High-Temperature Creep-Fatigue Behavior of Alloy 617

Abstract

:1. Introduction

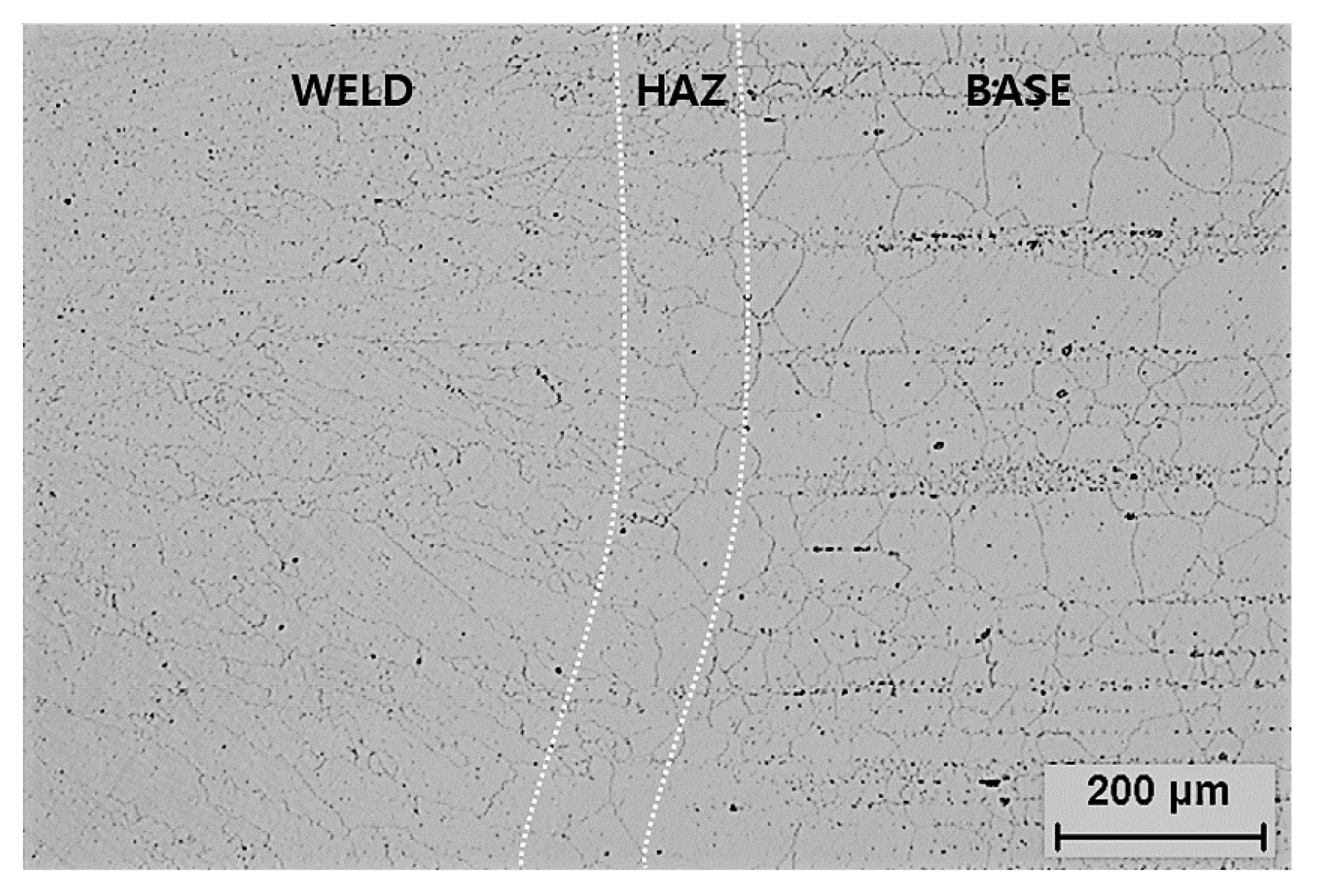

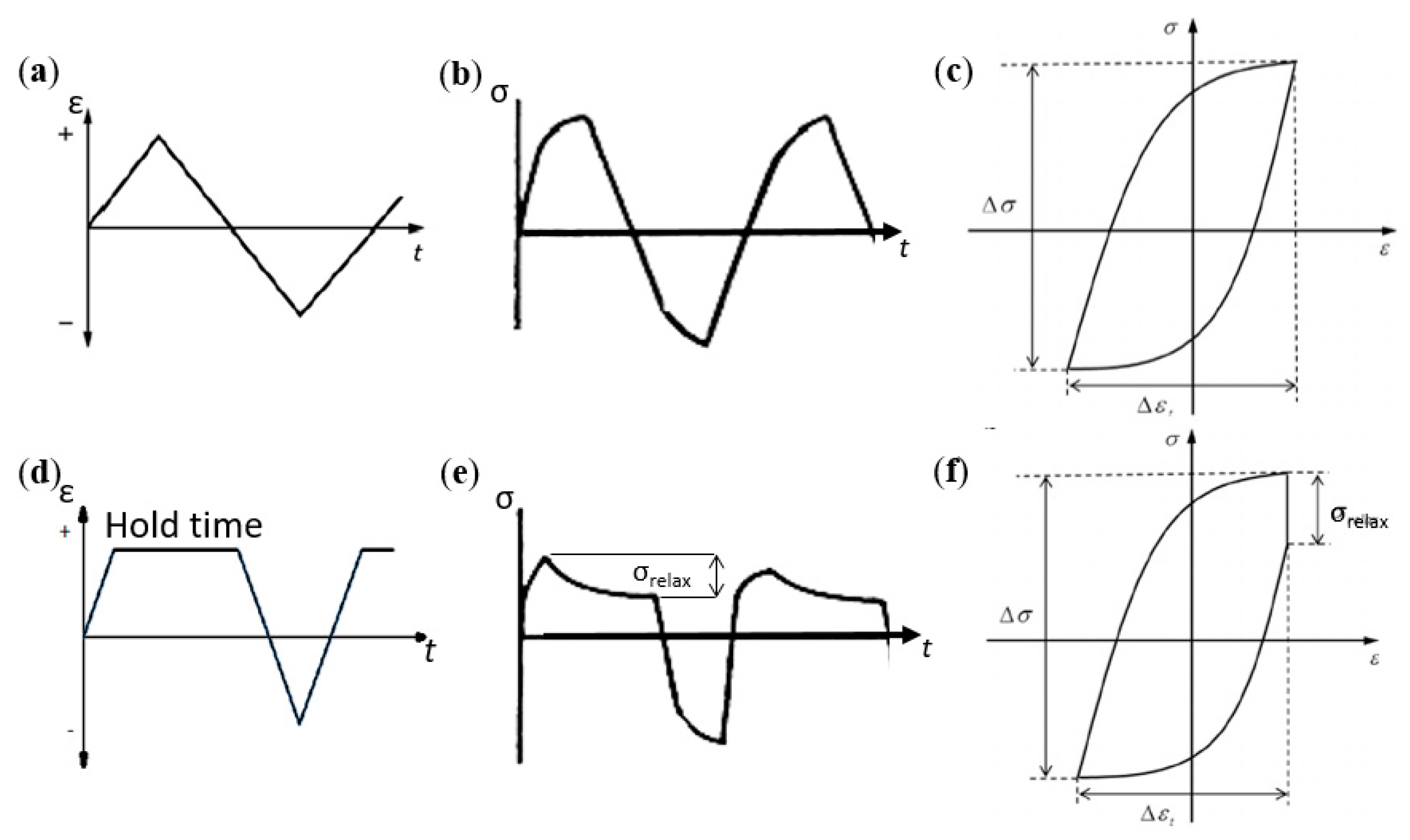

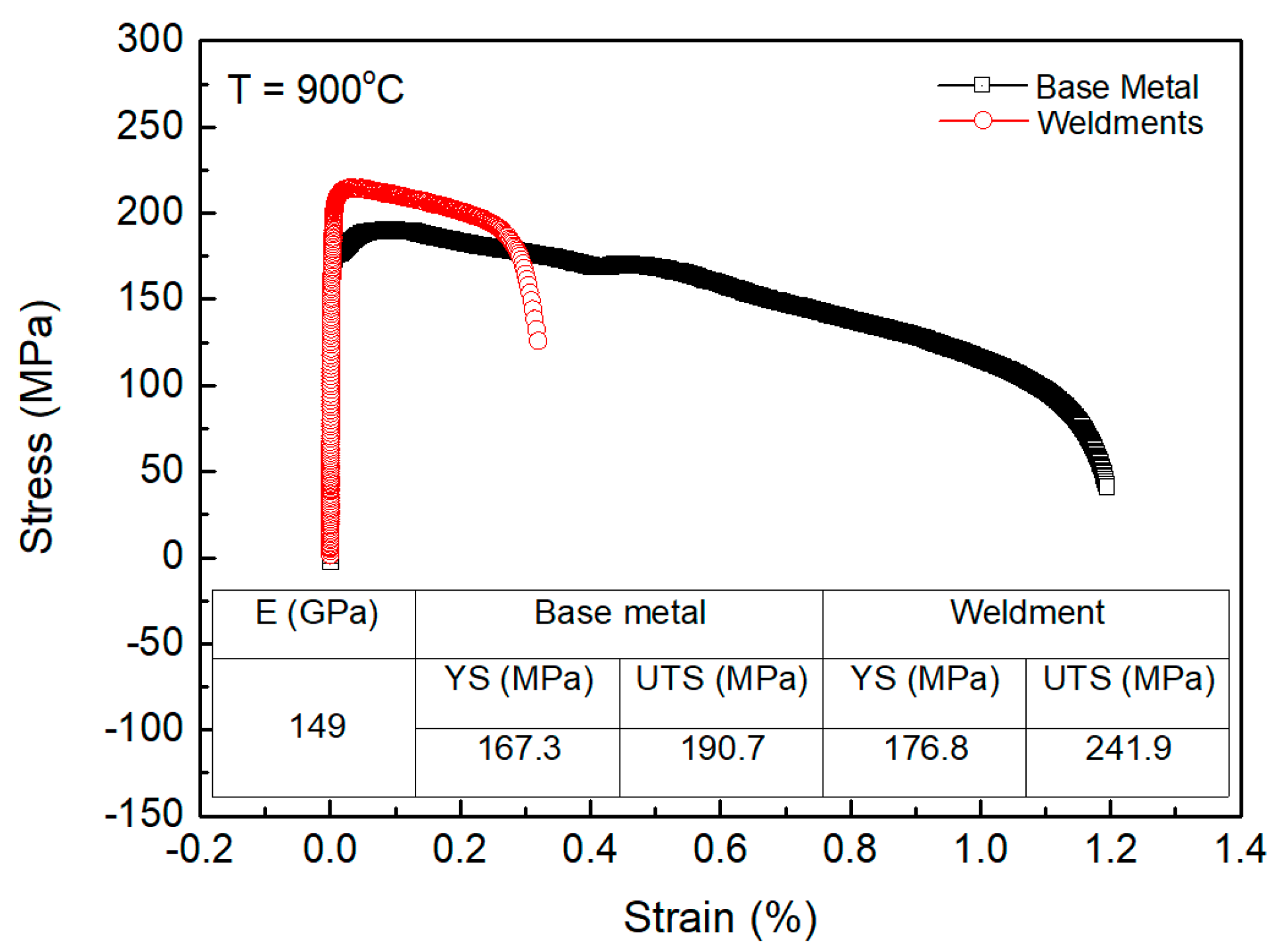

2. Materials and Methods

3. Results

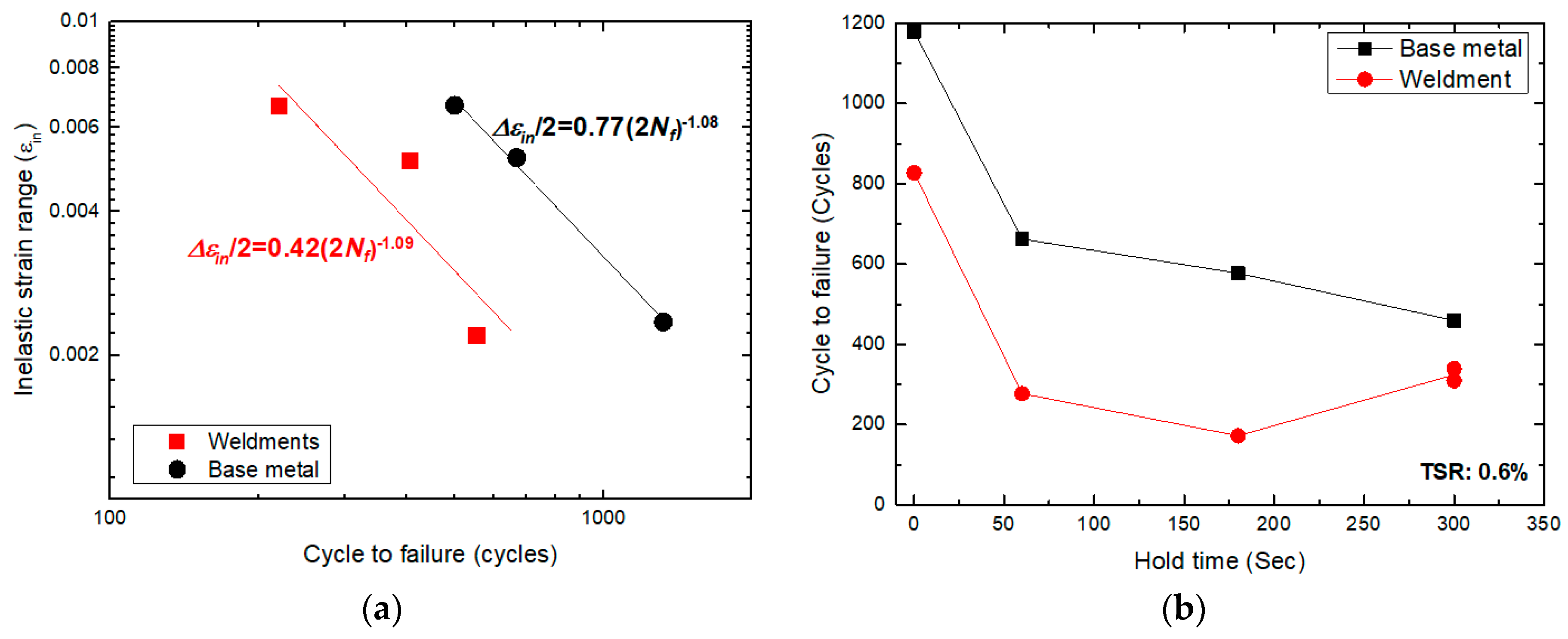

3.1. Creep-Fatigue Life

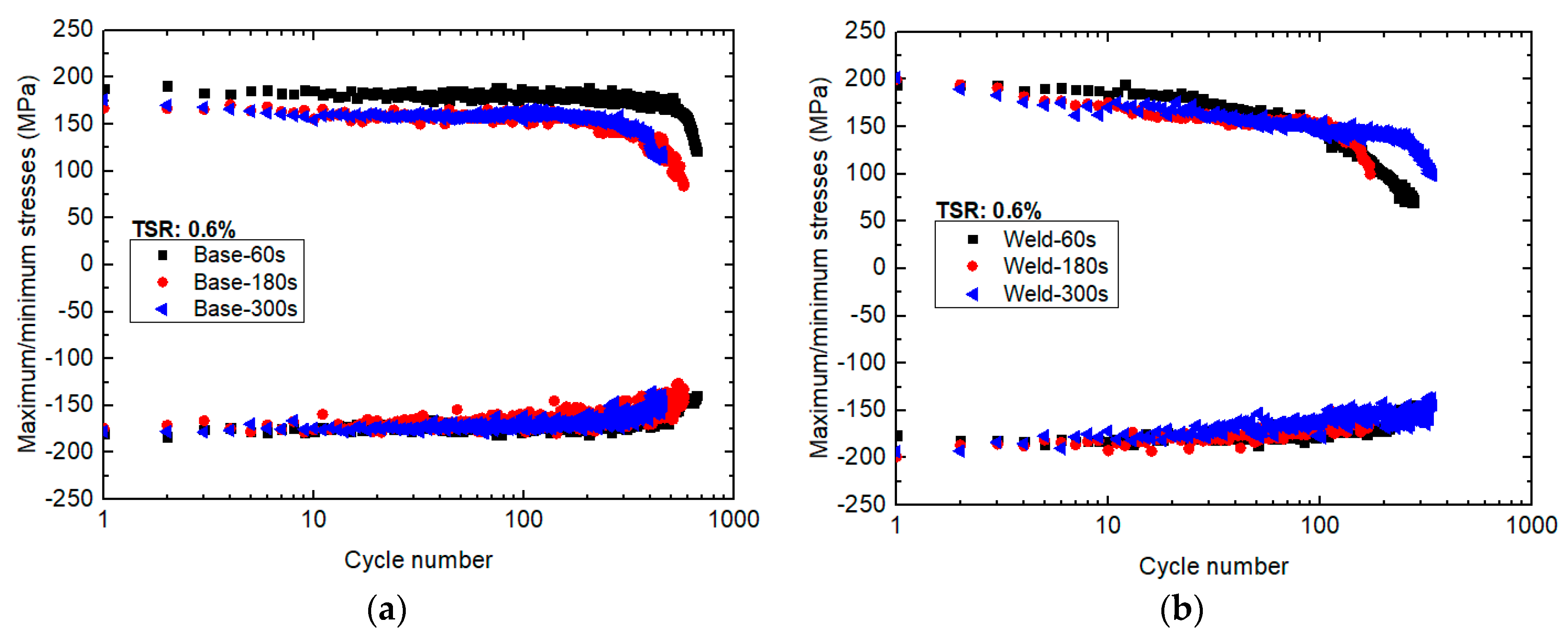

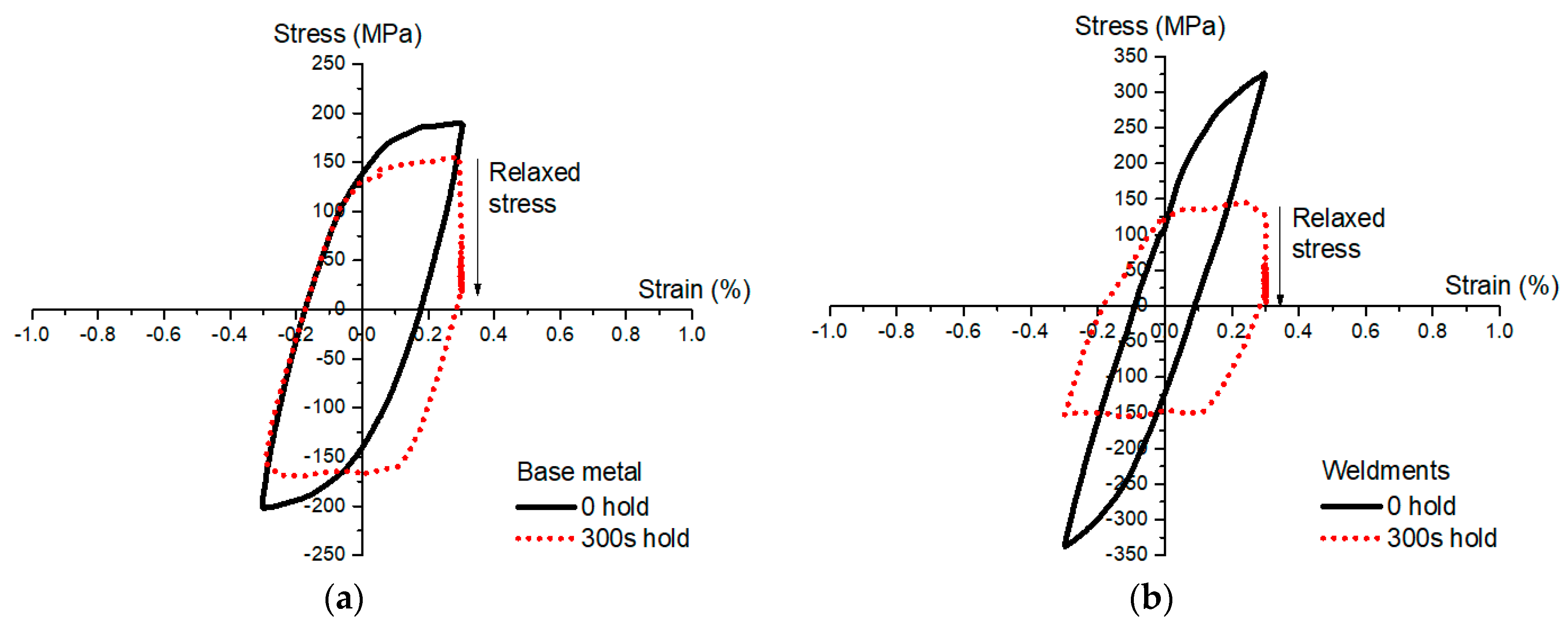

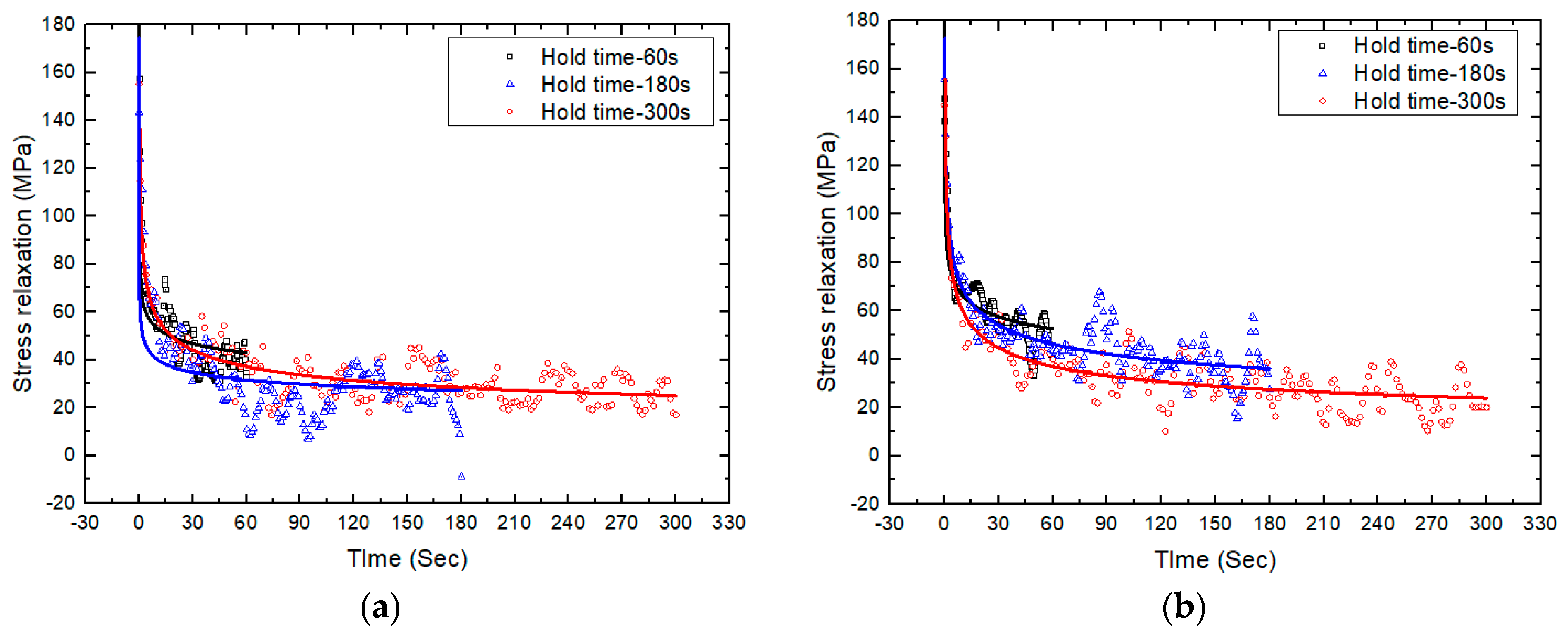

3.2. Creep-Fatigue Properties

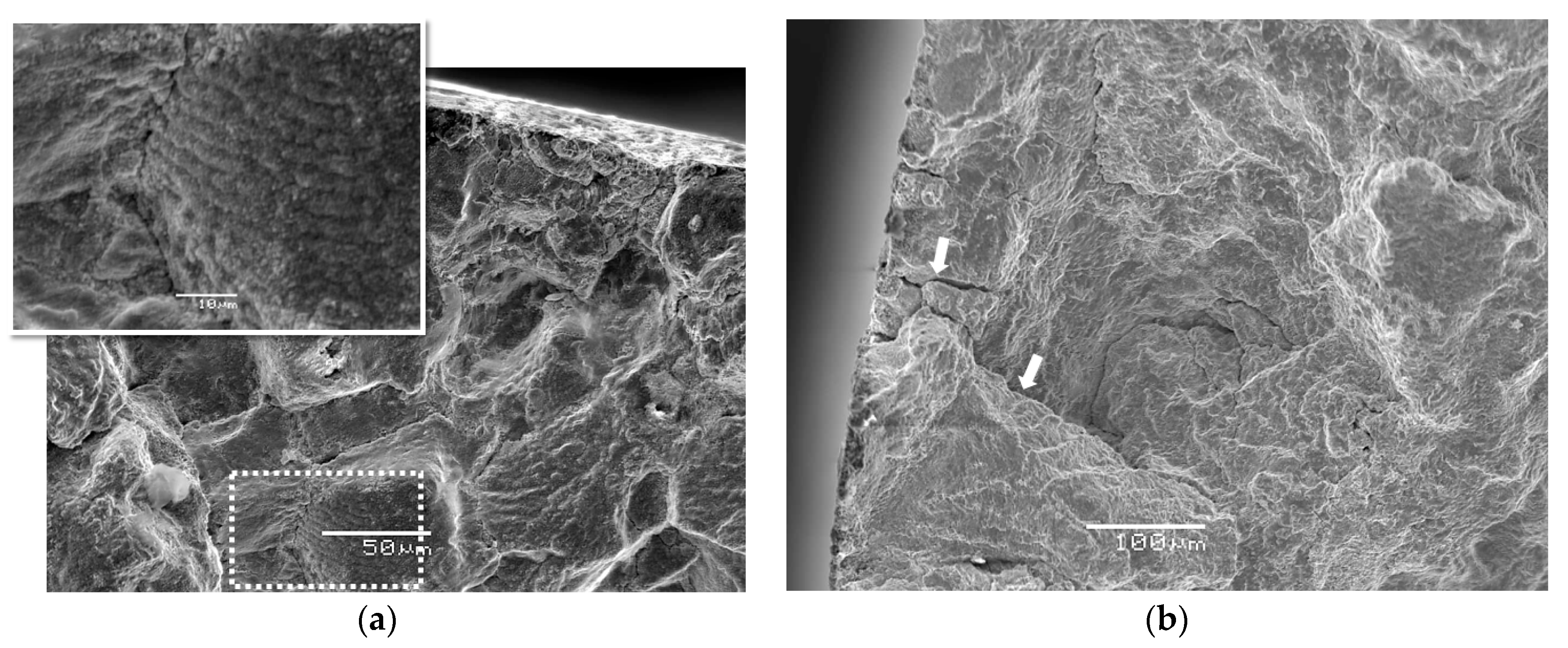

3.3. Crack Morphology

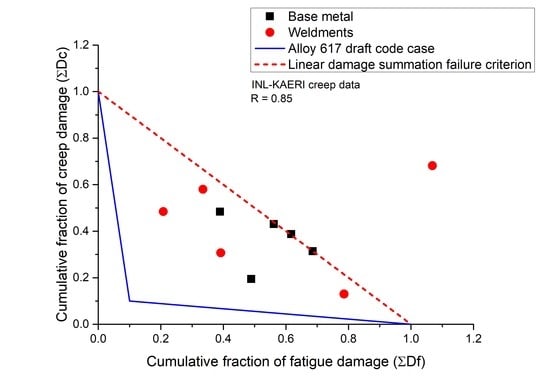

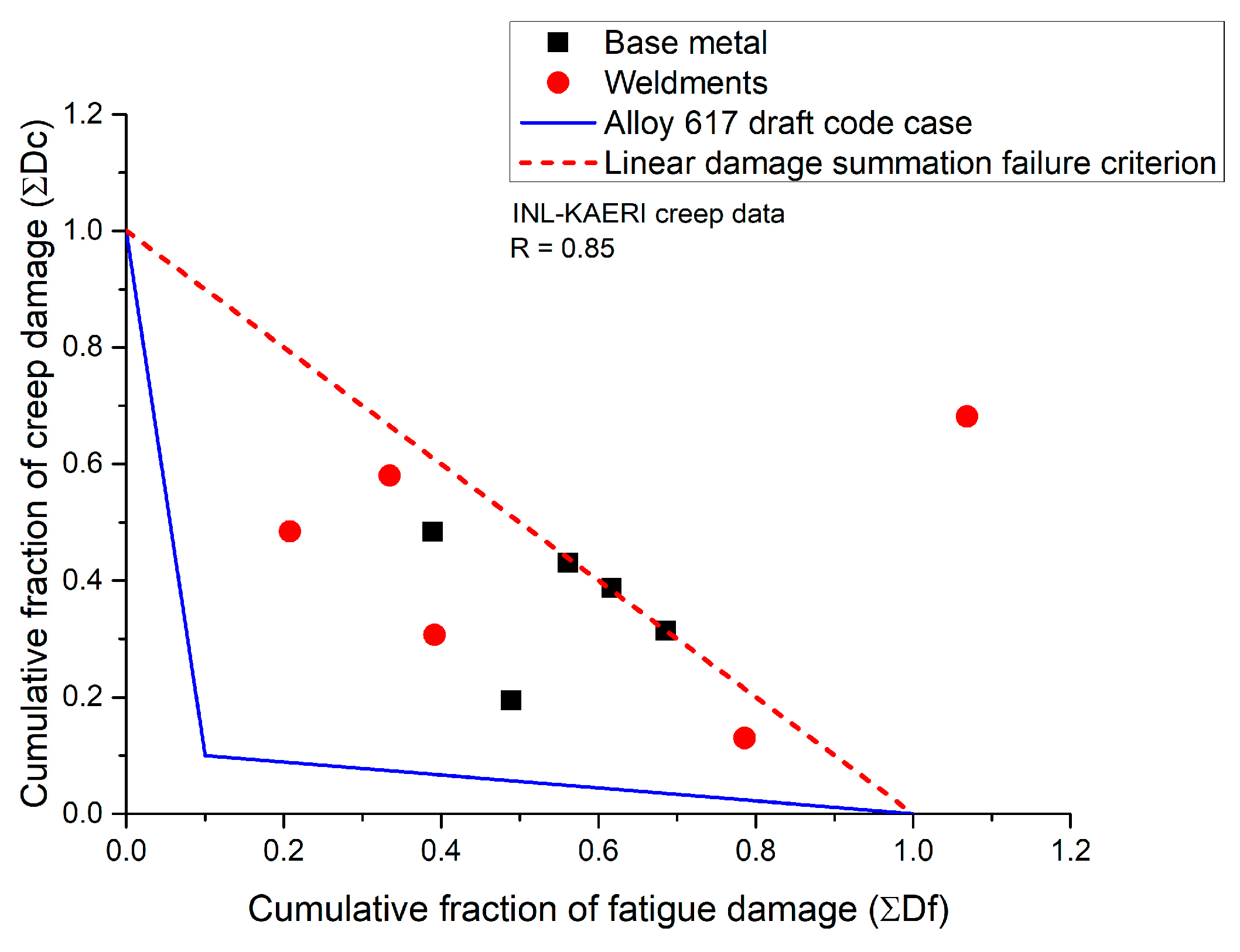

4. Linear Damage Summation

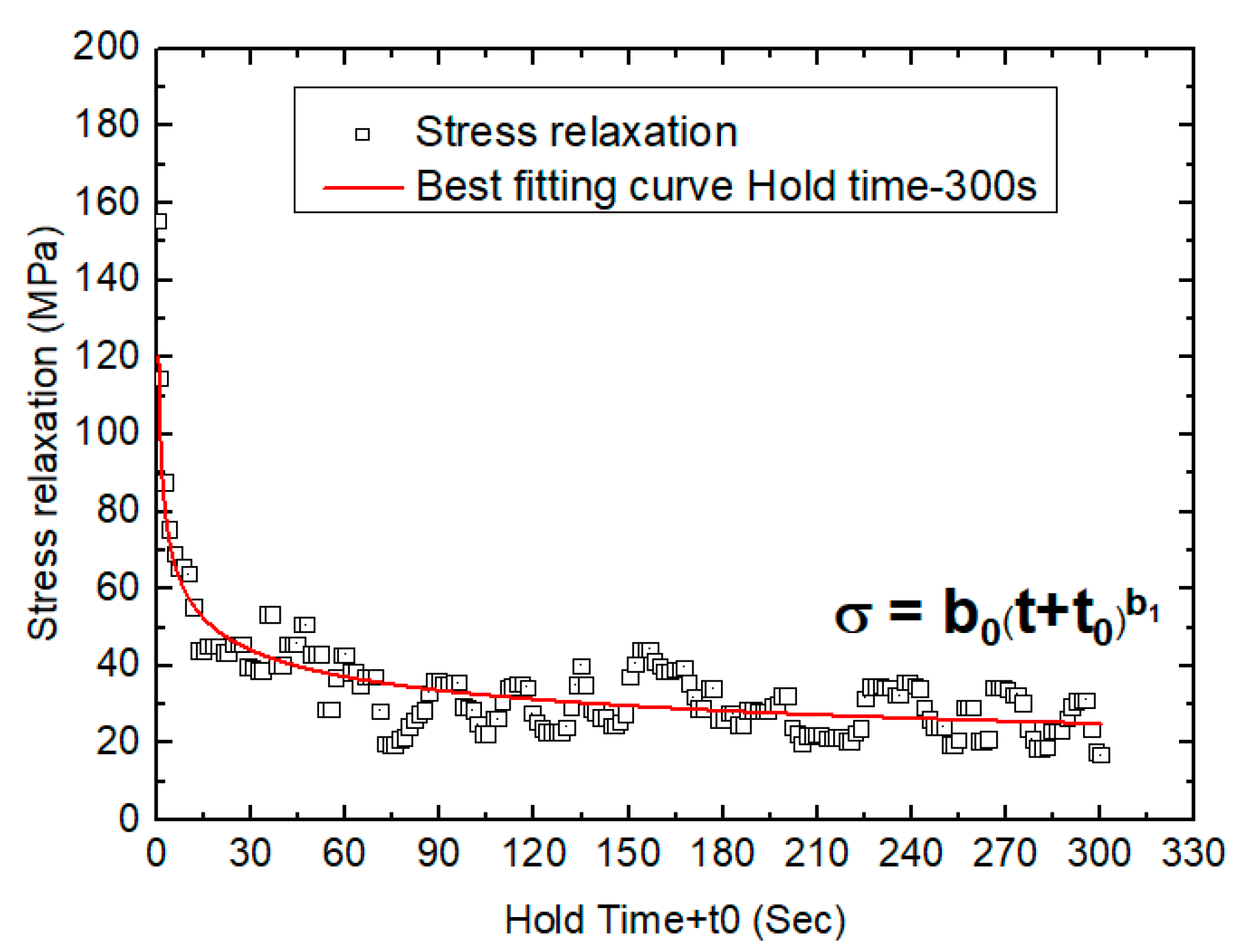

4.1. Fatigue and Creep Damage Calculations

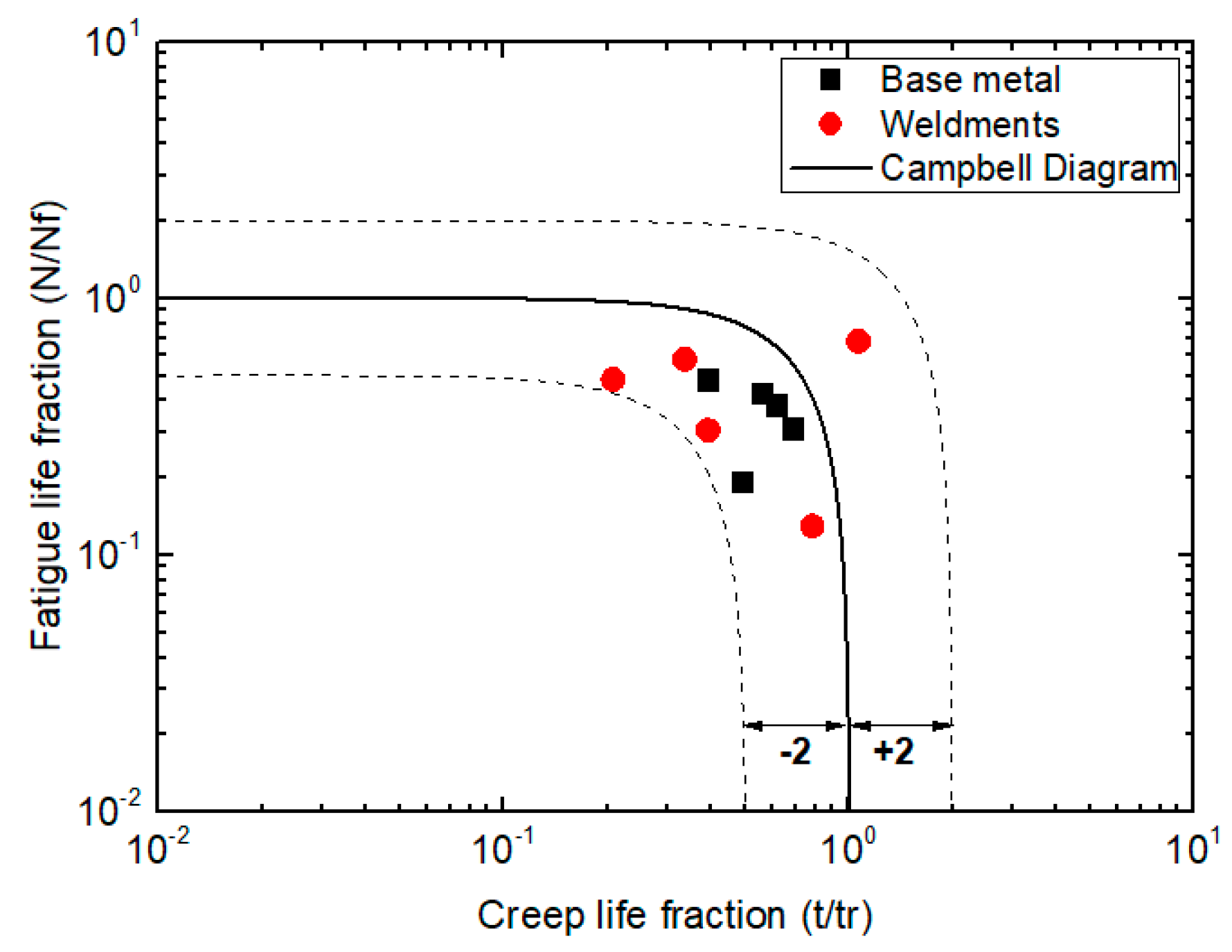

4.2. Creep-Fatigue Interaction Diagram

4.3. Creep Damage for Weldments

5. Discussion

6. Conclusions

- Under all creep-fatigue tests, the base metal indicated a superior creep-fatigue life to the weldments. It was noticed that the creep-fatigue life in the base metal was continually decreased by increasing the holding time. Otherwise, the effect of hold time on weldment life did not show a reduction at a longer hold time (>180 s), which indicates that the weldments were saturated at a relatively shorter holding time.

- The creep-fatigue lifetime was lower than that of the low-cycle fatigue lifetime. This result is due to the introduction of a hold time, which caused the amount of inelastic strain to increase as the stress was relaxed.

- The weldments cracks were located in the weld metal part due to the strain/stress concentration. However, there was not much difference between all creep-fatigue crack morphologies of the base metal and weldments. Fractography showed a combination of surface-connected intergranular brittle oxide cracks and mixed-mode cracks propagation induced by fatigue slip.

- The linear damage summation result shows that the fatigue damage was found to dominate at the higher total strain ranges, and the creep damage was dominated at a longer holding times. Although all of the damage fractions were higher than the ASME critical value of 0.1, those were still within the failure criterion for this Alloy. This method is promising because all of the damage fractions were within the ±2 scatter band of the linear damage equation according to the Campbell diagram.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Dewa, R.T.; Kim, S.J.; Kim, W.G.; Kim, E.S. Effect of strain range on the low cycle fatigue in Alloy 617 at high temperature. Metals 2017, 7, 54. [Google Scholar] [CrossRef]

- Dewa, R.T.; Kim, S.J.; Kim, W.G.; Kim, E.S. Understanding low cycle fatigue behavior of Alloy 617 base metal and weldments at 900 °C. Metals 2016, 6, 178. [Google Scholar] [CrossRef]

- Wright, J.K.; Carroll, L.J.; Cabet, C.; Lillo, T.M.; Benz, J.K.; Simpson, J.A.; Lloyd, W.R.; Chapman, J.A.; Wright, R.N. Characterization of elevated temperature properties of heat exchanger and steam generator alloys. Nucl. Eng. Des. 2012, 251, 252–260. [Google Scholar] [CrossRef]

- Totemeier, T.C.; Tian, H. Creep-fatigue-environment interactions in INCONEL 617. Mater. Sci. Eng. A 2007, 468–470, 81–87. [Google Scholar] [CrossRef]

- Carroll, L.; Carroll, M. Creep-Fatigue Behavior of Alloy 617 at 850 and 950 °C. Available online: https://www.osti.gov/scitech/servlets/purl/1084680 (accessed on 24 November 2015).

- Wright, J.K.; Lillo, T.M.; Wright, R.N.; Kim, W.G.; Sah, I.J.; Kim, E.S.; Park, J.Y.; Kim, M.H. Creep and creep-rupture of Alloy 617. Nucl. Eng. Des. 2017, in press. [Google Scholar] [CrossRef]

- Rao, K.B.S.; Meurer, H.P.; Schuster, H. Creep-fatigue interaction of lnconel 617 at 950 °C in simulated nuclear reactor helium. Mater. Sci. Eng. A 1988, 104, 37–51. [Google Scholar] [CrossRef]

- Totemeier, T.C. High-temperature creep-fatigue of Alloy 617 base metal and weldments. In Proceedings of the Eighth International Conference on Creep and Fatigue at Elevated Temperatures, San Antonio, TX, USA, 22–26 July 2007; Volume 9, pp. 255–260. [Google Scholar]

- Carroll, L.J.; Cabet, C.; Carroll, M.C.; Wright, R.N. The development of microstructural damage during high temperature creep-fatigue of a nickel alloy. Int. J. Fatigue 2013, 47, 115–125. [Google Scholar] [CrossRef]

- Chen, X.; Yang, Z.; Sokolov, M.A.; Erdman, D.L.; Mo, K.; Stubbins, J.F. Effect of creep and oxidation on reduced fatigue life of Ni-based alloy 617 at 850 °C. J. Nucl. Mater. 2014, 444, 393–403. [Google Scholar] [CrossRef]

- Holdsworth, S. Creep-fatigue failure diagnosis. Materials 2015, 8, 7757–7769. [Google Scholar] [CrossRef] [PubMed]

- Kojima, M.; Funai, M.; Dozaki, T.; Watanabe, O.; Matsuda, A. Effect of strain rate and hold time in creep-fatigue test. In Proceedings of the ASME Pressure Vessels and Piping Conference 2013, Paris, France, 14–18 July 2013; Volume 6A. [Google Scholar]

- Lu, Y.L.; Chen, L.J.; Wang, G.Y.; Benson, M.L.; Liaw, P.K.; Thompson, S.A.; Blust, J.W.; Browning, P.F.; Bhattacharya, A.K.; Aurrecoechea, J.M.; et al. Hold time effects on low cycle fatigue behavior of HAYNES 230 superalloy at high temperatures. Mater. Sci. Eng. A 2005, 409, 282–291. [Google Scholar] [CrossRef]

- Fournier, B.; Sauzay, M.; Caes, C.; Noblecourt, M.; Mottot, M.; Bougault, A.; Rabeau, V.; Pineau, A. Creep-fatigue-oxidation interactions in a 9Cr-1Mo martensitic steel. Part I: Effect of tensile holding period on fatigue lifetime. Int. J. Fatigue 2008, 30, 649–662. [Google Scholar] [CrossRef]

- Wright, J.K.; Carroll, L.J.; Wright, R.N. Creep and Creep-Fatigue of Alloy 617 Weldments. Available online: http://www.osti.gov/scitech/biblio/1168621 (accessed on 16 September 2015).

- Cabet, C.; Carroll, L.; Wright, R. Low cycle fatigue and creep-fatigue behavior of Alloy 617 at high temperature. J. Press. Vessel Technol. 2013, 135, 061401. [Google Scholar] [CrossRef]

- Carroll, M.C.; Carroll, L.J. Developing dislocation subgrain structures and cyclic softening during high-temperature creep-fatigue of a nickel alloy. Metall. Mater. Trans. A 2013, 44A, 3592–3607. [Google Scholar] [CrossRef]

- ASTM International. ASTM E2714-13, Standard Test Method for Creep-Fatigue Testing; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Kolluri, M.; ten Pierick, P.; Bakker, T. Characterization of high temperature tensile and creep-fatigue properties of Alloy 800H for intermediate heat exchanger components of (V)HTRs. Nucl. Eng. Des. 2015, 284, 38–49. [Google Scholar] [CrossRef]

- Wright, J.K.; Carroll, L.J.; Sham, T.L.; Lybeck, N.J.; Wright, R.N. Determination of the creep-fatigue interaction diagram for Alloy 617. In Proceedings of the ASME Pressure Vessels and Piping Conference 2016, Vancouver, BC, Canada, 17–21 July 2016; Volume 5. [Google Scholar]

- Chen, X.; Sokolov, M.A.; Sham, S.; Erdman, D.L.; Busby, J.T.; Mo, K.; Stubbins, J.F. Experimental and modeling results of creep-fatigue life of Inconel 617 and Haynes 230 at 850 °C. J. Nucl. Mater. 2013, 432, 94–101. [Google Scholar] [CrossRef]

- Zhang, X.; Tu, S.T.; Xuan, F. Creep-fatigue endurance of 304 stainless steels. Theor. Appl. Fract. Mech. 2014, 71, 51–66. [Google Scholar] [CrossRef]

- Cabrillat, M.; Allais, L.; Mottot, M.; Riou, B.; Escaravage, C. Creep fatigue behavior and damage assessment for Mod 9Cr 1Mo steel. In Proceedings of the ASME Pressure Vessels and Piping Conference 2006, Vancouver, BC, Canada, 23–27 July 2006; Volume 6, pp. 511–520. [Google Scholar]

- Skelton, R.P.; Gandy, D. Creep-fatigue damage accumulation and interaction diagram based on metallographic interpretation of mechanisms. Mater. High Temp. 2008, 25, 27–54. [Google Scholar] [CrossRef]

- Wright, J.K.; Lillo, T.L. Progress Report on Alloy 617 Time-Dependent Allowable Stresses. Available online: www.osti.gov/servlets/purl/1236836 (accessed on 4 July 2017).

- Nazmy, M.Y. Sequential effect of creep and fatigue in a cast Ni-base alloy. Scr. Metall. 1982, 16, 823–826. [Google Scholar] [CrossRef]

| Material | C | Ni | Fe | Si | Mn | Co | Cr | Ti | P | S | Mo | Al | B | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Alloy 617 | 0.08 | 53.11 | 0.949 | 0.084 | 0.029 | 12.3 | 22.2 | 0.41 | 0.003 | <0.002 | 9.5 | 1.06 | <0.002 | 0.027 |

| KW-T617 | 0.07 | Bal | 0.33 | 0.3 | 0.3 | 11.29 | 22.5 | 0.42 | <0.003 | 0.001 | 8.8 | 1.1 | - | <0.01 |

| Sample-ID | ∆εt (%) | Hold Time (s) | Inelastic Strain Range, ∆εin/2 (%) | Stress Amplitude, ∆σ/2 (MPa) | Cycle Number 1 | Time to Failure (h) |

|---|---|---|---|---|---|---|

| Weld-01 | 0.6 | 0 | 0.088 | 331.3 | 827 | 2.76 |

| Weld-1 | 0.6 | 60 | 0.220 | 161.3 | 277 | 5.54 |

| Weld-2 | 0.6 | 180 | 0.238 | 163.6 | 172 | 9.17 |

| Weld-3 | 0.6 | 300 | 0.240 | 156.4 | 339 | 29.4 |

| Weld-04 | 1.2 | 0 | 0.364 | 375.1 | 190 | 4.43 |

| Weld-4 | 1.2 | 60 | 0.510 | 169.0 | 203 | 4.73 |

| Weld-05 | 1.5 | 0 | 0.502 | 386.5 | 140 | 3.5 |

| Weld-5 | 1.5 | 60 | 0.665 | 178.5 | 110 | 2.75 |

| Base-01 | 0.6 | 0 | 0.176 | 193.5 | 1179 | 3.93 |

| Base-1 | 0.6 | 60 | 0.235 | 175.52 | 662 | 13.24 |

| Base-2 | 0.6 | 180 | 0.235 | 157.3 | 577 | 30.77 |

| Base-3 | 0.6 | 300 | 0.232 | 156.6 | 459 | 39.78 |

| Base-04 | 1.2 | 0 | 0.470 | 186.2 | 487 | 11.36 |

| Base-4 | 1.2 | 60 | 0.519 | 166.6 | 334 | 7.79 |

| Base-05 | 1.5 | 0 | 0.625 | 181.2 | 405 | 10.13 |

| Base-5 | 1.5 | 60 | 0.668 | 165.6 | 250 | 6.25 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dewa, R.T.; Park, J.H.; Kim, S.J.; Lee, S.Y. High-Temperature Creep-Fatigue Behavior of Alloy 617. Metals 2018, 8, 103. https://doi.org/10.3390/met8020103

Dewa RT, Park JH, Kim SJ, Lee SY. High-Temperature Creep-Fatigue Behavior of Alloy 617. Metals. 2018; 8(2):103. https://doi.org/10.3390/met8020103

Chicago/Turabian StyleDewa, Rando Tungga, Jeong Hun Park, Seon Jin Kim, and Sang Yeol Lee. 2018. "High-Temperature Creep-Fatigue Behavior of Alloy 617" Metals 8, no. 2: 103. https://doi.org/10.3390/met8020103

APA StyleDewa, R. T., Park, J. H., Kim, S. J., & Lee, S. Y. (2018). High-Temperature Creep-Fatigue Behavior of Alloy 617. Metals, 8(2), 103. https://doi.org/10.3390/met8020103