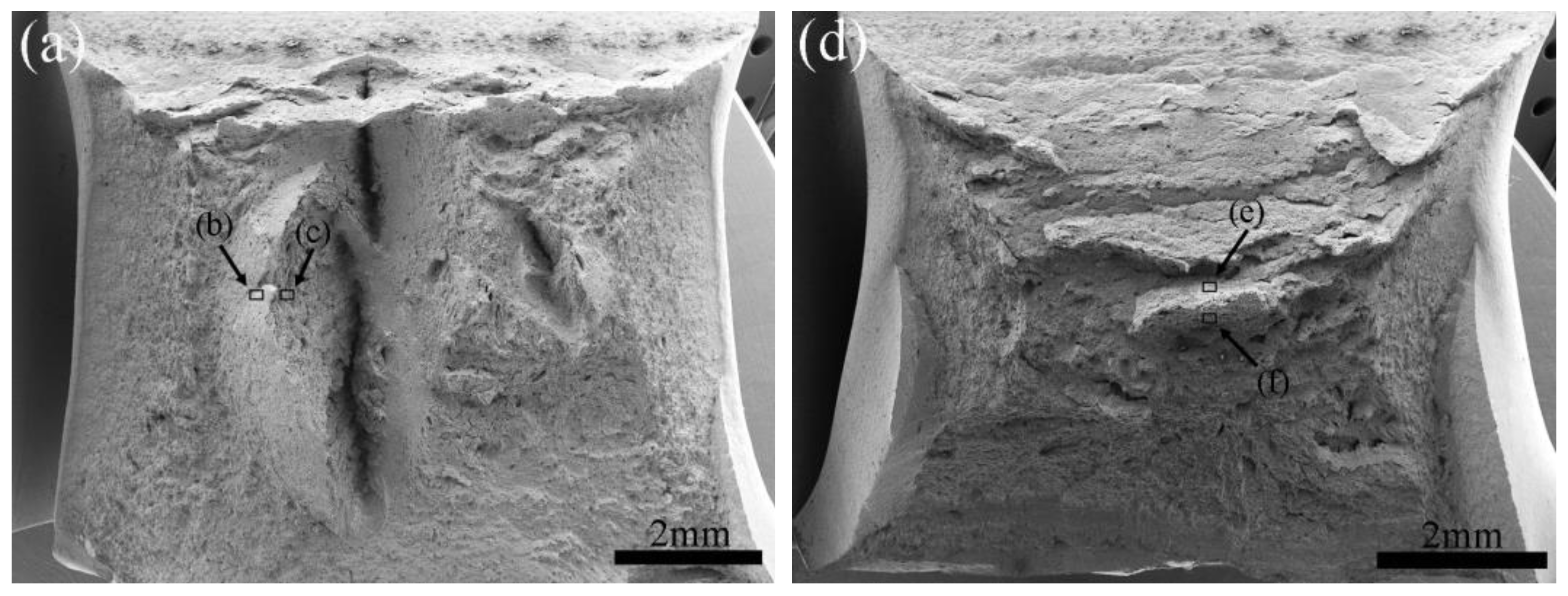

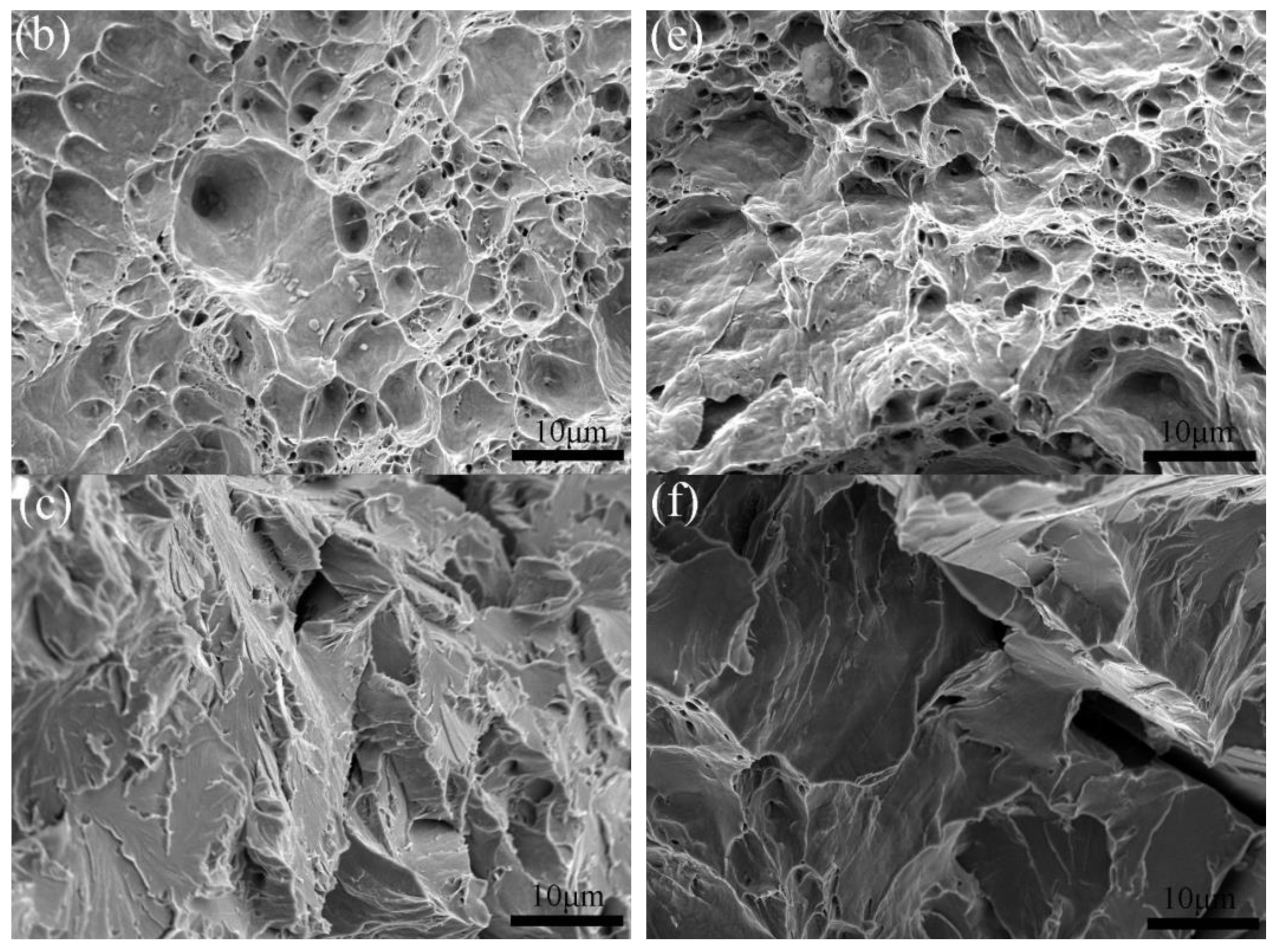

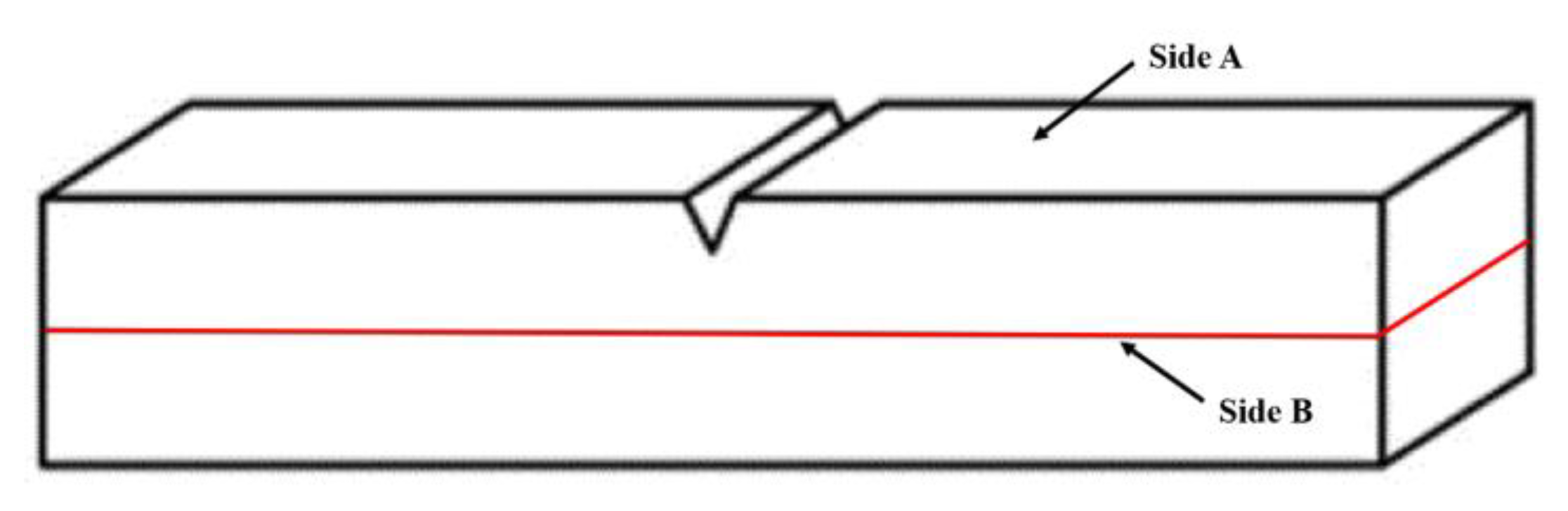

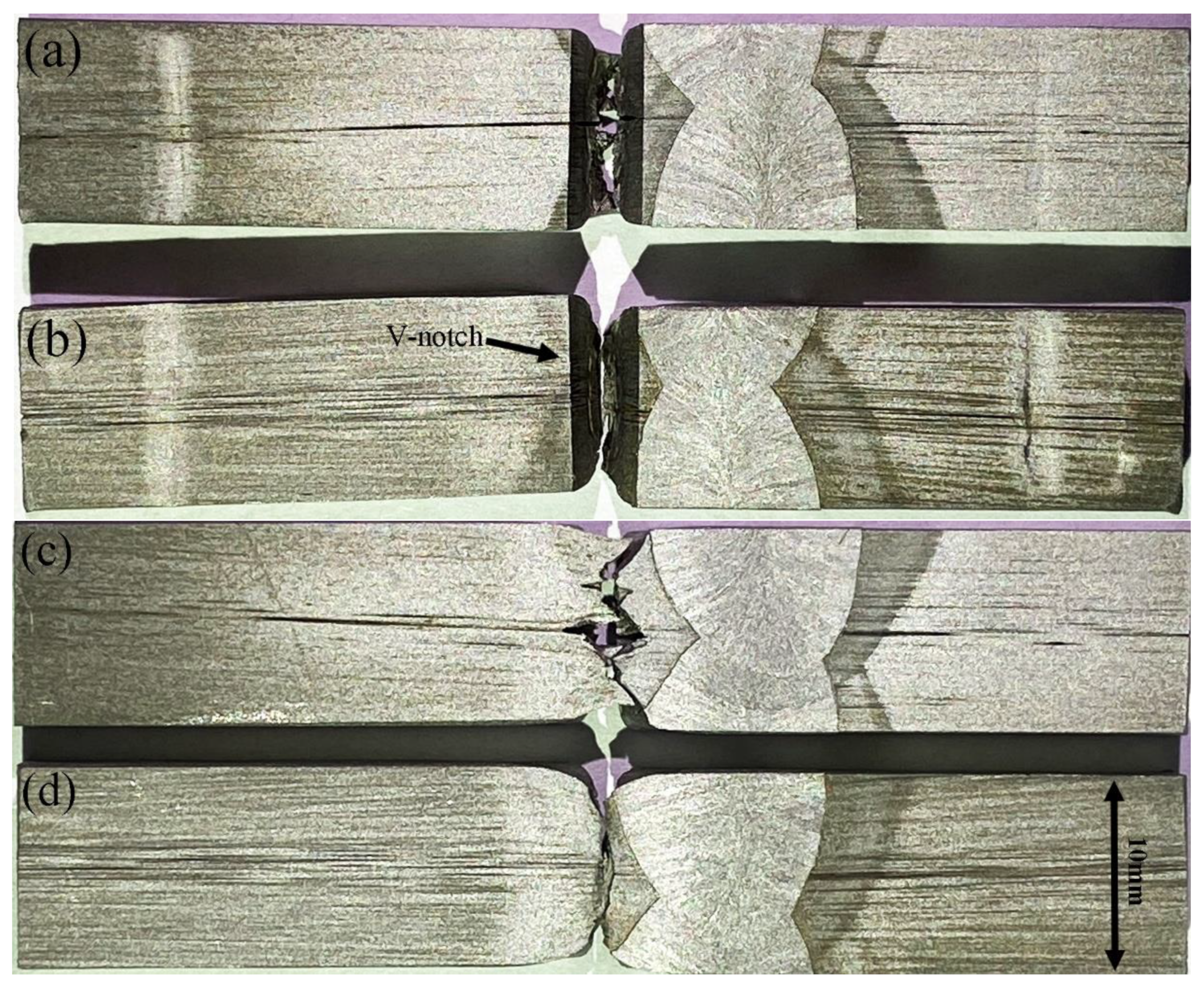

3.1. Low Temperature Impact Toughness and Fracture Morphology

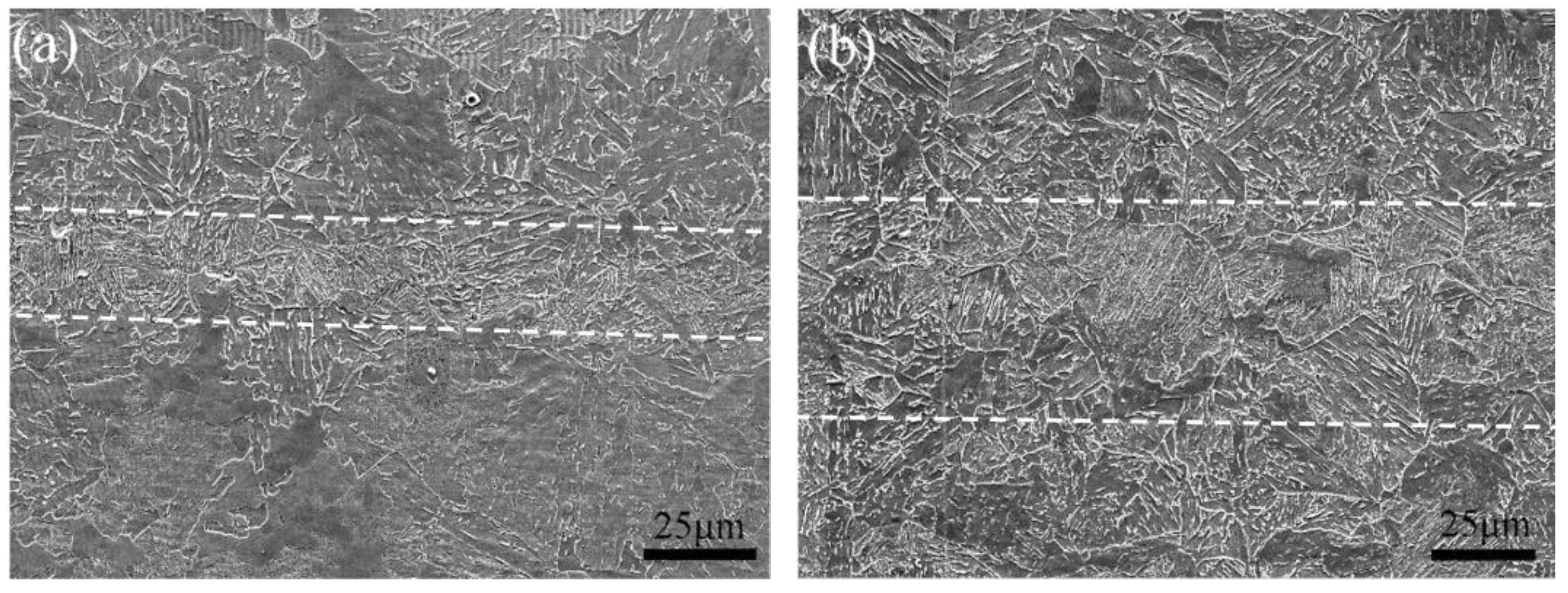

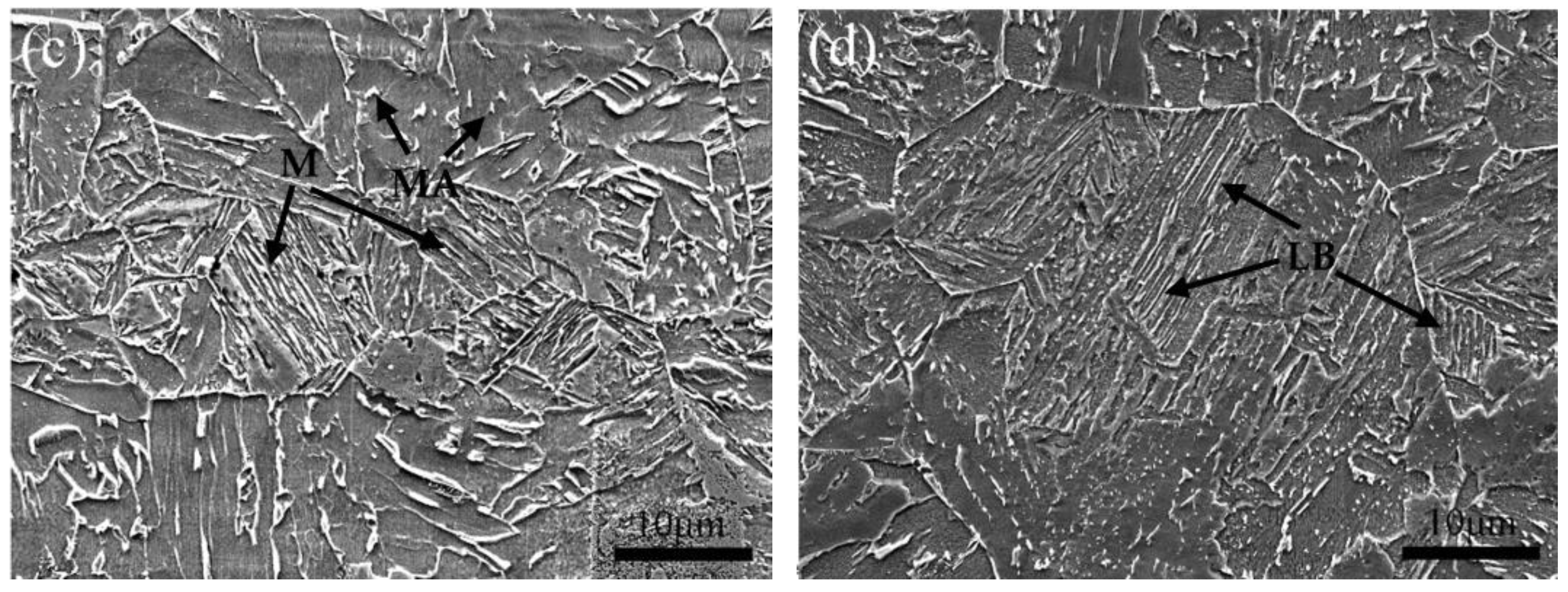

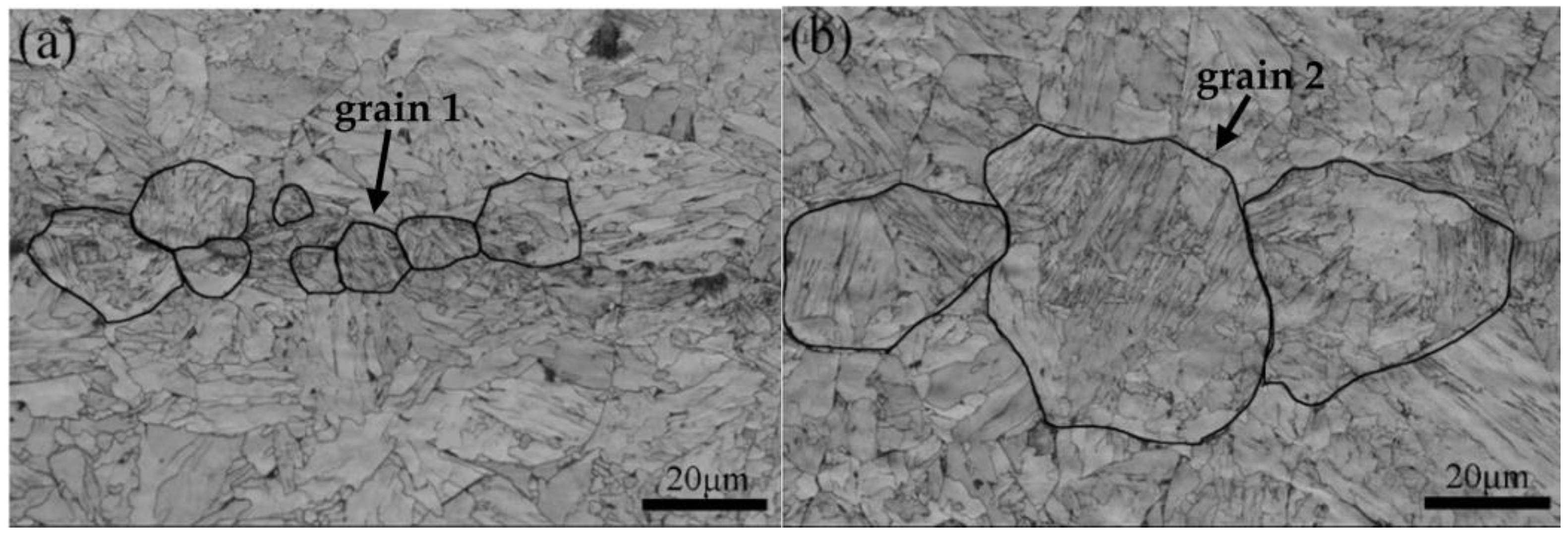

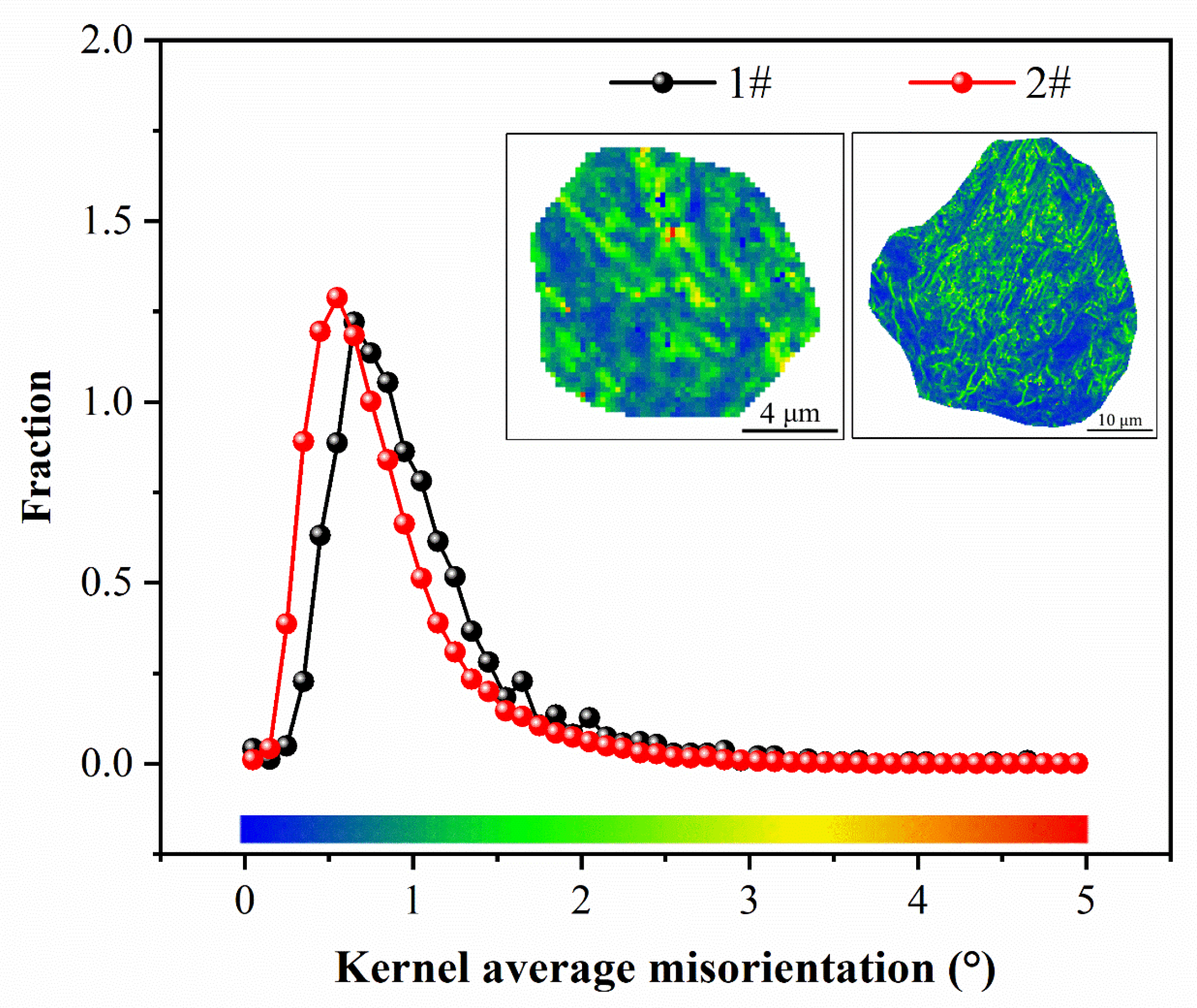

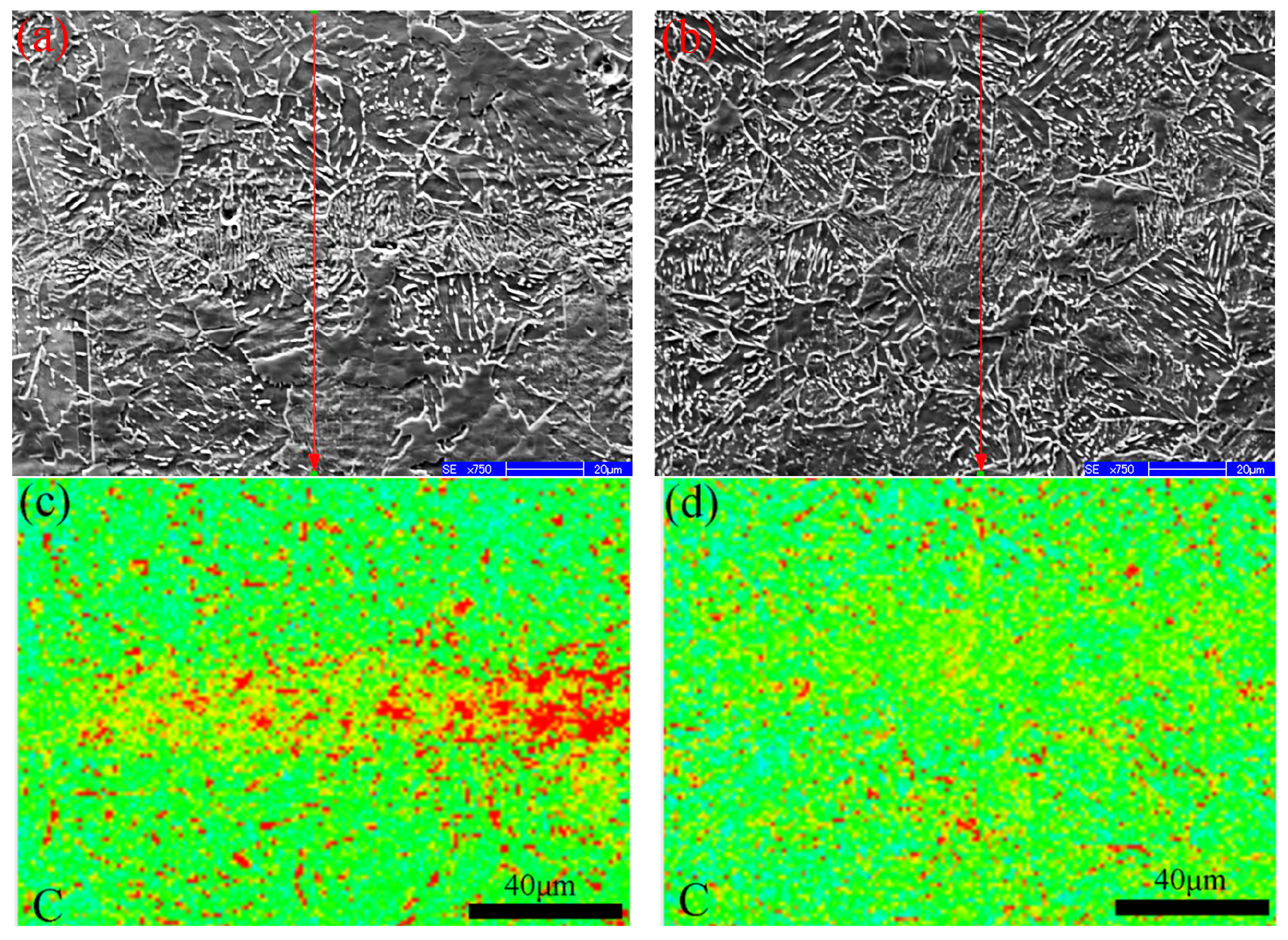

3.2. Microstructure of Centerline Segregated Area at HAZ

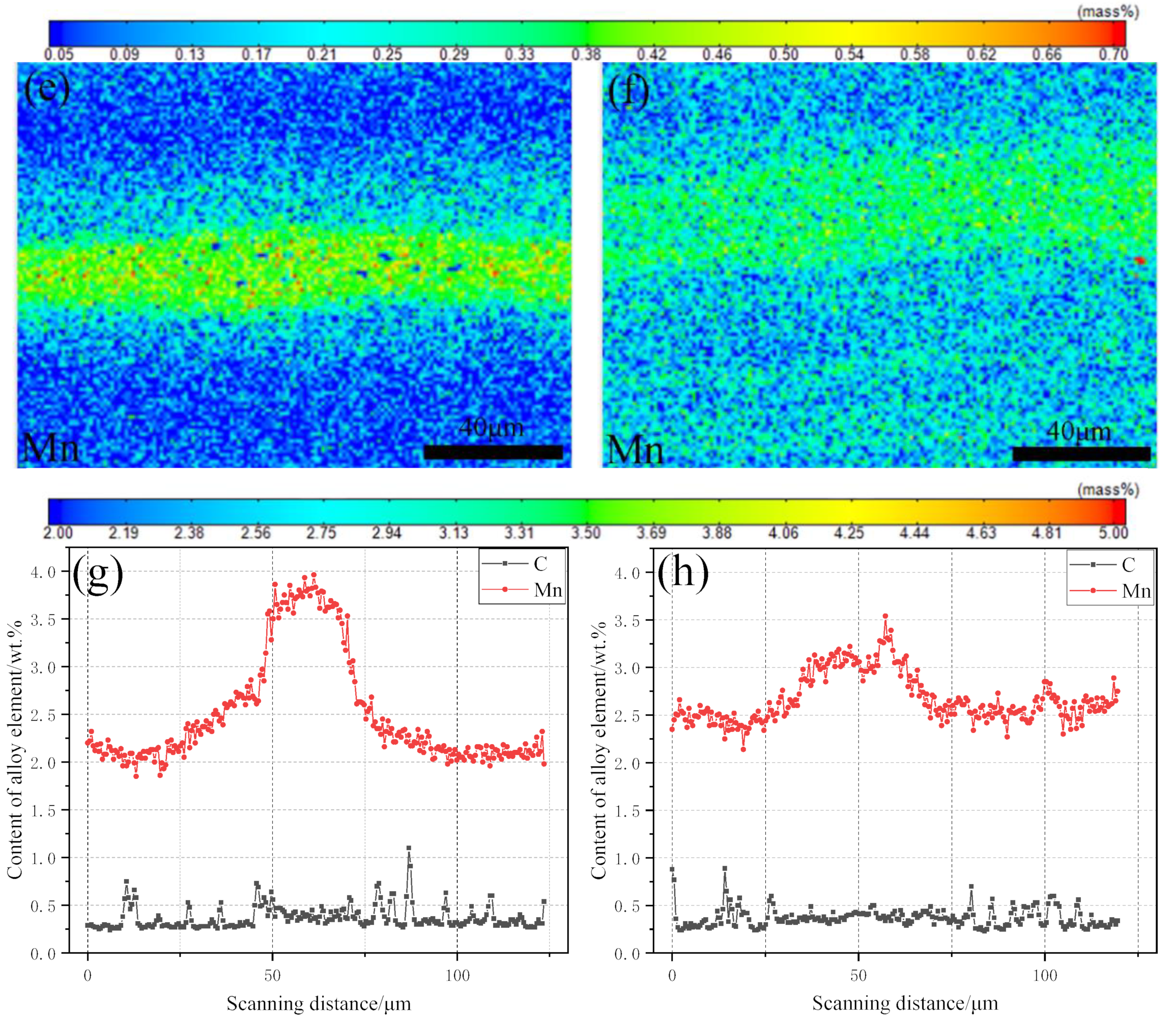

3.3. HAZ Segregation Distribution

3.4. Discussion

4. Conclusions

- (1)

- The HAZ of pipeline steel with centerline segregation of class 2 has good low-temperature toughness.

- (2)

- When the centerline segregation of the slab reaches class 3, the fracture of the impact specimen in the HAZ of the rolled plate welding appears delamination, and the fluctuation of the impact energy increases. As the test temperature decreases, the fluctuation of impact energy increases significantly.

- (3)

- The content and distribution of C and Mn elements enriched in the center segregation of pipeline steel plate are not affected by the welding thermal cycle.

- (4)

- The delamination of impact fracture and the large fluctuation of impact energy in the welding HAZ of pipeline steel is caused by the enrichment of C and Mn elements in the segregation zone. The phase transition point of the segregation zone decreases, and the cooling rate of the HAZ after welding is faster, which promotes the formation of martensite with a smaller grain size in the segregation zone. The stress distribution concentration is formed at the position of the segregation zone, which makes it easy to form the crack source and the crack propagation path.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.; Zhang, L.Z.; Gao, W.X. Historical development and future prospects of pipeline steel. Oil Gas Storage Transp. 2022, 41, 1355–1362. [Google Scholar]

- Gao, X.H.; Li, J.; Yang, Y.D.; Li, H. Development of High Deformability Pipeline Steel. Rare Met. Mater. Eng. 2011, 40, 273–275. [Google Scholar]

- Wang, X.X. Development progress of pipeline steel with Extra-high strength. Welded Pipe Tube 2010, 33, 5–12. [Google Scholar]

- Sharma, L. Study of weld bead chemical, microhardness & microstructural analysis using submerged arc welding fluxes for linepipe steel applications. Ceram. Int. 2020, 46, 24615–24623. [Google Scholar]

- Zhang, Z.Y. Application of Key Technologies in Design of X80 Φ1422 mm Pipeline Engineering of China-Russia East Natural Gas Pipeline Project. Welded Pipe Tube 2019, 41, 64–71. [Google Scholar]

- Li, B.; Liu, Q.; Jia, S.; Ren, Y.; Yang, P. Effect of V content and heat input on HAZ softening of deep-sea pipeline steel. Materials 2022, 15, 794. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Wang, D.; Dai, L.; Deng, C.; Li, C.; Wang, Y.; Shen, K. Effect of Post-Weld Heat Treatment on Microstructure and Fracture Toughness of X80 Pipeline Steel Welded Joint. Materials 2022, 15, 6646. [Google Scholar] [CrossRef]

- Qi, X.N.; Huan, P.C.; Wang, X.N.; He, J. Study on the mechanism of heat input on the grain boundary distribution and impact toughness in CGHAZ of X100 pipeline steel from the aspect of variant. Mater. Charact. 2021, 179, 111344. [Google Scholar] [CrossRef]

- Han, Y.D.; Fei, J.Y.; Xin, P.; Wang, R.; Xu, L. Microstructure and properties of intercritically reheated coarse-grained heat affected zone in pipeline steel after secondary thermal cycle. Int. J. Hydrogen Energy 2021, 05, 131. [Google Scholar] [CrossRef]

- Peng, Y.; Song, L.; Zhang, L.; Ma, C.Y.; Zhao, H.Y.; Tian, Z.L. Research Status of Weldability of Advanced Steel. Acta Metall. Sin. 2020, 56, 601–618. [Google Scholar]

- Zuo, Z.; Haowei, M.; Yarigarravesh, M.; Assari, A.H.; Tayyebi, M.; Tayebi, M.; Hamawandi, B. Microstructure, Fractography, and Mechanical Properties of Hardox 500 Steel TIG-Welded Joints by Using Different Filler Weld Wires. Materials 2020, 15, 8196. [Google Scholar] [CrossRef] [PubMed]

- Pouraliakbar, H.; Khalaj, G.; Jandaghi, M.R.; Khalaj, M.J. Study on the correlation of toughness with chemical composition and tensile test results in microalloyed API pipeline steels. J. Min. Metall. B Metall. 2015, 51, 173–178. [Google Scholar] [CrossRef]

- Sharma, S.K.; Maheshwari, S. A review on welding of high strength oil and gas pipeline steels. J. Nat. Gas Sci. Eng. 2017, 38, 203–217. [Google Scholar] [CrossRef]

- Zeng, H.L.; Zhang, Y.; Pi, Y.D.; Zou, Y.F. Research on laser-arc hybrid welding technology for long-distance pipeline. Met. Work. 2017, 04, 10–13. [Google Scholar]

- Zhang, Y.; Shuai, J.; Ren, W.; Lv, Z. Investigation of the tensile strain response of the girth weld of high-strength steel pipeline. J. Constr. Steel Res. 2022, 188, 107047. [Google Scholar] [CrossRef]

- Wu, K.; Zhang, H.; Yang, Y.; Liu, X. Strength matching factor of pipeline girth weld designed by reliability method. J. Pipeline Sci. Eng. 2021, 1, 298–307. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Tak, N.; Park, J.; Nahm, S.H.; Beak, U.B. Hydrogen embrittlement susceptibility of X70 pipeline steel weld under a low partial hydrogen environment. Int. J. Hydrogen Energy 2020, 45, 23739–23753. [Google Scholar] [CrossRef]

- Frantov, I.I.; Velichko, A.A.; Bortsov, A.N.; Utkin, I.Y. Weldability of niobium-containing high-strength steel for pipelines. Weld. J. 2014, 93, 23–29. [Google Scholar]

- Taban, E.; Kaluc, E.; Ojo, O.O. Properties, weldability and corrosion behavior of supermartensitic stainless steels for on-and offshore applications. Mater. Test. 2016, 58, 501–518. [Google Scholar] [CrossRef]

- Tas, Z. Mechanical properties of pipeline steel welds. Mater. Test. 2017, 59, 295–301. [Google Scholar] [CrossRef]

- Guo, F.; Liu, W.; Wang, X.; Misra, R.D.K.; Shang, C. Controlling variability in mechanical properties of plates by reducing centerline segregation to meet strain-based design of pipeline steel. Metals 2019, 9, 749. [Google Scholar] [CrossRef]

- Guo, F.; Wang, X.; Liu, W.; Shang, C.; Misra, R.D.K.; Wang, H.; Zhao, T.; Peng, C. The influence of centerline segregation on the mechanical performance and microstructure of X70 pipeline steel. Steel Res. Int. 2018, 89, 1800407. [Google Scholar] [CrossRef]

- No. SN 960: 2009; Classification of Defects in Materials-Standard Charts and Sample Guide. SMS Demag AG Mannesmann: Düsseldorf, Germany, 2009.

- ISO148-1; Metallic Materials—Charpy Pendulum Impact Test—Part 1: Test Method. ISO: Geneva, Switzerland, 2016.

| C | Si | Mn | Cr | P | S | Mo + V + Ti + Nb | Fe | |

|---|---|---|---|---|---|---|---|---|

| BM | 0.07 | 0.19 | 1.65 | 0.2 | 0.01 | 0.002 | 0.124 | Bal. |

| Current/A | Voltage/V | Welding Speed cm/min | Heat Input kJ/cm | |

|---|---|---|---|---|

| Outside welding | 700 | 38 | 60 | 26 |

| Inside welding | 600 | 36 | 65 | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, F.; Zhang, H.; Liu, W.; Wang, X.; Shang, C. The Influence of Centerline Segregation on Impact Toughness in Welding Heat-Affected Zone of X70 Pipeline Steel. Metals 2024, 14, 209. https://doi.org/10.3390/met14020209

Guo F, Zhang H, Liu W, Wang X, Shang C. The Influence of Centerline Segregation on Impact Toughness in Welding Heat-Affected Zone of X70 Pipeline Steel. Metals. 2024; 14(2):209. https://doi.org/10.3390/met14020209

Chicago/Turabian StyleGuo, Fujian, Han Zhang, Wenle Liu, Xuelin Wang, and Chengjia Shang. 2024. "The Influence of Centerline Segregation on Impact Toughness in Welding Heat-Affected Zone of X70 Pipeline Steel" Metals 14, no. 2: 209. https://doi.org/10.3390/met14020209

APA StyleGuo, F., Zhang, H., Liu, W., Wang, X., & Shang, C. (2024). The Influence of Centerline Segregation on Impact Toughness in Welding Heat-Affected Zone of X70 Pipeline Steel. Metals, 14(2), 209. https://doi.org/10.3390/met14020209