Thermal Performance of Double-Skin Roof with Inclined Upper Plate for Grain Depot: Modeling and Experimental Investigation

Abstract

:1. Introduction

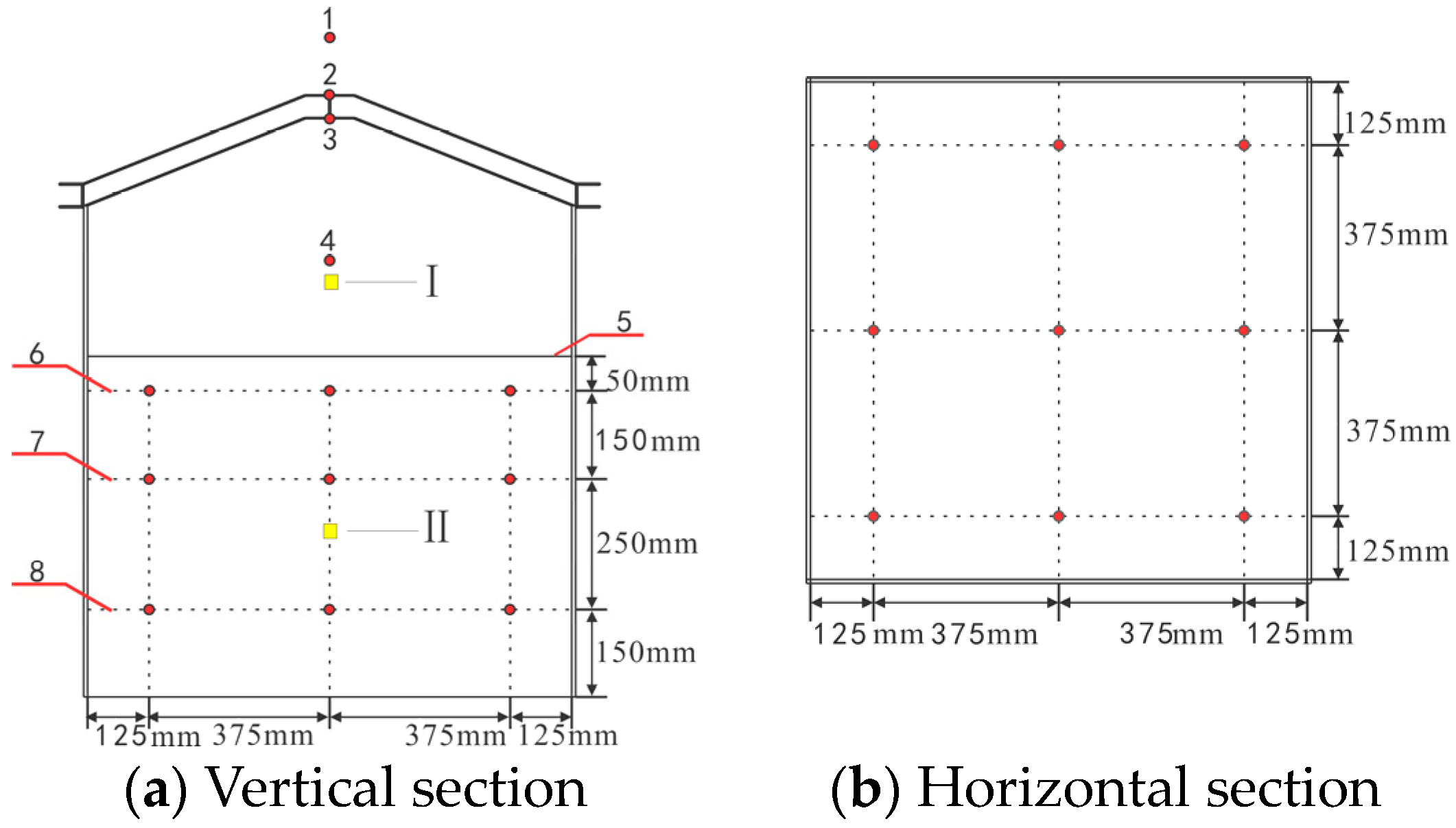

2. Experimental Setup

2.1. Experimental Grain Depot

2.2. Temperature-Controlling and Data Collecting Systems

2.3. Methods and Error Analysis

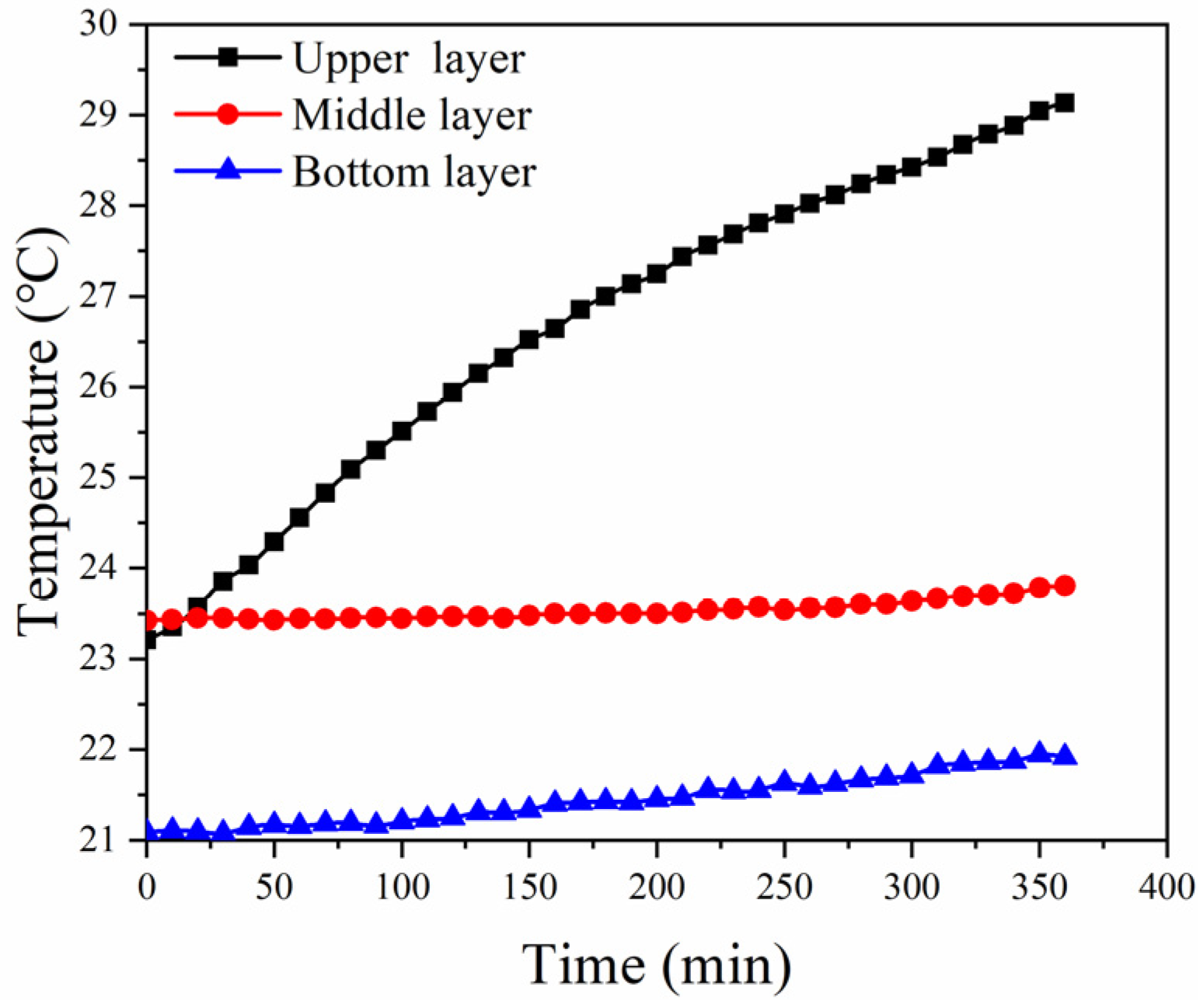

3. Experimental Results

3.1. Reference Experiment of Non-Suspended Ceiling

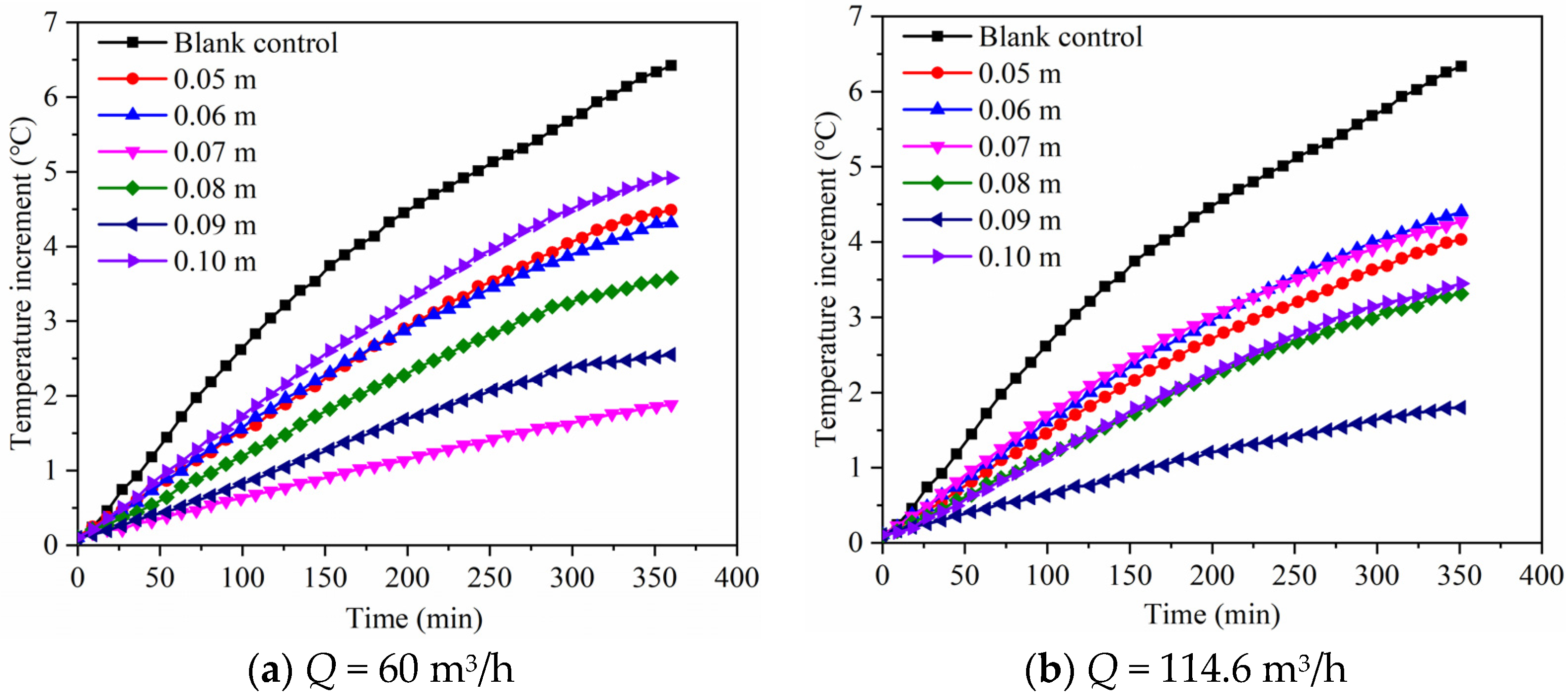

3.2. Experiment on Parallel Ceilings

3.3. Experiment on Inclined Ceilings

4. Simulation Results

4.1. Physical Model of the Depot

- (1)

- The depot air is an ideal incompressible fluid;

- (2)

- The depot walls are well-sealed and insulated;

- (3)

- The heat generated by the respiration of the grain can be neglected.

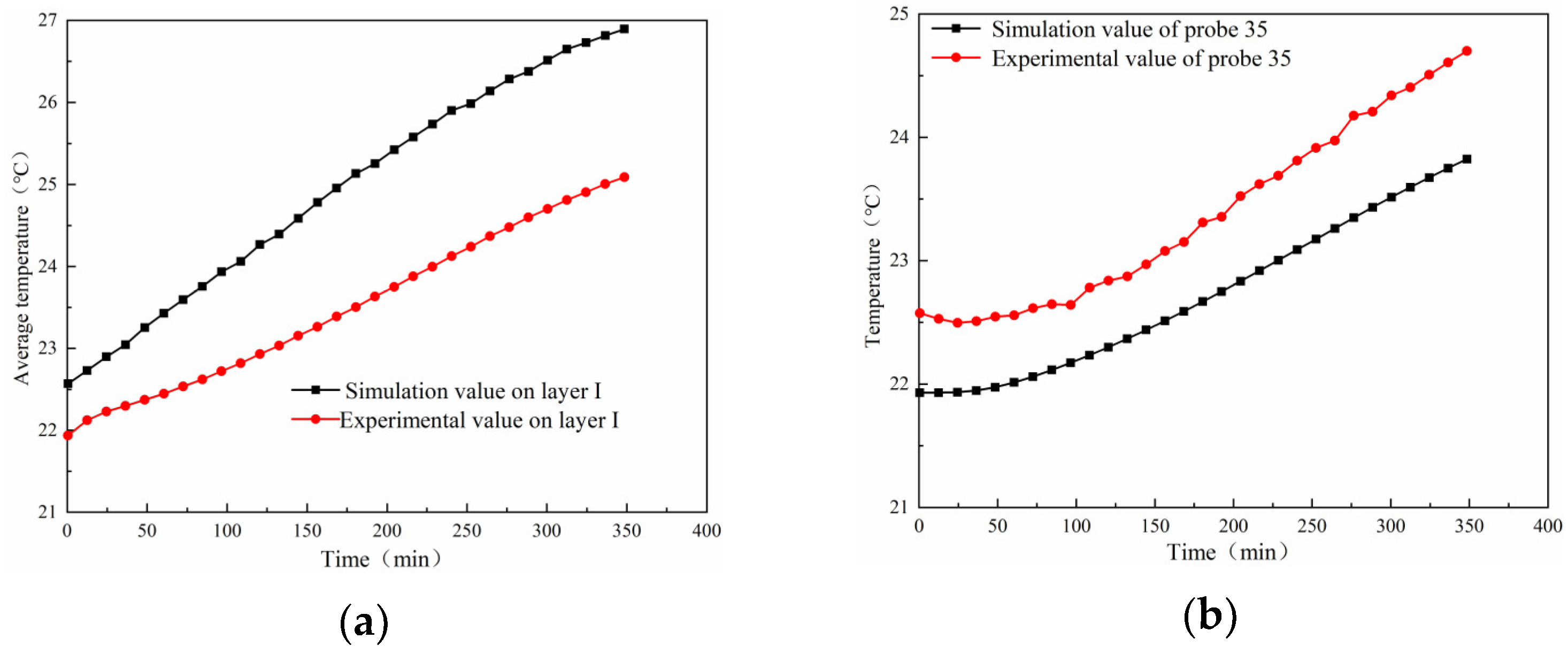

4.2. Validation of the Numerical Model

5. Analysis of Simulation

6. Conclusions

- (1)

- The flow rate and the air gap thickness have a comprehensive influence on the thermal performance of the double-skin roof. The optimal working condition of the parallel ceilings is δ = 0.07 m and Q = 60 m3/h, under which the temperature rise of the surface grain is 1.75 °C lower than that of the non-suspended mode.

- (2)

- The overall insulation performance of the double-skin roof was improved by the enhanced hot-air expelling arising from the converging flow path. Under the premise of a constant air volume, the temperature of the grain bulk can be controlled within 24 °C by using an inclined ceiling.

- (3)

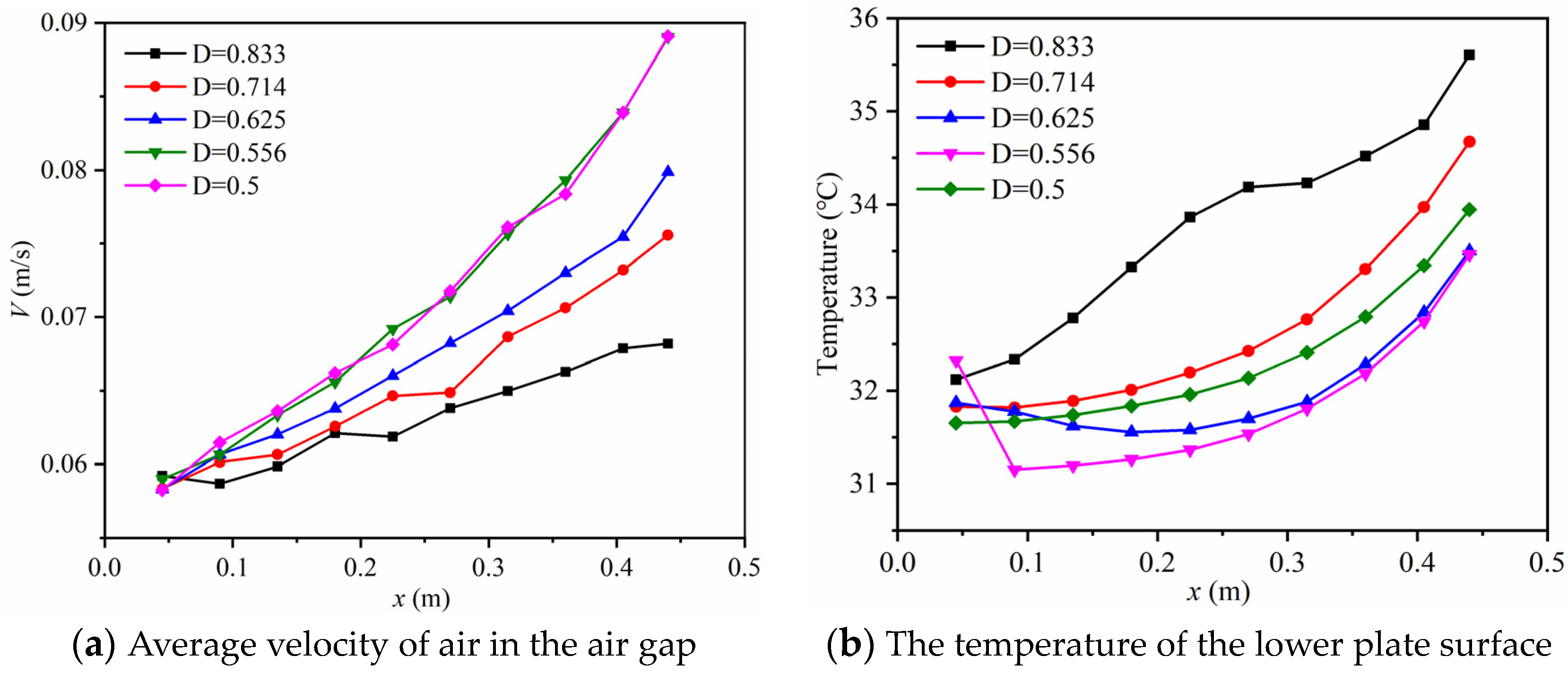

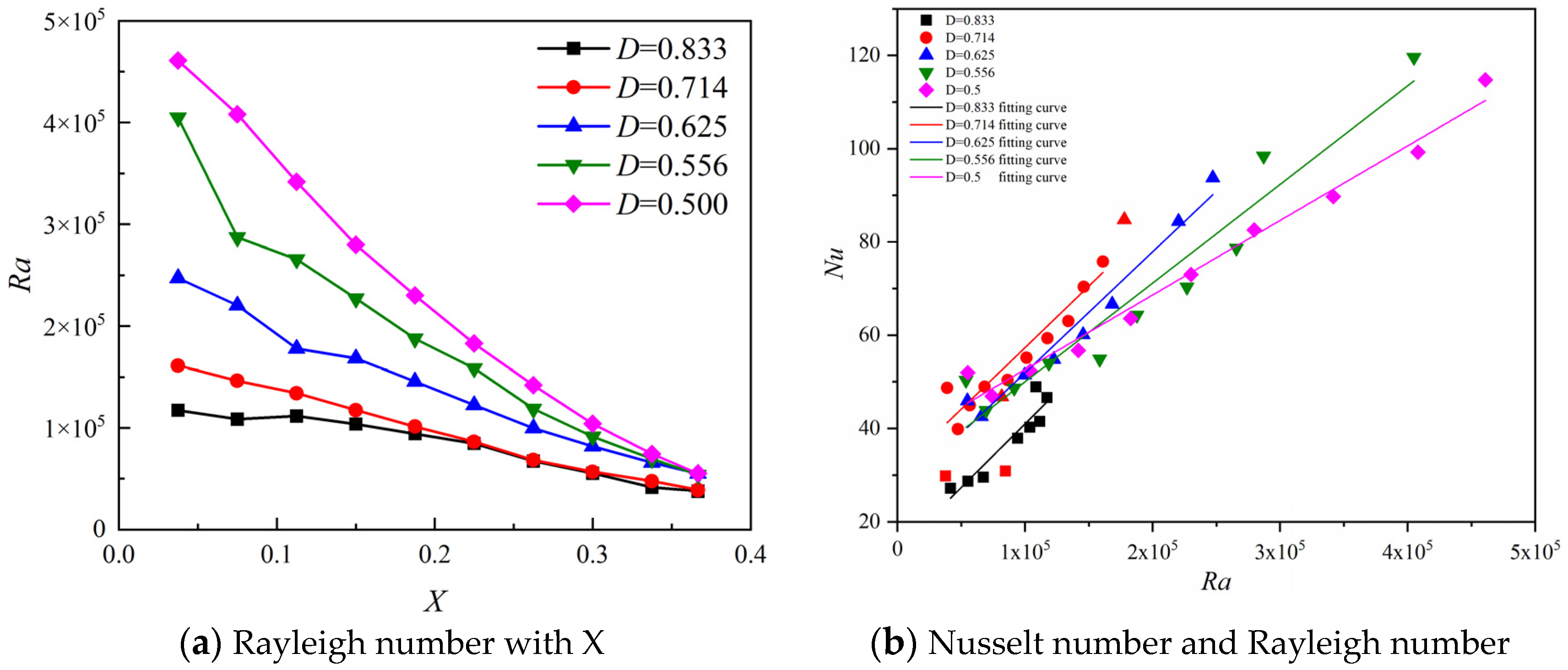

- In the inclined ceiling mode, given equal inlet velocities, a smaller reducing ratio is beneficial to expelling hot air, and the outlet velocity at the condition of D = 0.5 is about 30.6% higher than that of the other conditions. In the air gap, the Nusselt number Nu decreases with the dimensionless distance X and the Rayleigh number Ra. The overall convective heat transfer effect can be strengthened by the natural convection arising from the temperature difference in the air gap.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Nu | Nusselt number |

| Ra | Rayleigh number |

| X | dimensionless distance |

| D | the reducing ratio |

| Q | the flow rate through the air gap between the double ceilings (m3/h) |

| x | the distance from the inlet (m) |

| v | the average velocity in the air gap (m/s) |

| Greek letter | |

| δ | the thickness of the air gap (m) |

| Subscripts | |

| 1 | inlet |

| 2 | outlet |

References

- Duan, A.L.; Zhang, B.C. Exploration of Building Energy Management System in the Form of Energy Internet. In Proceedings of the 2018 China International Conference on Electricity Distribution (CICED), Tianjin, China, 17–19 September 2018. [Google Scholar]

- Hao, W.; Da-Kun, X.U.; Lu, G. Application of Ground Source Heat Pump Air Conditioning System in the Booster Station of Wind Power Plants. Build. Energy Effic. 2016, 124–127. [Google Scholar]

- Omar, A.I.; Virgone, J.; Vergnault, E.; David, D.; Idriss, A.I. Energy Saving Potential with a Double-skin Roof Ventilated by Natural Convection in Djibouti. Energy Procedia 2017, 140, 361–373. [Google Scholar] [CrossRef]

- Gagliano, A.; Patania, F.; Nocera, F.; Ferlito, A.; Galesi, A. Thermal Performance of Ventilated Roofs During Summer Period. Energy Build. 2012, 49, 611–618. [Google Scholar] [CrossRef]

- Zingre, K.T.; Yang, E.; Wan, M.P. Dynamic Thermal Performance of Inclined Double-skin Roof: Modeling and Experimental Investigation. Energy 2017, 133, 900–912. [Google Scholar] [CrossRef]

- Zhao, L. Study of the Thermal Insulation of Natural Convection of Double-Skin Roof. Master’s Thesis, Zhejiang University, Hangzhou, China, 2008. [Google Scholar]

- Zhou, Y. Study of the Thermal Insulation of Natural Convection of Double-Skin Roof. Master’s Thesis, Zhejiang University, Hangzhou, China, 2010. [Google Scholar]

- Biwole, P.; Woloszyn, M.; Pompeo, C. Heat Transfers in a Double-skin Roof Ventilated By Natural Convection in Summer Time. Energy Build. 2008, 40, 1487–1497. [Google Scholar] [CrossRef]

- Hamza, N.; Cook, M.; Cropper, P. Comparative Analysis of Natural Ventilation Performance in Non-unifrom Double Skin Facades in Temperate Climates. In Proceedings of the Building Simulation 2011, Sydney, Australia, 14–16 November 2011; pp. 2401–2406. [Google Scholar]

- Shi, Q. Green granary temperature control system modeling and simulation. Phys. Procedia 2012, 25, 2263–2267. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Y.; Chen, S.; Gong, S. How to reduce energy consumption by energy audits and energy management: The case of province Jilin in China. In Proceedings of the 2011 Proceedings of PICMET ‘11: Technology Management in the Energy Smart World (PICMET), Portland, OR, USA, 31 July–4 August 2011; p. 00604. [Google Scholar]

- Zhang, X.; Zhang, H.; Meng, Q. Research on temperature field of wheat grain piles in underground granary. Starch-Stärke 2023, 75, 2200260. [Google Scholar] [CrossRef]

- Ziegler, V.; Paraginski, R.T.; Ferreira, C.D. Grain storage systems and effects of moisture, temperature and time on grain quality—A review. J. Stored Prod. Res. 2021, 91, 101770. [Google Scholar] [CrossRef]

- de Pontes, E.R.; Neto, P.H.W.; Justino, A.; Rocha, C.H.; Garcia, L.C. Bulk soybean grain mass temperature in depots with isolated vents and vent-exhaust combined systems. Ciência Rural. 2016, 47. [Google Scholar] [CrossRef]

- Abuseif, M.; Gou, Z. A Review of Roofing Methods: Construction Features, Heat Reduction, Payback Period and Climatic Responsiveness. Energies 2018, 11, 3196. [Google Scholar] [CrossRef]

- Kumar, V.V.; Raut, N.; Akeel, N. Double skin polystyrene- aluminum radiation reflector roofs in arid environments for passive cooling—A case study in Sohar, Sultanate of Oman. Case Stud. Therm. Eng. 2021, 28, 101655. [Google Scholar] [CrossRef]

- Kumar, V.V.; Raut, N.; Akeel, N. An experimental investigation on passive and hybrid roof cooling systems with a double skin envelope. Energy Sources Part A Recovery Util. Environ. Effects 2021. [Google Scholar] [CrossRef]

- Gómez, H.; Hugo, V.; Gálvez; Morillón, D. Analytical model for double skin roofs. Appl. Therm. Eng. 2013, 60, 218–224. [Google Scholar] [CrossRef]

- Izadpanah, S.; Fazelpour, F.; Yazdi, M.E. Comparative study of simultaneous use of a double or a triple skin facade with phase change materials, green roof, and photovoltaics in residential buildings of Iran. Environ. Prog. Sustain. Energy 2023, 42, e13935. [Google Scholar] [CrossRef]

- Kumar, V.V. Energy Conservation of Residential Buildings in Extreme Climates with Phase Change Material-Aluminum Radiation Reflector Cool Roof. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 9703–9715. [Google Scholar] [CrossRef]

- Pak, R.; Ocak, Z.; Sorgüven, E. Developing a passive house with a double-skin envelope based on energy and airflow performance. Build. Simul. 2017, 11, 373–388. [Google Scholar] [CrossRef]

- Chang, P.C.; Chiang, C.M.; Lai, C.M. Development and preliminary evaluation of double roof prototypes incorporating RBS (radiant barrier system). Energy Build. 2008, 40, 140–147. [Google Scholar] [CrossRef]

- Szagri, D.; Nagy, B. Experimental and numerical hygrothermal analysis of a refurbished double-skin flat roof. Case Stud. Therm. Eng. 2021, 25, 100941. [Google Scholar] [CrossRef]

- Meng, E.; Yang, J.; Cai, R.; Zhou, B.; Wang, J. Experimental comparison of summer thermal performance of green roof (GR), double skin roof (DSR) and cool roof (CR) in lightweight rooms in subtropical climate. J. Build. Phys. 2022, 45, 809–832. [Google Scholar] [CrossRef]

- Binyaseen, A.M. Improving thermal performance of existing uninsulated R.C. domes through passive cooling measures using polyurethane foam in double skin layer in hot climate. Case Stud. Constr. Mater. 2022, 16, e00866. [Google Scholar] [CrossRef]

- Kishor, Z.; Man-Pun, W.; Swee, W.; Winston, T.; Irene, L. Modelling of cool roof performance for double-skin roofs in tropical climate. Energy 2015, 82, 813–826. [Google Scholar]

- Lai, C.M.; Huang, J.Y.; Chiou, J.S. Optimal spacing for double-skin roofs. Build. Environ. 2008, 43, 1749–1754. [Google Scholar] [CrossRef]

- Qin, Y.; He, Y.; Wu, B.; Ma, S.; Zhang, X. Regulating top albedo and bottom emissivity of concrete roof tiles for reducing building heat gains. Energy Build. 2017, 156, 218–224. [Google Scholar] [CrossRef]

- Kadri, M.; Bouchair, A.; Laafer, A. The contribution of double skin roof coupled with thermo reflective paint to improve thermal and energy performance for the ‘Mozabit’ houses: Case of Beni Isguen’s Ksar in southern Algeria. Energy Build. 2022, 256, 111746. [Google Scholar] [CrossRef]

- Mao, Q.Y.M. Experimental and numerical investigation on heat transfer performance of a solar double-slope hollow glazed roof. Appl. Therm. Eng. Des. Process. Equip. Econ. 2020, 180, 115832. [Google Scholar] [CrossRef]

- Tuck, N.W.; Zaki, S.A.; Hagishima, A. Affordable retrofitting methods to achieve thermal comfort for a terrace house in Malaysia with a hot-humid climate. Energy Build. 2020, 223, 110072. [Google Scholar] [CrossRef]

- Tuck, N.W.; Zaki, S.A.; Hagishima, A. Effectiveness of free running passive cooling strategies for indoor thermal environments: Example from a two-storey corner terrace house in Malaysia. Build. Environ. 2019, 160, 106214. [Google Scholar] [CrossRef]

| Q = 60 m3/h | Q = 114.6 m3/h | ||||

|---|---|---|---|---|---|

| No. | δ (m) | v (m/s) | No. | δ (m) | v (m/s) |

| 1 | 0.05 | 0.33 | 2 | 0.05 | 0.63 |

| 3 | 0.06 | 0.27 | 4 | 0.06 | 0.53 |

| 5 | 0.07 | 0.23 | 6 | 0.07 | 0.45 |

| 7 | 0.08 | 0.21 | 8 | 0.08 | 0.40 |

| 9 | 0.09 | 0.18 | 10 | 0.09 | 0.35 |

| 11 | 0.10 | 0.17 | 12 | 0.10 | 0.32 |

| Q = 60 m3/h | Q = 114.6 m3/h | ||||||

|---|---|---|---|---|---|---|---|

| No. | δ1 (m) | δ2 (m) | v (m/s) | No. | δ1 (m) | δ2 (m) | v (m/s) |

| 1 | 0.06 | 0.05 | 0.27 | 2 | 0.06 | 0.05 | 0.53 |

| 3 | 0.07 | 0.05 | 0.23 | 4 | 0.07 | 0.05 | 0.45 |

| 5 | 0.08 | 0.05 | 0.21 | 6 | 0.08 | 0.05 | 0.40 |

| 7 | 0.09 | 0.05 | 0.18 | 8 | 0.09 | 0.05 | 0.35 |

| 9 | 0.10 | 0.05 | 0.17 | 10 | 0.10 | 0.05 | 0.32 |

| Grid 1 | Grid 2 | Grid 3 | |

|---|---|---|---|

| Num elements | 476,795 | 624,054 | 8,878,152 |

| Maximum average temp. (°C) | 21.365 | 21.349 | 21.367 |

| Error (%) | 0.01 | 0.08 | — |

| Calculation time (s) | 21,600 | 21,600 | 21,600 |

| Material | Density (kg·m−3) | Specific Heat Capacity (J·kg−1·K−1) | Thermal Conductivity (W·m−1·K−1) |

|---|---|---|---|

| Grain bulk | 810.50 | 1927 | 0.167 |

| Air | 1.23 | 1006 | 0.024 |

| Plexiglass | 1180 | 1464 | 0.18 |

| Insulation layer | 40 | 1.38 | 0.034 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Li, X.; Du, X. Thermal Performance of Double-Skin Roof with Inclined Upper Plate for Grain Depot: Modeling and Experimental Investigation. Buildings 2023, 13, 2672. https://doi.org/10.3390/buildings13102672

Chen Y, Li X, Du X. Thermal Performance of Double-Skin Roof with Inclined Upper Plate for Grain Depot: Modeling and Experimental Investigation. Buildings. 2023; 13(10):2672. https://doi.org/10.3390/buildings13102672

Chicago/Turabian StyleChen, Yan, Xuechun Li, and Xiao Du. 2023. "Thermal Performance of Double-Skin Roof with Inclined Upper Plate for Grain Depot: Modeling and Experimental Investigation" Buildings 13, no. 10: 2672. https://doi.org/10.3390/buildings13102672