Wear and MnS Layer Adhesion in Uncoated Cutting Tools When Dry and Wet Turning Free-Cutting Steels

Abstract

:1. Introduction

2. Methodology

3. Results and Discussion

4. Conclusions

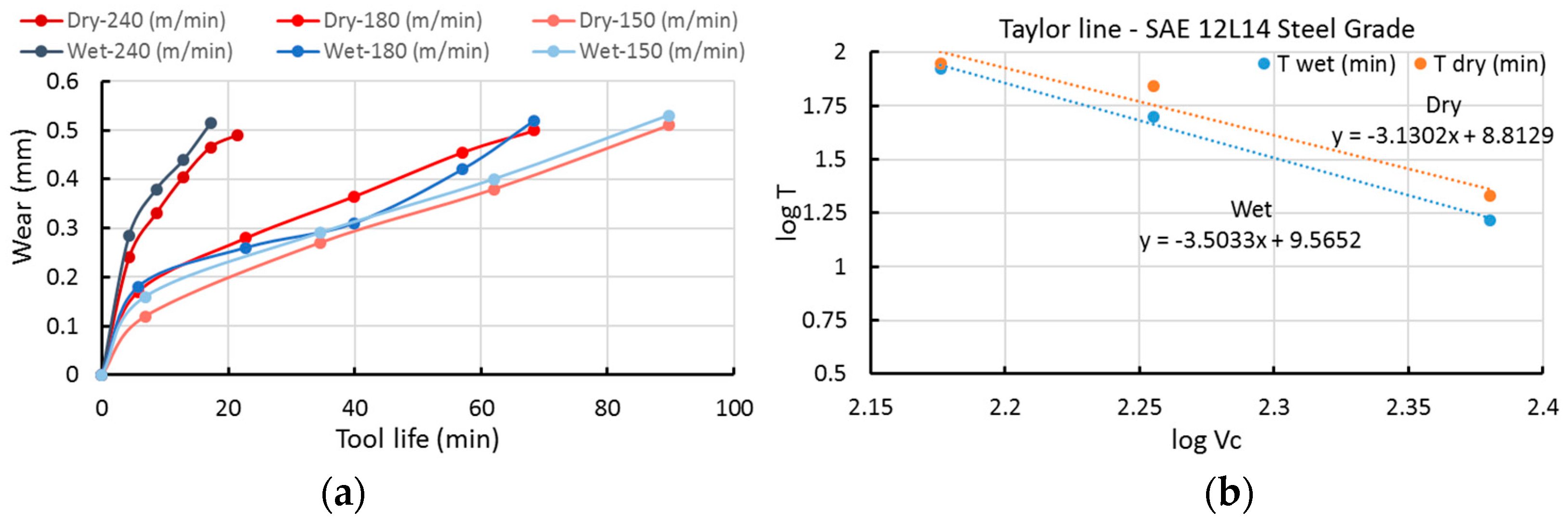

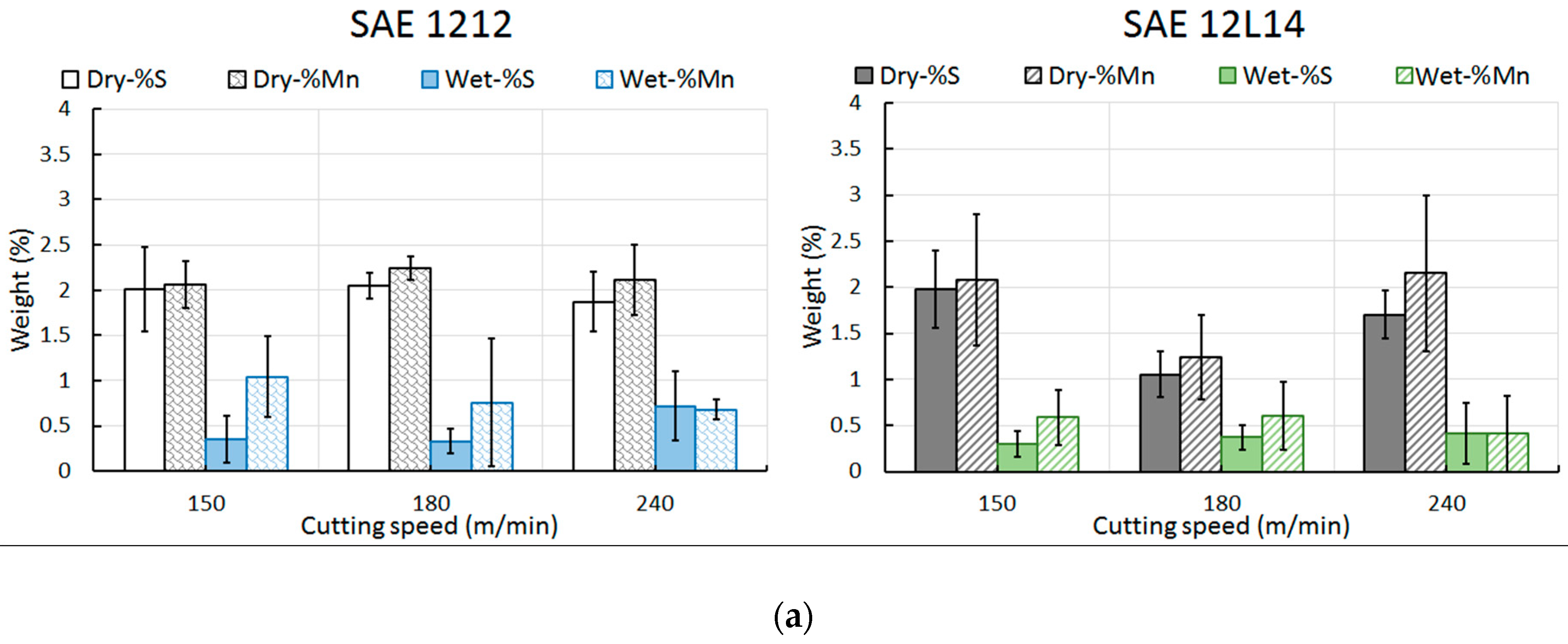

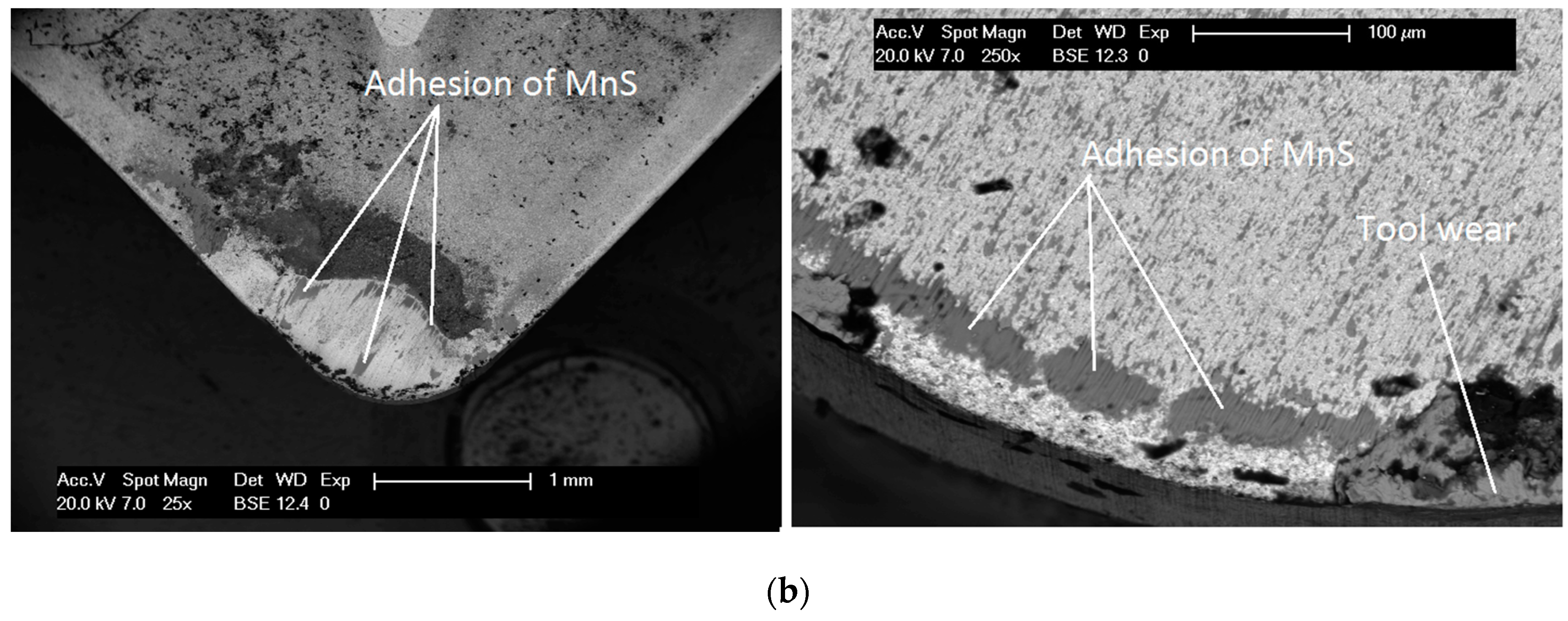

- The tool wear evolution was attenuated in dry machining with respect to wet machining independent of the steel alloy, and in particular, for higher cutting speeds (240 and 180 m/min). The main reason of the wear reduction was attributed to a higher adhesion of MnS found at the rake face of the cutting tool during the dry machining, as denoted in the EDS analysis. This MnS generated a protection layer between the surface of tool and machined surface, which decreased the friction and ultimately, reduced the wear on the cutting edge.

- In three free-cutting steels, the SAE 12L14 carbon steel, presented the best performance in terms of tool life for the lower cutting speeds, but no noticeable differences were found for cutting speed of 240 m/min. Additionally, the wear at the rake face of the cutting tool was lower at lower cutting speed and increased with the increase of the cutting speed at all machining condition of steel alloys.

- The Taylor curves showed that SAE 12L14 was more sensitive to the cutting speed and type of machining condition. This difference can be noted to the lead, which enhanced the material’s machinability and, consequently, affected the slope of these curves that were associated to the material of the cutting tool and the workpiece to be machined.

- Auto-lubrication characteristics of these steel grades have shown a better machining capabilities compare to the lubricated conditions. Consequently, lubrication did not bring any benefit for the studied machining conditions and materials; instead, it is showed economic and environmental disadvantages. Therefore, the lubrication should be considered for more challenging machining solicitations (high-speed machining) or hard-to-cut materials.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ferraresi, D. Fundamentos do usinagem dos metais. Nona reimpressao; Editora Edgard Blücher Ltd.a: Sao Paulo, Brazil, 1995. [Google Scholar]

- Astakhov, V.P. The assessment of cutting tool wear. Int. J. Mach. Tools Manuf. 2004, 44, 637–647. [Google Scholar] [CrossRef]

- Diniz, A.; Marcondes, F.; Coppini, N. Tecnologia da usinagem dos materiais, 5ta edicao; Artliber Editora: Sao Paulo, Brazil, 2006; ISBN 8587296019. [Google Scholar]

- Castellanos Díaz, R.; Martinez Krahmer, D.; Avila Rondón, R. Application of ISO 3685 in the evaluation of the machinability of steel SAE 1020 during the turning process. In Proceedings of the SAM CONAMET Congress, Buenos Aires, Argentina, 19–23 October 2009. [Google Scholar] [CrossRef]

- Sánchez Egea, A.J.; González Rojas, H.A.; Montilla Montaña, C.A.; Kallewaard Echeverri, V. Effect of electroplastic cutting on the manufacturing process and surface properties. J. Mater. Process. Technol. 2015, 222, 327–334. [Google Scholar] [CrossRef]

- Kaynak, Y.; Gharibi, A. Progressive Tool Wear in Cryogenic Machining: The Effect of Liquid Nitrogen and Carbon Dioxide. J. Manuf. Mater. Process. 2018, 2, 31. [Google Scholar] [CrossRef]

- Rubio, E.; Agustina, B.; Marin, M.; Bericua, A. Cooling systems based on cold compressed air: A review of the applications in machining processes. Procedia Eng. 2015, 132, 413–418. [Google Scholar] [CrossRef]

- Do, T.-V.; Hsu, Q.-C. Optimization of Minimum Quantity Lubricant Conditions and Cutting Parameters in Hard Milling of AISI H13 Steel. Appl. Sci. 2016, 6, 83. [Google Scholar] [CrossRef]

- Shaw, M. Metal Cutting Principles, 2nd ed.; Oxford University Press: New York, NY, USA, 2005; ISBN 0195142063. [Google Scholar]

- Çakīr, O.; Yardimeden, A.; Ozben, T.; Kilickap, E. Selection of cutting fluids in machining processes. J. Achiev. Mater. Manuf. Eng. 2007, 25, 99–102. [Google Scholar]

- Tanabe, I.; Hoshino, H. Development of a New Forced Cooling Technology Using a High-Pressure Coolant for Machining Difficult-To-Machine Materials. J. Manuf. Mater. Process. 2018, 2, 39. [Google Scholar] [CrossRef]

- Astakhov, V.P.; Outeiro, J. Importance of Temperature in Metal Cutting and its Proper Measurement/Modeling. In Measurement in Machining and Tribology. Materials Forming, Machining and Tribology; Davim, J., Ed.; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Sánchez Egea, A.J.; Martynenko, V.; Martínez Krahmer, D.; López de Lacalle, L.N.; Benítez, A.; Genovese, G. On the Cutting Performance of Segmented Diamond Blades when Dry-Cutting Concrete. Materials 2018, 11, 264. [Google Scholar] [CrossRef] [PubMed]

- Fernández Valdivieso, A.; López de Lacalle, L.N.; Urbikain, G.; Rodríguez, A. Detecting the key geometrical features and grades of carbide inserts for the turning of nickel-based alloys concerning surface integrity. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2016, 230, 3725–3742. [Google Scholar] [CrossRef]

- Isik, Y. An Experimental Investigation on Effect of Cutting Fluids in Turning with Coated Carbides Tool. J. Mech. Eng. 2010, 56, 195–201. [Google Scholar]

- Priarone, P.; Robiglio, M.; Settineri, L.; Tebaldo, V. Effectiveness of minimizing cutting fluid use when turning difficult-to-cut alloys. Procedia CIRP 2015, 29, 341–346. [Google Scholar] [CrossRef]

- Gill, S.; Singh, R. Wear behaviour of cryogenically treated tungsten carbide inserts under dry and wet turning conditions. Int. J. Mach. Tools Manuf. 2009, 49, 256–260. [Google Scholar] [CrossRef]

- Jomaa, W.; Zaghbani, I.; Songmene, V.; Philippe, L.; Boire, L.; Lehuy, H. Dry and Wet Machinability of Hardened Mould Steels. In Proceedings of the International Conference on Environmental Pollution and Remediation, Ottawa, ON, Canada, 17–19 August 2011; p. 210. [Google Scholar]

- Ibrahim, M.; Rahim, E.; Ghazali, M.; Chai, M.; Goh, Z. Experimental Analysis on Ultrasonic Assisted Turning (UAT) Based on Innovated Tool Holder in the Scope of Dry & Wet Machining. Appl. Mech. Mater. 2014, 660, 104–108. [Google Scholar] [CrossRef] [Green Version]

- Adegbuyi, P.; Lawal, G.; Oluseye, O.; Odunaiya, G. Analysing the effect of cutting fluids on the mechanical properties of mild steel in a turning operation. Am. J. Sci. Ind. Res. 2011, 2, 1–10. [Google Scholar] [CrossRef]

- Onuoha, O.; Abu, J.; Lawal, S.; Mudiare, E.; Adeyemi, M. Determining the effect of cutting fluids on surface roughness in turning AISI 1330 alloy steel using Taguchi method. Mod. Mech. Eng. 2016, 6, 51–59. [Google Scholar] [CrossRef]

- Kuram, E.; Ozcelik, B.; Demirbas, E.; Şık, E. Effects of the cutting fluid types and cutting parameters on surface roughness and thrust force. In Proceedings of the World Congress on Engineering Vol II, London, UK, 30 June–2 July 2010. [Google Scholar]

- Luiz, N.; Machado, A. Development trends and review of free-machining steels. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2008, 222, 347–360. [Google Scholar] [CrossRef]

- Almeida, M.; Ferreira, J.; Luis, N.; Machado, A.; Oliveira, D.; Pimentel, M. Study of the effect of residual elements (Cr, Ni, and Cu) on the machinability of free-machining steel AISI 12L14 using design of experiment. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2010, 224, 1481–1489. [Google Scholar] [CrossRef]

- Lane, B.; Shi, M.; Dow, T.; Scattergood, R. Diamond tool wear when machining Al6061 and 1215 steel. Wear 2010, 268, 1434–1441. [Google Scholar] [CrossRef]

- Leeba Varghese, L.; Aravind, S.; Shunmugesh, K. Multi-Objective Optimization of Machining Parameters during Dry Turning of 11SMn30 Free Cutting Steel Using Grey Relational Analysis. Mater. Today Proc. 2017, 4, 4196–4203. [Google Scholar] [CrossRef]

- Xu, J.; An, Q.; Chen, M. Experimental Study on High-speed Turning of Free-cutting Steel AISI 12L14 Using Multi-Layer Coated Carbide Tools. Adv. Mater. Res. 2012, 500, 3–7. [Google Scholar] [CrossRef]

- Xu, J.; Liu, Z.; Guo, G.; Chen, M. An investigation on wear mechanism of high-speed turning of free-cutting steel AISI 1215 using uncoated and multi-layer coated tools. Int. J. Adv. Manuf. Technol. 2013, 67, 517–533. [Google Scholar] [CrossRef]

- ASTM E112, Standard Test Methods for Determining Average Grain Size; ASTM International: West Conshohocken, PA, USA, 2013.

- ISO 3685:1993(E), International Standard, Tool Testing with Single Point Turning Tools; International Organization for Standardization: Geneve, Switzerland, 1993.

- Komvopoulos, K.; Do, V.; Yamaguchi, E.S.; Ryason, P.R. Effect of Sulfur- and Phosphorus-Containing Additives and Metal Deactivator on the Tribological Properties of Boundary-Lubricated Steel Surfaces. Tribol. Trans. 2003, 46, 315–325. [Google Scholar] [CrossRef]

| Material | C | Mn | S | P | Pb | Fe | HB |

|---|---|---|---|---|---|---|---|

| SAE 12L14 | 0.074 | 1.065 | 0.313 | 0.055 | 0.246 | Balance | 161 |

| SAE 1215 | 0.065 | 1.000 | 0.318 | 0.052 | - | Balance | 155 |

| SAE 1212 | 0.070 | 1.050 | 0.303 | 0.055 | - | Balance | 161 |

| Code | Geometrical Description | Sizes (mm) | Chemical Composition (wt%) | |||||

|---|---|---|---|---|---|---|---|---|

| s | r | l | C | Ti | Co | W | ||

| CNMG 120408ISO P40 |  | 4.76 | 0.8 | 12 | 16.60 | 3.85 | 12.10 | 60.80 |

| Cutting Speed Vc (m/min) | Feed Rate a (mm/v) | Depth of Cut p (mm) | Type of Lubricant | Flow (L/min) | VB (mm) |

|---|---|---|---|---|---|

| 150; 180; 240 | 0.125 | 1.25 | None | - | 0.5 |

| 5% of emulsifier | 10 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martinez Krahmer, D.; Hameed, S.; Sánchez Egea, A.J.; Pérez, D.; Canales, J.; López de Lacalle, L.N. Wear and MnS Layer Adhesion in Uncoated Cutting Tools When Dry and Wet Turning Free-Cutting Steels. Metals 2019, 9, 556. https://doi.org/10.3390/met9050556

Martinez Krahmer D, Hameed S, Sánchez Egea AJ, Pérez D, Canales J, López de Lacalle LN. Wear and MnS Layer Adhesion in Uncoated Cutting Tools When Dry and Wet Turning Free-Cutting Steels. Metals. 2019; 9(5):556. https://doi.org/10.3390/met9050556

Chicago/Turabian StyleMartinez Krahmer, D., S. Hameed, A. J. Sánchez Egea, D. Pérez, J. Canales, and L. N. López de Lacalle. 2019. "Wear and MnS Layer Adhesion in Uncoated Cutting Tools When Dry and Wet Turning Free-Cutting Steels" Metals 9, no. 5: 556. https://doi.org/10.3390/met9050556