Development and Characterisation of Aluminium Matrix Nanocomposites AlSi10Mg/MgAl2O4 by Laser Powder Bed Fusion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Specimen Manufacturing

2.3. Thermal Characterisation

2.4. Microstructural and Mechanical Characterisation

3. Results and Discussion

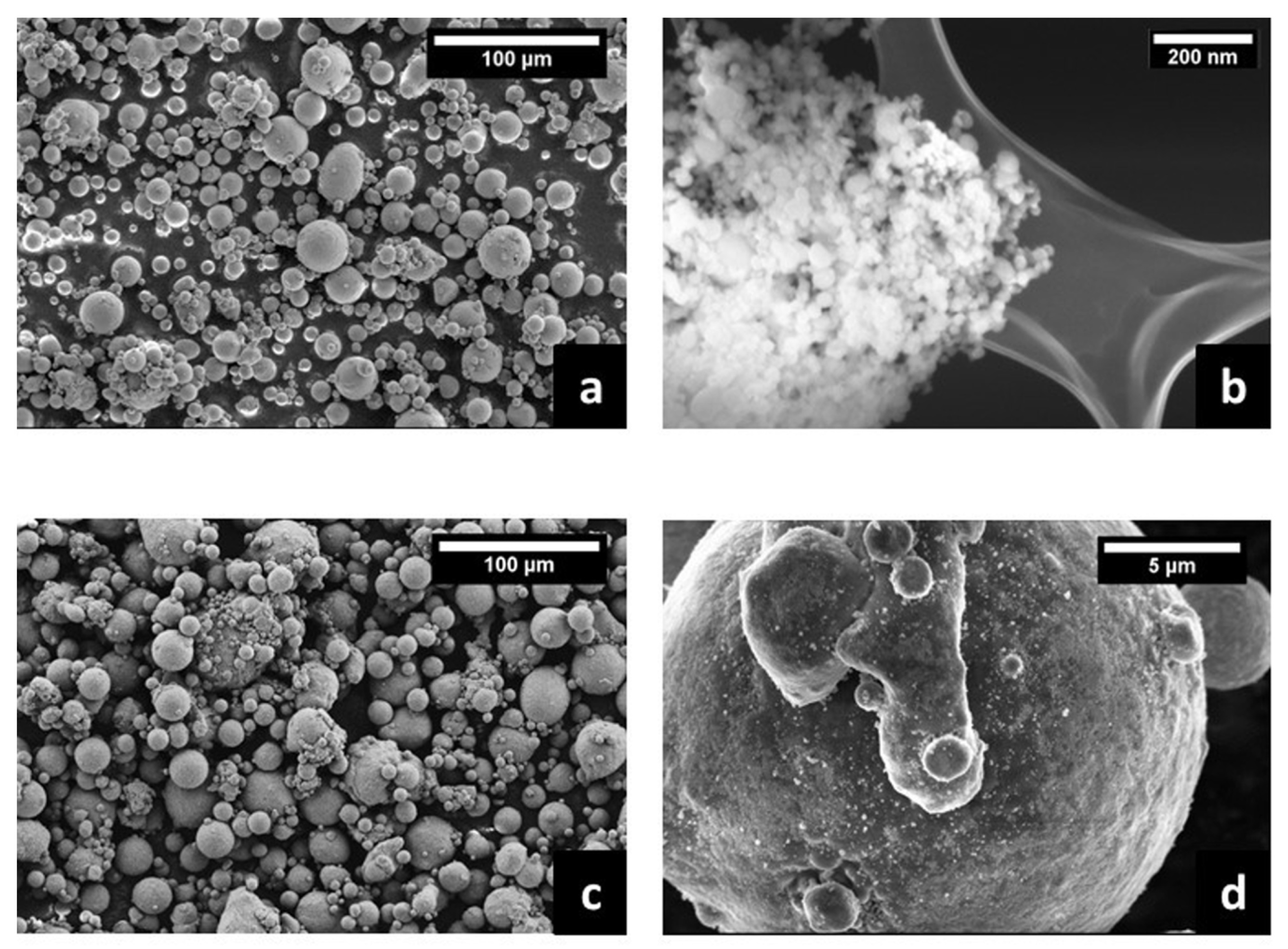

3.1. Powders Characterisation

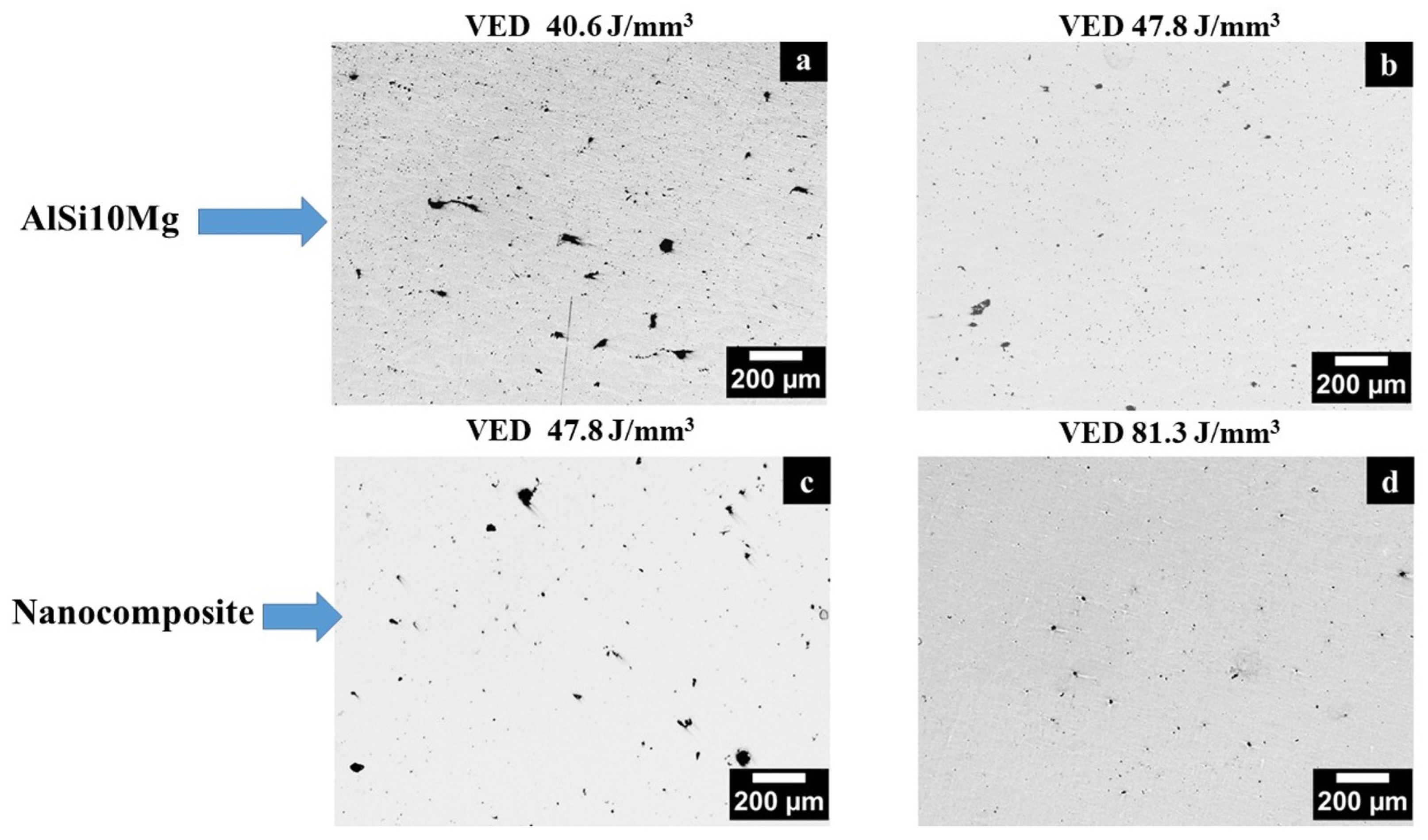

3.2. Effect of the Process Parameters on the Densification Levels

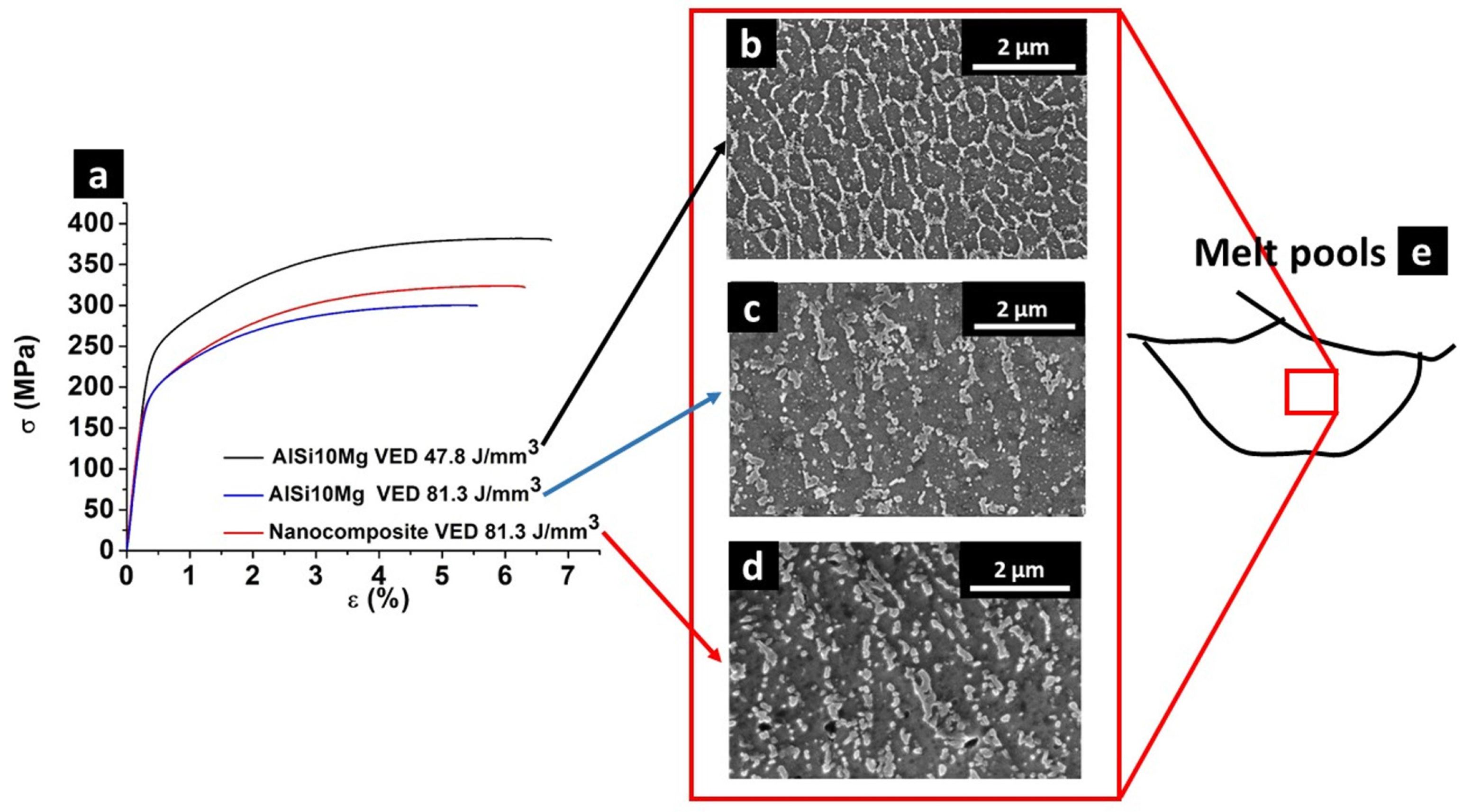

3.3. Microstructural Investigations

3.4. Thermal Properties

3.5. Mechanical Characterisation

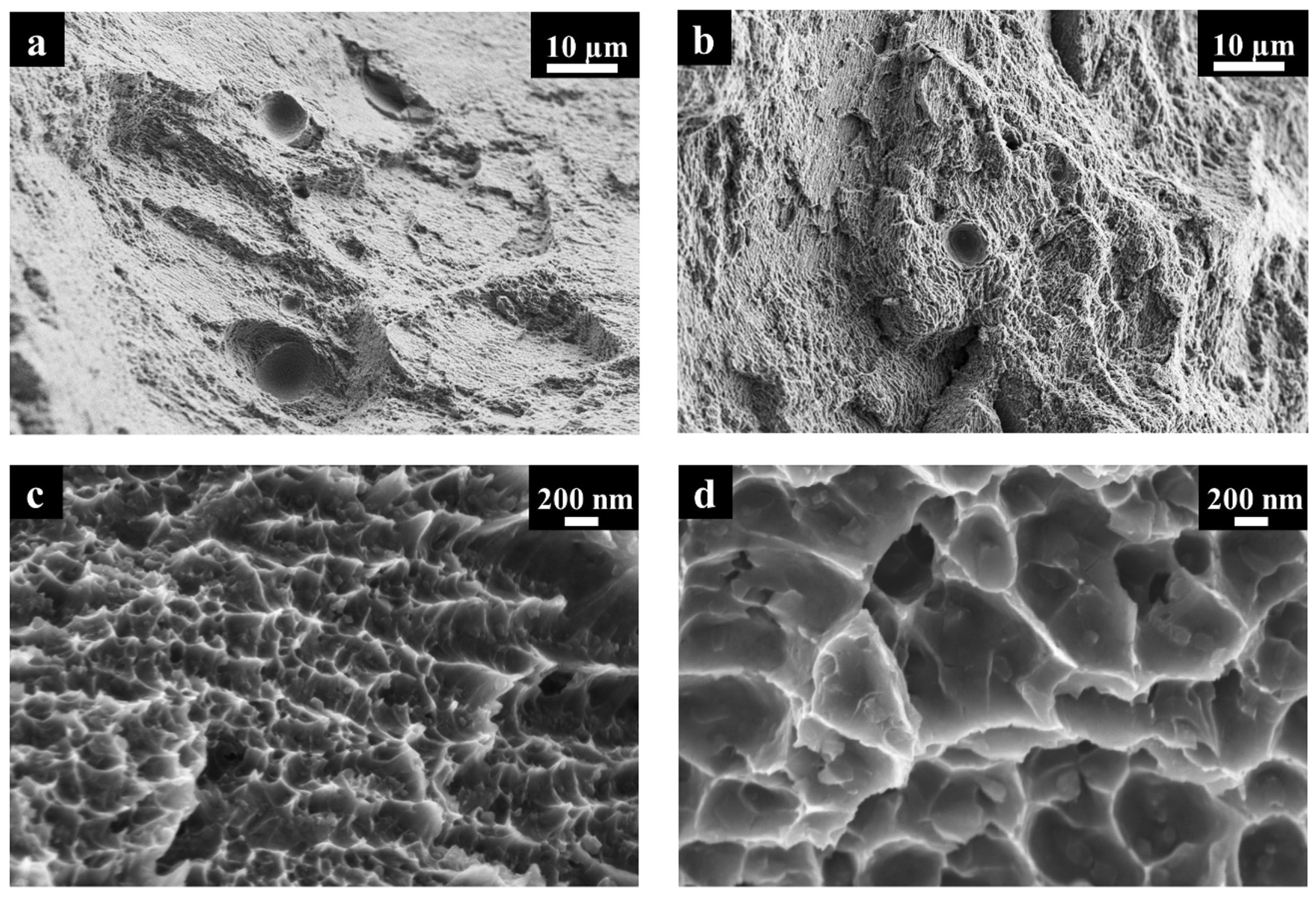

3.6. Fracture Surfaces Analysis

4. Conclusions

- (1)

- The effect of the combination of different process parameters on the densification levels allowed the fabrication of dense and crack-free nanocomposites with a residual porosity of 0.59 ± 0.09% using a VED of 81.3 J/mm3, reaching densification levels similar to AlSi10Mg alloy (residual porosity of 0.37 ± 0.08% using a VED of 47.8 J/mm3).

- (2)

- The nanocomposite samples built with a VED of 81.3 J/mm3 presented larger cellular structures and consequently, lower tensile properties than AlSi10Mg samples built with a lower VED value (47.8 J/mm3).

- (3)

- The different cellular dimensions appear to be chiefly influenced by the VED values; the higher is the VED values, the coarser is the cellular size. In fact, AlSi10Mg samples built with a higher VED value (81.3 J/mm3) exhibited lower tensile properties than AlSi10Mg built with a VED of 47.8 J/mm3.

- (4)

- When the samples obtained with equal VED value are considered, the nanocomposites revealed slight higher σUTS than AlSi10Mg samples, suggesting an effect of the nanoparticles on hindering the dislocations.

- (5)

- Both AlSi10Mg and nanocomposite materials built with selected VED exhibited mainly ductile fractures with dimples as well as some brittle fractures. It is interesting to note that the nanocomposite samples revealed larger dimples, mostly due to larger cellular structures with respect to the base alloy.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Aversa, A.; Marchese, G.; Lombardi, M.; Biamino, S.; Ugues, D.; Manfredi, D. Additive manufacturing of titanium alloys in the biomedical field: processes, properties and applications. J. Appl. Biomater. Funct. Mater. 2017. [Google Scholar] [CrossRef] [PubMed]

- Marchese, G.; Garmendia Colera, X.; Calignano, F.; Lorusso, M.; Biamino, S.; Minetola, P.; Manfredi, D. Characterization and comparison of inconel 625 processed by selective laser melting and laser metal deposition. Adv. Eng. Mater. 2017, 19, 1600635. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Manfredi, D.; Calignano, F.; Krishnan, M.; Canali, R.; Ambrosio, E.P.; Atzeni, E. From powders to dense metal parts: Characterization of a commercial AlSiMg alloy processed through direct metal laser sintering. Materials 2013, 6, 856–869. [Google Scholar] [CrossRef] [PubMed]

- Rao, H.; Giet, S.; Yang, K.; Wu, X.; Davies, C.H.J. The influence of processing parameters on aluminium alloy A357 manufactured by selective laser melting. Mater. Des. 2016, 109, 334–346. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Lorusso, M.; Pakkanen, J.; Aversa, A.; Ambrosio, E.P.; Lombardi, M.; Fino, P.; Manfredi, D. On the selective laser melting (SLM) of the AlSi10Mg alloy: Process, microstructure and mechanical properties. Materials 2017, 10, 76. [Google Scholar] [CrossRef] [PubMed]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. Densification mechanism and microstructural evolution in selective laser sintering of Al-12Si powders. J. Mater. Process. Technol. 2011, 211, 113–121. [Google Scholar] [CrossRef]

- Ma, P.; Prashanth, K.; Scudino, S.; Jia, Y.; Wang, H.; Zou, C.; Wei, Z.; Eckert, J. Influence of annealing on mechanical properties of Al-20Si processed by selective laser melting. Metals 2014, 4, 28–36. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.Q.; Wang, W.; Attallah, M.M.; Loretto, M.H. Microstructure and strength of selectively laser melted AlSi10Mg. Acta Mater. 2016, 117, 311–320. [Google Scholar] [CrossRef]

- Manfredi, D.; Calignano, F.; Krishnan, M.; Canali, R.; Ambrosio, E.P.; Biamino, S.; Ugues, D.; Pavese, M.; Fino, P. Additive manufacturing of Al alloys and aluminium matrix composites (AMCs). In Light Metal Alloys Applications; Monteirio, A., Waldemar, Eds.; InTech: Rijeka, Croatia, 2014; ISBN 978-953-51-1588-5. [Google Scholar]

- Chang, F.; Gu, D.; Dai, D.; Yuan, P. Selective laser melting of in-situ Al4SiC4 + SiC hybrid reinforced Al matrix composites: Influence of starting SiC particle size. Surf. Coat. Technol. 2015, 272, 15–24. [Google Scholar] [CrossRef]

- Gu, D.; Wang, H.; Dai, D.; Chang, F.; Meiners, W.; Hagedorn, Y. Densification behavior, microstructure evolution and wear property of TiC nanoparticle reinforced AlSi10Mg bulk-form nanocomposites prepared by selective laser melting. J. Laser Appl. 2015, 17003. [Google Scholar] [CrossRef]

- Dai, D.; Gu, D. Influence of thermodynamics within molten pool on migration and distribution state of reinforcement during selective laser melting of AlN/AlSi10Mg composites. Int. J. Mach. Tools Manuf. 2016, 100, 14–24. [Google Scholar] [CrossRef]

- De Vita, A.; Roitti, S.; Sbaizero, O. Creep of aluminum metal matrix composites reinforced with magnesium spinel. Key Eng. Mater. 2004, 264–268, 953–956. [Google Scholar] [CrossRef]

- Schweinfest, R.; Ernst, F.; Wagner, T.; Rühle, M. High-precision assessment of interface lattice offset by quantitative HRTEM. J. Microsc. 1999, 194, 142–151. [Google Scholar] [CrossRef] [PubMed]

- Manfredi, D.; Canali, R.; Krishnan, M.; Ambrosio, E.P.; Calignano, F.; Pavese, M.; Miranti, L.; Belardinelli, S.; Biamino, S.; Fino, P. Aluminium matrix composites (AMCs) by DMLS. In High Value Manufacturing: Advanced Research in Virtual and Rapid Prototyping, Proceedings of the 6th International Conference on Advanced Research in Virtual and Rapid Prototyping, Leiria, Portugal, 1–5 October 2013; CRC Press: Boca Raton, FL, USA, 2013; p. 249. [Google Scholar]

- Aversa, A.; Marchese, G.; Lorusso, M.; Calignano, F.; Biamino, S.; Ambrosio, E.P.; Manfredi, D.; Fino, P.; Lombardi, M.; Pavese, M. Microstructural and mechanical characterization of aluminum matrix composites produced by laser powder bed fusion. Adv. Eng. Mater. 2017, 19, 1700180. [Google Scholar] [CrossRef]

- Nanocerox Spinel—MgAl2O4. Available online: http://www.nanocerox.com/product_spinel (accessed on 7 February 2018).

- Olakanmi, E.O. Selective laser sintering/melting (SLS/SLM) of pure Al, Al-Mg and Al-Si powders: Effect of processing conditions and powder properties. J. Mater. Process. Technol. 2013, 213, 1387–1405. [Google Scholar] [CrossRef]

- Sercombe, T.B.; Li, X. Selective laser melting of aluminium and aluminium metal matrix composites: Review. Mater. Technol. 2016, 31, 77–85. [Google Scholar] [CrossRef]

- EOS GmbH—Electro Optical Systems Material Data Sheet: EOS Aluminium AlSi10Mg. Available online: www.agile-manufacturing.com/files/materials/aluminum.pdf (accessed on 7 February 2018).

- Kreyling, W.G.; Semmler-Behnke, M.; Chaudhry, Q. A complementary definition of nanomaterial. Nano Today 2010, 5, 165–168. [Google Scholar] [CrossRef]

- Spierings, A.B.; Schneider, M.; Eggenberg, R. Comparison of density measurement techniques for additive manufactured metallic parts. Rapid Prototyp. J. 2011, 5, 380–386. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, J.D. As-fabricated and heat-treated microstructures of the Ti-6Al-4V alloy processed by selective laser melting. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2011, 42, 3190–3199. [Google Scholar] [CrossRef]

- Yuan, P.; Gu, D. Molten pool behaviour and its physical mechanism during selective laser melting of TiC/AlSi10Mg nanocomposites: simulation and experiments. J. Phys. D Appl. Phys. 2015, 48, 35303. [Google Scholar] [CrossRef]

- Wei, P.; Wei, Z.; Chen, Z.; Du, J.; He, Y.; Li, J.; Zhou, Y. The AlSi10Mg samples produced by selective laser melting: Single track, densification, microstructure and mechanical behavior. Appl. Surf. Sci. 2017, 408, 38–50. [Google Scholar] [CrossRef]

- Chawla, N.; Chawla, K.K. Metal Matrix Composites; Springer-Verlag New York: New York, NY, USA, 2013; ISBN 978-1-4614-9547-5. [Google Scholar]

- Tang, M.; Pistorius, P.C.; Narra, S.; Beuth, J.L. Rapid solidification: Selective laser melting of AlSi10Mg. J. Miner. Met. Mater. Soc. 2016, 68, 960–966. [Google Scholar] [CrossRef]

- Liu, Y.J.; Liu, Z.; Jiang, Y.; Wang, G.W.; Yang, Y.; Zhang, L.C. Gradient in microstructure and mechanical property of selective laser melted AlSi10Mg. J. Alloy. Compd. 2017, 735, 1414–1421. [Google Scholar] [CrossRef]

- Davis, J.R. Aluminum and Aluminum Alloys; ASM Specialty Handbook; ASM International: Almere, The Netherlands, 1993; ISBN 9780871704962. [Google Scholar]

- Chen, B.; Moon, S.K.; Yao, X.; Bi, G.; Shen, J.; Umeda, J.; Kondoh, K. Strength and strain hardening of a selective laser melted AlSi10Mg alloy. Scr. Mater. 2017, 141, 45–49. [Google Scholar] [CrossRef]

- Tradowsky, U.; White, J.; Ward, R.M.; Read, N.; Reimers, W.; Attallah, M.M. Selective laser melting of AlSi10Mg: Influence of post-processing on the microstructural and tensile properties development. Mater. Des. 2016, 105, 212–222. [Google Scholar] [CrossRef]

| Volumetric Energy Density (VED) | Laser Power (P) | Scan Speed (v) | Hatching Distance (hd) | Layer Thickness (t) |

|---|---|---|---|---|

| (J/mm3) | (W) | (mm/s) | (mm) | (µm) |

| 40.6 | 195 | 1600 | 0.10 | 30 |

| 47.8 | 195 | 800 | 0.17 | 30 |

| 65.0 | 195 | 1000 | 0.10 | 30 |

| 81.3 | 195 | 800 | 0.10 | 30 |

| 108.3 | 195 | 600 | 0.10 | 30 |

| 130.0 | 195 | 500 | 0.10 | 30 |

| 162.5 | 195 | 400 | 0.10 | 30 |

| VED (J/mm3) | AlSi10Mg | Nanocomposite | ||

|---|---|---|---|---|

| Archimedes Method | Image Analysis | Archimedes Method | Image Analysis | |

| Residual Porosity (%) | Residual Porosity (%) | Residual Porosity (%) | Residual Porosity (%) | |

| 40.6 | 1.31 ± 0.22 | 2.21 ± 0.30 | 2.35 ± 0.12 | 2.87 ± 0.15 |

| 47.8 | 0.37 ± 0.08 | 1.21 ± 0.18 | 1.40 ± 0.13 | 2.03 ± 0.15 |

| 65.0 | 0.53 ± 0.10 | 1.22 ± 0.27 | 0.75 ± 0.02 | 1.43 ± 0.20 |

| 81.3 | 0.61 ± 0.07 | 1.20 ± 0.10 | 0.59 ± 0.09 | 0.96 ± 0.07 |

| 108.3 | 0.50 ± 0.09 | 0.95 ± 0.22 | 0.68 ± 0.05 | 1.37 ± 0.14 |

| 130.0 | 0.56 ± 0.03 | 1.01 ± 0.19 | 0.67 ± 0.07 | 0.97 ± 0.10 |

| 162.5 | 0.47 ± 0.05 | 1.00 ± 0.27 | 0.51 ± 0.02 | 1.00 ± 0.12 |

| T (°C) | AlSi10Mg (cm2/s) | Nanocomposite (cm2/s) |

|---|---|---|

| 200 | 0.69 ± 0.01 | 0.67 ± 0.03 |

| 300 | 0.66 ± 0.01 | 0.64 ± 0.02 |

| 400 | 0.63 ± 0.01 | 0.62 ± 0.01 |

| LPBF Specimens | Orientation | VED | Young Modulus | Yield Strength | Ultimate Tensile Strength | Elongation at Break |

|---|---|---|---|---|---|---|

| (J/mm3) | (GPa) | (MPa) | (MPa) | (%) | ||

| AlSi10Mg * | x | 47.8 | 73 ± 3 | 257 ± 2 | 384 ± 2 | 6.7 ± 0.8 |

| y | 47.8 | 73 ± 2 | 256 ± 2 | 382 ± 3 | 7.3 ± 0.2 | |

| Nanocomposite * | x | 81.3 | 76 ± 1 | 198 ± 1 | 323 ± 3 | 6.3 ± 0.7 |

| y | 81.3 | 74 ± 0.2 | 198 ± 1 | 322 ± 1 | 6.0 ± 0.1 |

| LPBF Specimens | VED | Young Modulus | Yield Strength | Ultimate Tensile Strength | Elongation at Break |

|---|---|---|---|---|---|

| (J/mm3) | (GPa) | (MPa) | (MPa) | (%) | |

| AlSi10Mg * | 47.8 | 73 ± 3 | 257 ± 2 | 384 ± 2 | 6.7 ± 0.8 |

| AlSi10Mg * | 81.3 | 71 ± 2 | 203 ± 3 | 301 ± 6 | 5.4 ± 0.4 |

| Nanocomposite * | 81.3 | 76 ± 1 | 198 ± 1 | 323 ± 3 | 6.3 ± 0.7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marchese, G.; Aversa, A.; Lorusso, M.; Manfredi, D.; Calignano, F.; Lombardi, M.; Biamino, S.; Pavese, M. Development and Characterisation of Aluminium Matrix Nanocomposites AlSi10Mg/MgAl2O4 by Laser Powder Bed Fusion. Metals 2018, 8, 175. https://doi.org/10.3390/met8030175

Marchese G, Aversa A, Lorusso M, Manfredi D, Calignano F, Lombardi M, Biamino S, Pavese M. Development and Characterisation of Aluminium Matrix Nanocomposites AlSi10Mg/MgAl2O4 by Laser Powder Bed Fusion. Metals. 2018; 8(3):175. https://doi.org/10.3390/met8030175

Chicago/Turabian StyleMarchese, Giulio, Alberta Aversa, Massimo Lorusso, Diego Manfredi, Flaviana Calignano, Mariangela Lombardi, Sara Biamino, and Matteo Pavese. 2018. "Development and Characterisation of Aluminium Matrix Nanocomposites AlSi10Mg/MgAl2O4 by Laser Powder Bed Fusion" Metals 8, no. 3: 175. https://doi.org/10.3390/met8030175