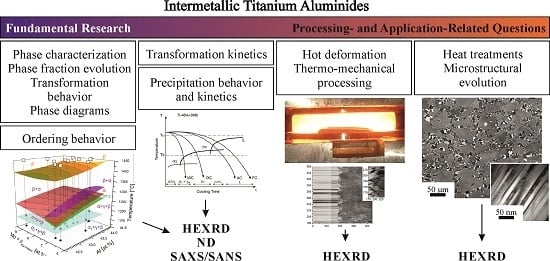

In Situ Characterization Techniques Based on Synchrotron Radiation and Neutrons Applied for the Development of an Engineering Intermetallic Titanium Aluminide Alloy

Abstract

:1. Introduction

2. Peculiarities in the Investigation of Titanium Aluminide Alloys Using X-rays and Neutrons

3. In Situ Studies of Phase Evolutions

3.1. HEXRD: State-of-the-Art Instrumental Setup

3.2. Studies of Phase Evolutions in TNM Alloys

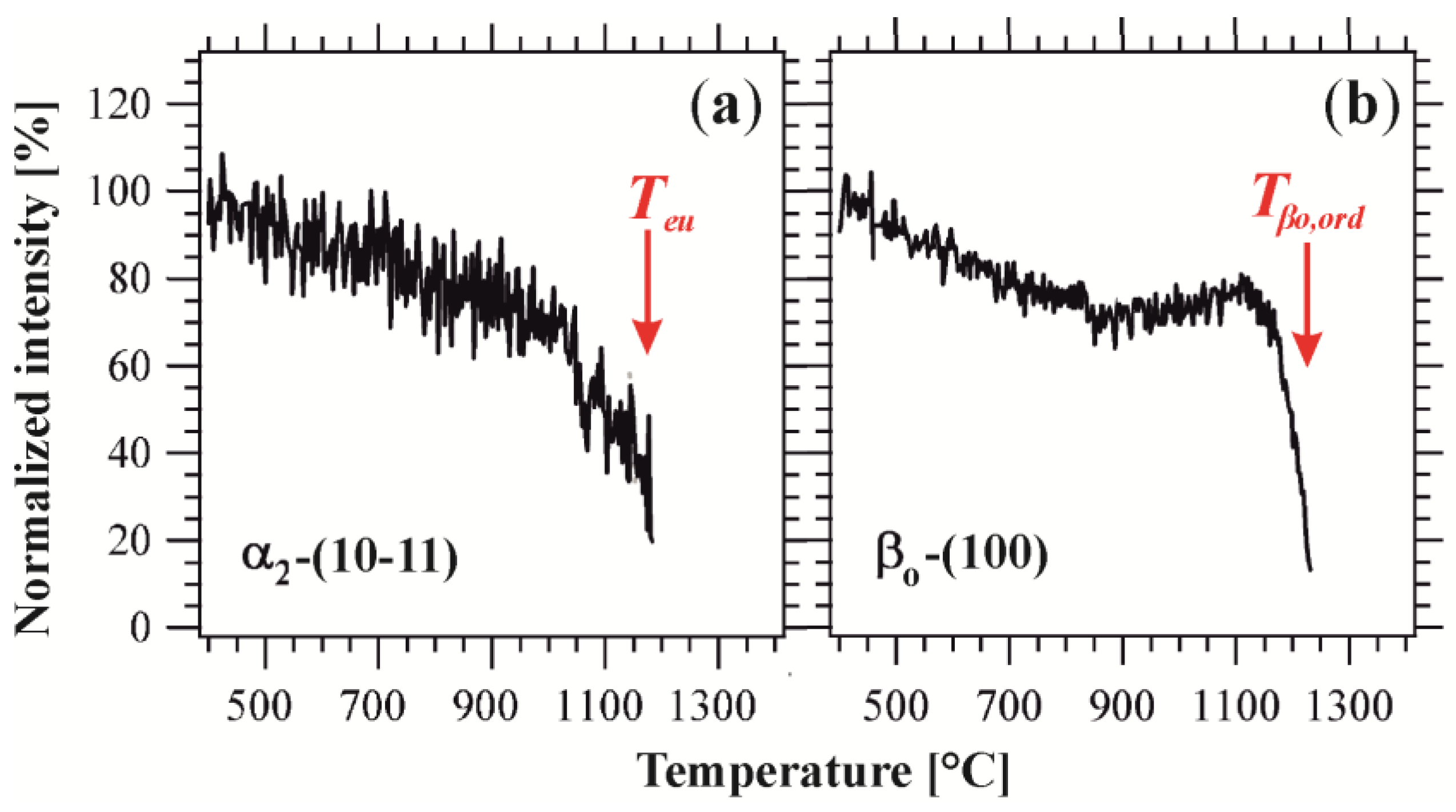

3.3. Neutron Diffraction Studies on Order/Disorder Transformations in TNM Alloys

3.4. Recent Advancements in the Alloy Development: The Introduction of Carbon to TNM Alloys

3.5. Small-Angle Scattering Experiments on Carbide Precipitation in TNM Alloys

4. TNM Alloys during Processing at Elevated Temperatures

4.1. General Considerations on the Mapping of Deformation, Recovery and Recrystallization

4.2. HEXRD Studies on the Hot Deformation Behavior of TNM Alloys

5. Heat Treatments for Balanced Mechanical Properties

5.1. Microstructural Evolution: The Formation of Lamellar α2/γ Colonies in a TNM Alloy

5.2. Studies Enabling the Targeted Optimization of Heat Treatment Steps

6. Summary

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bewlay, B.P.; Weimer, M.; Kelly, T.; Suzuki, A.; Subramanian, P.R. The science, technology, and implementation of TiAl alloys in commercial aircraft engines. MRS Proc. 2013, 1516, 49–58. [Google Scholar] [CrossRef]

- Clemens, H.; Smarsly, W.; Güther, V.; Mayer, S. Advanced intermetallic titanium aluminides. In Proceedings of the 13th World Conference on Titanium, San Diego, CA, USA, 16–20 August 2015.

- Habel, U.; Heutling, F.; Helm, D.; Kunze, C.; Smarsly, W.; Das, G.; Clemens, H. Forged intermetallic γ-TiAl based alloy low pressure turbine blade in geared turbofan. In Proceedings of the 13th World Conference on Titanium, San Diego, CA, USA, 16–20 August 2015.

- Yamaguchi, M.; Inui, H.; Ito, K. High-temperature structural intermetallics. Acta Mater. 2000, 48, 307–322. [Google Scholar] [CrossRef]

- Appel, F.; Wagner, R. Microstructure and deformation of two-phase γ-titanium aluminides. Mater. Sci. Eng. Rep. 1998, R22, 187–268. [Google Scholar] [CrossRef]

- Kim, Y.-W.; Clemens, H.; Rosenberger, A. Gamma Titanium Aluminides 2003; The Minerals, Metals and Materials Society (TMS): Warrendale, PA, USA, 2003. [Google Scholar]

- Kim, Y.-W.; Kim, S.; Dimiduk, D.M.; Woodward, C. Development of beta gamma alloys: Opening robust processing and greater application potential for TiAl-base alloys. In Structural Aluminides for Elevated Temperature Applications; The Minerals, Metals and Materials Society (TMS): Warrendale, PA, USA, 2008; pp. 215–216. [Google Scholar]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys; Wiley-VCH: Weinheim, Germany, 2003. [Google Scholar]

- Wu, X. Review of alloy and process development of TiAl alloys. Intermetallics 2006, 14, 1114–1122. [Google Scholar] [CrossRef]

- Appel, F.; Paul, J.D.H.; Oehring, M. Gamma Titanium Aluminide Alloys—Science and Technology; Wiley-VCH: Weinheim, Germany, 2011. [Google Scholar]

- Clemens, H.; Mayer, S. Design, processing, microstructure, properties, and applications of advanced intermetallic TiAl alloys. Adv. Eng. Mater. 2013, 15, 191–215. [Google Scholar] [CrossRef]

- Appel, F.; Oehring, M.; Wagner, R. Novel design concepts for gamma-base titanium aluminide alloys. Intermetallics 2000, 8, 1283–1312. [Google Scholar] [CrossRef]

- Cui, W.F.; Liu, C.M.; Bauer, V.; Christ, H.-J. Thermomechanical fatigue behaviours of a third generation γ-TiAl based alloy. Intermetallics 2007, 15, 675–678. [Google Scholar] [CrossRef]

- Baur, H.; Joos, R.; Smarsly, W.; Clemens, H. γ-TiAl for aeroengine and automotive applications. In Intermetallics and Superalloys; Wiley-VCH: Weinheim, Germany, 2000; pp. 384–390. [Google Scholar]

- Tetsui, T. Effect of composition on endurance of TiAl in turbocharger applications. In Gamma Titanium Aluminides 1999; Kim, Y.-W., Dimiduk, D.M., Loretto, M.H., Eds.; The Minerals, Metals and Materials Society (TMS): Warrendale, PA, USA, 1999; pp. 15–23. [Google Scholar]

- Sommer, A.; Keijzers, G. Gamma TiAl and the engine exhaust valve. In Gamma Titanium Aluminides 2003; The Minerals, Metals and Materials Society (TMS): Warrendale, PA, USA, 2003; pp. 3–8. [Google Scholar]

- Lasalmonie, A. Intermetallics: Why is it so difficult to introduce them in gas turbine engines? Intermetallics 2006, 14, 1123–1129. [Google Scholar] [CrossRef]

- Clemens, H.; Bartels, A.; Bystrzanowski, S.; Chladil, H.F.; Leitner, H.; Dehm, G.; Gerling, R.; Schimansky, F.P. Grain refinement in γ-TiAl-based alloys by solid state phase transformations. Intermetallics 2006, 14, 1380–1385. [Google Scholar] [CrossRef]

- Clemens, H.; Smarsly, W. Light-weight intermetallic titanium aluminides—Status of research and development. Adv. Mater. Res. 2011, 278, 551–556. [Google Scholar] [CrossRef]

- Clemens, H.; Wallgram, W.; Kremmer, S.; Güther, V.; Otto, A.; Bartels, A. Design of novel β-solidifying TiAl alloys with adjustable β/βo-phase fraction and excellent hot-workability. Adv. Eng. Mater. 2008, 10, 707–713. [Google Scholar] [CrossRef]

- Imayev, R.M.; Imayev, V.M.; Khismatullin, T.G.; Oehring, M.; Appel, F. New approaches to designing of alloys based on γ-TiAl + α2-Ti3Al. Rev. Adv. Mater. Sci. 2006, 11, 99–108. [Google Scholar] [CrossRef]

- Naka, S. Advanced titanium-based alloys. Curr. Opin. Solid State Mater. Sci. 1996, 1, 333–339. [Google Scholar] [CrossRef]

- Clemens, H.; Chladil, H.F.; Wallgram, W.; Zickler, G.A.; Gerling, R.; Liss, K.-D.; Kremmer, S.; Güther, V.; Smarsly, W. In and ex situ investigations of the β-phase in a Nb and Mo containing γ-TiAl based alloy. Intermetallics 2008, 16, 827–833. [Google Scholar] [CrossRef]

- Kainuma, R.; Fujita, Y.; Mitsui, H.; Ohnuma, I.; Ishida, K. Phase equilibria among α (hcp), β (bcc) and γ (L10) phases in Ti-Al base ternary alloys. Intermetallics 2000, 8, 855–867. [Google Scholar] [CrossRef]

- Tetsui, T.; Shindo, K.; Kobayashi, S.; Takeyama, M. A newly developed hot worked TiAl alloy for blades and structural components. Scr. Mater. 2002, 47, 399–403. [Google Scholar] [CrossRef]

- Tetsui, T.; Shindo, K.; Kaji, S.; Kobayashi, S.; Takeyama, M. Fabrication of TiAl components by means of hot forging and machining. Intermetallics 2005, 13, 971–978. [Google Scholar] [CrossRef]

- Kremmer, S.; Chladil, H.F.; Clemens, H.; Otto, A.; Güther, V. Near conventional forging of titanium aluminides. In Proceedings of the 11th World Conference on Titanium, Kyoto, Japan, 3–7 June 2008; pp. 989–992.

- Wallgram, W.; Schmoelzer, T.; Cha, L.; Das, G.; Güther, V.; Clemens, H. Technology and mechanical properties of advanced γ-TiAl based alloys. Int. J. Mater. Res. 2009, 100, 1021–1030. [Google Scholar] [CrossRef]

- Huber, D.; Clemens, H.; Stockinger, M. Near conventional forging of an advanced TiAl alloy. MRS Proc. 2012, 1516, 23–28. [Google Scholar] [CrossRef]

- Kestler, H.; Clemens, H. Production, processing and application of γ(TiAl)-based alloys. In Titanium and Titanium Alloys; Leyens, C., Peters, M., Eds.; Wiley-VCH: Weinheim, Germany, 2003; pp. 356–360. [Google Scholar]

- Crofts, P.; Bowen, P.; Jones, I. The effect of lamella thickness on the creep behaviour of Ti–48Al–2Nb–2Mn. Scr. Mater. 1996, 35, 1391–1396. [Google Scholar] [CrossRef]

- Maruyama, K.; Yamamoto, R.; Nakakuki, H.; Fujitsuna, N. Effects of lamellar spacing, volume fraction and grain size on creep strength of fully lamellar TiAl alloys. Mater. Sci. Eng. A 1997, 239–240, 419–428. [Google Scholar] [CrossRef]

- Voisin, T.; Monchoux, J.-P.; Hantcherli, M.; Mayer, S.; Clemens, H.; Couret, A. Microstructures and mechanical properties of a multi-phase β-solidifying TiAl alloy densified by spark plasma sintering. Acta Mater. 2014, 73, 107–115. [Google Scholar] [CrossRef]

- Jin, Y.; Wang, J.N.; Yang, J.; Wang, Y. Microstructure refinement of cast TiAl alloys by β solidification. Scr. Mater. 2004, 51, 113–117. [Google Scholar] [CrossRef]

- Imayev, V.M.; Imayev, R.M.; Khismatullin, T.G. Mechanical properties of the cast intermetallic alloy Ti–43Al–7(Nb,Mo)–0.2B (at. %) after heat treatment. Phys. Met. Metallogr. 2008, 105, 484–490. [Google Scholar] [CrossRef]

- Yang, J.; Wang, J.N.; Wang, Y.; Xia, Q. Refining grain size of a TiAl alloy by cyclic heat treatment through discontinuous coarsening. Intermetallics 2003, 11, 971–974. [Google Scholar] [CrossRef]

- Schwaighofer, E.; Clemens, H.; Mayer, S.; Lindemann, J.; Klose, J.; Smarsly, W.; Güther, V. Microstructural design and mechanical properties of a cast and heat-treated intermetallic multi-phase γ-TiAl based alloy. Intermetallics 2014, 44, 128–140. [Google Scholar] [CrossRef]

- Schwaighofer, E.; Rashkova, B.; Clemens, H.; Stark, A.; Mayer, S. Effect of carbon addition on solidification behavior, phase evolution and creep properties of an intermetallic β-stabilized γ-TiAl based alloy. Intermetallics 2014, 46, 173–184. [Google Scholar] [CrossRef]

- Kastenhuber, M.; Rashkova, B.; Clemens, H.; Mayer, S. Enhancement of creep properties and microstructural stability of intermetallic β-solidifying γ-TiAl based alloys. Intermetallics 2015, 63, 19–26. [Google Scholar] [CrossRef]

- Appel, F.; Lorenz, U.; Oehring, M.; Sparka, U.; Wagner, R. Thermally activated deformation mechanisms in micro-alloyed two-phase titanium aluminide alloys. Mater. Sci. Eng. A 1997, 233, 1–14. [Google Scholar] [CrossRef]

- Scheu, C.; Stergar, E.; Schober, M.; Cha, L.; Clemens, H.; Bartels, A.; Schimansky, F.-P.; Cerezo, A. High carbon solubility in a γ-TiAl-based Ti–45Al–5Nb–0.5C alloy and its effect on hardening. Acta Mater. 2009, 57, 1504–1511. [Google Scholar] [CrossRef]

- Staron, P.; Christoph, U.; Appel, F.; Clemens, H. SANS investigation of precipitation hardening of two-phase γ-TiAl alloys. Appl. Phys. A. 2002, 75, 1–3. [Google Scholar] [CrossRef]

- Staron, P.; Schimansky, F.-P.; Scheu, C.; Clemens, H. SANS study of carbon addition in Ti–45Al–5Nb. MRS Proc. 2011, 1295, 195–200. [Google Scholar] [CrossRef]

- Schwaighofer, E.; Staron, P.; Rashkova, B.; Stark, A.; Schell, N.; Clemens, H.; Mayer, S. In situ small-angle X-ray scattering study of the perovskite-type carbide precipitation behavior in a carbon-containing intermetallic TiAl alloy using synchrotron radiation. Acta Mater. 2014, 77, 360–369. [Google Scholar] [CrossRef]

- Abe, E.; Kumagai, T.; Nakamura, M. New ordered structure of TiAl studied by high-resolution electron microscopy. Intermetallics 1996, 4, 327–333. [Google Scholar] [CrossRef]

- Shull, R.D.; Cline, J.P. High temperature X-ray diffractometry of Ti-Al alloys. High Temp. Sci. 1988, 26, 95–117. [Google Scholar]

- Schloffer, M.; Schmoelzer, T.; Mayer, S.; Schwaighofer, E.; Hawranek, G.; Schimansky, F.-P.; Pyczak, F.; Clemens, H. The characterisation of a powder metallurgically manufactured TNM titanium aluminide alloy using complementary quantitative methods. Pract. Metallogr. 2011, 48, 594–604. [Google Scholar] [CrossRef]

- Novoselova, T.; Malinov, S.; Sha, W.; Zhecheva, A. High-temperature synchrotron X-ray diffraction study of phases in a gamma TiAl alloy. Mater. Sci. Eng. A 2004, 371, 103–112. [Google Scholar] [CrossRef]

- Watson, I.J.; Liss, K.-D.; Clemens, H.; Wallgram, W.; Schmoelzer, T.; Hansen, T.C.; Reid, M. In situ characterization of a Nb and Mo containing γ-TiAl based alloy using neutron diffraction and high-temperature microscopy. Adv. Eng. Mater. 2009, 11, 932–937. [Google Scholar] [CrossRef]

- Liss, K.-D.; Yan, K. Thermo-mechanical processing in a synchrotron beam. Mater. Sci. Eng. A 2010, 528, 11–27. [Google Scholar] [CrossRef]

- Liss, K.-D.; Bartels, A.; Schreyer, A.; Clemens, H. High-energy X-rays: A tool for advanced bulk investigations in materials science and physics. Textures Microstruct. 2003, 35, 219–252. [Google Scholar] [CrossRef]

- Schmoelzer, T.; Liss, K.-D.; Staron, P.; Mayer, S.; Clemens, H. The contribution of high-energy X-rays and neutrons to characterization and development of intermetallic titanium aluminides. Adv. Eng. Mater. 2011, 13, 685–699. [Google Scholar] [CrossRef]

- Kim, Y.-W. Effects of microstructure on the deformation and fracture of γ-TiAl alloys. Mater. Sci. Eng. A 1995, 192, 519–533. [Google Scholar] [CrossRef]

- Swaminathan, S. Debye-Waller factors in off-stoichiometric γ-TiAl: Effect of ordering of excess Al atoms on Ti sites. Philos. Mag. Lett. 1996, 73, 319–330. [Google Scholar] [CrossRef]

- Kim, Y.-W. Microstructural evolution and mechanical properties of a forged gamma titanium aluminide alloy. Acta Metall. Mater. 1992, 40, 1121–1134. [Google Scholar] [CrossRef]

- Grinfeld, M.A.; Hezzledine, P.M.; Shoykhet, B.; Dimiduk, D.M. Coherency stresses in lamellar Ti–Al. Metall. Mater. Trans. A 1998, 29A, 937–942. [Google Scholar]

- Hashimoto, K.; Kimura, M.; Mizuhara, Y. Alloy design of gamma titanium aluminides based on phase diagrams. Intermetallics 1998, 6, 667–672. [Google Scholar] [CrossRef]

- Kimura, M.; Hashimoto, K. High-temperature phase equilibria in Ti–Al–Mo system. J. Phase Equilibria 1999, 20, 224–230. [Google Scholar] [CrossRef]

- Qin, G.W.; Oikawa, K.; Sun, Z.M.; Sumi, S.; Ikeshoji, T.; Wang, J.J.; Guo, S.W.; Hao, S.M. Discontinuous coarsening of the lamellar structure of γ-TiAl-based intermetallic alloys and its control. Metall. Mater. Trans. A 2001, 32, 1927–1938. [Google Scholar] [CrossRef]

- Reimers, W.; Pyzalla, A.R.; Schreyer, A.; Clemens, H. Neutrons and Synchrotron Radiation in Engineering Materials Science—From Fundamentals to Application, 2nd ed.; Wiley-VCH: Weinheim, Germany, 2008. [Google Scholar]

- Sears, V.F. Neutron scattering lengths and cross sections. Neutron News 1992, 3, 29–37. [Google Scholar] [CrossRef]

- Schmoelzer, T. Investigation of γ-TiAl Alloys by Means of Diffraction Methods. Ph.D. Thesis, Montanuniversität Leoben, Leoben, Austria, April 2012. [Google Scholar]

- Liss, K.-D.; Whitfield, R.E.; Xu, W.; Buslaps, T.; Yeoh, L.A.; Wu, X.; Zhang, D.; Xia, K. In situ synchrotron high-energy X-ray diffraction analysis on phase transformations in Ti–Al alloys processed by equal-channel angular pressing. J. Synchrotron Radiat. 2009, 16, 825–834. [Google Scholar] [CrossRef] [PubMed]

- Staron, P.; Fischer, T.; Lippmann, T.; Stark, A.; Daneshpour, S.; Schnubel, D.; Uhlmann, E.; Gerstenberger, R.; Camin, B.; Reimers, W.; et al. In situ experiments with synchrotron high-energy X-rays and neutrons. Adv. Eng. Mater. 2011, 13, 658–663. [Google Scholar] [CrossRef]

- Schmoelzer, T.; Mayer, S.; Sailer, C.; Haupt, F.; Güther, V.; Staron, P.; Liss, K.-D.; Clemens, H. In situ diffraction experiments for the investigation of phase fractions and ordering temperatures in Ti–44 at. % Al–(3–7) at. % Mo alloys. Adv. Eng. Mater. 2011, 13, 306–311. [Google Scholar] [CrossRef]

- Erdely, P.; Stark, A.; Clemens, H.; Mayer, S. In situ high-energy X-ray diffraction on an intermetallic β-stabilised γ-TiAl based alloy. BHM Berg-und Hüttenmännische Monatshefte 2015, 160, 221–225. [Google Scholar] [CrossRef]

- Treusch, R. Radiation sources: Production and properties of synchrotron radiation. In Neutrons and Synchrotron Radiation in Engineering Materials Science; Reimers, W., Pyzalla, A., Schreyer, A., Clemens, H., Eds.; Wiley-VCH: Weinheim, Germany, 2008; pp. 97–112. [Google Scholar]

- Daniels, J.E. Determination of directionally dependent structural and microstructural information using high-energy X-ray diffraction. J. Appl. Crystallogr. 2008, 41, 1109–1114. [Google Scholar] [CrossRef]

- McCusker, L.B. Product characterization by X-ray powder diffraction. Microporous Mesoporous Mater. 1998, 22, 527–529. [Google Scholar] [CrossRef]

- McCusker, L.B.; von Dreele, R.B.; Cox, D.E.; Louër, D.; Scardi, P. Rietveld refinement guidelines. J. Appl. Crystallogr. 1999, 32, 36–50. [Google Scholar] [CrossRef]

- Spieß, L.; Teichert, G.; Schwarzer, R.; Behnken, H.; Genzel, C. Moderne Röntgenbeugung, 2nd ed.; Vieweg + Teubner: Wiesbaden, Germany, 2009. [Google Scholar]

- Clemens, H.; Boeck, B.; Wallgram, W.; Schmoelzer, T.; Droessler, L.M.; Zickler, G.A.; Leitner, H.; Otto, A. Experimental studies and thermodynamic simulations of phase transformations in Ti–(41–45)Al–4Nb–1Mo–0.1B alloys. In Proceedings of MRS Fall Meeting, Boston, MA, USA, 1–5 December 2008; pp. 115–120.

- Boeck, B. Untersuchung und Verifizierung des Quasibinären Zustandsdiagramms für β-erstarrende TNM-Legierungen auf Basis von Ti–(41–45)Al–4Nb–1Mo–0.1B. Diploma Thesis, Montanuniversität Leoben, Leoben, Austria, August 2008. [Google Scholar]

- Schmoelzer, T.; Liss, K.-D.; Zickler, G.A.; Watson, I.J.; Droessler, L.M.; Wallgram, W.; Buslaps, T.; Studer, A.; Clemens, H. Phase fractions, transition and ordering temperatures in TiAl–Nb–Mo alloys: An in and ex situ study. Intermetallics 2010, 18, 1544–1552. [Google Scholar] [CrossRef]

- Schloffer, M.; Iqbal, F.; Gabrisch, H.; Schwaighofer, E.; Schimansky, F.-P.; Mayer, S.; Stark, A.; Lippmann, T.; Göken, M.; Pyczak, F.; et al. Microstructure development and hardness of a powder metallurgical multi phase γ-TiAl based alloy. Intermetallics 2012, 22, 231–240. [Google Scholar] [CrossRef]

- Grujicic, M.; Zhang, Y. Crystal plasticity analysis of the effect of dispersed β-phase on deformation and fracture of lamellar γ + α2 titanium aluminide. Mater. Sci. Eng. A 1999, 265, 285–300. [Google Scholar] [CrossRef]

- Liss, K.-D.; Schmoelzer, T.; Yan, K.; Reid, M.; Peel, M.; Dippenaar, R.; Clemens, H. In situ study of dynamic recrystallization and hot deformation behavior of a multi-phase titanium aluminide alloy. J. Appl. Phys. 2009. [Google Scholar] [CrossRef]

- Sun, F.-S.; Cao, C.-X.; Kim, S.-E.; Lee, Y.-T.; Yan, M.-G. Alloying mechanism of beta stabilizers in a TiAl alloy. Metall. Mater. Trans. A 2001, 32, 1573–1589. [Google Scholar] [CrossRef]

- Kim, S.; Smith, G.D.W.; Roberts, S.G.; Cerezo, A. Alloying elements characterisation in γ-based titanium aluminides by APFIM. Mater. Sci. Eng. A 1998, 250, 77–82. [Google Scholar] [CrossRef]

- Kim, S.; Smith, G.D.W. AP-FIM investigation on γ-based titanium aluminides. Mater. Sci. Eng. A 1997, 239–240, 229–234. [Google Scholar] [CrossRef]

- Yeoh, L.A.; Liss, K.-D.; Bartels, A.; Chladil, H.F.; Avdeev, M.; Clemens, H.; Gerling, R.; Buslaps, T. In situ high-energy X-ray diffraction study and quantitative phase analysis in the α + γ phase field of titanium aluminides. Scr. Mater. 2007, 57, 1145–1148. [Google Scholar] [CrossRef]

- Liss, K.-D.; Bartels, A.; Clemens, H.; Bystrzanowski, S.; Stark, A.; Buslaps, T.; Schimansky, F.-P.; Gerling, R.; Scheu, C.; Schreyer, A. Recrystallization and phase transitions in a γ-TiAl-based alloy as observed by ex situ and in situ high-energy X-ray diffraction. Acta Mater. 2006, 54, 3721–3735. [Google Scholar] [CrossRef]

- Hoelzel, M.; Gilles, R.; Schlapp, M.; Boysen, H.; Fuess, H. Monte Carlo simulations of various instrument configurations of the new structure powder diffractometer (SPODI). Phys. B Condens. Matter 2004, 350, 671–673. [Google Scholar] [CrossRef]

- Gilles, R.; Hoelzel, M.; Schlapp, M.; Elf, F.; Krimmer, B.; Boysen, H.; Fuess, H. First test measurements at the new structure powder diffractometer (SPODI) at the FRM-II. Z. Krist. 2006, 1, 183–188. [Google Scholar] [CrossRef]

- Drössler, L.M. Characterization of β-Solidifying γ-TiAl Alloy Variants Using Advanced in and ex situ Investigation Methods. Diploma Thesis, Montanuniversität Leoben, Leoben, Austria, October 2008. [Google Scholar]

- Studer, A.J.; Hagen, M.E.; Noakes, T.J. Wombat: The high-intensity powder diffractometer at the OPAL reactor. Phys. B Condens. Matter 2006, 385–386, 1013–1015. [Google Scholar] [CrossRef]

- Erdely, P.; Werner, R.; Schwaighofer, E.; Clemens, H.; Mayer, S. In situ study of the time-temperature-transformation behaviour of a multi-phase intermetallic β-stabilised TiAl alloy. Intermetallics 2015, 57, 17–24. [Google Scholar] [CrossRef]

- Park, H.S.; Nam, S.W.; Kim, N.J.; Hwang, S.K. Refinement of the lamellar structure in TiAl-based intermetallic compound by addition of carbon. Scr. Mater. 1999, 41, 1197–1203. [Google Scholar] [CrossRef]

- Klein, T.; Schachermayer, M.; Mendez-Martin, F.; Schöberl, T.; Rashkova, B.; Clemens, H.; Mayer, S. Carbon distribution in multi-phase γ-TiAl based alloys and its influence on mechanical properties and phase formation. Acta Mater. 2015, 94, 205–213. [Google Scholar] [CrossRef]

- Kawabata, T.; Tadanoi, M.; Izumi, O. Effect of carbon and nitrogen on mechanical properties of TiAl alloys. ISIJ Int. 1991, 31, 1161–1167. [Google Scholar] [CrossRef]

- Tian, W.H.; Nemoto, M. Effect of carbon addition on the microstructures and mechanical properties of γ-TiAl alloys. Intermetallics 1997, 5, 237–244. [Google Scholar] [CrossRef]

- Christoph, U.; Appel, F.; Wagner, R. Dislocation dynamics in carbon-doped titanium aluminide alloys. Mater. Sci. Eng. A 1997, 239–240, 39–45. [Google Scholar] [CrossRef]

- Appel, F.; Paul, J.D.H.; Oehring, M.; Fröbel, U.; Lorenz, U. Creep behavior of TiAl alloys with enhanced high-temperature capability. Metall. Mater. Trans. A 2003, 34, 2149–2164. [Google Scholar] [CrossRef]

- Appel, F.; Fischer, F.D.; Clemens, H. Precipitation twinning. Acta Mater. 2007, 55, 4915–4923. [Google Scholar] [CrossRef]

- Gabrisch, H.; Stark, A.; Schimansky, F.-P.; Wang, L.; Schell, N.; Lorenz, U.; Pyczak, F. Investigation of carbides in Ti–45Al–5Nb–xC alloys (0 ≤ x ≤ 1) by transmission electron microscopy and high energy-XRD. Intermetallics 2013, 33, 44–53. [Google Scholar] [CrossRef]

- Wang, L.; Gabrisch, H.; Lorenz, U.; Schimansky, F.-P.; Schreyer, A.; Stark, A.; Pyczak, F. Nucleation and thermal stability of carbide precipitates in high Nb containing TiAl alloys. Intermetallics 2015, 66, 111–119. [Google Scholar] [CrossRef]

- Hammersley, A.P.; Svensson, S.O.; Hanfland, M.; Fitch, A.N.; Häusermann, D. Two-dimensional detector software: From real detector to idealised image or two-theta scan. High Press. Res. 1996, 14, 235–248. [Google Scholar] [CrossRef]

- Blackburn, M.J. Some aspects of phase transformations in titanium alloys. In The Science, Technology and Application of Titanium; Jaffee, R.I., Promisel, N.E., Eds.; Plenum Press: New York, NY, USA, 1970; pp. 639–642. [Google Scholar]

- Denquin, A.; Naka, S. Phase transformation mechanisms involved in two-phase TiAl-based alloys—II. Discontinuous coarsening and massive-type transformation. Acta Mater. 1996, 44, 353–365. [Google Scholar] [CrossRef]

- Margulies, L.; Lorentzen, T.; Poulsen, H.F.; Leffers, T. Strain tensor development in a single grain in the bulk of a polycrystal under loading. Acta Mater. 2002, 50, 1771–1779. [Google Scholar] [CrossRef]

- Poulsen, H.F. An introduction to three-dimensional X-ray diffraction microscopy. J. Appl. Crystallogr. 2012, 45, 1084–1097. [Google Scholar] [CrossRef]

- Margulies, L.; Winther, G.; Poulsen, H.F. In situ measurement of grain rotation during deformation of polycrystals. Science 2001, 291, 2392–2394. [Google Scholar] [CrossRef] [PubMed]

- Lauridsen, E.M.; Schmidt, S.; Suter, R.M.; Poulsen, H.F. Tracking: A method for structural characterization of grains in powders or polycrystals. Appl. Crystallogr. 2001, 34, 744–750. [Google Scholar] [CrossRef]

- Inui, H.; Matsumuro, M.; Wu, D.-H.; Yamaguchi, M. Temperature dependence of yield stress, deformation mode and deformation structure in single crystals of TiAl (Ti–56 at. % Al). Philos. Mag. A 1997, 75, 395–423. [Google Scholar] [CrossRef]

- Ihara, K.; Miura, Y. Dynamic recrystallization in Al-single crystals revealed by synchrotron radiation Laue technique. Mater. Sci. Eng. A 2004, 387–389, 651–654. [Google Scholar] [CrossRef]

- Miura, Y.; Ihara, K.; Fukaura, K. Dynamic recrystallization in Al single crystals revealed by rapid X-ray Laue method. Mater. Sci. Eng. A 2000, 280, 134–138. [Google Scholar] [CrossRef]

- Stark, A.; Rackel, M.; Tankoua, A.T.; Oehring, M.; Schell, N.; Lottermoser, L.; Schreyer, A.; Pyczak, F. In situ high-energy X-ray diffraction during hot-forming of a multiphase TiAl alloy. Metals 2015, 5, 2252–2265. [Google Scholar] [CrossRef]

- Liss, K.-D.; Clemens, H.; Bartels, A.; Stark, A.; Buslaps, T. Phase transitions and recrystallization in a Ti-46 at. % Al-9 at. % Nb alloy as observed by in situ high-energy X-ray diffraction. MRS Proc. 2007. [Google Scholar] [CrossRef]

- Liss, K.-D.; Stark, A.; Bartels, A.; Clemens, H.; Buslaps, T.; Phelan, D.; Yeoh, L.A. Directional atomic rearrangements during transformations between the α- and γ-phases in titanium aluminides. Adv. Eng. Mater. 2008, 10, 389–392. [Google Scholar] [CrossRef]

- Yan, K.; Liss, K.-D.; Garbe, U.; Daniels, J.; Kirstein, O.; Li, H.; Dippenaar, R. From single grains to texture. Adv. Eng. Mater. 2009, 11, 771–773. [Google Scholar] [CrossRef]

- Liss, K.-D.; Garbe, U.; Li, H.; Schambron, T.; Almer, J.D.; Yan, K. In situ observation of dynamic recrystallization in the bulk of zirconium alloy. Adv. Eng. Mater. 2009, 11, 637–640. [Google Scholar] [CrossRef]

- Schmoelzer, T.; Liss, K.-D.; Rester, M.; Yan, K.; Stark, A.; Reid, M.; Peel, M.; Clemens, H. Dynamic recovery and recrystallisation during hot-working in an advanced TiAl alloy. Pract. Metallogr. 2011, 48, 632–642. [Google Scholar] [CrossRef]

- Sahu, P. Lattice imperfections in intermetallic Ti–Al alloys: An X-ray diffraction study of the microstructure by the Rietveld method. Intermetallics 2006, 14, 180–188. [Google Scholar] [CrossRef]

- Schwaighofer, E.; Clemens, H.; Lindemann, J.; Stark, A.; Mayer, S. Hot-working behavior of an advanced intermetallic multi-phase γ-TiAl based alloy. Mater. Sci. Eng. A 2014, 614, 297–310. [Google Scholar] [CrossRef]

- Cha, L.; Clemens, H.; Dehm, G. Microstructure evolution and mechanical properties of an intermetallic Ti–43.5Al–4Nb–1Mo–0.1B alloy after ageing below the eutectoid temperature. Int. J. Mater. Res. 2011, 102, 1–6. [Google Scholar] [CrossRef]

- Cha, L.; Scheu, C.; Clemens, H.; Chladil, H.F.; Dehm, G.; Gerling, R.; Bartels, A. Nanometer-scaled lamellar microstructures in Ti–45Al–7.5Nb–(0; 0.5)C alloys and their influence on hardness. Intermetallics 2008, 16, 868–875. [Google Scholar] [CrossRef]

- Veeraraghavan, D.; Pilchowski, U.; Natarajan, B.; Vasudevan, V.K. Phase equilibria and transformations in Ti–(25–52) at. % Al alloys studied by electrical resistivity measurements. Acta Mater. 1998, 46, 405–421. [Google Scholar] [CrossRef]

- Beschliesser, M.; Chatterjee, A.; Lorich, A.; Knabl, W.; Kestler, H.; Dehm, G.; Clemens, H. Designed fully lamellar microstructures in a γ-TiAl based alloy: Adjustment and microstructural changes upon long-term isothermal exposure at 700 and 800 °C. Mater. Sci. Eng. A 2002, 329–331, 124–129. [Google Scholar] [CrossRef]

- Takeyama, M.; Kumagai, T.; Nakamura, M.; Kikuchi, M. Cooling rate dependence of the α2/γ phase transformation in titanium aluminides and its application to alloy development. In Structural Intermetallics 1993; Darolia, R., Lewandowski, J.J., Liu, C.T., Martin, P.L., Miracle, D.B., Nathal, M.V., Eds.; The Minerals, Metals and Materials Society (TMS): Warrendale, PA, USA, 1993; pp. 167–176. [Google Scholar]

- Zhu, H.; Seo, D.Y.; Maruyama, K.; Au, P. Effect of microstructural stability on creep behavior of 47XD TiAl alloys with fine-grained fully lamellar structure. Scr. Mater. 2005, 52, 45–50. [Google Scholar] [CrossRef]

- Tang, J.; Huang, B.; Zhou, K.; Liu, W.; He, Y.; Liu, Y. Factors affecting the lamellar spacing in two-phase TiAl alloys with fully lamellar microstructures. Mater. Res. Bull. 2001, 36, 1737–1742. [Google Scholar] [CrossRef]

- Droessler, L.M.; Schmoelzer, T.; Wallgram, W.; Cha, L.; Das, G.; Clemens, H. Microstructure and tensile ductility of a Ti–43Al–4Nb–1Mo–0.1B alloy. MRS Proc. 2009, 1128, 121–126. [Google Scholar]

- Guyon, J.; Hazotte, A.; Bouzy, E. Evolution of metastable α phase during heating of Ti48Al2Cr2Nb intermetallic alloy. J. Alloy. Compd. 2015, 656, 667–675. [Google Scholar] [CrossRef]

- Zhu, H.; Matsuda, J.; Maruyama, K. Influence of heating rate in α + γ dual phase field on lamellar morphology and creep property of fully lamellar Ti–48Al alloy. Mater. Sci. Eng. A 2005, 397, 58–64. [Google Scholar] [CrossRef]

- Dehm, G.; Motz, C.; Scheu, C.; Clemens, H.; Mayrhofer, P.H.; Mitterer, C. Mechanical size-effects in miniaturized and bulk materials. Adv. Eng. Mater. 2006, 8, 1033–1045. [Google Scholar] [CrossRef]

- Cha, L.; Clemens, H.; Dehm, G.; Zhang, Z. In situ TEM heating study of the γ lamellae formation inside the α2 matrix of a Ti–45Al–7.5Nb alloy. Adv. Mater. Res. 2011, 146–147, 1365–1368. [Google Scholar]

- Clemens, H.; Mayer, S. Micro- and nanostructure evolution in intermetallic titanium aluminides. In Proceedings of the Ti-2011—12th World Conference on Titanium, Beijing, China, 19–24 June 2012; Zhou, L., Chang, H., Lu, Y., Xu, D., Eds.; Science Press: Beijing, China, 2012; pp. 395–403. [Google Scholar]

- Schwaighofer, E.; Schloffer, M.; Schmoelzer, T.; Mayer, S.; Lindemann, J.; Güther, V.; Klose, J.; Clemens, H. Influence of heat treatments on the microstructure of a multi-phase titanium aluminide alloy. Pract. Metallogr. 2012, 49, 124–137. [Google Scholar] [CrossRef]

- Clemens, H.; Wallgram, W.; Schloffer, M. Method for Producing a Component and Components of a Titanium-Aluminum Base Alloy. US Patent 2011,0277,891 A1, 17 November 2011. [Google Scholar]

- Bolz, S.; Oehring, M.; Lindemann, J.; Pyczak, F.; Paul, J.; Stark, A.; Lippmann, T.; Schrüfer, S.; Roth-Fagaraseanu, D.; Schreyer, A.; et al. Microstructure and mechanical properties of a forged β-solidifying γ TiAl alloy in different heat treatment conditions. Intermetallics 2015, 58, 71–83. [Google Scholar] [CrossRef]

- Huber, D.; Werner, R.; Clemens, H.; Stockinger, M. Influence of process parameter variation during thermo-mechanical processing of an intermetallic β-stabilized γ-TiAl based alloy. Mater. Charact. 2015, 109, 116–121. [Google Scholar] [CrossRef]

- Kim, Y. Ordered intermetallic alloys, part III: Gamma titanium aluminides. JOM 1994, 46, 30–39. [Google Scholar] [CrossRef]

- Perdrix, F.; Trichet, M.F.; Bonnentien, J.L.; Cornet, M.; Bigot, J. Influence of cooling rate on microstructure and mechanical properties of a Ti–48Al alloy. Intermetallics 1999, 7, 1323–1328. [Google Scholar] [CrossRef]

- Cao, G.; Fu, L.; Lin, J.; Zhang, Y.; Chen, C. The relationships of microstructure and properties of a fully lamellar TiAl alloy. Intermetallics 2000, 8, 647–653. [Google Scholar] [CrossRef]

- Djanarthany, S.; Servant, C.; Penelle, R. Phase transformations in Ti3Al and Ti3Al + Mo aluminides. J. Mater. Res. 1991, 6, 969–986. [Google Scholar] [CrossRef]

- Djanarthany, S.; Servant, C.; Penelle, R. Influence of an increasing content of molybdenum on phase transformations of Ti–Al–Mo aluminides—Relation with mechanical properties. Mater. Sci. Eng. A 1992, 152, 48–53. [Google Scholar] [CrossRef]

- Schnitzer, R.; Chladil, H.F.; Scheu, C.; Clemens, H.; Bystrzanowski, S.; Bartels, A.; Kremmer, S. The production of lamellar microstructures in intermetallic TiAl alloys and their characterisation. Pract. Metallogr. 2007, 44, 430–442. [Google Scholar] [CrossRef]

- Novoselova, T.; Malinov, S.; Sha, W. Experimental study of the effects of heat treatment on microstructure and grain size of a gamma TiAl alloy. Intermetallics 2003, 11, 491–499. [Google Scholar] [CrossRef]

- Kenel, C.; Leinenbach, C. Influence of Nb and Mo on microstructure formation of rapidly solidified ternary TiAl–(Nb,Mo) alloys. Intermetallics 2016, 69, 82–89. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Erdely, P.; Schmoelzer, T.; Schwaighofer, E.; Clemens, H.; Staron, P.; Stark, A.; Liss, K.-D.; Mayer, S. In Situ Characterization Techniques Based on Synchrotron Radiation and Neutrons Applied for the Development of an Engineering Intermetallic Titanium Aluminide Alloy. Metals 2016, 6, 10. https://doi.org/10.3390/met6010010

Erdely P, Schmoelzer T, Schwaighofer E, Clemens H, Staron P, Stark A, Liss K-D, Mayer S. In Situ Characterization Techniques Based on Synchrotron Radiation and Neutrons Applied for the Development of an Engineering Intermetallic Titanium Aluminide Alloy. Metals. 2016; 6(1):10. https://doi.org/10.3390/met6010010

Chicago/Turabian StyleErdely, Petra, Thomas Schmoelzer, Emanuel Schwaighofer, Helmut Clemens, Peter Staron, Andreas Stark, Klaus-Dieter Liss, and Svea Mayer. 2016. "In Situ Characterization Techniques Based on Synchrotron Radiation and Neutrons Applied for the Development of an Engineering Intermetallic Titanium Aluminide Alloy" Metals 6, no. 1: 10. https://doi.org/10.3390/met6010010