Structure of Solidified Films of CaO-SiO2-Na2O Based Low-Fluorine Mold Flux

Abstract

:1. Introduction

2. Experimental Method

2.1. Mold Flux Selection and Slag Film Acquisition

2.2. Measurements on Solidified Films

3. Results and Discussions

3.1. Thickness and Heat Flux Density of Solid Films

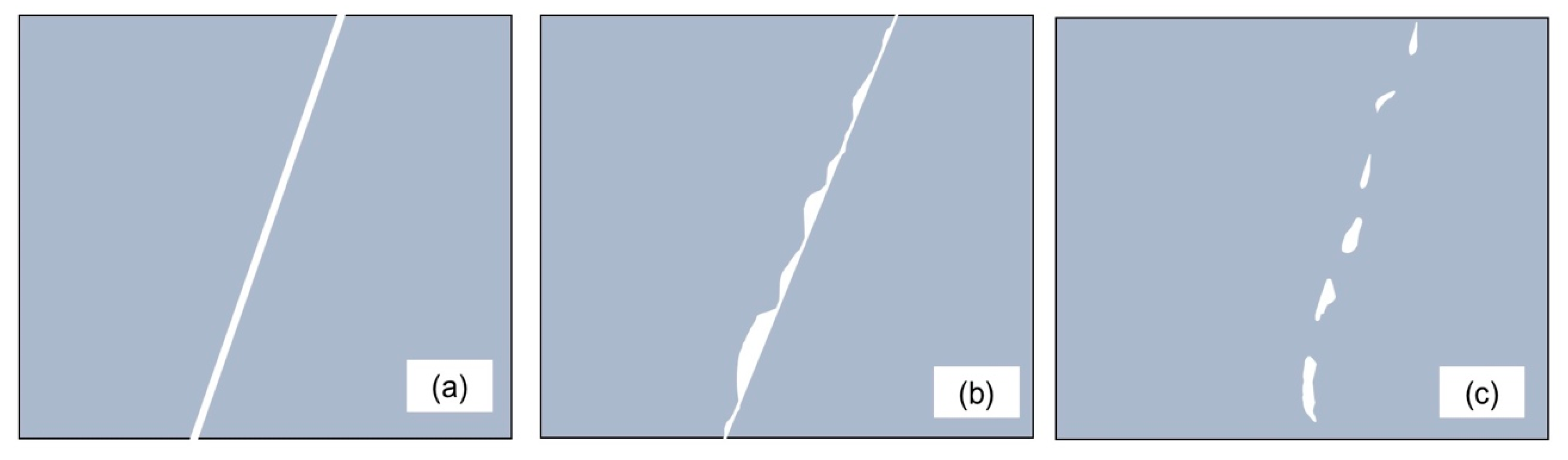

3.2. Cracks Formed in the Glassy Layer

3.3. Surface Roughness of Solid Films

3.4. Closed Porosity and Crystallization of Films

3.5. Density Evolution of Solidified Films

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nakada, H.; Susa, M.; Seko, Y.; Hayashi, M.; Nagata, K. Mechanism of Heat Transfer Reduction by Crystallization of Mold Flux for Continuous Casting. ISIJ Int. 2008, 48, 446–453. [Google Scholar] [CrossRef] [Green Version]

- Yamauchi, A.; Sorimachi, K.; Sakuraya, T.; Fujii, T. Heat Transfer between Mold and Strand through Mold Flux Film in Continuous Casting of Steel. ISIJ Int. 1993, 33, 140–147. [Google Scholar] [CrossRef]

- Mills, K.C.; Fox, A.B. The Role of Mould Fluxes in Continuous Casting-So Simple Yet So Complex. ISIJ Int. 2003, 43, 1479–1486. [Google Scholar] [CrossRef] [Green Version]

- Mills, K.C.; Fox, A.B.; Li, Z.; Thackray, R.P. VII International Conference on Molten Slags, Fluxes & Salts: 25–28 January 2004, Cape Town, South Africa]; The South African Institute of Mining and Metallurgy: Johannesburg, South Africa, 2004. [Google Scholar]

- Brimacombe, J.; Sorimachi, K. Crack formation in the continuous casting of steel. Metall. Trans. B 1977, 8, 489–505. [Google Scholar] [CrossRef]

- Fox, A.; Mills, K.; Lever, D.; Bezerra, C.; Valadares, C.; Unamuno, I.; Laraudogoitia, J.; Gisby, J. Development of Fluoride-Free Fluxes for Billet Casting. ISIJ Int. 2005, 45, 1051–1058. [Google Scholar] [CrossRef] [Green Version]

- Nakada, H.; Fukuyama, H.; Nagata, K. Effect of NaF Addition to Mold Flux on Cuspidine Primary Field. ISIJ Int. 2006, 46, 1660–1667. [Google Scholar] [CrossRef] [Green Version]

- Nakada, H.; Nagata, K. Crystallization of CaO–SiO2–TiO2 slag as a candidate for fluorine free mold flux. ISIJ Int. 2006, 46, 441–449. [Google Scholar] [CrossRef]

- Cho, J.W.; Emi, T.; Shibata, H.; Suzuki, M. Heat transfer across mold flux film in mold during initial solidification in continuous casting of steel. ISIJ Int. 1998, 38, 834–842. [Google Scholar] [CrossRef]

- Seo, M.D.; Shi, C.B.; Cho, J.W.; Kim, S.H. Crystallization behaviors of CaO-SiO2-Al2O3-Na2O-CaF2-(Li2O-B2O3) mold fluxes. Metall. Mater. Trans. B 2014, 45, 1874–1886. [Google Scholar] [CrossRef]

- Persson, M.; Sridhar, S.; Seetharaman, S. Kinetic Studies of Fluoride Evaporation from Slags. ISIJ Int. 2007, 47, 1711–1717. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Shu, Q.; Chou, K. Viscosity of Fluoride-Free Mold Fluxes Containing B2O3 and TiO2. Steel Res. Int. 2013, 84, 766–776. [Google Scholar] [CrossRef]

- Fan, G.; He, S.; Wu, T.; Wang, Q. Effect of Fluorine on the Structure of High Al2O3-Bearing System by Molecular Dynamics Simulation. Metall. Mater. Trans. B 2015, 46, 2005–2013. [Google Scholar] [CrossRef]

- Lu, B.; Wang, W. Effects of Fluorine and BaO on the Crystallization Behavior of Lime–Alumina-Based Mold Flux for Casting High-Al Steels. Metall. Mater. Trans. B 2015, 46, 852–862. [Google Scholar] [CrossRef]

- He, S.; Wang, Q.; Xie, D.; Xu, C.; Li, Z.S.; Mills, K.C. Solidification and crystallization properties of CaO-SiO2-Na2O based mold fluxes. Int. J. Min. Metall. Mater. 2009, 16, 261–264. [Google Scholar] [CrossRef]

- Wen, G.; Sridhar, S.; Tang, P.; Qi, X.; Liu, Y. Development of fluoride-free mold powders for peritectic steel slab casting. ISIJ Int. 2007, 47, 1117–1125. [Google Scholar] [CrossRef]

- Wang, Q.; Lu, Y.; He, S.; Mills, K.; Li, Z.S. Formation of TiN and Ti (C, N) in TiO2 containing, fluoride free, mould fluxes at high temperature. Ironmak. Steelmak. 2011, 38, 297–301. [Google Scholar] [CrossRef]

- Ryu, H.; Zhang, Z.; Wen, J.W.C.G.; Sridhar, S. Crystallization behaviors of slags through a heat flux simulator. ISIJ Int. 2010, 50, 1142–1150. [Google Scholar] [CrossRef]

- Lara Santos Assis, K. Heat Transfer through Mold Fluxes: A New Approach to Measure Thermal Properties of Slags. Ph.D. Thesis, Carnegie Mellon University, Pittsburgh, PA, USA, February 2016. [Google Scholar]

- Long, X.; He, S.; Xu, J.; Huo, X.; Wang, Q. Properties of high basicity mold fluxes for peritectic steel slab casting. J. Iron Steel Res. Int. 2012, 19, 39–45. [Google Scholar] [CrossRef]

- He, S.; Long, X.; Xu, J.; Wu, T.; Wang, Q. Effects of crystallisation behaviour of mould fluxes on properties of liquid slag film. Ironmak. Steelmak. 2012, 39, 593–598. [Google Scholar] [CrossRef]

- Wu, T.; Wang, Q.; He, S.; Xu, J.; Long, X.; Lu, Y. Study on properties of alumina-based mould fluxes for high-Al steel slab casting. Steel Res. Int. 2012, 83, 1194–1202. [Google Scholar] [CrossRef]

- Long, X.; Wang, Q.; He, S.; Pistorius, P.C. Structure evolution of slag films of ultrahigh-basicity mold flux during solidification. Metall. Mater. Trans. B 2017, 48, 1938–1942. [Google Scholar] [CrossRef]

- Long, X.; He, S.; Wang, Q.; Pistorius, P.C. Structure of solidified films of mold flux for peritectic steel. Metall. Mater. Trans. B 2017, 48, 1652–1658. [Google Scholar] [CrossRef]

- Kromhout, J.A.; Dekker, E.R.; Kawamoto, M.; Boom, R. Challenge to control mould heat transfer during thin slab casting. Ironmak. Steelmak. 2013, 40, 206–215. [Google Scholar] [CrossRef]

- Andersson, S.P.; Eggertson, C. Thermal conductivity of powders used in continuous casting of steel, part 1—Glassy and crystalline slags. Ironmak. Steelmak. 2015, 42, 456–464. [Google Scholar] [CrossRef]

| CaO%/SiO2% | Al2O3 | Na2O | F |

|---|---|---|---|

| 0.7 | 1 | 23 | 3 |

| Viscosity1300°C, Pa·s | Melting Temperature, K | Break Temperature, K |

|---|---|---|

| 0.183 | 1431 | 1480 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, J.; Long, X.; You, X.; Li, M.; Wang, Q.; He, S. Structure of Solidified Films of CaO-SiO2-Na2O Based Low-Fluorine Mold Flux. Metals 2019, 9, 93. https://doi.org/10.3390/met9010093

Zeng J, Long X, You X, Li M, Wang Q, He S. Structure of Solidified Films of CaO-SiO2-Na2O Based Low-Fluorine Mold Flux. Metals. 2019; 9(1):93. https://doi.org/10.3390/met9010093

Chicago/Turabian StyleZeng, Jianhua, Xiao Long, Xinchen You, Min Li, Qiangqiang Wang, and Shengping He. 2019. "Structure of Solidified Films of CaO-SiO2-Na2O Based Low-Fluorine Mold Flux" Metals 9, no. 1: 93. https://doi.org/10.3390/met9010093