Effect of Manganese on the Structure-Properties Relationship of Cold Rolled AHSS Treated by a Quenching and Partitioning Process

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Transformation Behavior

3.2. Microstructure

3.3. Tensile Testing

3.4. Retained Austenite Stability

4. Discussion

4.1. Influence of Heat-Treatment Parameter

4.2. Influence of Mn-Content

5. Conclusions

- Regardless of the chemical composition, by increasing TQ the volume fraction of α’prim steadily decreased, accompanied by a rising amount of αB and RA. The exceedance of a critical TQ, depending on the Mn-content, resulted in an insufficient chemical stabilization of RA, triggering the formation of α’final during final cooling to RT.

- A significant influence of the Mn-content on the phase transformation behavior could be observed, particularly with increasing TQ and thus decreasing α’prim fraction. The addition of enhanced Mn-contents led to an appreciable delay in γ → αB transformation during the partitioning step. Thus, on the one hand, larger volume fractions of RA could be stabilized with increasing Mn-content. On the other hand, the increase of the Mn-content adversely affected the RA-stability due to the declining C-content in RA, which was only partially counterbalanced by the enhanced Mn-content in RA.

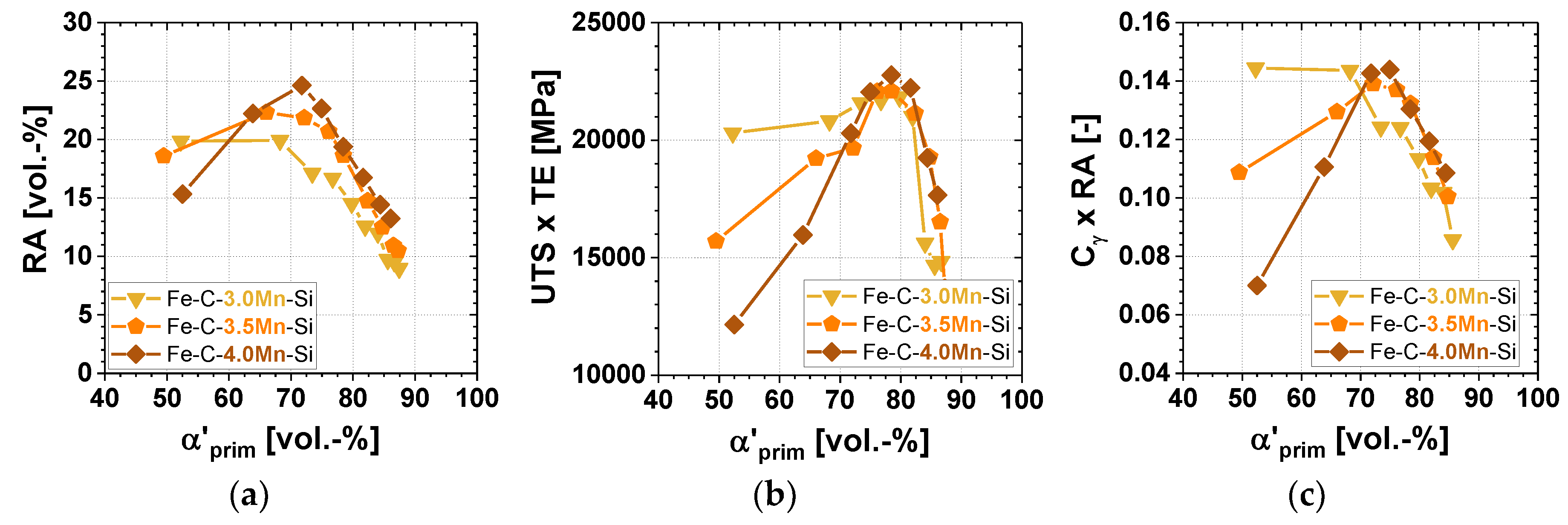

- The mechanical properties achieved by the Q&P process were pronouncedly determined by both, volume fraction and stability of RA. With increasing Mn-content, a remarkably stronger sensitivity against TQ-fluctuations in terms of RA-content and its stability was observed. As a result, the increase of the Mn-content resulted in a narrower process window with regard to the robustness of mechanical properties.

- For all investigated steels, the best combination of UTS and TE was observed for microstructures containing 75–80 vol.% α’prim. For this reason, a TQ 40 °C below the maximum RA-content had to be set in order to obtain the optimum mechanical properties. By increasing the Mn-content, the maximum value of UTS × TE could exceed 22,500 MPa%, since the larger volume fraction of RA by approximately 5% contributed to an enhanced TRIP-effect.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| α | ferrite |

| α’ | martensite |

| α’final | final martensite |

| α’prim | primary martensite |

| α’’ | tempered martensite |

| αB | bainitic ferrite |

| aγ | austenite lattice parameter |

| Cγ | carbon content in retained austenite |

| γremain | remaining austenite |

| ΔGm | difference in Gibb’s free energy |

| EDX | energy dispersive X-ray spectroscopy |

| kP | factor indicating the RA-stability |

| LOM | light optical microscopy |

| MULTIPAS | multipurpose annealing simulator |

| p | strain exponent related to the autocatalytic effect |

| Q&P | quenching & partitioning |

| RA | retained austenite |

| RAmax | maximum retained austenite |

| RT | room temperature |

| SEM | scanning electron microscopy |

| SIMT | strain induced martensitic transformation |

| TE | total elongation |

| TP | partitioning temperature |

| TQ | quenching temperature |

| tQ | quenching time |

| TRIP | transformation induced plasticity |

| UTS | ultimate tensile strength |

| Vγ0 | initial volume fraction of retained austenite |

| XAl | aluminum content in retained austenite |

| XC | carbon content in retained austenite |

| XMn | manganese content in retained austenite |

| XRD | X-ray diffraction |

| YS | yield strength |

References

- Fonstein, N. Advanced High Strength Sheet Steels, 1st ed.; Springer International Publishing: Cham, Switzerland, 2015; pp. 5–7. [Google Scholar]

- Kwon, O.; Lee, K.; Kim, G.; Chin, K. New trends in advanced high strength steel - Developments for automotive application. Mater. Sci. Forum 2010, 638–642, 136–141. [Google Scholar] [CrossRef]

- Steineder, K.; Krizan, D.; Schneider, R.; Béal, C.; Sommitsch, C. On the microstructural characteristics influencing the yielding behavior of ultra-fine grained medium-Mn steels. Acta Mater. 2017, 139, 39–50. [Google Scholar] [CrossRef]

- Matlock, D.; Speer, J.; De Moor, E.; Gibbs, P. Recent developments in advanced high strength steels for automotive applications: An overview. JESTECH 2012, 15, 1–12. [Google Scholar]

- De Cooman, B.C.; Speer, J. Quench and partitioning steel: A new AHSS concept for automotive anti-intrusion applications. Steel Res. Int. 2006, 77, 634–640. [Google Scholar] [CrossRef]

- Steineder, K.; Krizan, D.; Schneider, R.; Béal, C.; Sommitsch, C. On the damage behavior of a 0.1C6Mn Medium-Mn Steel. Steel Res. Int. 2017, 89, 1700378. [Google Scholar] [CrossRef]

- Steineder, K.; Schneider, R.; Krizan, D.; Béal, C.; Sommitsch, C. Comparative investigation of phase transformation behavior as a function of annealing temperature and cooling rate of two medium-Mn steels. Steel Res. Int. 2015, 85, 1–8. [Google Scholar] [CrossRef]

- Arlazarov, A.; Gouné, M.; Bouaziz, O.; Hazotte, A.; Petitgand, G.; Berger, P. Evolution of microstructure and mechanical properties of medium Mn steels during double annealing. Mater. Sci. Eng. A 2012, 542, 31–39. [Google Scholar] [CrossRef]

- Speer, J.; Matlock, D.; De Cooman, B.C.; Schroth, J. Carbon partitioning into austenite after martensite transformation. Acta Mater. 2003, 51, 2611–2622. [Google Scholar] [CrossRef]

- Speer, J.; Aussuncao, F.; Matlock, D.; Edmonds, D. The quenching and partitioning process: Background and recent progress. Mater. Res. 2005, 51, 2611–2622. [Google Scholar] [CrossRef]

- Owen, W. Effect of silicon on the kinetics of tempering. Trans. ASM 1954, 46, 812–829. [Google Scholar]

- De Moor, E.; Lacroix, S.; Clarke, A.; Penning, J.; Speer, J. Effect of Retained Austenite Stabilized via Quench and Partitioning on the Strain Hardening of Martensitic Steels. Metall. Mater. Trans. A 2008, 39A, 2586–2595. [Google Scholar] [CrossRef]

- Speich, G.; Leslie, W. Tempering of steel. Metall. Trans. 1972, 3, 1043–1054. [Google Scholar] [CrossRef]

- Krauss, G. Tempering and structural change in ferrous martensitic structures. In Phase Transformations in Ferrous Alloys: Proceedings of an International Conference, Proceedings of the International Conference on Phase Transformations in Ferrous Alloys, TMS-AIME, Warrendale, PA, USA, 1984; Marder, A.R., Goldstein, J.I., Eds.; AIME: Englewood, CO, USA, 1984; pp. 101–123. [Google Scholar]

- De Moor, E.; Speer, J.; Matlock, D.; Kwak, J.; Lee, S.-B. Effect of carbon and manganese on the quenching and partitioning response of CMnSi steels. ISIJ Int. 2011, 51, 137–144. [Google Scholar] [CrossRef]

- De Moor, E.; Speer, J.; Matlock, D.; Kwak, J.-H.; Lee, S.-B. Quenching and partitioning of CMnSi steels containing elevated manganese levels. Steel Res. Int. 2012, 83, 322–327. [Google Scholar] [CrossRef]

- Seo, E.-J.; Cho, L.; De Cooman, B.C. Application of quenching and partitioning processing to medium Mn steel. Metall. Mater. Trans. A 2015, 46, 27–31. [Google Scholar] [CrossRef]

- Seo, E.-J.; Cho, L.; De Cooman, B.C. Kinetics of the partitioning of carbon and substitutional alloying elements during quenching and partitioning (Q&P) processing of medium Mn steel. Acta Mater. 2016, 107, 354–365. [Google Scholar]

- Ludwigson, D.; Berger, J. Plastic behaviour of metastable austenitic stainless steels. J. Iron Steel Inst. 1969, 207, 63–69. [Google Scholar]

- Matsumura, O.; Sakuma, Y.; Takechi, H. TRIP and its kinetic aspects in austempered 0.4C-1.5Si-0.8Mn steel. Scr. Metall. 1987, 21, 1301–1306. [Google Scholar] [CrossRef]

- Dyson, D.; Holmes, B. Effect of alloying additions on the lattice parameter austenite. J. Iron Steel Inst. 1970, 208, 469–474. [Google Scholar]

- Kaar, S.; Schneider, R.; Krizan, D.; Béal, C.; Sommitsch, C. Influence of the quenching and partitioning process on the transformation kinetics and hardness in a lean medium manganese TRIP steel. Metals 2019, 9, 353. [Google Scholar] [CrossRef]

- Kaar, S.; Schneider, R.; Krizan, D.; Béal, C.; Sommitsch, C. Influence of the phase transformation behaviour on the microstructure and mechanical properties of a 4.5 wt.-% Mn Q&P steel. HTM J. Heat Treatm. Mat. 2010, 74, 70–83. [Google Scholar]

- Santofimia, M.; Zhao, L.; Petrov, R.; Kwakernaak, C.; Sloof, W.; Sietsma, J. Microstructural development during the quenching and partitioning process in a newly designed low-carbon steel. Acta Mater. 2011, 59, 6059–6068. [Google Scholar] [CrossRef]

- HajyAkbary, F.; Santofimia, M.; Sietsma, J. Optimizing mechanical properties of a 0.3C-1.5Si-3.5Mn quenched and partitioned steel. Adv. Mater. Res. 2014, 829, 100–104. [Google Scholar] [CrossRef]

- Koistinen, D.; Marburger, R. A general equation prescribing the extent of the austenite-martensite transformation in pure iron-carbon alloys and plain carbon steels. Acta Metall. 1959, 7, 59–60. [Google Scholar] [CrossRef]

- Speer, J.; Streicher, A.; Matlock, D.; Rizzo, F. Quenching and partitioning: A fundamentally new process to create high strength TRIP sheet microstructures. In Proceedings of the Austenite Formation and Decomposition MS&T, Chicago, IL, USA, 9–12 November 2003; pp. 505–522. [Google Scholar]

- De Knijf, D.; Petrov, R.; Föjer, C.; Kestens, L. Effect of fresh martensite on the stability of retained austenite in quenching and partitioning steel. Mater. Sci. Eng. A 2014, 615, 107–115. [Google Scholar] [CrossRef]

- Steineder, K.; Krizan, D.; Schneider, R.; Béal, C.; Sommitsch, C. The effects of intercritical annealing temperature and initial microstructure on the stability of retained austenite in a 0.1C-6Mn steel. Mater. Sci. Forum 2016, 879, 1847–1852. [Google Scholar] [CrossRef]

- Seo, E.; Cho, L.; Estrin, Y.; De Cooman, B.C. Microstructure-mechanical properties relationships for quenching and partitioning (Q&P) processed steel. Acta Mater. 2016, 113, 124–139. [Google Scholar]

- Mahieu, J.; Maki, J.; De Cooman, B.C.; Claessens, S. Phase transformation and mechanical properties of Si-free CMnAl transformation-induced plasticity-aided steel. Metall. Mater. Trans. A 2002, 33, 2573–2580. [Google Scholar] [CrossRef]

- Schneider, R.; Steineder, K.; Watanebe, A.; Okumiya, M.; Krizan, D.; Sommitsch, C. Determination of a new empirical MS-formula suitable for medium-Mn-steels. In Proceedings of the 24th IFHTSE Congress 2017—European Conference on Heat Treatment and Surface Engineering, Nice, France, 26–29 June 2017; pp. 1–9. [Google Scholar]

- Satzinger, K. Einfluss von Chrom und Mangan auf die Bainitbildung in Dualphasenstählen; Diplomarbeit, Montanuniversität Leoben: Leoben, Austria, 2008. [Google Scholar]

- Röthler, B. Möglichkeiten zur Beeinflussung der Mechanischen Eigenschaften von Kaltgewalzten TRIP-Stählen. Ph.D. Thesis, Technische Universität München, München, Germany, 2005. [Google Scholar]

- Paul, S. Entwicklung Neuer Legierungskonzepte für Höchstfeste TRIP-Stähle mit Nicht Ferritischer Matrix und Reduziertem Siliziumgehalt. Ph.D. Thesis, Technische Universität München, München, Germany, 2012. [Google Scholar]

- Eggbauer, G. Charakterisierung bainitischer Gefügezustände für Gesenkschmiedeteile. BHM 2014, 159, 5, 194–200. [Google Scholar]

- Bleck, W.; Moeller, E. Handbuch Stahl: Auswahl, Verarbeitung, Anwendung, 1st ed.; Carl Hanser Verlag: Rastatt, Germany, 2017; pp. 292–293. [Google Scholar]

- De Moor, E.; Matlock, D.; Speer, J.; Merwin, M. Austenite stabilization through manganese enrichment. Scr. Mat. 2011, 64, 185–188. [Google Scholar] [CrossRef]

| Steel | C | Mn | Si |

|---|---|---|---|

| Fe-C-3.0Mn-Si | 0.20 | 3.06 | 1.52 |

| Fe-C-3.5Mn-Si | 0.20 | 3.47 | 1.51 |

| Fe-C-4.0Mn-Si | 0.20 | 3.94 | 1.50 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaar, S.; Krizan, D.; Schneider, R.; Béal, C.; Sommitsch, C. Effect of Manganese on the Structure-Properties Relationship of Cold Rolled AHSS Treated by a Quenching and Partitioning Process. Metals 2019, 9, 1122. https://doi.org/10.3390/met9101122

Kaar S, Krizan D, Schneider R, Béal C, Sommitsch C. Effect of Manganese on the Structure-Properties Relationship of Cold Rolled AHSS Treated by a Quenching and Partitioning Process. Metals. 2019; 9(10):1122. https://doi.org/10.3390/met9101122

Chicago/Turabian StyleKaar, Simone, Daniel Krizan, Reinhold Schneider, Coline Béal, and Christof Sommitsch. 2019. "Effect of Manganese on the Structure-Properties Relationship of Cold Rolled AHSS Treated by a Quenching and Partitioning Process" Metals 9, no. 10: 1122. https://doi.org/10.3390/met9101122