Simulation of Compound Rolls Produced by Electroslag Remelting Cladding Method

Abstract

:1. Introduction

2. Process of ESRC

3. Mathematical Model

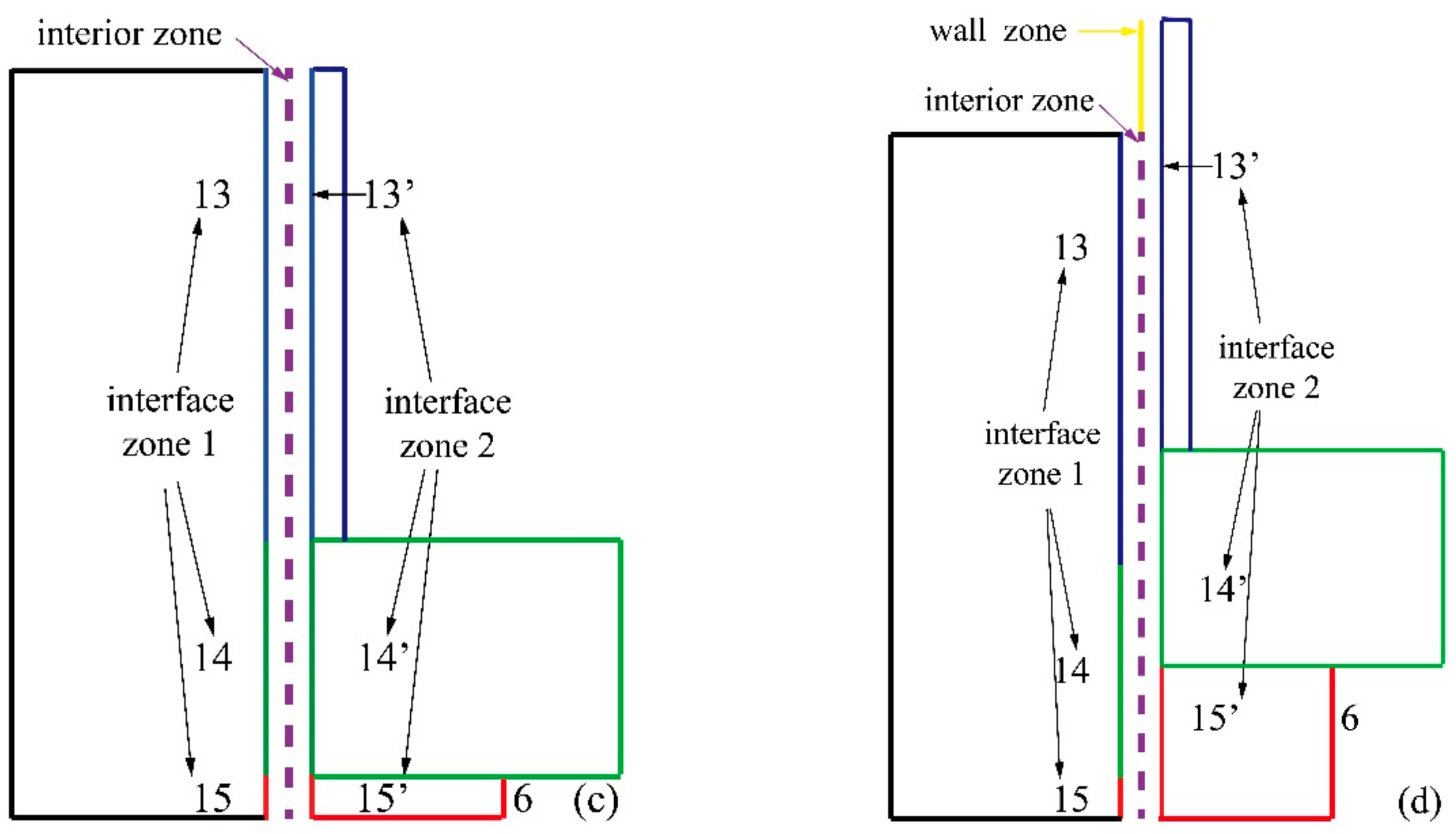

3.1. Geometric Model

3.2. Hypothesis of Model

- (1)

- As far as the physical parameters of slag and Cr5 steel are concerned, only thermal conductivity is related to temperature, and the rest is constant.

- (2)

- The melting depth into the mandrel surface was considered as the thickness of the fusion layer.

- (3)

- To improve the convergence rate, the electrical conductivity of Cr5 steel is set as zero.

- (4)

- The electrode melting rate can reach a constant within 2 min. During this period, the melting rate can be neglected, so the withdrawal starts from the steady state of the melting rate.

- (5)

- The volume of molten steel that melts from the mandrel surface is so small that its effect on the process can be ignored.

3.3. Equation

3.3.1. Electromagnetic Field Equation

3.3.2. Multiphase Flow Equation

3.3.3. Fluid Flow Equation

3.3.4. Temperature Field Equation

3.3.5. Dynamic Mesh

3.4. Physical Parameter

3.5. Process Parameters

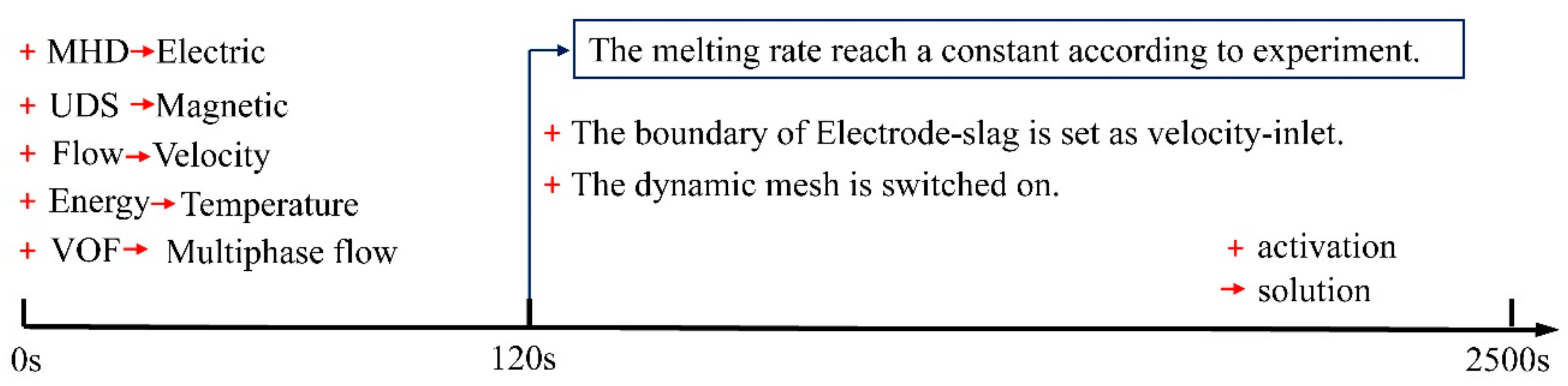

4. Solution Method

5. Results and Discussion

5.1. Basic Phenomena

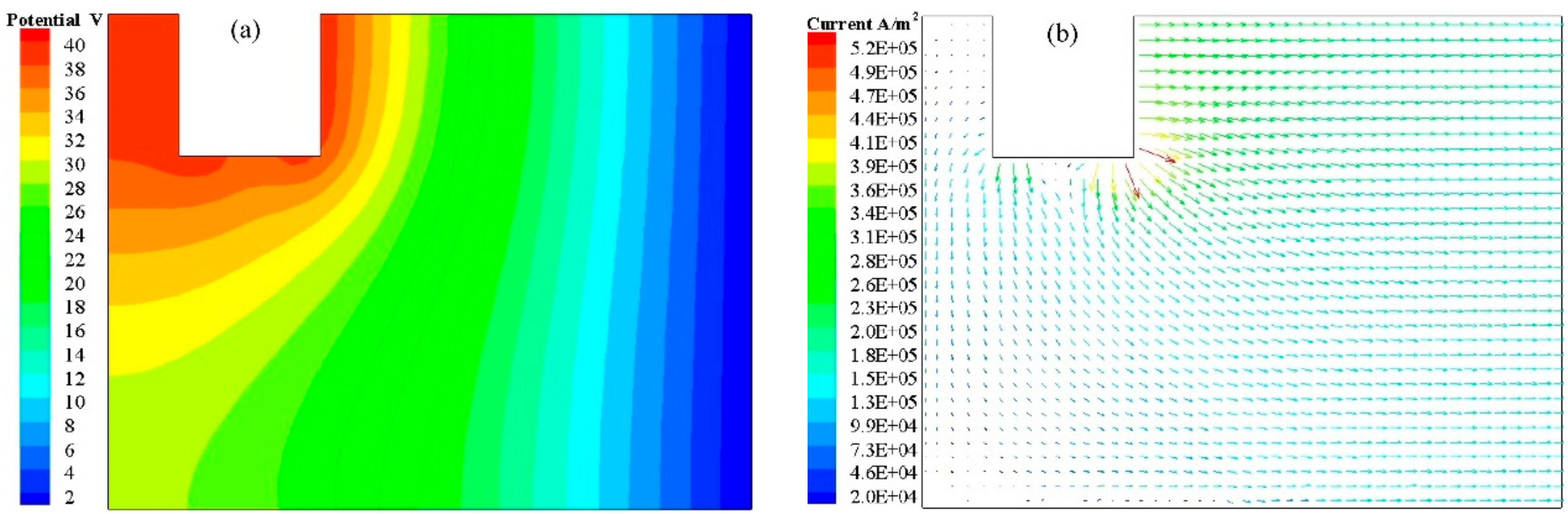

5.1.1. Electromagnetic Phenomena

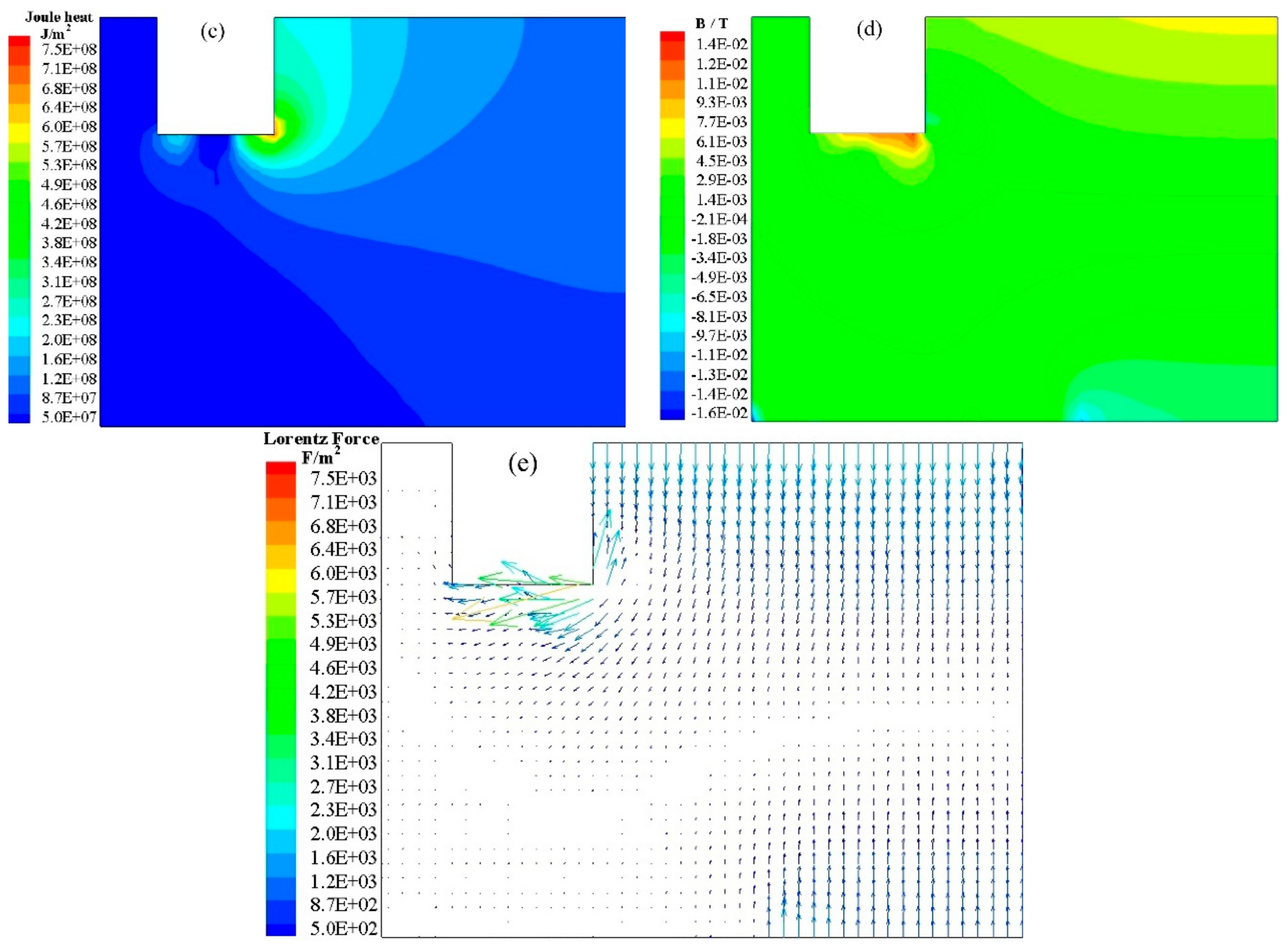

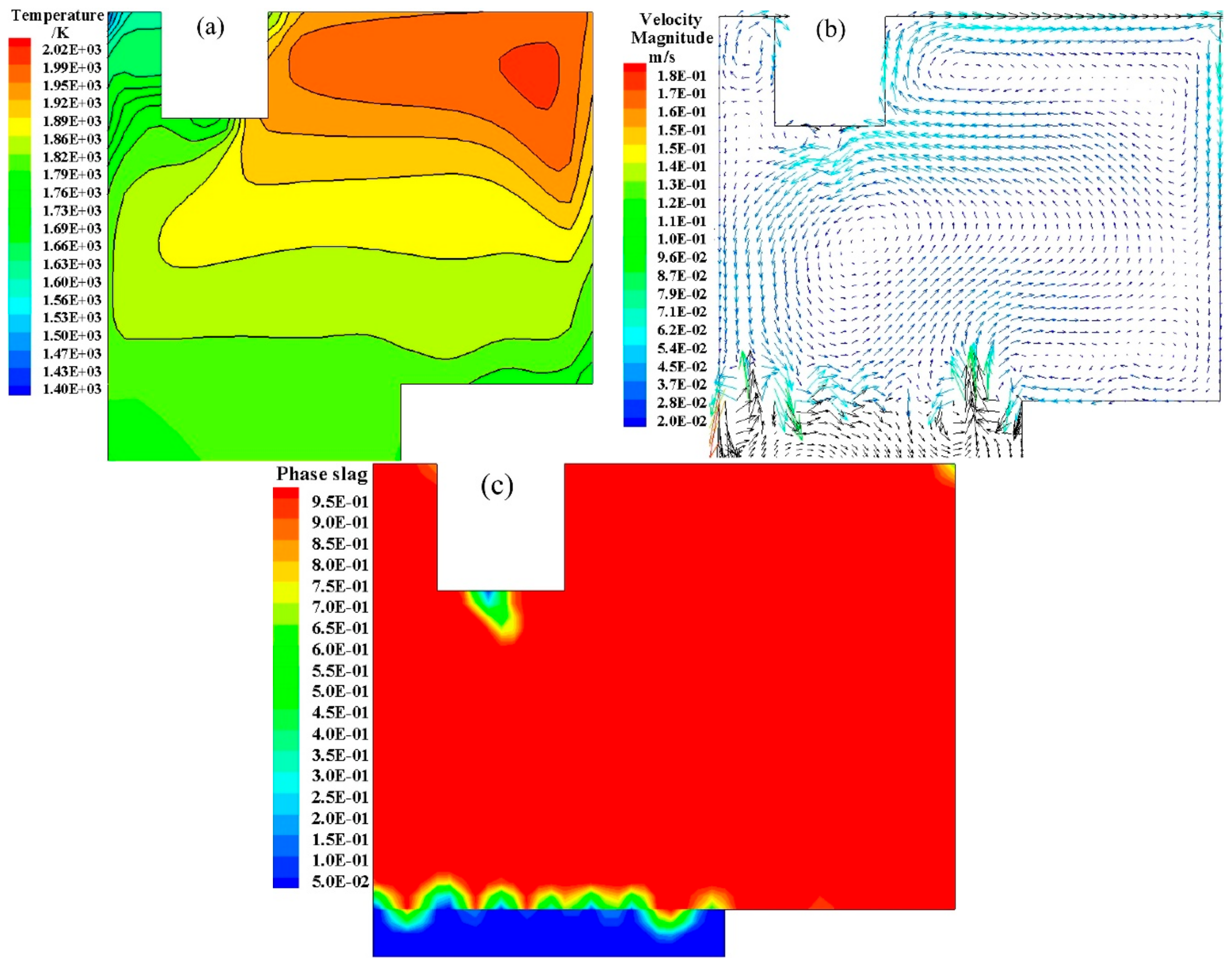

5.1.2. Flow Field and Temperature Field

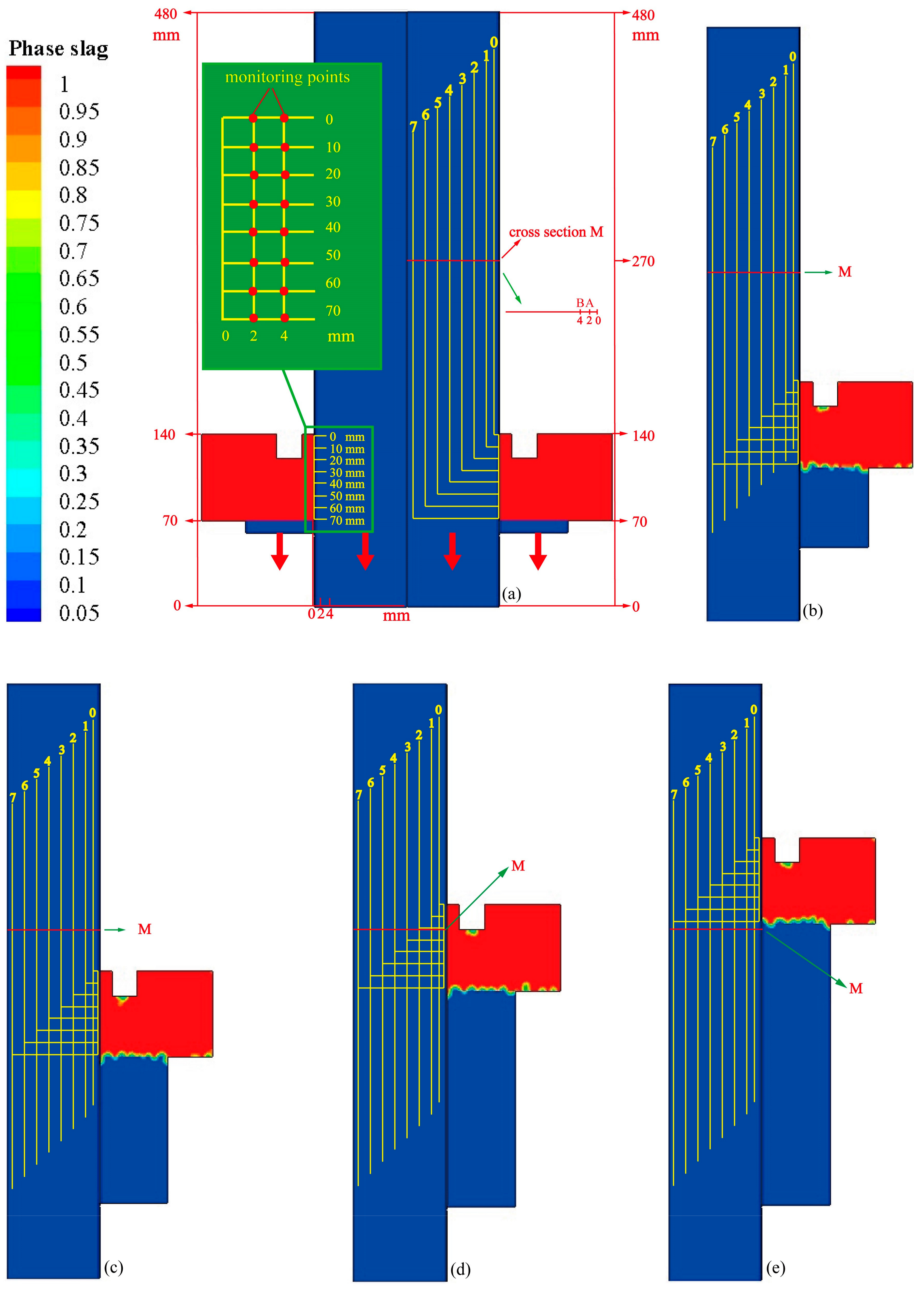

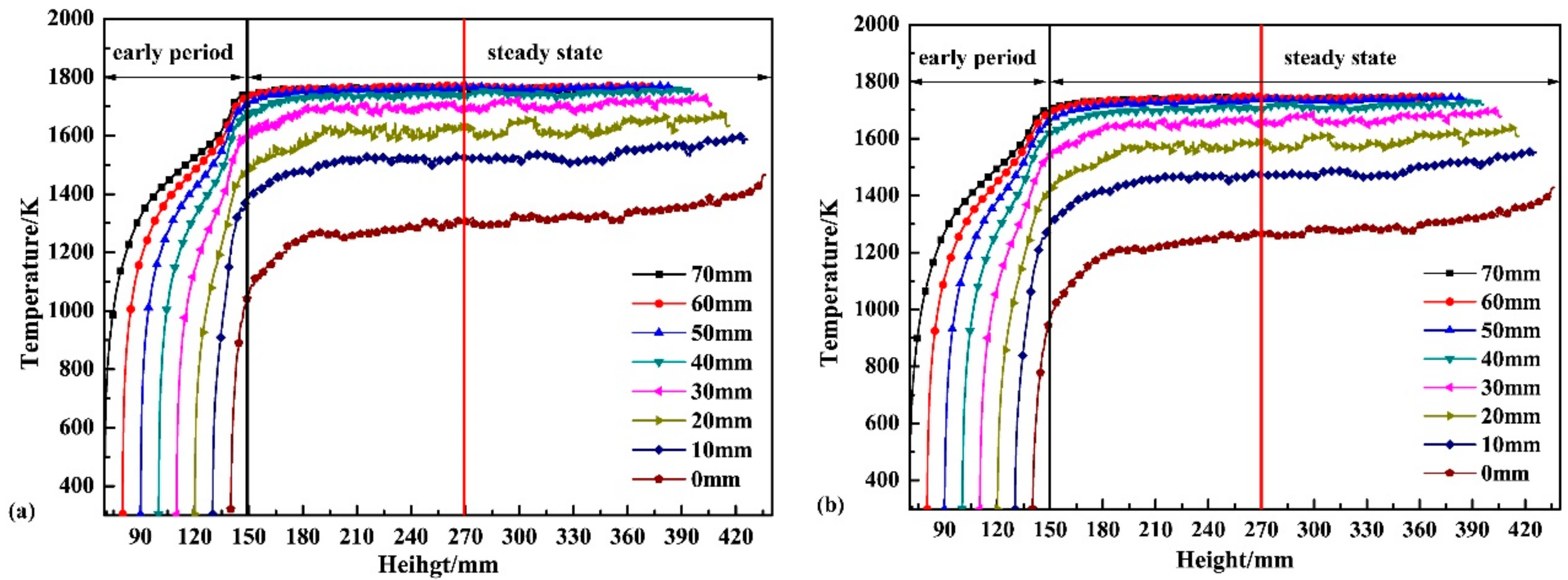

5.2. Interface Bonding Quality along the Height of the Compound Roll

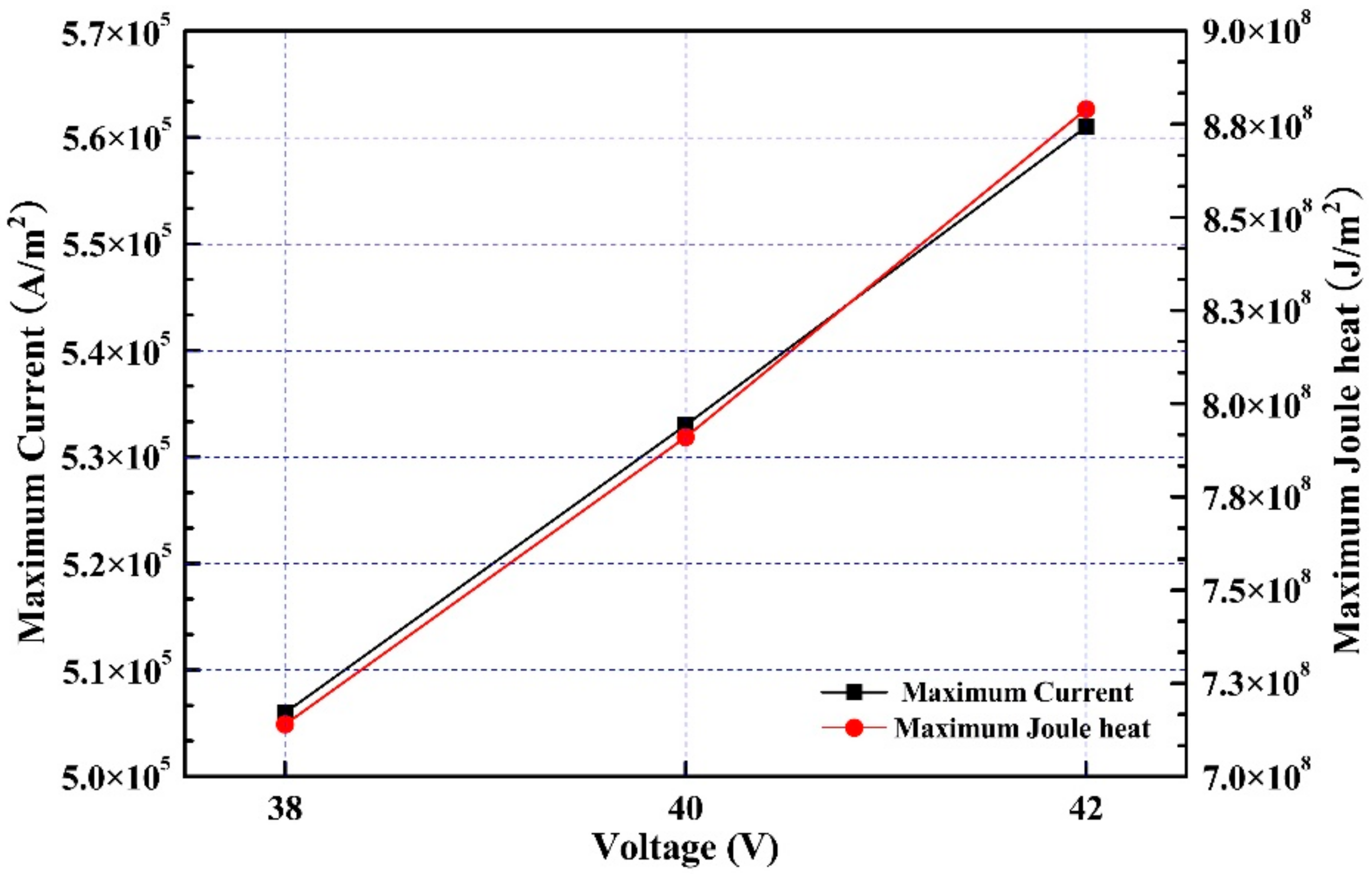

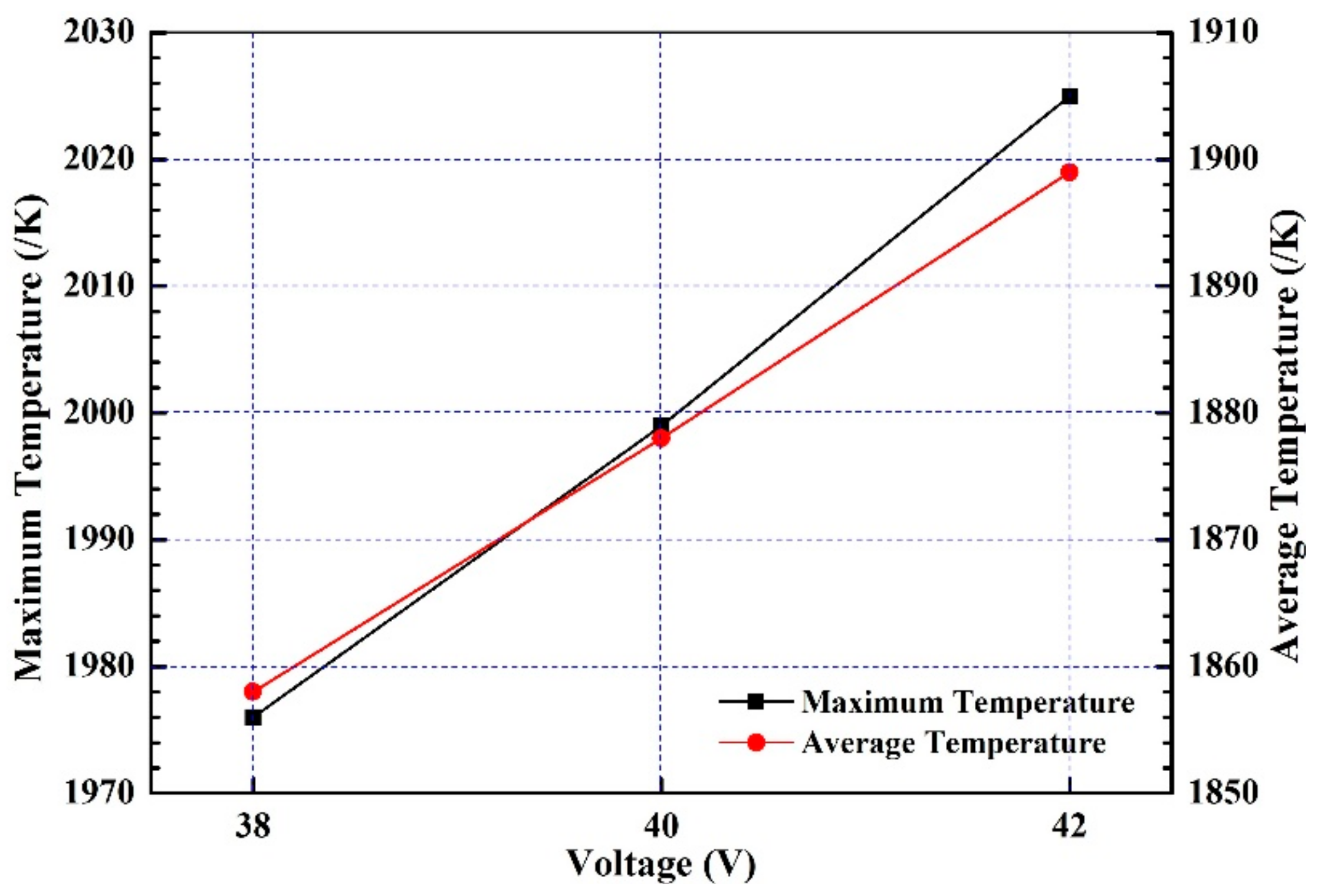

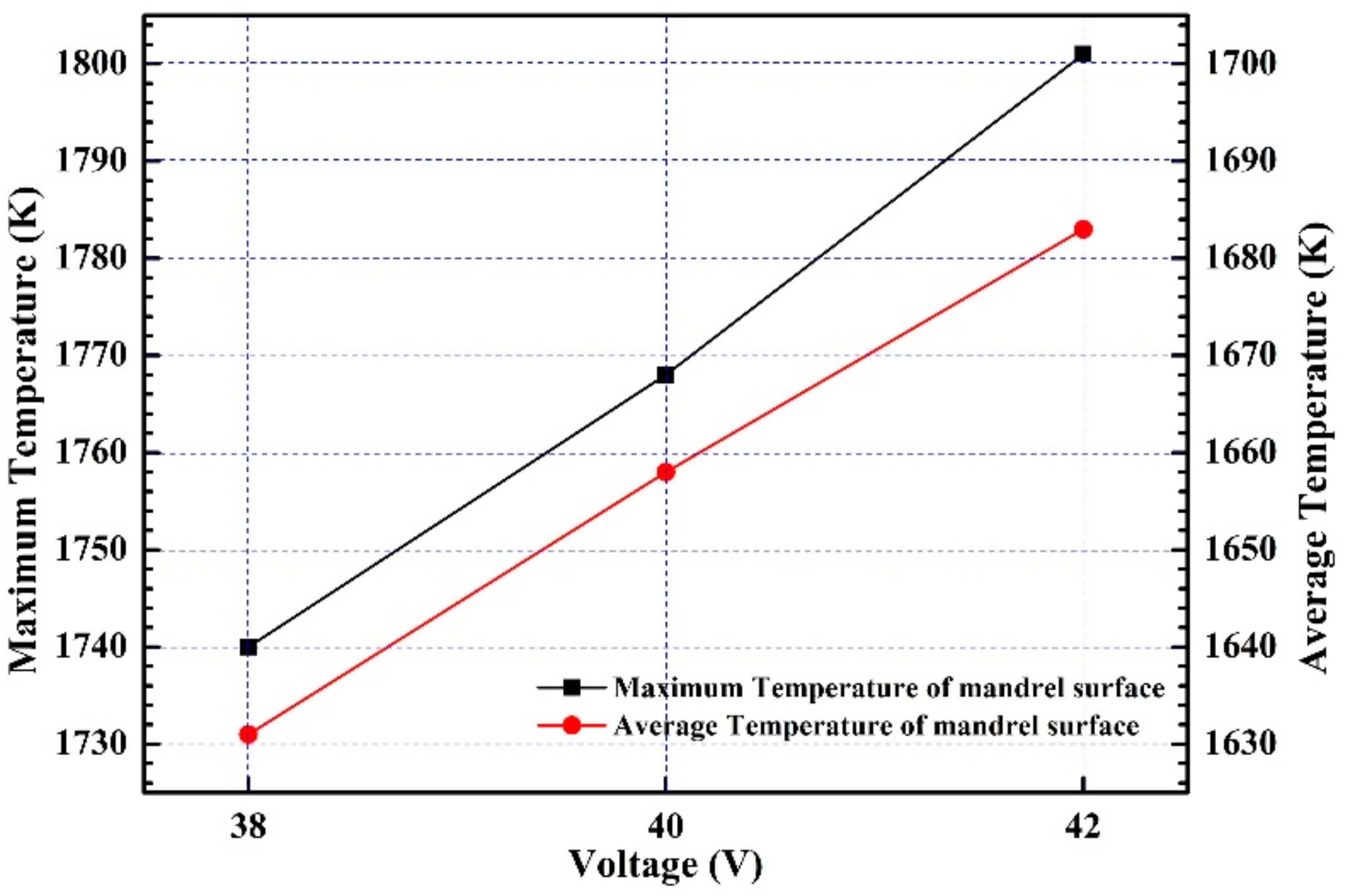

5.3. Impact of Voltage/Power on the Interface Bonding Quality

6. Conclusions

- (1)

- The current density is mainly distributed between the electrode and the mold. The joule heat density is positively correlated with the current density, so the area between electrode and mold is the highest temperature zone. Under the electrode, the Lorentz force leads to a counter-clockwise flow which helps to uniform the temperature of slag pool as well as increase the temperature of the mandrel.

- (2)

- The mandrel is divided into infinite cross sections. In the transient withdrawal process, the temperature of cross sections is analyzed to study the change of interface bonding quality along compound roll height. The temperature of mandrel surface increases until the temperature field reaches steady. The mandrel and working layer are separated in the early period because the temperature of mandrel surface is below the liquidus temperature. In steady state, the interfacial quality is dependent on the interface temperature that is affected by the voltage/power.

- (3)

- The cross-section (M) passing through slag pool is simulated to study the effect of voltage/power on interface bonding quality. The temperature of mandrel surface increases with more joule heat when the voltage ranges from 38 V to 42 V. The state of the working layer and mandrel changes from separation to connection. In the condition of 40 V, the mandrel and working layer are connected by the fusion layer thickness of 2~4 mm that is helpful to obtain a good interface bonding quality.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Pellizzari, M.; Molinari, A.; Straffelini, G. Tribological behaviour of hot rolling rolls. Wear 2005, 259, 1281–1289. [Google Scholar] [CrossRef]

- Pellizzari, M.; Cescato, D.; Flora, M.G.D. Hot friction and wear behaviour of high speed steel and high chromium iron for rolls. Wear 2009, 267, 467–475. [Google Scholar] [CrossRef]

- Luan, Y.; Song, N.; Bai, Y.; Kang, X.; Li, D. Effect of solidification rate on the morphology and distribution of eutectic carbides in centrifugal casting high-speed steel rolls. J. Mater. Process. Technol. 2010, 210, 536–541. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, Q.; Song, X.; Fu, H. Effect of electromagnetic centrifugal casting on solidification microstructure of cast high speed steel roll. Materialwiss. Werkstofftech. 2011, 42, 557–561. [Google Scholar] [CrossRef]

- Hashimoto, M.; Otomo, S.; Yoshida, K.; Kimura, K.; Kurahashi, R.; Kawakami, T.; Kouga, T. Development of high-performance roll by continuous pouring process for cladding. ISIJ Int. 1992, 32, 1202–1210. [Google Scholar] [CrossRef]

- Medovar, B.I.; Medovar, L.B.; Chemets, A.V.; Shabanov, V.B.; Sviridov, O.V. Ukrain ESS LM HSS Rolls for Hot Strip Mills. Iron and Steel Society. In Proceedings of the 42nd Mechanical Working and Steel Processing Conference, Toronto, ON, Canada, 22–25 October 2000; pp. 647–653. [Google Scholar]

- Oda, N.; Nozaki, Y.; Honda, R.; Ohata, T. Centrifugally Cast Composite Roll for Hot Rolling and Its Production Method. U.S. Patent 9757779 B2, 12 September 2017. [Google Scholar]

- Fu, H.G.; Xiao, Q.; Xing, J. Manufacture of centrifugal cast high speed steel rolls for wire rod mills. Ironmak. Steelmak. 2004, 31, 389–392. [Google Scholar] [CrossRef]

- Hashimoto, M.; Tanaka, T.; Inoue, T.; Yamashita, M.; Kurahashi, R.; Terakado, R. Development of cold rolling mill rolls of high speed steel type by using continuous pouring process for cladding. ISIJ Int. 2002, 42, 982–989. [Google Scholar] [CrossRef]

- Cao, Y.L.; Jiang, Z.H.; Dong, Y.W.; Deng, X.; Medovar, L.; Stovpchenko, G. Research on the bimetallic composite roll produced by an improved electroslag cladding method: mathematical simulation of the power supply circuits. ISIJ Int. 2018. [Google Scholar] [CrossRef]

- Dong, Y.W.; Hou, Z.H.; Jiang, Z.H.; Cao, H.B.; Feng, Q.L.; Cao, Y.L. Study of a single-power two-circuit esr process with current-carrying mold: mathematical simulation of the process and experimental verification. Metall. Mater. Trans. B 2018, 49, 249–360. [Google Scholar] [CrossRef]

- Takeuchi, E.; Zeze, M.; Tanaka, H.; Harada, H.; Mizoguchi, S. Novel continuous casting process for clad steel slabs with level dc magnetic field. Ironmak. Steelmak. 1997, 24, 257–263. [Google Scholar]

- Sano, Y.; Hattori, T.; Haga, M. Characteristics of high-carbon high speed steel rolls for hot strip mill. ISIJ Int. 1992, 32, 1194–1201. [Google Scholar] [CrossRef]

- Rao, L.; Wang, S.J.; Zhao, J.H.; Geng, M.P.; Ding, G. Experimental and simulation studies on fabricating GCr15/40Cr bimetallic compound rollers using electroslag surfacing with liquid metal method. Iron Steel Res. Int. 2014, 21, 869–877. [Google Scholar] [CrossRef]

- Yanke, J.; Fezi, K.; Trice, R.; Krane, M.J.M. Simulation of slag-skin formation in electroslag remelting using a volume-of-fluid method. Numer. Heat Transf. A 2015, 67, 268–292. [Google Scholar] [CrossRef]

- Fluent 14.5 User’s Guide; Fluent Inc.: Pittsburgh, PA, USA, 2012.

- Karimi-Sibaki, E.; Kharicha, A.; Bohacek, J.; Wu, M.H.; Ludwing, A. A dynamic mesh-based approach to model melting and shape of an ESR electrode. Metall. Mater. Trans. B 2015, 46, 2049–2061. [Google Scholar] [CrossRef]

- Kharicha, A.; Ludwig, A.; Wu, M.H. On melting of electrodes during electro-slag remelting. ISIJ Int. 2014, 54, 1621–1628. [Google Scholar] [CrossRef]

- Song, H.; Ida, N. An eddy current constraint formulation for 3D electromagnetic field calculations. IEEE Trans. Magn. 1991, 27, 4012–4015. [Google Scholar] [CrossRef]

- Kharicha, A.; Schütenhöer, W.; Ludwig, A.; Tanzer, R. Multiphase modelling of the slag region in ESR Process. In Proceedings of the 2007 International Symposium on Liquid Metal Processing and Casting, Nancy, France, 20–23 September 2007; pp. 107–116. [Google Scholar]

- Kharicha, A.; Schütenhöer, W.; Ludwig, A.; Reiter, G. Influence of the slag/pool interface on the solidification in an electro-slag remelting process. Mater. Sci. Forum 2010, 649, 229–236. [Google Scholar] [CrossRef]

- Jardy, A.; Ablitzer, D.; Wadier, J.F. Magnetohydronamic and thermal behavior of electroslag remelting slags. Metall. Mater. Trans. B 1991, 22, 111–120. [Google Scholar] [CrossRef]

- Dong, Y.W.; Jiang, Z.H.; Cao, Y.L.; Hou, D.; Liang, L.K.; Duan, J.C. Effective thermal conductivity of slag crust for ESR slag. ISIJ Int. 2015, 55, 904–906. [Google Scholar] [CrossRef]

- Yu, J.; Jiang, Z.H.; Liu, F.B.; Chen, K.; Li, H.B.; Geng, X. Effects of metal droplets on electromagnetic field, fluid flow and temperature field in electroslag remelting process. ISIJ Int. 2017, 57, 1205–1212. [Google Scholar] [CrossRef]

| Air-slag: , , , |

| Electrode-slag lateral: 1758 K, , |

| Electrode-slag: 1758 K, , |

| Ingot-slag: interior |

| Mold bottom: 1650 K, , |

| Ingot lateral: , , |

| Ingot bottom: , , |

| Slag-lateral: 1650 K, , |

| Mandrel-slag, mandrel-ingot: coupled, , |

| Item | Parameter | Value |

|---|---|---|

| Slag | Density | 2850 kg/m3 |

| Viscosity | 0.01 kg/m/s | |

| Specific heat, liquid Cp | 1404 J/kg/K | |

| 9 × 10−5/K | ||

| Emissivity of slag | 0.6 | |

| Cr5 | Density | 7800 kg/m3 |

| Viscosity of molten steel | 0.006 kg/m/s | |

| Specific heat, liquid Cp | 760 J/kg/K | |

| Thermal conductivity of solid steel | 26.5 W/m/K | |

| Thermal conductivity of molten steel | 32.5 W/m/K | |

| Steel liquidus temperature | 1758 K | |

| Steel solidus temperature | 1683 K | |

| Latent heat of solidification | 247,000 J/kg | |

| 45# | Density | 7850 kg/m3 |

| Viscosity of molten steel | 0.006 kg/m/s | |

| Specific heat, liquid Cp | 700 J/kg/K | |

| Thermal conductivity of solid steel | 25.1 w/m/K | |

| Thermal conductivity of molten steel | 33.2 w/m/K | |

| Steel liquidus temperature | 1760 K | |

| Steel solidus temperature | 1700 K | |

| Latent heat of solidification | 228,000 J/kg | |

| Air | Density | 1.2 kg/m3 |

| Viscosity | 1.7 × 10−5 kg/m/s | |

| Specific heat, liquid Cp | 1000 J/kg/K | |

| Thermal conductivity | 0.02 W/m/K |

| Case | Voltage (V) | Electrode Insertion Depth (mm) | Electrode Descending Velocity (mm/s) | Withdrawal Velocity (mm/s) |

|---|---|---|---|---|

| 1 | 42 | 20 | 0.312 | 0.105 |

| 2 | 40 | 20 | 0.257 | 0.087 |

| 3 | 38 | 20 | 0.223 | 0.075 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, Z.; Dong, Y.; Jiang, Z.; Deng, X.; Cao, Y.; Cao, H.; Medovar, L.; Stovpchenko, G. Simulation of Compound Rolls Produced by Electroslag Remelting Cladding Method. Metals 2018, 8, 504. https://doi.org/10.3390/met8070504

Hou Z, Dong Y, Jiang Z, Deng X, Cao Y, Cao H, Medovar L, Stovpchenko G. Simulation of Compound Rolls Produced by Electroslag Remelting Cladding Method. Metals. 2018; 8(7):504. https://doi.org/10.3390/met8070504

Chicago/Turabian StyleHou, Zhiwen, Yanwu Dong, Zhouhua Jiang, Xin Deng, Yulong Cao, Haibo Cao, Lev Medovar, and Ganna Stovpchenko. 2018. "Simulation of Compound Rolls Produced by Electroslag Remelting Cladding Method" Metals 8, no. 7: 504. https://doi.org/10.3390/met8070504

APA StyleHou, Z., Dong, Y., Jiang, Z., Deng, X., Cao, Y., Cao, H., Medovar, L., & Stovpchenko, G. (2018). Simulation of Compound Rolls Produced by Electroslag Remelting Cladding Method. Metals, 8(7), 504. https://doi.org/10.3390/met8070504