Experimental and Statistical Analysis of Repeated Impact Records of Hybrid Fiber-Reinforced High-Performance Concrete

Abstract

:1. Introduction

2. The Experimental Work

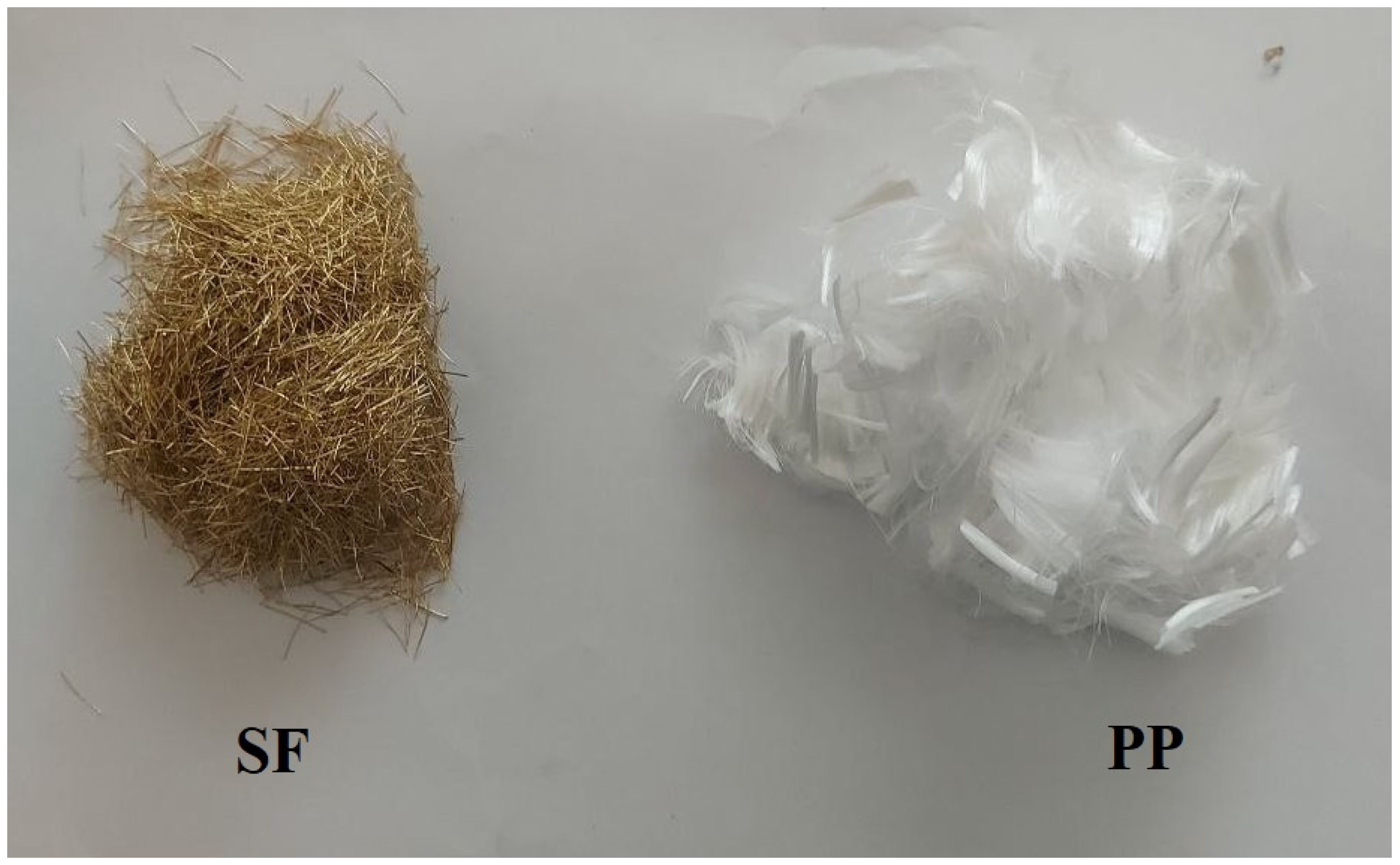

2.1. Materials and Mixtures

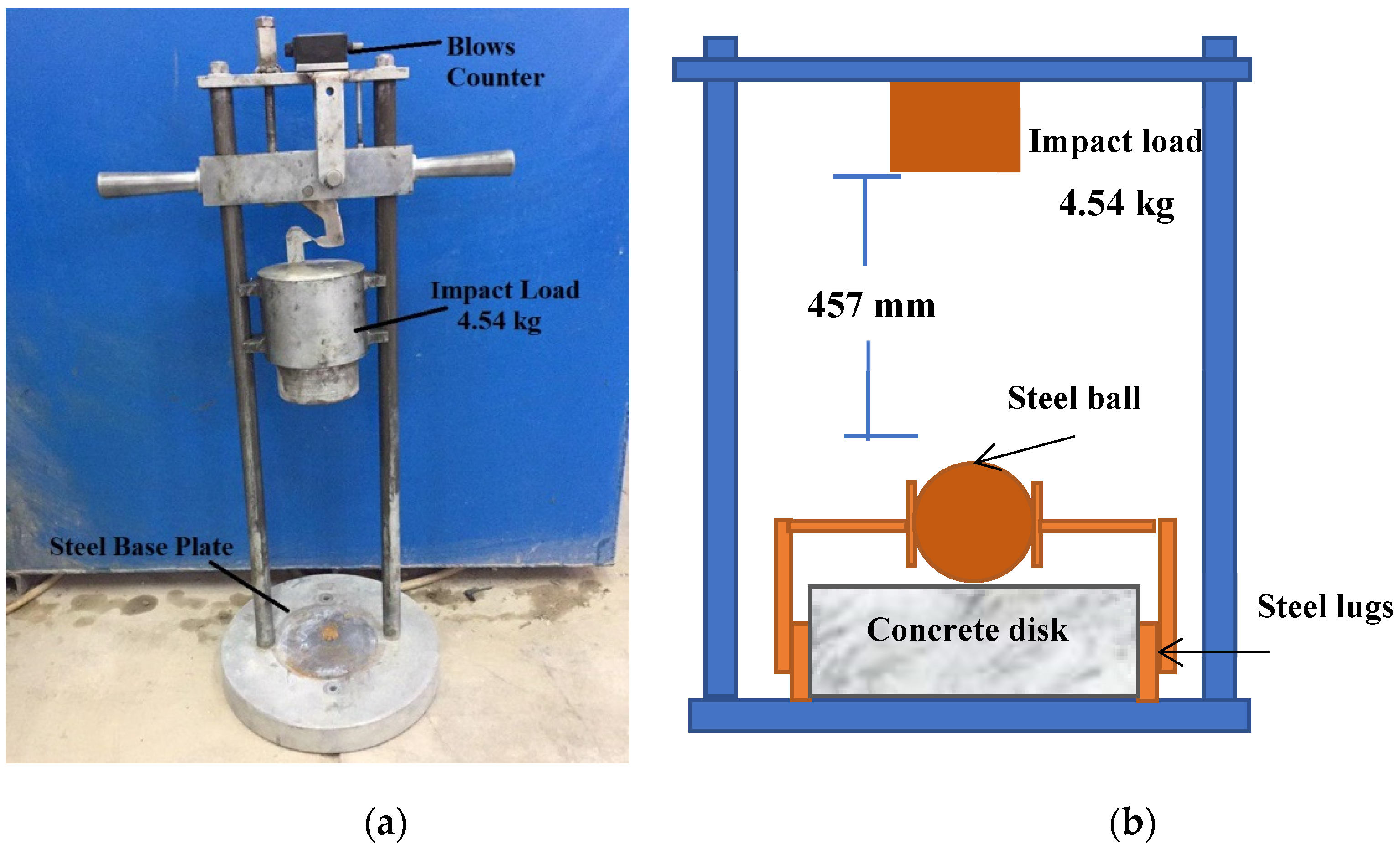

2.2. The Repeated Impact Test

3. Results and Discussion

3.1. Compressive Strength

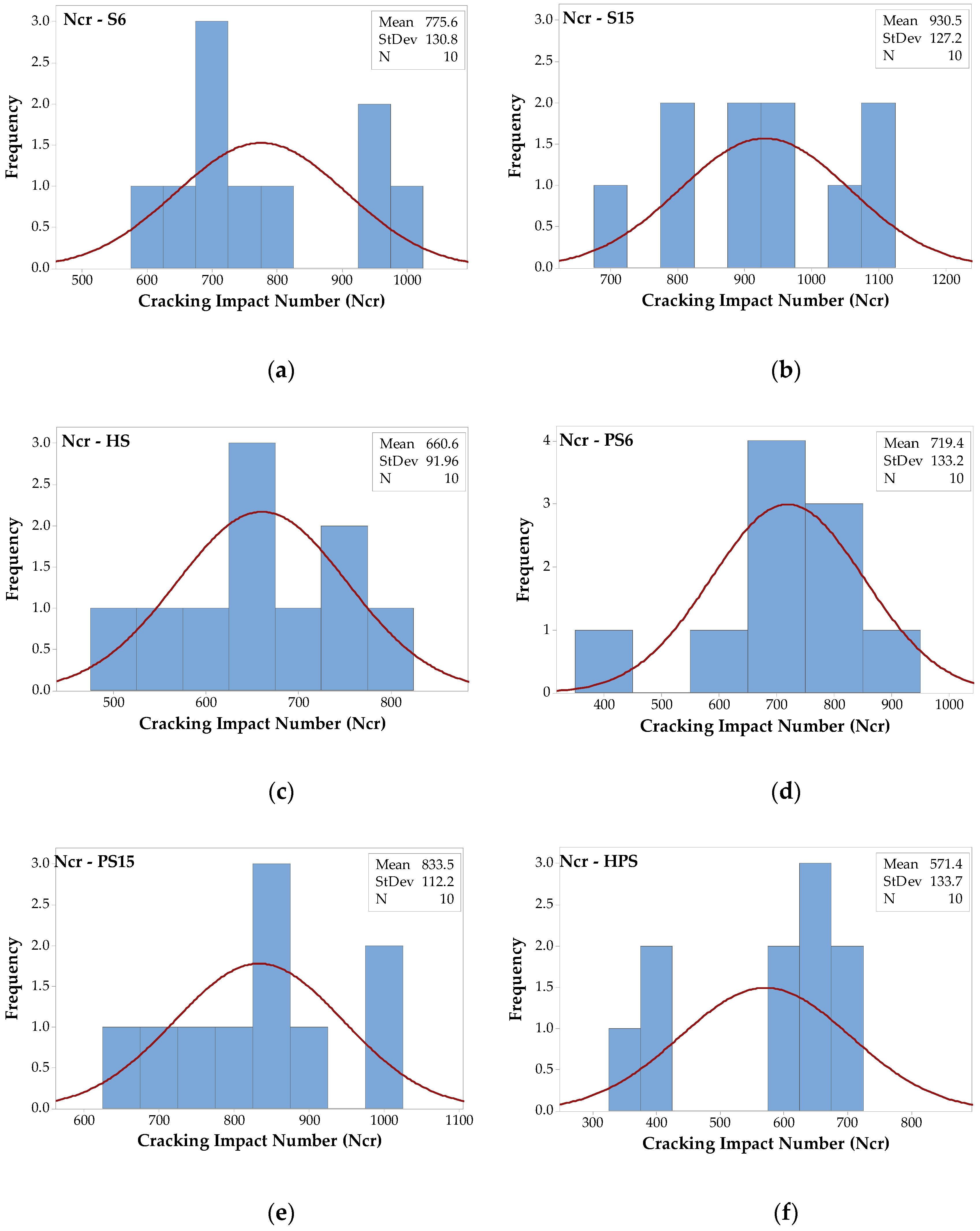

3.2. Cracking Impact Numbers

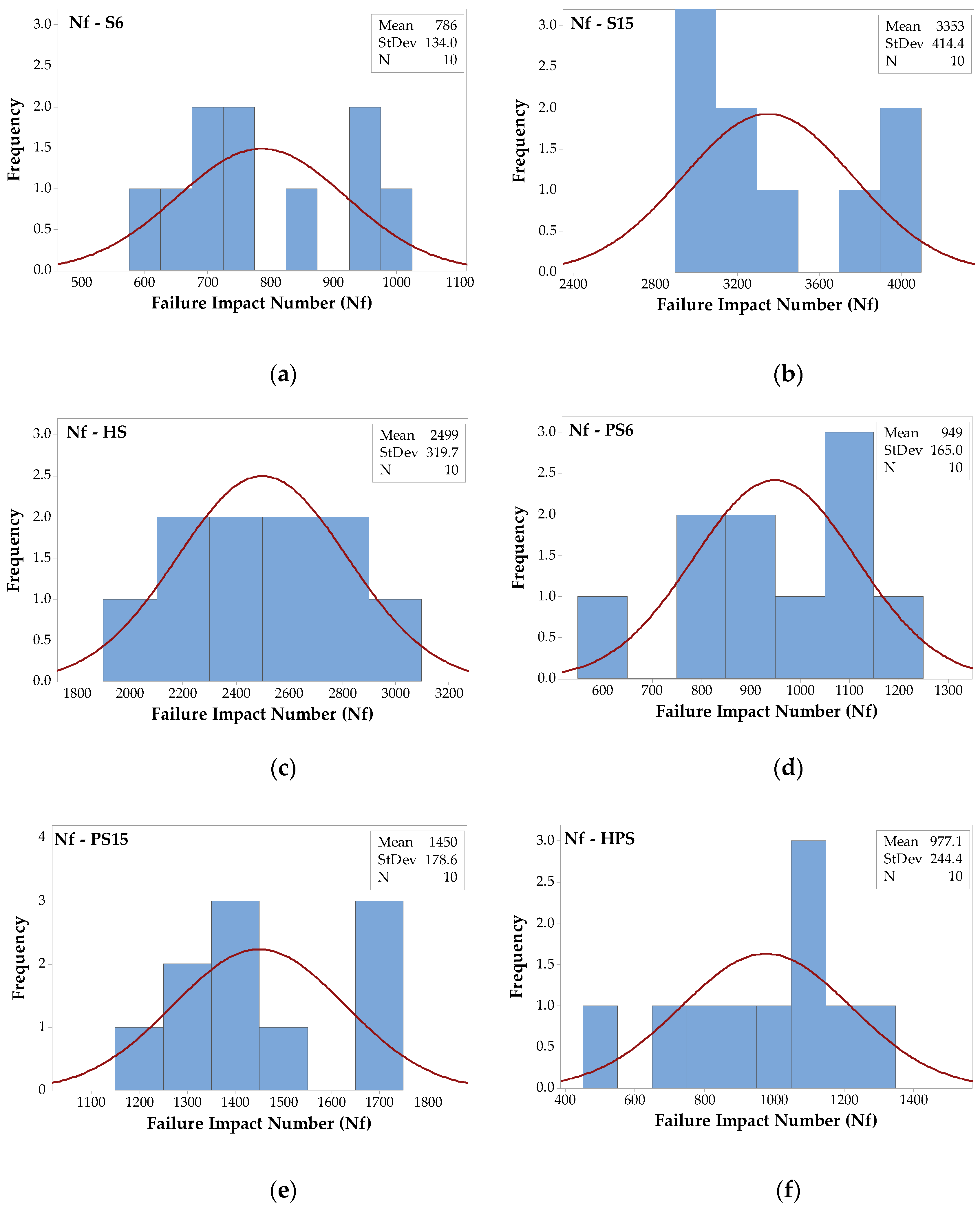

3.3. Failure Impact Numbers

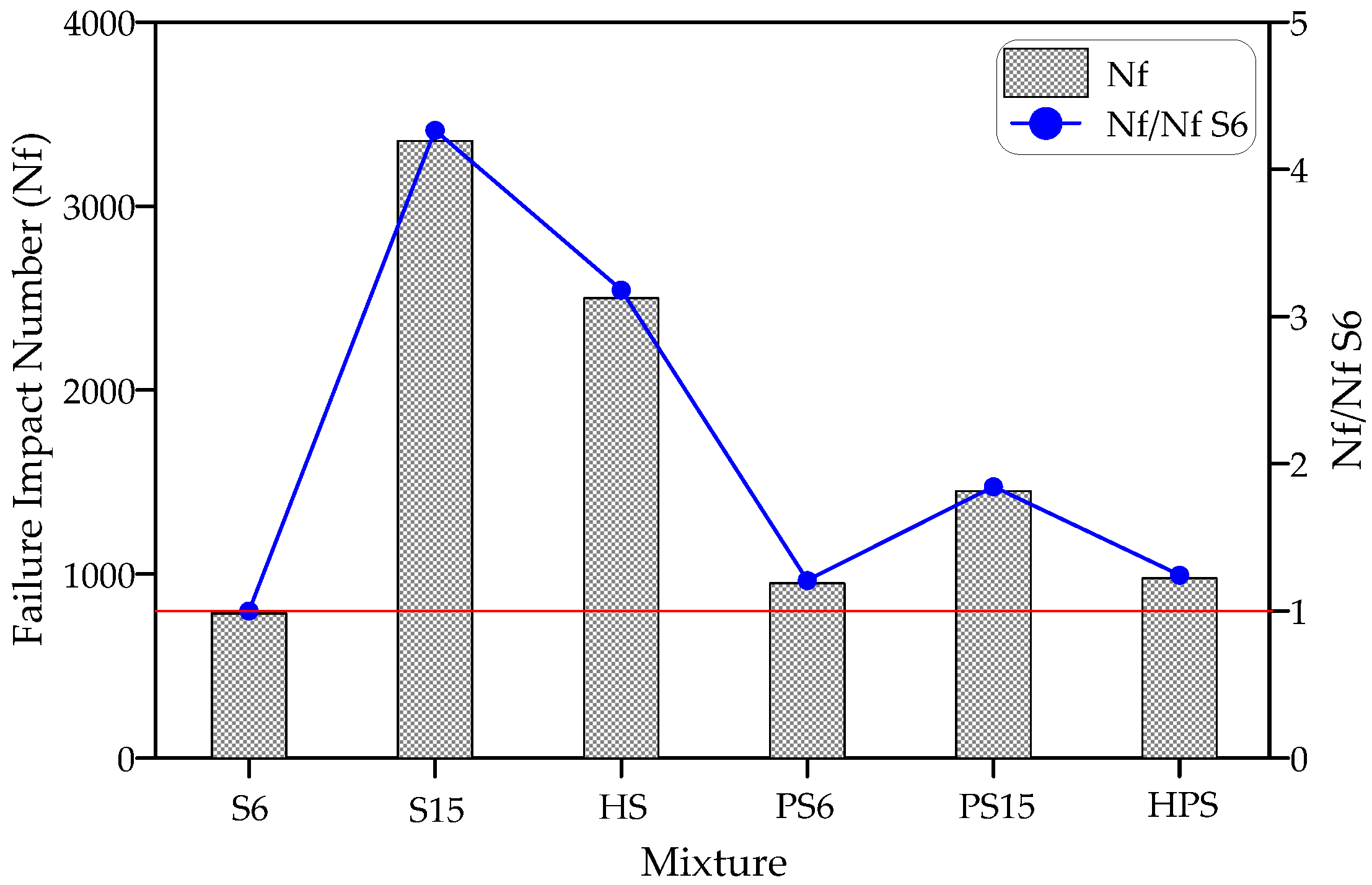

3.4. Impact Ductility

4. Statistical Analysis of Repeated Impact Results

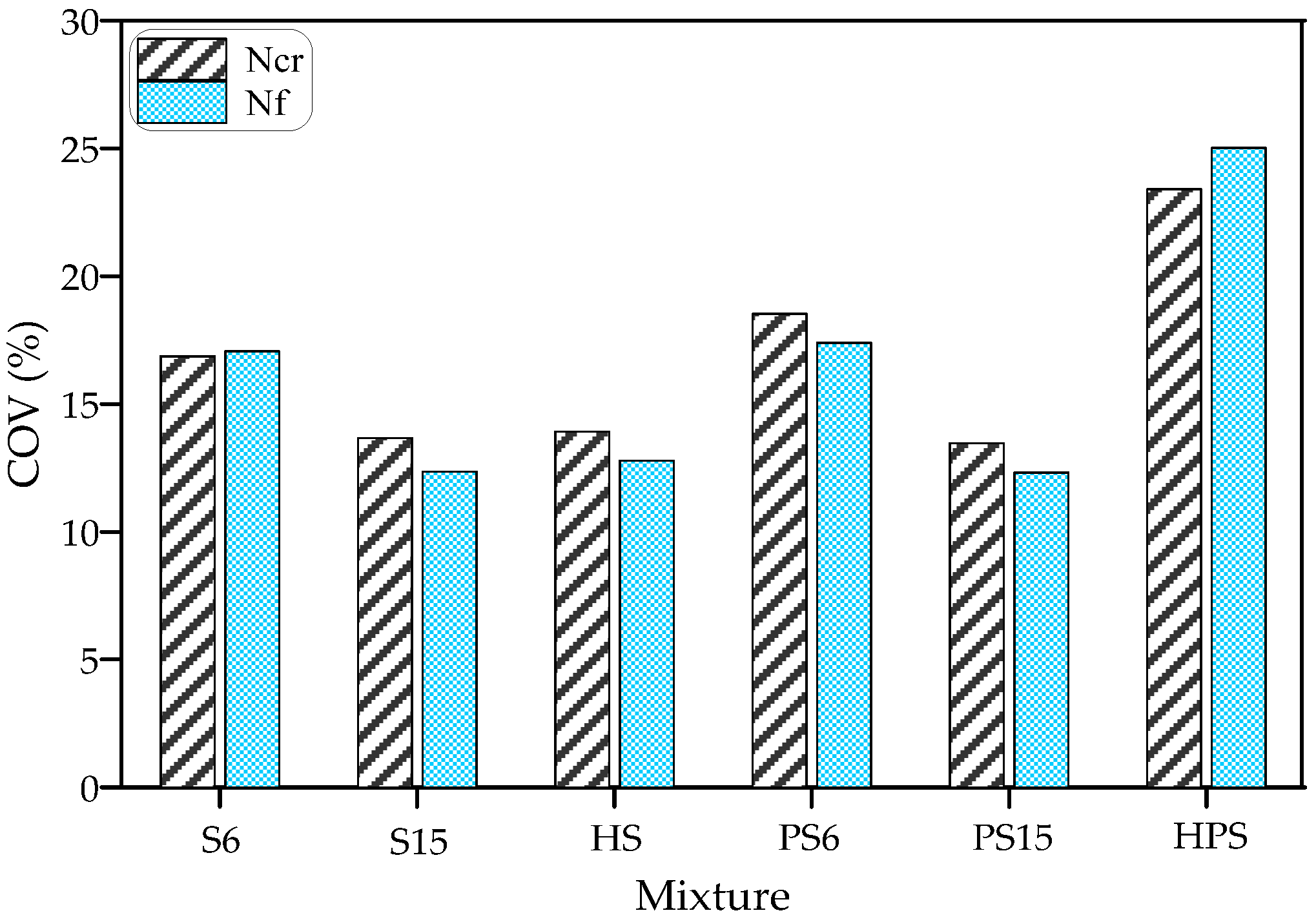

4.1. Variation of Impact Numbers

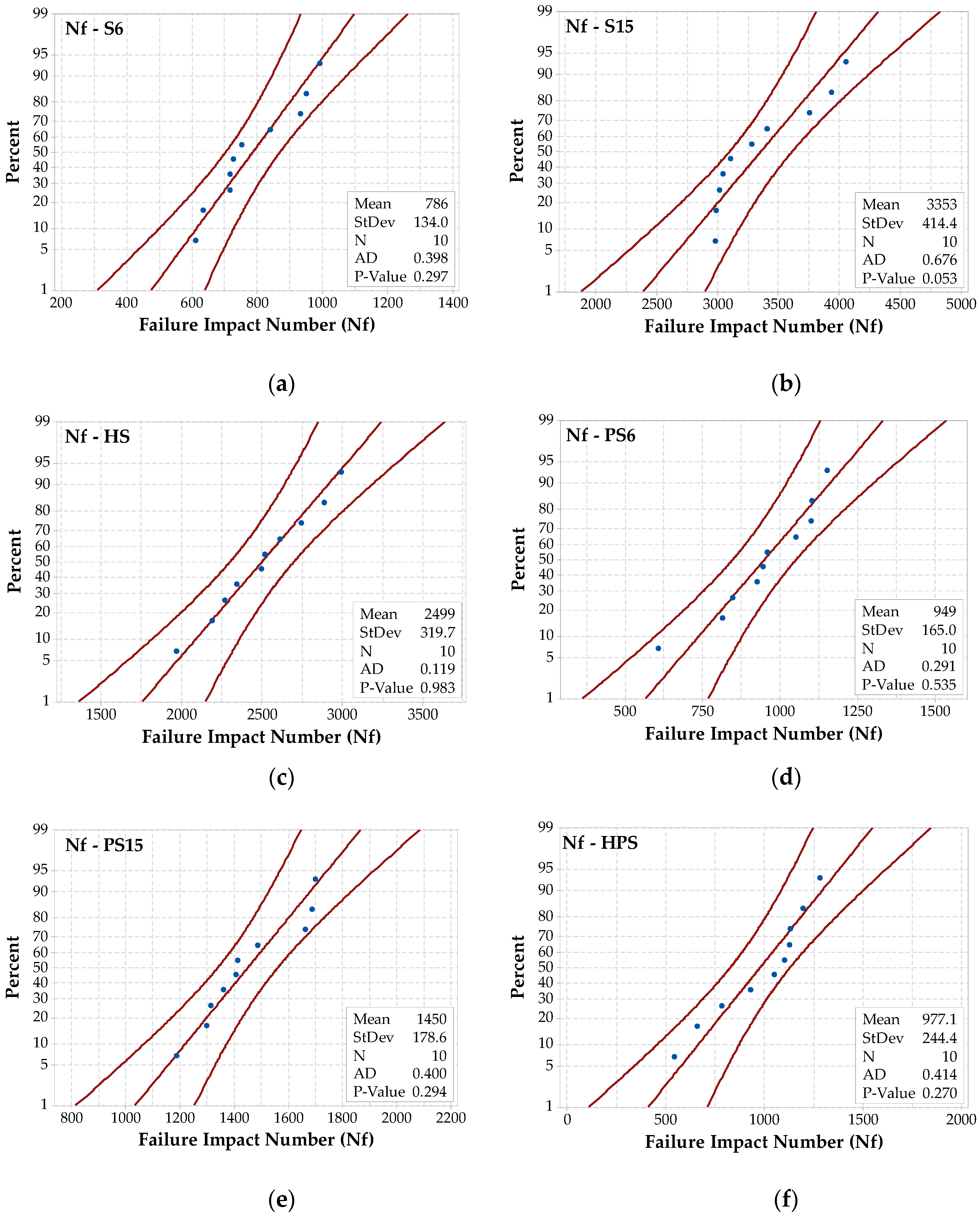

4.2. Normal Probability of Impact Numbers

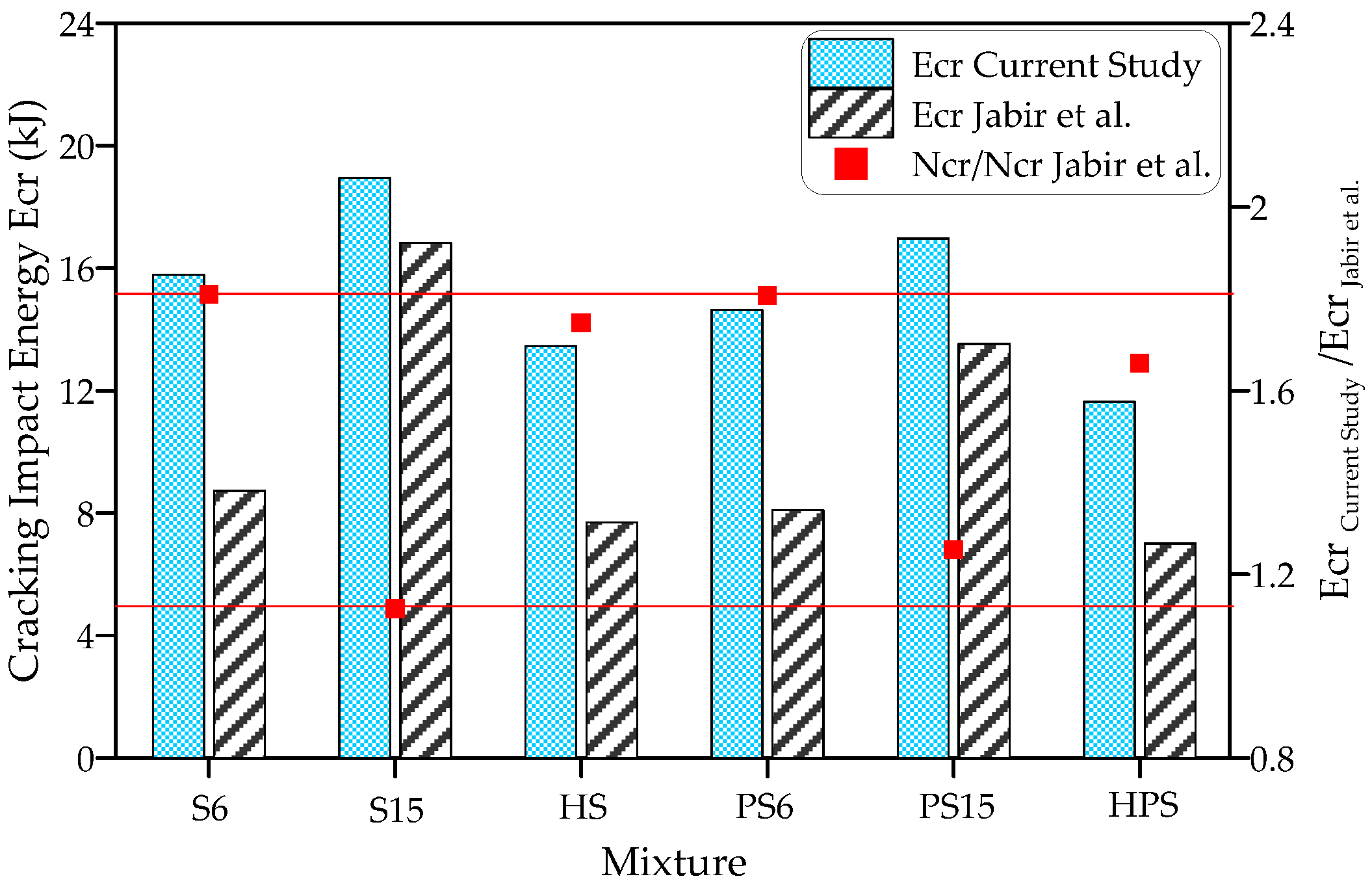

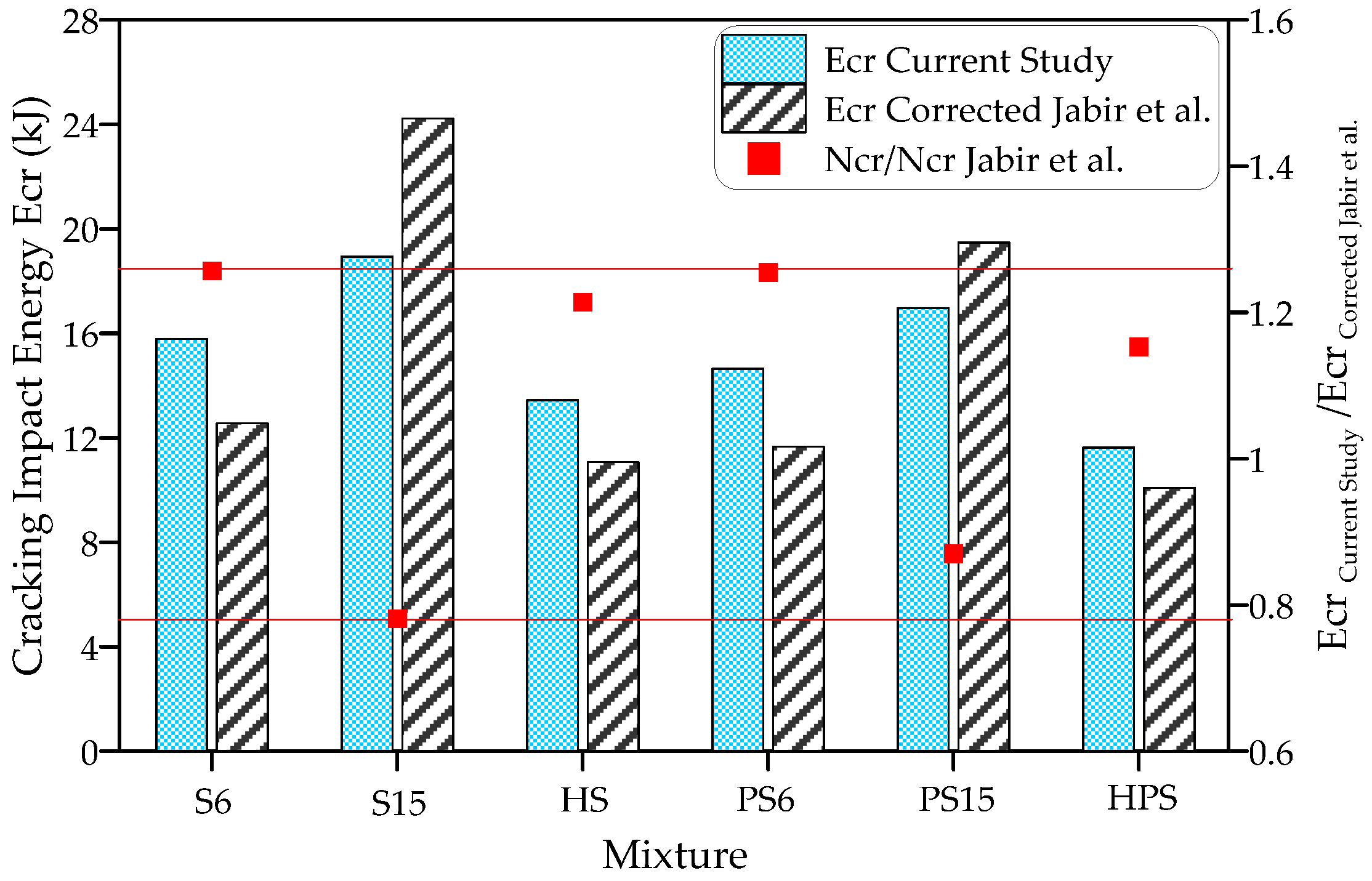

5. Comparison of Impact Results with Those of the Study by Jabir et al.

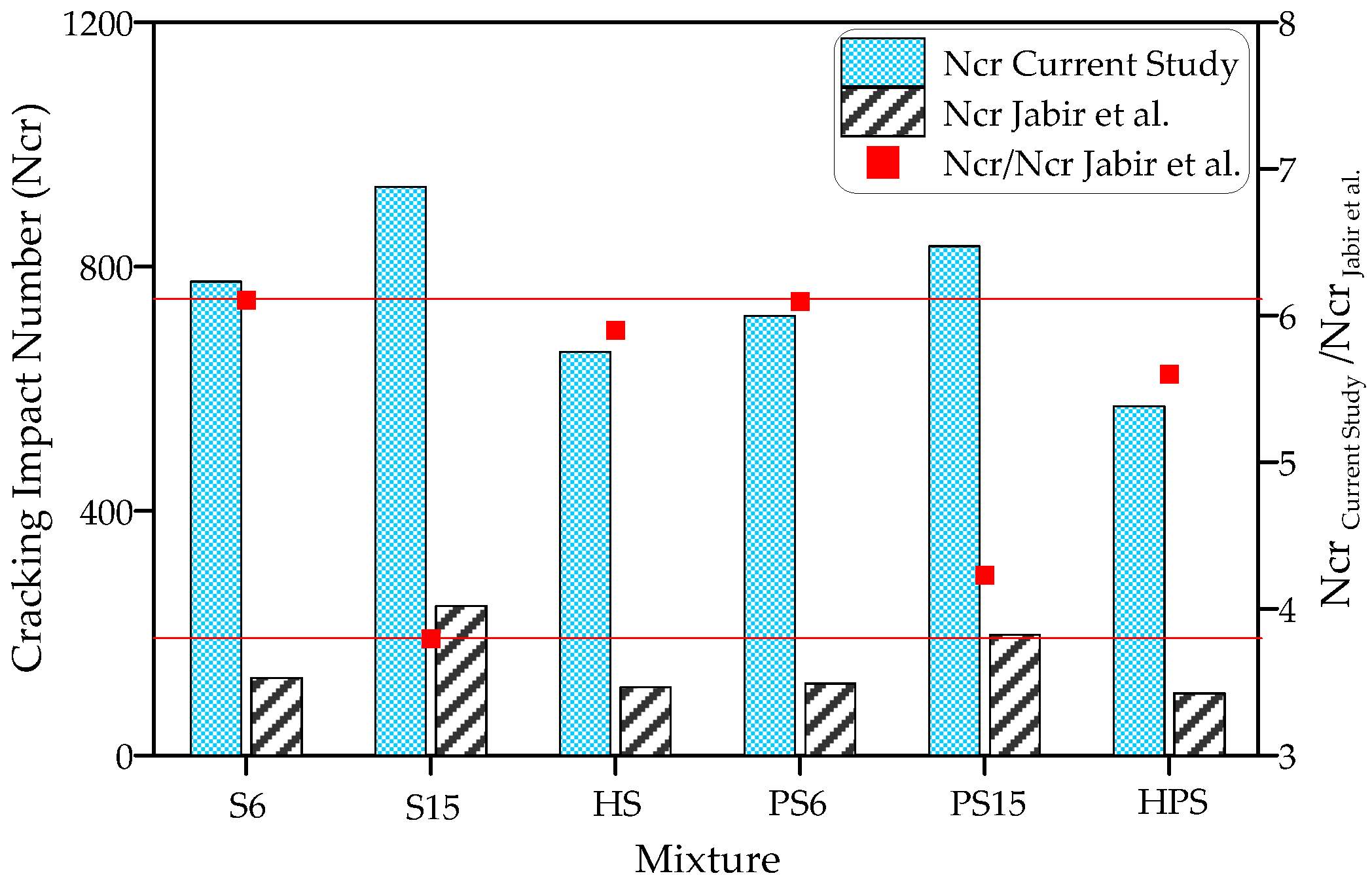

5.1. Repeated Impact Numbers

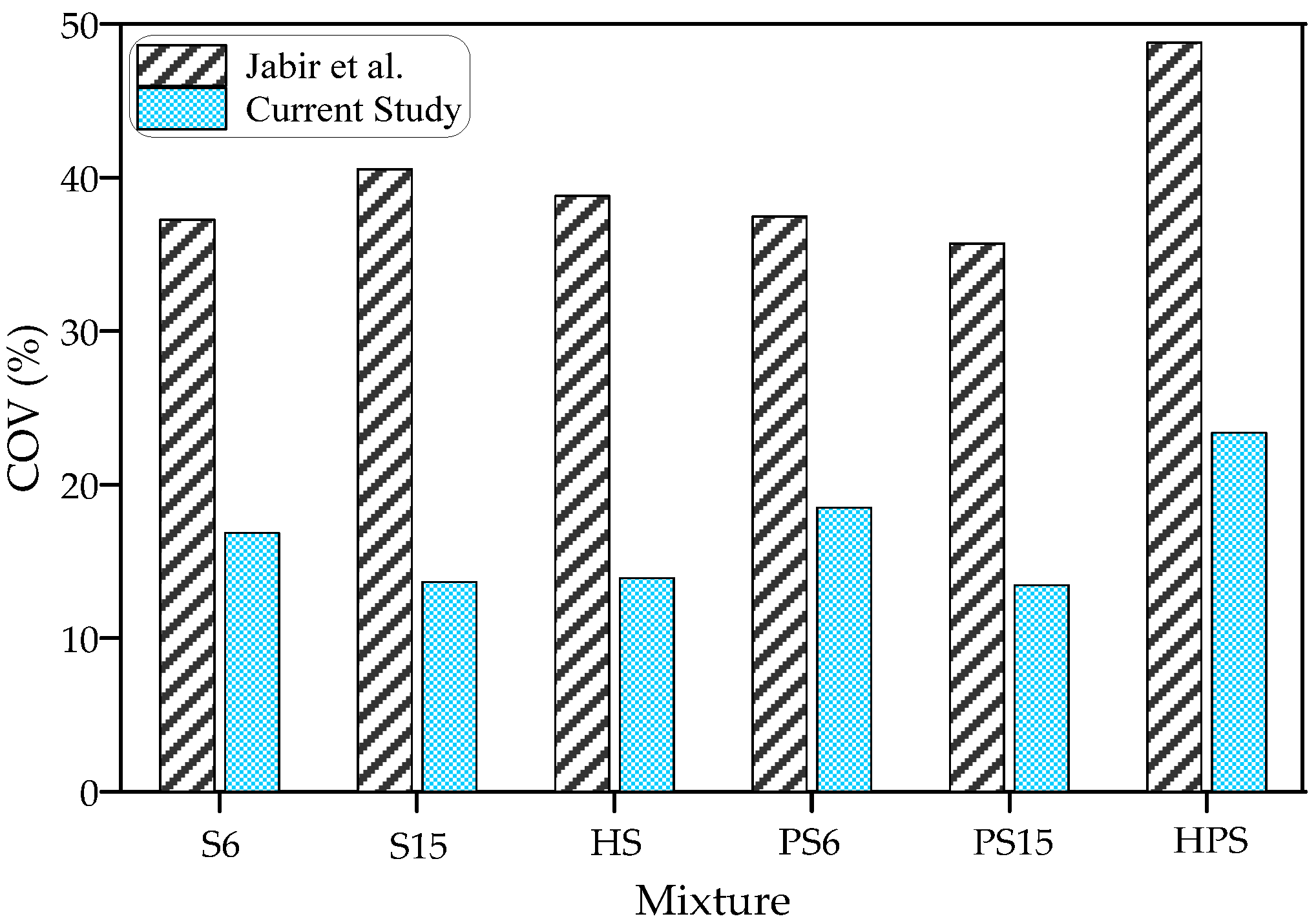

5.2. Variation of Impact Numbers

6. Conclusions

- Comparing each SF-reinforced mixture with its corresponding hybrid fiber-reinforced mixture, it was found that replacing 0.5% SF with PP reduced the compressive strength by approximately 5.0%, which was attributed to the higher stiffness and tensile strength of steel fibers compared to polypropylene fibers. On the other hand, the difference between the compressive strengths of mixtures of each of the two groups (SF-reinforced and hybrid fiber-reinforced mixtures) was in general less than 2.0%.

- The Ncr results showed that the differences among the six mixtures were not large, while it was clear that specimens with longer SF could better resist cracking under impact loads than those with shorter SF by approximately 20%. This action was attributed to the better ability of longer fibers to afford adequate anchorage lengths inside the matrix across both sides of the crack, which delayed the propagation of cracks.

- S15 specimens with pure 15 mm SF obtained the highest Nf record (3353 impact blows), while S6 specimens with pure 6 mm SF obtained the lowest Nf record (786 impact blows). Thus, Nf of S15 was more than 4 times that of S6, revealing the weakness of short SF and adequacy of long SF to afford the required bond that arrests cracking and prevents crack widening and propagation. The hybridization of both fibers led to an Nf record of 2499 blows, which was higher than the Nf record of S6 and lower than that of S15.

- The long SF could compose a shielding zone under the central impact area of the specimen’s top surface, thereby resisting a wide central fracturing area and increasing crack bridging effectiveness, which enhanced the failure capacity and altered the brittle fracturing behavior of concrete to adopt a more ductile characteristic. In addition, the ductility index values of specimens with high 15 mm SF content were in the range of 3.60 to 3.78. On the other hand, the short SF failed to compose a central shielding zone and the failure of S6 specimens was characterized by a very low ductility index (DI = 1.01).

- The effect of hybridization of HPC with SF and PP was found to be dependent on the test stage and length of SF fibers. The results revealed that replacing 0.5% SF with 0.5% PP reduced the crack resistance capacity (Ncr) of the three SF-reinforced mixtures by 7% to 15%. On the other hand, it was found that PP had minor post-cracking crack arresting activity compared to 15 mm SF, but they exhibited better activity than 6 mm SF. The ductility index values of SF-PP hybrid mixtures ranged from 1.32 to 1.74, meaning that PP had a much smaller effect on enhancing post-cracking resistance than long SF, but a better effect than short SF.

- The specimens with long SF exhibited lower Ncr and Nf variations than those with short SF, where the COV values of mixtures with long and short SF were in the ranges of 12.3% to 13.9% and 16.9% to 18.5%, respectively. On the other hand, mixing the three fiber types resulted in the highest result scattering, with the highest COV value of 25.0 recorded for the HPS hybrid mixture. The Anderson-Darling normal probability test indicated that most of the Ncr and Nf records did not perfectly follow normal distribution, but they also did not exhibit significant departures from this distribution.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Canbolat, B.; Parra-Montesinos, G.; Wight, J. Experimental study on seismic behavior of high-performance fiber-reinforced cement composite coupling beams. ACI Struct. J. 2005, 102, 159–166. [Google Scholar]

- Kuang, J.S.; Baczkowski, B.J. Steel-fiber-reinforced concrete coupling beams subjected to monotonic loading. Mag. Concr. Res. 2009, 61, 35–41. [Google Scholar] [CrossRef]

- Cai, G.; Zhao, J.; Degée, H.; Vandoren, B. Shear capacity of steel fiber reinforced concrete coupling beams using conventional reinforcements. Eng. Struct. 2016, 128, 428–440. [Google Scholar] [CrossRef]

- Mihaylov, B.I.; Franssen, I. Shear-flexure interaction in the critical sections of short coupling beams. Eng. Struct. 2017, 152, 370–380. [Google Scholar] [CrossRef] [Green Version]

- Sachan, A.K.; Kameswara Rao, C.V.S. Behaviour of fibre reinforced concrete deep beams. Cem. Concr. Compos. 1990, 12, 211–218. [Google Scholar] [CrossRef]

- Vengatachalapathy, V.; Ilangovan, R. A study on steel fibre reinforced concrete deep beams with and without openings. Int. J. Civ. Struct. Eng. 2010, 1, 509–517. [Google Scholar]

- Tuchscherer, R.G.; Quesada, A. Replacement of deformed side-face steel reinforcement in deep beams with steel fibers. Structures 2015, 3, 130–136. [Google Scholar] [CrossRef]

- Mina, A.L.; Petrou, M.F.; Trezos, K.G. Resistance of an optimized ultra-high performance fiber reinforced concrete to projectile impact. Buildings 2021, 11, 63. [Google Scholar] [CrossRef]

- Lee, M.; Park, G.K.; Kim, S.W.; Kwak, H.G. Damage characteristics of high performance fiber-reinforced cement composites panels subjected to projectile impact. Int. J. Mech. Sci. 2022, 214, 106919. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Banthia, N. Mechanical and structural behaviors of ultra-high-performance fiber-reinforced concrete subjected to impact and blast. Constr. Build. Mater. 2017, 149, 416–431. [Google Scholar] [CrossRef]

- Abid, S.R.; Gunasekaran, M.; Ali, S.H.; Kadhum, A.L.; Al-Gasham, T.S.; Fediuk, R.; Vatin, N.; Karelina, M. Impact performance of steel fiber-reinforced self-compacting concrete against repeated drop weight impact. Crystals 2021, 11, 91. [Google Scholar] [CrossRef]

- Al-ameri, R.A.; Abid, S.R.; Murali, G.; Ali, S.H.; Özakça, M. Residual repeated impact strength of concrete exposed to elevated temperatures. Crystals 2021, 11, 941. [Google Scholar] [CrossRef]

- Abid, S.R.; Abbass, A.A.; Murali, G.; Al-Sarray, M.L.J.; Nader, I.A.; Ali, S.H. Repeated Impact Response of Normal- and High-Strength Concrete Subjected to Temperatures up to 600 °C. Materials 2022, 15, 5283. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, S.; Zhang, N.; Zhou, Y. Low-velocity flexural impact response of steel fiber reinforced concrete subjected to freeze-thaw cycles in NaCl solution. Constr. Build. Mater. 2015, 101, 522–526. [Google Scholar] [CrossRef]

- Salaimanimagudam, M.P.; Suribabu, C.R.; Murali, G.; Abid, S.R. Impact response of hammerhead pier fibrous concrete beams designed with topology optimization. Period. Polytech. Civ. Eng. 2020, 64, 1244–1258. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, S.; Liu, Y. Effect of weight and drop height of hammer on the flexural impact performance of fiber-reinforced concrete. Constr. Build. Mater. 2017, 140, 31–35. [Google Scholar] [CrossRef]

- Pan, Y.; Wu, C.; Cheng, X.; Li, V.C.; He, L. Impact fatigue behaviour of GFRP mesh reinforced engineered cementitious composites for runway pavement. Constr. Build. Mater. 2020, 230, 116898. [Google Scholar] [CrossRef]

- Abid, S.R.; Abdul Hussein, M.L.; Ali, S.H.; Kazem, A.F. Suggested modified testing techniques to the ACI 544-R repeated drop-weight impact test. Constr. Build. Mater. 2020, 244, 118321. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Muhyaddin, G.F.; Asaad, D.S. Strain hardening ultra-high performance fiber reinforced cementitious composites: Effect of fiber type and concentration. Compos. Part B 2016, 103, 74–83. [Google Scholar] [CrossRef]

- ACI Committee 544. ACI 544.9R–2017; Report on Measuring Mechanical Properties of Hardened Fiber-Reinforce Concrete. American Concrete Institute (ACI): Farmington Hills, MI, USA, 2017.

- Yoo, D.-Y.; Banthia, N. Mechanical properties of ultra-high-performance fiber reinforced concrete: A review. Cem. Concr. Compos. 2016, 73, 267–280. [Google Scholar] [CrossRef]

- Abid, S.R.; Abdul-Hussein, M.L.; Ayoob, N.S.; Ali, S.H.; Kadhum, A.L. Repeated drop-weight impact tests on self-compacting concrete reinforced with micro-steel fiber. Heliyon 2020, 6, e03198. [Google Scholar] [CrossRef] [Green Version]

- Narayanan, R.; Darwish, I.Y.S. Use of steel fibers as shear reinforcement. ACI Struct. J. 1987, 84, 216–227. [Google Scholar]

- Yoo, D.-Y.; Moon, D.-Y. Effect of steel fibers on the flexural behavior of RC beams with very low reinforcement ratios. Constr. Build. Mater. 2018, 188, 237–254. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Kim, S.; Kim, J.-J.; Chun, B. An experimental study on pullout and tensile behavior of ultra-high-performance concrete reinforced with various steel fibers. Construct. Build. Mater. 2019, 206, 46–61. [Google Scholar] [CrossRef]

- Abbass, A.A.; Arnaot, F.H.; Abid, S.R.; Özakça, M. Flexural behavior of ECC hollow beams incorporating different synthetic fibers. Front. Struct. Civ. Eng. 2021, 15, 399–411. [Google Scholar] [CrossRef]

- ACI Committee 544. ACI 544.6R–15; Report on Design and Construction of Steel Fiber-Reinforce Concrete Elevated Slabs. American Concrete Institute (ACI): Farmington Hills, MI, USA, 2015.

- Li, B.; Chi, Y.; Xu, L.; Shi, Y.; Li, C. Experimental investigation on the flexural behavior of steel-polypropylene hybrid fiber reinforced concrete. Construct. Build. Mater. 2018, 191, 80–94. [Google Scholar] [CrossRef]

- Wang, D.; Ju, Y.; Shen, H.; Xu, L. Mechanical properties of high performance concrete reinforced with basalt fiber and polypropylene fiber. Constr. Build. Mater. 2019, 197, 464–473. [Google Scholar] [CrossRef]

- Smarzewski, P. Influence of basalt-polypropylene fibres on fracture properties of high performance concrete. Compos. Struct. 2019, 209, 23–33. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Banthia, N. Impact resistance of fiber-reinforced concrete—A review. Cem. Concr. Compos. 2019, 104, 103389. [Google Scholar] [CrossRef]

- Abousnina, R.; Premasiri, S.; Anise, V.; Lokuge, W.; Vimonsatit, V.; Ferdous, W.; Alajarmeh, O. Mechanical properties of macro polypropylene fibre-reinforced concrete. Polymers 2021, 13, 4112. [Google Scholar] [CrossRef]

- Ismail, M.K.; Hassan, A.A.A. Impact resistance and mechanical properties of self-consolidating rubberized concrete reinforced with steel fibers. J. Mater. Civ. Eng. 2017, 29, 04016193. [Google Scholar] [CrossRef]

- Haridharan, M.K.; Matheswaran, S.; Murali, G.; Abid, S.R.; Fediuk, R.; Mugahed Amran, Y.H.; Abdelgader, H.S. Impact response of two-layered grouted aggregate fibrous concrete composite under falling mass impact. Constr. Build. Mater. 2020, 263, 120628. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Amran, M.; Fediuk, R.; Vatin, N.; Karelina, M. Combined effect of multi-walled carbon nanotubes, steel fibre and glass fibre mesh on novel two-stage expanded clay aggregate concrete against impact loading. Crystals 2021, 11, 720. [Google Scholar] [CrossRef]

- Kathirvel, P.; Murali, G.; Vatin, N.I.; Abid, S.R. Experimental study on self compacting fibrous concrete comprising cagnesium sulphate solution treated recycled aggregates. Materials 2022, 15, 340. [Google Scholar] [CrossRef] [PubMed]

- Badr, A.; Ashour, A.F. Modified ACI drop-weight impact test for concrete. ACI Mater. J. 2005, 102, 249–255. [Google Scholar]

- Badr, A.; Ashour, A.F.; Platten, A.K. Statistical variations in impact resistance of polypropylene fibre-reinforced concrete. Int. J. Impact Eng. 2006, 32, 1907–1920. [Google Scholar] [CrossRef] [Green Version]

- Song, P.S.; Wu, J.C.; Hwang, S.; Sheu, B.C. Statistical analysis of impact strength and strength reliability of steel-polypropylene hybrid fiber-reinforced concrete. Constr. Build. Mater. 2005, 19, 1–9. [Google Scholar] [CrossRef]

- Song, P.S.; Wu, J.C.; Hwang, S.; Sheu, B.C. Assessment of statistical variations in impact resistance of high-strength concrete and high-strength steel fiber-reinforced concrete. Cem. Concr. Res. 2005, 35, 393–399. [Google Scholar] [CrossRef]

- Yildirim, S.T.; Ekinci, C.E.; Findik, F. Properties of Hybrid Fiber reinforced concrete under repeated impact loads. Russ. J. Nondestruct. Test. 2010, 46, 538–546. [Google Scholar] [CrossRef]

- Nili, M.; Afroughsabet, V. Combined effect of silica fume and steel fibers on the impact resistance and mechanical properties of concrete. Int. J. Impact Eng. 2010, 37, 879–886. [Google Scholar] [CrossRef] [Green Version]

- Nia, A.A.; Hedayatian, M.; Nili, M.; Sabet, V.A. An experimental and numerical study on how steel and polypropylene fibers affect the impact resistance in fiber-reinforced concrete. Int. J. Impact Eng. 2012, 46, 62–73. [Google Scholar]

- Rahmani, T.; Kiani, B.; Shekarchi, M.; Safari, A. Statistical and experimental analysis on the behavior of fiber reinforced concretes subjected to drop weight test. Constr. Build. Mater. 2012, 37, 360–369. [Google Scholar] [CrossRef]

- Myers, J.J.; Tinsley, M. Impact resistance of blast mitigation material using modified aci drop-weight impact test. ACI Mater. J. 2013, 110, 339–348. [Google Scholar]

- Fakharifar, M.; Dalvand, A.; Arezoumandi, M.; Sharbatdar, M.K.; Chen, G.; Kheyroddin, A. Mechanical properties of high performance fiber reinforced cementitious composites. Comput. Chem. Eng. 2014, 71, 510–520. [Google Scholar] [CrossRef]

- Murali, G.; Prasad, N.; Klyuev, S.; Fediuk, R.; Abid, S.R.; Amran, M.; Vatin, N. Impact resistance of functionally layered two-stage fibrous concrete. Fibers 2021, 9, 88. [Google Scholar] [CrossRef]

- Murali, G.; Prasad, N.; Abid, S.R.; Vatin, N.I. Response of Functionally Graded Preplaced Aggregate Fibrous Concrete with Superior Impact Strength. Buildings 2022, 12, 563. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Amran, M.; Vatin, N.I.; Fediuk, R. DropWeight Impact Test on Prepacked Aggregate Fibrous Concrete—An Experimental Study. Materials 2022, 15, 3096. [Google Scholar] [CrossRef]

- Vatin, N.I.; Murali, G.; Abid, S.R.; de Azevedo, A.R.G.; Tayeh, B.; Dixit, S. Enhancing the Impact Strength of Prepacked Aggregate Fibrous Concrete Using Asphalt-Coated Aggregates. Materials 2022, 15, 2598. [Google Scholar] [CrossRef] [PubMed]

- Ramakrishnan, K.; Depak, S.R.; Hariharan, K.R.; Abid, S.R.; Murali, G.; Cecchin, D.; Fediuk, R.; Mugahed Amran, Y.H.; Abdelgader, H.S.; Khatib, J.M. Standard and modified falling mass impact tests on preplaced aggregate fibrous concrete and slurry infiltrated fibrous concrete. Constr. Build. Mater. 2021, 298, 123857. [Google Scholar] [CrossRef]

- Al-Ameri, R.A.; Abid, S.R.; Özakça, M. Mechanical and Impact Properties of Engineered Cementitious Composites Reinforced with PP Fibers at Elevated Temperatures. Fire 2022, 5, 3. [Google Scholar] [CrossRef]

- Al-Ameri, R.A.; Abid, S.R.; Murali, G.; Ali, S.H.; Özakça, M.; Vatin, N.I. Residual Impact Performance of ECC Subjected to Sub-High Temperatures. Materials 2022, 15, 454. [Google Scholar] [CrossRef]

- Nataraja, M.C.; Dhang, N.; Gupta, A.P. Statistical variations in impact resistance of steel fiber-reinforced concrete subjected to drop weight test. Cem. Concr. Res. 1999, 29, 989–995. [Google Scholar] [CrossRef]

- Abid, S.R.; Ali, S.H.; Goaiz, H.A.; Al-Gasham, T.S.; Kadhim, A.L. Impact resistance of steel fiber-reinforced self-compacting concrete. Mag. Civ. Eng. 2021, 105, 2712–8172. [Google Scholar]

- Ding, Y.; Li, D.; Zhang, Y.; Azevedo, C. Experimental investigation on the composite effect of steel rebars and macro fibers on the impact behavior of high performance self-compacting concrete. Constr. Build. Mater. 2017, 136, 495–505. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.Y.; Ding, Y.N.; Azevedo, C. Combined effect of steel fibres and steel rebars on impact resistance of high performance concrete. J. Cent. South Univ. Technol. 2011, 18, 1677–1684. [Google Scholar] [CrossRef] [Green Version]

- Murali, G.; Abid, S.R.; Mugahed Amran, Y.H.; Abdelgader, H.S.; Fediuk, R.; Susrutha, A.; Poonguzhali, K. Impact performance of novel multi-layered prepacked aggregate fibrous composites under compression and bending. Structures 2020, 28, 1502–1515. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of steel fiber content and shape on mechanical properties of ultra high performance concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K.H. Investigation of mechanical properties and shrinkage of ultra-high performance concrete: Influence of steel fiber content and shape. Compos. Part B 2019, 174, 107021. [Google Scholar] [CrossRef]

- Xu, L.; Wu, F.; Chi, Y.; Cheng, P.; Zeng, Y.; Chen, Q. Effects of coarse aggregate and steel fibre contents on mechanical properties of high performance concrete. Constr. Build. Mater. 2019, 206, 97–110. [Google Scholar] [CrossRef]

- Komlos, K.; Babal, B.; Nurnbergerova, T. Hybrid fibre-reinforced concrete under repeated loading. Nucl. Eng. Des. 1995, 156, 195–200. [Google Scholar] [CrossRef]

- Park, H.S.; Kim, J.D.; Ryu, S.G.; Koh, T.K. Tensile behavior of ultra high performance hybrid Fiber reinforced concrete. Cem. Concr. Compos. 2012, 34, 172–184. [Google Scholar] [CrossRef]

- Ali, S.H.; Ayoob, N.S.; Abdul-Hussein, M.L.; Abid, S.R. Water impact-abrasion erosion of hybrid fiber-reinforced high performance concrete. Nano Hybrids Compos. 2020, 30, 63–72. [Google Scholar] [CrossRef]

- ACI 544.2R-89; Measurement of Properties of Fiber Reinforced Concrete. American Concrete Institute: Farmington Hills, MI, USA, 1999; Volume 89, pp. 1–12.

- Mahakavi, P.; Chithra, R. Impact resistance, microstructures and digital image processing on self-compacting concrete with hooked end and crimped steel fiber. Constr. Build. Mater. 2019, 220, 651–666. [Google Scholar] [CrossRef]

- Jabir, H.A.; Abid, S.R.; Murali, G.; Ali, S.H.; Klyuev, S.; Fediuk, R.; Vatin, N.; Promakhov, V.; Vasilev, Y. Experimental tests and reliability analysis of the cracking impact resistance of uhpfrc. Fibers 2020, 8, 74. [Google Scholar] [CrossRef]

- Schrader, E.K. Impact Resistance and Test Procedure for Concrete. J. Am. Concr. Inst. 1981, 78, 141–146. [Google Scholar] [CrossRef]

- Noaman, A.T.; Abu Bakar, B.H.; Akil, H.M. The effect of combination between crumb rubber and steel fiber on impact energy of concrete beams. Procedia Eng. 2015, 125, 825–831. [Google Scholar] [CrossRef] [Green Version]

- Bernardo, L.F.A.; Lopes, S.M.R. Neutral axis depth versus flexural ductility in high-strength concrete beams. J. Struct. Eng. 2004, 30, 452–459. [Google Scholar] [CrossRef]

- Shin, S.W.; Ghosh, S.K.; Moreno, J. Flexural ductility of ultra-high-strength concrete members. ACI Struct. J. 1989, 86, 394–400. [Google Scholar]

- Abid, S.R.; Murali, G.; Ahmad, J.; Al-Ghasham, T.S.; Vatin, N.I. Repeated drop-weight impact testing of fibrous concrete: State-of-the-art literature review, analysis of results variation and test improvement suggestions. Materials 2022, 15, 3948. [Google Scholar] [CrossRef]

- Soroushian, P.; Nagi, M.; Alhozaimy, A. Statistical variations in the mechanical properties of carbon fiber reinforced cement composites. ACI Mater. J. 1992, 89, 131–138. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Alrshoudi, F.; Tahir, M.M.; Alyousef, R.; Alghamdi, H.; Alharbi, Y.R.; Alsaif, A. Performance evaluation of novel prepacked aggregate concrete reinforced with waste polypropylene fibers at elevated temperatures. Constr. Build. Mater. 2020, 259, 120418. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A.R. The impact resistance and mechanical properties of reinforced self-compacting concrete with recycled glass fibre reinforced polymers. J. Clean. Prod. 2016, 124, 312–324. [Google Scholar] [CrossRef]

| Mixture | SF (6 mm) | SF (15 mm) | PP |

|---|---|---|---|

| S6 | 2.5 | 0 | 0 |

| S15 | 0 | 2.5 | 0 |

| HS | 1.25 | 1.25 | 0 |

| PS6 | 2.0 | 0 | 0.5 |

| PS15 | 0 | 2.0 | 0.5 |

| HPS | 1.0 | 1.0 | 0.5 |

| Fiber Type | Length (mm) | Diameter (mm) | Density (kg/m3) | Tensile Strength (GPa) |

|---|---|---|---|---|

| SF6 | 6 | 0.12 | 7800 | 2.85 |

| SF15 | 15 | 0.20 | 7800 | 2.60 |

| PP | 18 | 0.50 | 910 | 0.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, S.H.; Abid, S.R.; Al-Lami, K.; Calabrese, A.S.; Yosri, A.M.; Al-Ghasham, T.S. Experimental and Statistical Analysis of Repeated Impact Records of Hybrid Fiber-Reinforced High-Performance Concrete. Buildings 2023, 13, 678. https://doi.org/10.3390/buildings13030678

Ali SH, Abid SR, Al-Lami K, Calabrese AS, Yosri AM, Al-Ghasham TS. Experimental and Statistical Analysis of Repeated Impact Records of Hybrid Fiber-Reinforced High-Performance Concrete. Buildings. 2023; 13(3):678. https://doi.org/10.3390/buildings13030678

Chicago/Turabian StyleAli, Sajjad H., Sallal R. Abid, Karrar Al-Lami, Angelo Savio Calabrese, Ahmed M. Yosri, and Thaar S. Al-Ghasham. 2023. "Experimental and Statistical Analysis of Repeated Impact Records of Hybrid Fiber-Reinforced High-Performance Concrete" Buildings 13, no. 3: 678. https://doi.org/10.3390/buildings13030678