Microstructure and Mechanical Properties of Friction Stir Welded Dissimilar Titanium Alloys: TIMET-54M and ATI-425

Abstract

:1. Introduction

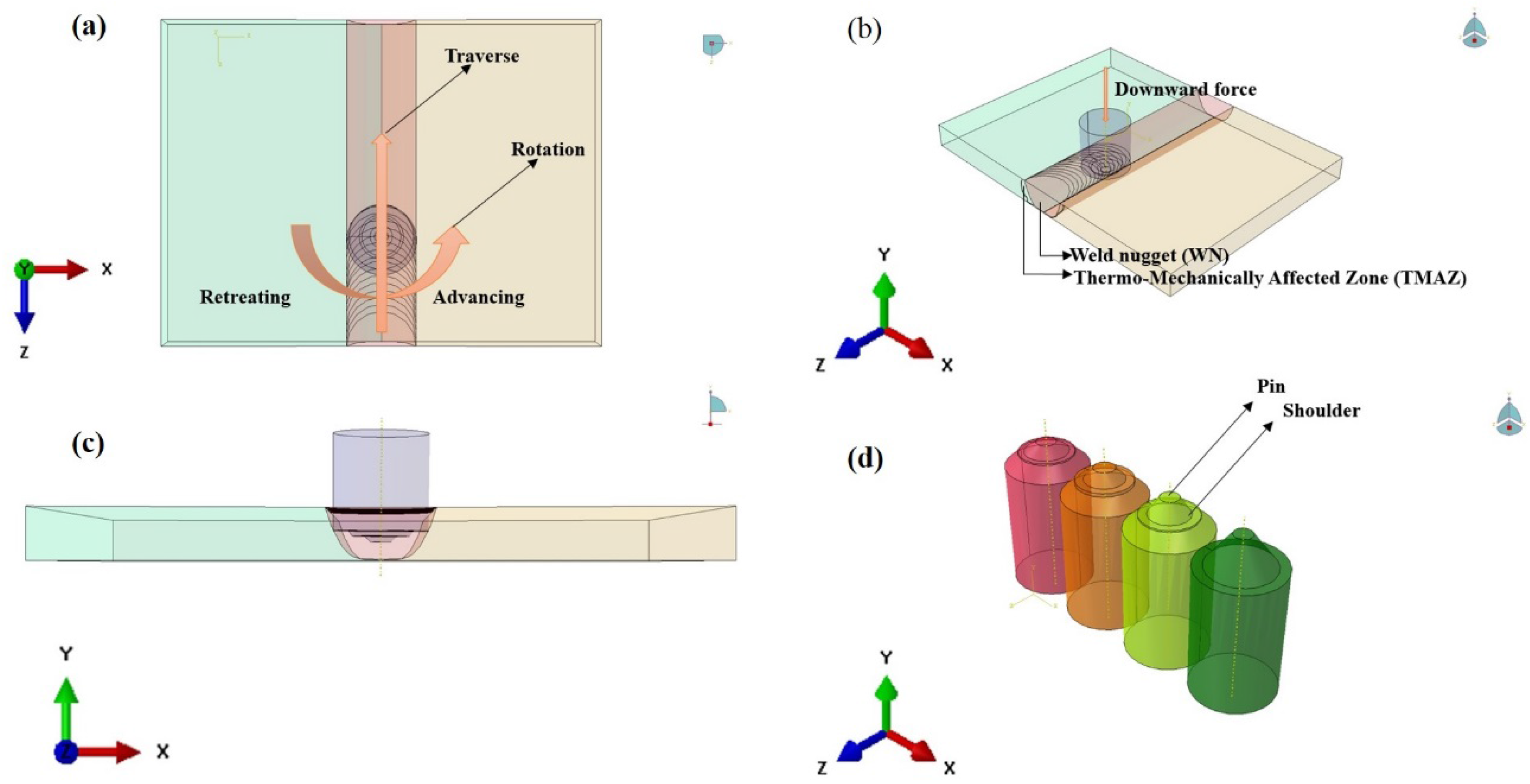

2. Materials and Methods

2.1. Processing

2.2. Mettalurgical Characterization

2.3. Microhardness

2.4. Tensile Specimens

3. Results

3.1. Metalography

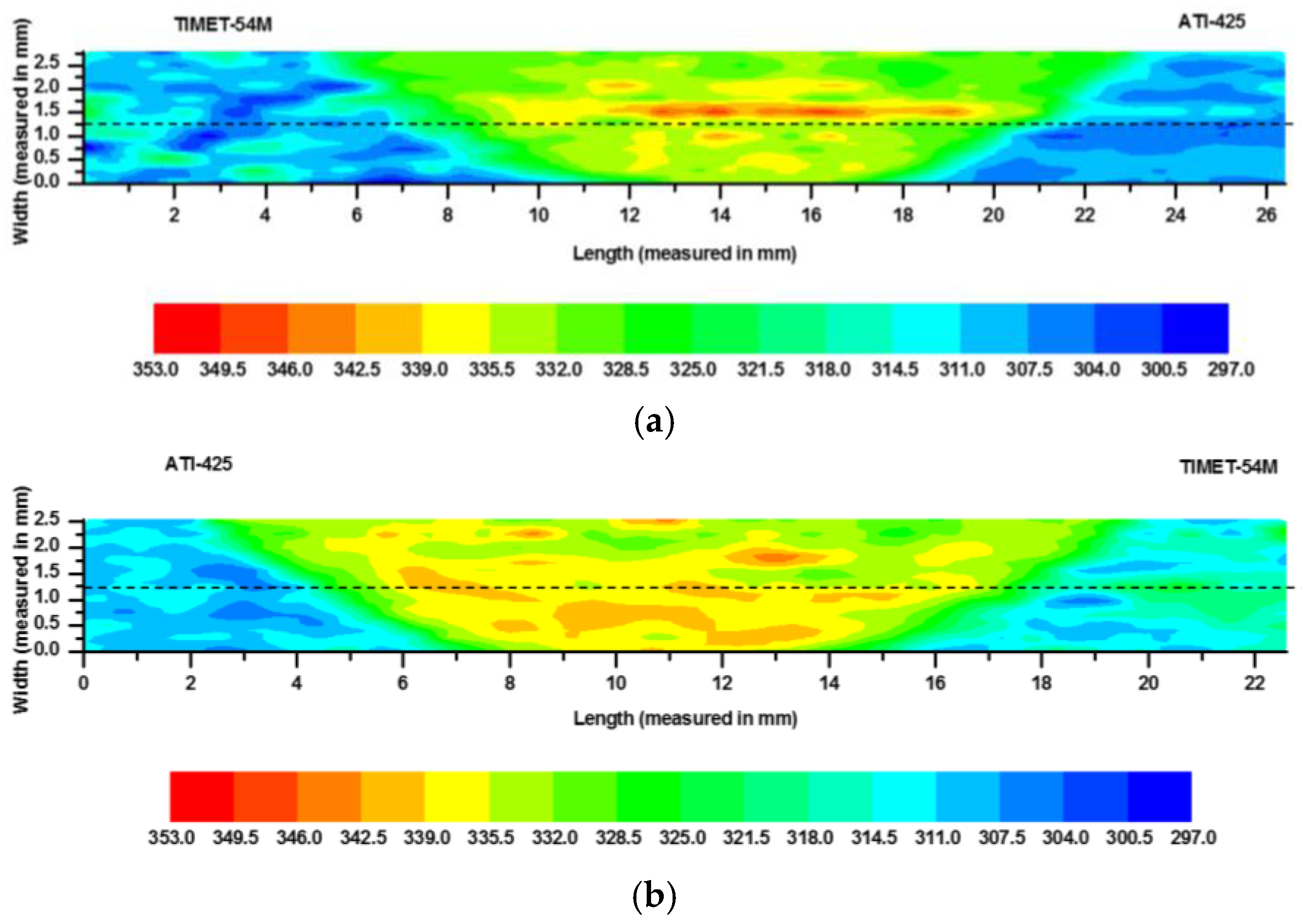

3.2. Microhardness

3.3. Tensile Specimens

4. Discussion

4.1. Morphology of the Welds

4.2. Microstructural Evolution

4.2.1. P1: TIMET-54M on the Retreating Side

4.2.2. P4: ATI-425 on the Retreating Side

4.3. Microhardness

- (1)

- If a material with lower β transus is kept on the retreating side, this results in the formation of a Widmanstätten microstructure with coarser α lamellae for most of the WN and slightly lower hardness values.

- (2)

- If a material with higher β transus is kept on the retreating side, an increase in the hardness values on the retreating side is marked by the deformation of the α phase. In the weld center the microstructure mostly consists of a basket-weave morphology with finer α lamellae. As we approach the boundary on the advancing side, the hardness increase is a result of both grain refinement and of acicular α in prior β grains.

- (3)

- As such, no uniformity can be conformed based on the evolution of the microstructure but, for the case of P4, higher values of hardness have been observed on the retreating side suggesting that grain refinement is more dominant in comparison with the finer acicular α formation.

4.4. Mechanical and Microstructural Relationship

5. Conclusions

- (1)

- The typical microstructure as it evolved inside, and around, the WN, is dependent on the initial BM microstructure. If a material with a lower β transus temperature (TIMET-54M) is kept on the advancing side(P4), the majority of the microstructure inside the WN is characterized by the refined prior β grains and finer acicular α. On the other hand, if same material with a lower transus temperature (TIMET-54M) is kept on the retreating side (P1), the microstructure in the WN is characterized by coarser α lamellae with grain boundary α.

- (2)

- Higher values of hardness have been observed for the case when TIMET-54M was kept on the advancing side (P4).

- (3)

- The global stress strain curve showed an increase in the mechanical properties when TIMET-54M was kept on the advancing side.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Thomas, W.M.; Nicholas, E.D.; NeedHam, J.C.; Murch, M.G.; Templesmith, P.; Dawes, C.J. Friction Stir Welding; The Welding Institure: Cambridge, UK, 1991. [Google Scholar]

- Boyer, R.R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. Process. 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Peters, J.O.; Lutjering, G. Comparison of the fatigue and fracture of alpha plus beta and beta titanium alloys. Metall. Mater. Trans. Phys. Metall. Mater. Sci. 2001, 32, 2805–2818. [Google Scholar] [CrossRef]

- Lutjering, G. Influence of processing on microstructure and mechanical properties of (alpha + beta) titanium alloys. Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. Process. 1998, 243, 32–45. [Google Scholar] [CrossRef]

- Kim, J.S.; Kim, J.H.; Lee, Y.T.; Park, C.G.; Lee, C.S. Microstructural analysis on boundary sliding and its accommodation mode during superplastic deformation of Ti-6Al-4V alloy. Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. Process. 1999, 263, 272–280. [Google Scholar] [CrossRef]

- Fonda, R.W.; Knipling, K.E. Texture development in near-alpha Ti friction stir welds. Acta Mater. 2010, 58, 6452–6463. [Google Scholar] [CrossRef]

- Fonda, R.W.; Knipling, K.E. Texture development in friction stir welds. Sci. Technol. Weld. Join. 2011, 16, 288–294. [Google Scholar] [CrossRef]

- Pao, P.S.; Fonda, R.W.; Jones, H.N.; Feng, C.R.; Moon, D.W. Fatigue crack growth in friction stir welded Ti-5111. In Friction Stir Welding and Processing V; Rajiv, M.W.M., Mishra, S., Lienert, T.J., Eds.; TMS (The Minerals, Metals & Materials Society): Warrendale, PA, USA, 2009. [Google Scholar]

- Reynolds, A.P.; Hood, E.; Tang, W. Texture in friction stir welds of Timetal 21S. Scr. Mater. 2005, 52, 491–494. [Google Scholar] [CrossRef]

- Yoon, S.; Ueji, R.; Fujii, H. Microstructure and texture distribution of Ti-6Al-4V alloy joints friction stir welded below beta-transus temperature. J. Mater. Process. Technol. 2016, 229, 390–397. [Google Scholar] [CrossRef]

- Zhang, Y.; Sato, Y.S.; Kokawa, H.; Park, S.H.C.; Hirano, S. Stir zone microstructure of commercial purity titanium friction stir welded using pcBN tool. Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. Process. 2008, 488, 25–30. [Google Scholar] [CrossRef]

- Zhang, Y.; Sato, Y.S.; Kokawa, H.; Park, S.H.C.; Hirano, S. Microstructural characteristics and mechanical properties of Ti-6Al-4V friction stir welds. Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. Process. 2008, 485, 448–455. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, H.J.; Liu, Q.W. Effect of process parameters on stir zone microstructure in Ti-6Al-4V friction stir welds. J. Mater. Sci. 2010, 45, 39–45. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, H.J.; Wu, L.Z. Texture of friction stir welded Ti-6Al-4V alloy. Trans. Nonferr. Met. Soc. China 2014, 24, 368–372. [Google Scholar] [CrossRef]

- Edwards, P.; Ramulu, M. Identification of Process Parameters for Friction Stir Welding Ti-6Al-4V. J. Eng. Mater. Technol. Trans. Asme 2010, 132. [Google Scholar] [CrossRef]

- Rai, R.; De, A.; Bhadeshia, H.K.D.H.; DebRoy, T. Review: Friction stir welding tools. Sci. Technol. Weld. Join. 2011, 16, 325–342. [Google Scholar] [CrossRef]

- Edwards, P.D.; Ramulu, M. Material flow during friction stir welding of Ti-6Al-4V. J. Mater. Process. Technol. 2015, 218, 107–115. [Google Scholar] [CrossRef]

- Pilchak, A.L.; Williams, J.C. Microstructure and Texture Evolution during Friction Stir Processing of Fully Lamellar Ti-6Al-4V. Metall. Mater. Trans. Phys. Metall. Mater. Sci. 2011, 42, 773–794. [Google Scholar] [CrossRef]

- Edwards, P.; Ramulu, M. Fracture toughness and fatigue crack growth in Ti-6Al-4V friction stir welds. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 970–982. [Google Scholar] [CrossRef]

- Edwards, P.; Ramulu, M. Fatigue performance of Friction Stir Welded titanium structural joints. Int. J. Fatigue 2015, 70, 171–177. [Google Scholar] [CrossRef]

- Edwards, P.; Ramulu, M. Fatigue performance of Friction Stir Welded Ti-6Al-4V subjected to various post weld heat treatment temperatures. Int. J. Fatigue 2015, 75, 19–27. [Google Scholar] [CrossRef]

- Edwards, P.D.; Ramulu, M. Comparative study of fatigue and fracture in friction stir and electron beam welds of 24mm thick titanium alloy Ti-6Al-4V. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 1226–1240. [Google Scholar] [CrossRef]

- Sanders, D.G.; Edwards, P.; Cantrell, A.M.; Gangwar, K.; Ramulu, M. Friction Stir-Welded Titanium Alloy Ti-6Al-4V: Microstructure, Mechanical and Fracture Properties. JOM 2015, 67, 1054–1063. [Google Scholar] [CrossRef]

- Fazel-Najafabadi, M.; Kashani-Bozorg, S.F.; Zarei-Hanzaki, A. Dissimilar lap joining of 304 stainless steel to CP-Ti employing friction stir welding. Mater. Des. 2011, 32, 1824–1832. [Google Scholar] [CrossRef]

- Liao, J.S.; Yamamoto, N.; Liu, H.; Nakata, K. Microstructure at friction stir lap joint interface of pure titanium and steel. Mater. Lett. 2010, 64, 2317–2320. [Google Scholar] [CrossRef]

- Ishida, K.; Gao, Y.; Nagatsuka, K.; Takahashi, M.; Nakata, K. Microstructures and mechanical properties of friction stir welded lap joints of commercially pure titanium and 304 stainless steel. J. Alloy. Compd. 2015, 630, 172–177. [Google Scholar] [CrossRef]

- Fazel-Najafabadi, M.; Kashani-Bozorg, S.F.; Zarei-Hanzaki, A. Joining of CP-Ti to 304 stainless steel using friction stir welding technique. Mater. Des. 2010, 31, 4800–4807. [Google Scholar] [CrossRef]

- Buffa, G.; Baffari, D.; di Caro, A.; Fratini, L. Friction stir welding of dissimilar aluminium-magnesium joints: Sheet mutual position effects. Sci. Technol. Weld. Join. 2015, 20, 271–279. [Google Scholar] [CrossRef]

- Yuan, W.; Mishra, R.S.; Carlson, B.; Verma, R.; Mishra, R.K. Material flow and microstructural evolution during friction stir spot welding of AZ31 magnesium alloy. Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. Process. 2012, 543, 200–209. [Google Scholar] [CrossRef]

- Chen, Y.H.; Ni, Q.; Ke, L.M. Interface characteristic of friction stir welding lap joints of Ti/Al dissimilar alloys. Trans. Nonferr. Met. Soc. China 2012, 22, 299–304. [Google Scholar] [CrossRef]

- Hong, J.K.; Lee, C.H.; Kim, J.H.; Yeom, J.T.; Lee, C.G. Friction Stir Welding of Dissimilar Al 5052 to Ti-6Al-4V Alloy with WC-Co Tool. Steel Res. Int. 2010, 81, 1092–1095. [Google Scholar]

- Zhang, Z.H.; Li, B.; Feng, X.M.; Shen, Y.F.; Hu, W.Y. Friction-stir welding of titanium/aluminum dissimilar alloys: Joint configuration design, as-welded interface characteristics and tensile properties. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 228, 1469–1480. [Google Scholar] [CrossRef]

- Vaidya, W.V.; Horstmann, M.; Ventzke, V.; Petrovski, B.; Kocak, M.; Kocik, R.; Tempus, G. Structure-property investigations on a laser beam welded dissimilar joint of aluminium AA6056 and titanium Ti6Al4V for aeronautical applications Part I: Local gradients in microstructure, hardness and strength. Mater. Werkst. 2009, 40, 623–633. [Google Scholar] [CrossRef]

- Hsieh, C.T.; Chu, C.Y.; Shiue, R.K.; Tsay, L.W. The effect of post-weld heat treatment on the notched tensile fracture of Ti-6Al-4V to Ti-6Al-6V-2Sn dissimilar laser welds. Mater. Des. 2014, 59, 227–232. [Google Scholar] [CrossRef]

- Jata, K.V.; Subramanian, P.R.; Reynolds, A.P.; Trapp, T.; Helder, E. Friction stir welding of titanium alloys for aerospace application: Microstructure and mechanical behavior. In Proceedings of the Fourteenth (2004) International Offshore and Polar Engineering Conference, Toulon, France, 23–28 May 2004.

- ATI Technical Data Sheet. Available online: https://www.atimetals.com/Documents/ati_425_alloy_tds_en_v5.pdf (accessed on 21 October 2016).

- Kosaka, Y.; Gudipati, P. Supreplastic Forming Prperties of TIMETAL 54M. Available online: http://c.ymcdn.com/sites/www.titanium.org/resource/resmgr/2010_2014_papers/KosakaYogi_2010_AerospaceMat.pdf (accessed on 21 October 2016).

- Edwards, P.; Ramulu, M. Surface Residual Stresses in Ti-6Al-4V Friction Stir Welds: Pre- and Post-Thermal Stress Relief. J. Mater. Eng. Perform. 2015, 24, 3263–3270. [Google Scholar] [CrossRef]

- Lienert, T.J. Microstructure and mechanical properties of friction stir welded titanium alloys. In Friction Stir Welding and Processing; Rajiv, M.W.M., Mishra, S., Eds.; ASM International: Geauga County, OH, USA, 2007; p. 128. [Google Scholar]

- Frankel, J.; Abbate, A.; Scholz, W. The Effect of Residual-Stresses on Hardness Measurements. Exp. Mech. 1993, 33, 164–168. [Google Scholar] [CrossRef]

| Alloys | wt. % | Al | Mo | V | Fe | O | C | N | H | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| ATI-425 | Min | 3.5 | 2 | 1.2 | 0.2 | Bal. | ||||

| Max | 4.5 | 3 | 1.8 | 0.3 | 0.08 | 0.03 | 0.015 | |||

| TIMET-54M | Min | 4.5 | 0.4 | 3 | 0.2 | 0.015 | Bal. | |||

| Max | 5.5 | 1 | 5 | 0.8 | 0.2 | 0.1 |

| Parameters | Values |

|---|---|

| Spindle Speed | 300 rpm |

| Tool Traverse Speed | ~75–100 mm/min |

| Forging Load | ~15.6 kN |

| Tool Plunging Depth | ~1.6 mm |

| Tool Tilt | 3° from direction of traverse |

| Tool Material | W-La |

| Tool Pin Length | ~1.4 mm |

| Tool Pin Diameter | ~8.6 mm |

| Tool Shoulder Diameter | ~15.9 mm |

| Specimen | YS (in MPa) | St. Dev. in YS (MPa) | UTS (MPa) | St. Dev. in UTS (MPa) | % Elong. | St. Dev. in % Elong. |

|---|---|---|---|---|---|---|

| P1 | 966.48 | 15.87 | 995.64 | 18.29 | 6.37 | 0.62 |

| P4 | 989 | 12.33 | 1019.07 | 16.1 | 6.57 | 0.48 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gangwar, K.; Ramulu, M.; Cantrell, A.; Sanders, D.G. Microstructure and Mechanical Properties of Friction Stir Welded Dissimilar Titanium Alloys: TIMET-54M and ATI-425. Metals 2016, 6, 252. https://doi.org/10.3390/met6100252

Gangwar K, Ramulu M, Cantrell A, Sanders DG. Microstructure and Mechanical Properties of Friction Stir Welded Dissimilar Titanium Alloys: TIMET-54M and ATI-425. Metals. 2016; 6(10):252. https://doi.org/10.3390/met6100252

Chicago/Turabian StyleGangwar, Kapil, M. Ramulu, Andrew Cantrell, and Daniel G. Sanders. 2016. "Microstructure and Mechanical Properties of Friction Stir Welded Dissimilar Titanium Alloys: TIMET-54M and ATI-425" Metals 6, no. 10: 252. https://doi.org/10.3390/met6100252

APA StyleGangwar, K., Ramulu, M., Cantrell, A., & Sanders, D. G. (2016). Microstructure and Mechanical Properties of Friction Stir Welded Dissimilar Titanium Alloys: TIMET-54M and ATI-425. Metals, 6(10), 252. https://doi.org/10.3390/met6100252