Effect of Nb on δ Phase Precipitation and the Tensile Properties in Cast Alloy IN625

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

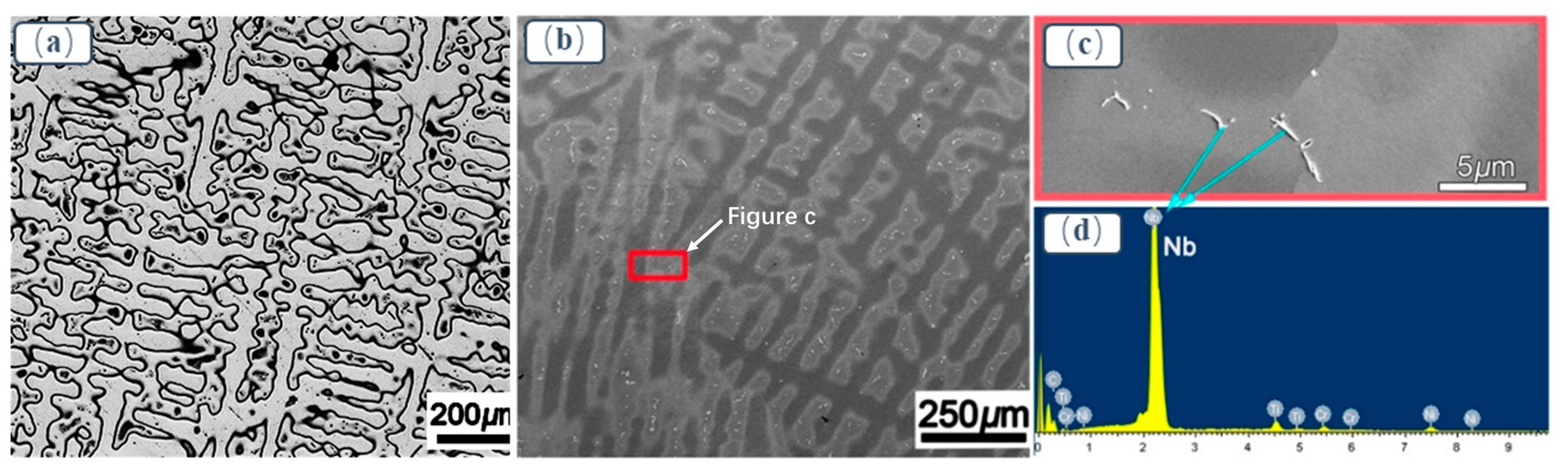

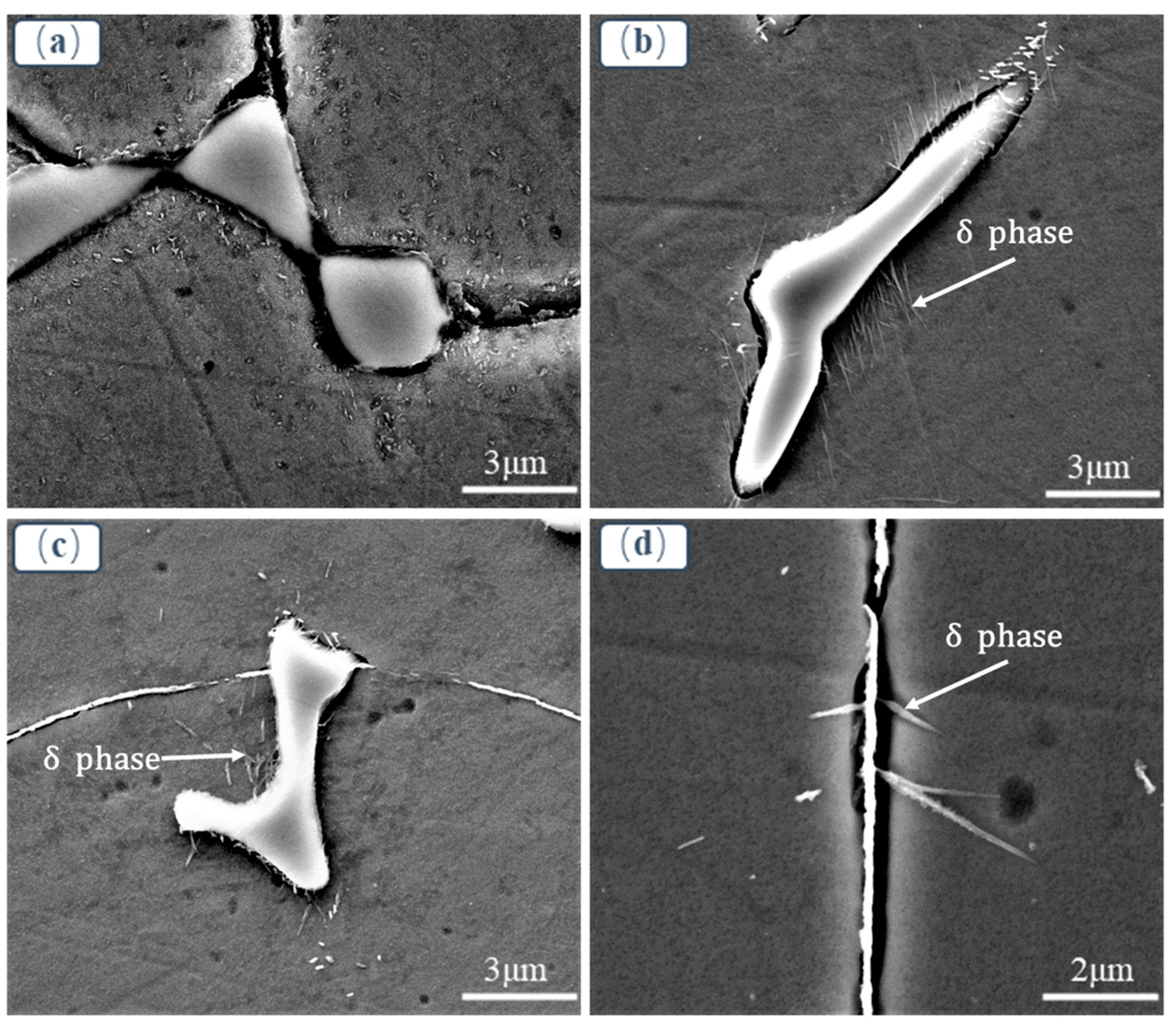

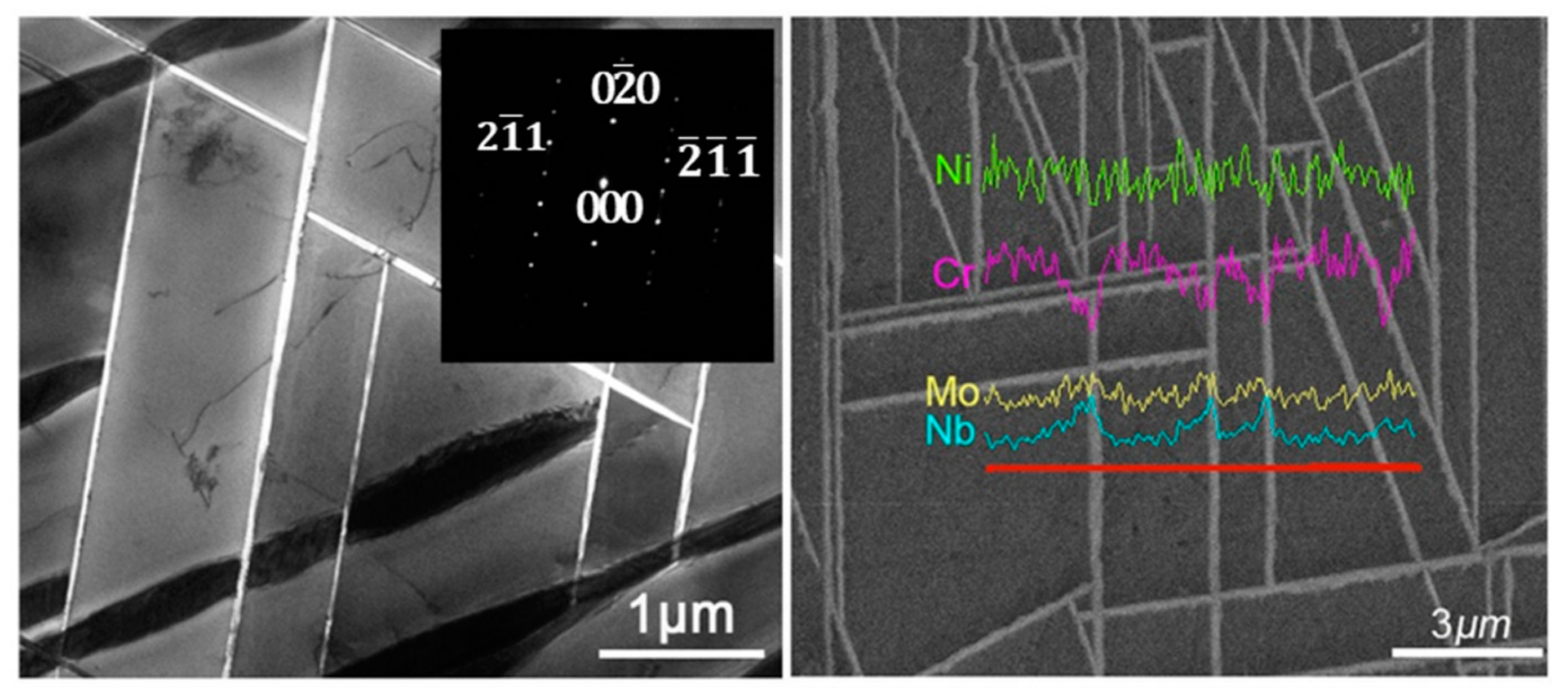

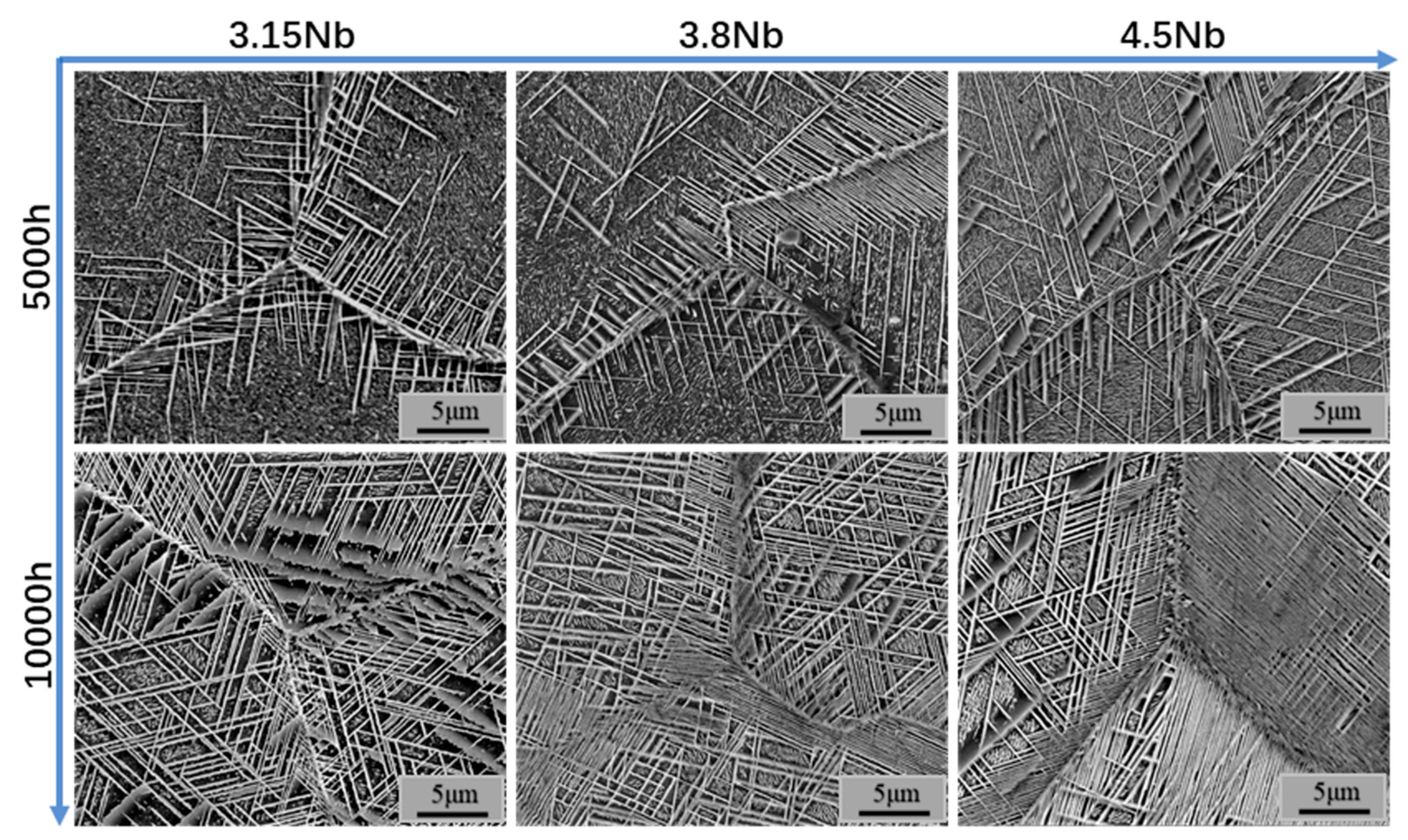

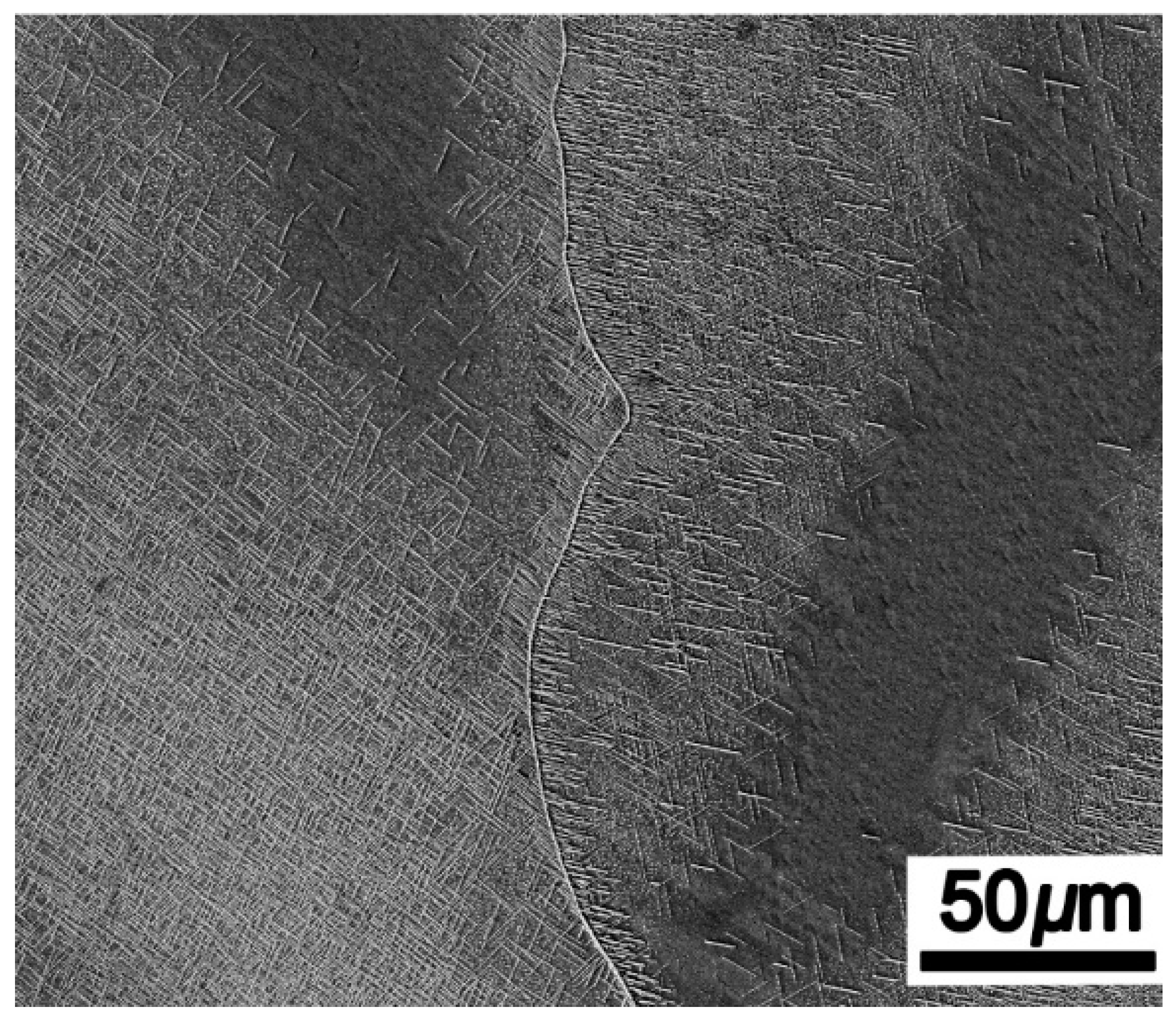

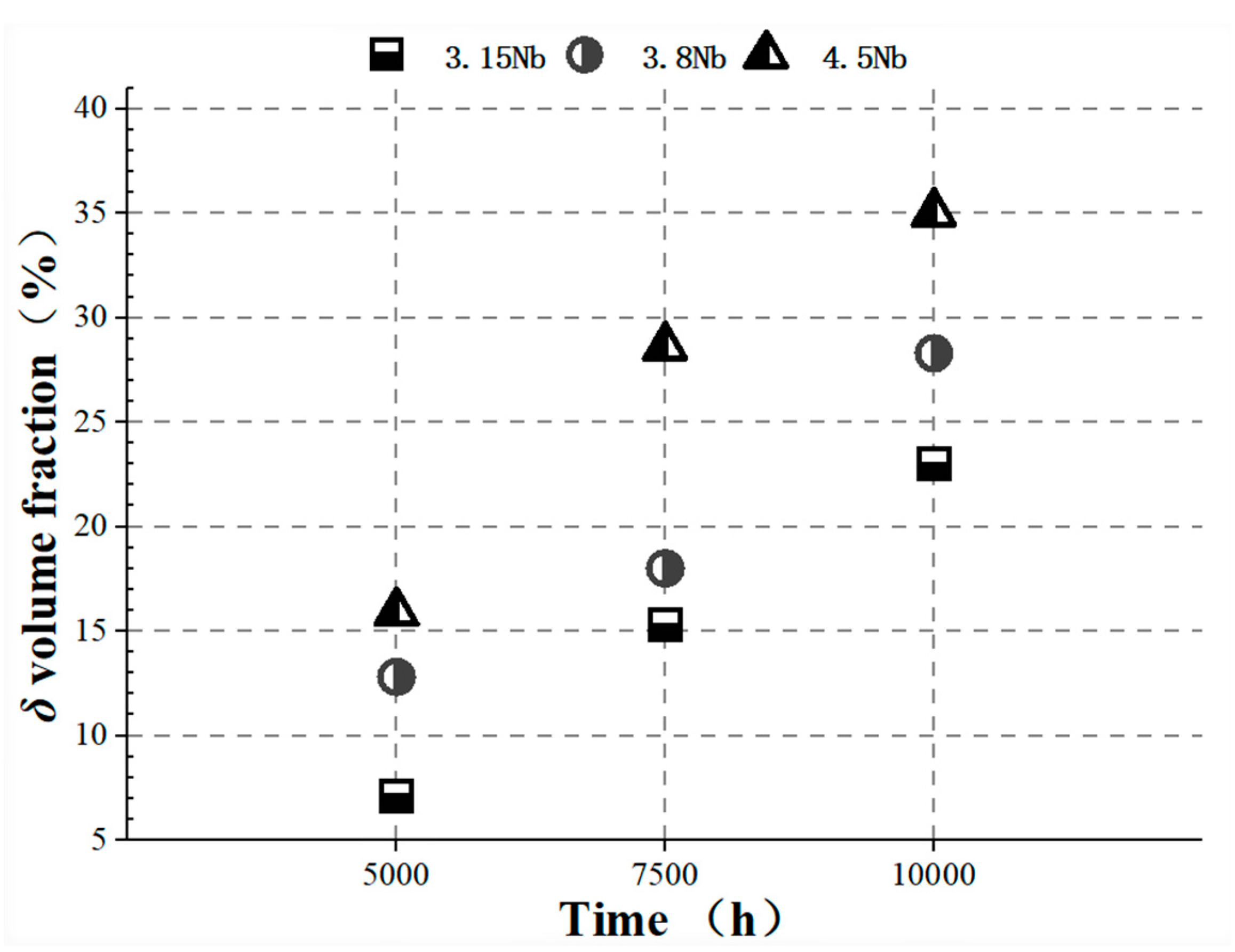

3.1. Microstructure Evolution

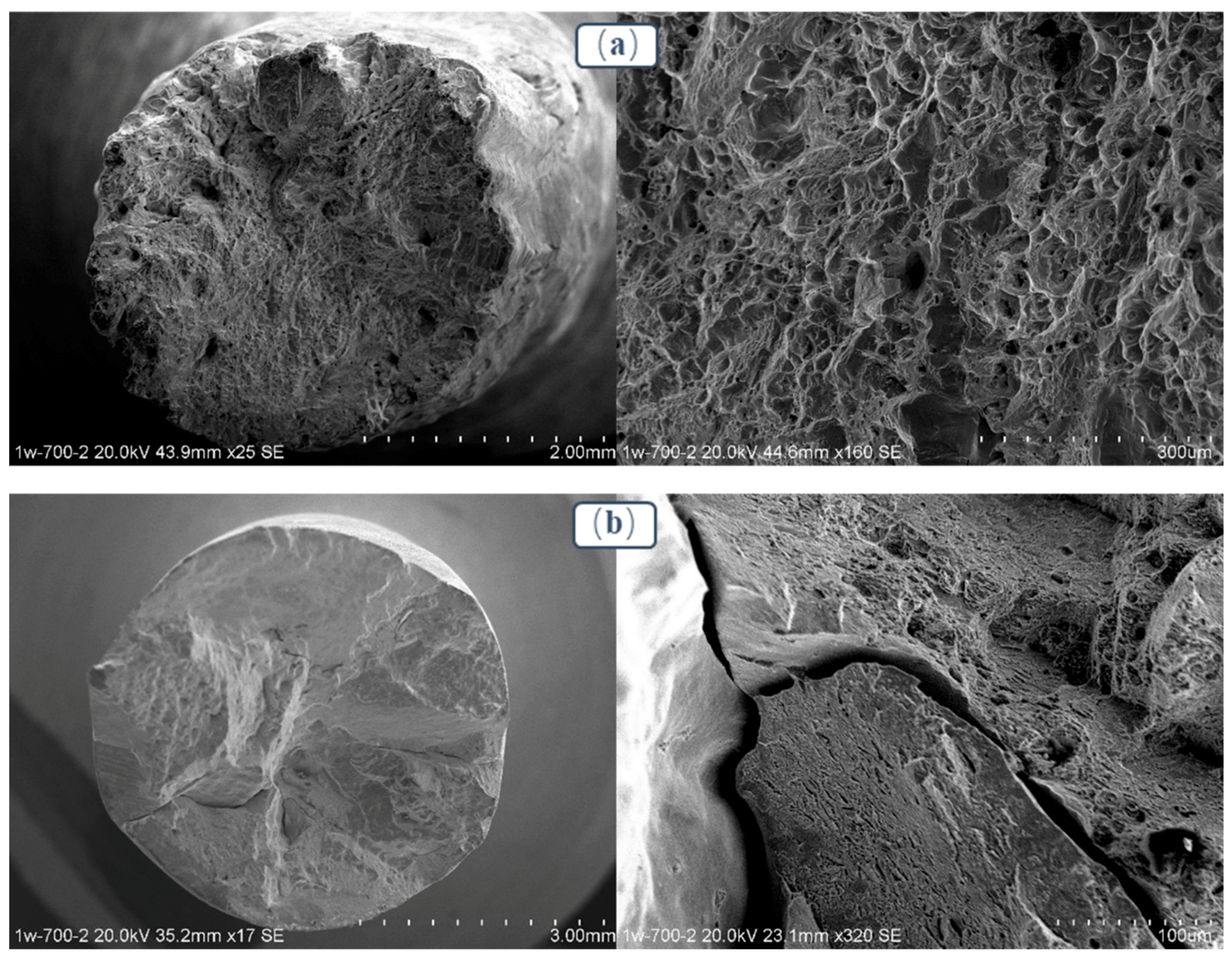

3.2. Tensile Properties

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jablonski, P.D.; Hawk, J.A.; Cowen, C.J.; Maziasz, P.J. Processing of advanced cast alloys for A-USC steam turbine applications. JOM 2012, 64, 271–279. [Google Scholar] [CrossRef]

- Nair, A.; Kumanan, S. Newer Materials for Supercritical Power Plant Components—A Manufacturability Study. In Proceedings of the International Conference on Advances in Production and Industrial Engineering, Tiruchirappalli, India, 20–21 February 2015; pp. 326–332. [Google Scholar]

- De Albuquerque, V.H.C.; Barbosa, C.V.; Silva, C.C.; Moura, E.P.; Filho, P.P.R.; Papa, J.P.; Tavares, J.M.R.S. Ultrasonic Sensor Signals and Optimum Path Forest Classifier for the Microstructural Characterization of Thermally-Aged Inconel 625 Alloy. Sensors 2015, 15, 12474–12497. [Google Scholar] [CrossRef] [PubMed]

- Abe, F. Research and Development of Heat-Resistant Materials for Advanced USC Power Plants with Steam Temperatures of 700 °C and Above. Engineering 2015, 1, 211–224. [Google Scholar] [CrossRef]

- Lückemeyer, N.; Kirchner, H.; Almstedt, H. Challenges in Advanced-USC Steam Turbine Design for 1300°F/700°C, GT2012-69822. In Proceedings of the ASME Turbo Expo 2012: Turbine Technical Conference and Exposition, Copenhagen, Denmark, 11–15 June 2012. [Google Scholar]

- Siefert, J.A.; Shingledecker, J.P.; DuPont, J.N.; David, S.A. Weldability and weld performance of candidate nickel based superalloys for advanced ultrasupercritical fossil power plants Part II: Weldability and cross-weld creep performance. Sci. Technol. Weld. Join. 2016, 21, 397–427. [Google Scholar] [CrossRef]

- Castello, D.; Rolli, B.; Kruse, A.; Fiori, L. Supercritical Water Gasification of Biomass in a Ceramic Reactor: Long-Time Batch Experiments. Energies 2017, 10, 1734. [Google Scholar] [CrossRef]

- Cárcel-Carrasco, F.-J.; Pérez-Puig, M.-A.; Pascual-Guillamón, M.; Pascual-Martinez, R. An Analysis of the Weldability of Ductile Cast Iron Using Inconel 625 for the Root Weld and Electrodes Coated in 97.6% Nickel for the Filler Welds. Metals 2016, 6, 283. [Google Scholar] [CrossRef]

- Floreen, S.; Fuchs, G.E.; Yang, W.J. The metallurgy of alloy 625. In Superalloys 718, 625 and Various Derivatives; TMS-AIME: Warrendale, PA, USA, 1991; pp. 13–37. [Google Scholar]

- Moore, I.J.; Taylor, J.I.; Tracy, M.W.; Burke, M.G.; Palmiere, E.J. Grain coarsening behaviour of solution annealed Alloy 625 between 600–800 °C. Mater. Sci. Eng. A 2017, 682, 402–409. [Google Scholar] [CrossRef]

- Suave, L.M.; Bertheau, D.; Cormier, J.; Villechaise, P.; Soula, A.; Hervier, Z.; Laigo, J. Impact of microstructural evolutions during thermal aging of Alloy 625 on its monotonic mechanical properties. In Proceedings of the MATEC Web of Conferences, Giens, France, 12–16 May 2014; p. 21001. [Google Scholar]

- Lass, E.A.; Stoudt, M.R.; Williams, M.E.; Katz, M.B.; Levine, L.E.; Phan, T.Q.; Gnaeupel-Herold, T.H.; Ng, D.S. Formation of the Ni3Nb/delta-Phase in Stress-Relieved Inconel 625 Produced via Laser Powder-Bed Fusion Additive Manufacturing. Metall. Mater. Trans. A 2017, 48, 5547–5558. [Google Scholar] [CrossRef]

- Suave, L.M.; Cormier, J.; Villechaise, P.; Soula, A.; Hervier, Z.; Bertheau, D.; Laigo, J. Microstructural evolutions during thermal aging of alloy 625: Impact of temperature and forming process. Metall. Mater. Trans. A 2014, 45, 2963–2982. [Google Scholar] [CrossRef]

- Eiselstein, H.L.; Tillack, D.J. The invention and definition of alloy 625. In Superalloys 718, 625 and Various Derivatives; TMS-AIME: Warrendale, PA, USA, 1991; pp. 1–14. [Google Scholar]

- Mathew, M.D.; Bhanu Sankara Rao, K.; Mannan, S.L. Creep properties of service-exposed Alloy 625 after re-solution annealing treatment. Mater. Sci. Eng. A 2004, 372, 327–333. [Google Scholar] [CrossRef]

- Kim, J.-S.; Lee, H.-W. A Study on Effect of Intergranular Corrosion by Heat Input on Inconel 625 Overlay Weld Metal. Int. J. Electrochem. Sci. 2015, 10, 6454–6464. [Google Scholar]

- Malej, S.; Medved, J.; Batič, B.Š.; Tehovnik, F.; Godec, M. Microstructural evolution of Inconel 625 during thermal aging. Metalurgija 2017, 56, 319–322. [Google Scholar]

- Di, X.J.; Xing, X.X.; Wang, B.S. Nucleation and Coarsening Mechanism of Δ Phase in Inconel 625 Deposited Metal. Acta Metall. Sin. 2014, 50, 323–328. [Google Scholar]

- Sundararaman, M.; Mukhopadhyay, P.; Banerjee, S. Precipitation of the delta-Ni3Nb phase in two nickel base superalloys. Metall. Trans. A 1988, 19, 453–465. [Google Scholar] [CrossRef]

- Muzyka, D.R.; Maniar, G.N. Effects of solution treating temperature and microstructure on the properties of hot-rolled 718 alloy. Met. Eng. Q 1969, 9, 23–37. [Google Scholar]

- Zhu, Z.Y.; Sui, Y.; Dai, A.L.; Cai, Y.F.; Xu, L.L.; Wang, Z.X.; Chen, H.M.; Shao, X.M.; Liu, W. Long term aging treatment impact on ultralow iron Alloy 625 intergranular corrosion property. Preprints 2017. [Google Scholar] [CrossRef]

- Ding, Y.T.; Gao, Y.B.; Dou, Z.Y.; Gao, X.; Liu, D.X.; Jia, Z. Precipitation Behavior of delta Phase of Deformation Induced GH3625 Superalloy Hot-Extruded Tube. Acta Metall. Sin. 2017, 53, 695–702. [Google Scholar]

- Kirman, I. Precipitation in the Fe-Ni-Cr-Nb system. J. Iron Steel Inst. 1969, 207, 1612–1618. [Google Scholar]

- Singh, J.B.; Verma, A.; Jaiswal, D.M.; Kumar, N.; Patel, R.D.; Chakravartty, J.K. Rejuvenation of service exposed ammonia cracker tubes of cast Alloy 625 and their re-use. Mater. Sci. Eng. A 2015, 644, 254–267. [Google Scholar] [CrossRef]

- Singh, J.B.; Sundararaman, M.; Mukhopadhyay, P.; Prabhu, N. Effect of ternary Nb additions on the stability of the D022 structure of the Ni3V phase. Scr. Mater. 2003, 48, 261–267. [Google Scholar] [CrossRef]

- International Organization for Standardization. Metallic Materials—Tensile Testing at Elevated Temperature (ISO 783: 1999, MOD); GB/T4338-2006; International Organization for Standardization: Geneva, Switzerland, 1999; p. 5. [Google Scholar]

- Gao, G.; Zhang, M.; Dong, J.; Yao, Z.; Zheng, L. Effects of Nb Content Variations on Precipitates Evolution of GH4169 Ingots during Their Solidification and Homogenization Processes. Rare Met. Mater. Eng. 2014, 43, 103–108. [Google Scholar]

- McEvily, A.J.; Johnston, T.L. The role of cross-slip in brittle fracture and fatigue. Int. J. Fract. Mech. 1967, 3, 45–74. [Google Scholar] [CrossRef]

- McLaren, A.C.; Retchford, J.A. Transmission electron microscope study of the dislocations in plastically deformed synthetic quartz. Phys. Stat. Solidi 1969, 33, 657–668. [Google Scholar] [CrossRef]

| Alloy | Nb | Mo | Cr | C | Ni |

|---|---|---|---|---|---|

| 3.15Nb | 3.15 | 9 | 21.5 | 0.05 | Bal. |

| 3.8Nb | 3.8 | 9 | 21.5 | 0.05 | Bal. |

| 4.5Nb | 4.5 | 9 | 21.5 | 0.05 | Bal. |

| Alloy | 3.15Nb | 3.8Nb | 4.5Nb | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Element | Nb | Mo | Cr | Ni | Nb | Mo | Cr | Ni | Nb | Mo | Cr | Ni |

| CD, wt. % | 1.8 | 8.5 | 22.9 | 66.9 | 1.9 | 7.5 | 23.0 | 67.6 | 1.9 | 7.5 | 23.0 | 66.9 |

| CI, wt. % | 5.1 | 9.9 | 20.8 | 64.2 | 5.8 | 10.1 | 21.0 | 63.1 | 7.2 | 10.2 | 20.3 | 62.3 |

| K | 2.83 | 1.16 | 0.91 | 0.96 | 3.05 | 1.34 | 0.91 | 0.93 | 3.60 | 1.31 | 0.87 | 0.93 |

| Condition | As-Heat-Treated | Aged at 700 °C for 10,000 h | ||||

|---|---|---|---|---|---|---|

| Alloy | 3.15Nb | 3.8Nb | 4.5Nb | 3.15Nb | 3.8Nb | 4.5Nb |

| YS | 175 | 180 | 175 | 595 | 650 | 710 |

| UTS | 420 | 410 | 385 | 720 | 780 | 880 |

| EL | 62 | 50 | 63 | 9 | 13 | 8 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mu, Y.; Wang, C.; Zhou, W.; Zhou, L. Effect of Nb on δ Phase Precipitation and the Tensile Properties in Cast Alloy IN625. Metals 2018, 8, 86. https://doi.org/10.3390/met8020086

Mu Y, Wang C, Zhou W, Zhou L. Effect of Nb on δ Phase Precipitation and the Tensile Properties in Cast Alloy IN625. Metals. 2018; 8(2):86. https://doi.org/10.3390/met8020086

Chicago/Turabian StyleMu, Yiqiang, Changshuai Wang, Wenlong Zhou, and Lanzhang Zhou. 2018. "Effect of Nb on δ Phase Precipitation and the Tensile Properties in Cast Alloy IN625" Metals 8, no. 2: 86. https://doi.org/10.3390/met8020086