The Influence of Microstructural Heterogeneity on Mechanical Properties of Friction Stir Welded Joints of T6-Treated Al-Zn-Mg Alloy 7A52

Abstract

:1. Introduction

2. Material and Experimental Details

3. Results

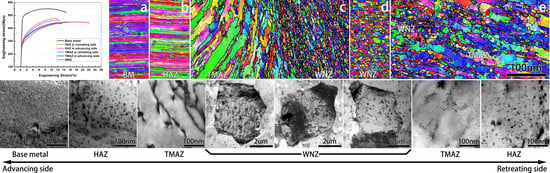

3.1. Mechanical Properties

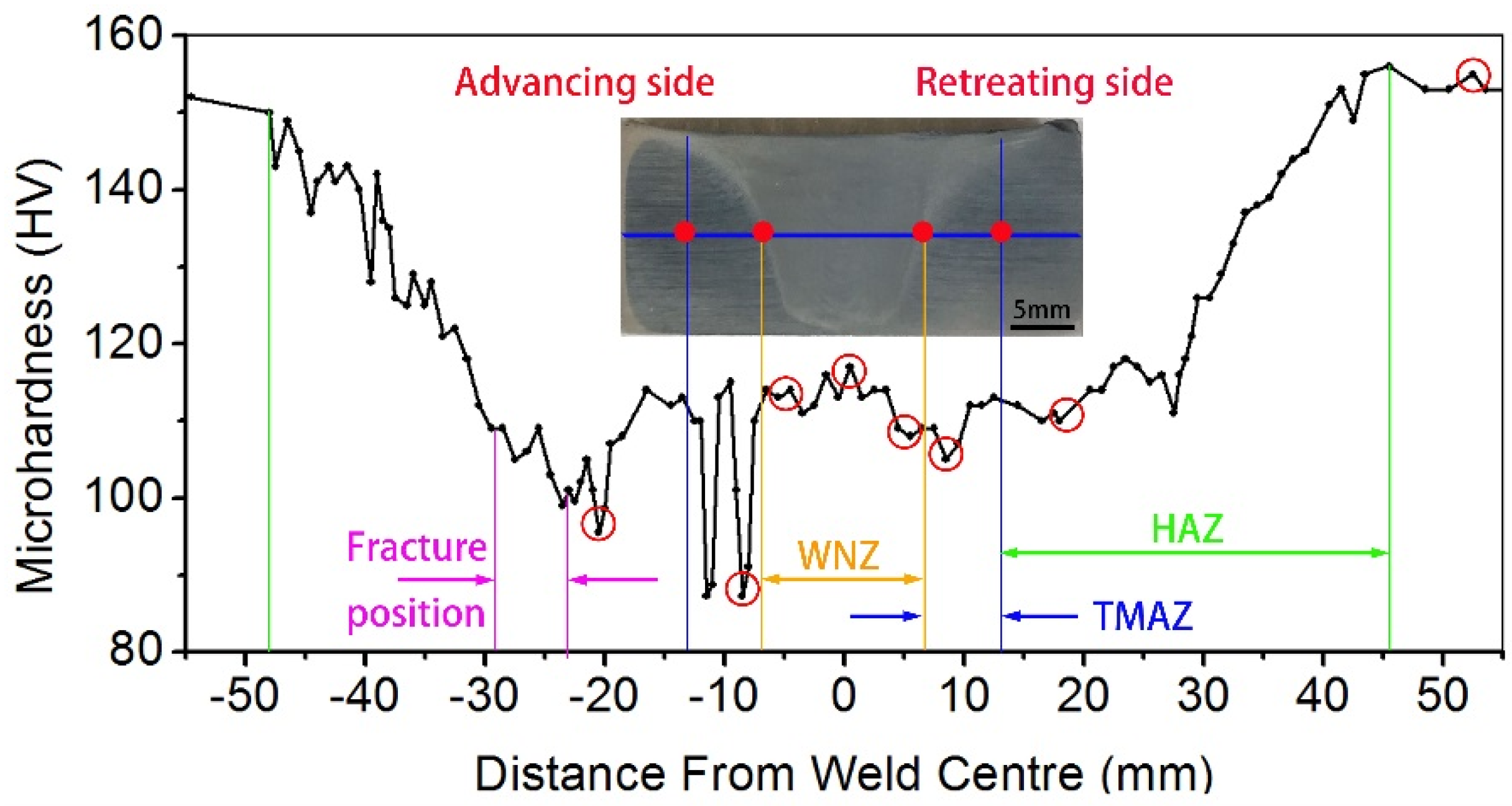

3.1.1. Hardness

3.1.2. Tensile Properties

3.2. Microstructures

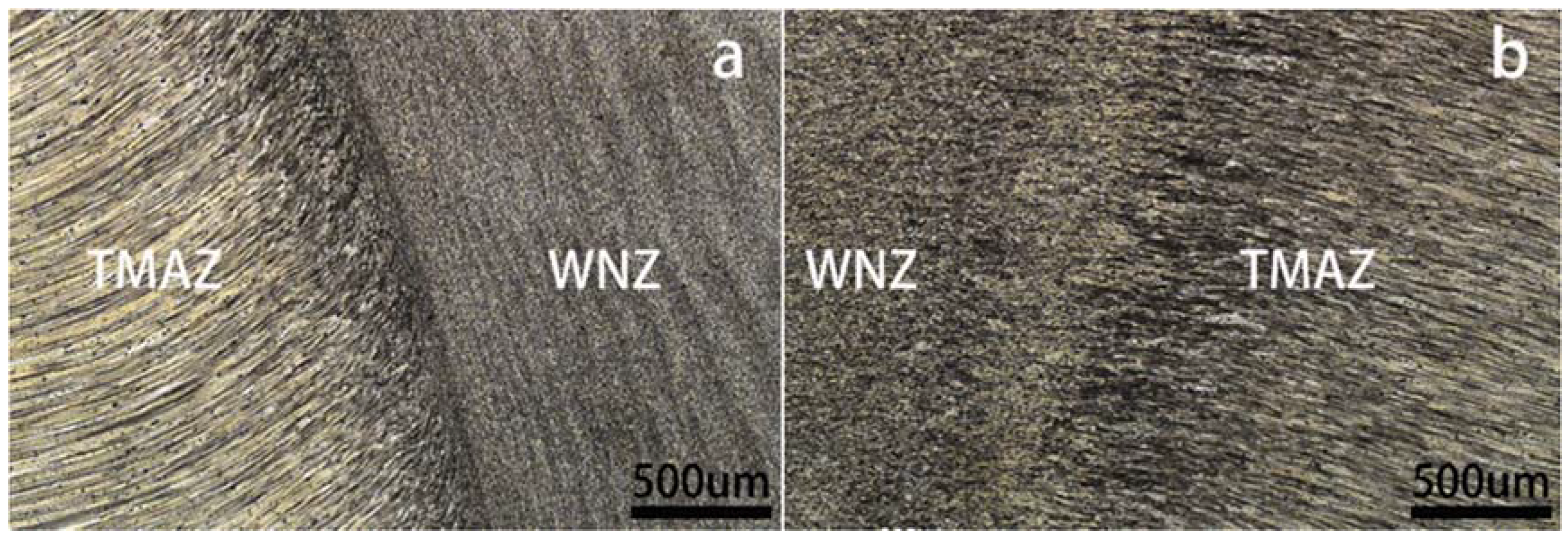

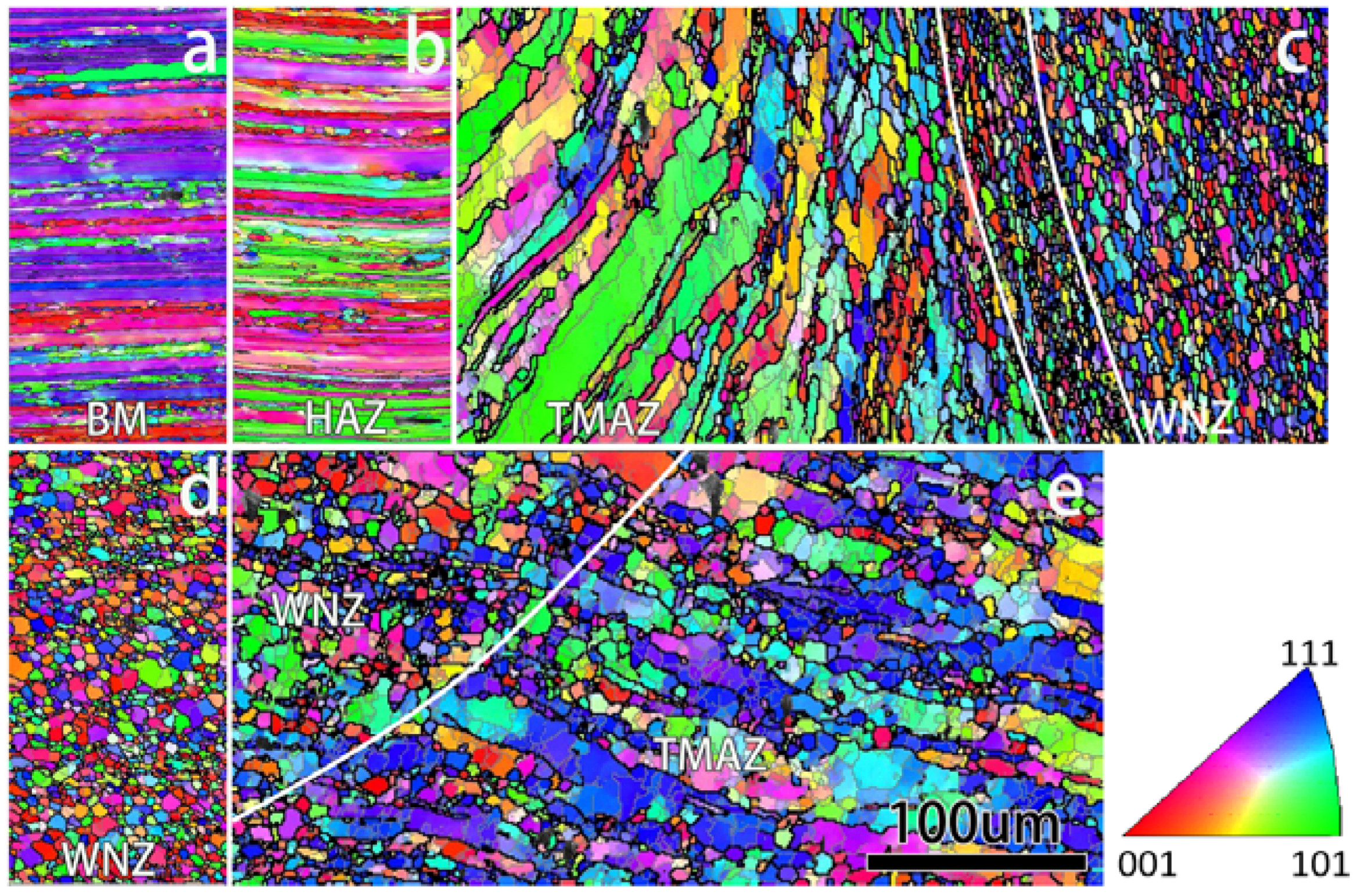

3.2.1. Grains

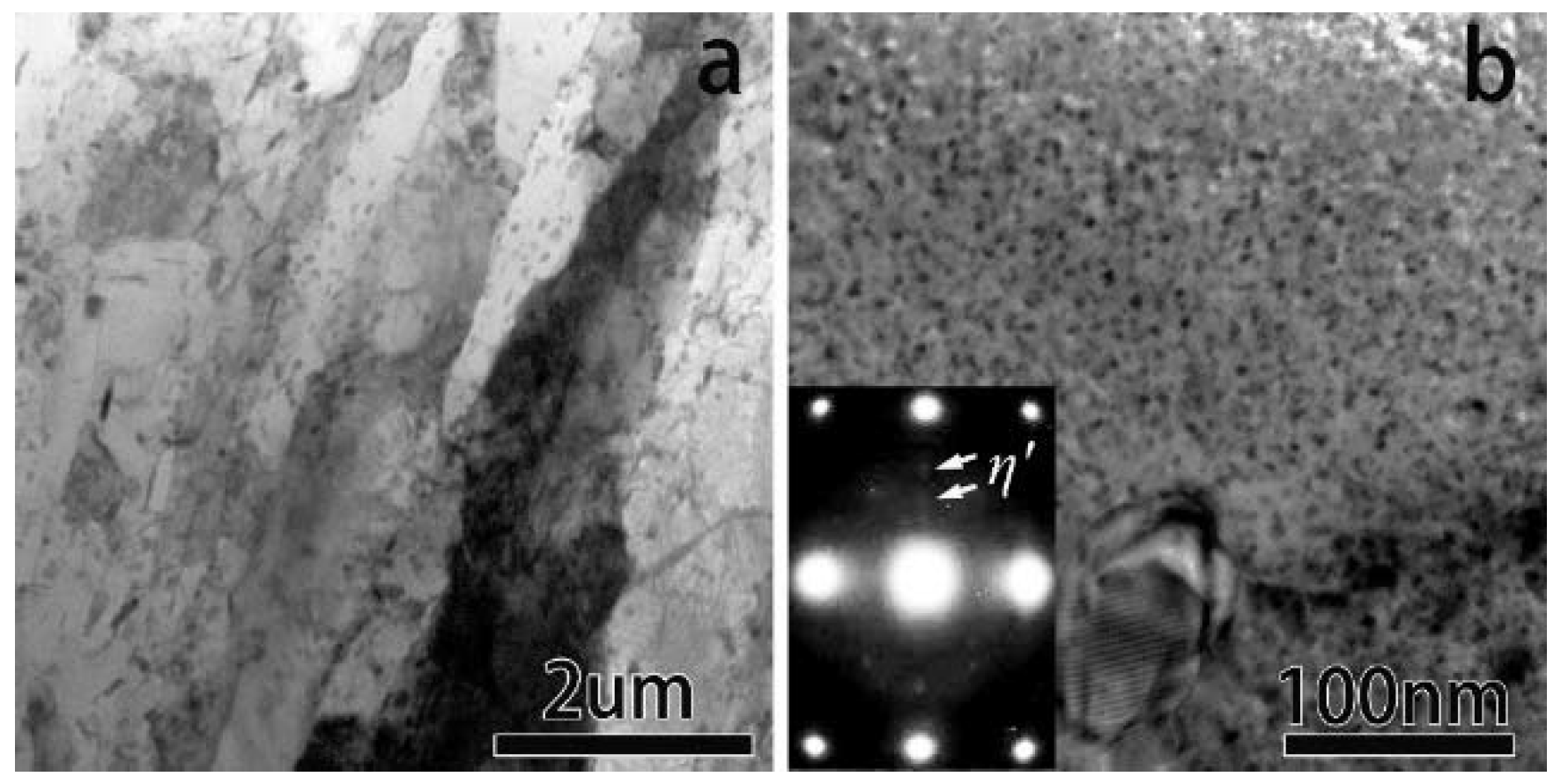

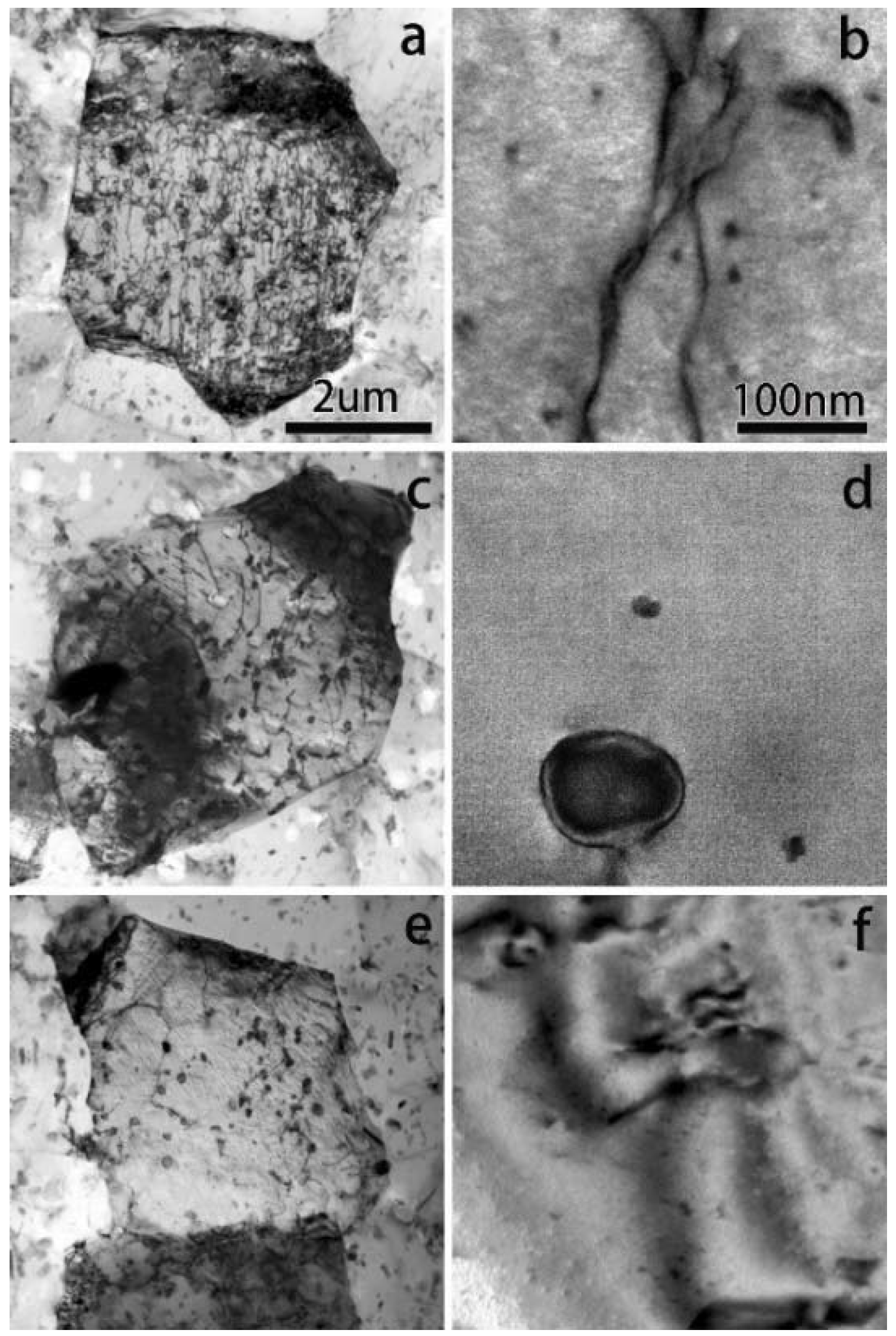

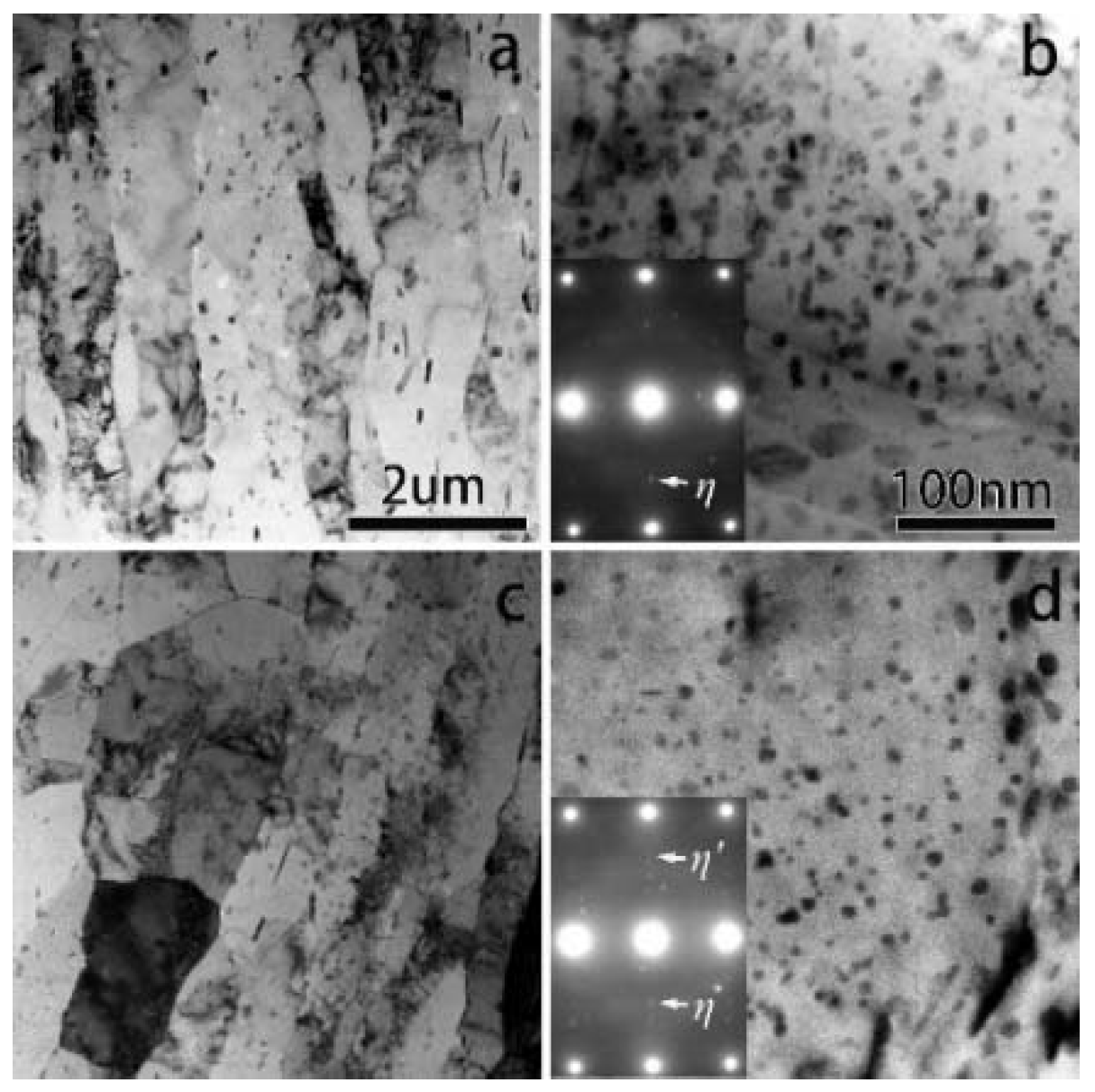

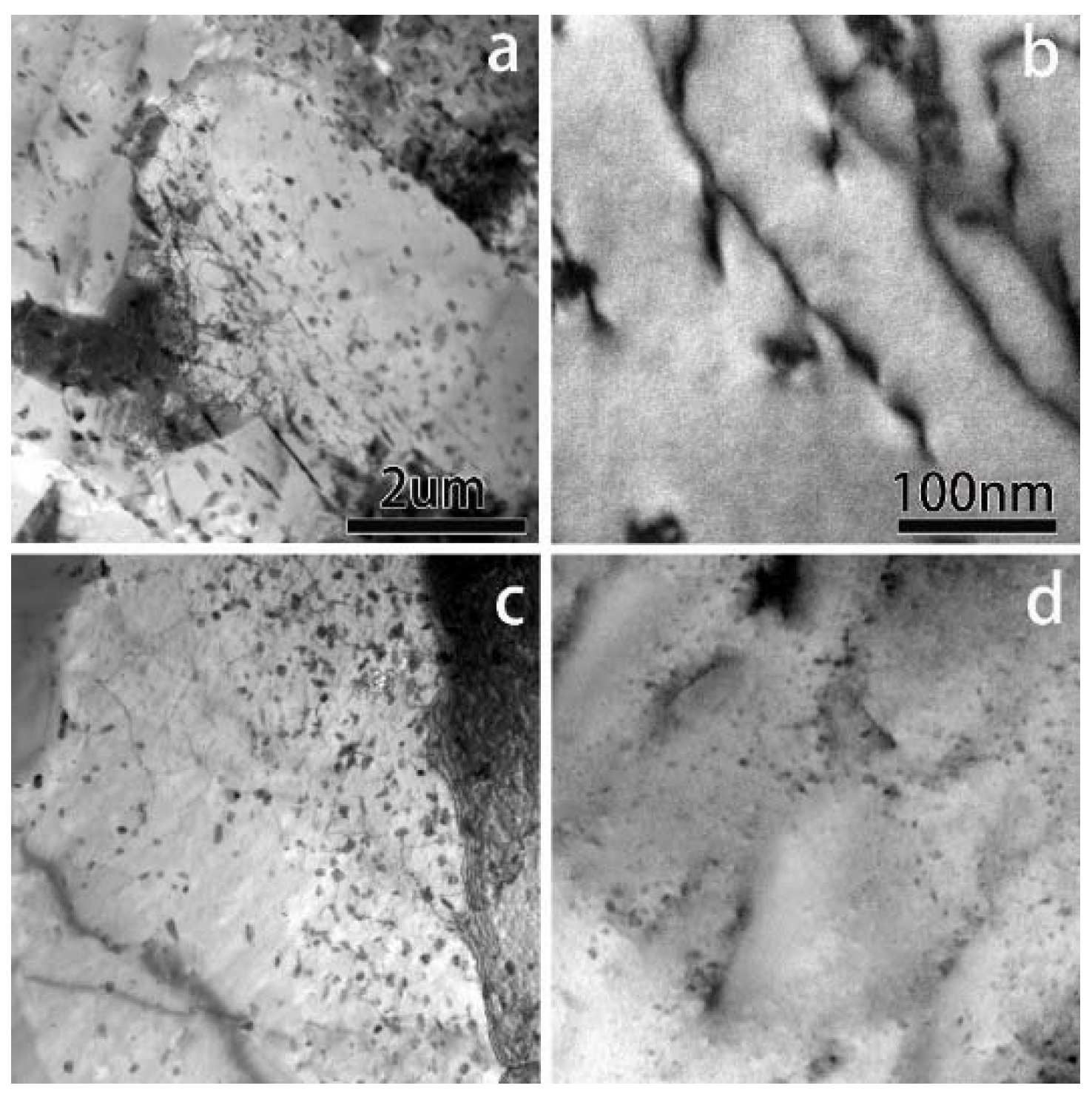

3.2.2. Microstructures in the Interior of Grains

4. Discussion

5. Conclusions

- (1)

- The hardness curve of the FSW joint is asymmetrical with respect to the weld center because of different microstructures on the advancing side and on the retreating side, introduced by non-uniform field of plastic flow.

- (2)

- Micro-tensile test results show the HAZ on the advancing side has lower strength but higher elongation than that on the retreating side because in the HAZ on the retreating side there are more η′ precipitates providing strengthening, although grain structures and the second phase are very similar in the HAZs on both sides.

- (3)

- Micro-tensile test results show the TMAZ on the advancing side has lower strength and elongation than on the retreating side. The higher strength is partially due to nano-sized precipitates, while the higher elongation is due to the higher degree of recrystallization, compared with the TMAZ on the advancing side.

- (4)

- Tensile tests with the large sample show that fracture occurs near the position in the HAZ on the advancing side with the lowest hardness. Both strength and elongation are much lower than in all other zones due to stress concentration in the area with the lowest hardness.

- (5)

- In the WNZ, the dislocation density gradually decreases from the advancing side to the retreating side, although they both contain only dynamic recrystallized grains. These dislocations are mainly caused by vacancy collapse induced by severe plastic deformation during FWS.

- (6)

- The mechanical properties of the FWS joints depend on the hardness difference throughout the joint. With larger differences in hardness, the stress concentration in the lowest hardness zone becomes more pronounced, resulting in premature failure and lowest tensile elongation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, S.S.; Jiang, J.T.; Fan, G.H.; Panindre, A.M.; Frankel, G.S.; Zhen, L. Accelerated precipitation and growth of phases in an Al-Zn-Mg-Cu alloy processed by surface abrasion. Acta Mater. 2017, 131, 233–245. [Google Scholar] [CrossRef]

- Ma, K.; Hu, T.; Yang, H.; Topping, T.; Yousefiani, A.; Lavernia, E.J.; Schoenung, J.M. Coupling of dislocations and precipitates: Impact on the mechanical behavior of ultrafine grained Al-Zn-Mg alloys. Acta Mater. 2016, 103, 153–164. [Google Scholar] [CrossRef]

- Williams, J.C.; Starke, E.A. Progress in structural materials for aerospace systems 11 The Golden Jubilee Issue-Selected topics in Materials Science and Engineering: Past, Present and Future, edited by S. Suresh. Acta Mater. 2003, 51, 5775–5799. [Google Scholar] [CrossRef]

- Sharma, C.; Dwivedi, D.K.; Kumar, P. Influence of pre-weld temper conditions of base metal on microstructure and mechanical properties of friction stir weld joints of Al-Zn-Mg alloy AA7039. Mater. Sci. Eng. 2015, 620, 107–119. [Google Scholar] [CrossRef]

- Starke, E.A.; Staley, J.T. Application of modern aluminum alloys to aircraft. Prog. Aerosp. Sci. 1996, 32, 131–172. [Google Scholar] [CrossRef]

- Zhang, Z.; Xiao, B.L.; Ma, Z.Y. Hardness recovery mechanism in the heat-affected zone during long-term natural aging and its influence on the mechanical properties and fracture behavior of friction stir welded 2024Al–T351 joints. Acta Mater. 2014, 73, 227–239. [Google Scholar] [CrossRef]

- Hornbogen, E. Hundred years of precipitation hardening. J. Light Met. 2001, 1, 127–132. [Google Scholar] [CrossRef]

- Lendvai, J. Precipitation and Strengthening in Aluminium Alloys. Mate. Sci. Forum 1996, 217, 43–56. [Google Scholar] [CrossRef]

- Liu, F.C.; Nelson, T.W. Grain structure evolution, grain boundary sliding and material flow resistance in friction welding of Alloy 718. Mater. Sci. Eng. 2018, 710, 280–288. [Google Scholar] [CrossRef]

- Komarasamy, M.; Alagarsamy, K.; Ely, L.; Mishra, R.S. Characterization of 3″ through-thickness friction stir welded 7050-T7451 Al alloy. Mater. Sci. Eng. 2018, 716, 55–62. [Google Scholar] [CrossRef]

- Dos Santos, J.F.; Staron, P.; Fischer, T.; Robson, J.D.; Kostka, A.; Colegrove, P.; Wang, H.; Hilgert, J.; Bergmann, L.; Hütsch, L.L.; et al. Understanding precipitate evolution during friction stir welding of Al-Zn-Mg-Cu alloy through in-situ measurement coupled with simulation. Acta Mater. 2018, 148, 163–172. [Google Scholar] [CrossRef]

- Sun, T.; Reynolds, A.P.; Roy, M.J.; Withers, P.J.; Prangnell, P.B. The Effect of Shoulder Coupling on the Residual Stress and Hardness Distribution in AA7050 Friction Stir Butt Welds. Mater. Sci. Eng. 2017. [Google Scholar] [CrossRef]

- Hannard, F.; Castin, S.; Maire, E.; Mokso, R.; Pardoen, T.; Simar, A. Ductilization of aluminium alloy 6056 by friction stir processing. Acta Mater. 2017, 130, 121–136. [Google Scholar] [CrossRef]

- Malard, B.; De Geuser, F.; Deschamps, A. Microstructure distribution in an AA2050 T34 friction stir weld and its evolution during post-welding heat treatment. Acta Mater. 2015, 101, 90–100. [Google Scholar] [CrossRef] [Green Version]

- Xu, W.F.; Liu, J.H.; Chen, D.L.; Luan, G.H.; Yao, J.S. Change of microstructure and cyclic deformation behavior along the thickness in a friction-stir-welded aluminum alloy. Scr. Mater. 2012, 66, 5–8. [Google Scholar] [CrossRef]

- Sato, Y.S.; Watanabe, H.; Kokawa, H. Grain growth phenomena in friction stir welded 1100 Al during post-weld heat treatment. Sci. Technol. Weld. Join. 2007, 12, 318–323. [Google Scholar] [CrossRef]

- Cabibbo, M.; McQueen, H.J.; Evangelista, E.; Spigarelli, S.; Di Paola, M.; Falchero, A. Microstructure and mechanical property studies of AA6056 friction stir welded plate. Mater. Sci. Eng. A 2007, 460–461, 86–94. [Google Scholar] [CrossRef]

- Fratini, L.; Buffa, G.; Shivpuri, R. Mechanical and metallurgical effects of in process cooling during friction stir welding of AA7075-T6 butt joints. Acta Mater. 2010, 58, 2056–2067. [Google Scholar] [CrossRef]

- Cai, B.; Adams, B.L.; Nelson, T.W. Relation between precipitate-free zone width and grain boundary type in 7075-T7 Al alloy. Acta Mater. 2007, 55, 1543–1553. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Mishra, R.S. Cavitation in superplastic 7075Al alloys prepared via friction stir processing. Acta Mater. 2003, 51, 3551–3569. [Google Scholar] [CrossRef]

- Rhodes, C.G.; Mahoney, M.W.; Bingel, W.H.; Spurling, R.A.; Bampton, C.C. Effects of friction stir welding on microstructure of 7075 aluminum. Scr. Mater. 1997, 36, 69–75. [Google Scholar] [CrossRef]

- Su, J.Q.; Nelson, T.W.; Mishra, R.; Mahoney, M. Microstructural investigation of friction stir welded 7050-T651 aluminium. Acta Mater. 2003, 51, 713–729. [Google Scholar] [CrossRef]

- Sharma, C.; Dwived, D.K.; Kumar, P. Friction Stir Welding of Al–Zn–Mg Alloy AA7039. In Light Metals 2012; Suarez, C.E., Ed.; Springer: Cham, Switzerland, 2016; pp. 503–507. [Google Scholar]

- Singh, R.K.R.; Sharma, C.; Dwivedi, D.K.; Mehta, N.K.; Kumar, P. The microstructure and mechanical properties of friction stir welded Al-Zn-Mg alloy in as welded and heat treated conditions. Mater. Des. 2011, 32, 682–687. [Google Scholar] [CrossRef]

- Sharma, C.; Dwivedi, D.K.; Kumar, P. Effect of welding parameters on microstructure and mechanical properties of friction stir welded joints of AA7039 aluminum alloy. Mater. Des. 2012, 36, 379–390. [Google Scholar] [CrossRef]

- Sharma, C.; Dwived, D.K.; Kumar, P. Effect of post weld heat treatments on microstructure and mechanical properties of friction stir welded joints of Al-Zn-Mg alloy AA7039. Mater. Des. 2013, 43, 134–143. [Google Scholar] [CrossRef]

- Sharma, C.; Dwivedi, D.K.; Kumar, P. Fatigue behavior of friction stir weld joints of Al–Zn–Mg alloy AA7039 developed using base metal in different temper condition. Mater. Des. 2014, 64, 334–344. [Google Scholar] [CrossRef]

- Steuwer, A.; Dumont, M.; Peel, M.; Preuss, M.; Withers, P.J. The variation of the unstrained lattice parameter in an AA7010 friction stir weld. Acta Mater. 2007, 55, 4111–4120. [Google Scholar] [CrossRef]

- Liu, J.Z.; Chen, J.H.; Yuan, D.W.; Wu, C.L.; Zhu, J.; Cheng, Z.Y. Fine precipitation scenarios of AlZnMg(Cu) alloys revealed by advanced atomic-resolution electron microscopy study Part I: Structure determination of the precipitates in AlZnMg(Cu) alloys. Mater. Charact. 2015, 99, 277–286. [Google Scholar] [CrossRef]

- Liu, J.Z.; Chen, J.H.; Liu, Z.R.; Wu, C.L. Fine precipitation scenarios of AlZnMg(Cu) alloys revealed by advanced atomic-resolution electron microscopy study Part II: Fine precipitation scenarios in AlZnMg(Cu) alloys. Mater. Charact. 2015, 99, 142–149. [Google Scholar] [CrossRef]

- Sha, G.; Cerezo, A. Early-stage precipitation in Al-Zn-Mg-Cu alloy (7050). Acta Mater. 2004, 52, 4503–4516. [Google Scholar] [CrossRef]

- Auld, J.H.; Cousland, S.M. The structure of the metastable η′ phase in aluminium-zinc-magnesium Alloys. J. Aust. Inst. Met. 1974, 19, 194–199. [Google Scholar]

- Kverneland, A.; Hansen, V.; Vincent, R.; Gjønnes, K.; Gjønnes, J. Structure analysis of embedded nano-sized particles by precession electron diffraction. η′-precipitate in an Al–Zn–Mg alloy as example. Ultramicroscopy 2006, 106, 492–502. [Google Scholar] [CrossRef] [PubMed]

- Waterloo, G.; Hansen, V.; Gjønnes, J.; Skjervold, S.R. Effect of predeformation and preaging at room temperature in Al–Zn–Mg–(Cu,Zr) alloys. Mater. Sci. Eng. A 2001, 303, 226–233. [Google Scholar] [CrossRef]

- Li, X.Z.; Hansen, V.; GjØnnes, J.; Wallenberg, L.R. HREM study and structure modeling of the η′ phase, the hardening precipitates in commercial Al-Zn-Mg alloys. Acta Mater. 1999, 47, 2651–2659. [Google Scholar] [CrossRef]

- Berg, L.K.; Gjønnes, J.; Hansen, V.; Li, X.Z.; Knutson-Wedel, M.; Waterloo, G.; Schryvers, D.; Wallenberg, L.R. GP-zones in Al-Zn-Mg alloys and their role in artificial aging. Acta Mater. 2001, 49, 3443–3451. [Google Scholar] [CrossRef]

- Stiller, K.; Warren, P.J.; Hansen, V.; Angenete, J.; Gjønnes, J. Investigation of precipitation in an Al-Zn-Mg alloy after two-step ageing treatment at 100° and 150 °C. Mater. Sci. Eng. A 1999, 270, 55–63. [Google Scholar] [CrossRef]

- Blaschko, O.; Ernst, G.; Fratzl, P.; Bernole, M.; Auger, P. A neutron scattering investigation of the early stages of guinier-preston zone formation in AlZnMg(Cu)-alloys. Acta Met. 1982, 30, 547–552. [Google Scholar] [CrossRef]

- Murakami, M.; Kawano, O.; Murakami, Y. The formation and reversion of guinier-preston zones in an aluminium-6.7 at. % zinc alloy and the effects of small concentrations of magnesium and silver. Acta Met. 1969, 17, 29–40. [Google Scholar] [CrossRef]

- Jiang, X.J.; Tafto, J.; Noble, B.; Holme, B.; Waterloo, G. Differential scanning calorimetry and electron diffraction investigation on low-temperature aging in Al-Zn-Mg alloys. Met. Mater. Trans. A 2000, 31, 339–348. [Google Scholar] [CrossRef]

- Frigaard, Ø.; Grong, Ø.; Midling, O.T. A process model for friction stir welding of age hardening aluminum alloys. Met. Mater. Trans. A 2001, 32, 1189–1200. [Google Scholar] [CrossRef]

| Al | Zn | Mg | Mn | Cr | Zr | Ti | V | Cu | Fe | Si |

|---|---|---|---|---|---|---|---|---|---|---|

| Bal. | 4.40 | 2.33 | 0.27 | 0.18 | 0.083 | 0.094 | 0.008 | 0.10 | 0.21 | 0.071 |

| Locations | UTS (MPa) | YS (MPa) | Elongation (%) | Strength Coefficient (%) | Elongation Coefficient (%) |

|---|---|---|---|---|---|

| Base metal | 551.5 ± 15 | 483.7 ± 12 | 14.7 ± 1 | - | - |

| HAZ on advancing side | 464.5 ± 15 | 286.6 ± 10 | 12.5 ± 1 | 84.2 | 85.0 |

| TMAZ on advancing side | 442.9 ± 15 | 270.9 ± 10 | 13.3 ± 1 | 80.3 | 90.5 |

| WNZ | 449.2 ± 8 | 247.9 ± 5 | 21.9 ± 1 | 81.5 | 149.0 |

| TMAZ on retreating side | 448.8 ± 10 | 275.9 ± 8 | 16.6 ± 1 | 81.4 | 113.0 |

| HAZ on retreating side | 477.9 ± 10 | 290.8 ± 8 | 11.9 ± 1 | 86.7 | 81.0 |

| The whole weld joint | 420.0 ± 20 | - | 10.0 ± 2 | 76.2 | 68.0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, Y.; Qin, Y.; Ou, Y.; Wang, K.; Liu, J. The Influence of Microstructural Heterogeneity on Mechanical Properties of Friction Stir Welded Joints of T6-Treated Al-Zn-Mg Alloy 7A52. Metals 2018, 8, 527. https://doi.org/10.3390/met8070527

Jia Y, Qin Y, Ou Y, Wang K, Liu J. The Influence of Microstructural Heterogeneity on Mechanical Properties of Friction Stir Welded Joints of T6-Treated Al-Zn-Mg Alloy 7A52. Metals. 2018; 8(7):527. https://doi.org/10.3390/met8070527

Chicago/Turabian StyleJia, Yang, Yonggui Qin, Yiwen Ou, Kehong Wang, and Jizi Liu. 2018. "The Influence of Microstructural Heterogeneity on Mechanical Properties of Friction Stir Welded Joints of T6-Treated Al-Zn-Mg Alloy 7A52" Metals 8, no. 7: 527. https://doi.org/10.3390/met8070527