A new Dynamic Plasticity and Failure Model for Metals

Abstract

:1. Introduction

2. Development of a New Dynamic Plasticity and Failure Model

2.1. Strength Model

2.1.1. Quasi-Static True Stress-True Strain Relationship

2.1.2. Strain Rate Effect

2.1.3. Temperature Effect

2.2. Failure Criterion

2.3. Determination of the Values of Various Parameters

- (1)

- Quasi-static smooth bar tension tests at ambient (room) temperature are conducted to determine the values of the parameters in the strength model (Equation (1) and Equation (7)); pure (tubular torsion) shear tests at ambient (room) temperature are performed to determine the values of the parameters in Equation (2), and hence the value of the parameter in the strength model (Equation (7)); the values of the parameters in the failure criterion (Equation (9)) can also be determined from the quasi-static tension and shear tests.

- (2)

- Quasi-static (smooth bar) tension/compression, SHTB/SHPB and plate impact tests are performed to determine the values of the parameters and in Equation (6) for the strain rate effects in the strength model (Equation (7)) and the value of the parameter in the failure criterion (Equation (9)).

- (3)

- Quasi-static (smooth bar) tension/compression tests at different temperatures are carried out to determine the values of the parameters and in the strength model (Equation (7)) and the value of the parameter in the failure criterion (Equation (9)).

3. Verification of the New Dynamic Plasticity and Failure Model

3.1. Comparison with Some Available Material Test Data

3.1.1. Quasi-Static True Stress-True Strain Curves

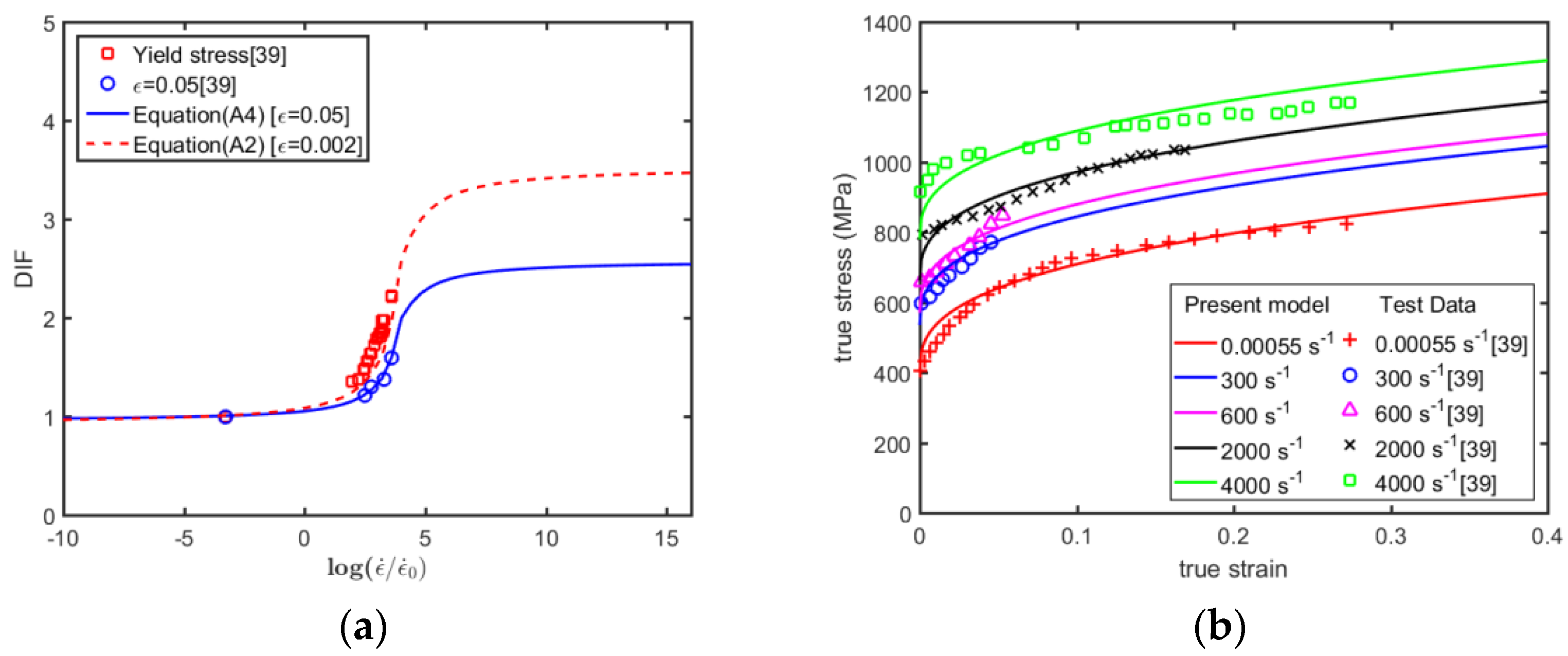

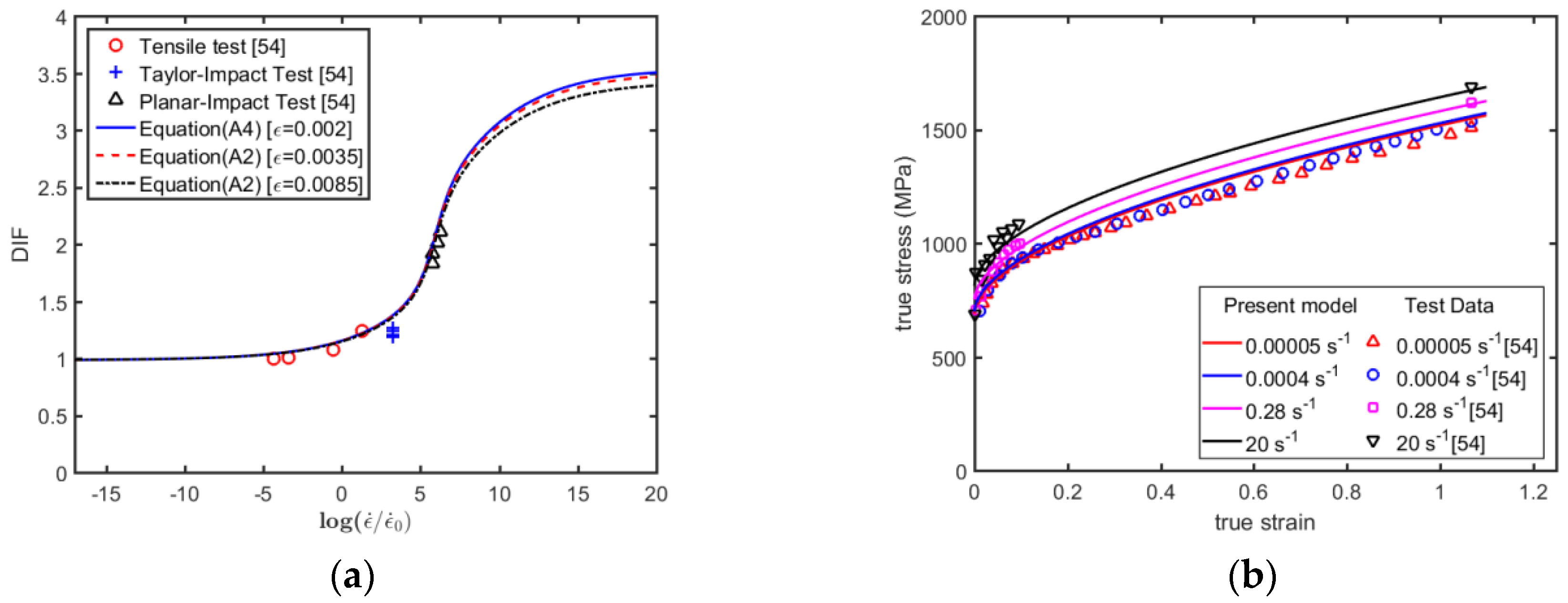

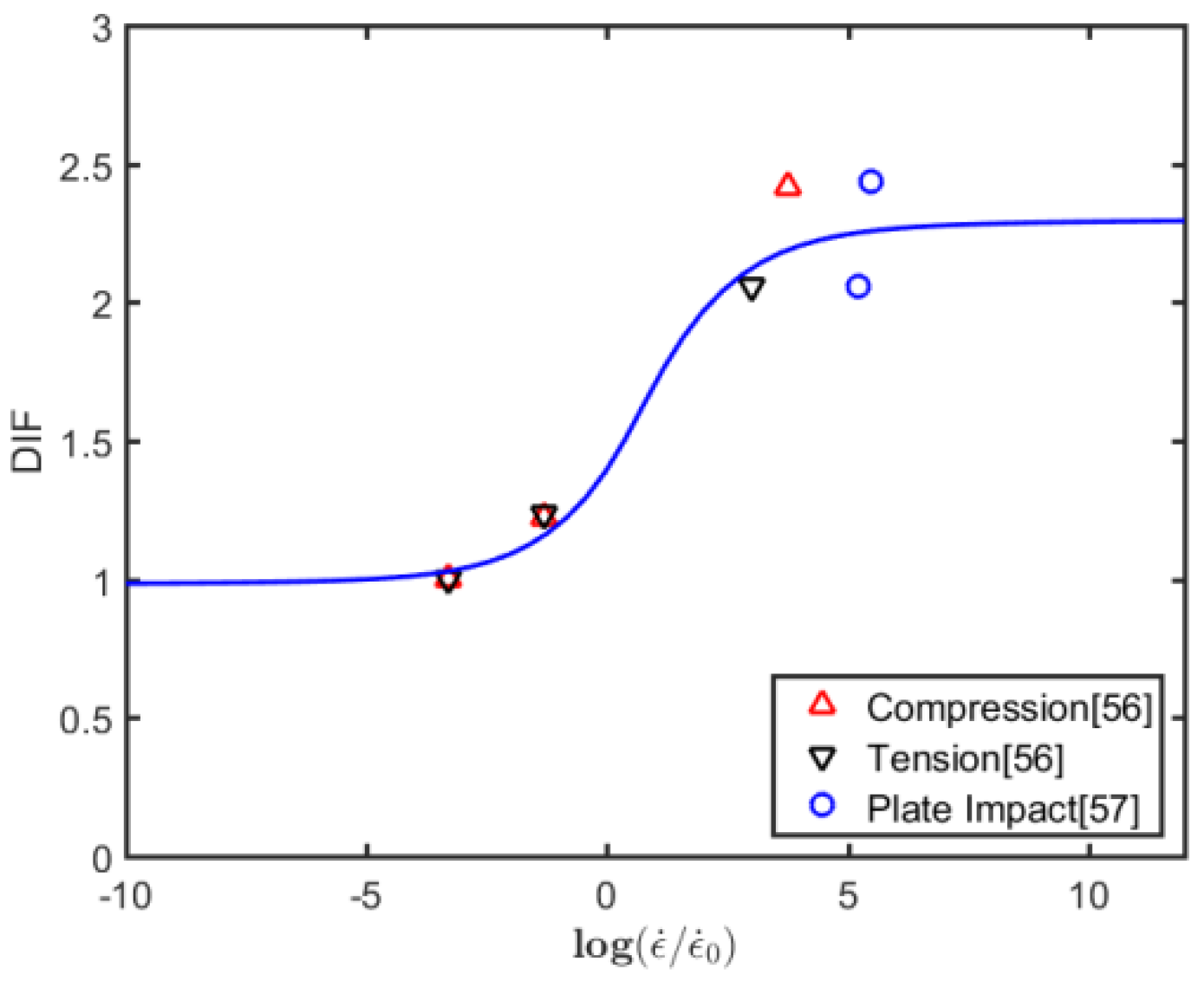

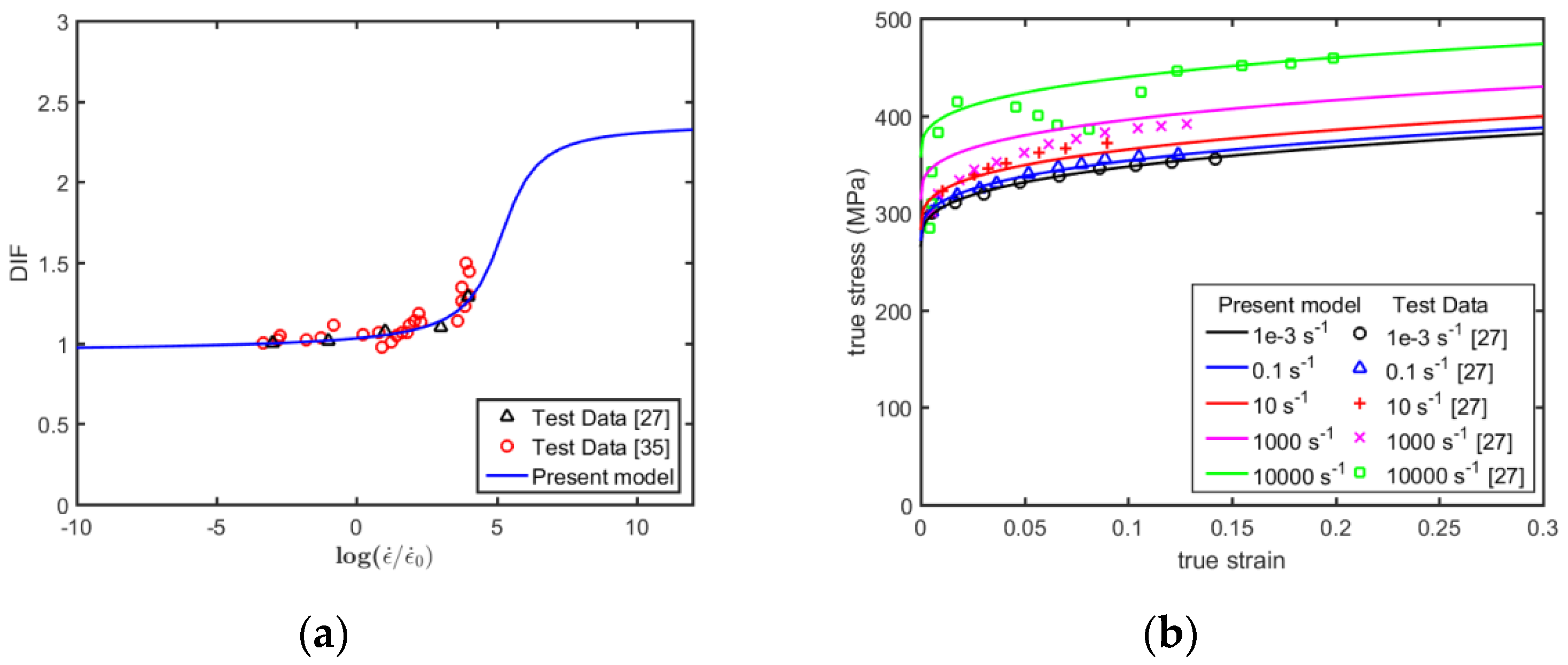

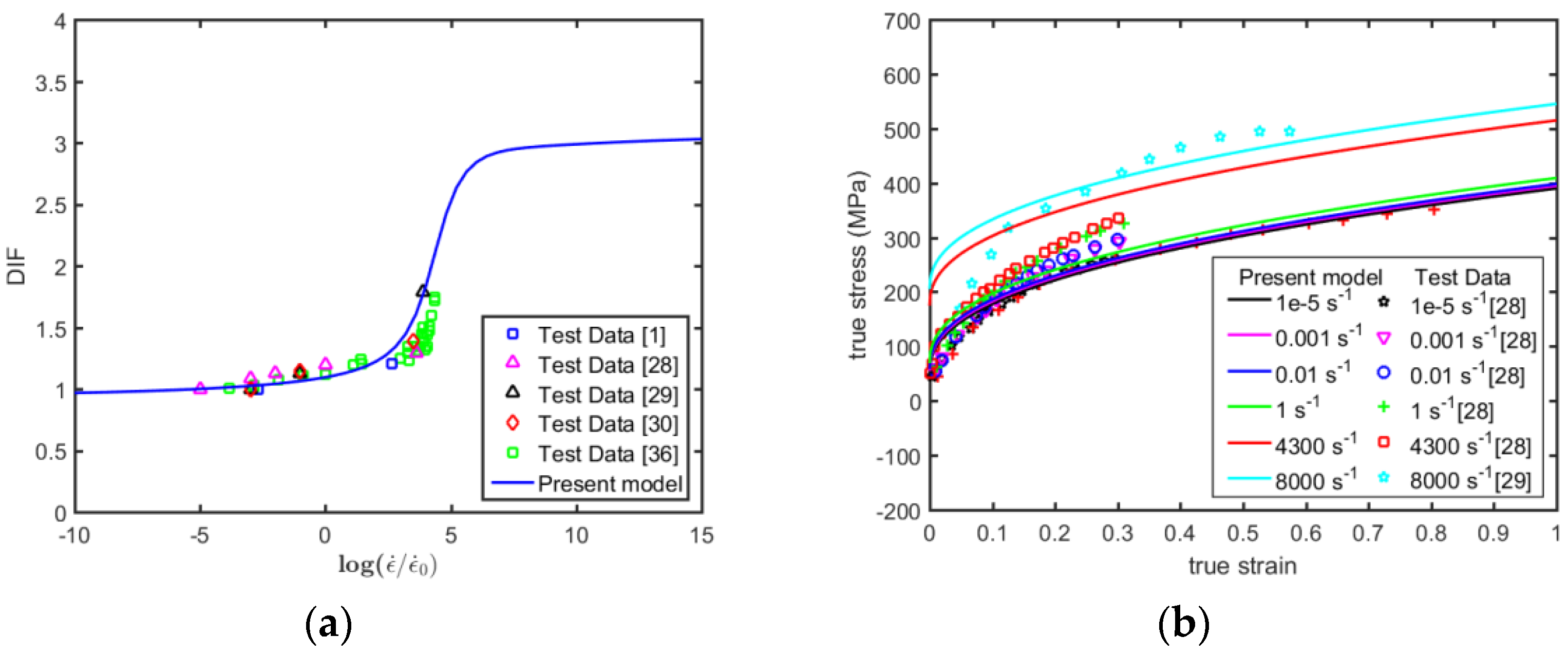

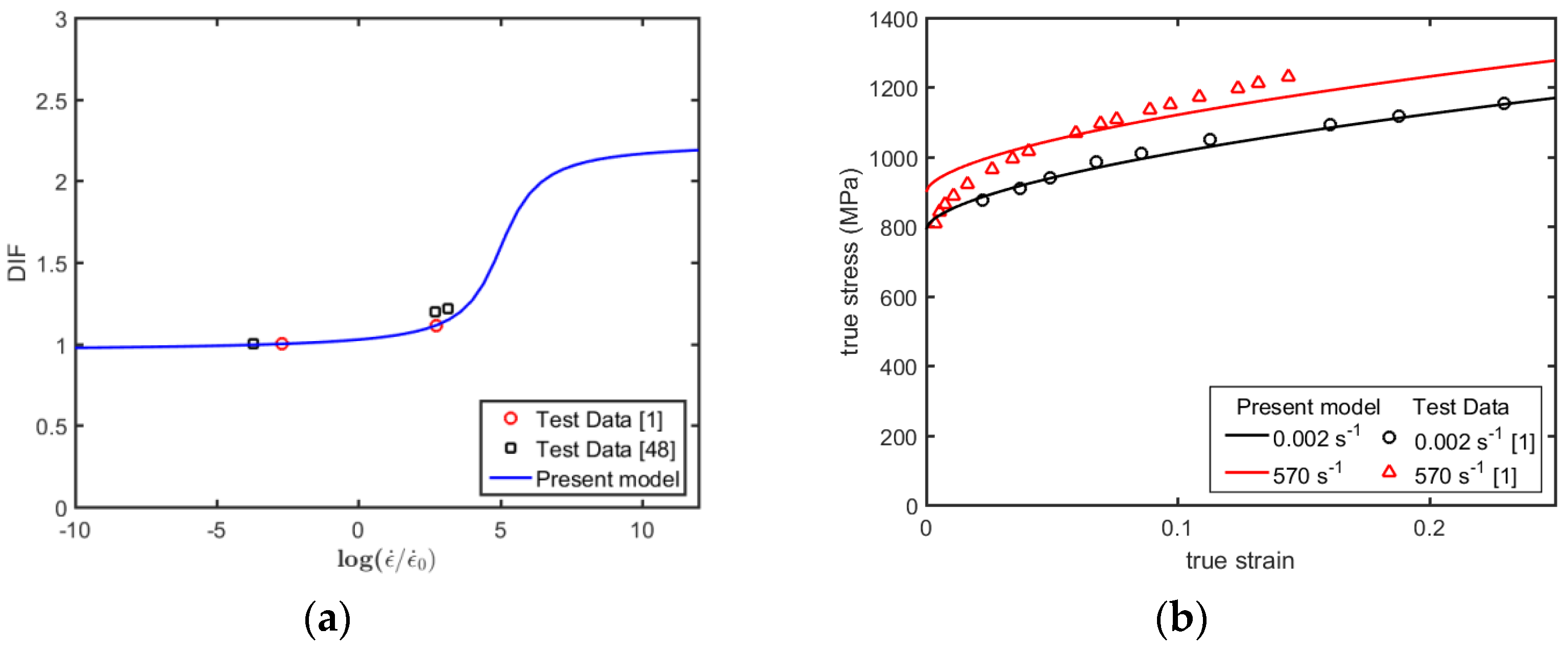

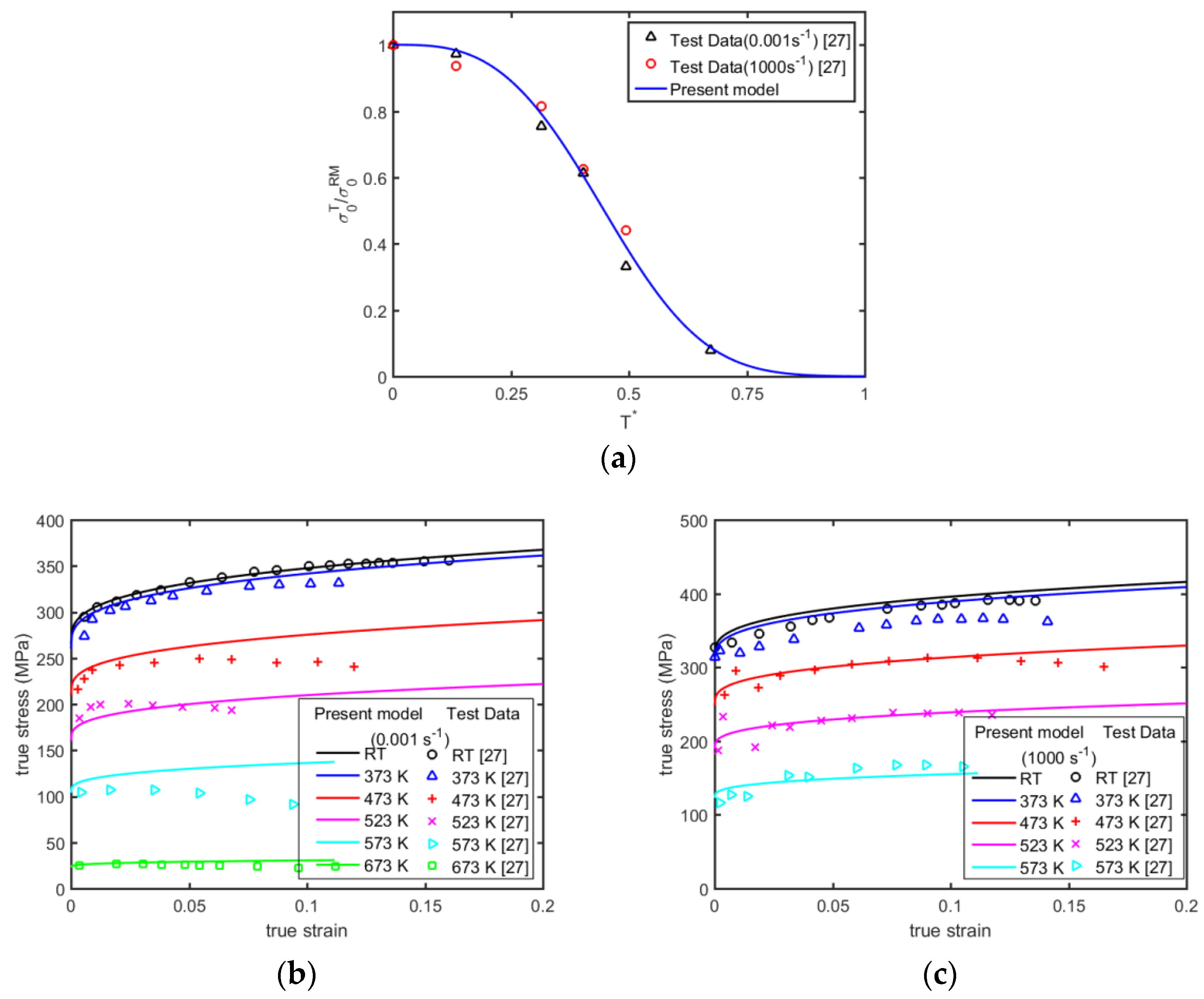

3.1.2. Strain Rate Effects

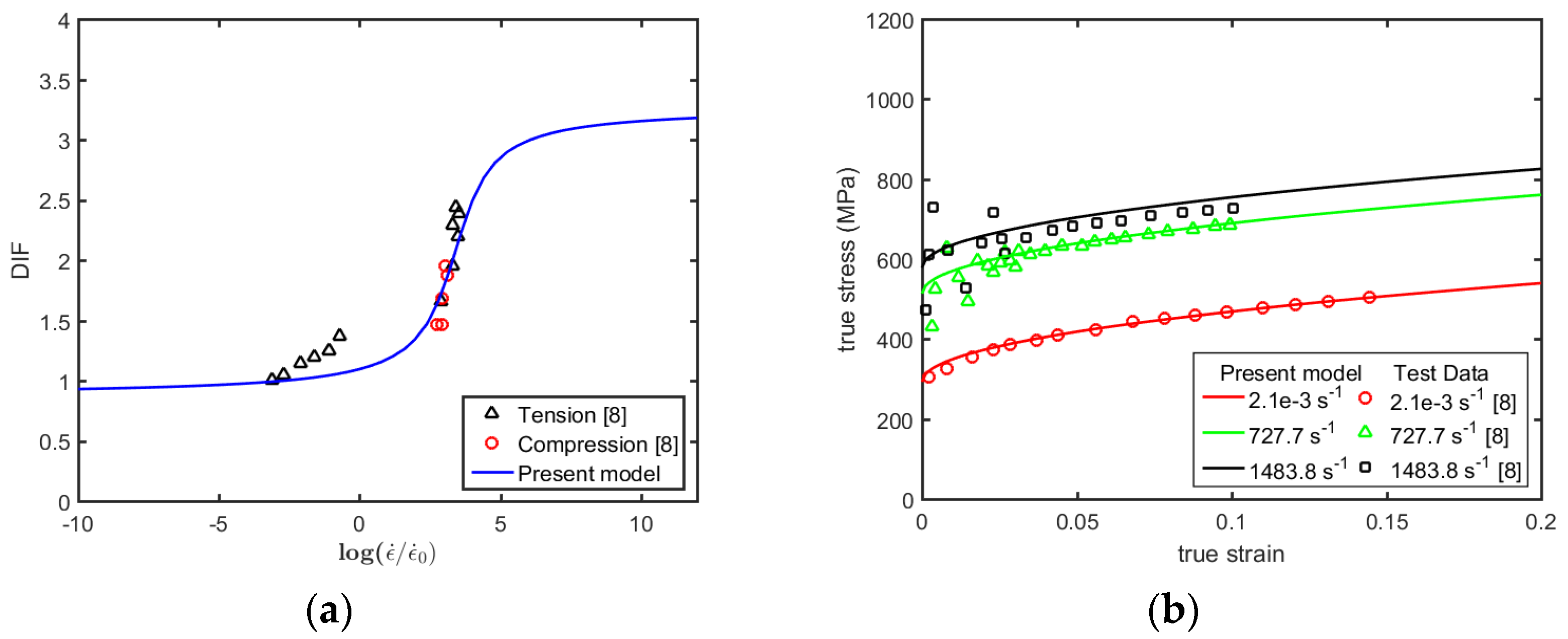

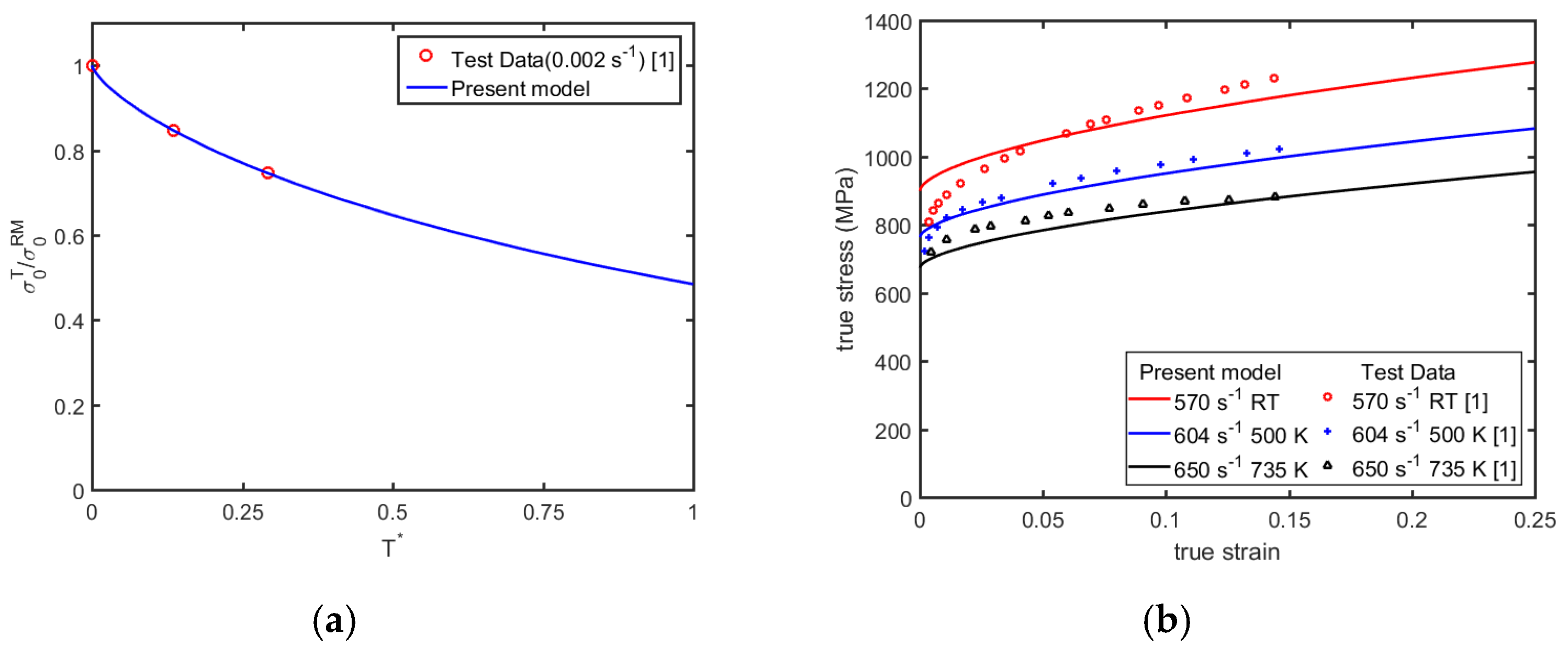

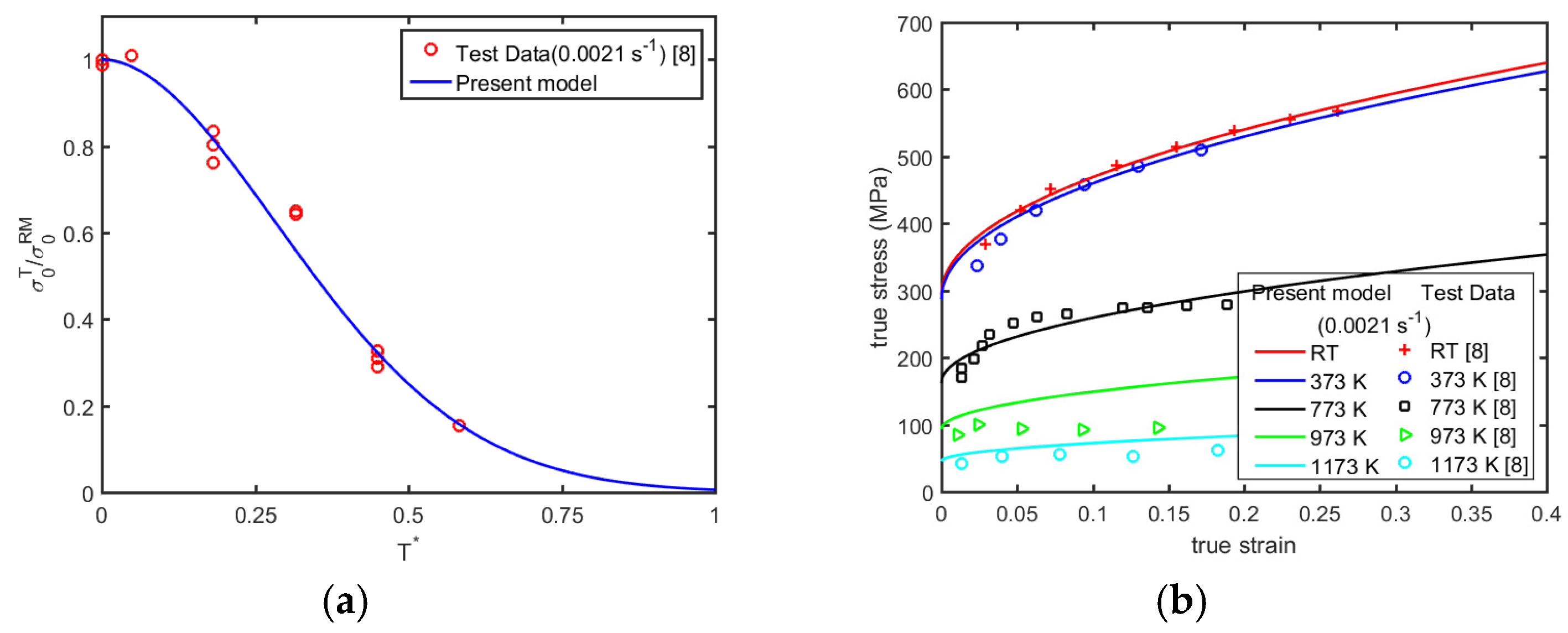

3.1.3. Temperature Effects

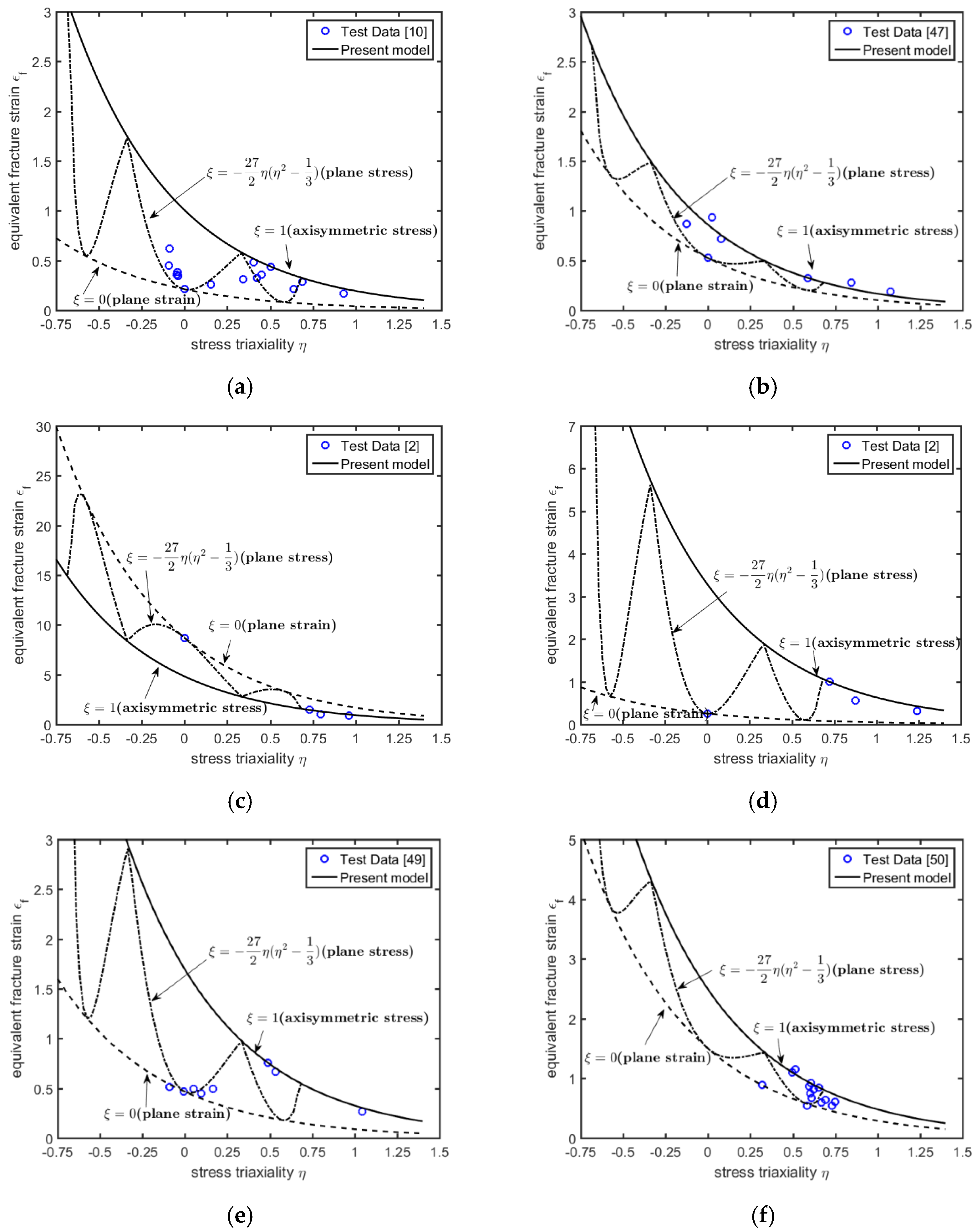

3.1.4. Failure Criterion

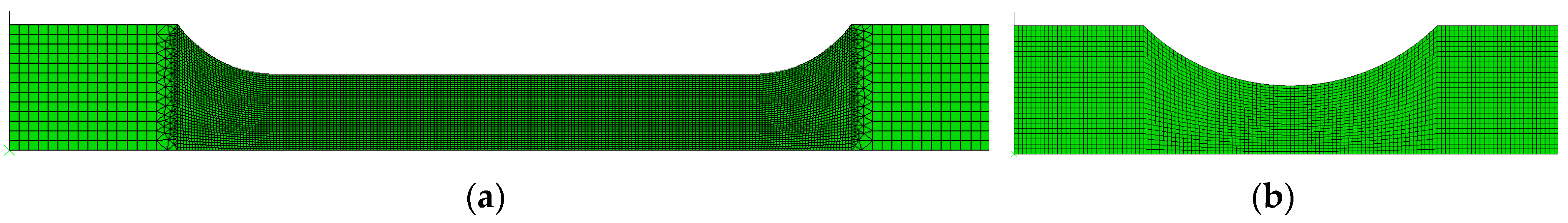

3.2. Numerical Results

3.2.1. Single Element Approach

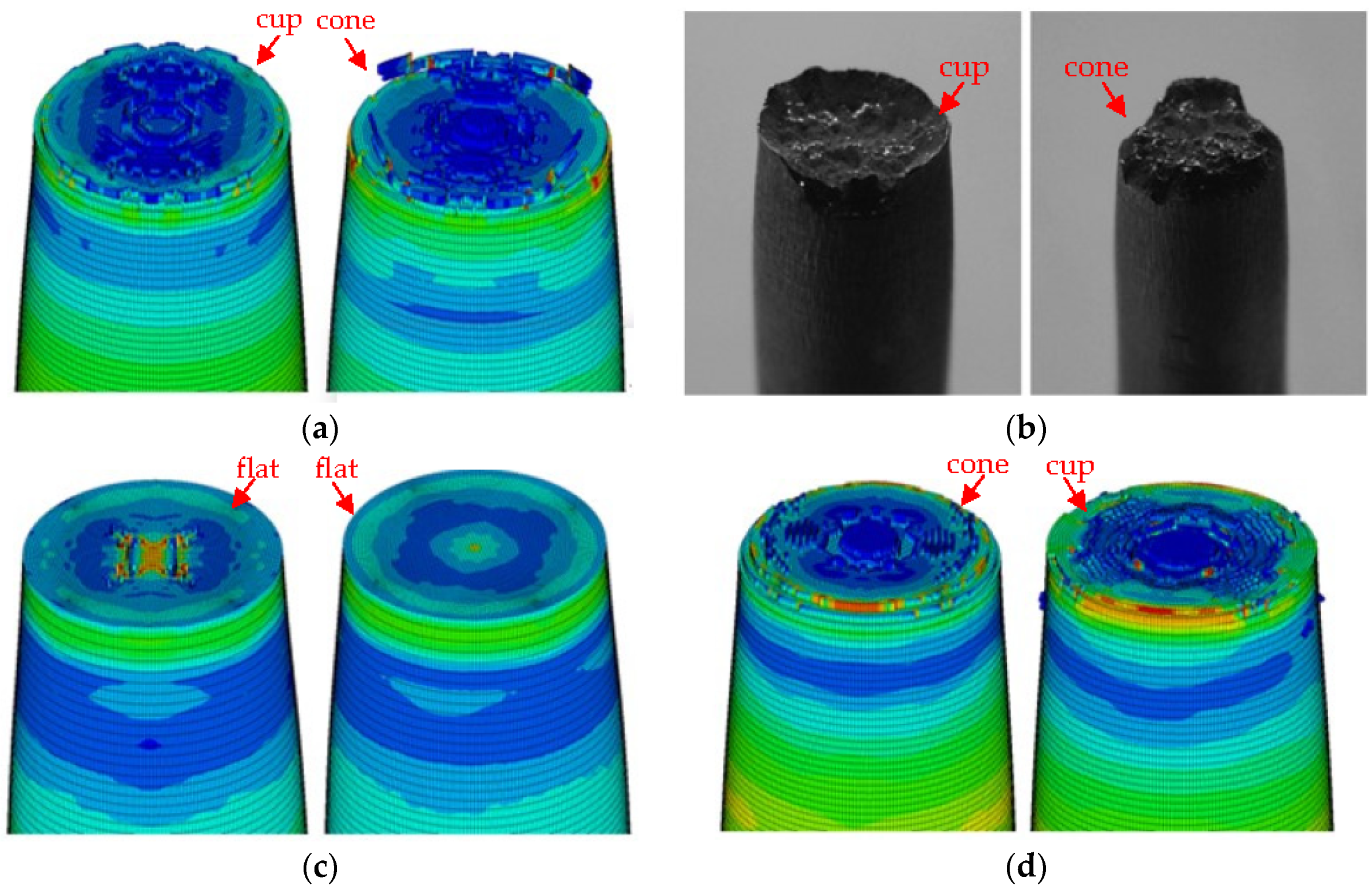

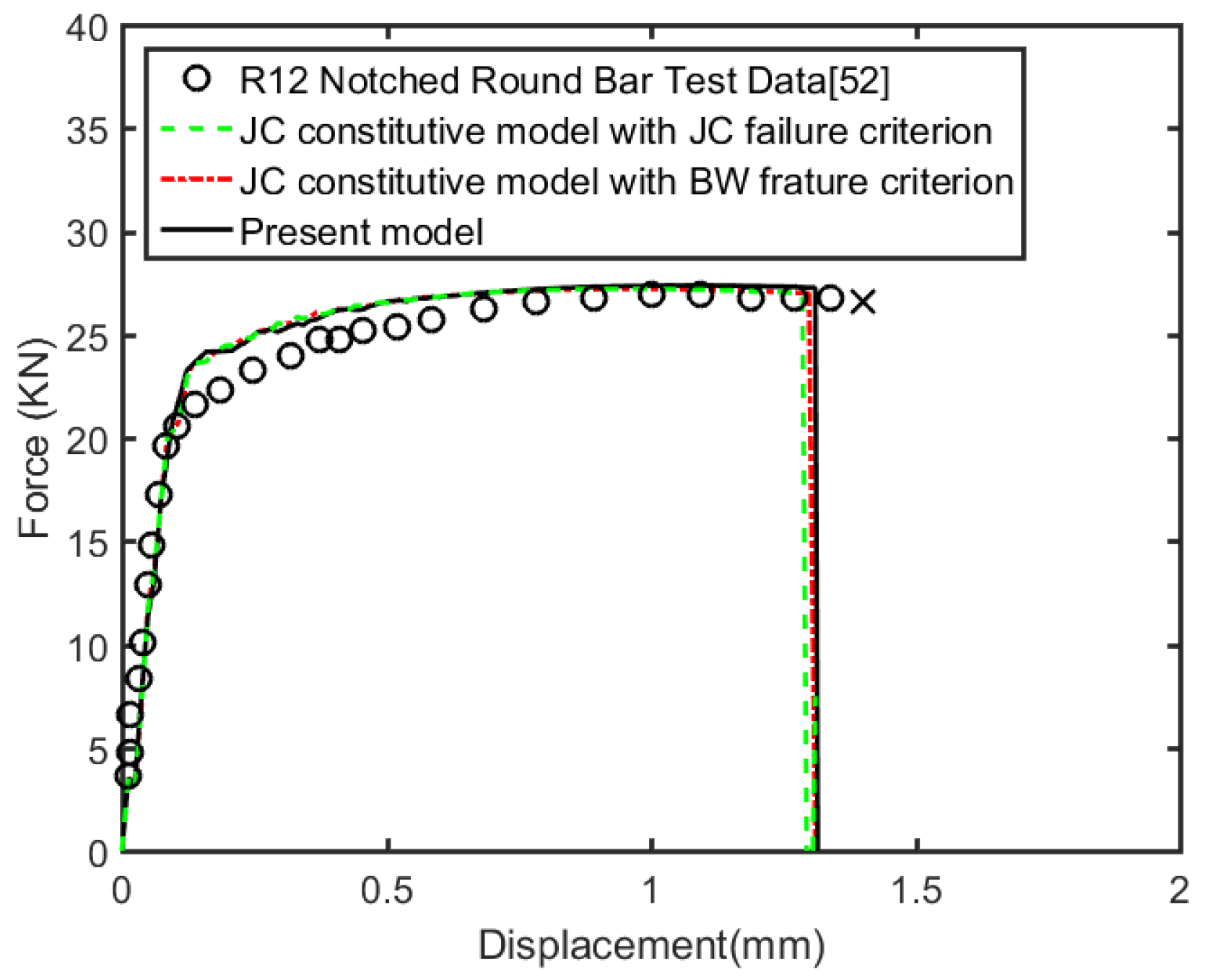

3.2.2. Smooth and Notched Bar Tension Tests

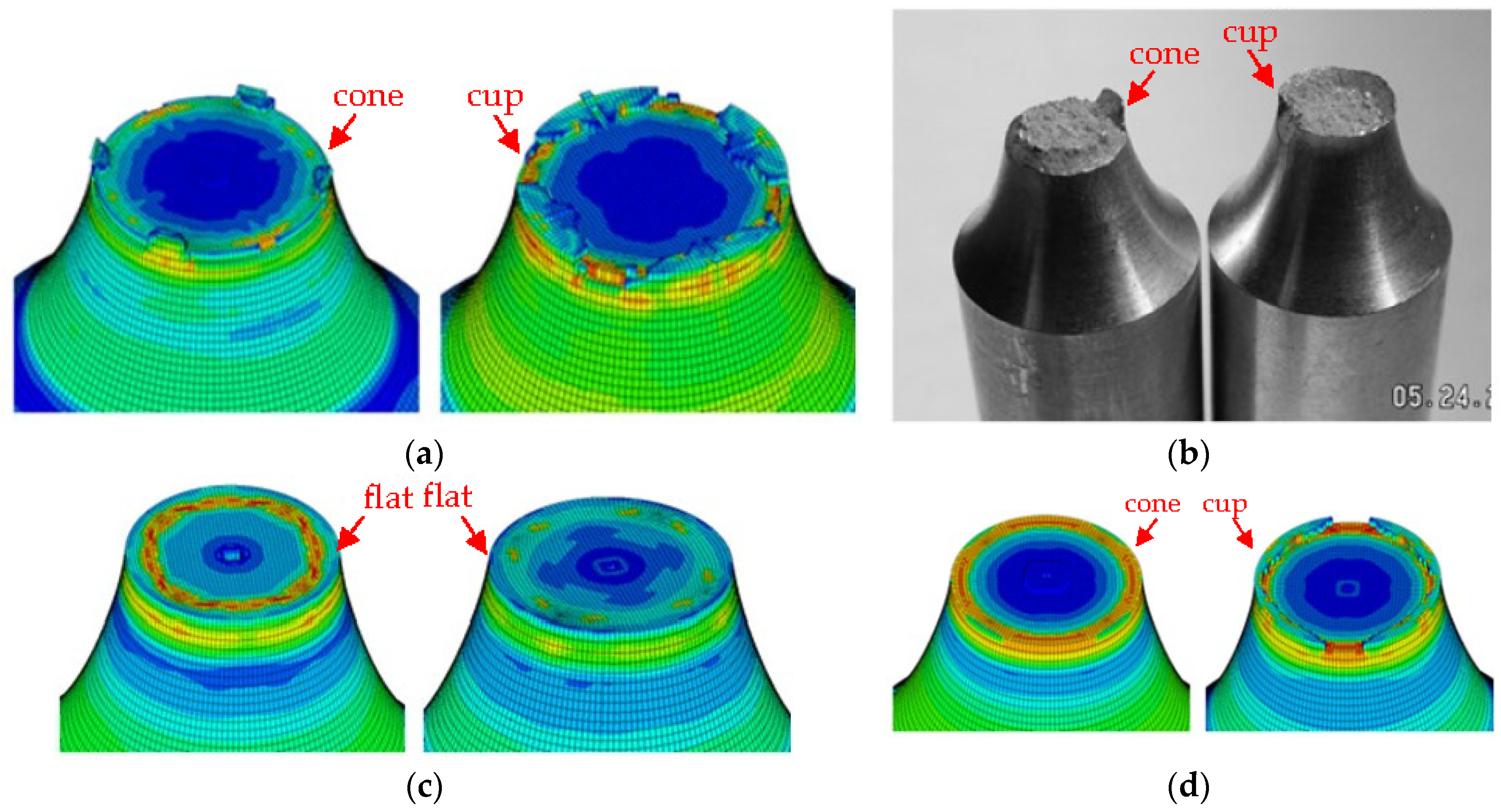

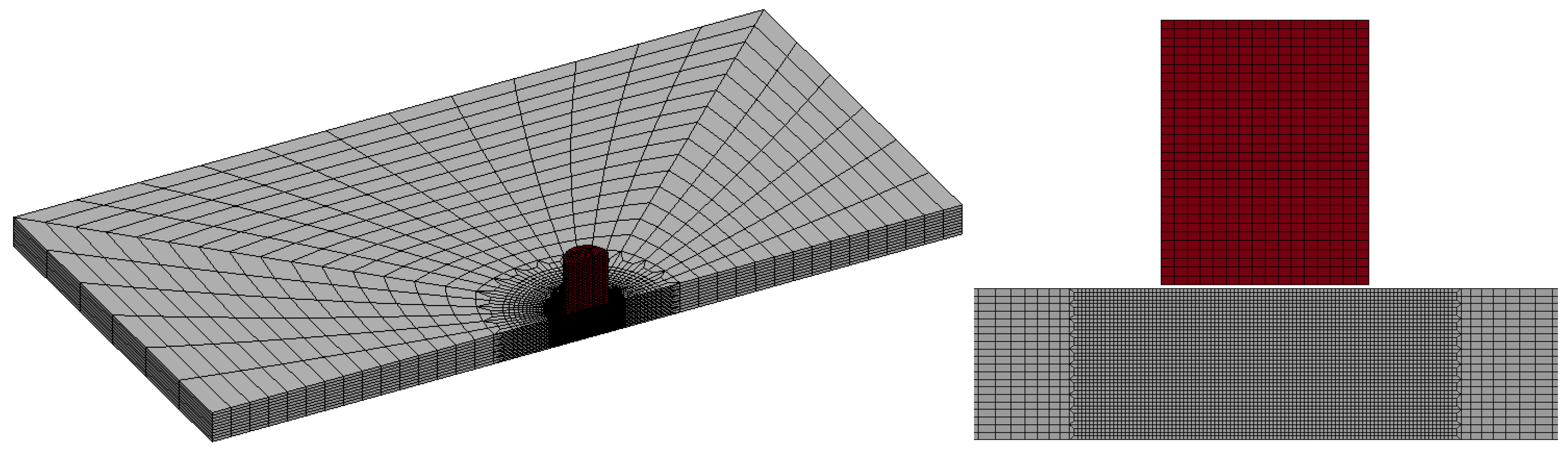

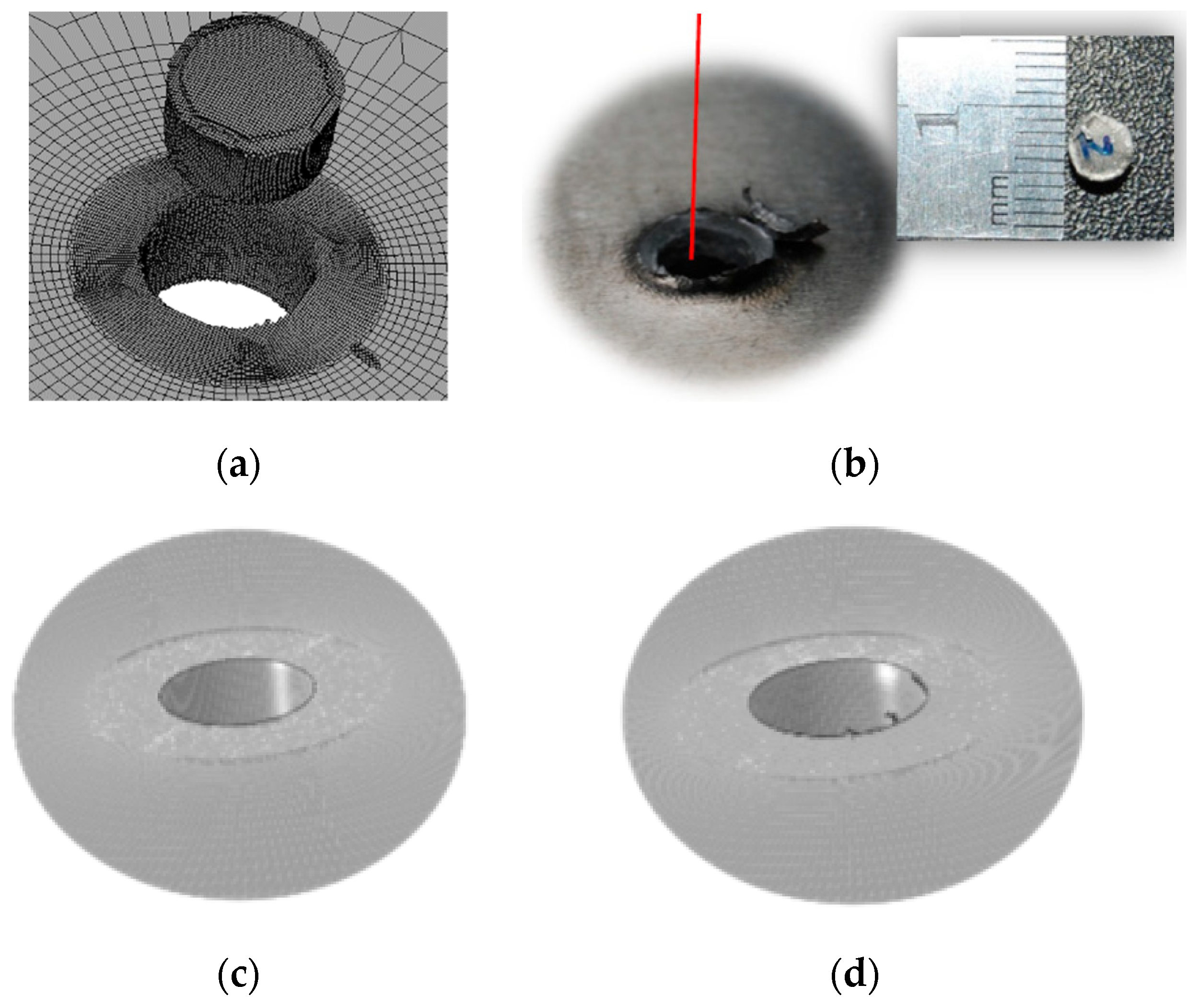

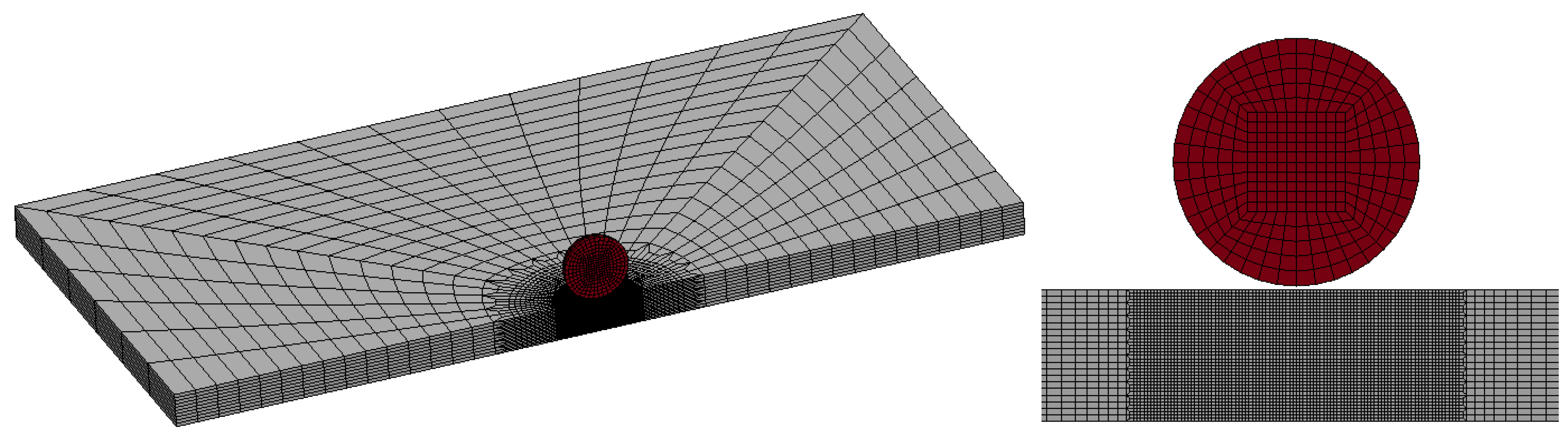

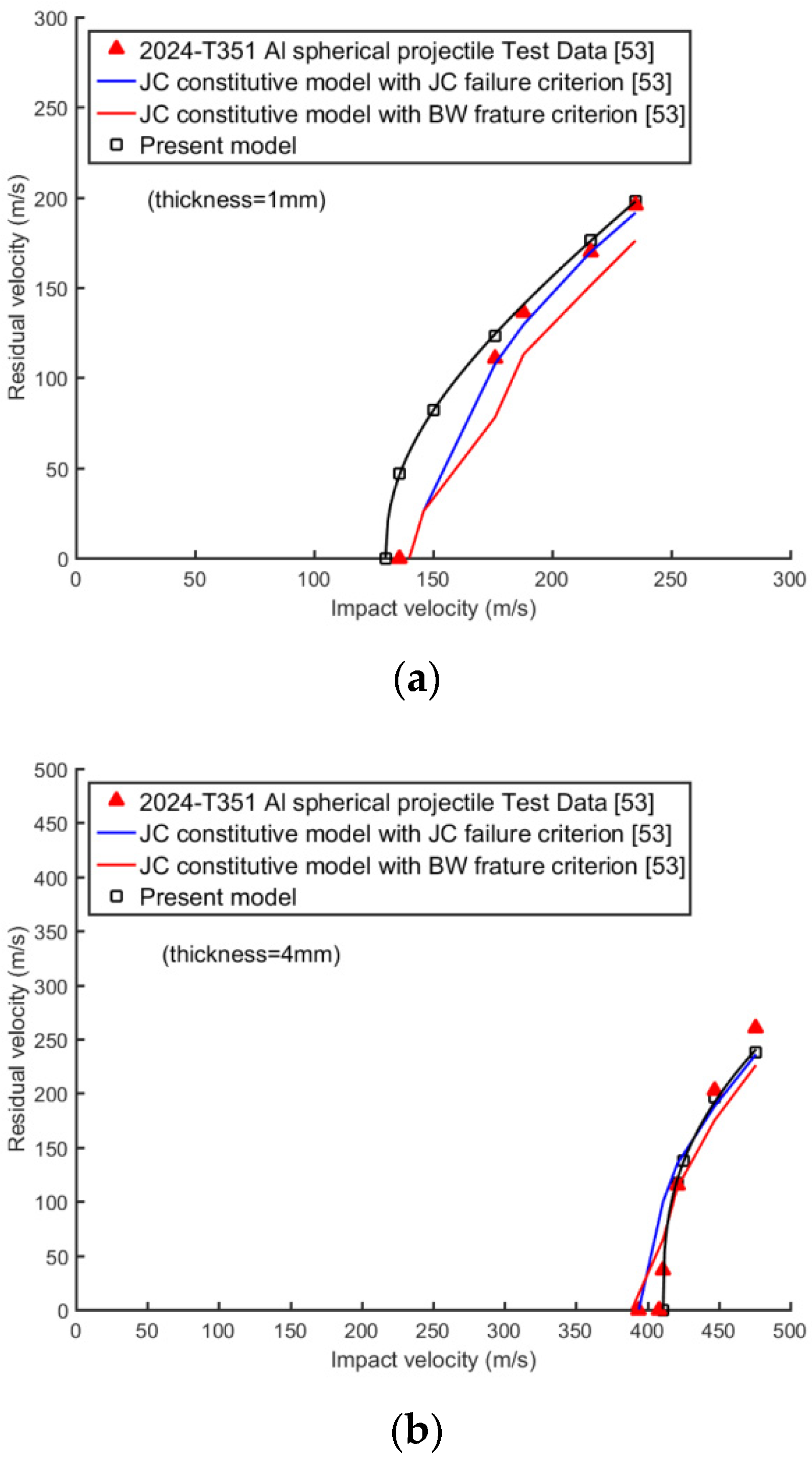

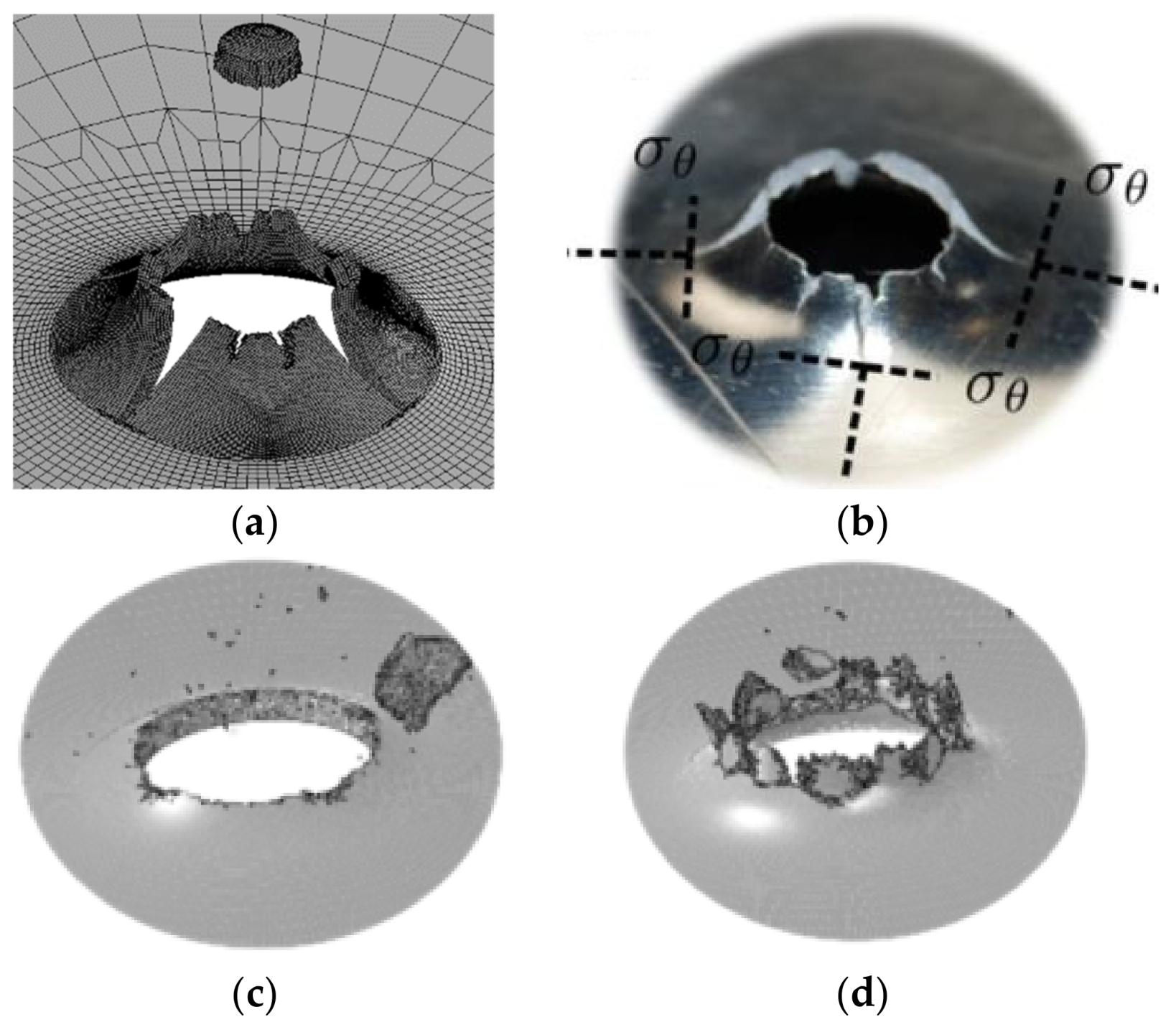

3.2.3. Ballistic Perforation Tests

3.3. Discussion

4. Conclusions

- (1)

- A new dynamic plasticity and failure model for metals, which includes a strength model and a failure criterion, has been developed. The new model takes into account the effects of stress triaxiality, Lode angle, strain rate and temperature.

- (2)

- A new non-linear relationship between the dynamic increase factor (DIF) and the strain rate has been suggested and, in particular, the DIF at zero plastic strain, which can be determined from that at a specific plastic strain, has been used in the formulation of the new strength model.

- (3)

- The new model has been verified against the available test data for 2024-T351 aluminum alloy, 6061-T6 aluminum alloy, OFHC copper, 4340 steel, Ti-6Al-4V alloys and Q235 mild steel under different loading conditions in terms of stress–strain curve, strain rate effect, temperature effect and fracture.

- (4)

- The new model has been further verified against the corresponding experimental results for 2024-T351 aluminum alloy by employing it in the numerical simulations of the material behavior in terms of stress-strain relationship and fracture pattern (i.e., cup and cone), as well as ballistic perforation in terms of residual velocity and perforation mode (namely, shear plugging and petalling).

- (5)

- The new model has been proven to be advantageous over the existing models such as the JC constitutive model with the JC failure criterion or the BW fracture criterion. This section may be divided by subheadings. It should provide a concise and precise description of the experimental results, their interpretation as well as the experimental conclusions that can be drawn.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- Johnson, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In Proceedings of the 7th International Symposium on Ballistics, The Hague, The Netherlands, 19–21 April 1983; pp. 541–547. [Google Scholar]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Borvik, T.; Hopperstad, O.S.; Berstad, T.; Langseth, M. A computational model of viscoplasticity and ductile failure for impact and penetration. Eur. J. Mech. A Solids 2001, 20, 685–712. [Google Scholar] [CrossRef]

- Clausen, A.H.; Borvik, T.; Hopperstad, O.S.; Benallal, A. Flow and fracture characteristics of aluminum alloy AA5083-H116 as function of strain rate, temperature and triaxiality. J. Mater. Sci. Eng. A 2004, 364, 260–272. [Google Scholar] [CrossRef]

- Khan, A.S.; Liu, H. Variable strain rate sensitivity in an aluminum alloy: Response and constitutive modeling. Int. J. Plast. 2012, 36, 1–14. [Google Scholar] [CrossRef]

- Khan, A.S.; Suh, Y.S.; Kazmi, R. Quasi-static and dynamic loading responses and constitutive modeling of titanium alloys. Int. J. Plast. 2004, 20, 2233–2248. [Google Scholar] [CrossRef]

- Meyers, M.A.; Chen, Y.J.; Marquis, F.D.S.; Kim, D.S. High-strain, high-strain-rate behavior of tantalum. Metall. Mater. Trans. A 1995, 26, 2493–2501. [Google Scholar] [CrossRef]

- Guo, Z.T.; Gao, B.; Guo, Z.; Zhang, W. Dynamic constitutive relation based on J-C model of Q235 steel. Explos. Shock Waves 2018, 38, 804–810. (In Chinese) [Google Scholar]

- Bao, Y.; Wierzbicki, T. On fracture locus in the equivalent strain and stress triaxiality space. Int. J. Mech. Sci. 2004, 46, 81–98. [Google Scholar] [CrossRef]

- Wierzbicki, T.; Bao, Y.; Lee, Y.W.; Bai, Y. Calibration and evaluation of seven fracture models. Int. J. Mech. Sci. 2005, 47, 719–743. [Google Scholar] [CrossRef]

- Bai, Y.; Wierzbicki, T. A new model of metal plasticity and fracture with pressure and Lode dependence. Int. J. Plast. 2008, 24, 1071–1096. [Google Scholar] [CrossRef]

- Bai, Y.; Wierzbicki, T. Application of extended Mohr-Coulomb criterion to ductile fracture. Int. J. Fract. 2010, 161, 1–20. [Google Scholar] [CrossRef]

- Chocron, S.; Erice, B.; Anderson, C.E. A new plasticity and failure model for ballistic application. Int. J. Impact Eng. 2011, 38, 755–764. [Google Scholar] [CrossRef]

- Erice, B.; Gálvez, F. A coupled elastoplastic-failure constitutive model with Lode angle dependent failure criterion. Int. J. Solids Struct. 2014, 51, 93–110. [Google Scholar] [CrossRef]

- Zhou, L.; Wen, H.M. A new approach for the failure of metallic materials. Chin. J. High Pressure Phys. 2019, 33, 014103-1. [Google Scholar]

- Zhou, L.; Wang, Z.H.; Wen, H.M. On the accuracy of the Johnson-Cook constitutive model for metals. Chin. J. High Pressure Phys. 2019, 33, 1–14. [Google Scholar]

- Langer, J.S.; Bouchbinder, E.; Lookman, T. Thermodynamic theory of dislocation-mediated plasticity. Acta Mater. 2010, 58, 3718–3732. [Google Scholar] [CrossRef] [Green Version]

- Langer, J.S. Thermal effects in dislocation theory. Phys. Rev. E 2016, 94, 063004. [Google Scholar] [CrossRef] [Green Version]

- Le, K.C.; Tran, T.M.; Langer, J.S. Thermodynamic dislocation theory of high-temperature deformation in aluminum and steel. Phys. Rev. E 2017, 96, 013004. [Google Scholar] [CrossRef] [Green Version]

- Le, K.C.; Tran, T.M.; Langer, J.S. Thermodynamic dislocation theory of adiabatic shear banding in steel. Scr. Mater. 2017, 149, 62–65. [Google Scholar] [CrossRef]

- Le, K.C. Thermodynamic dislocation theory for non-uniform plastic deformations. J. Mech. Phys. Solids 2018, 111, 157–169. [Google Scholar] [CrossRef] [Green Version]

- Le, K.C.; Piao, Y.; Tran, T.M. Thermodynamic dislocation theory: Torsion of bars. Phys. Rev. E 2018, 98, 063006. [Google Scholar] [CrossRef] [Green Version]

- Le, K.C.; Piao, Y. Thermodynamic dislocation theory: Size effect in torsion. Int. J. Plast. 2019, 115, 56–70. [Google Scholar] [CrossRef]

- Le, K.C.; Piao, Y. Thermal softening during high-temperature torsional deformation of aluminum bars. Int. J. Eng. Sci. 2019, 137, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Seidt, J.D.; Gilat, A. Plastic deformation of 2024-T351 Aluminum plate over a wide range of loading conditions. Int. J. Solids Struct. 2013, 50, 1781–1790. [Google Scholar] [CrossRef]

- Wilkins, M.L.; Streit, R.D.; Reaugh, J.E. Cumulative-Strain-Failure Model of Ductile Fracture: Simulation and Prediction of Engineering Fracture Tests; Technical Report UCRL-53058; Lawrence Livermore National Laboratories: Livermore, CA, USA, 1980.

- Scapina, M.; Manes, A. Behaviour of Al6061-T6 alloy at different temperatures and strain-rates: Experimental characterization and material modeling. J. Mater. Sci. Eng. A 2018, 734, 318–328. [Google Scholar] [CrossRef]

- Baig, M.; Khan, A.S.; Choi, S.H.; Jeong, A. Shear and multiaxial responses of oxygen free high conductivity (OFHC) copper over wide range of strain-rates and temperatures and constitutive modeling. Int. J. Plast. 2013, 40, 65–80. [Google Scholar] [CrossRef]

- Nemat-Nasser, S.; Li, Y. Flow stress of FCC polycrystals with application to OFHC Cu. Acta Mater. 1998, 46, 565–577. [Google Scholar] [CrossRef]

- Guo, W.G. Flow stress and constitutive model of OFHC Cu for large deformation, different temperatures and different strain rates. Explos. Shock Waves 2005, 25, 244–250. (In Chinese) [Google Scholar]

- Anand, L.; Kalidindi, S.R. The process of shear band formation in plane strain compression of fcc metals: Effects of crystallographic texture. Mech. Mater. 1994, 17, 223–243. [Google Scholar] [CrossRef]

- Mirone, G.; Barbagallo, R.; Corallo, D. A new yield criteria including the effect of lode angle and stress triaxiality. Procedia Struct. Integrity 2016, 2, 3684–3696. [Google Scholar] [CrossRef] [Green Version]

- Nemat-Nasser, S.; Guo, W.G.; Nesterenko, V.F.; Indrakanti, S.S.; Gu, Y.B. Dynamic response of conventional and hot isostatically pressed Ti-6Al-4V alloys: Experiments and modeling. Mech. Mater. 2001, 33, 425–439. [Google Scholar] [CrossRef]

- Lin, L.; Zhi, X.D.; Fan, F.; Meng, S.J.; Su, J.J. Determination of parameters of Johnson-Cook models of Q235B steel. J. Vib. Shock 2014, 33, 153–158. (In Chinese) [Google Scholar]

- Lesuer, D.R.; Kay, G.J.; Leblanc, M.M. Modeling Large-Strain, High-Rate Deformation in Metals; Technical report UCRL-JC-134118; Lawrence Livermore National Laboratory: Livermore, CA, USA, 2001.

- Follansbee, P.S.; Kocks, U.F. A constitutive description of the deformation of copper based on the use of the mechanical threshold stress as an internal state variable. Acta Metall. 1988, 36, 81–93. [Google Scholar] [CrossRef] [Green Version]

- Campbell, J.D.; Cooper, R.H. Yield and flow of low-carbon steel at medium strain rates. In Proceedings of the Conference on the Physical Basis of Yield and Fracture; Institute of Physics and Physical Society: London, UK, 1966; pp. 77–87. [Google Scholar]

- Jones, N. Structural Impact, 2nd ed.; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Chen, G.; Chen, Z.F.; Tao, J.L.; Niu, W.; Zhang, Q.P.; Huang, X. Investigation and validation on plastic constitutive parameters of 45 steel. Explos. Shock Waves 2005, 25, 451–456. (In Chinese) [Google Scholar]

- Xu, H.; Wen, H.M. A computational constitutive model for concrete subjected to dynamic loadings. Int. J. Impact Eng. 2016, 91, 116–125. [Google Scholar] [CrossRef]

- Xu, H.; Wen, H.M. Semi-empirical equations for the dynamic strength enhancement of concrete-like materials. Int. J. Impact Eng. 2013, 60, 76–81. [Google Scholar] [CrossRef]

- Xu, P.B.; Xu, H.; Wen, H.M. 3D meso-mechanical modelling of concrete spall tests. Int. J. Impact Eng. 2016, 97, 46–56. [Google Scholar] [CrossRef]

- Zhao, F.Q.; Wen, H.M. Effect of free water content on the penetration of concrete. Int. J. Impact Eng. 2018, 121, 180–190. [Google Scholar] [CrossRef]

- Zhao, F.Q.; Wen, H.M. A comment on the maximum dynamic tensile strength of a concrete-like material. Int. J. Impact Eng. 2018, 115, 32–35. [Google Scholar] [CrossRef]

- Xin, S.H.; Wen, H.M. A progressive failure model for fiber reinforced plastic composites subjected to impact loading. Int. J. Impact Eng. 2015, 75, 40–52. [Google Scholar] [CrossRef]

- Xin, S.H.; Wen, H.M. Numerical study on the perforation of fiber reinforced plastic laminates struck by high velocity projectiles. J. Strain Anal. Eng. Des. 2012, 47, 513–523. [Google Scholar] [CrossRef]

- Gilioli, A.; Manes, A.; Giglio, M.; Wierzbicki, T. Predicting ballistic impact failure of aluminum 6061-T6 with the rate-independent Bao-Wierzbicki fracture model. Int. J. Impact Eng. 2015, 76, 207–220. [Google Scholar] [CrossRef]

- Banerjee, B. The Mechanical Threshold Stress model for various tempers of AISI 4340 steel. Int. J. Solids Struct. 2007, 44, 834–859. [Google Scholar] [CrossRef] [Green Version]

- Giglio, M.; Manes, A.; Viganò, F. Ductile fracture locus of Ti-6Al-4V titanium alloy. Int. J. Mech. Sci. 2012, 54, 121–135. [Google Scholar] [CrossRef]

- Guo, Z.T.; Shu, K.O.; Gao, B.; Zhang, W. J-C model based failure criterion and verification of Q235 steel. Explos. Shock Waves 2018, 38, 1325–1332. (In Chinese) [Google Scholar]

- Bao, Y. Prediction of Ductile Crack Formation in Uncracked Bodies. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2003. [Google Scholar]

- Teng, X. Numerical prediction of slant fracture with continuum failure mechanics. Eng. Fract. Mech. 2008, 75, 2020–2041. [Google Scholar] [CrossRef]

- Rodriguez-Millan, M.; Garcia-Gonzalez, D.; Rusinek, A.; Arias, A. Influence of Stress State on the Mechanical Impact and Deformation Behaviors of Aluminum Alloys. Metals 2018, 8, 520. [Google Scholar] [CrossRef]

- Rohr, I.; Nahme, H.; Thoma, K. Material characterization and constitutive modeling of ductile high strength steel for a wide range of strain rates. Int. J. Impact Eng. 2005, 31, 401–433. [Google Scholar] [CrossRef]

- Chen, J.L.; Shu, W.Y.; Li, J.W. Experimental study on dynamic mechanical property of Q235 steel at different strain rates. J. Tongji Univ. (Natural Sci.) 2015, 44, 1071–1075. (In Chinese) [Google Scholar]

- Chen, Q.S.; Miao, Y.G.; Guo, Y.Z.; Li, Y.L. Comparative analysis of 3 constitutive models for 93 tungsten alloy. Chin. J. High Pressure Phys. 2017, 31, 753–760. (In Chinese) [Google Scholar]

- Wang, Z.H.; Zheng, H.; Wen, H.M. Determination of the mechanical properties of metals at very high strain rates. Chin. J. High Pressure Phys. 2019. in press (In Chinese) [Google Scholar]

| Materials Parameters | 2024-T351 Al | 6061-T6 Al | OFHC Copper | 4340 Steel | Ti-6Al-4V Alloy | Q235 Mild Steel |

|---|---|---|---|---|---|---|

| (MPa) | 340 | 265 | 50 | 792 | 938 | 293 |

| (MPa) | 510 | 170 | 340 | 846 | 947 | 543 |

| 0.5100 | 0.3140 | 0.4250 | 0.5820 | 0.6360 | 0.4890 | |

| (MPa) | 280 | 255 | 40 | 760 | 850 | 223 |

| (MPa) | 510 | 98 | 274 | 417 | 509 | 440 |

| 0.5060 | 0.2830 | 0.4230 | 0.3120 | 0.3235 | 0.4226 | |

| 4.1550 | 5.2006 | 4.4020 | 5 | 4.2470 | 3.4300 | |

| 100 | 2 | 1.1000 | 2.6000 | 12 | 1.2500 | |

| 1.3481 | 0.9757 | 0.8120 | 1.0200 | 1.3100 | 0.9833 | |

| 2.0922 | 0.2286 | 0.3000 | 0.6000 | 0.1400 | 0.4584 | |

| 9.0 × 10−5 | 1.0 × 10−3 | 1.0 × 10−5 | 2.0 × 10−3 | 1.0 × 10−5 | 2.1 × 10−3 | |

| 0.075 | 0.1000 | 0.1500 | 0.0500 | 0.0500 | 0.0020 | |

| −2.5240 | −8.2350 | −5.0690 | −0.7248 | −1.4230 | −5.1330 | |

| 3.1500 | 3.0800 | 2 | 0.7354 | 0.8594 | 1.8920 | |

| 1.0055 | 0.8600 | 4.8220 | 3.2864 | 1.6934 | 2.4893 | |

| 0.2107 | 0.5250 | 8.7000 | 0.2536 | 0.4651 | 1.5000 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, L.; Wen, H. A new Dynamic Plasticity and Failure Model for Metals. Metals 2019, 9, 905. https://doi.org/10.3390/met9080905

Zhou L, Wen H. A new Dynamic Plasticity and Failure Model for Metals. Metals. 2019; 9(8):905. https://doi.org/10.3390/met9080905

Chicago/Turabian StyleZhou, Lin, and Heming Wen. 2019. "A new Dynamic Plasticity and Failure Model for Metals" Metals 9, no. 8: 905. https://doi.org/10.3390/met9080905