Numerical Simulation of Temperature Evolution, Solid Phase Transformation, and Residual Stress Distribution during Multi-Pass Welding Process of EH36 Marine Steel

Abstract

:1. Introduction

2. Numerical Simulation and Experiment Methods

2.1. Establishment of Numerical Models

2.1.1. Temperature Field

2.1.2. Solid-State Phase Transformation

2.1.3. Residual Stress Field

2.2. Experimental Methods

- i.

- Specimens were heated to a peak temperature of 1300 K at a heating rate of 200 K/s, with a soaking duration of 1 s at peak temperature.

- ii.

- The heated specimen are initially cooled from 1300 K to 920 K within 4 s, corresponding to an approximate cooling rate of 100 K/s.

- iii.

- For the second cooling stage, the temperature was allowed to drop freely from 920 K to 200 K. To simulate a wide range of cooling conditions and capture various phase transformations, 12 distinct cooling rates were established, including 100 K/s, 75 K/s, 50 K/s, 25 K/s, 15 K/s, 8.5 K/s, 5 K/s, 3 K/s, 1.67 K/s, 1 K/s, 0.6 K/s, and 0.2 K/s.

- iv.

- Table 3 presents the cooling rates’ input into the simulation corresponding to various cooling times (t8/5). To align with the actual cooling rates, two-stage cooling rates were selected for input. At higher temperatures, a rapid cooling rate was designated. The heating and comparison data from the simulation experiment are presented in Table 3. The first cooling time is denoted as t1 with a cooling rate of V1; the second cooling time is t2 with a cooling rate of V2; and the total time is represented as t3.

3. Results and Discussions

3.1. Analysis of Thermal Simulation Results

3.2. Validation of the Phase Transformation Model

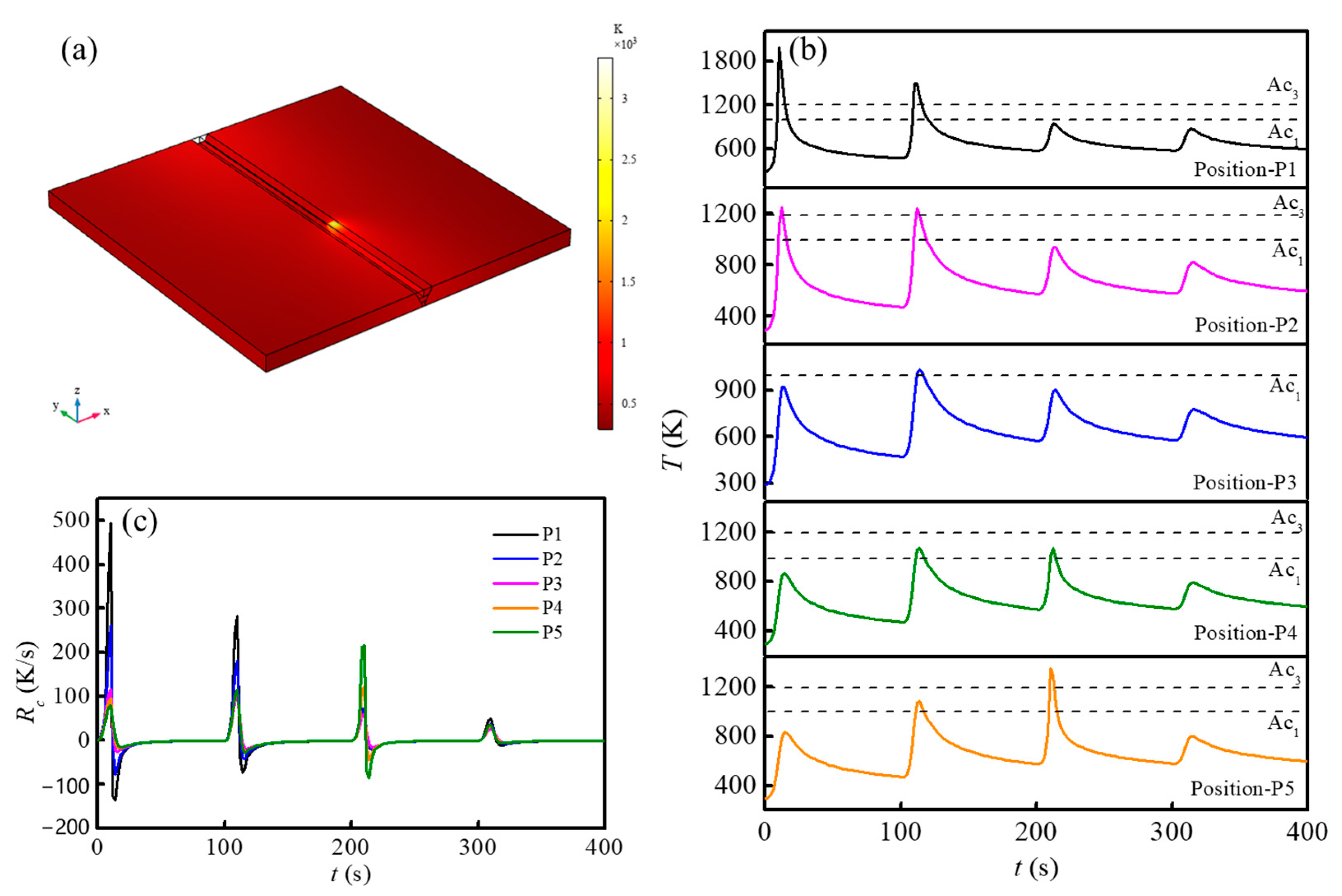

3.3. Temperature Field Distribution

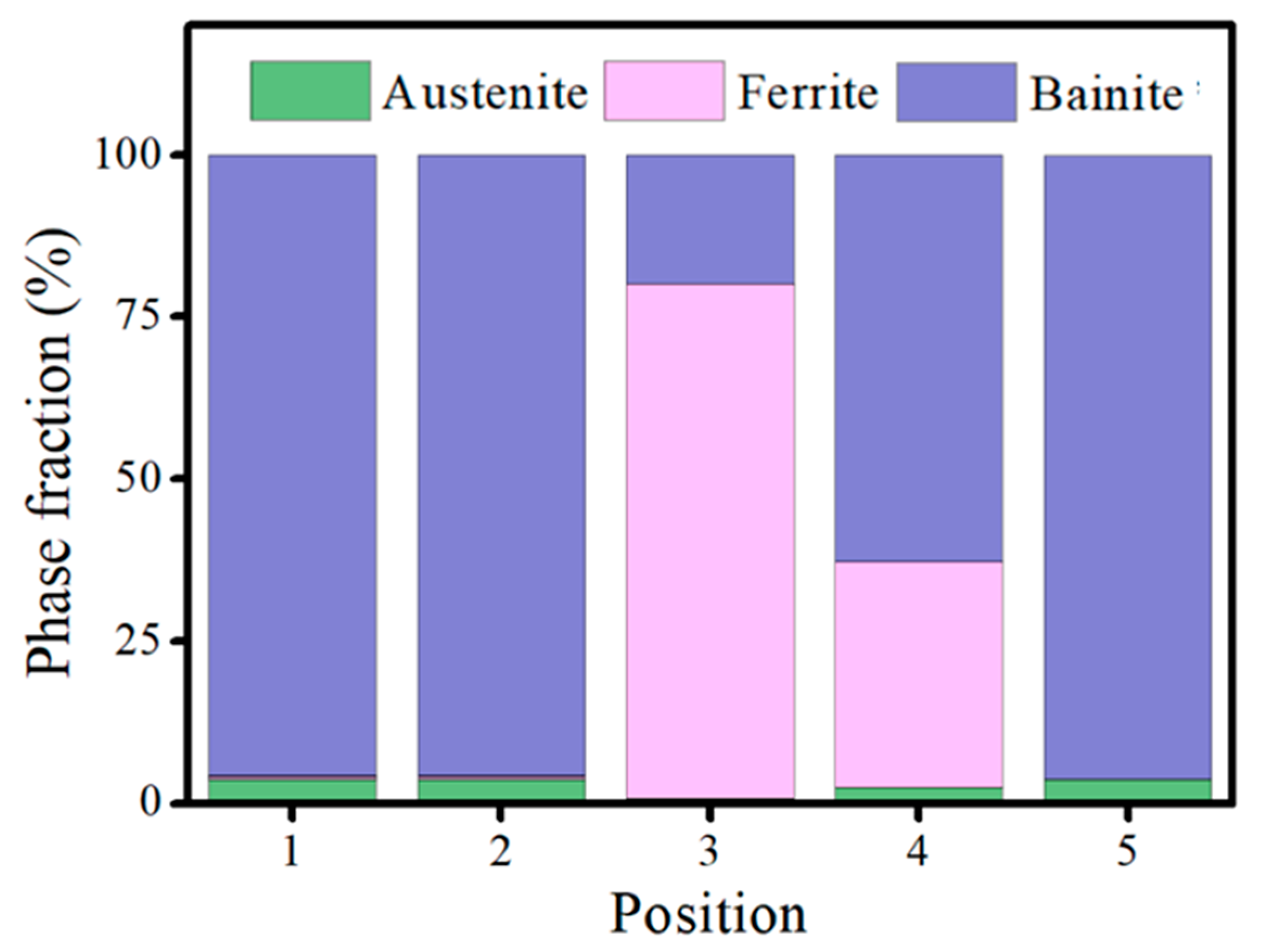

3.4. Microstructure Distribution

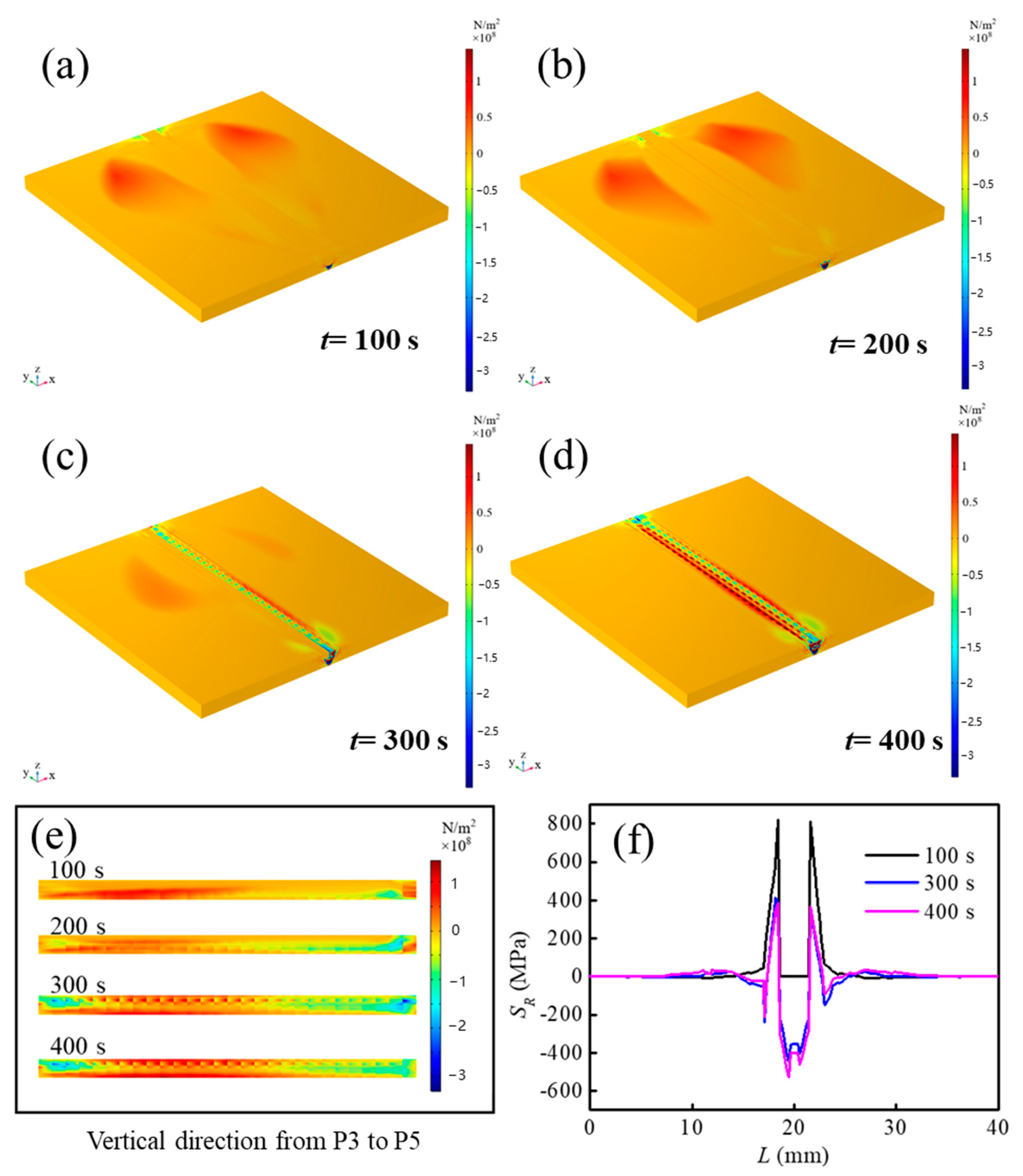

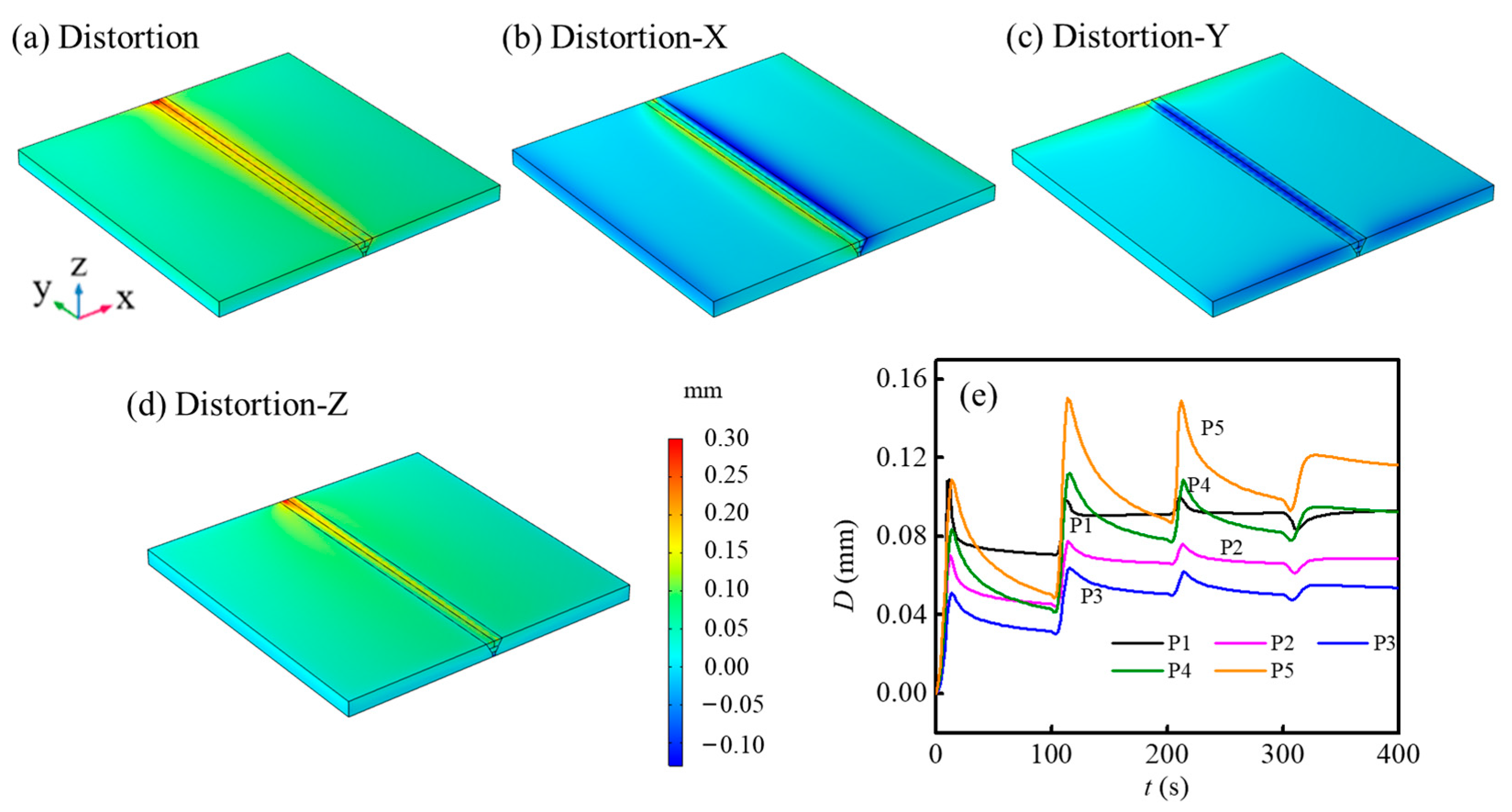

3.5. Residual Stress and Deformation

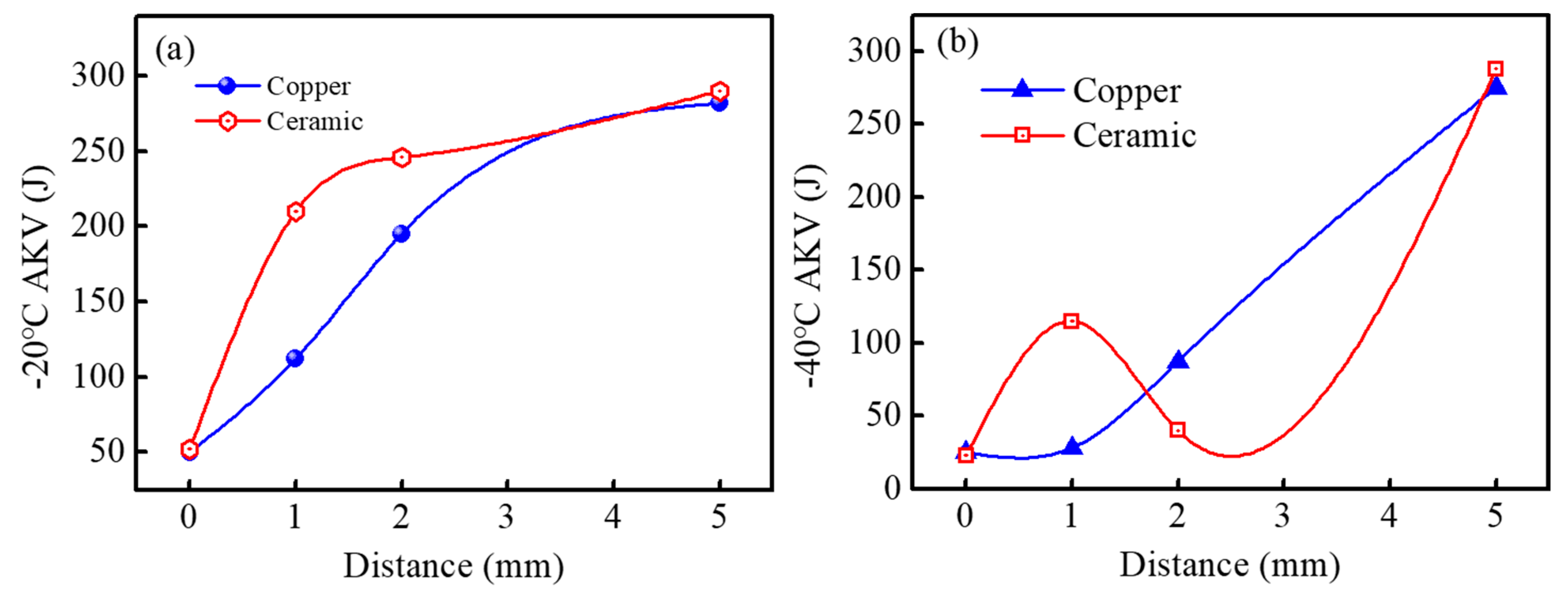

3.6. Impact Performance Test of EH36 Steel

4. Conclusions

- Throughout the process of multi-pass fusion welding, the peak temperature values and the rate of heating/cooling in the area surrounding the heat source gradually decreases. The absorption of heat consistently reduces in the horizontal direction as the location moves away from the heat source, whereas a potential uptick may occur in the vertical direction owing to the additional heat supplied by subsequent welding passes.

- The specific parameters of the solid phase transformation model for EH36 steel were confirmed using the experimentally derived SH-CCT curve. Both numerical and experimental findings reveal that multi-pass welding promotes the transformation to bainite in the vicinity of the heat source. Concurrently, an increase in the proportion of acicular ferrite is observed with increasing distance from the welding fusion line in the horizontal plane.

- The residual stress evolution during the welding process of EH36 revealed that residual stresses are primarily concentrated at the interface between the weld and the heat-affected zone. Maximum residual stresses are predicted near the fusion line at the base of the model, while severe distortion occurs near the fusion line at the top of the model. Furthermore, multi-pass welding may alleviate the residual stress, particularly when coupled with the formation of acicular ferrite during cooling, which results in improved low-temperature impact toughness in areas distant from the heat source. Therefore, this model is intended to facilitate the systematic optimization of the multi-pass welding procedure in forthcoming applications to achieve a more favorable distribution of residual stresses and minimized distortion.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Corigliano, P.; Crupi, V. Review of Fatigue Assessment Approaches for Welded Marine Joints and Structures. Metals 2022, 12, 1010. [Google Scholar] [CrossRef]

- Pranav, N.P.; Sai, B.; Arun, D. Microstructure and mechanical integrity relationship of PDC weld joints involving dissimilar marine grade alloys. J. Manuf. Process. 2020, 50, 111–122. [Google Scholar] [CrossRef]

- Wang, D.; Yan, L.; Yin, W.; Zhang, P.; Wang, Z.; Li, G.; Hu, X.; Li, B.; Zhang, W.; Zhu, J. Study on the Tensile and Fatigue Properties of the FH36 Ship Steel Plates at Room and Low Temperatures. Metals 2023, 13, 1563. [Google Scholar] [CrossRef]

- Shen, Y.; Liu, S.; Yuan, M.; Dai, X.; Lan, J. Immune Optimization of Double-Sided Welding Sequence for Medium-Small Assemblies in Ships Based on Inherent Strain Method. Metals 2022, 12, 1091. [Google Scholar] [CrossRef]

- Verma, J.; Taiwade, R.V. Effect of welding processes and conditions on the microstructure, mechanical properties and corrosion resistance of duplex stainless steel weldments—A review. J. Manuf. Process. 2017, 25, 134–152. [Google Scholar] [CrossRef]

- Tsirkas, S.A.; Papanikos, P.; Kermanidis, T. Numerical simulation of the laser welding process in butt-joint specimens. J. Mater. Process. Technol. 2003, 134, 59–69. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Y.; Han, T. Numerical and experimental investigation of the formation mechanism and the distribution of the welding residual stress induced by the hybrid laser arc welding of AH36 steel in a butt joint configuration. J. Mater. Process. Technol. 2020, 51, 95–108. [Google Scholar] [CrossRef]

- Zhang, K.; Dong, W.; Lu, S. Finite element and experiment analysis of welding residual stress in S355J2 steel considering the bainite transformation. J. Mater. Process. Technol. 2021, 62, 80–89. [Google Scholar] [CrossRef]

- Han, S.W.; Cho, W.; Zhang, L. Coupled simulation of thermal-metallurgical-mechanical behavior in laser keyhole welding of AH36 steel. Mater. Des. 2021, 212, 110275. [Google Scholar] [CrossRef]

- Ahmed, M.; El-Sayed Seleman, M.; Touileb, K.; Albaijan, I.; Habba, M.I.A. Microstructure, crystallographic texture, and mechanical properties of friction stir welded mild steel for shipbuilding applications. Materials 2022, 15, 2905–2930. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, M.; Abdelazem, K.; El-Sayed Seleman, M.; Alzahrani, B.; Touileb, K.; Jouini, N.; El-Batanony, I.G.; El-Aziz, H.M.A. Friction stir welding of 2205 duplex stainless steel: Feasibility of butt joint groove filling in comparison to gas tungsten arc welding. Materials 2021, 14, 4597–4613. [Google Scholar] [CrossRef] [PubMed]

- Albaijan, I.; Ahmed, M.; El-Sayed Seleman, M.; Touileb, K.; Habba, M.I.A.; Fouad, R.A. Optimization of Bobbin tool friction stir processing parameters of AA1050 using response surface methodology. Materials 2022, 15, 6886–6902. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.S.; Lee, K.; Han, M.S. Finite Element Analysis of Welding Processes by Way of Hypoelasticity-Based Formulation. J. Eng. Mater. Technol. 2011, 133, 021003. [Google Scholar] [CrossRef]

- Chen, M.Y.; Linkens, D.A.; Howarth, D.J.; Beynon, J.H. Fuzzy Model-based Charpy Impact Toughness Assessment for Ship Steels. ISIJ Int. 2004, 44, 1108–1113. [Google Scholar] [CrossRef]

- Han, Y. Multiphysics Study of Thermal Profiles and Residual Stress in Welding. Materials 2024, 17, 886. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Yang, D.; Yang, W.; Wu, Z.; Liu, C. Multiphysics Numerical Simulation of the Transient Forming Mechanism of Magnetic Pulse Welding. Metals 2022, 12, 1149. [Google Scholar] [CrossRef]

- Cho, D.W.; Cho, W.I.; Na, S.J. Modeling and simulation of arc: Laser and hybrid welding process. J. Manuf. Process. 2014, 16, 26–55. [Google Scholar] [CrossRef]

- Mani, H.; Taherizadeh, A.; Sadeghian, B.; Sadeghi, B.; Cavaliere, P. Thermal–Mechanical and Microstructural Simulation of Rotary Friction Welding Processes by Using Finite Element Method. Materials 2024, 17, 815. [Google Scholar] [CrossRef] [PubMed]

- Qi, H.; Pang, Q.; Li, W.; Bian, S. The Influence of the Second Phase on the Microstructure Evolution of the Welding Heat-Affected Zone of Q690 Steel with High Heat Input. Materials 2024, 17, 613. [Google Scholar] [CrossRef] [PubMed]

- Yeo, H.; Son, M.; Ki, H. Investigation of microstructure and residual stress development during laser surface melting of AH36 steel using 3-D fully coupled numerical model. J. Heat Mass Transf. 2022, 197, 123366. [Google Scholar] [CrossRef]

- Weisz-Patrault, D. Fast simulation of temperature and phase transitions in directed energy deposition additive manufacturing. Addit. Manuf. 2020, 31, 100990. [Google Scholar] [CrossRef]

- Ni, J.; Wahab, M.A. A numerical kinematic model of welding process for low carbon steels. Comput. Struct. 2017, 186, 35. [Google Scholar] [CrossRef]

- Cho, C.B.; Lee, J.-H.; Lee, C.-H. Distribution and Characteristics of Residual Stresses in Super Duplex Stainless Steel Pipe Weld. Metals 2024, 14, 136. [Google Scholar] [CrossRef]

- Fu, J.; El-Fallah, G.M.A.M.; Tao, Q.; Dong, H. A Parameterized Leblond–Devaux Equation for Predicting Phase Evolution during Welding E36 and E36Nb Marine Steels. Materials 2023, 16, 3150. [Google Scholar] [CrossRef] [PubMed]

- Winarto, W.; Adhi, P.; Siradj, E.S. Effects of Heat Input on Microstructures, Hardness, and Residual Stress of GMA Weld Dissimilar butt joints between Stainless Steel SUS 316 and Marine Steel AH 36. ISIJ Int. 2020, 38, 182–185. [Google Scholar] [CrossRef]

- Zubairuddin, M.; Albert, S.; Vasudevan, M. Numerical simulation of multi-pass GTA welding of grade 91 steel. J. Manuf. Process. 2017, 27, 87. [Google Scholar] [CrossRef]

- García-García, V.; Mejía, I.; Reyes-Calderón, F. Thermo-mechanical-microstructural simulation of double-pass welding process in a TWIP steel by FE formulation and probabilistic model. Int. J. Adv. Manuf. Technol. 2020, 111, 1115–1134. [Google Scholar] [CrossRef]

- Maekawa, A.; Kawahara, A.; Serizawa, H. Fast three-dimensional multipass welding simulation using an iterative substructure method. J. Mater. Process. Technol. 2015, 215, 30–41. [Google Scholar] [CrossRef]

- Mostafa, J.; Reza, T.; Ammar, M.M. Using double ellipsoid heat source model for prediction of HAZ grain growth in GTAW of stainless steel 304. Mater. Today Commun. 2022, 31, 103411. [Google Scholar] [CrossRef]

- Mi, G.; Xiong, L.; Wang, C. A thermal-metallurgical-mechanical model for laser welding Q235 steel. J. Mater. Process. Technol. 2016, 238, 39–48. [Google Scholar] [CrossRef]

- Genchev, G.; Dreibati, O.; Ossenbrink, R. Physical and Numerical Simulation of the Heat-Affected Zone of Multi-Pass Welds. Mater. Sci. Forum. 2013, 762, 544–550. [Google Scholar] [CrossRef]

- Chandrappa, N.; Bernacki, M. A level-set formulation to simulate diffusive solid/solid phase transformation in polycrystalline metallic materials—Application to austenite decomposition in steels. Comput. Mater. Sci. 2023, 216, 111840–111855. [Google Scholar] [CrossRef]

- Jorge, J.; De Souza, L.; Mendes, M.; Bott, I.; Araújo, L.; Santos, V.; Rebello, J.; Evans, G. Microstructure characterization and its relationship with impact toughness of C–Mn and high strength low alloy steel weld metals—A review. J. Mater. Res. Technol. 2021, 10, 471–501. [Google Scholar] [CrossRef]

| Temperature (K) | Density (kg/m3) | Thermal Conductivity (W/m·K) | Specific Heat (J/kg·K) | Poisson’s Ratio | Young’s Modulus (GPa) |

|---|---|---|---|---|---|

| 298 | 7830 | 45.74 | 450 | 0.29 | 196.38 |

| 373 | 7810 | 45.88 | 480 | 0.293 | 191.06 |

| 473 | 7780 | 45.02 | 520 | 0.297 | 182.09 |

| 573 | 7740 | 43.16 | 560 | 0.301 | 172.98 |

| 673 | 7710 | 40.62 | 570 | 0.305 | 163.74 |

| 773 | 7670 | 37.79 | 580 | 0.308 | 154.36 |

| 873 | 7640 | 35.05 | 590 | 0.312 | 144.83 |

| 973 | 7600 | 32.37 | 600 | 0.318 | 137.74 |

| 1073 | 7580 | 29.66 | 605 | 0.327 | 125.86 |

| 1173 | 7542 | 27.77 | 610 | 0.346 | 115.47 |

| 1273 | 7505 | 28.98 | 630 | 0.352 | 105.45 |

| 1473 | 7430 | 31.38 | 660 | 0.364 | 85 |

| 1673 | 7320 | 33.8 | 690 | 0.376 | 59 |

| 1753 | 7250 | 34.61 | 1420 | - | - |

| 1773 | 7210 | 34.68 | 1120 | - | - |

| 1793 | 6980 | 33.74 | 820 | - | - |

| 3273 | 6980 | 33.74 | 820 | - | - |

| Element | C | Si | Mn | N | Al | Ti | S | P | Nb | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| wt.% | 0.09 | 0.38 | 1.43 | 0.0024 | 0.029 | 0.014 | 0.003 | 0.014 | 0.025 | Rest |

| Serial Number | t8/5 (s) | t1 (s) | V1 (K/s) | t2 (s) | V2 (K/s) | t3 (s) |

|---|---|---|---|---|---|---|

| 1 | 3 | 4 | 100 | 7.2 | 100 | 11.2 |

| 2 | 4.5 | 4 | 100 | 10.6 | 75 | 14.6 |

| 3 | 6 | 4 | 100 | 14.4 | 50 | 18.4 |

| 4 | 12 | 4 | 100 | 29 | 25 | 33 |

| 5 | 20 | 4 | 100 | 48 | 15 | 52 |

| 6 | 35 | 4 | 100 | 85 | 8.5 | 89 |

| 7 | 60 | 4 | 100 | 144 | 5 | 148 |

| 8 | 100 | 4 | 100 | 240 | 3 | 244 |

| 9 | 180 | 4 | 100 | 431 | 1.67 | 435 |

| 10 | 300 | 4 | 100 | 720 | 1 | 724 |

| 11 | 500 | 4 | 100 | 1200 | 0.6 | 1204 |

| 12 | 1500 | 4 | 100 | 3600 | 0.2 | 3604 |

| Phase Fraction (%) | Heat Input (100 kJ/cm) | Heat Input (250 kJ/cm) | ||

|---|---|---|---|---|

| Experiment | Simulation | Experiment | Simulation | |

| Ferrite | 12.1 | 14.0 | 85.9 | 86.0 |

| Pearlite | 0 | 0.5 | 14.1 | 11.9 |

| Bainite | 87.9 | 82.4 | 0 | 2.1 |

| Austenite | 0 | 3.1 | 0 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, P.; Wang, J.; Jiao, Z.; Fu, K.; Li, L.; Guo, J. Numerical Simulation of Temperature Evolution, Solid Phase Transformation, and Residual Stress Distribution during Multi-Pass Welding Process of EH36 Marine Steel. Metals 2024, 14, 476. https://doi.org/10.3390/met14040476

Wen P, Wang J, Jiao Z, Fu K, Li L, Guo J. Numerical Simulation of Temperature Evolution, Solid Phase Transformation, and Residual Stress Distribution during Multi-Pass Welding Process of EH36 Marine Steel. Metals. 2024; 14(4):476. https://doi.org/10.3390/met14040476

Chicago/Turabian StyleWen, Pengyu, Jiaji Wang, Zhenbo Jiao, Kuijun Fu, Lili Li, and Jing Guo. 2024. "Numerical Simulation of Temperature Evolution, Solid Phase Transformation, and Residual Stress Distribution during Multi-Pass Welding Process of EH36 Marine Steel" Metals 14, no. 4: 476. https://doi.org/10.3390/met14040476