Enhancing the Mechanical Properties of Hot Roll Bonded Al/Ti Laminated Metal Composites (LMCs) by Pre-Rolling Diffusion Process

Abstract

:1. Introduction

2. Experimental Materials and Procedures

2.1. Experimental Materials

2.2. Fabrication Process of Al/Ti LMCs

2.3. Characterization of Microstructure and Mechanical Properties

3. Results and Discussion

3.1. Microstructure after Pre-Rolling Diffusion Process

3.2. Effect of Pre-Rolling Diffusion on Mechanical Properties of Hot-Rolled Al/Ti LMCs

3.3. Effect of Annealing on Mechanical Properties of Al/Ti LMCs

4. Conclusions

- (1)

- With increasing diffusion temperature, the thickness in diffusion layer comprising the diffusion intermetallic compounds (IMCs) was increased gradually at the bonding interface, resulting in the oxide was inhibited and the bonding strength was improved.

- (2)

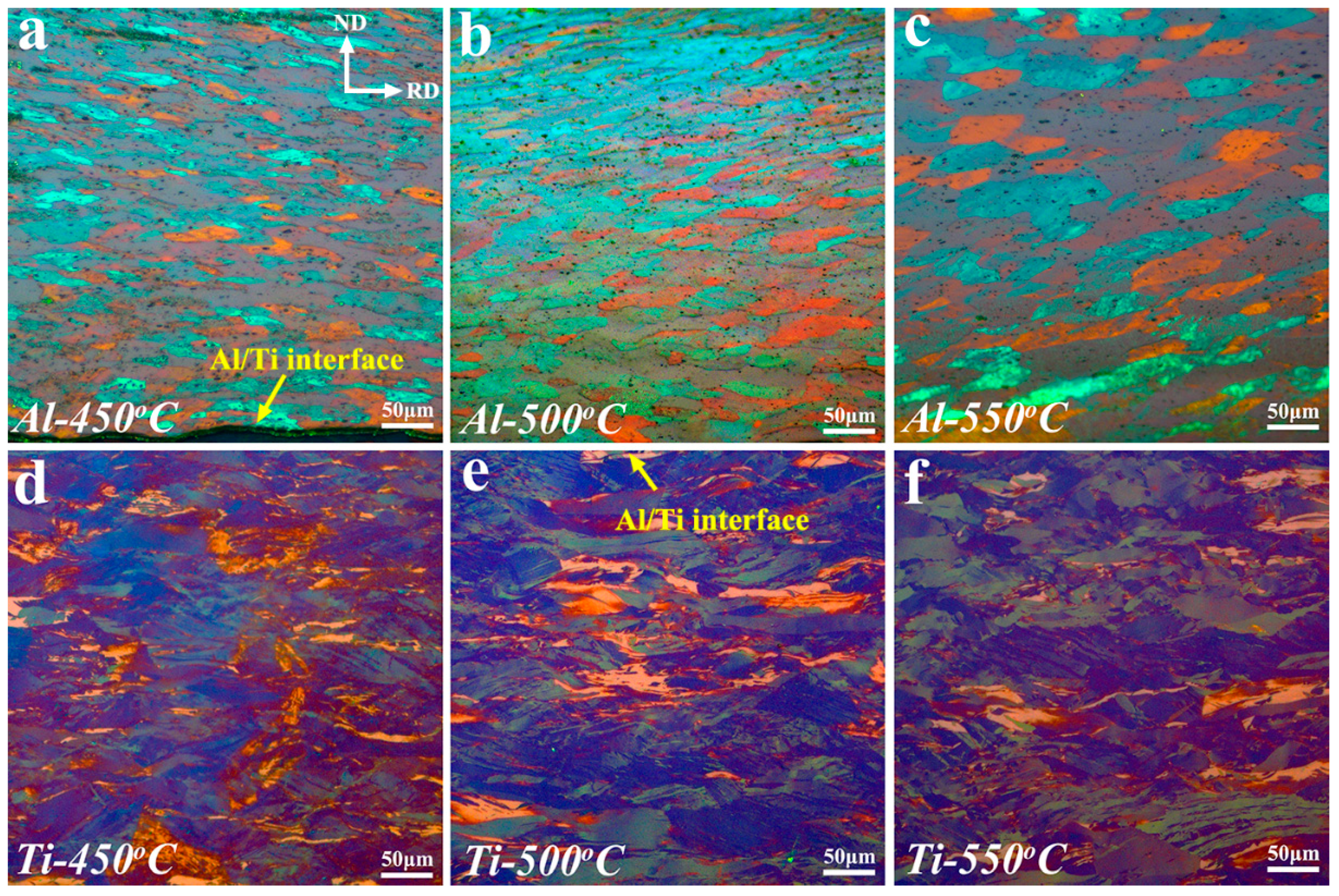

- The development of microstructure in Al layers was observed from elongated grain to equiaxed grain with increasing diffusion temperature, while the microstructure of Ti layers was found to be a constant. The inhomogeneity of microstructure through the thickness of Al layer can be attributed to the effect of the friction between the roll and sheet surface and the uncoordinated between constituent layers.

- (3)

- The extra strengthening effect was revealed using rule of mixture (ROM) in the pre-rolling diffusion processed Al/Ti LMCs, which indicated that the interfacial optimization played an important role on the improvement of mechanical properties.

Author Contributions

Funding

Conflicts of Interest

References

- Li, L.; Nagai, K.; Yin, F. Progress in cold roll bonding of metals. Sci. Technol. Adv. Mater. 2008, 9, 023001. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Fan, G.; Yu, T.; Hansen, N.; Geng, L.; Huang, X. Laminated Ti-Al composites: Processing, structure and strength. Mater. Sci. Eng. A 2016, 673, 572–580. [Google Scholar] [CrossRef] [Green Version]

- Altıntas, Y.; Aksöz, S.; Keşlioğlu, K.; Maraşlı, N. Determination of thermodynamic properties of aluminum based binary and ternary alloys. J. Alloy. Compd. 2015, 649, 453–460. [Google Scholar] [CrossRef]

- Guo, X.; Fan, M.; Liu, Z.; Ma, F.; Wang, L.; Jie, T. Explosive cladding and hot pressing of Ti/Al/Ti laminates. Rare Met. Mater. Eng. 2017, 46, 1192–1196. [Google Scholar]

- Zhao, H.; Yu, M.; Jiang, Z.; Zhou, L.; Song, X. Interfacial microstructure and mechanical properties of Al/Ti dissimilar joints fabricated via friction stir welding. J. Alloys Compd. 2019, 789, 139–149. [Google Scholar] [CrossRef]

- Siddiq, A.; Schmauder, S.; Huang, Y. Fracture of bicrystal metal/ceramic interfaces: A study via the mechanism-based strain gradient crystal plasticity theory. Int. J. Plast. 2007, 23, 665–689. [Google Scholar] [CrossRef]

- Shokrani, A.; Dhokia, V.; Newman, S.T. Environmentally conscious machining of difficult-to-machine materials with regard to cutting fluids. Int. J. Mach. Tools Manuf. 2012, 57, 83–101. [Google Scholar] [CrossRef] [Green Version]

- Kuemmel, F.; Kreuz, M.; Hausöel, T.; Höeppel, H.W.; Göeken, M. Microstructure and mechanical properties of accumulative roll-bonded AA1050A/AA5005 laminated metal composites. Metals 2016, 6, 56. [Google Scholar] [CrossRef]

- Cepeda-Jiménez, C.M.; Pozuelo, M.; Ruano, O.A.; Carreño, F. Influence of the thermomechanical processing on the fracture mechanisms of high strength aluminium/pure aluminium multilayer laminate materials. Mater. Sci. Eng. A 2008, 490, 319–327. [Google Scholar] [CrossRef] [Green Version]

- Ma, M.; Huo, P.; Liu, W.C.; Wang, G.J.; Wang, D.M. Microstructure and mechanical properties of Al/Ti/Al LMCs prepared by roll bonding. Mater. Sci. Eng. A 2015, 636, 301–310. [Google Scholar] [CrossRef]

- Motevalli, P.D.; Eghbali, B. Microstructure and mechanical properties of Tri-metal Al/Ti/Mg laminated composite processed by accumulative roll bonding. Mater. Sci. Eng. A 2015, 628, 135–142. [Google Scholar] [CrossRef]

- Wu, F.; Zhou, W.L.; Zhao, B.; Hou, H.L. Interface microstructure and bond strength of 1420/7B04 composite sheets prepared by diffusion bonding. Rare Met. 2018, 37, 613–620. [Google Scholar] [CrossRef]

- Bian, H.; Lei, Y.; Fu, W.; Hu, S.; Song, X.; Feng, J. Diffusion bonding of Ti2AlNb alloy and high-Nb-containing TiAl alloy: Interfacial microstructure and mechanical properties. Metals 2018, 8, 1061. [Google Scholar] [CrossRef]

- Fronczek, D.M.; Chulist, R.; Litynska-Dobrzynska, L.; Szulc, Z.; Zieba, P.; Wojewoda-Budka, J. Microstructure changes and phase growth occurring at the interface of the Al/Ti explosively welded and annealed joints. J. Mater. Eng. Perform. 2016, 25, 3211–3217. [Google Scholar] [CrossRef]

- Fronczek, D.M.; Wojewoda-Budka, J.; Chulist, R.; Sypien, A.; Korneva, A.; Szulc, Z.; Schell, N.; Zieba, P. Structural properties of Ti/Al clads manufactured by explosive welding and annealing. Mater. Des. 2016, 91, 80–89. [Google Scholar] [CrossRef]

- Fan, M.; Luo, Z.; Fu, Z.; Guo, X.; Jie, T. Vacuum hot pressing and fatigue behaviors of Ti/Al laminate composites. Vacuum 2018, 154, 101–109. [Google Scholar] [CrossRef]

- Liang, Q.; Fan, M.; Guo, X.; Jie, T. Plastic deformation behaviors of Ti-Al laminated composite fabricated by vacuum hot-pressing. Vacuum 2018, 155, 96–107. [Google Scholar]

- Kong, F.; Chen, Y.; Zhang, D. Interfacial microstructure and shear strength of Ti-6Al-4V/TiAl laminate composite sheet fabricated by hot packed rolling. Mater. Des. 2011, 32, 3167–3172. [Google Scholar] [CrossRef]

- Chaudhari, G.P.; Acoff, V.L. Titanium aluminide sheets made using roll bonding and reaction annealing. Intermetallics 2010, 18, 472–478. [Google Scholar] [CrossRef]

- Yu, H.; Cheng, L.; Tieu, A.K.; Li, H.; Godbole, A.; Kong, C. Annealing effect on microstructure and mechanical properties of Al/Ti/Al laminate sheets. Mater. Sci. Eng. A 2016, 660, 195–204. [Google Scholar] [CrossRef]

- Bataev, I.A.; Bataev, A.A.; Mali, V.I.; Pavliukova, D.V. Structural and mechanical properties of metallic–intermetallic laminate composites produced by explosive welding and annealing. Mater. Des. 2012, 35, 225–234. [Google Scholar] [CrossRef]

- Mirjalili, M.; Soltanieh, M.; Matsuura, K.; Ohno, M. On the kinetics of TiAl3 intermetallic layer formation in the titanium and aluminum diffusion couple. Intermetallics 2013, 32, 297–302. [Google Scholar] [CrossRef]

- Xu, F.; Zhang, X.; Ni, H.; Cheng, Y.; Zhu, Y.; Liu, Q. Effect of twinning on microstructure and texture evolutions of pure Ti during dynamic plastic deformation. Mater. Sci. Eng. A 2013, 564, 22–33. [Google Scholar] [CrossRef]

- Sahoo, S.; Sabat, R.; Sahni, S.; Suwas, S. Texture and microstructure evolution of commercially pure titanium during hot rolling: Role of strain-paths. Mater. Des. 2016, 91, 58–71. [Google Scholar] [CrossRef]

- Yang, D.; Cizek, P.; Hodgson, P.; Wen, C.E. Ultrafine equiaxed-grain Ti/Al composite produced by accumulative roll bonding. Scr. Mater. 2010, 62, 321–324. [Google Scholar] [CrossRef]

- Lyu, S.; Sun, Y.; Lei, R.; Xiao, W.; Ma, C. Simultaneously achieving high tensile strength and fracture toughness of Ti/Ti-Al multilayered composites. Intermetallics 2017, 90, 16–22. [Google Scholar] [CrossRef]

- Gang, C.; Song, X.; Nan, H.; Wang, H.; Tian, Y. Effect of initial Ti powders size on the microstructures and mechanical properties of Al3Ti/2024 Al composites prepared by ultrasonic assisted in-situ casting. J. Alloys Compd. 2017, 694, 539–548. [Google Scholar]

| Zn | Si | Fe | Ti | Al |

|---|---|---|---|---|

| 0.01 | 0.6 | 0.2 | 0.02 | Balance |

| Fe | C | N | H | O | Ti |

|---|---|---|---|---|---|

| 0.3 | 0.1 | 0.05 | 0.015 | 0.25 | Balance |

| Samples | Shear Area (mm2) | Load (N) | Maximum Shear Strength (MPa) |

|---|---|---|---|

| Conventional process | 4.13 | 92.36 | 22.36 |

| D450 | 4.13 | 107.3 | 25.98 |

| D500 | 4.07 | 112.8 | 27.72 |

| D550 | 4.00 | 120.24 | 30.06 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Wang, S.; Qiao, H.; Chen, Z.; Mo, T.; Liu, Q. Enhancing the Mechanical Properties of Hot Roll Bonded Al/Ti Laminated Metal Composites (LMCs) by Pre-Rolling Diffusion Process. Metals 2019, 9, 795. https://doi.org/10.3390/met9070795

Zhang C, Wang S, Qiao H, Chen Z, Mo T, Liu Q. Enhancing the Mechanical Properties of Hot Roll Bonded Al/Ti Laminated Metal Composites (LMCs) by Pre-Rolling Diffusion Process. Metals. 2019; 9(7):795. https://doi.org/10.3390/met9070795

Chicago/Turabian StyleZhang, Cheng, Shouxin Wang, Hanxue Qiao, Zejun Chen, Taiqian Mo, and Qing Liu. 2019. "Enhancing the Mechanical Properties of Hot Roll Bonded Al/Ti Laminated Metal Composites (LMCs) by Pre-Rolling Diffusion Process" Metals 9, no. 7: 795. https://doi.org/10.3390/met9070795