Electrochemical Behavior of Niobium Oxide and Titanium Oxide in NaF–Na3AlF6 Molten Salt

Abstract

:1. Introduction

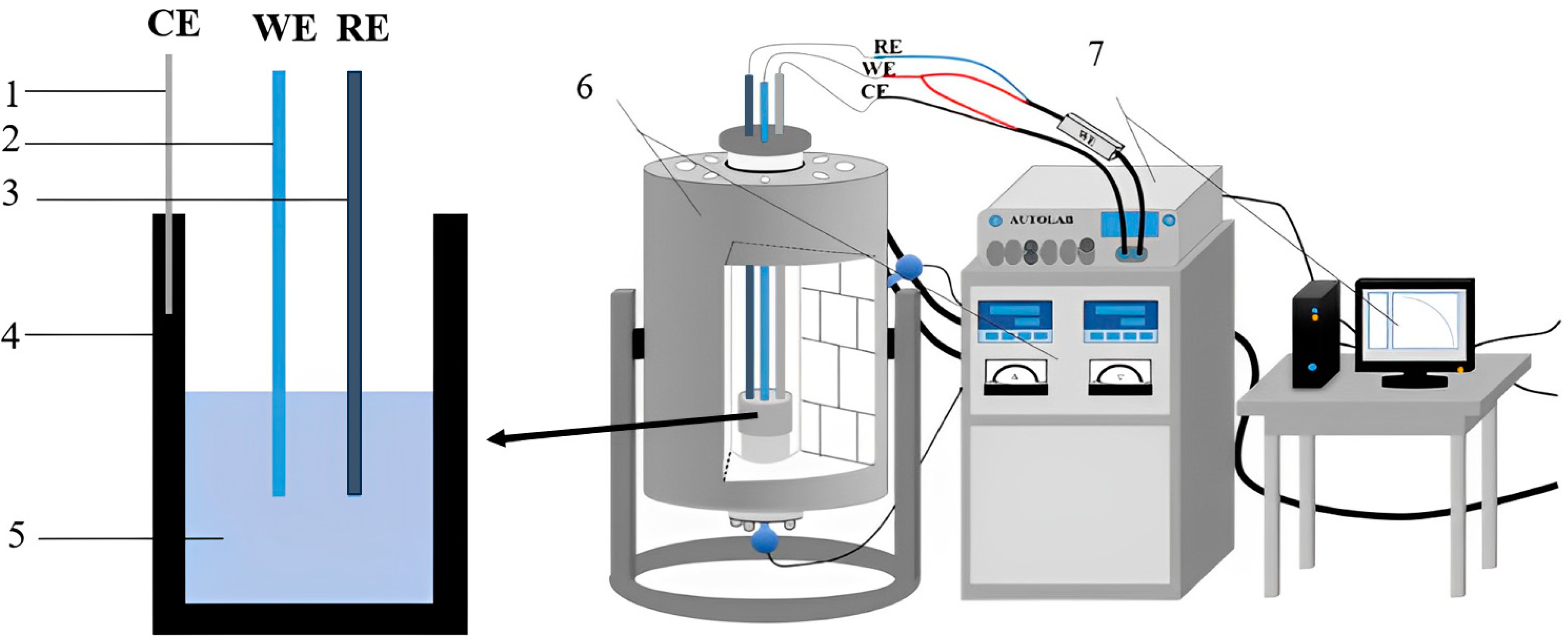

2. Experimental Methods

3. Results and Discussion

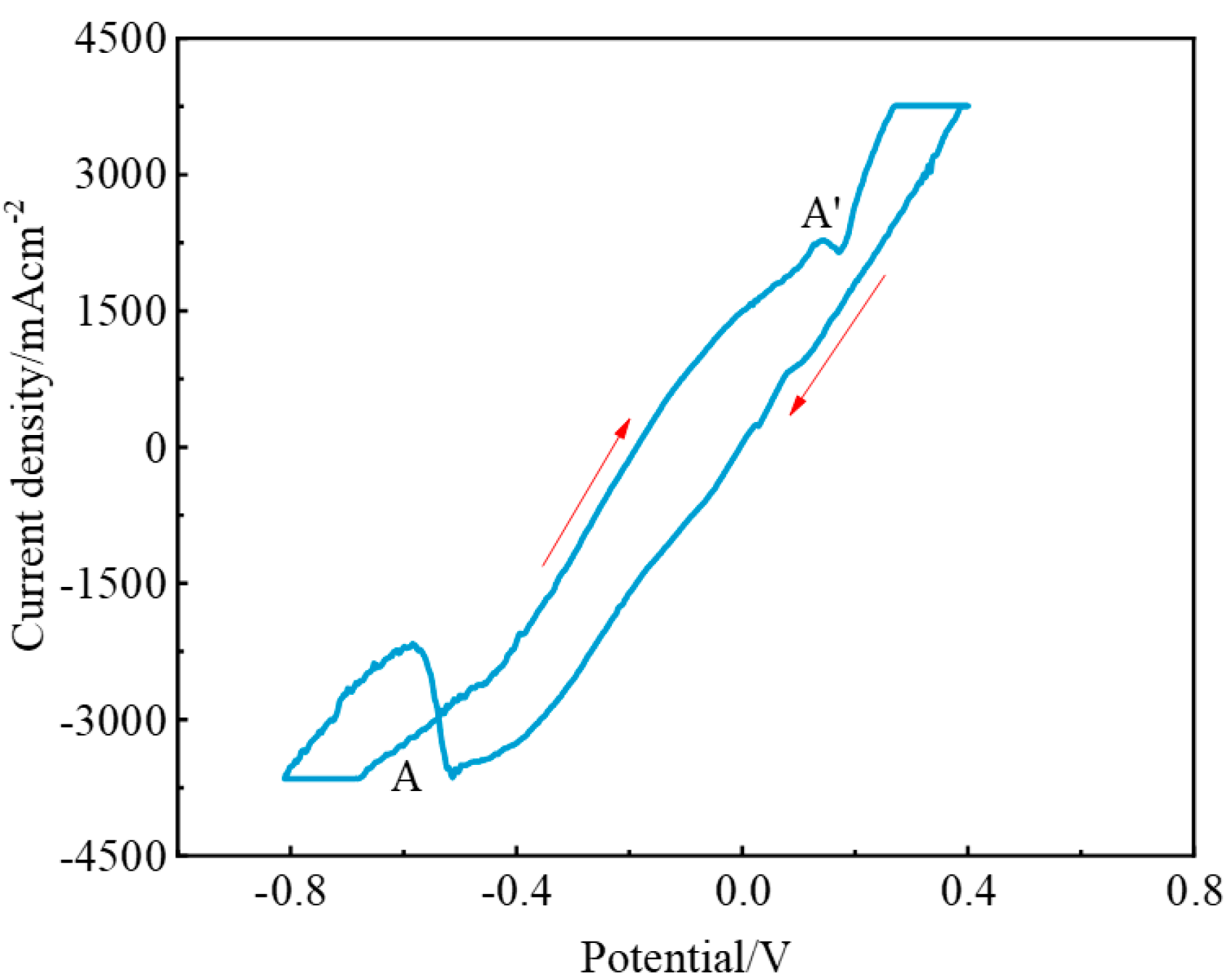

3.1. Electrochemical Behavior of NaF–Na3AlF6 Molten Salt

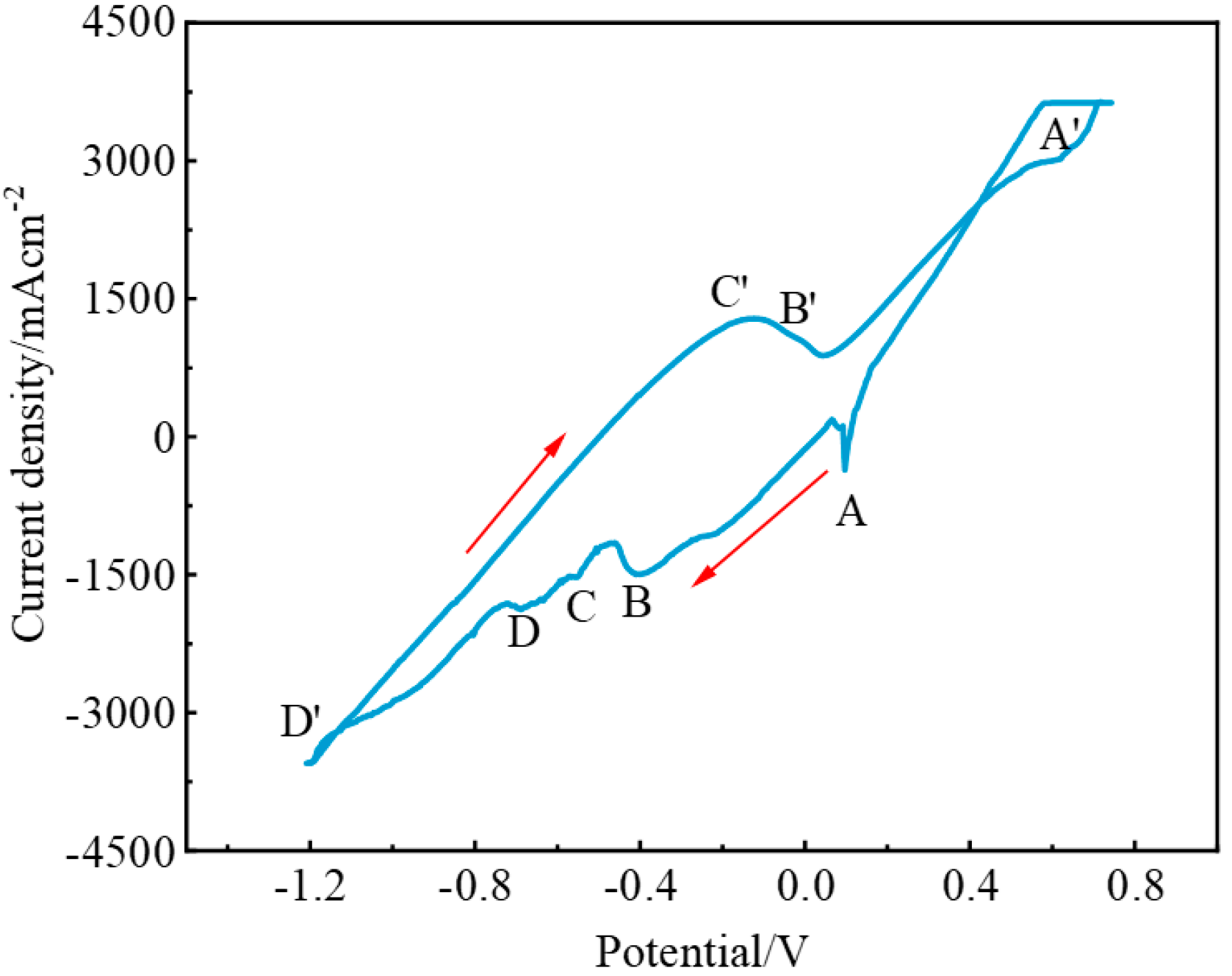

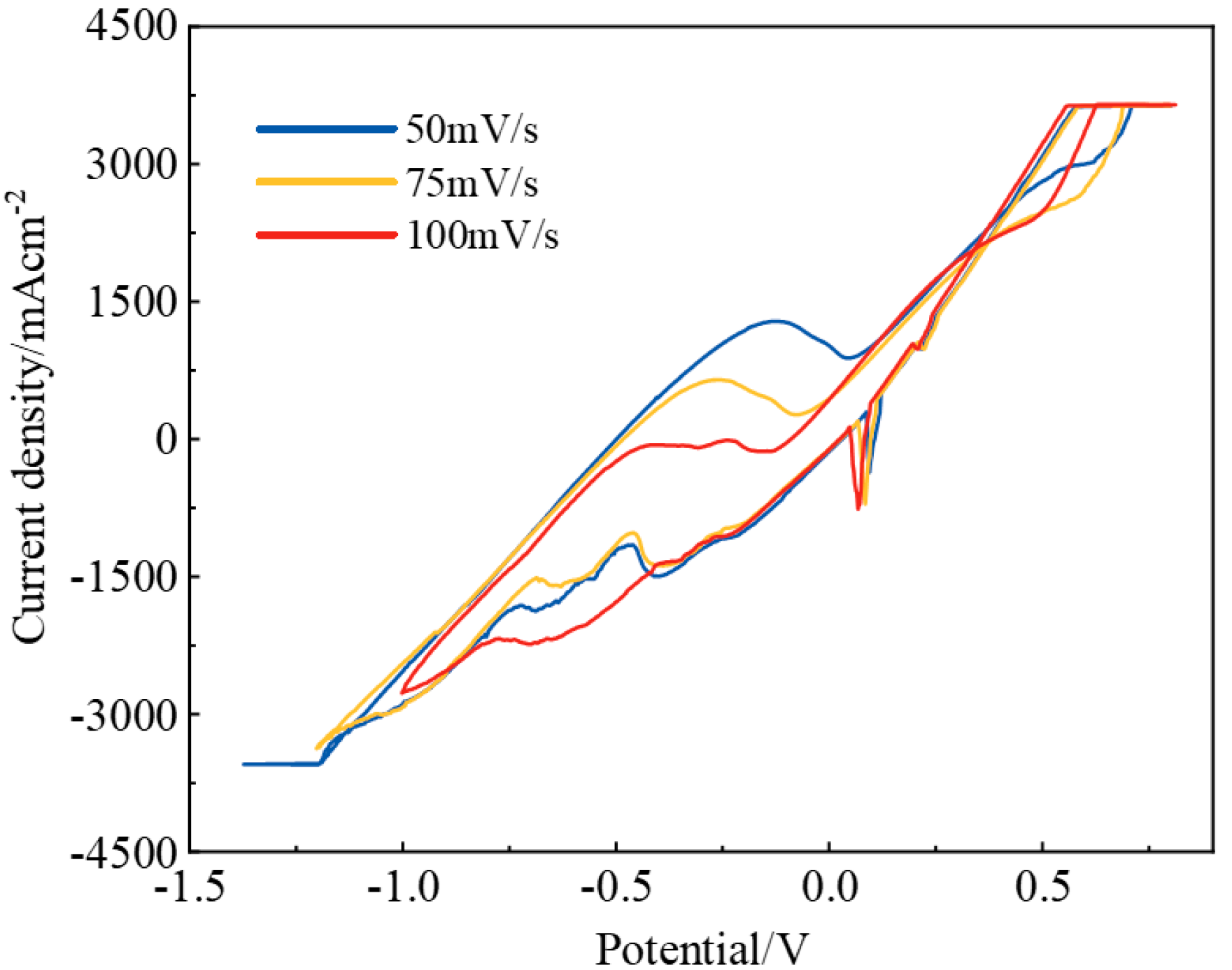

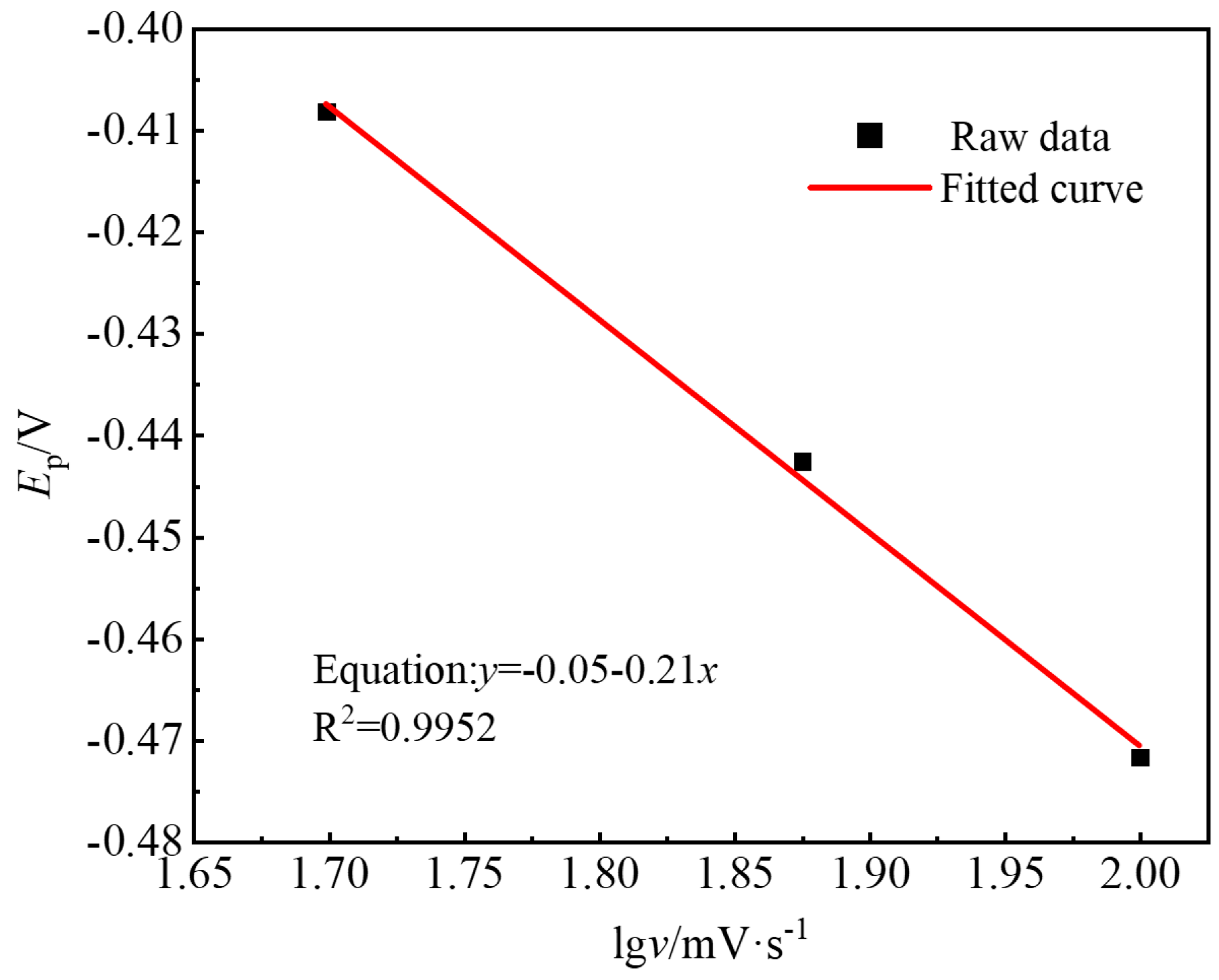

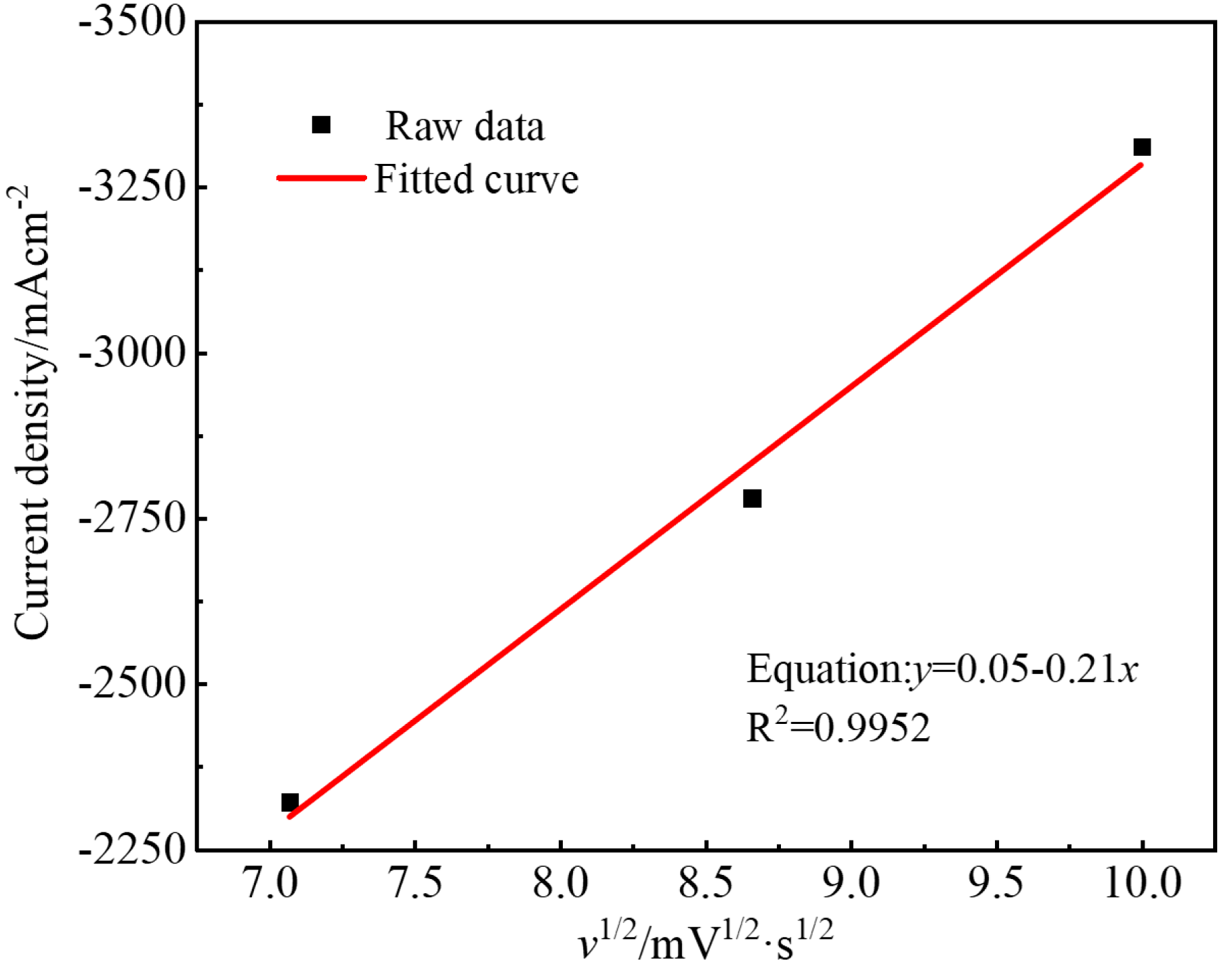

3.2. Electrochemical Behavior of the NaF–Na3AlF6–2 wt% Nb2O5 Molten Salt System

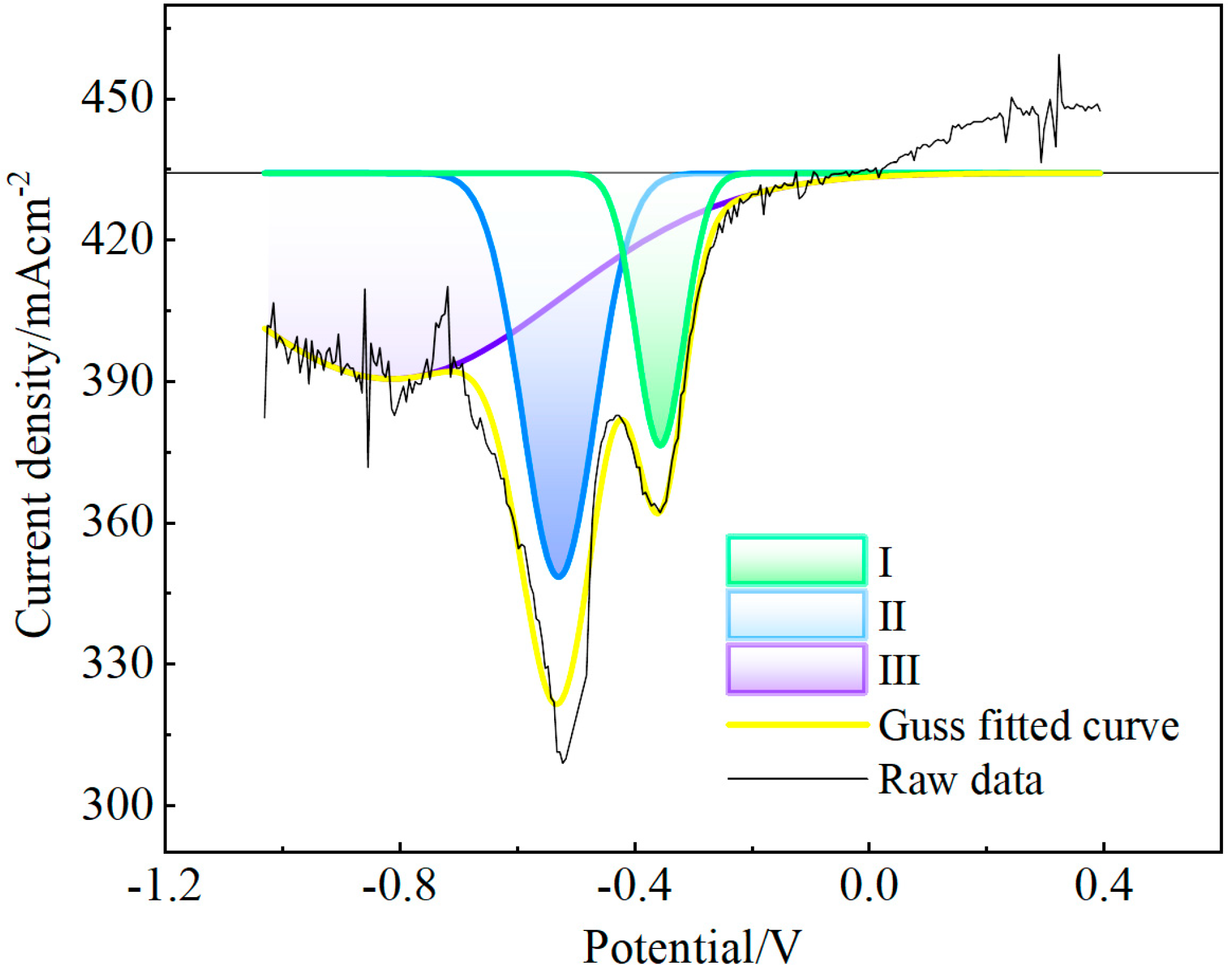

3.3. Electrochemical Behavior of the NaF–Na3AlF6–2 wt% TiO2 Molten Salt System

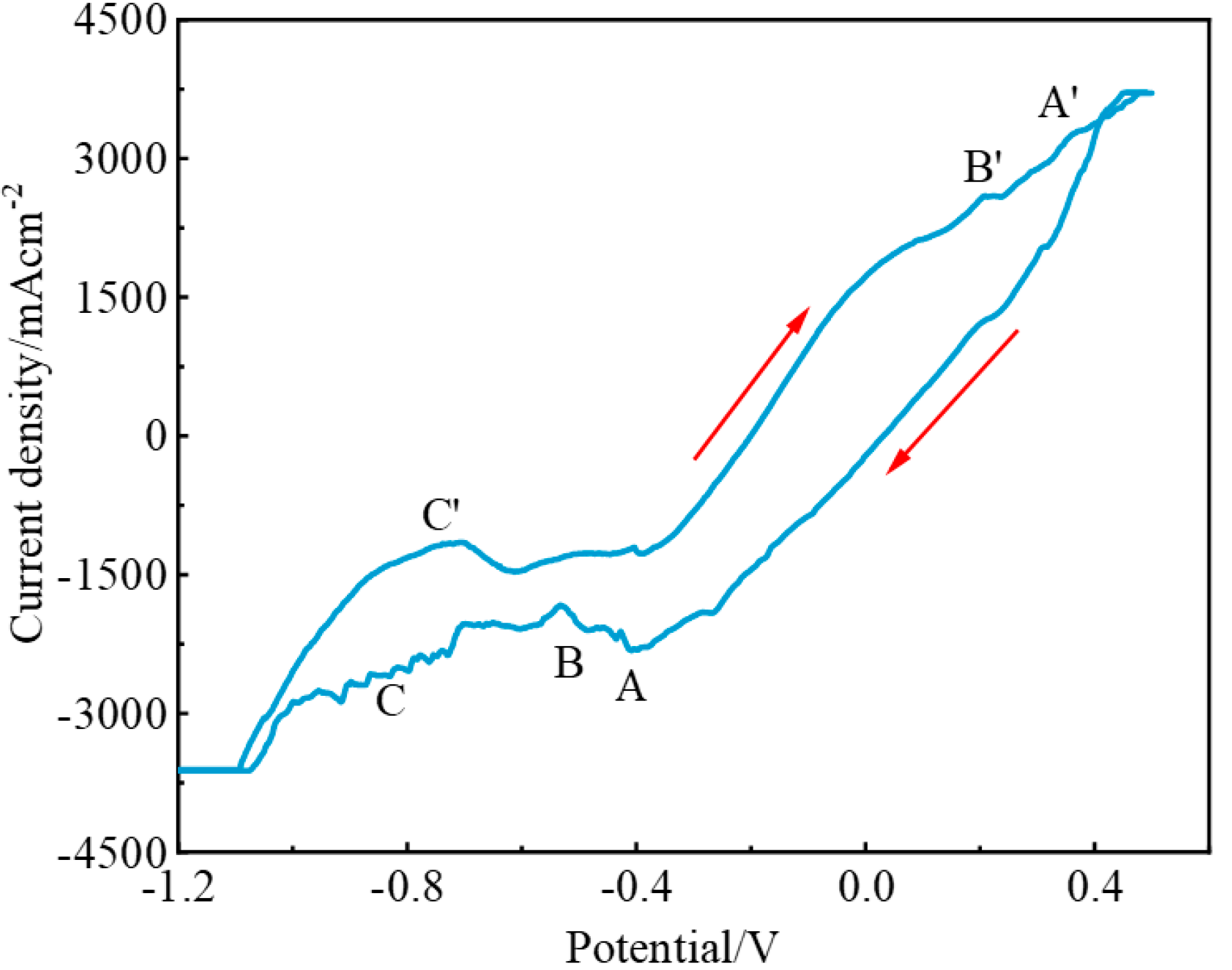

3.4. Electrochemical Behavior of the NaF–Na3AlF6–2 wt% Nb2O5–2 wt% TiO2 Molten Salt System

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- She, H.D.; Fan, H.R.; Yang, K.F.; Li, X.C.; Yang, Z.F.; Wang, Q.W.; Zhang, L.F.; Wang, Z.J. Complex, multi-stage mineralization processes in the giant Bayan Obo REE-Nb-Fe deposit. Ore Geol. Rev. 2021, 139, 104461. [Google Scholar] [CrossRef]

- Zhang, B.; Ma, C.; Wang, R.; Liu, C.; Jiang, M. Selective Smelting Reduction of Metal Oxides in REE-Nb-Fe Deposit. JOM 2022, 74, 993–1001. [Google Scholar] [CrossRef]

- Zhang, S.; Rao, M.; Xiao RYou, J.; Li, G. Beneficiation of Nb and Ti carbides from pyrochlore ore via carbothermic reduction followed by magnetic separation. Miner. Eng. 2022, 180, 107492. [Google Scholar] [CrossRef]

- Zhang, S.H.; Rao, M.J.; Xiao, R.D.; You, J.X.; Li, G.H.; Jiang, T. Enrichment of Nb and Ti from carbonatite pyrochlore ore via calcining-slaking followed by gravity separation. Int. J. Min. Sci. Technol. 2022, 32, 615–626. [Google Scholar] [CrossRef]

- Zhang, B.; Xue, X.; Yang, H. A novel process for recovery of scandium, rare earth and niobium from Bayan Obo tailings: NaCl-Ca(OH)2-coal roasting and acid leaching. Miner. Eng. 2022, 178, 107401. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, C.J.; Li, C.L.; Jiang, M.F. A novel approach for recovery of rare earths and niobium from Bayan Obo tailings. Miner. Eng. 2014, 65, 17–23. [Google Scholar] [CrossRef]

- Sun, L.; Yu, H.; Meng, F.; Qi, T.; Zheng, S.; Peng, Y.; Wang, L. A novel method for the separation of niobium and titanium from sulfuric acid-oxalate solutions using N235 and MIBK. Hydrometallurgy 2021, 205, 105748. [Google Scholar] [CrossRef]

- Sun, L.; Yu, H.; Meng, F.; Qi, T.; Wang, L.; Peng, Y. Recovery of niobium and titanium from ilmenorutile by NaOH roasting-H2SO4 leaching process. J. Mater. Res. Technol. 2021, 15, 2575–2583. [Google Scholar] [CrossRef]

- Sun, L.; Zhang, X.; Wang, L. Separation and extraction of niobium from H2SO4 solution containing titanium and iron impurities. Sep. Purif. Technol. 2022, 295, 121207. [Google Scholar] [CrossRef]

- Li, H.E.; Lu, X.G.; Chen, C.Y.; Li, Q.; Li, C.H.; Zhong, Q.D. Metal niobium by solid oxygen-ion membrane. Chin. J. Nonferrous Met. 2008, 18, 1336–1341. [Google Scholar]

- Li, C.; Li, S.; Che, Y.; Li, J.; Shu, Y.; He, J.; Song, J. Electrochemical behavior of niobium ions in molten KCl-NaCl. J. Mater. Res. Technol. 2020, 9, 9341–9347. [Google Scholar] [CrossRef]

- Christensen, E.; Wang, X.D.; Barner JH, V.; Ostfold, T.; Bjerrum, N.J. The Influence of Oxide on the Electrodeposition of Niobium from Alkali Fluoride Melts. Cheminform 2010, 25, 141. [Google Scholar] [CrossRef]

- Matthiessen, F.; Christensen, E. The Redox Chemistry of Niobium(V) Fluoro and Oxofluoro Complexes in LiF-NaF-KF Melts. J. Electrochem. Soc. 1996, 143, 1793–1799. [Google Scholar] [CrossRef]

- Bailey, R.A.; Yoko, T. High-temperature electroplating of chromium from molten FLINAK. J. Appl. Electrochem. 1986, 16, 737–744. [Google Scholar] [CrossRef]

- Kuznetsov, S.A. Electrolytic production of niobium powder from chloride—Fluoride melts containing compounds of niobium and zirconium. Russ. J. Electrochem. 2000, 36, 509–515. [Google Scholar] [CrossRef]

- Lantelme, F.; Salmi, A. Electrochemistry of Titanium in NaCl - KCl Mixtures and Influence of Dissolved Fluoride Ions. J. Electrochem. Soc. 1995, 142, 3451–3456. [Google Scholar] [CrossRef]

- Chen, G.S.; Masazumi, O.; Takeo, O. Electrochemical studies of titanium ions (Ti4+) in equimolar KCl-NaCl molten salts with 1 wt% K2TiF6. Electrochim. Acta 1987, 32, 1637–1642. [Google Scholar] [CrossRef]

- Robin, A.; Lepinay, J.D. Determination of the apparent standard potential of the Ti/Ti(III) system in the LiF-NaF-KF eutectic using voltammetry, chronopotentiometry and open-circuit potentiometry. Electrochim. Acta 1991, 36, 1009–1012. [Google Scholar] [CrossRef]

- Jun, L.; Bing, L. Electrochemical reduction and electrocrystallization process of B(III) in the LiF-NaF-KF-KBF4 molten salt. Rare Met. Mater. Eng. 2007, 36, 15–19. [Google Scholar] [CrossRef]

- Jiao, H.; Zhang, L.; Jiao, S. Electrochemical Behavior of Titanium Ions at Liquid Metal Cathodes in Molten Salts. In Proceedings of the 13th World Conference on Titanium; VenkateshVenkatesh, V., Pilchak, A.L., Allison, J.E., Eds.; John Wiley & Sons: San Diego, CA, USA, 2016; Volume 28, pp. 183–186. [Google Scholar]

- Yuan, T.C.; Weng, Q.G.; Zhou, Z.H.; Li, J.; He, Y.H. Preparation of High-Purity Titanium by Molten-Salt Electrolysis Process. Adv. Mater. Res. 2011, 284–286, 1477–1482. [Google Scholar] [CrossRef]

- Ma, M.; Wang, D.; Wang, W. Extraction of titanium from different titania precursors by the FFC Cambridge process. J. Alloys Compd. 2019, 25, 6107–6114. [Google Scholar] [CrossRef]

- Wei, Y.; Yang, W.; Guo, H. Functional COFs for Electrochemical Sensing: From Design Principles to Analytical Applications. ChemistrySelect 2023, 8, 2365–6549. [Google Scholar] [CrossRef]

- Pogliano, U.; Durbiano, F.; Serazio, D. A system for controlling electrical and chemical parameters in the Faraday constant determination by dissolution of silver. Meas. Sci. Technol. 2011, 22, 055102. [Google Scholar] [CrossRef]

- Su, C.; An, M.; Yang, P.; Gu, H.; Guo, X. Electrochemical behavior of cobalt from 1-butyl-3-methylimidazolium tetrafluoroborate ionic liquid. Appl. Surf. Sci. 2010, 256, 4888–4893. [Google Scholar] [CrossRef]

- He, X.; Hou, B.; Li, C.; Zhu, Q.; Jiang, Y.; Wu, L. Electrochemical mechanism of trivalent chromium reduction in 1-butyl-3-methylimidazolium bromide ionic liquid. Electrochem. Acta 2014, 130, 245–252. [Google Scholar] [CrossRef]

- Halford, G.C.; Personick, M.L. Bridging Colloidal and Electrochemical Nanoparticle Growth with In Situ Electrochemical Measurements. Acc. Chem. Res. 2023, 56, 1228–1238. [Google Scholar] [CrossRef] [PubMed]

| Electrolyte System | Test Method | Scan Rate |

|---|---|---|

| NaF–Na3AlF6 | CV | 50 mV/s |

| NaF–Na3AlF6–2 wt% Nb2O5 | CV, SWV | 50 mV/s, 75 mV/s, 100 mV/s |

| NaF–Na3AlF6–2 wt% TiO2 | CV, SWV | 50 mV/s, 75 mV/s, 100 mV/s |

| NaF–Na3AlF6–2 wt% Nb2O5–2 wt% TiO2 | CV | 50 mV/s |

| Reduction Process | Reduction Potential | ||

|---|---|---|---|

| NaF–Na3AlF6– 2 wt% Nb2O5 | NaF–Na3AlF6– 2 wt% TiO2 | NaF–Na3AlF6– 2 wt% Nb2O5–2 wt% TiO2 | |

| Nb (Ⅴ)→Nb (Ⅳ) | 0.09 V | – | −0.07 V |

| Ti (Ⅳ)→Ti (Ⅰ) | – | −0.43 V | −0.43 V |

| Nb (Ⅳ)→Nb (Ⅰ) | −0.38 V | – | −0.46 V |

| Nb (Ⅰ)→Nb | −0.68 V | – | −0.64 V |

| Ti (Ⅰ)→Ti | – | −0.84 V | −0.77 V |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Yu, S.; Liang, Y.; Jiang, M. Electrochemical Behavior of Niobium Oxide and Titanium Oxide in NaF–Na3AlF6 Molten Salt. Metals 2024, 14, 297. https://doi.org/10.3390/met14030297

Zhang B, Yu S, Liang Y, Jiang M. Electrochemical Behavior of Niobium Oxide and Titanium Oxide in NaF–Na3AlF6 Molten Salt. Metals. 2024; 14(3):297. https://doi.org/10.3390/met14030297

Chicago/Turabian StyleZhang, Bo, Shuiqing Yu, Yudong Liang, and Maofa Jiang. 2024. "Electrochemical Behavior of Niobium Oxide and Titanium Oxide in NaF–Na3AlF6 Molten Salt" Metals 14, no. 3: 297. https://doi.org/10.3390/met14030297