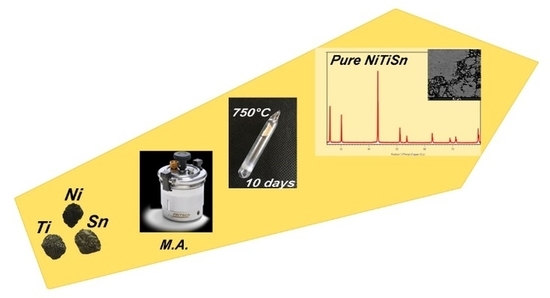

Synthesis of Pure NiTiSn by Mechanical Alloying: An Investigation of the Optimal Experimental Conditions Supported by First Principles Calculations

Abstract

:1. Introduction

2. Experimental Techniques and Calculation Methods

2.1. Classical Routes (Arc Melting, Diffusion…)

2.2. Mechanical Alloying (MA)

2.3. X-ray Diffraction

2.4. Electron Microscopy

2.5. Calculation Methods

3. Results and Discussion

3.1. Preparation by Classical Fusion Methods

3.2. Preparation by Solid–Liquid Reacting Methods

3.3. Preparation by Mechanical Alloying (MA)

3.3.1. Influence of the Provided Energy

3.3.2. Influence of the Reaction Time

3.3.3. The Special Case of MA Experiments at 400 rpm

3.3.4. Comment on Previous Results

3.4. Formation Enthalpies from DFT Calculations

3.5. Influence of Thermal Treatments

3.5.1. Annealing Temperature

3.5.2. Annealing Duration

4. Concluding Remarks

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Graf, T.; Felser, C.; Parkin, S.S.P. Simple rules for the understanding of Heusler compounds. Prog. Solid State Chem. 2011, 39, 1–50. [Google Scholar] [CrossRef]

- Aliev, F.G.; Brandt, N.B.; Moshchalkov, V.V.; Kozyrkov, V.V.; Skolozdra, R.V.; Belogorokhov, A.I. Gap at the Fermi level in the intermetallic vacancy system RNiSn (R = Ti, Zr, Hf). Z. Phys. B Condens. Matter 1989, 75, 167–171. [Google Scholar] [CrossRef]

- Aliev, F.G.; Kozyrkov, V.V.; Moshchalkov, V.V.; Scolozdra, R.V.; Durczewski, K. Narrow band in the intermetallic compounds MNiSn (M = Ti, Zr, Hf). Z. Phys. B Condens. Matter 1990, 80, 353–357. [Google Scholar] [CrossRef]

- Katayama, T.; Kim, S.W.; Kimura, Y.; Mishismai, Y. The effects of quaternary additions on thermoelectric properties of TiNiSn-based half-Heusler alloys. J. Electron. Mater. 2003, 32, 1160–1165. [Google Scholar] [CrossRef]

- Zou, M.; Li, J.-F.; Dua, B.; Liu, D.; Kita, T. Fabrication and thermoelectric properties of fine-grained TiNiSn compounds. J. Solid State Chem. 2009, 182, 3138–3142. [Google Scholar] [CrossRef]

- Joshi, G.; Yan, X.; Wang, H.; Liu, W.; Chen, G.; Ren, Z. Enhancement in thermoelectric figure-of-merit of an n-type half-Heusler compound by the nanocomposite approach. Adv. Energy Mater. 2011, 1, 643–647. [Google Scholar] [CrossRef]

- Jung, D.-Y.; Kurosaki, K.; Kim, C.-E.; Muta, H.; Yamanaka, S. Thermal expansion and melting temperature of the half-Heusler compounds: MNiSn (M = Ti, Zr, Hf). J. Alloys Compd. 2010, 489, 328–331. [Google Scholar] [CrossRef]

- Birkel, C.S.; Douglas, J.E.; Lettiere, B.R.; Seward, G.; Zhang, Y.; Pollock, T.M.; Seshadri, R.; Stucky, G.D. Influence of Ni nanoparticle addition and spark plasma sintering on the TiNiSn-Ni system: Structure, microstructure, and thermoelectric properties. Solid State Sci. 2013, 26, 16–22. [Google Scholar] [CrossRef]

- Chai, Y.W.; Kimura, Y. Microstructure evolution of nanoprecipitates in half-Heusler TiNiSn alloys. Acta Mater. 2013, 61, 6684–6697. [Google Scholar] [CrossRef]

- Hermet, P.; Niedziolka, K.; Jund, P. A first-principles investigation of the thermodynamic and mechanical properties of Ni–Ti–Sn Heusler and half-Heusler materials. RSC Adv. 2013, 3, 22176–22184. [Google Scholar] [CrossRef]

- Romaka, V.V.; Rogl, P.; Romaka, L.P.; Stadnyk, Y.V.; Melnychenko, N.O.; Grytsiv, A.V.; Falmbigl, M.; Skryabina, N.E. Phase equilibria, formation, crystal and electronic structure of ternary compounds in Ti-Ni-Sn and Ti-Ni-Sb ternary systems. J. Solid State Chem. 2013, 197, 103–112. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Gürth, M.; Tavassoli, A.; Ebner, C.; Wünschek, A.; Puchegger, S.; Soprunyuk, V.; Schranz, W.; Bauer, E.; et al. Mechanical properties of half-Heusler alloys. Acta Mater. 2016, 107, 178–195. [Google Scholar] [CrossRef]

- Birkel, C.S.; Douglas, J.E.; Lettiere, B.R.; Seward, G.; Verma, N.; Zhang, Y.; Pollock, T.M.; Seshadri, R.; Stucky, G.D. Improving the thermoelectric properties of half-Heusler TiNiSn through inclusion of a second full-Heusler phase: Microwave preparation and spark plasma sintering of TiNi1+xSn. Phys. Chem. Chem. Phys. 2013, 15, 6990–6997. [Google Scholar] [CrossRef] [PubMed]

- Gelbstein, Y.; Tal, N.; Yarmek, A.; Rosenberg, Y.; Dariel, M.P.; Ouardi, S.; Balke, B.; Felser, C.; Köhne, M. Thermoelectric properties of spark plasma sintered composites based on TiNiSn half-Heusler alloys. J. Mater. Res. 2011, 26, 1919–1924. [Google Scholar] [CrossRef]

- Jager, T. Thermoelectric Properties of TiNiSn and Zr0.5Hf0.5NiSn Thin Films and Superlattices with Reduced Thermal Conductivities. Ph.D. Thesis, Johannes Gutenberg-Universität Mainz, Mainz, Germany, 2013. [Google Scholar]

- Birkel, C.S.; Zeier, W.G.; Douglas, J.E.; Lettiere, B.R.; Mills, C.E.; Seward, G.; Birkel, A.; Snedaker, M.L.; Zhang, Y.; Snyder, G.J.; et al. Rapid microwave preparation of thermoelectric TiNiSn and TiCoSb half-Heusler compounds. Chem. Mater. 2012, 24, 2558–2565. [Google Scholar] [CrossRef]

- Lei, Y.; Li, Y.; Xu, L.; Yang, J.; Wan, R.; Long, H. Microwave synthesis and sintering of TiNiSn thermoelectric bulk. J. Alloys Compd. 2016, 660, 166–170. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Ivanov, E.; Boldyrev, V.V. The science and technology of mechanical alloying. Mater. Sci. Eng. A 2001, 304–306, 151–158. [Google Scholar] [CrossRef]

- Suryanarayana, C. Phase formation under non-equilibrium processing conditions: Rapid solidification processing and mechanical alloying. J. Mater. Sci. 2018, 53, 13364–13379. [Google Scholar] [CrossRef]

- Le Brun, P.; Froyen, L.; Delaey, L. The modelling of the mechanical alloying process in a planetary ball mill: Comparison between theory and in-situ observations. Mater. Sci. Eng. A Struct. 1993, 161, 75–82. [Google Scholar] [CrossRef]

- Soban, B.; Gaffet, E. Mechanosynthesis: An Improved Mathematical Contribution to the Planetary Ball Mill Kinematics. Available online: https://www.researchgate.net/publication/256228753_Mechanosynthesis_An_improved_mathematical_contribution_to_the_planetary_ball_mill_kinematics (accessed on 1 September 2018).

- Delogu, F.; Takacs, L. Information on the mechanism of mechanochemical reaction from detailed studies of the reaction kinetics. J. Mater. Sci. 2017, 53, 13331–13342. [Google Scholar] [CrossRef]

- Skakov, Y.A. Metastable phase state during mechanical alloying. Sci. Sinter. 2005, 37, 131–138. [Google Scholar] [CrossRef]

- Dreizin, E.L.; Schoenitz, M. Mechanochemically prepared reactive and energetic materials: A review. J. Mater. Sci. 2017, 52, 11789–11809. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- El-Eskandarany, M.S. Mechanical Alloying for Fabrication of Advanced Engineering Materials; Noyes Publications/William Andrew Publishing: Norwich, NY, USA, 2001. [Google Scholar]

- Takacs, L. The historical development of mechanochemistry. Chem. Soc. Rev. 2013, 42, 7649–7659. [Google Scholar] [CrossRef] [PubMed]

- Abenojar, J.; Velasco, F.; Mota, J.M.; Martínez, M.A. Preparation of Fe/B powders by mechanical alloying. J. Solid State Chem. 2004, 177, 382–388. [Google Scholar] [CrossRef]

- Abu, M.J.; Mohamed, J.J.; Ahmad, Z.A. Synthesis of high purity titanium silicon carbide from elemental powders using arc melting method. Int. J. Refract. Met. Hard Mater. 2014, 47, 86–92. [Google Scholar] [CrossRef]

- Padyukov, K.L.; Levashov, E.A. Self-propagating high-temperature synthesis: A new method for the production of diamond-containing materials. Diamond Relat. Mater. 1993, 2, 207–210. [Google Scholar] [CrossRef]

- Ipus, J.J.; Blázquez, J.S.; Franco, V.; Millán, M.; Conde, A.; Oleszak, D.; Kulik, T. An equivalent time approach for scaling the mechanical alloying processes. Intermetallics 2008, 16, 470–478. [Google Scholar] [CrossRef]

- Petricek, V.; Dusek, M.; Palatinus, L. Crystallographic computing system JANA2006: General features. Z. Kristallogr. Cryst. Mater. 2014, 229, 345–352. [Google Scholar] [CrossRef]

- Density Functional Theory. Available online: https://en.wikipedia.org/wiki/Density_functional_theory (accessed on 28 September 2018).

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 1996, 77, 3865–3868. [Google Scholar] [CrossRef] [PubMed]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Erratum: Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 1996, 78, 1396. [Google Scholar] [CrossRef]

- Monkhorst, H.J.; Pack, J.D. Special points for Brillouin-zone integrations. Phys. Rev. B 1976, 13, 5188–5192. [Google Scholar] [CrossRef]

- Gladyshevskii, E.I.; Markiv, V.Y.; Kuz’ma, Y.B.; Cherkashyn, E.E. Crystal structure of some ternary intermetallic titanium compounds. Titanium Its Alloys Engl. Transl. 1966, 10, 73–75. [Google Scholar]

- Romaka, V.A.; Stadnyk, Y.V.; Fruchart, D.; Romaka, V.V.; Rogl, P.; Davydov, V.M.; Gorelenko, Y.K.; Goryn’, A.M. Investigation of the mechanisms of local amorphization in a heavily doped crystalline semiconductor n-TiNiSn. Ukrayins’ kij Fyizichnij Zhurnal (Kyiv) 2008, 53, 42–49. [Google Scholar]

- Nowotny, H.; Schubert, K. Die kristallstruktur von Ni3Sn4. Naturwissenschaften 1944, 32, 76b. [Google Scholar] [CrossRef]

- Bhargava, M.K.; Schubert, K. Kristallstruktur von NiSn. J. Less-Common Met. 1973, 33, 181–189. [Google Scholar] [CrossRef]

- Fjellvag, H.; Kjekshus, A. Structural properties of Co3Sn2, Ni3Sn2 and some ternary derivatives. Acta Chem. Scand. A 1986, 40, 23–30. [Google Scholar] [CrossRef]

- Rahlfs, P. Die kristallstruktur des Ni3Sn (Mg3Cd-Typ: Überstruktur der hexagonal dichtesten kugelpackung). Metallwirtsch. Metallwiss. Metalltech. 1937, 16, 343–345. [Google Scholar]

- Kleinke, H.; Waldeck, M.; Gütlich, P. Ti2Sn3: A novel binary intermetallic phase, prepared by chemical transport at intermediate temperature. Chem. Mater. 2000, 12, 2219–2224. [Google Scholar] [CrossRef]

- Schubert, K.; Frank, K.; Gohle, R.; Maldonado, A.; Meissner, H.G.; Raman, A.; Rossteutscher, W. Einige strukturdaten metallischer phasen. Naturwissenschaften 1963, 50, 41. [Google Scholar] [CrossRef]

- Pietrokowsky, P.; Duwez, P.E. Crystal structure of Ti5Si3, Ti5Ge3, and Ti5Sn3. Trans. Am. Inst. Min. Metall. Pet. Eng. 1951, 191, 772–773. [Google Scholar] [CrossRef]

- Banumathy, S.; Singh, A.K. Rietveld refinement of the A3B (D019) and A2B (B82) phases in Ti-Sn and Ti-Ga alloys. Intermetallics 2011, 19, 1594–1598. [Google Scholar] [CrossRef]

- Pietrokowsky, P. Crystal Structure of Ti3Sn. Trans. Am. Inst. Min. Metall. Pet. Eng. 1952, 194, 211–212. [Google Scholar] [CrossRef]

- Yurko, G.A.; Barton, J.W.; Parr, J.G. The crystal structure of Ti2Ni. Acta Crystallogr. 1959, 12, 909–911. [Google Scholar] [CrossRef]

- Bührer, W.; Gotthardt, R.; Kulik, A.V.; Mercier, O.; Staub, F. Powder neutron diffraction study of nickel-titanium martensite. J. Phys. F Met. Phys. 1983, 13, L77–L81. [Google Scholar] [CrossRef]

- Michal, G.M.; Sinclair, R. The structure of TiNi martensite. Acta Crystallogr. B 1981, 37, 1803–1807. [Google Scholar] [CrossRef] [Green Version]

- Saburi, T.; Nenno, S.; Fukuda, T. Crystal structure and morphology of the metastable X phase in shape memory Ti-Ni alloys. J. Less-Common Met. 1986, 125, 157–166. [Google Scholar] [CrossRef]

- Laves, F.; Wallbaum, H.J. Die Kristallstruktur von Ni3Ti und Si2Ti (zwei neue Typen). Z. Kristallogr. Cryst. Mater. 1939, 101, 78–93. [Google Scholar] [CrossRef]

- Hull, A.W. X-ray crystal analysis of thirteen common metals. Phys. Rev. B 1921, 17, 571–588. [Google Scholar] [CrossRef]

- Mark, H.; Polanyl, M. Die Gitterstruktur, Gleitrichtungen und Gleitebenen des weissen Zinns. Z. Phys. 1923, 18, 75–96. [Google Scholar] [CrossRef]

- Kresse, G.; Forthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 1996, 6, 15–50. [Google Scholar] [CrossRef]

- Kresse, G.; Forthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 1996, 54, 11169–11186. [Google Scholar] [CrossRef]

- Vanderbilt, D. Soft self-consistent pseudopotentials in a generalized eigenvalue formalism. Phys. Rev. B 1990, 41, 7892–7895. [Google Scholar] [CrossRef]

- Kresse, G.; Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 1999, 59, 1758–1775. [Google Scholar] [CrossRef]

- Blöchl, P.E. Projector augmented-wave method. Phys. Rev. B. 1994, 50, 17953–17979. [Google Scholar] [CrossRef] [Green Version]

- Dudarev, S.L.; Botton, G.A.; Savrasov, S.Y.; Humphreys, C.J.; Sutton, A.P. Electron-energy-loss spectra and the structural stability of nickel oxide: An LSDA+U study. Phys. Rev. B. 1988, 57, 1505–1509. [Google Scholar] [CrossRef]

- Berche, A.; Jund, P. Oxidation of half-Heusler NiTiSn materials: Implications for thermoelectric applications. Intermetallics 2018, 92, 62–71. [Google Scholar] [CrossRef]

- Douglas, J.E.; Birkel, C.S.; Verma, N.; Miller, V.M.; Miao, M.-S.; Stucky, G.D.; Pollock, T.M.; Seshadri, R. Phase stability and property evolution of biphasic Ti–Ni–Sn alloys for use in thermoelectric applications. J. Appl. Phys. 2014, 115, 043720. [Google Scholar] [CrossRef] [Green Version]

- Downie, R.A.; MacLaren, D.A.; Smith, R.I.; Bos, J.W.G. Enhanced thermoelectric performance in TiNiSn-based half-Heuslers. Chem. Commun. 2013, 49, 4184–4186. [Google Scholar] [CrossRef] [PubMed]

- Berche, A.; Tédenac, J.C.; Fartushna, J.; Jund, P. Calphad assessment of the Ni–Sn–Ti system. Calphad 2016, 54, 67–75. [Google Scholar] [CrossRef]

- Gürth, M.; Grytsiv, A.; Vrestal, J.; Romaka, V.V.; Giester, G.; Bauer, E.; Rogl, P. On the constitution and thermodynamic modelling of the system Ti–Ni–Sn. RSC Adv. 2015, 5, 92270–92291. [Google Scholar] [CrossRef]

- Zou, M.; Li, J. Fabrication of TiNiSn-Based Half-Heusler Thermoelectric Compound by Mechanical Alloying and Spark Plasma Sintering. Rare Met. Mater. Eng. 2009, 38, 1079–1082. [Google Scholar]

- Flandorfer, H.; Saeed, U.; Luef, C.; Sabbar, A.; Ipser, H. Interfaces in lead-free solder alloys: Enthalpy of formation of binary Ag–Sn, Cu–Sn and Ni–Sn intermetallic compounds. Thermochim. Acta 2007, 459, 34–39. [Google Scholar] [CrossRef]

- Guo, Q.; Kleppa, O.J. Standard enthalpies of formation of some alloys formed between group IV elements and group VIII elements, determined by high-temperature direct synthesis calorimetry: II. Alloys of (Ti, Zr, Hf) with (Co, Ni). J. Alloys Compd. 1998, 269, 181–186. [Google Scholar] [CrossRef]

- Meschel, S.V.; Kleppa, O.J. Standard enthalpies of formation of some 3d, 4d and 5d transition-metal stannides by direct synthesis calorimetry. Thermochim. Acta 1998, 314, 205–212. [Google Scholar] [CrossRef]

- Moser, Z.; Gasior, W.; Rzyman, K.; Debski, A. Calorimetric Studies of the Enthalpies of Formation of NiTi2, NiTi and Ni3Ti. Arch. Metall. Mater. 2006, 51, 605–608. [Google Scholar]

- Predel, B.; Ruge, H. Bildungsenthalpien und bindungsverhältnisse in einigen intermetallischen verbindungen vom NiAs-Typ. Thermochim. Acta 1972, 3, 411–419. [Google Scholar] [CrossRef]

- Predel, B.; Vogelbein, W. Bildungsenthalpien fester legierungen der binären systeme des eisens, kobalts und nickels mit germanium und zinn. Thermochim. Acta 1979, 30, 201–215. [Google Scholar] [CrossRef]

- Vassiliev, G.P.; Liloa, K.I.; Gachon, J.C. Enthalpies of formation of Ni–Sn compounds. Thermochim. Acta 2006, 447, 106–108. [Google Scholar] [CrossRef]

- Yin, M.; Nash, P. Standard enthalpies of formation of selected XYZ half-Heusler compounds. J. Chem. Thermodyn. 2015, 91, 1–7. [Google Scholar] [CrossRef]

- Yin, M.; Nash, P. Standard enthalpies of formation of selected Ni2YZ Heusler compounds. J. Alloys Compd. 2016, 660, 258–265. [Google Scholar] [CrossRef]

- Offernes, L.; Ravindran, P.; Seim, C.W.; Kjekshus, A. Prediction of composition for stable half-Heusler phases from electronic-band-structure analyses. J. Alloys Compd. 2008, 458, 47–60. [Google Scholar] [CrossRef]

- Muta, H.; Kanemitsu, T.; Kurosaki, K.; Yamanaka, S. High-temperature thermoelectric properties of Nb-doped MNiSn (M = Ti, Zr) half-Heusler compound. J. Alloys Compd. 2009, 469, 50–55. [Google Scholar] [CrossRef]

- Ke, S.; Pan, Z.; Wang, Y.; Ning, C.; Zheng, S.; Huang, J. Effect of mechanical activation on solid-state synthesis process of neodymium disilicate ceramic pigment. Dyes Pigments 2017, 145, 160–167. [Google Scholar] [CrossRef]

- Mostaan, H.; Mehrizi, M.Z.; Rafiei, M.; Beygi, R.; Abbasian, A.R. Contribution of mechanical activation and annealing in the formation of nanopowders of Al(Cu)/TiC-Al2O3 hybrid nanocomposite. Ceram. Int. 2017, 43, 2680–2685. [Google Scholar] [CrossRef]

- Bernard, F.; Paris, S.; Gaffet, E. Mechanical Activation as a New method for SHS. Adv. Sci. Technol. 2006, 45, 979–988. [Google Scholar] [CrossRef]

- Streletskii, A.N.; Sivak, M.V.; Dolgoborodov, A.Y. Nature of high reactivity of metal/solid oxidizer nanocomposites prepared by mechanoactivation: A review. J. Mater. Sci. 2017, 52, 11810–11825. [Google Scholar] [CrossRef]

- Takacs, L. Self-sustaining reactions induced by ball milling. Prog. Mater. Sci. 2002, 47, 355–414. [Google Scholar] [CrossRef]

- Posnjak, E.; Barth, T.F.W. Notes on some structures of the ilmenite type. Z. Kristallogr. Cryst. Mater. 1934, 88, 271. [Google Scholar] [CrossRef]

- Karlsson, N. Metallic Oxides with the Structure of High-speed Steel Carbide. Nature 1951, 168, 558. [Google Scholar] [CrossRef]

| Compound | System | Space Group | Lattice Parameters (Å,°) | Ref. |

|---|---|---|---|---|

| Ni2TiSn | Cubic | Fmm | a = 6.10 | [37] |

| NiTiSn | Cubic | F3m | a = 5.93 | [38] |

| Ni2Ti2Sn | Tetragonal | P42/mnm | a = 6.81, c = 6.43 | [11] |

| NiTi5Sn3 | Hexagonal | P63/mcm | a = 8.18, c = 5.56 | [11] |

| Ni3Sn4 | Monoclinic | C2/m | a = 12.20, b = 4.05, c = 5.21, β = 105.03 | [39] |

| NiSn | Orthorhombic | Pbam | a = 5.20, b = 24.45, c = 4.09 | [40] |

| Ni3Sn2 | Orthorhombic | Pnma | a = 7.12, b = 5.20 c = 8.16 | [41] |

| Ni3Sn | Hexagonal | P63/mmc | a = 5.27, c = 4.23 | [42] |

| Ti2Sn3 | Orthorhombic | Cmce | a = 5.95, b = 19.96, c = 7.03 | [43] |

| Ti6Sn5 | Hexagonal | P63/mmc | a = 9.25, c = 5.69 | [44] |

| Ti5Sn3 | Hexagonal | P63/mcm | a = 8.05, c = 5.45 | [45] |

| Ti2Sn | Hexagonal | P63/mmc | a = 4.63, c = 5.67 | [46] |

| Ti3Sn | Hexagonal | P63/mmc | a = 5.92, c = 4.76 | [47] |

| NiTi2 | Cubic | Fdm | a = 11.28 | [48] |

| NiTi | Monoclinic | P21/m | a = 2.89, b = 4.11, c = 4.66, β = 98.10 | [49,50] |

| Ni4Ti3 (m) | Rhombohedral | R | a = 11.24, c = 5.08 | [51] |

| Ni3Ti | Hexagonal | P63/mmc | a = 5.11, c = 8.30 | [52] |

| Ni | Cubic | Fmm | a = 3.54 | [53] |

| Ti | Hexagonal | P63/mmc | a = 2.94, c = 4.72 | [53] |

| Sn | Tetragonal | I41/amd | a = 5.84, c = 3.15 | [54] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tillard, M.; Berche, A.; Jund, P. Synthesis of Pure NiTiSn by Mechanical Alloying: An Investigation of the Optimal Experimental Conditions Supported by First Principles Calculations. Metals 2018, 8, 835. https://doi.org/10.3390/met8100835

Tillard M, Berche A, Jund P. Synthesis of Pure NiTiSn by Mechanical Alloying: An Investigation of the Optimal Experimental Conditions Supported by First Principles Calculations. Metals. 2018; 8(10):835. https://doi.org/10.3390/met8100835

Chicago/Turabian StyleTillard, Monique, Alexandre Berche, and Philippe Jund. 2018. "Synthesis of Pure NiTiSn by Mechanical Alloying: An Investigation of the Optimal Experimental Conditions Supported by First Principles Calculations" Metals 8, no. 10: 835. https://doi.org/10.3390/met8100835