1. Introduction

The maximum force principle has been extensively used in the past to study sheet formability. Considère’s maximum force criterion (MFC) states that diffuse necking is initiated in a tensile test of a bar when the maximum force is reached. The classical models of Swift [

1] and Hill [

2] are extensions of the MFC for the determination of necking in metal sheets subjected to different stretching conditions in the sheet plane. The former is applicable to the prediction of diffuse necking in the entire domain of the forming limit diagram (FLD). The latter is coupled with the initiation of strain localisation along a narrow band and is limited to predict localised necking in the left side of the FLD. Later, Hora et al. [

3] extended the MFC to predict strain localisation for both sides of the FLD by including the contribution of the minor principal strain.

The simplicity of necking criteria based on the maximum force principle make them very attractive. However, their predictions do not always agree with experimental results. Many extensions and alternatives to the MFC have been proposed to date, to deal with predicting localised necking. For instance, Bressan and Williams [

4] suggested that failure occurs when the shear stress reaches a maximum. Hora et al. [

5] proposed a phenomenological criterion, which states that once the maximum force is reached, the loading path gradually evolves towards plane strain and then localisation occurs. Brunet and Morestin [

6] included the effects of damage to refine the material model for the prediction of the necking curve in the FLD. Recently, Aretz [

7] assumed that localised necking does not necessarily occur when the axial force reaches a maximum, but rather when it reaches a critical value. This method aimed to scale the Hill’s model so that the major strain predicted by the M–K model [

8] or its experimental counterpart at plane-strain conditions (usually referred to as

) was matched.

The above criteria, which are collectively referred to as maximum force criteria (MFCs), were developed to predict necking in nearly stretching operations, neglecting implicitly the strain and stress gradients through the sheet thickness. However, in sheet metal forming processes such as stretch-bending or stamping with punches of mild or severe radii, it is well known that the occurrence of bending has a “beneficial effect” on the initiation of necking. In practice, the average strain through the sheet thickness (or the strain at the middle of the sheet surface) has been used to characterise failure criteria. However, the predictions of this approach, sometimes called the mid-plane rule (MPR), are in general very conservative.

Research carried out to analyse the sheet failure in simultaneous stretching and bending conditions has followed a different approach from the maximum force principle. Tharrett and Stoughton [

9] studied the bending effect on sheet failure and proposed a necking criterion referred to as the concave-side rule (CSR). This criterion establishes that the failure is initiated when the strain at the inner surface (concave side) of the sheet reaches a critical value at the bending zone, which matches the limit strain of in-plane stretching. This criterion notably improved the predictions of sheet failure in some materials compared to the MPR. In a later study, authors recognised that stresses are less sensitive to strain path changes, and consequently they reformulated the CSR in terms of stresses [

10].

In a previous work, the present authors proposed a natural improvement of the CSR [

11]. The model assumes that necking should be controlled by the development of damage in a material volume located at the inner side of the sheet. The study concludes that the critical size of this volume (represented by a certain critical distance from the sheet surface) should be related to the material microstructure.

This work analyses the maximum force principle under stretch-bending conditions, proposing an analytical deformation model to characterise the stretch-bending process under plane-strain conditions. Different generalisations of the MFC for stretch-bending conditions are presented and discussed. As a result, the study suggests that the effect of the existence of strain and stress gradients on sheet thickness may be assessed by applying the MFCs locally at a given material’s critical distance from the inner surface. The proposed necking models are successfully applied to describe the failure by necking in sheets under stretch-bending conditions in different materials, such as 1008 AK steel, 70/30 brass, 6010 aluminium alloy and 7075-O aluminium alloy.

2. Maximum Force Criteria

Considère’s analysis of the uniaxial tension of a metal bar states that diffuse necking appears when the maximum force is applied, that is,

, with

. Swift extended this model to biaxial loading of a metal sheet of thickness

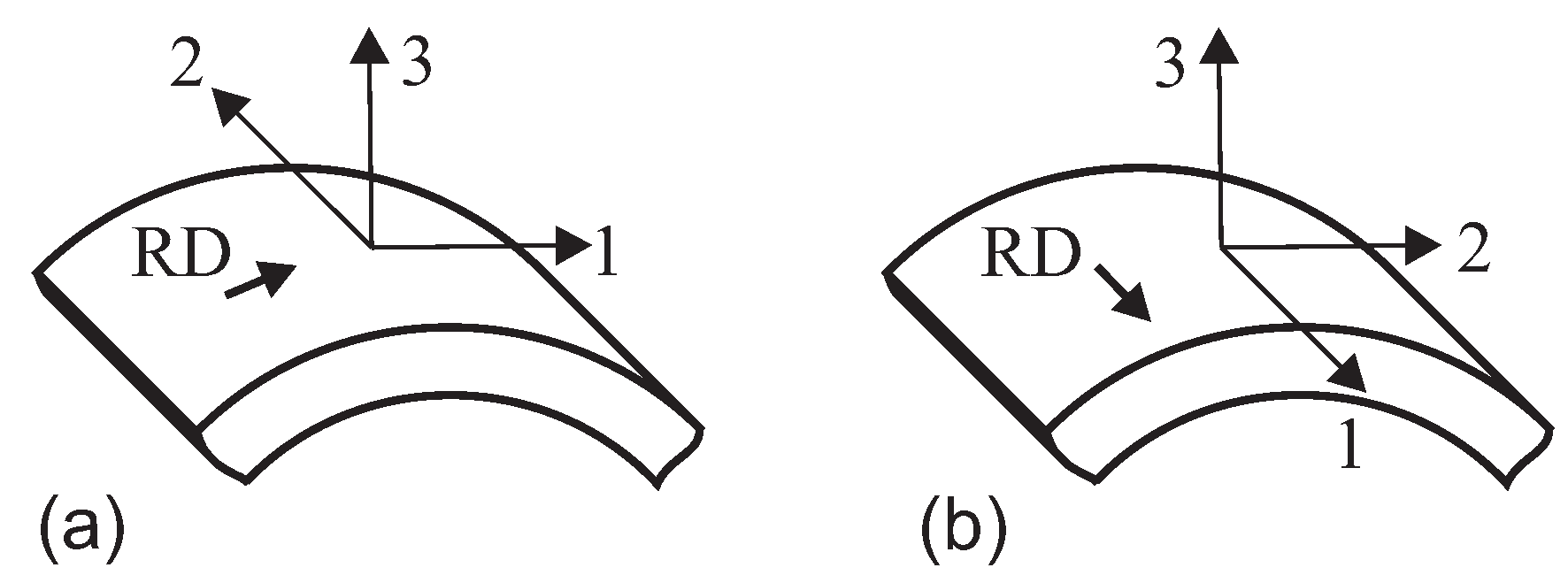

, represented schematically in

Figure 1, assuming a simultaneous maximum of both components of the force

,

, with

and

[

1].

Hill also formulated a criterion to predict localised necking in metal sheets [

2]. A simplified formulation of this model states that the localisation is initiated when the load per unit of width reaches its maximum:

, with

. The application of the Hill criterion is restricted to the left-hand side of the FLD, that is, uniaxial-stretching.

To predict localised necking in both sides of the FLD, Hora extended Considère’s model to biaxial loading of a metal sheet and considered that the major principal stress (

) is a function of both major (

) and minor (

) principal strains in the plane of the sheet [

3].

The above models of plastic instability lead to the formulation of the MFCs in a single and unified expression:

where the left-hand side is a material property, sometimes referred to as the

non-dimensional strain-hardening characteristic, whereas

Z is the critical value for the subtangent of the stress–strain curve [

12]. The former is evaluated using a stress–strain constitutive equation and the latter, by a yield function under plane-stress conditions, which can be characterised by the following parameters:

The expressions for the above parameters are given in

Appendix A for both Hosford and Mises yield criteria.

It is not intended in this article to review the formulation of these well-known models. There are several works in the literature that analyse these and provide specific expressions of Equation (

1) (e.g., [

13,

14,

15]). Most of these assume a Hollomon law (

) to evaluate the aforementioned material characteristic and a Mises yield function to evaluate

. For instance, the Hill necking criterion [

2] under proportional load transforms Equation (

1) to

which leads to algebraic expressions to evaluate the principal strains:

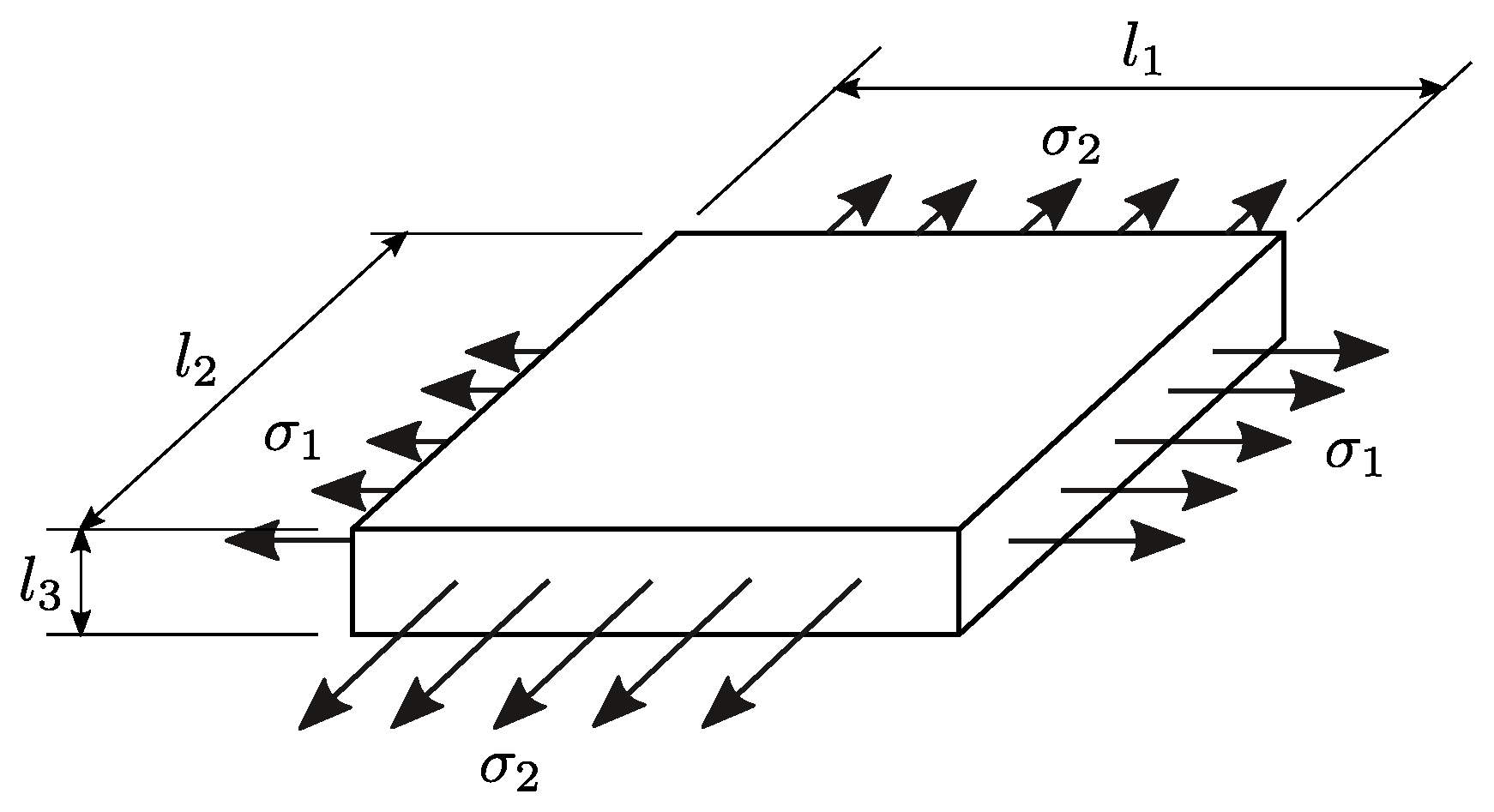

Figure 2 presents an illustrative example of the application of the Swift [

1], Hill [

2] and Hora [

3] criteria to predict necking in AA7075-O metals sheets. Both sides of Equation (

1) have been evaluated by assuming a Hollomon law and a Mises yield criterion, respectively. Critical values of

are represented in

Figure 2a as functions of the strain path

under proportional loading conditions.

Figure 2b presents necking predictions in the FLD along with the experimental data of localised necking reported by Martínez-Donaire et al. [

16] for AA7075-O sheets of 1.6 mm thickness. The coefficient of the Hollomon law was found to be

. As can be observed, both Hill and Hora criteria for localised necking reproduce the experimental data in their respective ranges of application reasonably well.

Figure 2 also presents the failure predictions of a modified Hill criterion based on Aretz’s approach [

7]. Aretz assumed that necking is initiated when the axial force reaches a critical value, rather than its maximum value. The fundamental idea of this approach lies in the calibration of the critical load, which is obtained by scaling the prediction of Hill’s model (

4) to fit the major strain at necking under plane-strain conditions (

). Accordingly, Equation (

1) is turned into

which leads to

3. Stretch-Bending Deformation Model

Under stretch-bending conditions, strain and stress gradients through the sheet thickness are induced in the metal sheet. In this situation, the MFCs must to be reformulated to take into account these gradients.

The following deformation model is an extension of a stretch-bending model developed in a previous work [

11]. This model assumed that the sheet adapts to the punch geometry in an earlier stage mainly by bending followed by a dominant stretching process until the sheet failure is reached. By simplicity, the evolution of the sheet curvature at the earlier stage is neglected, assuming this to be fixed and equal to the punch curvature. The model assumes that the deformation process is controlled by the reduction of sheet thickness.

In order to be able to integrate analytically the radial equilibrium equation, which relates principal stresses through the sheet thickness, only a plane-strain condition () is assumed hereafter. The effect on sheet failure of the through-thickness stress is also taken into account.

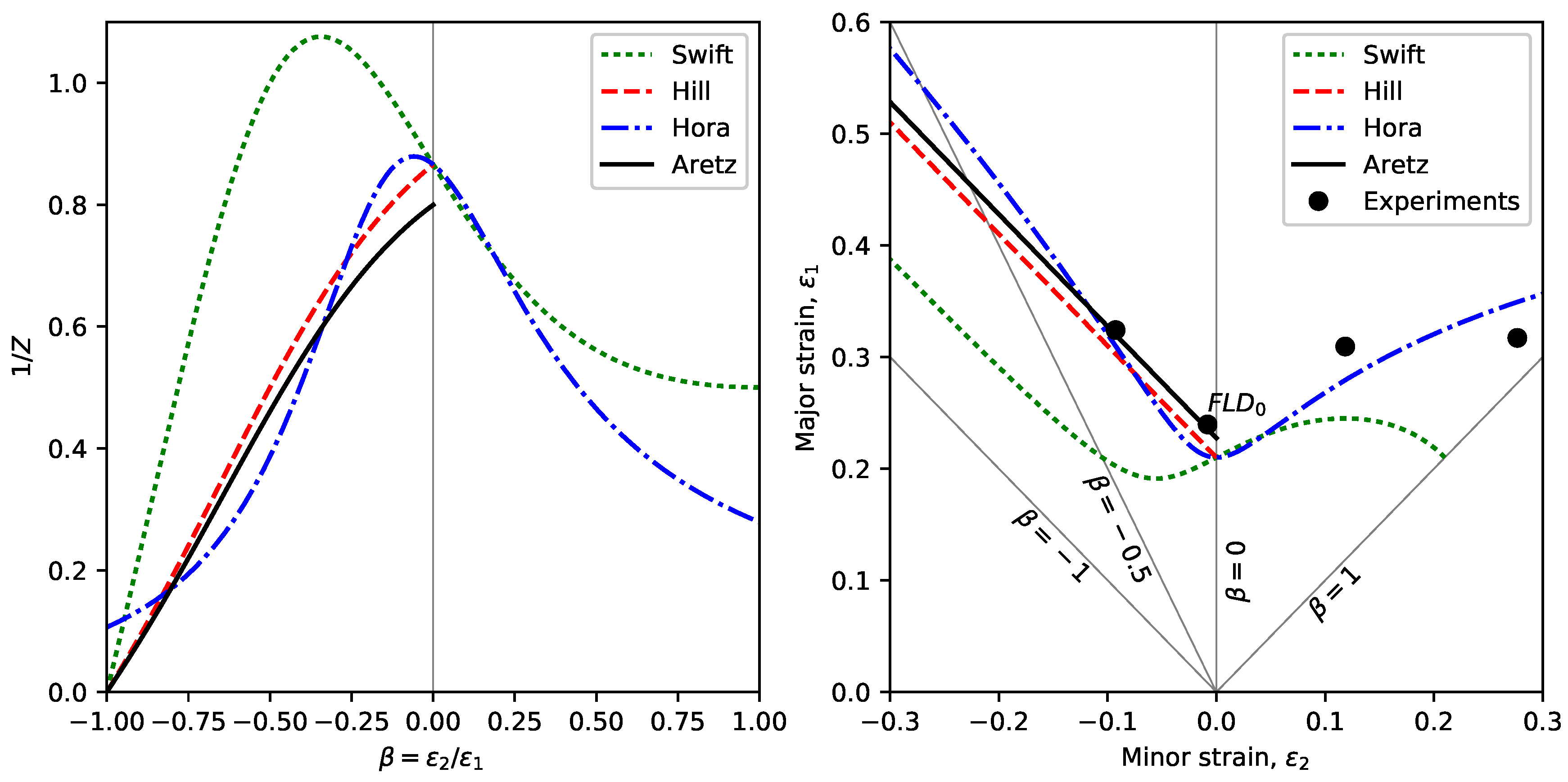

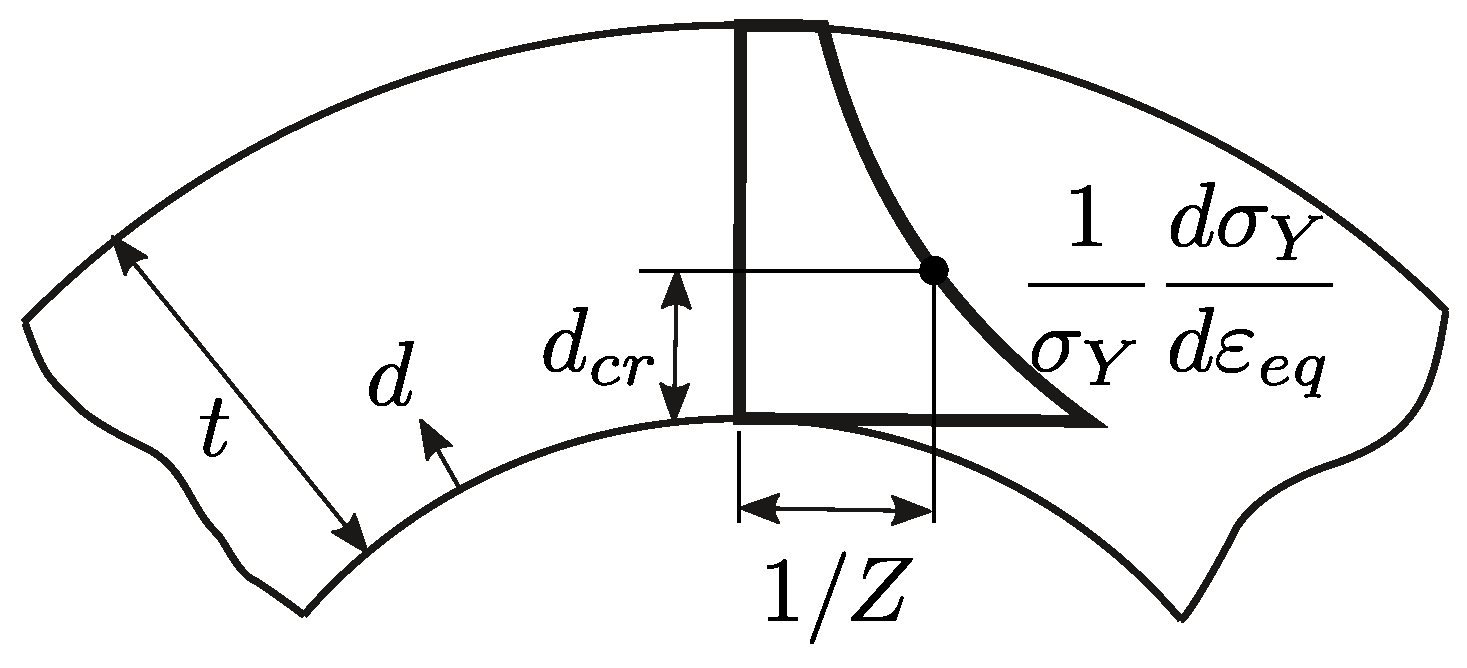

Figure 3 shows the model variables in a sheet element located at the dome of the punch that is subjected to stretch-bending. The undeformed sheet dimensions are

and the initial thickness is

. In the deformed configuration,

t is the current thickness, and the punch radius

R matches the radius of curvature of the inner surface.

In this configuration, is the bent angle, r is the radius of curvature of a given layer, is the position of the layer measured from the middle surface, and is the radius of curvature of the unstretched surface. We note that all layers on the thickness are stretched () when stretching dominates over bending. The current length of a generic layer, which initially had an undeformed length of , is .

The principal true strain distributions through the sheet thickness can be written as

where

can be obtained from the material incompressibility condition of the sheet element:

leading to

Substituting Equation (

9) into Equation (

7), the major strain can be expressed as a function of the variables

t and

r, and the parameters

and

R, as follows:

We note that the major strain at the outer and inner sides of the sheet (

and

, as shown in

Figure 3) are given by Equation (

10) by substituting

and

, respectively.

The distribution of principal stresses in the sheet thickness are obtained from the radial equilibrium equation [

17]:

Given that

from Equation (

7), it is convenient to change the variable

r for

in Equation (

11) and write the radial equilibrium equation as

The anisotropic non-quadratic yield criterion proposed by Hosford is assumed. This provides simplified expressions for the equivalent stress and strain under plane-strain conditions (see

Appendix B):

where

C is a function of the anisotropic parameters of the material. For instance, if the longitudinal or circumferential direction (axis 1) is aligned with the rolling direction of the sheet,

C is given by

A material behaviour following the Hollomon power law is assumed:

Thus, setting

and substituting Equations (

13), (

14) and (

16) into Equation (

12), the radial equilibrium condition becomes

where

.

Integrating the differential Equation (

17), being

at the outer surface of the sheet, the distribution of

through the sheet thickness is obtained as

The circumferential stress gradient through the sheet thickness can be now determined from Equations (

13), (

14), (

16) and (

18) as

and its derivative is given by

On the other hand, the yield stress is found from Equations (

12)–(

14) and (

17) as

Differentiating Equations (

13) and (

14) and combining with Equations (

17) and (

20), one obtains

Finally, dividing the last two expressions, the non-dimensional strain-hardening function in stretch-bending for a certain layer on the thickness is given by

We note that this expression is equivalent to Equation (

3) for in-plane stretching.

5. Critical-Distance Rule for Necking

In a recent research work [

11,

18,

19], the present authors developed a mesoscopic approach to predict failure in stretch-bent sheets. The proposed necking model combines the concepts of CSR and critical distance to predict the failure of the sheet. The model assumes that necking is controlled by the development of damage in a certain material volume located at the inner side of the sheet. The size of the critical volume is assumed to be a material constant, which can be related with the microstructure of the material.

According to the above idea, the less-stressed material at the inner zone is responsible for containing the plastic instability of the entire sheet thickness. In previous works, the sheet failure was characterised in terms of principal strains [

19] or principal stresses, which was more appropriate to analyse non-proportional strain paths [

11]. In both cases, the experimental data were successfully analysed. Following the MFC concepts, in the present work, the use of the non-dimensional strain-hardening function (left-hand side of Equation (

1)) is proposed to assess necking initiation under stretch-bending conditions.

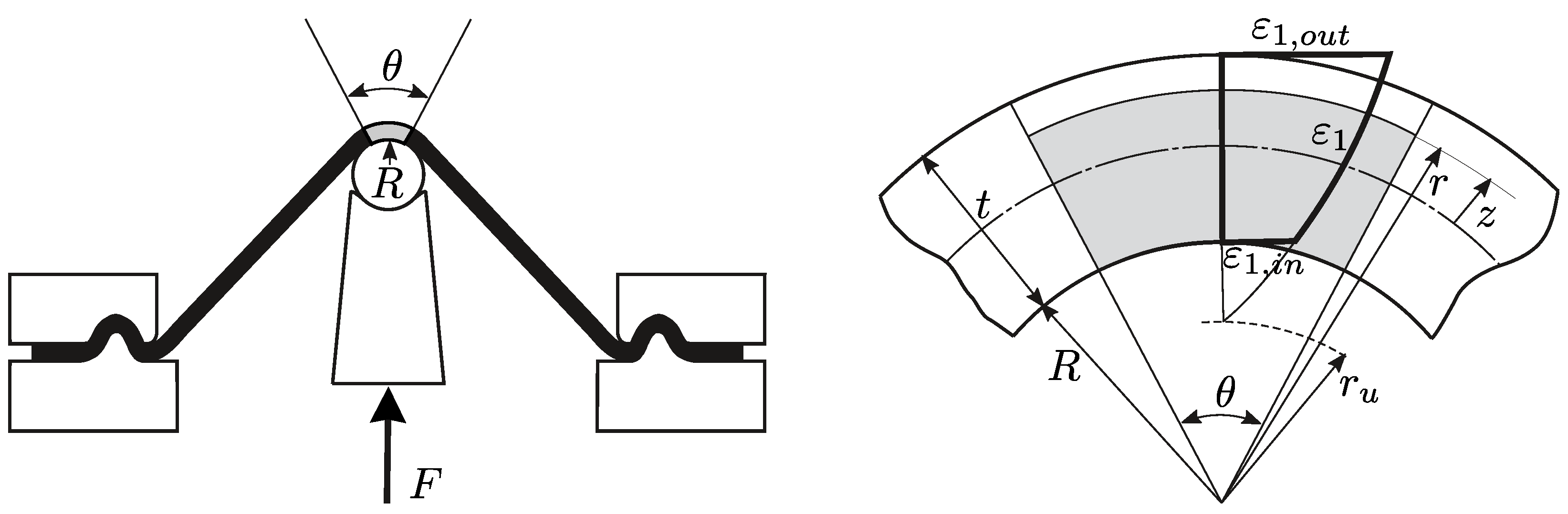

Figure 4 shows schematically the evolution of the strain-hardening function through the sheet thickness at the onset of necking. To rationalise the present model, the sheet can be assumed to be formed by the superposition of layers or fibres in the thickness, all having the mechanical behaviour of the base material. For a given layer located at a distance

d measured from the inner side of the sheet, a

local stability index can be defined as

where

depends on the failure criteria; for example, in the case of using the Aretz approach,

is

.

Thus, layers exhibiting

less than unity are assumed to be layers that are not able to resist the plastic instability of the sheet thickness. We note, from

Figure 4, that this condition is first reached at the upper side and propagates downwards in thickness during the forming process.

Otherwise, fibres having a value greater than unity are considered to be fibres that contain the plastic instability of the entire thickness. As can be seen, this material extends from the bottom layer to a depth , called here the critical distance, at which takes the unit value. This material volume prevents the sheet from necking.

According to the above description, the failure by necking of the sheet will occur when, at a certain critical distance from the inner side of the sheet, the local stability index becomes equal to the unit value. As is discussed in the next section, the value of is influenced only slightly by the bending ratio in stretch-bending; thus it can be considered in practice a material property to be determined experimentally.

This criterion is called here the critical-distance rule (CDR) by analogy to those previously proposed in the literature, such as the MPR, CSR and convex-side rule (CxSR).

6. Practical Application and Discussion

This section evaluates the capability of the failure criteria described above to predict localised necking under stretch-bending conditions. The experimental results analysed were found from the literature and have already been used in a previous work [

11].

Briefly, the experiments involved stretch-bending tests under plane-strain conditions using cylindrical punches of different radii. The materials were 1008 AK steel, 70/30 brass, and 6010 aluminium, from experimental work conducted by Tharrett and Stoughton [

9,

20], and 7075-O aluminium, from the research carried out by Martínez-Donaire et al. [

16]. All specimens failed in the zone in contact with the punch, under simultaneous bending and streching conditions. The material properties are reported in

Table 1.

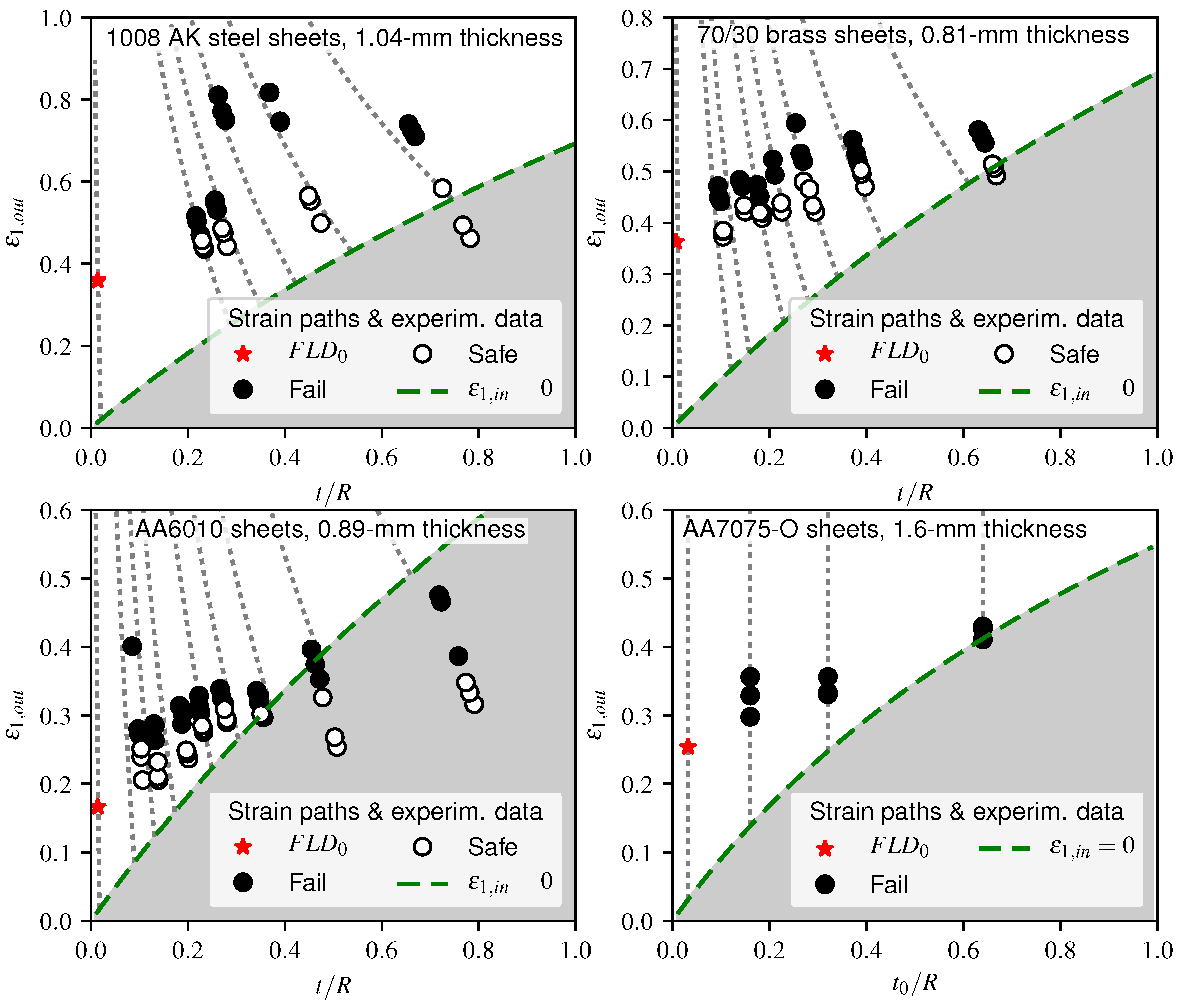

Figure 5 presents the experimental results provided in the mentioned references.

Figure 5a–c depicts the major strains measured on the convex side of the sheet

as a function of the

current bending ratio

. Instead,

Figure 5d shows

versus the

initial bending ratio

. The cases for which a visible neck was observed are represented as solid circles. Otherwise, open circles are used. The values of

(see

Table 1) are represented as solid stars.

Figure 5 also presents the strain paths predicted by the proposed stretch-bending deformation model for the different punch radii

R. As can be observed, these agree reasonably well with the experimental results. The major differences are obtained by the largest values of

, and they may be attributed to a potential indentation of the forming tool into the sheet thickness. In this situation, the transverse shear stress cannot be neglected, and the plane-section assumption in the deformed sheet element is no longer valid.

The shaded areas in

Figure 5 and subsequent figures represent stretch-bending conditions for which the material in the inner side of the sheet was shortened, that is,

. This situation inhibits the onset of the plastic instability, giving way to the eventual development of failure by ductile fracture at the outer side of the sheet. It should be noted that for 70/30 brass and 6010 aluminium sheets, the authors observed the initiation of cracks before necking for the largest values of

. As can be observed, this observation agreed very well with the model predictions.

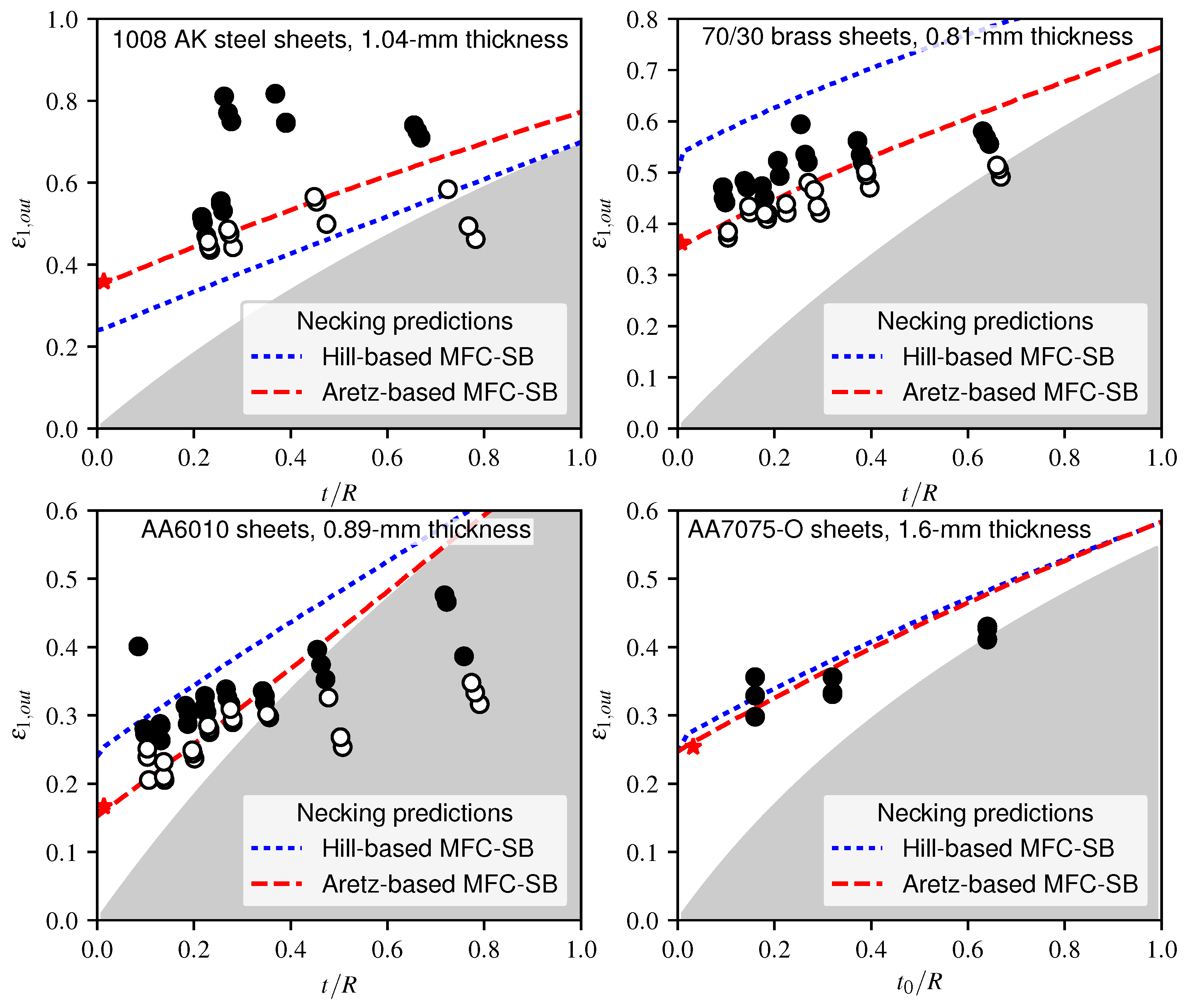

The value of the strains at the outer sheet surface predicted by Hill- and Aretz-based MFC-SB criteria at the onset of necking are represented in

Figure 6. As can be seen, the Hill-based MFC-SB criterion given by Equation (

27) underestimated the experimental results for 1008 AK steel sheets, whereas it overestimated these for 70/30 brass and 6010 aluminium sheets. Instead, the predictions of the Aretz-based MFC-SB (

28) agreed very well with the experimental results for all materials analysed, except in general for the smallest punch radii.

It should be noted that both Hill- and Aretz-based MFC-SB criteria showed the same trend with the bending ratio. The basic difference was that the Aretz-based approach had been calibrated to meet the experimental value.

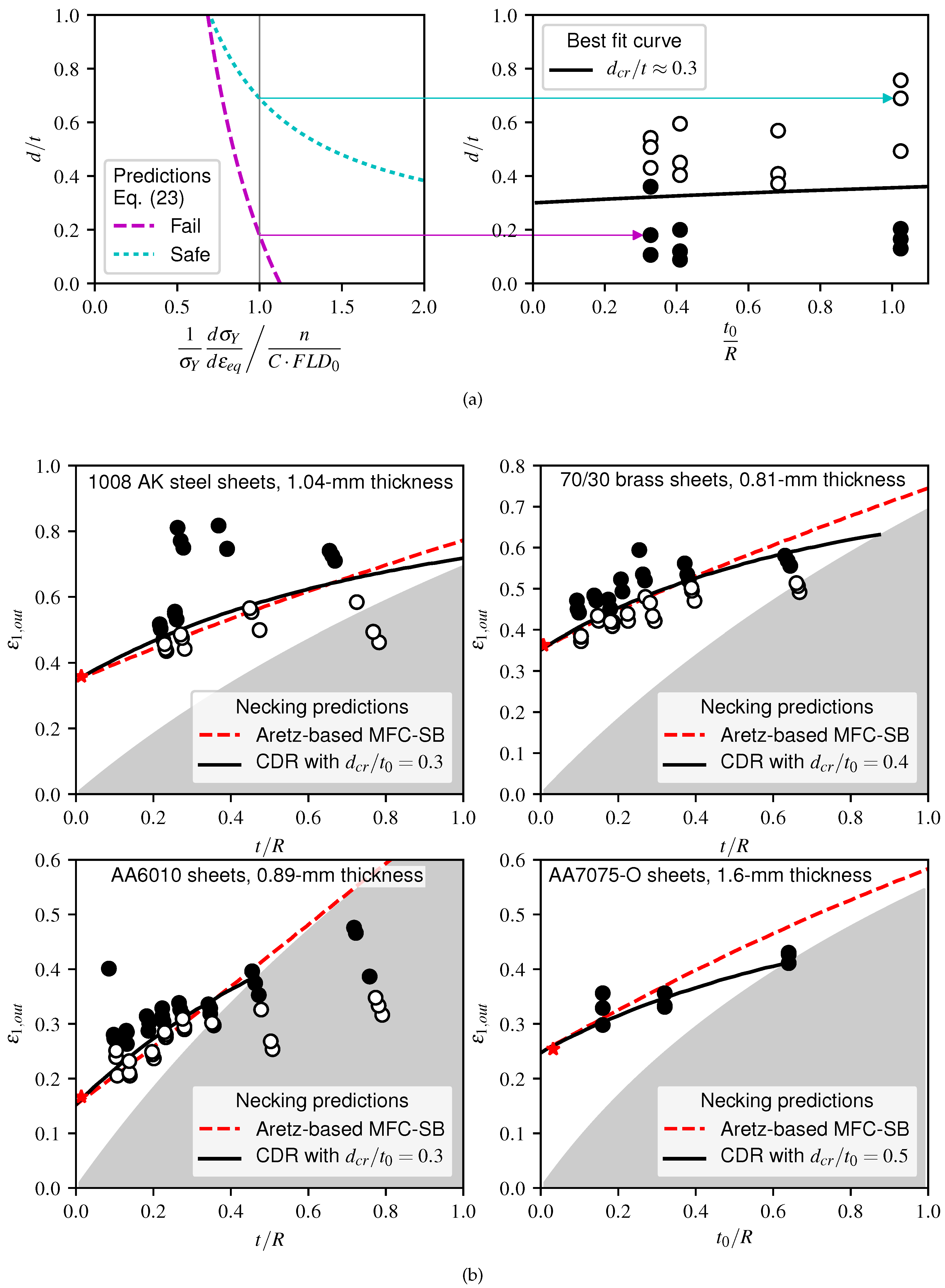

To assess the proposed CDR criterion, the critical distance

on the sheet thickness was estimated for the different materials.

Figure 7a reproduces graphically the calculation procedure to obtain

for 1008 AK steel sheets.

Figure 7a (left) shows the gradient through the sheet thickness of the local stability index based on the Aretz correction.

As can be seen, the distance

d at which the

value becomes equal to 1 was smaller in the failed specimen that in the successful specimen. This clearly indicates that the material volume resisting the necking of the sheet was smaller in the former than in the latter.

Figure 7a (right) depicts the non-dimensional value

for a local stability index equal to 1 versus the bending ratio

for all tested specimens of 1008 AK steel. The almost horizontal line dividing successful tests from failures determines the value of the critical distance, which here is

for the steel sheets. We note that the slight slope of the line is due to the material thickening as the sheet curvature increased.

In practice, it is enough to choose a few significant experimental data in the range of intermediate or high values of to determine the critical distance. The following values were obtained for the different materials: for 1008 AK steel and AA6010, for 70/30 brass and for AA7075-O sheets.

Figure 7b shows the necking predictions of the CDR criterion along with the Aretz-based MFC-SB discussed previously. In general, the CDR criterion improved the predictions over the whole range of

values. As can be seen, for low values of

, the slight improvement led to excellent predictions of experimental data of steel, brass and AA6010 sheets. However, for higher values of

, the enhancements of predictions was clearly more pronounced, particularly in aluminium sheets.