Residual Properties of Fibre Grids Embedded in Cementitious Matrices after Exposure to Elevated Temperatures

Abstract

:1. Introduction

2. Literature Review

3. Materials and Test Design

3.1. General Information

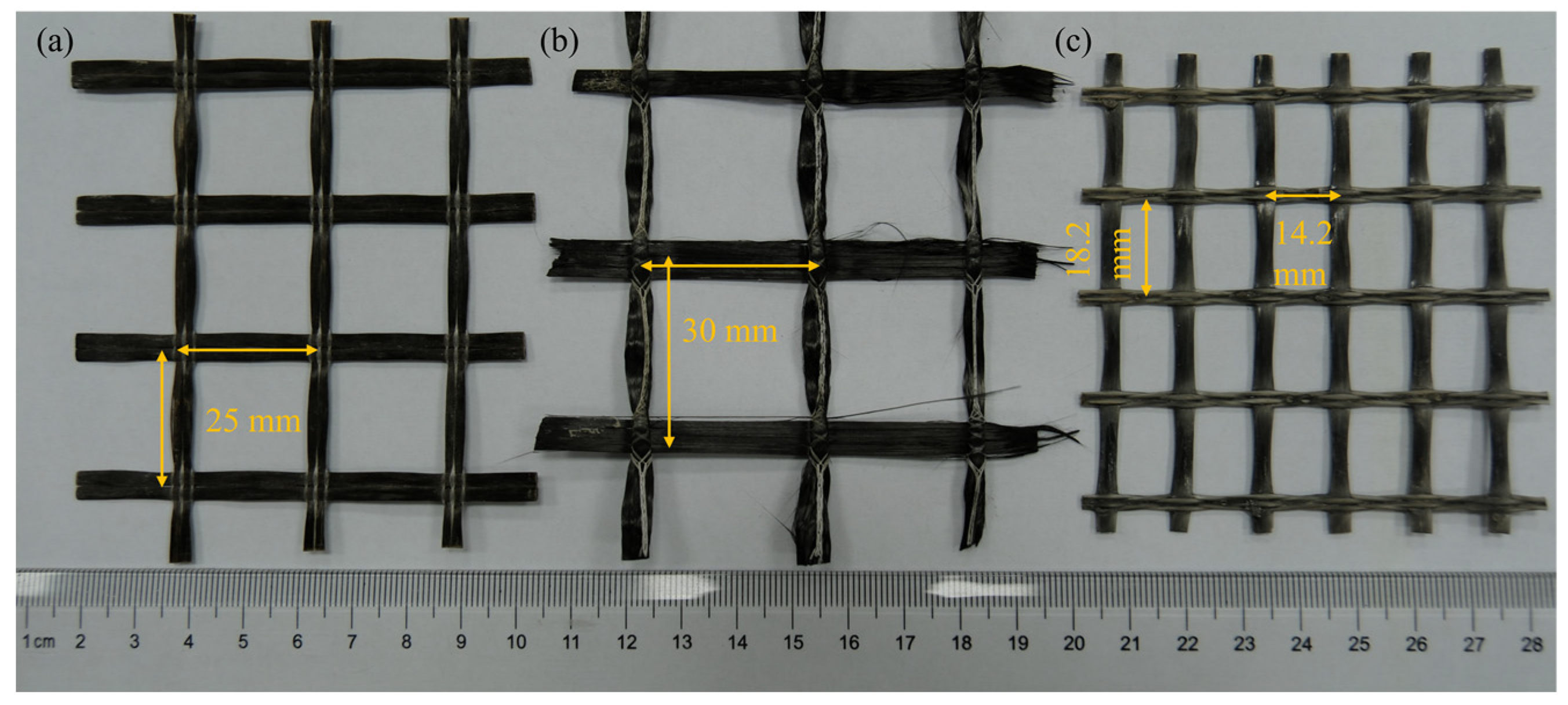

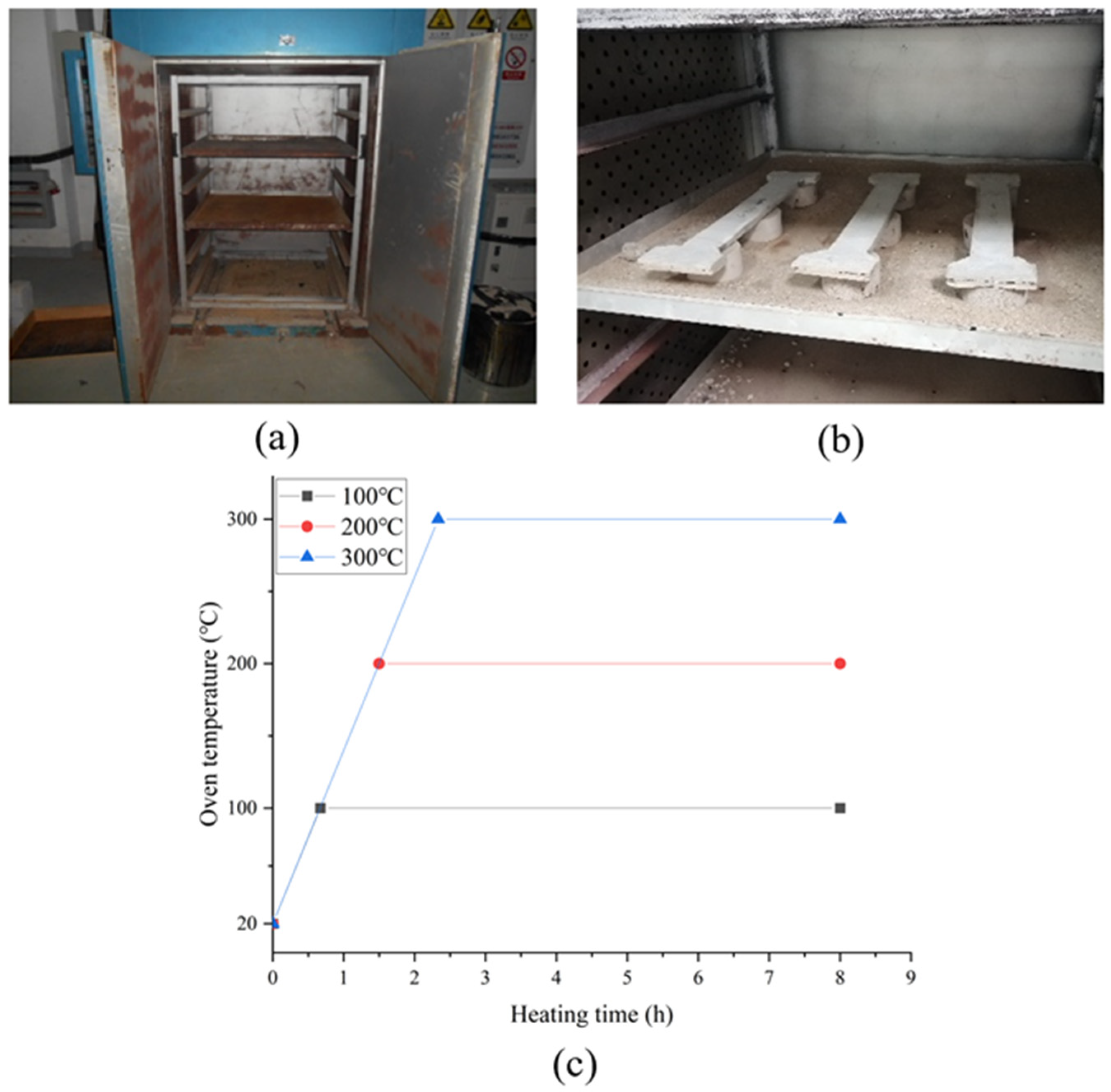

3.2. Specimen Preparation

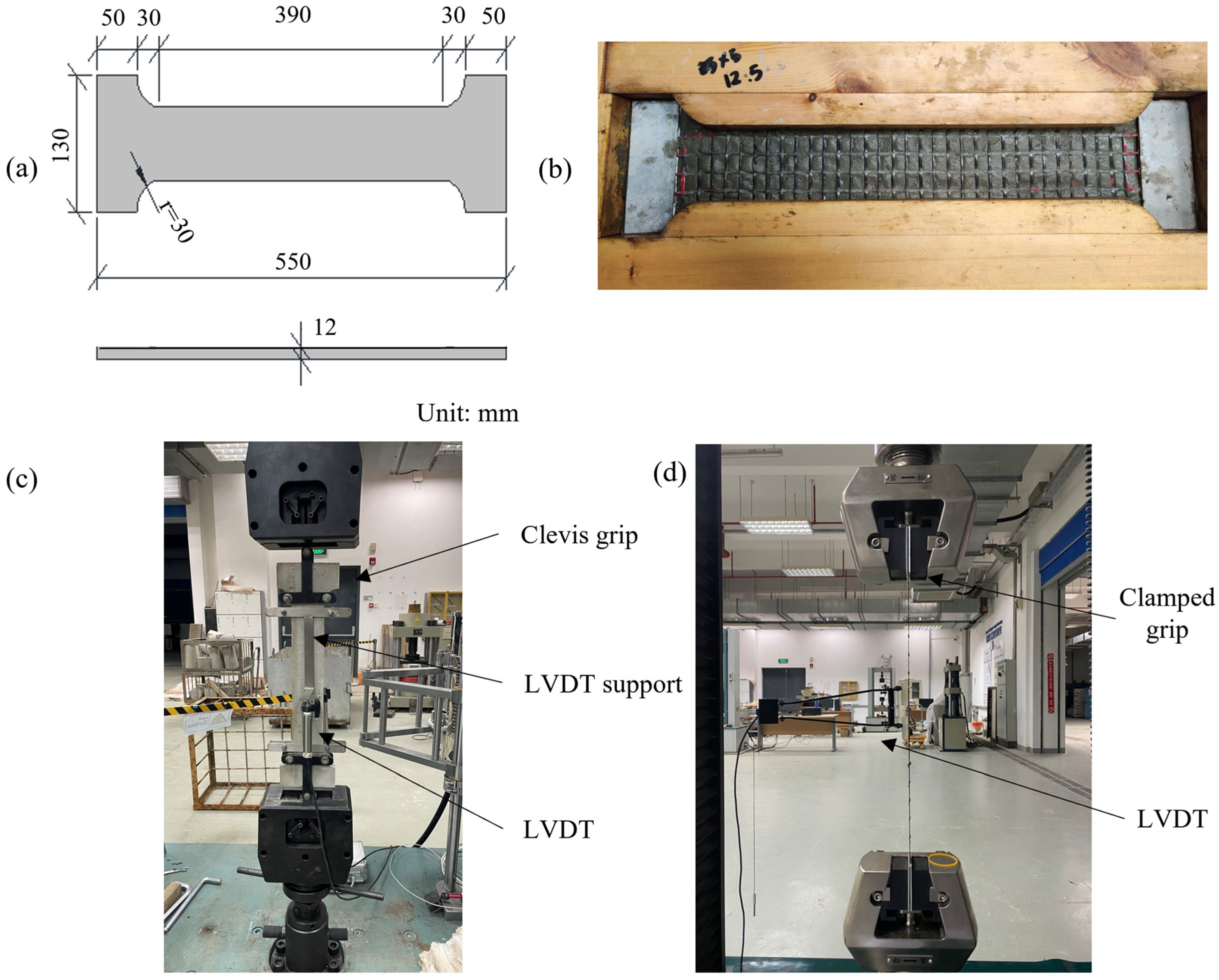

3.3. Test Set-Up

4. Results and Discussion

4.1. Flexural and Compressive Tests on Mortar Specimens

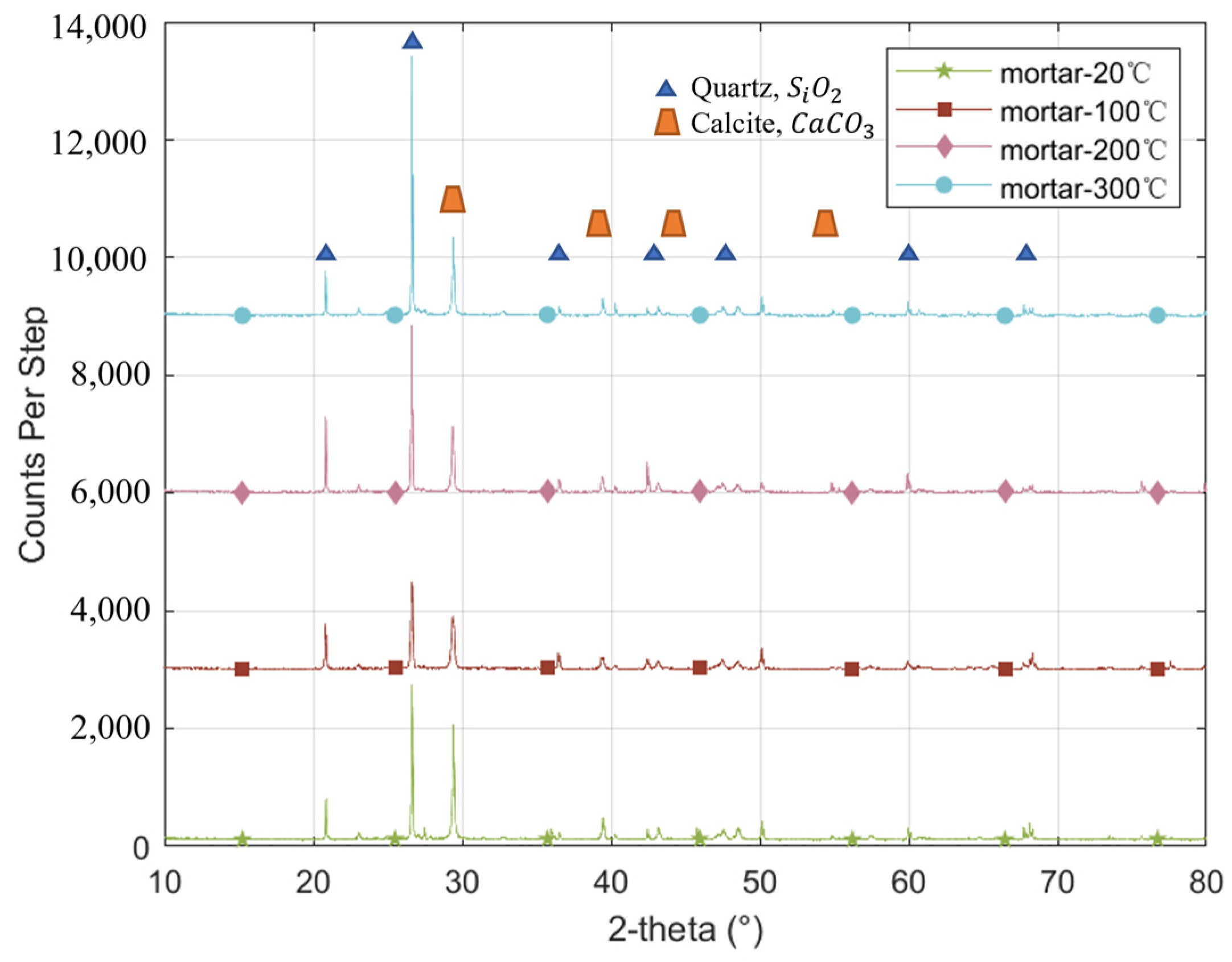

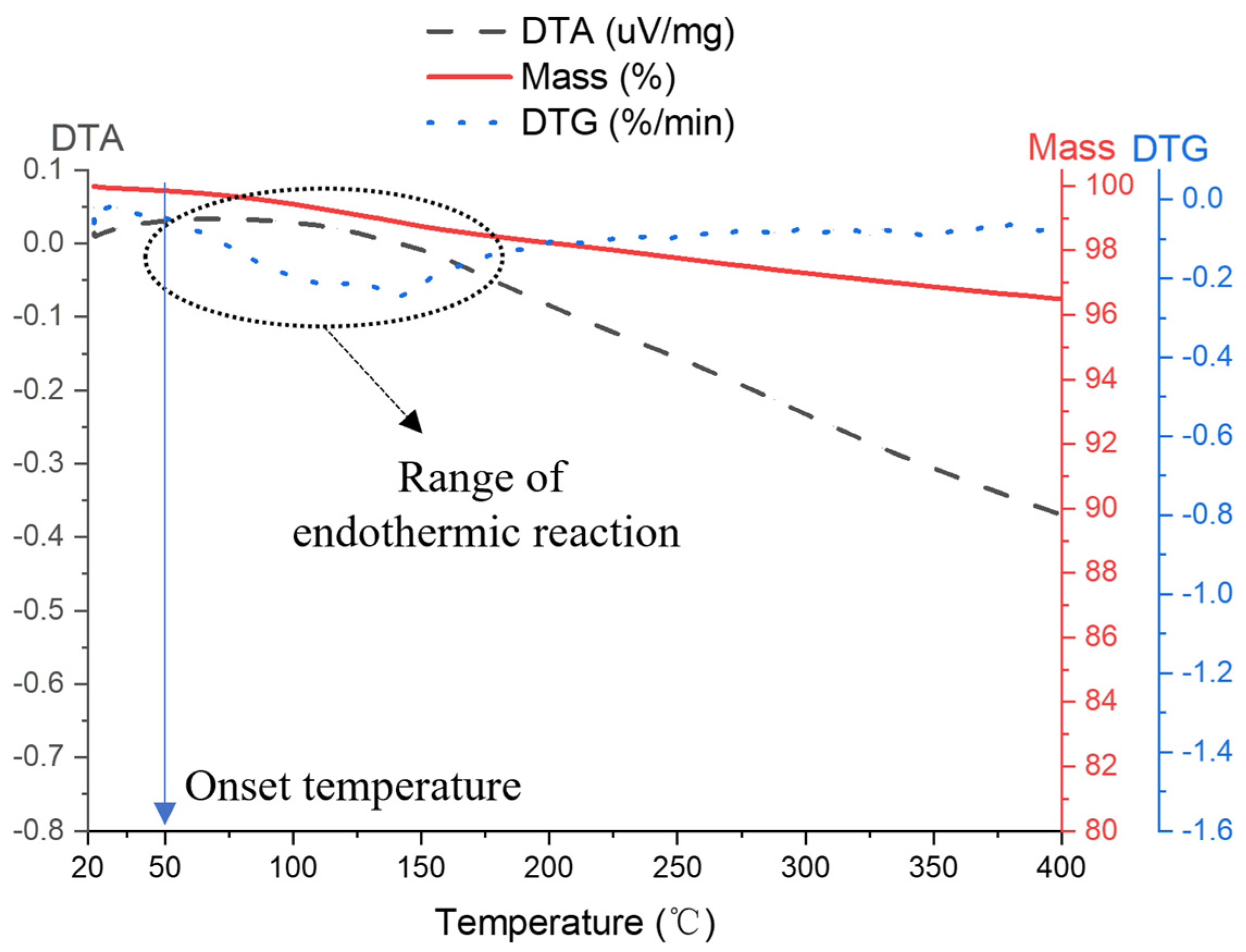

4.2. XRD, SEM, and TGA for the Mortar

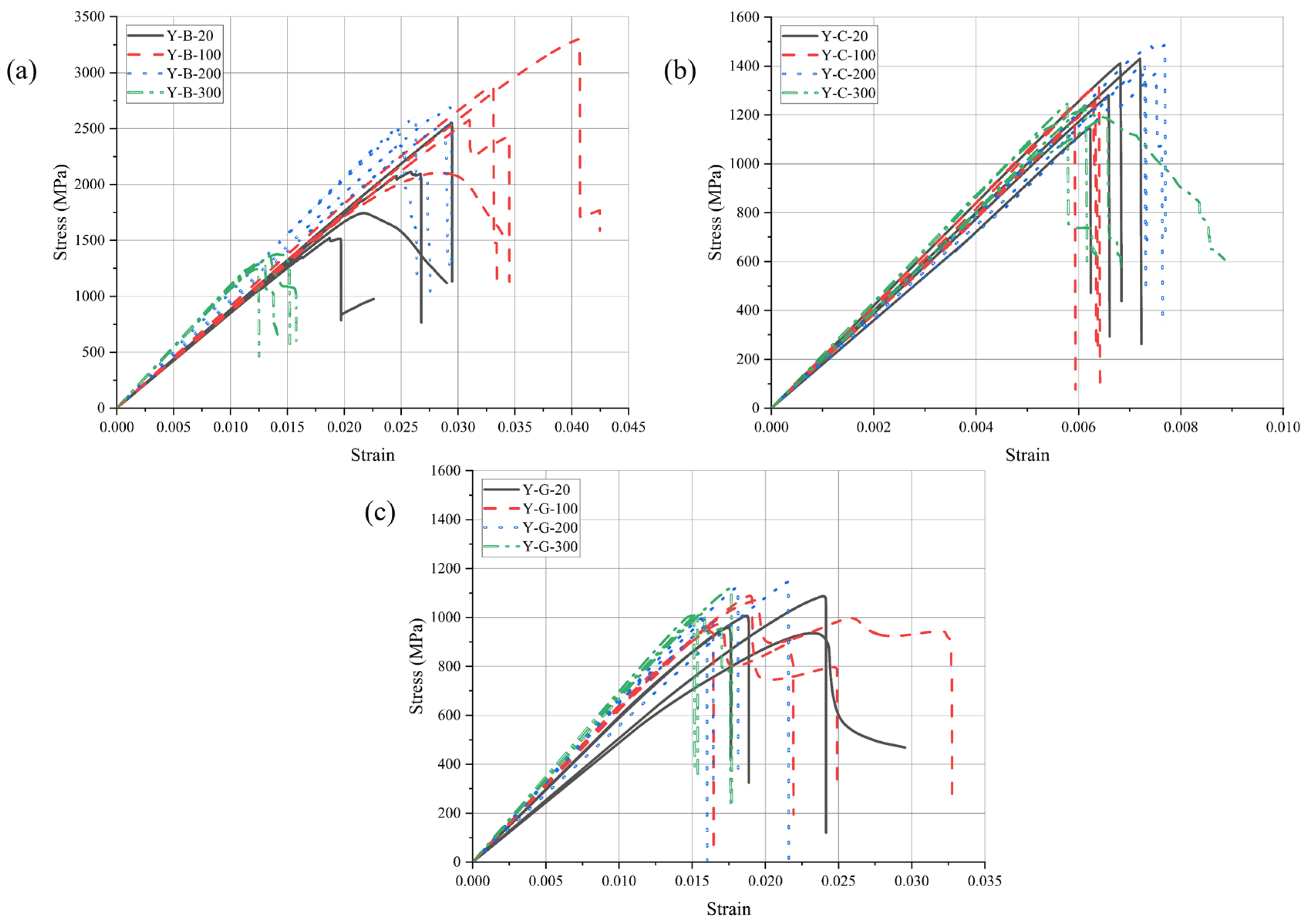

4.3. Fabric Yarns Tensile Test

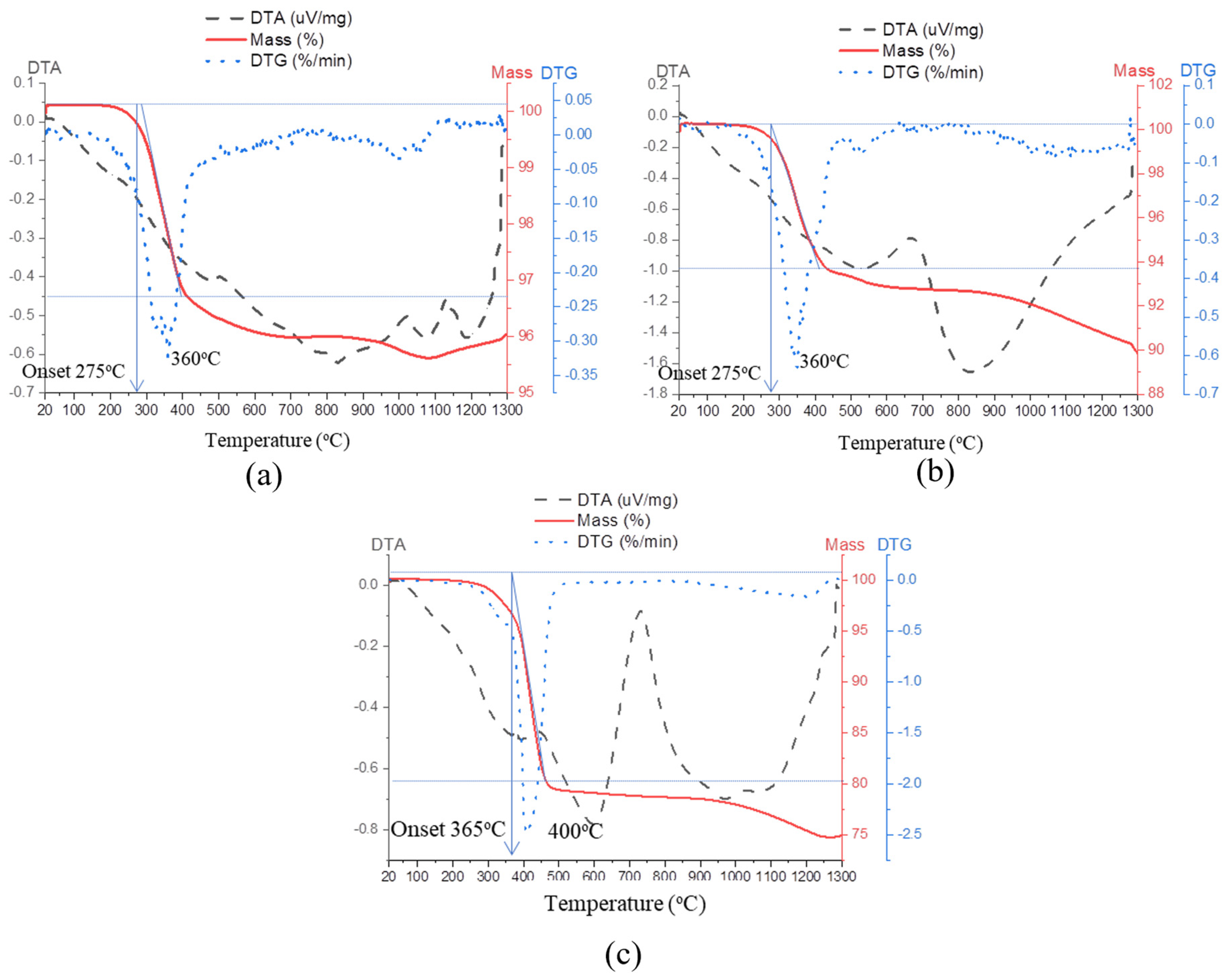

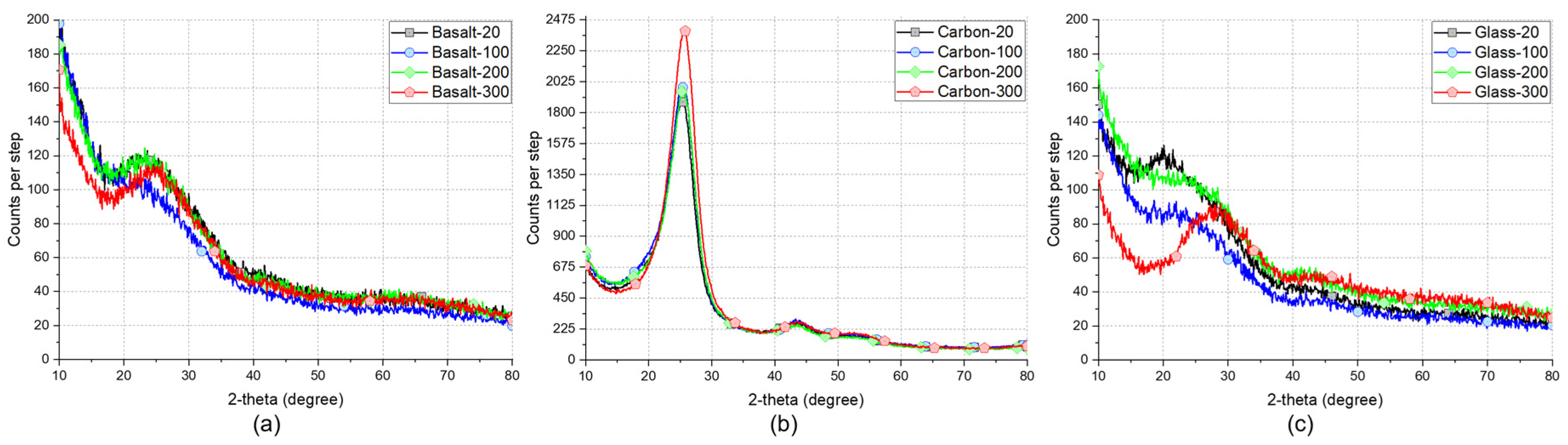

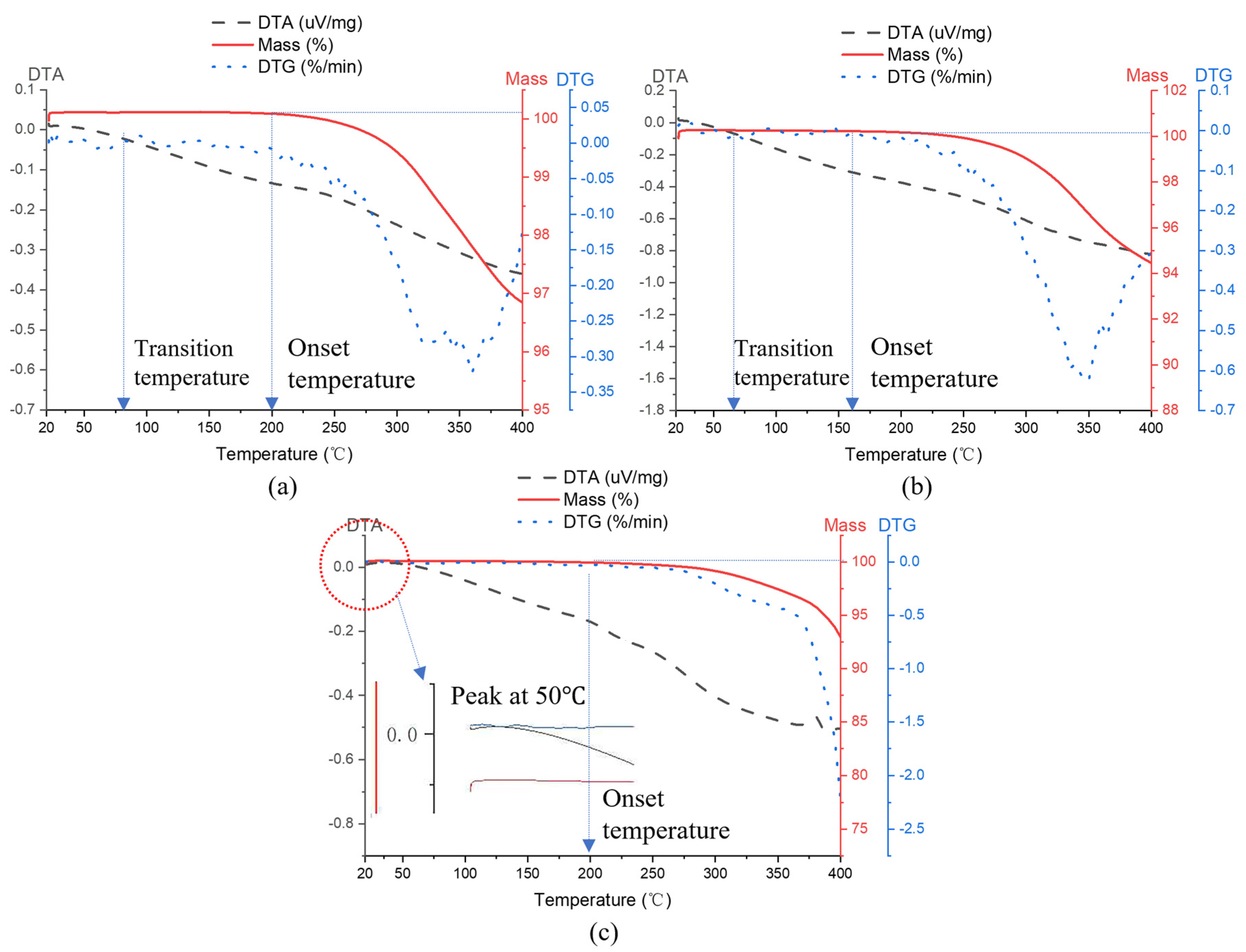

4.4. XRD, SEM, and TGA Tests for the Yarns

4.5. TRM Coupons Tensile Test

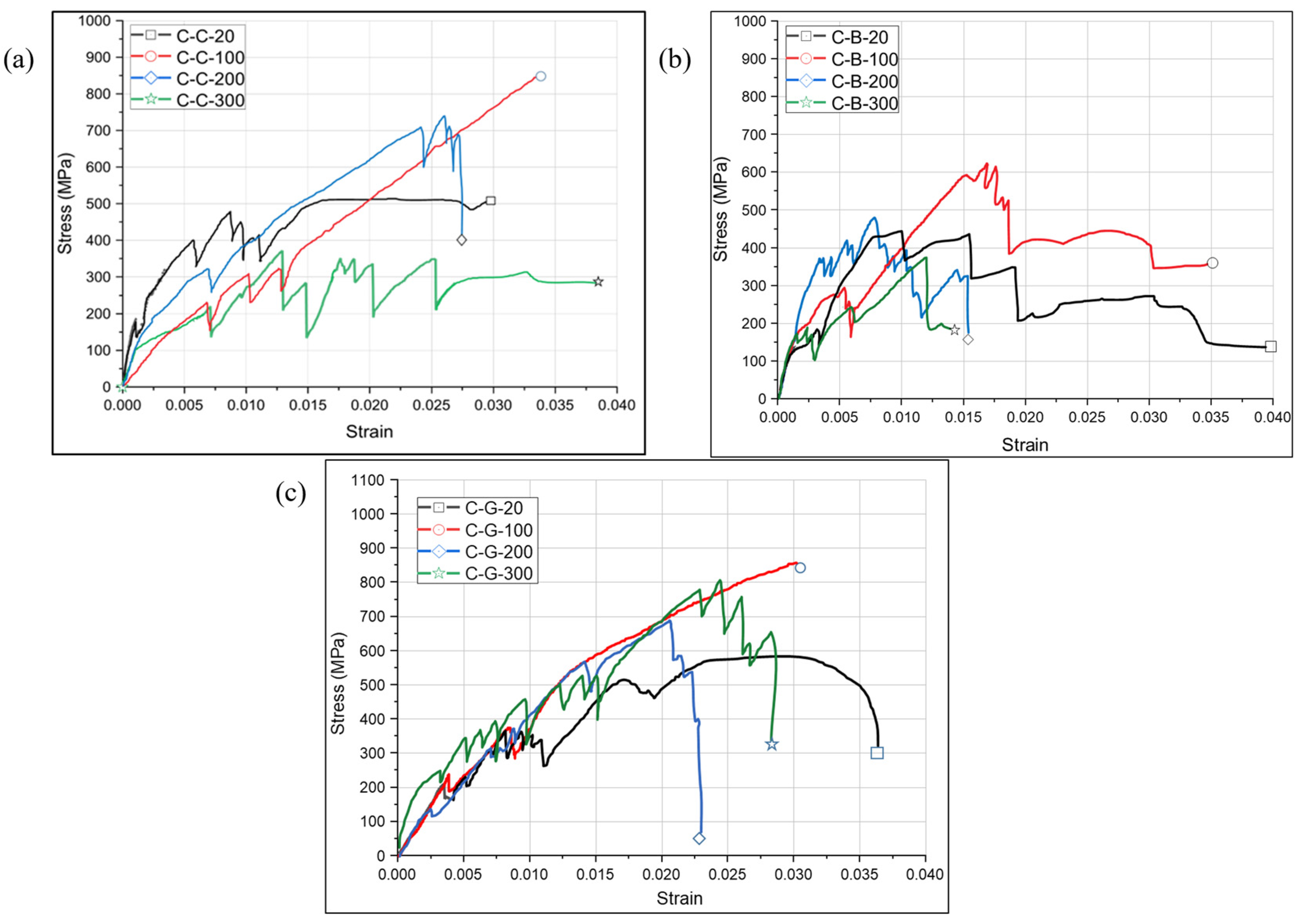

4.5.1. Stress–Strain Diagrams

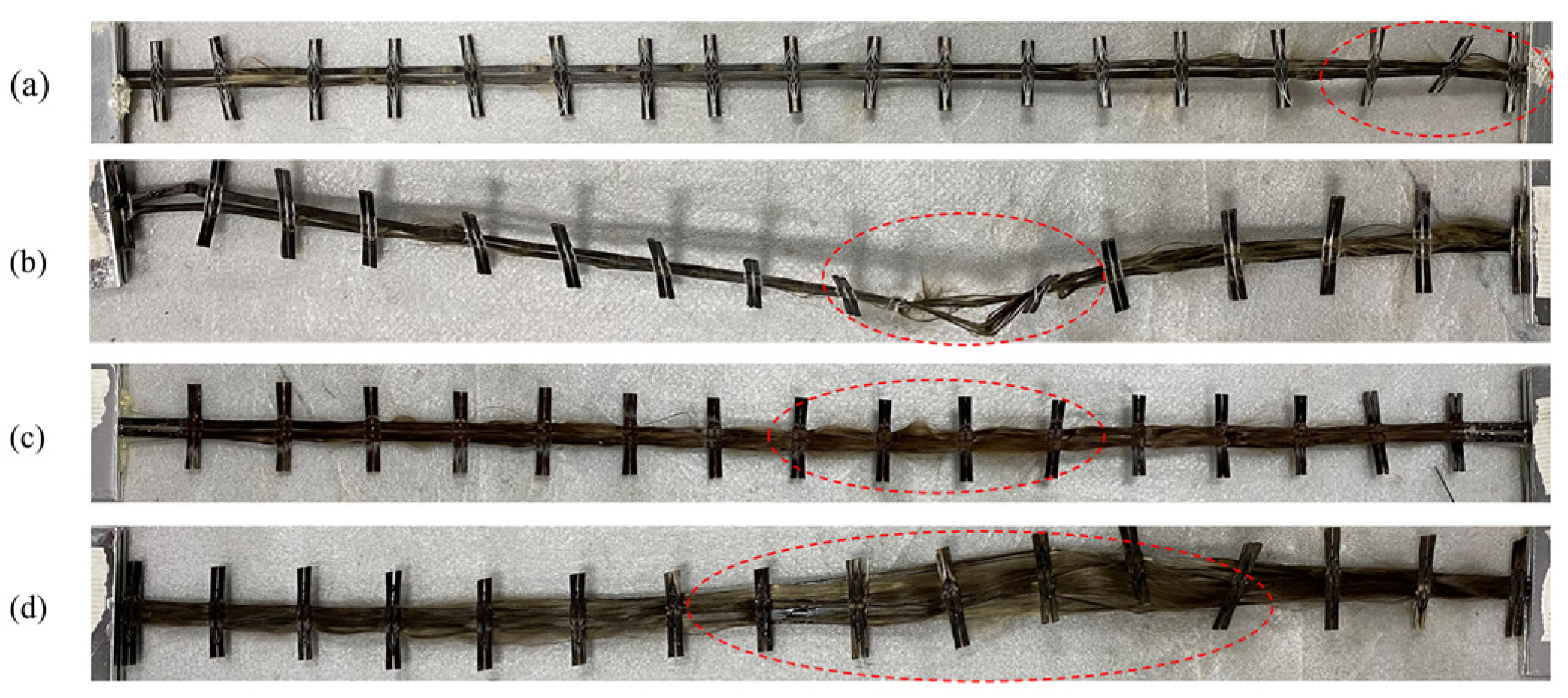

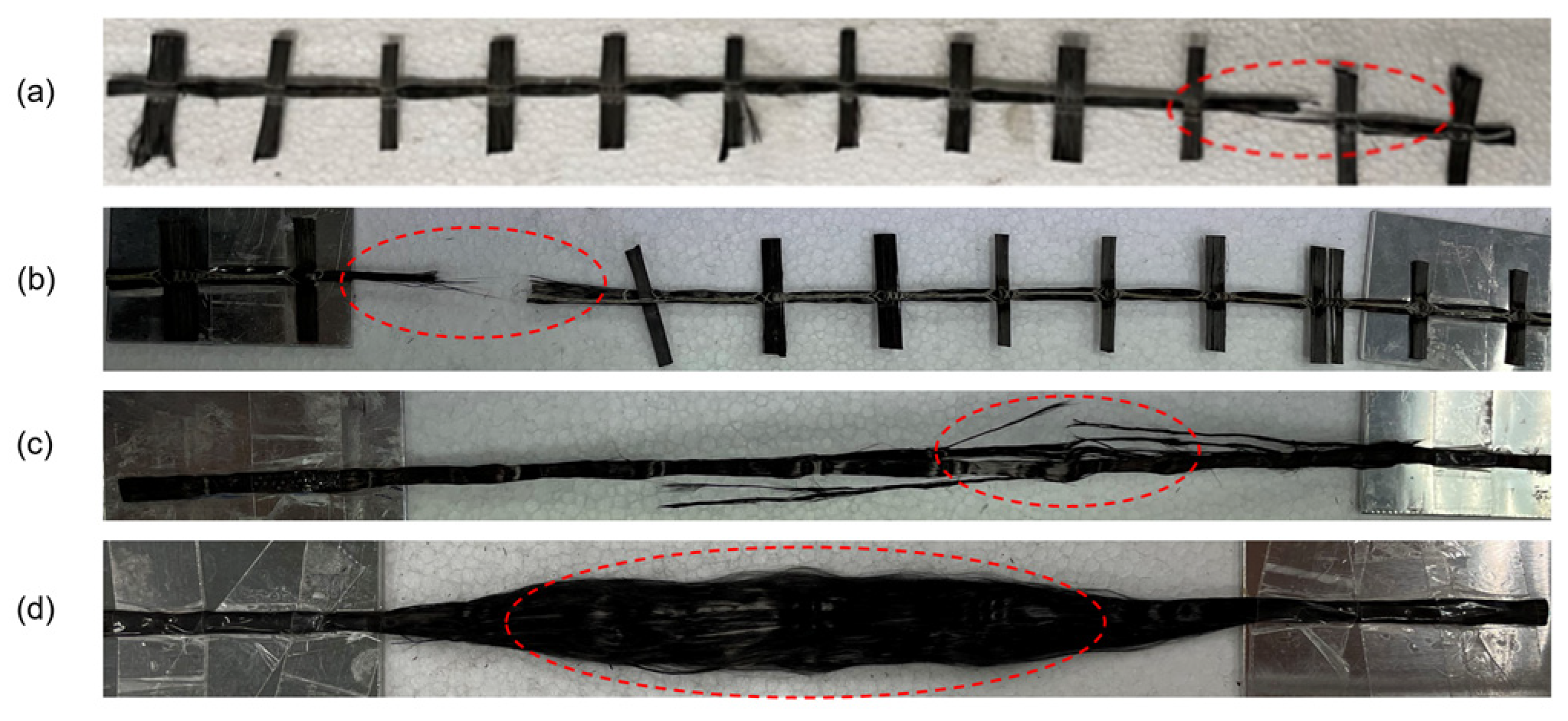

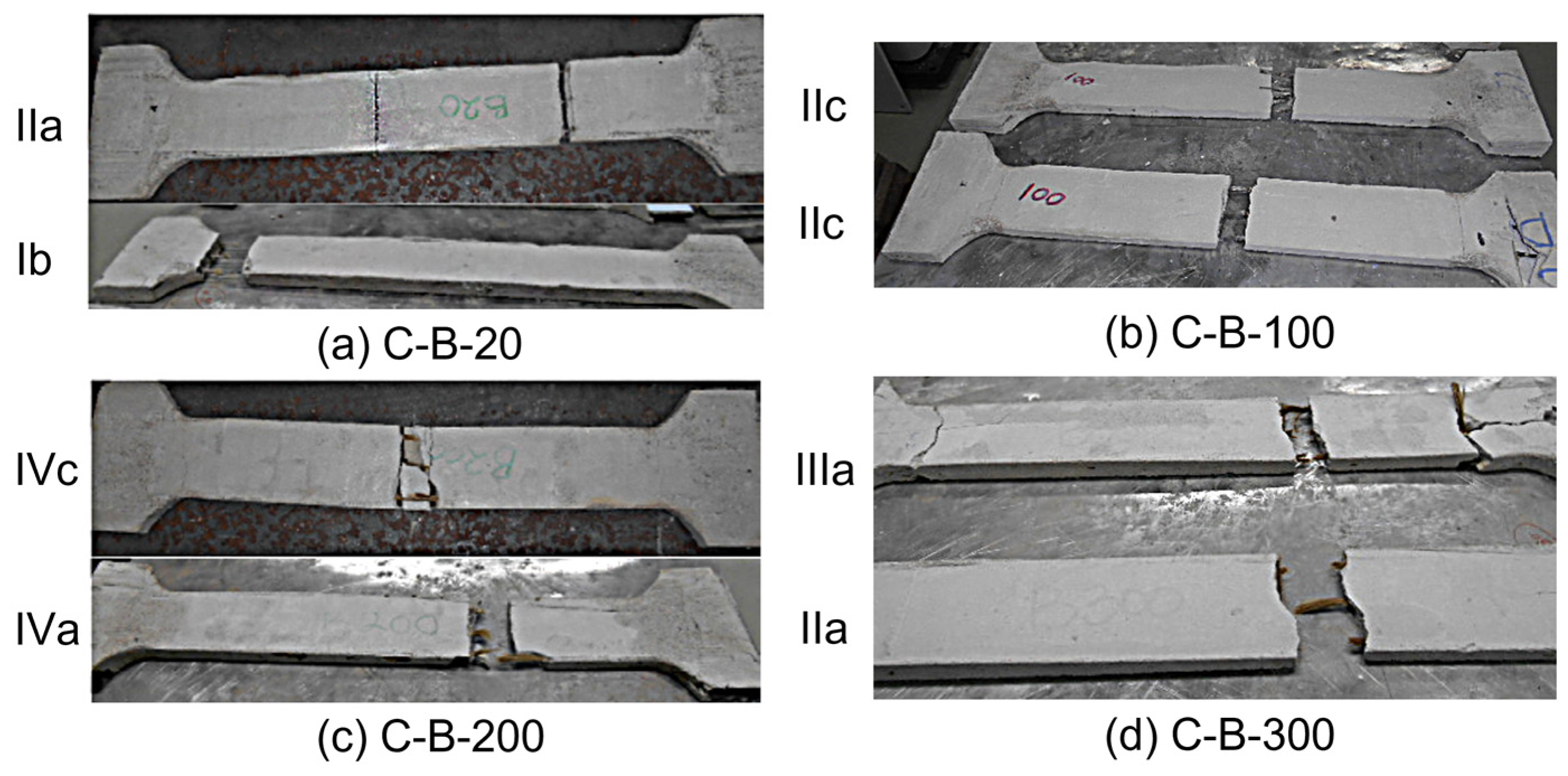

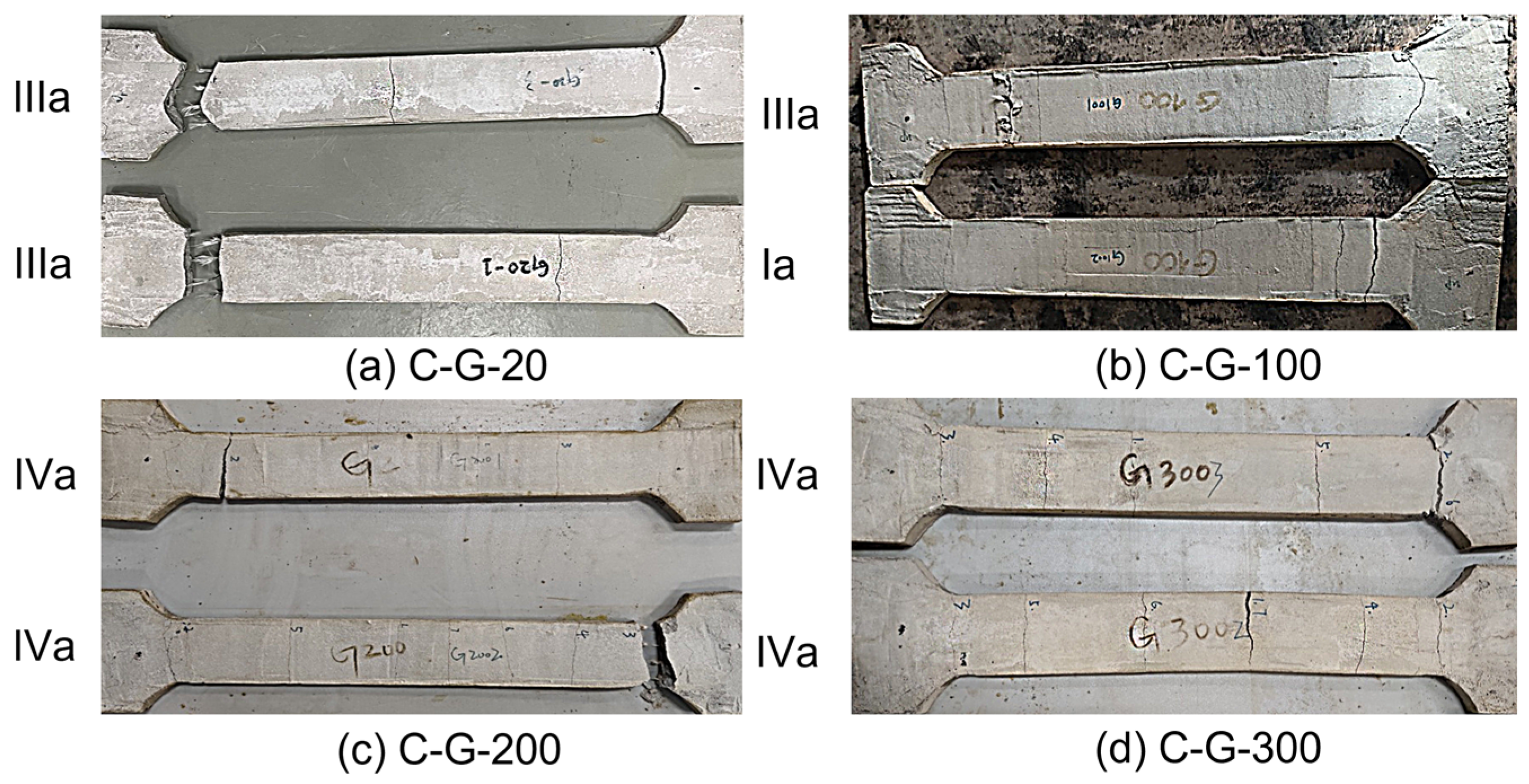

4.5.2. Modes of Failure

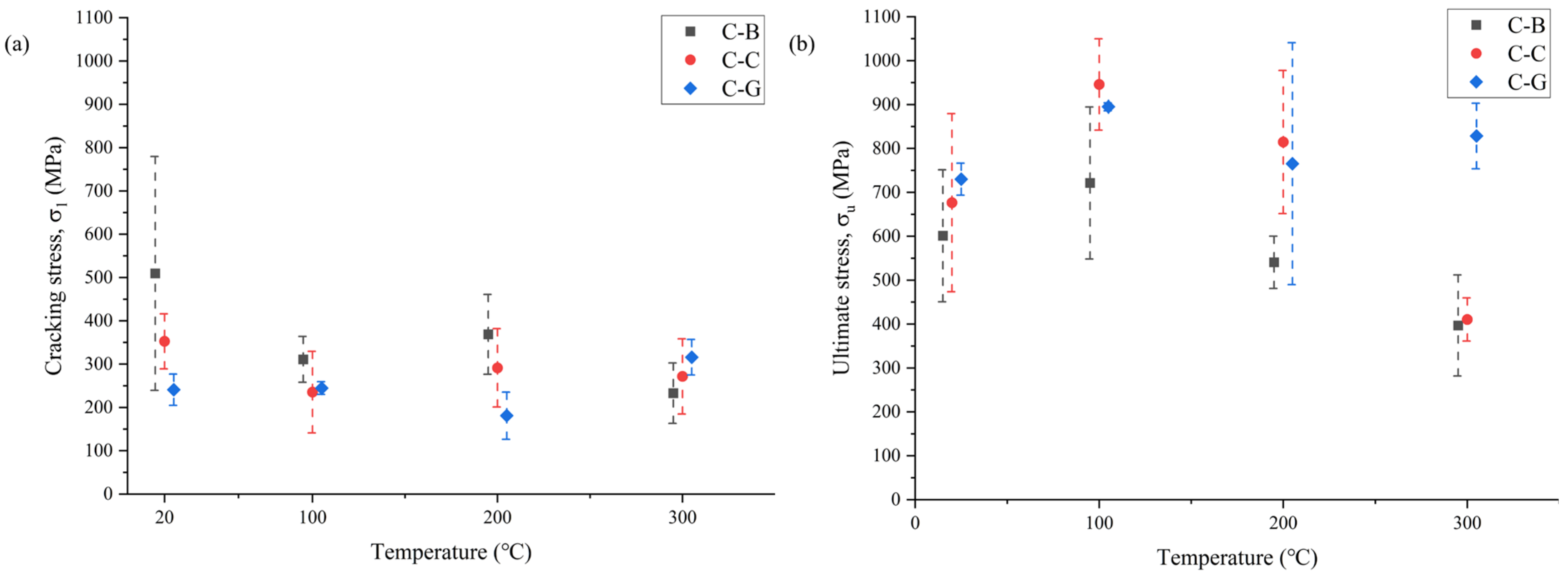

4.5.3. Stress, Deformability, and Precracked and Postcracking Behavior

5. Conclusions

- –

- The polymer-modified mortar up to 100 °C retains its flexural strength due to the improved dispersion of the polymeric agent, but the compressive strength drops significantly. Above 100 °C, the increased porosity harms the flexural strength. The compressive strength at the same range of temperatures experiences a marginal increase due to the dehydration of C-S-H and the ettringite.

- –

- The behavior of the fiber yarns remains unaffected up to 100 °C. The changes in the coating agent increase the tensile strength up to 200 °C due to better impregnation of the individual filaments. The coating agent starts to deteriorate at around 270 °C, hence the significant decrease in tensile strength at 300 °C; between 200 °C and 300 °C, the tensile strength drops by 48.9%, 13.30%, and 6% for the basalt, carbon, and glass yarns, respectively.

- –

- The contribution of the polymer-modified mortar to the overall behavior of the TRMs is not significant.

- –

- At 300 °C, the cracking stress (or ), for the glass fabric coupons are increased due to a prestress effect attributed to fiber contraction.

- –

- At 100 °C, the coupons’ tensile strength and ultimate strain are increased due to better bonding conditions between the matrix and the grids.

- –

- At 200 °C, the carbon fiber coupons and the glass counterparts increase their original strength by 20.4% and 6%, respectively. At the same temperature, the basalt coupons lost 10% of the original strength and became less efficient.

- –

- At 300 °C, the basalt and the carbon coupons lost between 34% and 40% of their original strength, while the glass fiber coupons demonstrate an increase of 15% attributed to the coating material and the inherent behavior of glass.

- –

- From 200 °C onwards, the composite action gradually shows signs of deterioration due to the decay of the coating agent and the changes within the mortar.

- –

- The exposure to different temperatures alters the crack pattern of the different groups of coupons at failure. Moreover, at 300 °C, all types of specimens failed due to slippage of the fibers from the matrix.

- –

- In general, carbon and glass fibers are more resilient when exposed to a heated environment.

- –

- The grids’ architecture plays a significant role in overall performance, since the stitched-bond type deteriorates faster than the thermofixed type, affecting the bond between the mortar and the grid.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| cross-sectional area of the yarns | |

| number of yarns | |

| elastic modulus of specimen in uncracked phase | |

| elastic modulus of TRM specimen in postcracked phase | |

| compressive strength of mortar prisms | |

| mean tensile strength of mortar prisms | |

| flexural strength of mortar prisms | |

| extrapolated onset temperature | |

| tensile stress of the TRM specimen at the first cracking point | |

| tensile cracking stress of the TRM matrix | |

| ultimate tensile strength of TRM specimen | |

| strain value of TRM specimen at the first cracking point | |

| strain value of TRM specimen at the ultimate tensile stress |

Appendix A

References

- Shenghu, C.; Zhis, W.U.; Xin, W. Tensile Properties of CFRP and Hybrid FRP Composites at Elevated Temperatures. J. Compos. Mater. 2009, 43, 315–330. [Google Scholar] [CrossRef]

- Kim, M.T.; Rhee, K.Y.; Lee, B.H.; Kim, C.J. Effect of carbon nanotube addition on the wear behavior of basalt/epoxy woven composites. J. Nanosci. Nanotechnol. 2013, 13, 5631–5635. [Google Scholar] [CrossRef]

- Çavdar, A. The effects of high temperature on mechanical properties of cementitious composites reinforced with polymeric fibers. Compos. Part B Eng. 2013, 45, 78–88. [Google Scholar] [CrossRef]

- Asadi, A.; Baaij, F.; Mainka, H.; Rademacher, M.; Thompson, J.Y.; Kalaitzidou, K. Basalt fibers as a sustainable and cost-effective alternative to glass fibers in sheet molding compound (SMC). Compos. Part B Eng. 2017, 123, 210–218. [Google Scholar] [CrossRef]

- Ahmed, A.; Zillur Rahman, M.; Ou, Y.; Liu, S.; Mobasher, B.; Guo, S.; Zhu, D. A review on the tensile behavior of fiber-reinforced polymer composites under varying strain rates and temperatures. Constr. Build. Mater. 2021, 294, 123565. [Google Scholar] [CrossRef]

- Signorini, C.; Sola, A.; Nobili, A.; Siligardi, C. Lime-cement textile reinforced mortar (TRM) with modified interphase. J. Appl. Biomater. Funct. Mater. 2019, 17, 22808000019827823. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bompadre, F.; Donnini, J. Surface Modification of Glass Textile for the Reinforcement of a Cement-Based Composite: A Review. Appl. Sci. 2021, 11, 2028. [Google Scholar] [CrossRef]

- Bisby, L.; Stratford, T.; Smith, J.; Halpin, S. Comparative performance of Fibre Reinforced Polymer and Fibre Reinforced Cementitious Mortar Strengthening Systems in Elevated Temperature Service Environments. In Structural Faults and Repair 2010; Engineering Technics Press: Scotland, UK, 2010. [Google Scholar]

- Ehlig, D.; Hothan, S. Reinforced Concrete Slabs Strengthened with Textile Reinforced Concrete Subjected to Fire. In Proceedings of the 2nd International RILEM Workshop on Concrete Spalling Due to Fire Exposure, Delft, The Netherlands, 5–7 October 2011. [Google Scholar]

- Papakonstantinou, C.G.; Balaguru, P.; Lyon, R.E. Comparative study of high temperature composites. Compos. Part B Eng. 2001, 32, 637–649. [Google Scholar] [CrossRef]

- Kapsalis, P.; Tysmans, T.; Van Hemelrijck, D.; Triantafillou, T.C. State-of-the-Art Review on Experimental Investigations of Textile-Reinforced Concrete Exposed to High Temperatures. J. Compos. Sci. 2021, 5, 290. [Google Scholar] [CrossRef]

- Al-Lami, K.; D’Antino, T.; Colombi, P. Durability of Fabric-Reinforced Cementitious Matrix (FRCM) Composites: A Review. Appl. Sci. 2020, 10, 1714. [Google Scholar] [CrossRef] [Green Version]

- Colombo, I.; Colombo, M.; Magri, A.; Zani, G.; di Prisco, M. Textile Reinforced Mortar at High Temperatures. Appl. Mech. Mater. 2011, 82, 202–207. [Google Scholar] [CrossRef]

- Rambo, D.A.S.; de Andrade Silva, F.; Toledo Filho, R.D.; da Fonseca Martins Gomes, O. Effect of elevated temperatures on the mechanical behavior of basalt textile reinforced refractory concrete. Mater. Des. (1980–2015) 2015, 65, 24–33. [Google Scholar] [CrossRef]

- Strauss Rambo, D.A.; de Andrade Silva, F.; Toledo Filho, R.D.; Ukrainczyk, N.; Koenders, E. Tensile strength of a calcium-aluminate cementitious composite reinforced with basalt textile in a high-temperature environment. Cem. Concr. Compos. 2016, 70, 183–193. [Google Scholar] [CrossRef]

- Donnini, J.; Basalo, F.D.C.y.; Corinaldesi, V.; Lancioni, G.; Nanni, A. Fabric-reinforced cementitious matrix behavior at high-temperature: Experimental and numerical results. Compos. Part B-Eng. 2017, 108, 108–121. [Google Scholar] [CrossRef] [Green Version]

- Tlaiji, T.; Vu, X.H.; Ferrier, E.; Larbi, A.S. Thermomechanical behaviour and residual properties of textile reinforced concrete (TRC) subjected to elevated and high temperature loading: Experimental and comparative study. Compos. Part B Eng. 2018, 144, 99–110. [Google Scholar] [CrossRef]

- Messori, M.; Nobili, A.; Signorini, C.; Sola, A. Effect of high temperature exposure on epoxy-coated glass textile reinforced mortar (GTRM) composites. Constr. Build. Mater. 2019, 212, 765–774. [Google Scholar] [CrossRef] [Green Version]

- Truong, G.T.; Park, S.-H.; Choi, K.-K. Tensile Behaviors of Lap-Spliced Carbon Fiber-Textile Reinforced Mortar Composites Exposed to High Temperature. Materials 2019, 12, 1512. [Google Scholar] [CrossRef] [Green Version]

- Estevan, L.; Varona, F.B.; Baeza, F.J.; Torres, B.; Bru, D. Textile Reinforced Mortars (TRM) tensile behavior after high temperature exposure. Constr. Build. Mater. 2022, 328, 127116. [Google Scholar] [CrossRef]

- Ombres, L.; Mazzuca, P.; Verre, S. Effects of Thermal Conditioning at High Temperatures on the Response of Concrete Elements Confined with a PBO-FRCM Composite System. J. Mater. Civ. Eng. 2022, 34, 04021413. [Google Scholar] [CrossRef]

- Calabrese, A.S.; D’Antino, T.; Colombi, P.; Poggi, C. Long-Term Behavior of PBO FRCM and Comparison with Other Inorganic-Matrix Composites. Materials 2022, 15, 3281. [Google Scholar] [CrossRef]

- Silva, F.d.A.; Butler, M.; Hempel, S.; Filho, R.D.T.; Mechtcherine, V. Effects of elevated temperatures on the interface properties of carbon textile-reinforced concrete. Cem. Concr. Compos. 2014, 48, 26–34. [Google Scholar] [CrossRef]

- Liu, S.; Rawat, P.; Chen, Z.; Guo, S.; Shi, C.; Zhu, D. Pullout behaviors of single yarn and textile in cement matrix at elevated temperatures with varying loading speeds. Compos. Part B Eng. 2020, 199, 108251. [Google Scholar] [CrossRef]

- Xu, S.; Shen, L.; Wang, J. The high-temperature resistance performance of TRC thin-plates with different cementitious materials: Experimental study. Constr. Build. Mater. 2016, 115, 506–519. [Google Scholar] [CrossRef]

- Xu, P.; Cui, Y.; Dai, J.; Zhang, M.; Ding, Y. High-Temperature Deterioration Mechanism of Textile-Reinforced Concrete with Different Cementitious Materials. J. Mater. Civ. Eng. 2022, 34, 04021388. [Google Scholar] [CrossRef]

- Rambo, D.A.S.; Yao, Y.; de Andrade Silva, F.; Toledo Filho, R.D.; Mobasher, B. Experimental investigation and modelling of the temperature effects on the tensile behavior of textile reinforced refractory concretes. Cem. Concr. Compos. 2017, 75, 51–61. [Google Scholar] [CrossRef]

- EN1015-11:2019; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. CEN: Brussels, Belgium, 2019.

- De Santis, S.; Carozzi, F.G.; de Felice, G.; Poggi, C. Test methods for Textile Reinforced Mortar systems. Compos. Part B Eng. 2017, 127, 121–132. [Google Scholar] [CrossRef]

- Ekenel, M.; Nanni, A.; De Caso y Basalo, F. Acceptance Criteria for Concrete and Masonry Strengthening Using Fabric-Reinforced Cementitious Matrix (FRCM) and Steel Reinforced Grout (SRG) Composites. ACI Spec. Publ. 2018, 352, 4. [Google Scholar]

- Molter, M. Zum Tragverhalten von textilbewehrtem Beton; Lehrstuhl und Inst. für Massivbau [u.a.]: Aachen, Germany, 2005. [Google Scholar]

- Aattache, A.; Mahi, A.; Soltani, R.; Mouli, M.; Benosman, A.S. Experimental study on thermo-mechanical properties of Polymer Modified Mortar. Mater. Des. (1980–2015) 2013, 52, 459–469. [Google Scholar] [CrossRef]

- D’Antino, T.; Papanicolaou, C. Comparison between different tensile test set-ups for the mechanical characterization of inorganic-matrix composites. Constr. Build. Mater. 2018, 171, 140–151. [Google Scholar] [CrossRef]

- Focacci, F.; D’Antino, T.; Carloni, C. The role of the fiber–matrix interfacial properties on the tensile behavior of FRCM coupons. Constr. Build. Mater. 2020, 265, 120263. [Google Scholar] [CrossRef]

- Focacci, F.; D’Antino, T.; Carloni, C. Tensile Testing of FRCM Coupons for Material Characterization: Discussion of Critical Aspects. J. Compos. Constr. 2022, 26, 04022039. [Google Scholar] [CrossRef]

- FIB. Fib Model Code for Concrete Structures 2010; Fédération Internationale du Béton Wilhelm Ernst & Sohn, Verlag für Architektur und Technische Wissenschaften GmbH & Co. KG: Berlin, Germany, 2013. [Google Scholar]

- Taylor, H.F.W.; Famy, C.; Scrivener, K.L. Delayed ettringite formation. Cem. Concr. Res. 2001, 31, 683–693. [Google Scholar] [CrossRef]

- Zhou, Q.; Glasser, F.P. Thermal Stability and Decomposition Mechanisms of Ettringite at <120 °C. Cem. Concr. Res. 2001, 31, 1333–1339. [Google Scholar] [CrossRef]

- Jeong, Y.; Hargis, C.W.; Kang, H.; Chun, S.C.; Moon, J. The Effect of Elevated Curing Temperatures on High Ye′elimite Calcium Sulfoaluminate Cement Mortars. Materials 2019, 12, 1072. [Google Scholar] [CrossRef] [Green Version]

- Khoury, G.A. Compressive strength of concrete at high temperatures: A reassessment. Mag. Concr. Res. 1992, 44, 291–309. [Google Scholar] [CrossRef]

- Hachemi, S.; Ounis, A. Effet de la température sur les propriétés mécaniques du béton ordinaire et de haute performance. In Proceedings of the Séminaire International sur le Bâtiment Intelligent au Cœur du Développement Durable (BATIDEV 2013), Oran, Algeria, 30 April 2013. [Google Scholar]

- Kim, H.; Park, J.; Suh, H.; Cho, B.; Park, W.-J.; Bae, S. Mechanical Degradation and Thermal Decomposition of Ethylene-Vinyl Acetate (EVA) Polymer-Modified Cement Mortar (PCM) Exposed to High-Temperature. Sustainability 2019, 11, 500. [Google Scholar] [CrossRef] [Green Version]

- ASTM D2256-02; Standard Test Method for Tensile Properties of Yarns by the Single-Strand Method. ASTM: West Conshohocken, PA, USA, 2010.

- Gao, Y.; Jia, C.; Meng, L.; Li, X. Heat resistance study of basalt fiber material via mechanical tests. IOP Conf. Ser. Mater. Sci. Eng. 2017, 283, 012016. [Google Scholar] [CrossRef]

- Stockhorst, H.; Brückner, R. Structure sensitive measurements on phosphate glass fibers. J. Non. Cryst. Solids 1986, 85, 105–126. [Google Scholar] [CrossRef]

- Jenkins, P.G. Understanding physical changes and strength loss of E-glass fibres following exposure to elevated temperatures. Mater. Sci. Technol. 2017, 33, 255–264. [Google Scholar] [CrossRef] [Green Version]

- Murugan, S.; Rai, S.K.; Kumar, P.V.; Jayakumar, T.; Raj, B.; Bose, M.S.C. Temperature distribution and residual stresses due to multipass welding in type 304 stainless steel and low carbon steel weld pads. Int. J. Press. Vessel. Pip. 2001, 78, 307–317. [Google Scholar] [CrossRef]

- Kapsalis, P.; Triantafillou, T.; Korda, E.; Van Hemelrijck, D.; Tysmans, T. Tensile Performance of Textile-Reinforced Concrete after Fire Exposure: Experimental Investigation and Analytical Approach. J. Compos. Constr. 2022, 26, 04021067. [Google Scholar] [CrossRef]

- Mahieux, C.A.; Reifsnider, K.L. Property modeling across transition temperatures in polymers: Application to thermoplastic systems. J. Mater. Sci. 2002, 37, 911–920. [Google Scholar] [CrossRef]

- Kockritz, U.O.P.; Jesse, F.; Curbach, M. Influence of textile manufacturing technology on load bearing behavior of textile reinforced concrete. In Proceedings of the 13th International Techtextil-Symposium 2005, Frankfurt, Germany, 6–9 June 2005. [Google Scholar]

- Boutenel, F.; Dusserre, G.; Cutard, T. Strength Loss of Basalt-Based Mineral Fibers after Thermal Desizing. Rev. Des Compos. Et Des Matériaux Avancés 2020, 30, 115–122. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Seghini, M.C. Influence of thermal conditioning on tensile behaviour of single basalt fibres. Compos. Part B Eng. 2018, 132, 77–86. [Google Scholar] [CrossRef]

- Kim, H.-J.; Park, W.-J. Combustion and Mechanical Properties of Polymer-Modified Cement Mortar at High Temperature. Adv. Mater. Sci. Eng. 2017, 2017, 5853687. [Google Scholar] [CrossRef] [Green Version]

- Overkamp, T.; Mahltig, B.; Kyosev, Y. Strength of basalt fibers influenced by thermal and chemical treatments. J. Ind. Text. 2018, 47, 815–833. [Google Scholar] [CrossRef]

- Feih, S.; Manatpon, K.; Mathys, Z.; Gibson, A.G.; Mouritz, A.P. Strength degradation of glass fibers at high temperatures. J. Mater. Sci. 2009, 44, 392–400. [Google Scholar] [CrossRef]

- Feih, S.; Boiocchi, E.; Kandare, E.; Mathys, Z.; Gibson, A.G.; Mouritz, A.P. Strength Degradation of Glass and Carbon Fibres at High Temperature. 2009. Available online: https://iccm-central.org/Proceedings/ICCM17proceedings/Themes/Behaviour/COMPOSITES%20IN%20FIRE/F4.6%20Feih.pdf (accessed on 11 June 2023).

- Bianchi, G.; Arboleda, D.; Carozzi, F.G.; Poggi, C.; and Nanni, A. Fabric Reinforced Cementitious Matrix (FRCM) Materials For Structural Rehabilitation. In Proceedings of the IAHS 2013: 39th World Congress on Housing Science, Milan, Italy, 17–20 September 2013. [Google Scholar]

- Arboleda, D.; Carozzi, F.G.; Nanni, A.; Poggi, C. Testing Procedures for the Uniaxial Tensile Characterization of Fabric-Reinforced Cementitious Matrix Composites. J. Compos. Constr. 2016, 20, 04015063. [Google Scholar] [CrossRef]

- D′Antino, T.; Papanicolaou, C. Mechanical characterization of textile reinforced inorganic-matrix composites. Compos. Part B Eng. 2017, 127, 78–91. [Google Scholar] [CrossRef]

- Bernat-Maso, E.; Gil, L.; Mercedes, L.; Escrig, C. Mechanical properties of pre-stressed fabric-reinforced cementitious matrix composite (PFRCM). Constr. Build. Mater. 2018, 191, 228–241. [Google Scholar] [CrossRef]

- ACI 549.3R-20; Guide to Design and Construction of Externally Bonded Fabric-Reinforced Cementitious Matrix (FRCM) and Steel-Reinforced Grout (SRG) Systems for Repair and Strengthening Masonry Structures. ACI: Geneva, Switzerland, 2020.

- ASTM E2550-21; Standard Test Method for Thermal Stability by Thermogravimetry. ASTM: West Conshohocken, PA, USA, 2021.

- CSN EN ISO 11358-1:2022; Plastics-Thermogravimetry (TG) of Polymers—Part 1: General Principles. CEN: Brussels, Belgium, 2022.

| Fabric Textile | Basalt Fabric Textile | Carbon Fabric Textile | Glass Fabric Textile |

|---|---|---|---|

| Area density | 220/170 * | 270/220 | 360/280 |

| Yarn area | 0.81 | 1.61 | 1.015 |

| Nominal thickness (mm) | 0.032 | 0.054 | 0.011 |

| Number of yarns per coupon | 3 | 2 | 4 |

| Coating material | High-temperature resistive coating | High-temperature resistive coating | SBR coating |

| 20 °C | 100 °C | 200 °C | 300 °C | |

|---|---|---|---|---|

| Flexural strength, (MPa) | 7.5 (0.016) | 7.6 (0.065) | 7.1 (0.140) | 5.0 (0.015) |

| Mean tensile strength (MPa) | 3.0 | 2.0 | 2.2 | 2.4 |

| Compressive strength, (MPa) | 34.2 (0.045) | 20.3 (0.070) | 21.4 (0.140) | 22.7 (0.090) |

| Components | Integrated Peak Intensity (in Counts) | ||||

|---|---|---|---|---|---|

| 20 °C | 100 °C | 200 °C | 300 °C | ||

| Portlandite | 18 | 57 | 15 | 136 | 88 |

| Quartz | 26 | 19,478 | 17,022 | 20,955 | 25,099 |

| Calcite | 29 | 21,187 | 15,279 | 14,566 | 15,328 |

| Ettringite | 50 | 3018 | 4102 | 1719 | 2836 |

| C-S-H | 47 | 3618 | 4290 | 4261 | 3366 |

| Group of Specimens | Y-B-20 | Y-B-100 | Y-B-200 | Y-B-300 |

|---|---|---|---|---|

| Tensile strength (MPa) | 1983.1 (0.2) * | 2718.5 (0.16) | 2591.4 (0.02) | 1325.3 (0.04) |

| Ultimate strain | 0.0239 (0.17) | 0.0332 (0.14) | 0.0273 (0.07) | 0.0132 (0.05) |

| Elastic modulus (GPa) | 87.9 (0.01) | 95.7 (0.02) | 101.2 (0.04) | 109.8(0.01) |

| Y-C-20 | Y-C-100 | Y-C-200 | Y-C-300 | |

| Tensile strength (MPa) | 1317.1 (0.09) | 1260.8 (0.05) | 1411.1 (0.03) | 1222.9 (0.02) |

| Ultimate strain | 0.0067 (0.05) | 0.0062 (0.03) | 0.0074 (0.01) | 0.0061 (0.04) |

| Elastic modulus (GPa) | 204.6 (0.03) | 215.7 (0.02) | 217.6 (0.03) | 220.0 (0.03) |

| Y-G-20 | Y-G-100 | Y-G-200 | Y-G-300 | |

| Tensile strength (MPa) | 996.9 (0.06) | 1019.6 (0.06) | 1067.1 (0.07) | 1037.3 (0.05) |

| Ultimate strain | 0.0208 (0.13) | 0.0178 (0.07) | 0.0180 (0.12) | 0.0159 (0.07) |

| Elastic modulus (GPa) | 57.9 (0.06) | 65.9 (0.01) | 65.4 (0.05) | 69.6 (0.01) |

| Types of Fibers | FWHM | |||

|---|---|---|---|---|

| 20 °C | 100 °C | 200 °C | 300 °C | |

| Basalt | 10.51 | 7.6 | 9.06 | 7.06 |

| Carbon | 2.64 | 3.63 | 2.60 | 2.56 |

| Glass | 9.3 | 7.75 | 8.76 | 7.33 |

| Cracking Condition | Fibers’ Performance | ||

|---|---|---|---|

| I | Close to the grips | a | Rupture |

| II | In the middle of the specimen | b | Slippage of the yarns within the matrix |

| III | A combination of I and II | c | Combination of the a and b |

| IV | Multiple cracking | ||

| Specimen Type | Failure Mode | Specimen Type | Failure Mode | ||||||

| C-B-201 | 135.8 | 411.3 | 0.39 | IIa | C-C-201 | 317.9 | 963.0 | 1.43 | IVa |

| C-B-202 | 785.9 * | 785.9 | 2.24 | Ib | C-C-202 | 444.3 | 527.2 | 2.00 | IVc |

| C-B-203 | 607.1 * | 607.1 | 1.73 | Ib | C-C-203 | 296.1 | 539.5 | 1.33 | IVb |

| Average | 509.6 | 601.2 | 1.46 | Average | 352.8 | 676.5 | 1.6 | ||

| CoV | 0.53 | 0.25 | 0.53 | CoV | 0.18 | 0.30 | 0.18 | ||

| C-B-1001 | 257.3 | 545.4 | 0.86 | IIc | C-C-1001 | 115.0 | 796.3 | 0.52 | IVa |

| C-B-1002 | 364.9 | 897.5 | 1.22 | IIc | C-C-1002 | 244.6 | 1047.8 | 1.10 | IVa |

| C-B-1003 | - | - | - | C-C-1003 | 346.6 | 993.5 | 1.56 | IVa | |

| Average | 311.1 | 721.5 | 1.04 | Average | 235.4 | 945.9 | 1.06 | ||

| CoV | 0.17 | 0.24 | 0.17 | CoV | 0.40 | 0.11 | 0.40 | ||

| C-B-2001 | 499.2 * | 499.2 | 1.66 | IVa | C-C-2001 | 210.3 | 764.2 | 0.95 | IVa |

| C-B-2002 | 306.8 | 623.3 | 1.02 | IVc | C-C-2002 | 244.4 | 643.2 | 1.10 | IVa |

| C-B-2003 | 300.9 | 512.1 | 1.00 | IVa | C-C-2003 | 419.4 | 1036.7 | 1.89 | IVa |

| Average | 368.9 | 540.7 | 1.23 | Average | 291.4 | 814.7 | 1.31 | ||

| CoV | 0.25 | 0.11 | 0.25 | CoV | 0.31 | 0.20 | 0.31 | ||

| C-B-3001 | 306.5 | 537.5 | 1.02 | ΙΙa | C-C-3001 | 244.6 | 478.7 | 1.10 | IIIc |

| C-B-3002 | 254.5 * | 254.2 | 0.85 | IIa | C-C-3002 | 389.8 | 387.7 | 1.75 | IIIc |

| C-B-3003 | 137.8 | 399.0 | 0.46 | IIIa | C-C-3003 | 180.6 | 364.5 | 0.81 | IIIc |

| Average | 232.9 | 396.9 | 0.78 | Average | 271.7 | 410.5 | 1.22 | ||

| CoV | 0.30 | 0.29 | 0.30 | CoV | 0.32 | 0.12 | 0.32 | ||

| Specimen Type | (MPa) | (MPa) | (MPa) | Failure mode | Specimen Type | (MPa) | (MPa) | (MPa) | Failure mode |

| C-G-201 | 191.2 | 681.8 | 0.78 | IIIa | C-G-2001 | 140.1 | 749.7 | 0.57 | IVa |

| C-G-202 | 276.5 | 737.8 | 1.13 | IIIb | C-G-2002 | 258.3 | 112.9 | 1.06 | IVa |

| C-G-203 | 255.2 | 770.7 | 1.04 | IIIa | C-G-2003 | 144.6 | 433.5 * | 0.59 | IVa |

| Average | 240.9 | 730.1 | 0.98 | Average | 181.0 | 765.4 | 0.74 | ||

| CoV | 0.15 | 0.05 | 0.15 | CoV | 0.30 | 0.36 | 0.31 | ||

| C-G-1001 | 257.4 | 901.1 | 1.05 | IIIa | C-G-3001 | 260.8 | 785.3 | 1.07 | IVa |

| C-G-1002 | 224.0 | 880.6 | 0.92 | Ia | C-G-3002 | 333.4 | 768.3 | 1.36 | IVc |

| C-G-1003 | 253.0 | 902.6 | 1.04 | IIIa | C-G-3003 | 353.5 | 940.0 | 1.45 | IVa |

| Average | 244.8 | 895.1 | 1.00 | Average | 315.9 | 831.2 | 1.29 | ||

| CoV | 0.06 | 0.01 | 0.06 | CoV | 0.13 | 0.09 | 0.13 |

| Type of Specimens | ||||

|---|---|---|---|---|

| C-B-20 | 0.0037 (0.58) * | 0.0115 (0.29) | 180.19 (0.26) | 35.5 (0.47) |

| C-B-100 | 0.0072 (0.36) | 0.0204 (0.24) | 95.05 (0.22) | 38.4 (0.07) |

| C-B-200 | 0.0028 (0.32) | 0.0112 (0.32) | 217.12 (0.25) | 96.4 (0.61) |

| C-B-300 | 0.0028 (0.18) | 0.0102 (0.54) | 155.90 (0.39) | 55.5 (0.38) |

| C-C-20 | 0.0024 (0.51) | 0.0244 (0.41) | 214.40 (0.25) | 14.4 (0.49) |

| C-C-100 | 0.0057 (0.71) | 0.0371 (0.07) | 139.9 (0.21) | 28.0 (0.21) |

| C-C-200 | 0.0063 (0.36) | 0.0306 (0.14) | 90.6 (0.35) | 21.2 (0.42) |

| C-C-300 | 0.0083 (0.50) | 0.0190 (0.23) | 97.1 (0.44) | 12.8 (0.08) |

| C-G-20 | 0.0059 (0.34) | 0.0296 (0.30) | 73.0 (0.38) | 19.8 (0.39) |

| C-G-100 | 0.0071 (0.18) | 0.0331 (0.09) | 67.4 (0.22) | 20.5 (0.19) |

| C-G-200 | 0.0033 (0.39) | 0.0212 (0.46) | 69.9 (0.25) | 41.2 (0.28) |

| C-G-300 | 0.0052 (0.25) | 0.0279 (0.03) | 68.9 (0.23) | 26.9 (0.17) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, P.; Krevaikas, T. Residual Properties of Fibre Grids Embedded in Cementitious Matrices after Exposure to Elevated Temperatures. Buildings 2023, 13, 1900. https://doi.org/10.3390/buildings13081900

Yang P, Krevaikas T. Residual Properties of Fibre Grids Embedded in Cementitious Matrices after Exposure to Elevated Temperatures. Buildings. 2023; 13(8):1900. https://doi.org/10.3390/buildings13081900

Chicago/Turabian StyleYang, Pengliang, and Theofanis Krevaikas. 2023. "Residual Properties of Fibre Grids Embedded in Cementitious Matrices after Exposure to Elevated Temperatures" Buildings 13, no. 8: 1900. https://doi.org/10.3390/buildings13081900

APA StyleYang, P., & Krevaikas, T. (2023). Residual Properties of Fibre Grids Embedded in Cementitious Matrices after Exposure to Elevated Temperatures. Buildings, 13(8), 1900. https://doi.org/10.3390/buildings13081900