Thermal Cycles and Deformation Characters During High-Speed Micro Friction Stir Welding Process of AA7075-T6 Sheets

Abstract

:1. Introduction

2. Experimental Procedure

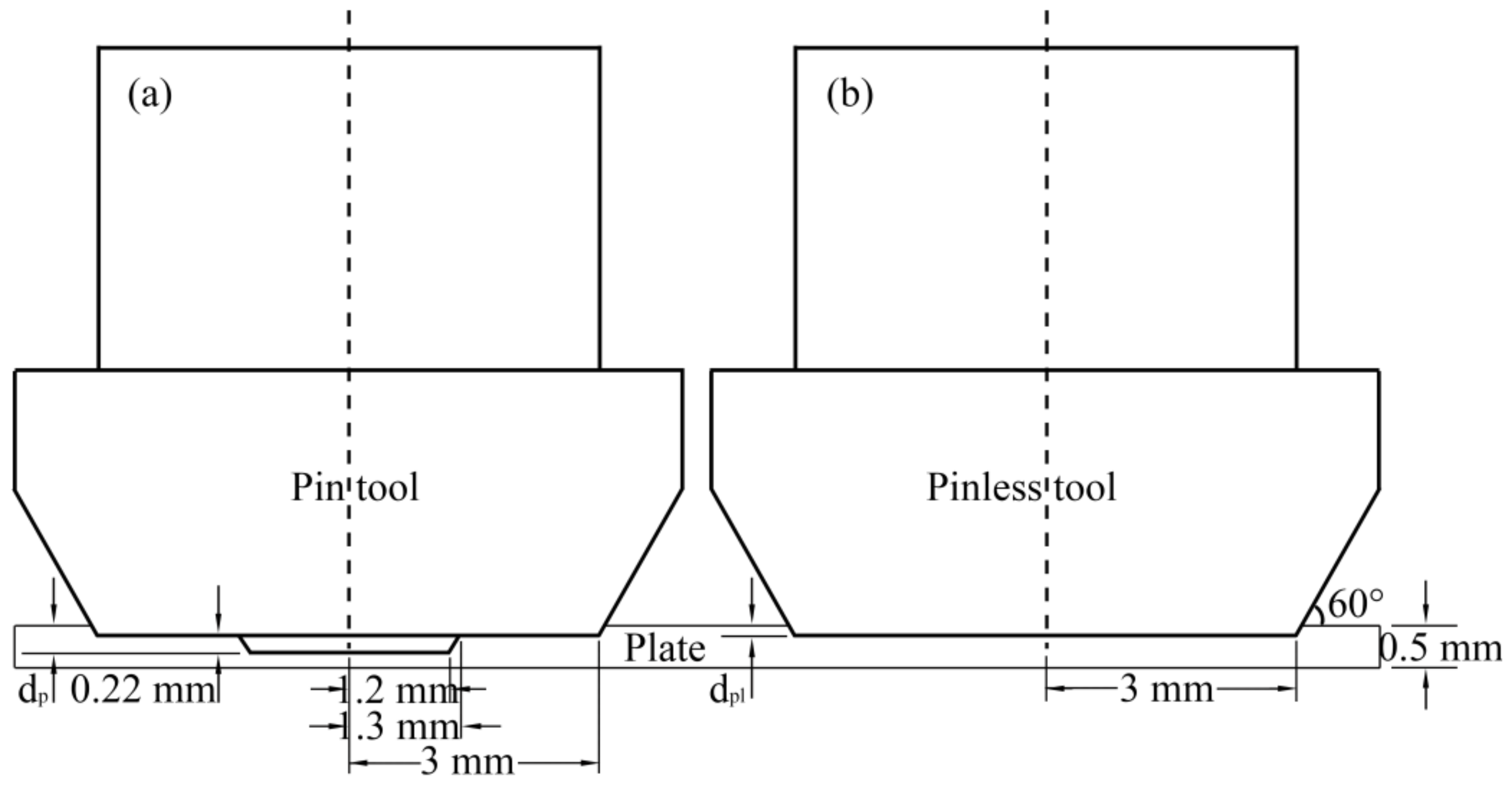

2.1. FSW Experiment

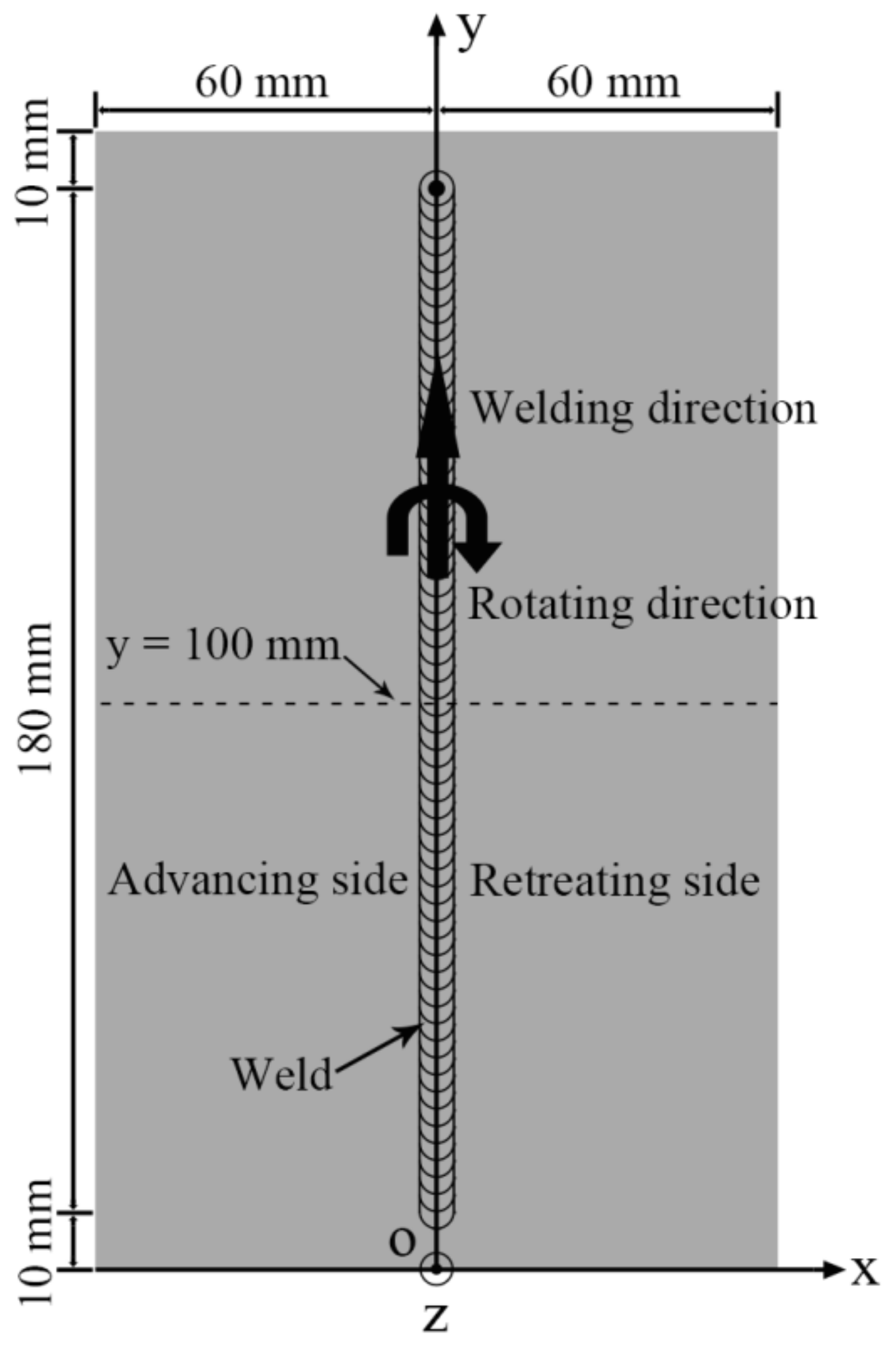

2.2. Coordinate Definition

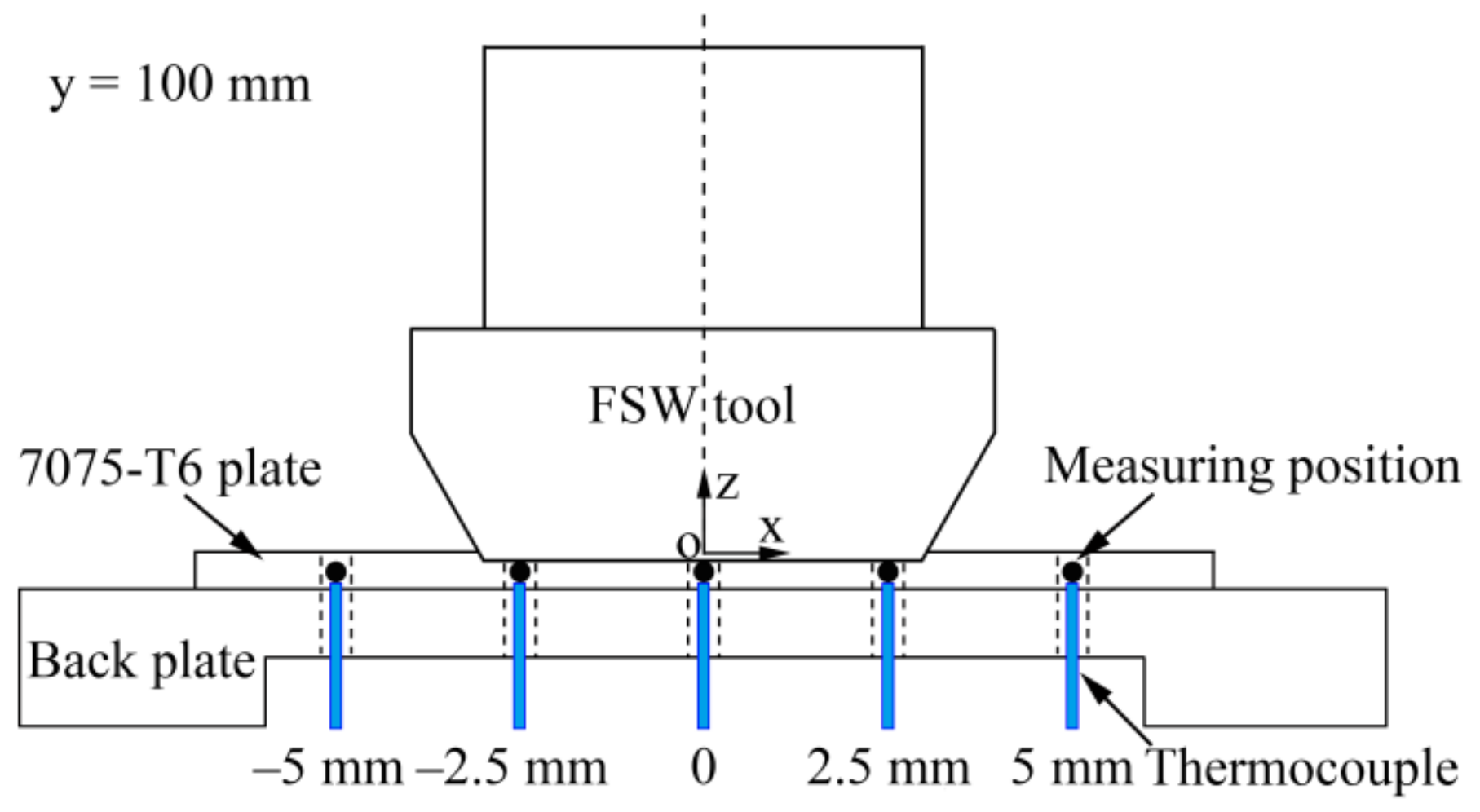

2.3. Temperature Measurement

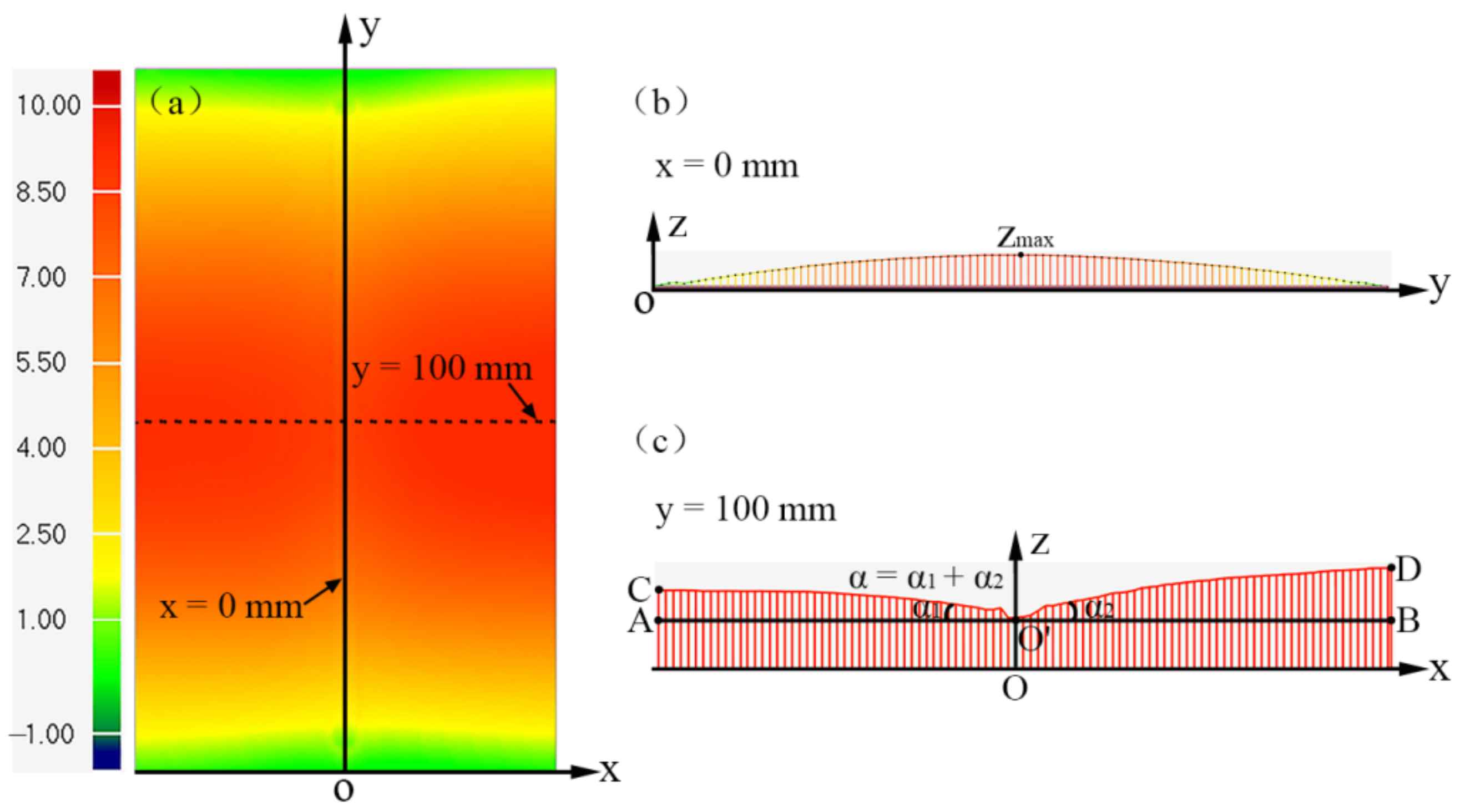

2.4. Deformation Measurement and Characterization

3. Results and Discussion

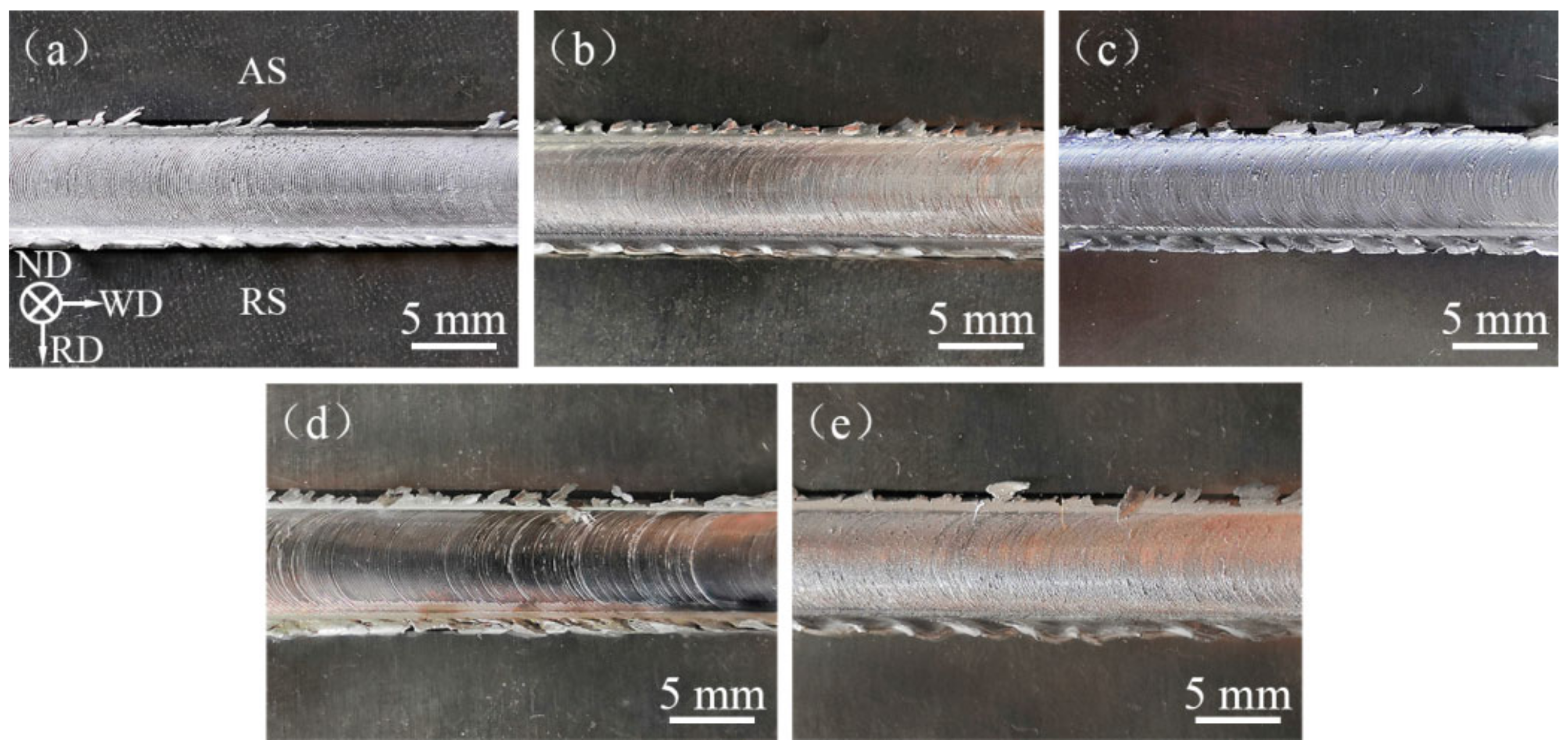

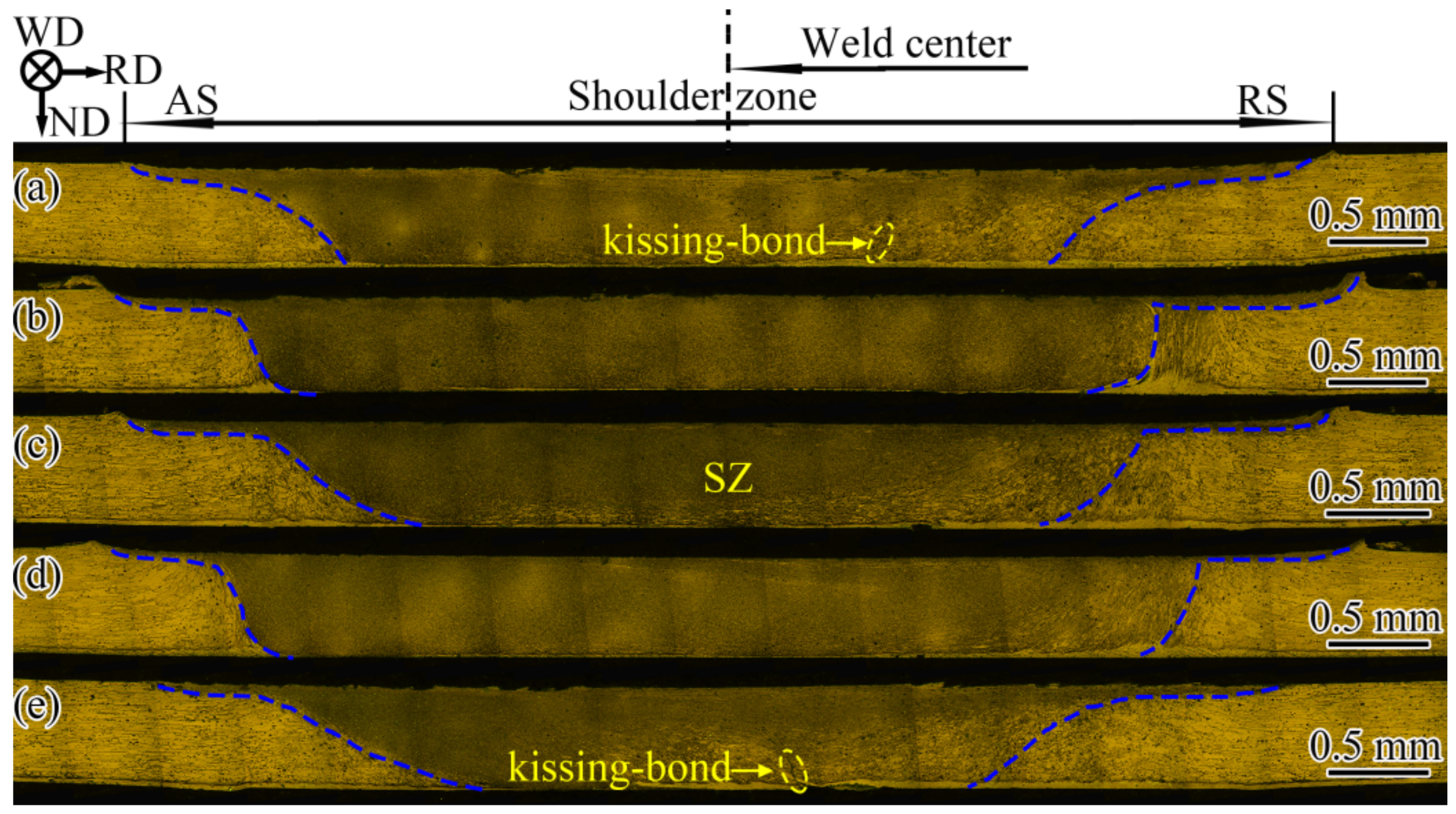

3.1. Weld Morphology

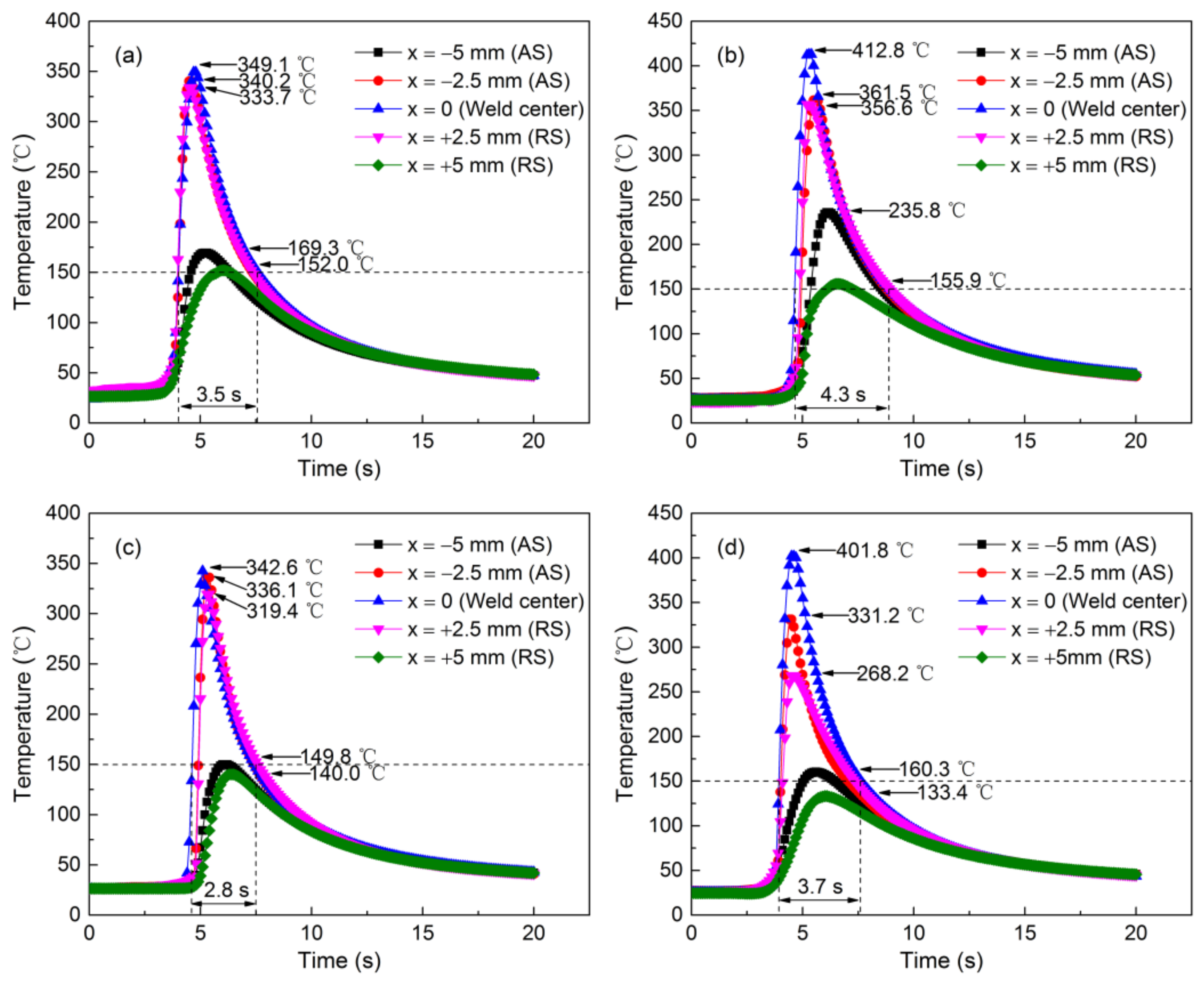

3.2. Thermal Cycles

3.3. Deformations

3.3.1. Deformation Comparison for Different Rotational Speeds

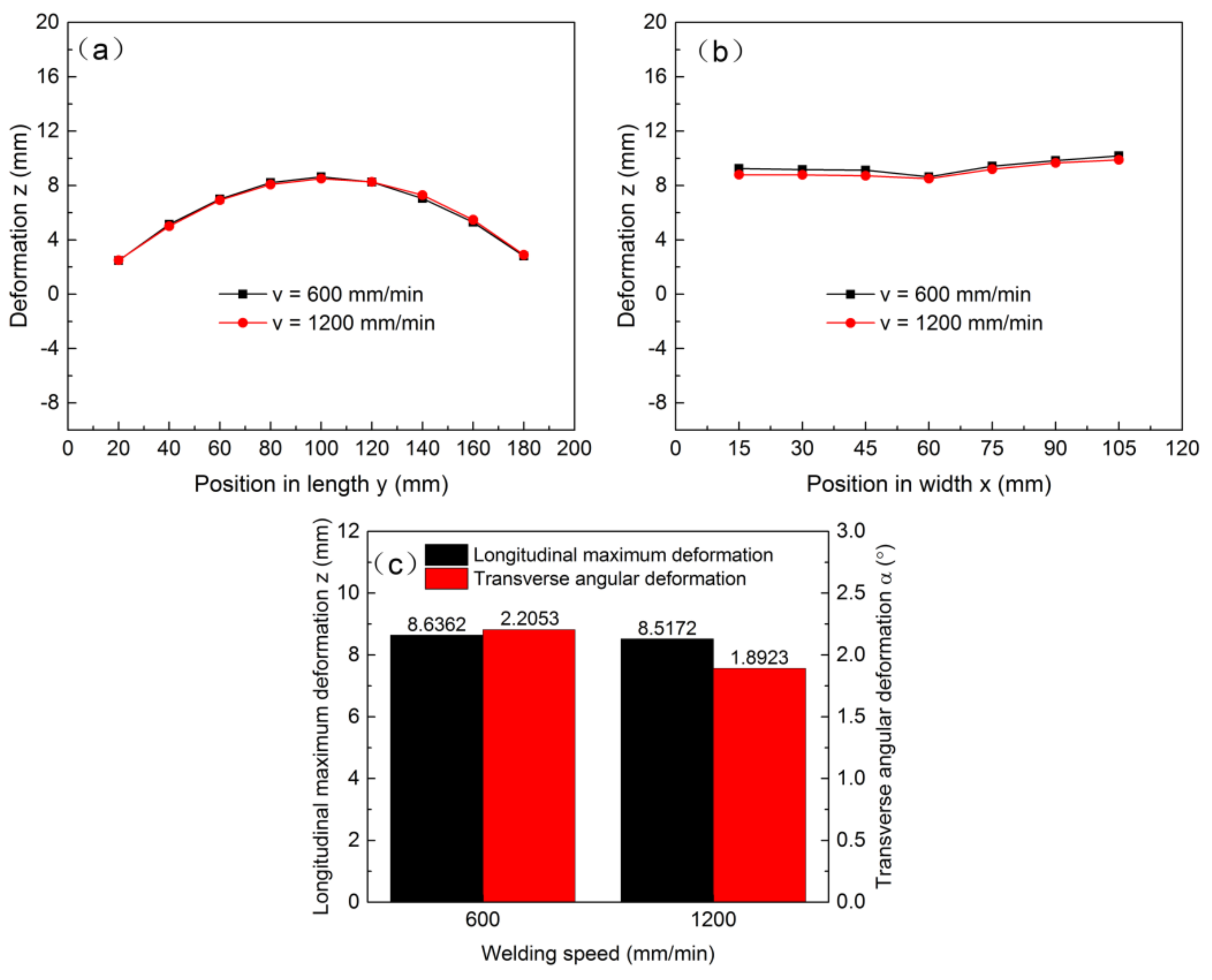

3.3.2. Deformation Comparison for Different Welding Speeds

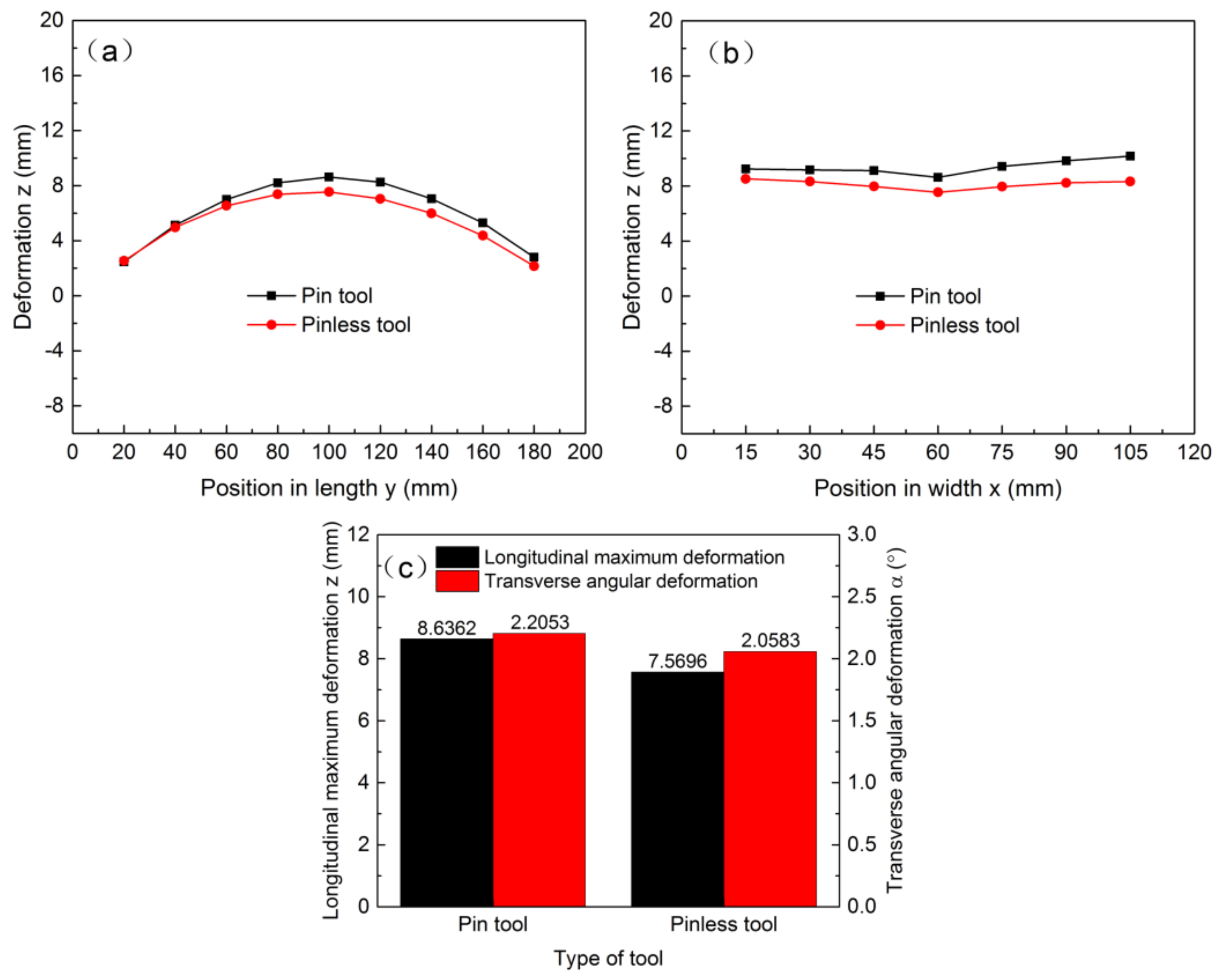

3.3.3. Deformation Comparison for Different Tools

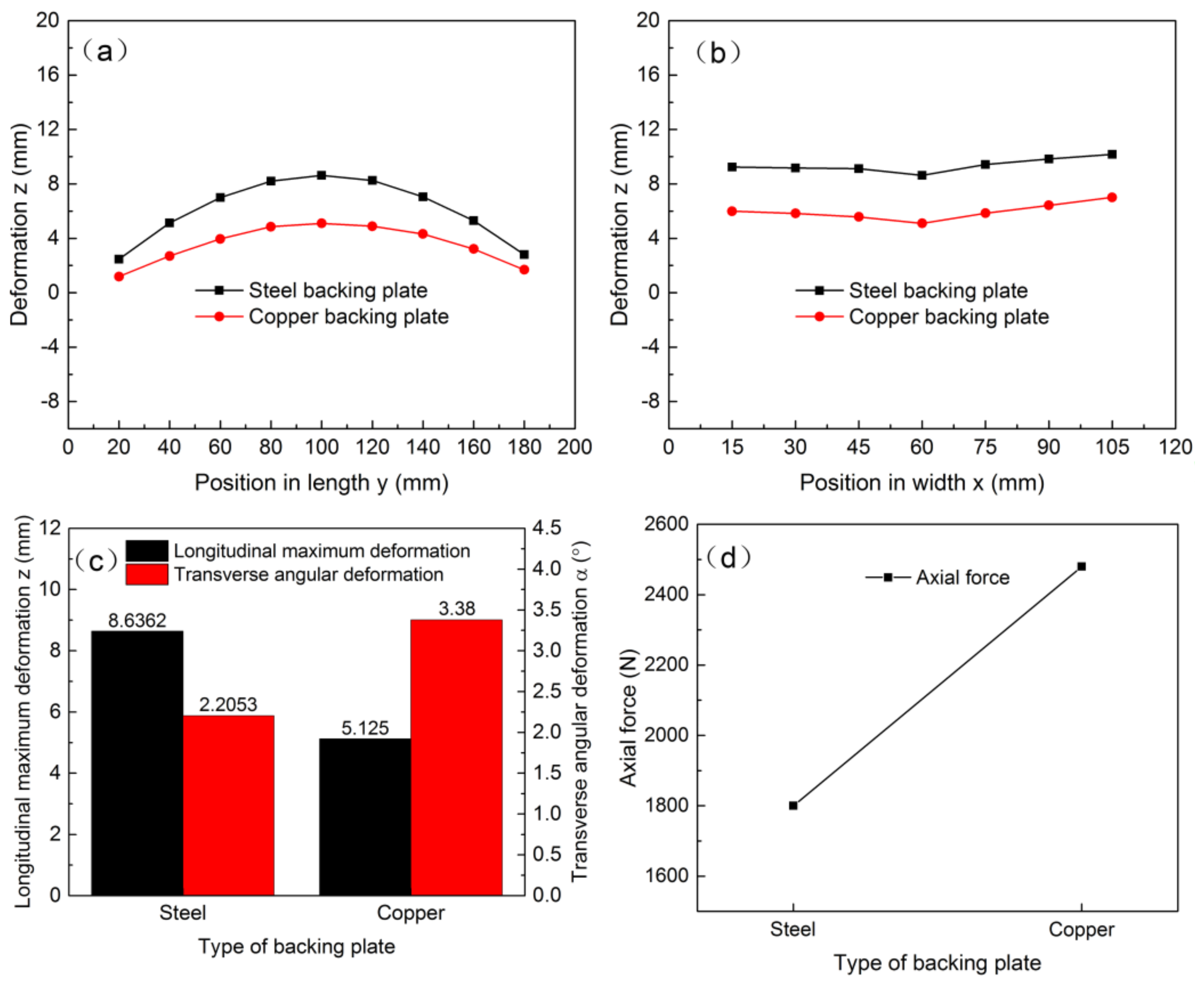

3.3.4. Deformation Comparison for Different Backing Plates

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Shen, Z.K.; Ding, Y.Q.; Gerlich, A.P. Advances in friction stir spot welding. Crit. Rev. Solid State 2019. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Upadhyay, P.; Hovanski, Y.; Field, D.P. High-speed friction stir welding of AA7075-T6 sheet: microstructure, mechanical properties, micro-texture, and thermal history. Metall. Mater. Trans. A 2018, 49, 210–222. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Upadhyay, P.; Hovanski, Y.; Field, D.P. High-Speed FSW aluminum alloy 7075 microstructure and corrosion properties. In Friction Stir Welding and Processing, 9th ed.; Hovanski, Y., Mishra, R., Sato, Y., Upadhyay, P., Yan, D., Eds.; Springer: Cham, Switzerland, 2017; pp. 125–135. [Google Scholar]

- Azimzadegan, T.; Serajzadeh, S. An investigation into microstructures and mechanical properties of AA7075-T6 during friction stir welding at relatively high rotational speeds. J. Mater. Eng. Perform. 2010, 19, 1256–1263. [Google Scholar] [CrossRef]

- Sithole, K.; Rao, V.V. Recent developments in micro friction stir welding: A review. Mater. Sci. Eng. 2016. [Google Scholar] [CrossRef]

- Jamshidi Aval, H.; Serajzadeh, S.; Kokabi, A.H. Experimental and theoretical evaluations of thermal histories and residual stresses in dissimilar friction stir welding of AA5086-AA6061. Int. J. Adv. Manuf. Technol. 2012, 61, 149–160. [Google Scholar] [CrossRef]

- Wang, W.D.; Deng, D.A.; Mao, Z.T.; Tong, Y.G.; Ran, Y. Influence of tool rotation rates on temperature profiles and mechanical properties of friction stir welded AZ31 magnesium alloy. Int. J. Adv. Manuf. Technol. 2017, 88, 2191–2200. [Google Scholar] [CrossRef]

- Mao, Y.Q.; Ke, L.M.; Liu, F.C.; Chen, Y.H.; Li, X. Investigations on temperature distribution, microstructure evolution, and property variations along thickness in friction stir welded joints for thick AA7075-T6 plates. Int. J. Adv. Manuf. Technol. 2016, 86, 141–154. [Google Scholar]

- Shi, Q.Y.; Silvanus, J.; Liu, Y.; Yan, D.Y.; Li, H.K. Experimental study on distortion of Al-6013 plate after friction stir welding. Sci. Technol. Weld. Join. 2008, 13, 472–478. [Google Scholar] [CrossRef]

- Xu, W.F.; Liu, J.H.; Zhu, H.Q. Analysis of residual stresses in thick aluminum friction stir welded butt joints. Mater. Des. 2017, 32, 2000–2005. [Google Scholar] [CrossRef]

- Prime, M.B.; Gnaupel-Herold, T.; Baumann, J.A.; Lederich, R.J.; Bowden, D.M.; Sebring, R.J. Residual stress measurements in a thick, dissimilar aluminum alloy friction stir weld. Acta. Mater. 2006, 54, 4013–4021. [Google Scholar] [CrossRef]

- Zapata, J.; Toro, M.; Lopez, D. Residual stresses in friction stir dissimilar welding of aluminum alloys. J. Mater. Process. Technol. 2016, 229, 121–127. [Google Scholar] [CrossRef]

- Lombard, H.; Hattingh, D.G.; Steuwer, A.; James, M.N. Effect of process parameters on the residual stresses in AA5083-H321 friction stir welds. Mater. Sci. Eng. A 2009, 501, 119–124. [Google Scholar] [CrossRef]

- Liu, X.L.; Xie, P.; Wimpory, R.; Li, W.Y.; Lai, R.L.; Chen, D.F.; Liu, Y.T.; Zhao, H.Y. Residual stress, microstructure and mechanical properties in thick 6005A-T6 aluminium alloy friction stir welds. Metals 2019, 9, 803. [Google Scholar] [CrossRef]

- Wei, H.Y.; Tariq, M.; Hussain, G.; Khan, I.; Khan, M.I.; Khan, W.A. Butt joining of Bi-layered aluminum sheets through friction stir welding: Tensile stresses, bending stresses, residual stresses, and fractrography. Metals 2019, 9, 384. [Google Scholar] [CrossRef]

- Altenkirch, J.; Steuwer, A.; Withers, P.J.; Williams, S.W.; Poad, M.; Wen, S.W. Residual stress engineering in friction stir welds by roller tensioning. Sci. Technol. Weld. Join. 2009, 14, 185–192. [Google Scholar] [CrossRef]

- Richards, D.G.; Prangnell, P.B.; Williams, S.W.; Withers, P.J. Global mechanical tensioning for the management of residual stresses in welds. Mater. Sci. Eng. A 2008, 489, 351–362. [Google Scholar] [CrossRef]

- Hatamleh, O.; Rivero, I.V.; Swain, S.E. An investigation of the residual stress characterization and relaxation in peened friction stir welded aluminum-lithium alloy joints. Mater. Des. 2009, 30, 3367–3373. [Google Scholar] [CrossRef]

- Li, T.; Shi, Q.Y.; Li, H.K. Residual stresses simulation for friction stir welded joint. Sci. Technol. Weld. Join. 2007, 12, 664–670. [Google Scholar] [CrossRef]

- Buffa, G.; Ducato, A.; Fratini, L. Numerical procedure for residual stresses prediction in friction stir welding. Finite Elem. Anal. Des. 2011, 47, 470–476. [Google Scholar] [CrossRef]

- Feng, Z.; Wang, X.L.; David, S.A.; Sklad, P.S. Modelling of residual stresses and property distributions in friction stir welds of aluminium alloy 6061-T6. Sci. Technol. Weld. Join. 2007, 12, 348–356. [Google Scholar] [CrossRef]

- Woo, W.; Choo, H.; Brown, D.W.; Feng, Z.L.; Liaw, P.K. Angular distortion and through-thickness residual stress distribution in the friction-stir processed 6061-T6 aluminum alloy. Mater. Sci. Eng. A 2006, 437, 64–69. [Google Scholar] [CrossRef]

- Richter-Trummer, V.; Suzano, E.; Beltrao, M.; Roos, A.; dos Santos, J.F.; de Castro, P.M.S.T. Influence of the FSW clamping force on the final distortion and residual stress field. Mater. Sci. Eng. A 2012, 538, 81–88. [Google Scholar] [CrossRef]

- Yan, D.Y.; Wu, A.P.; Silvanus, J.; Shi, Q.Y. Predicting residual distortion of aluminum alloy stiffened sheet after friction stir welding by numerical simulation. Mater. Des. 2011, 32, 2284–2291. [Google Scholar] [CrossRef]

- Costa, M.I.; Leital, C.; Rodrigues, D.M. Parametric study of friction stir welding induced distortion in thin aluminium alloy plates: A coupled numerical and experimental analysis. Thin Wall Struct. 2019, 134, 268–276. [Google Scholar] [CrossRef]

- Wen, Q.; Ji, S.D.; Zhang, L.G.; Yue, Y.M.; Lv, Z. Temperature, stress and distortion of Ti–6Al–4V alloy low-temperature friction stir welding assisted by trailing intensive cooling. Trans. Indian Inst. Met. 2018, 71, 3003–3009. [Google Scholar] [CrossRef]

- He, W.L.; Li, M.S.; Song, Q.; Liu, J.L.; Hu, W. Efficacy of external stationary shoulder for controlling residual stress and distortion in friction stir welding. Trans. Indian Inst. Met. 2019, 72, 1349–1359. [Google Scholar] [CrossRef]

| Sample Number | Welding Parameter | Rotational Speed (rpm) | Welding Speed (mm/min) | Tool Geometry | Backing Plate Material |

|---|---|---|---|---|---|

| 1 | 3000-600-P-Fe | 3000 | 600 | Pin tool | Steel |

| 2 | 6000-600-P-Fe | 6000 | 600 | Pin tool | Steel |

| 3 | 6000-1200-P-Fe | 6000 | 1200 | Pin tool | Steel |

| 4 | 6000-600-PL-Fe | 6000 | 600 | Pinless tool | Steel |

| 5 | 6000-600-P-Cu | 6000 | 600 | Pin tool | Copper |

| Welding Parameter | Peak Temperature (°C) | Elevated-Temperature Exposure Time (t150) (s) | Heating Rate (°C/s) | Cooling Rate (°C/s) |

|---|---|---|---|---|

| 3000-600-P-Fe | 349.1 | 3.5 | 199.2 | 68.7 |

| 6000-600-P-Fe | 412.8 | 4.3 | 294.1 | 72.8 |

| 6000-1200-P-Fe | 342.6 | 2.8 | 389.1 | 83.4 |

| 6000-600-PL-Fe | 401.8 | 3.7 | 371.1 | 80.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ni, Y.; Mao, Y.; Qin, D.; Xiao, X.; Fu, L. Thermal Cycles and Deformation Characters During High-Speed Micro Friction Stir Welding Process of AA7075-T6 Sheets. Metals 2019, 9, 1236. https://doi.org/10.3390/met9111236

Ni Y, Mao Y, Qin D, Xiao X, Fu L. Thermal Cycles and Deformation Characters During High-Speed Micro Friction Stir Welding Process of AA7075-T6 Sheets. Metals. 2019; 9(11):1236. https://doi.org/10.3390/met9111236

Chicago/Turabian StyleNi, Yu, Yue Mao, Dingqiang Qin, Xuan Xiao, and Li Fu. 2019. "Thermal Cycles and Deformation Characters During High-Speed Micro Friction Stir Welding Process of AA7075-T6 Sheets" Metals 9, no. 11: 1236. https://doi.org/10.3390/met9111236