Variability Analysis of the Hysteretic Behavior of Fiber-Reinforced Polymer (FRP)-Confined Concrete Columns Based on a Secondary Development Model

Abstract

:1. Introduction

2. Secondary Development of a Modified FRP-Confined Concrete Model

2.1. Uniaxial and Cyclic Constitutions of Lam and Teng

2.2. A New Modified Model of FRP-Confined Concrete

- (1)

- The envelope curve under cyclic compression

- (2)

- Unloading and reloading paths under cyclic compression

- (3)

- Partial unloading and partial reloading under cyclic compression

- (4)

- The envelope curve under cyclic tension

- (5)

- Unloading and reloading paths under cyclic tension

2.3. OpenSees Program Realization of the Modified Model

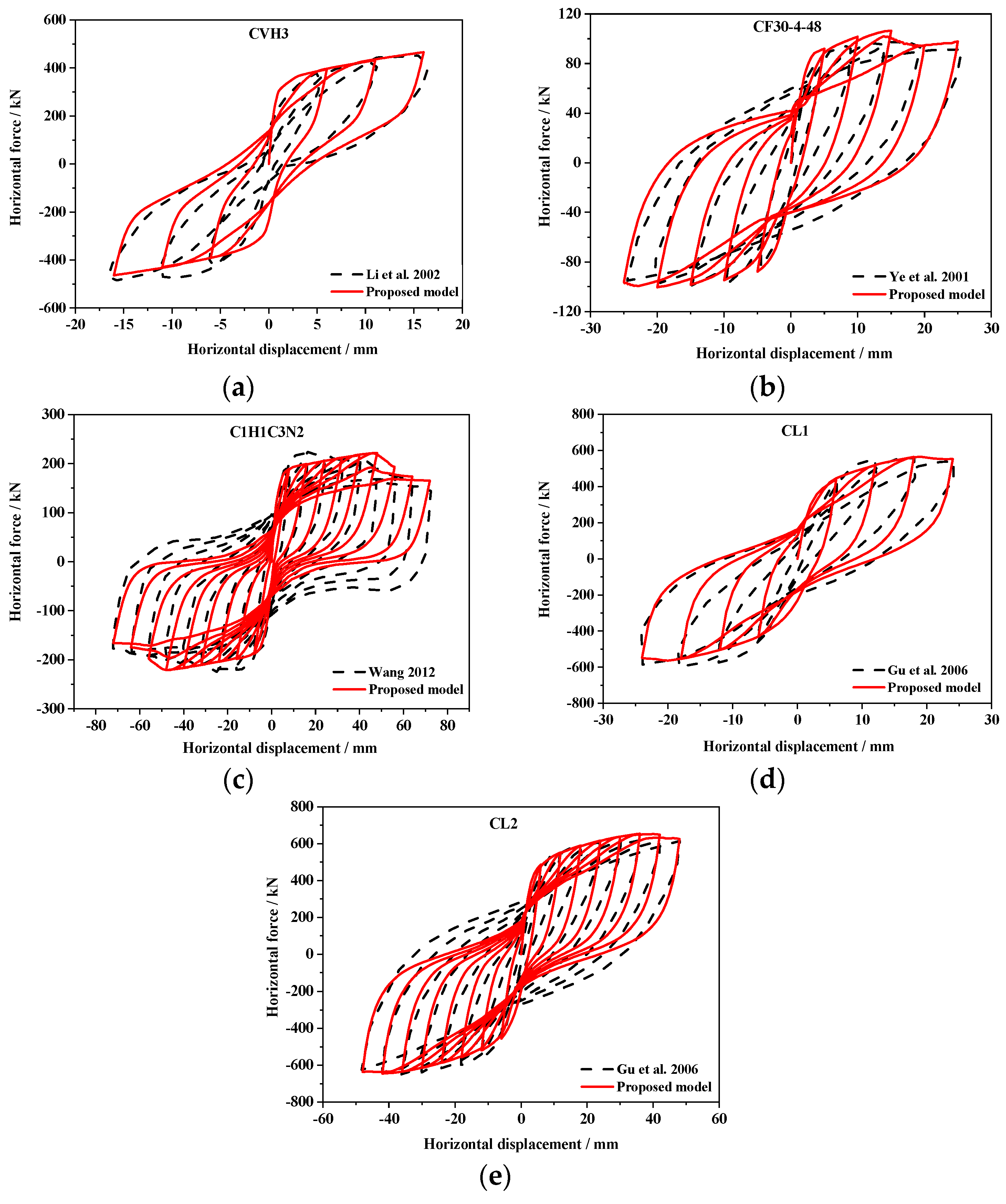

3. Validation of the Modified FRP-Confined Concrete Model

3.1. Basic Information of the FRP-C RC Column

3.2. Comparison with Test Data

4. Hysteretic Behavior Variability of FRP-C RC Columns Considering Concrete Strength Variations

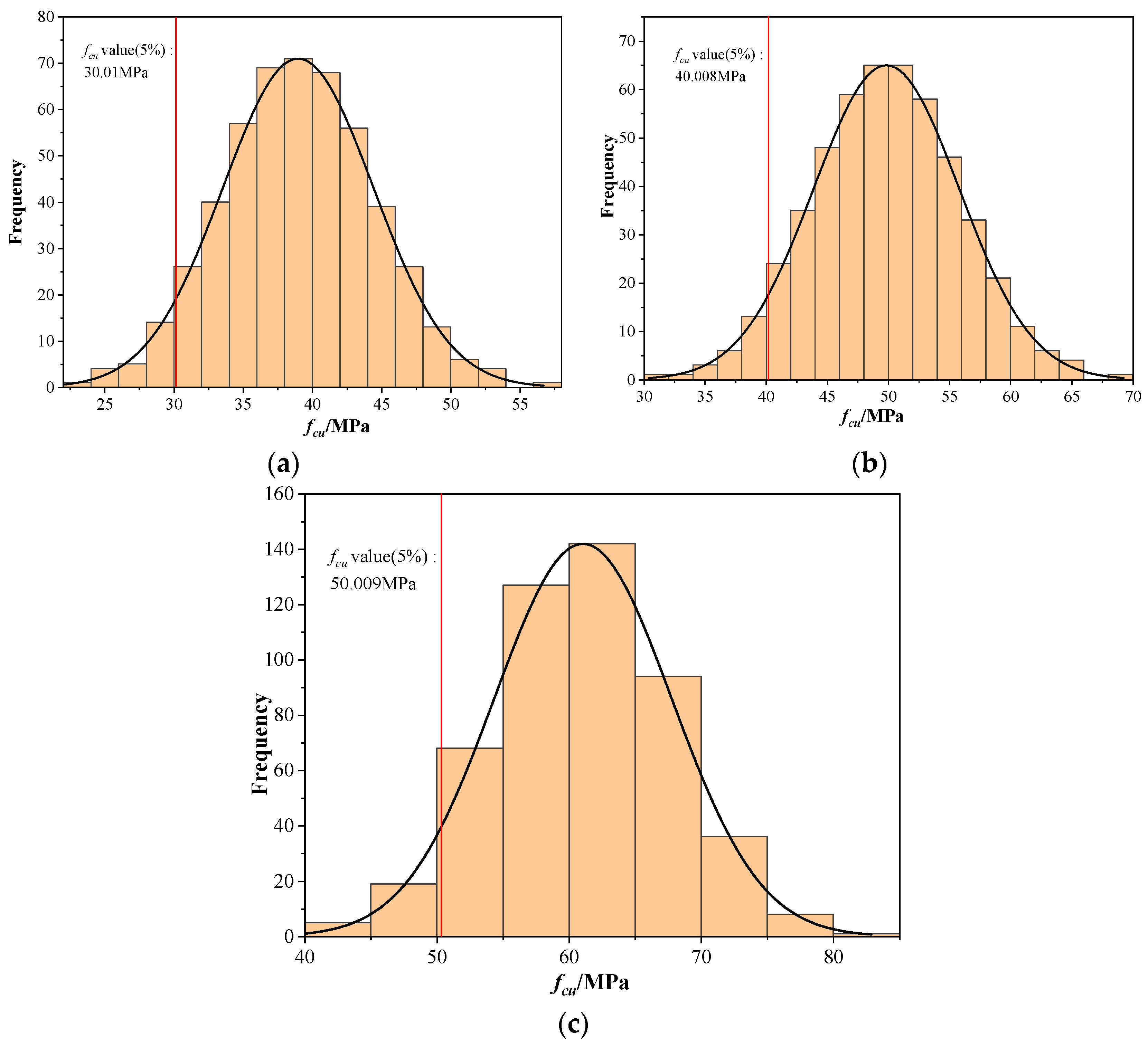

4.1. Major Random Variable for Concrete Material

4.2. Random Sampling Methods

4.3. Variability Analysis for Hysteretic Behavior of FRP-C RC Columns

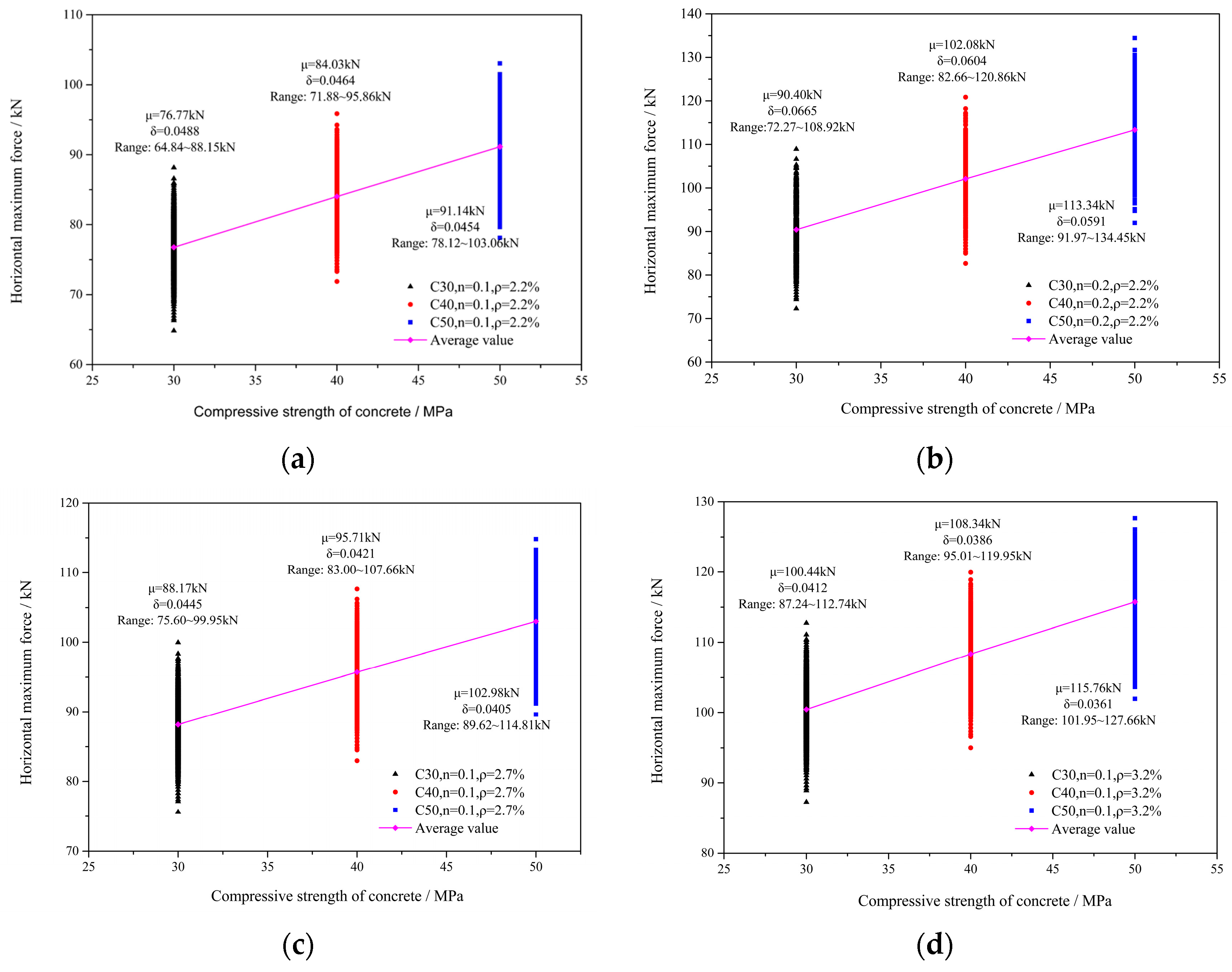

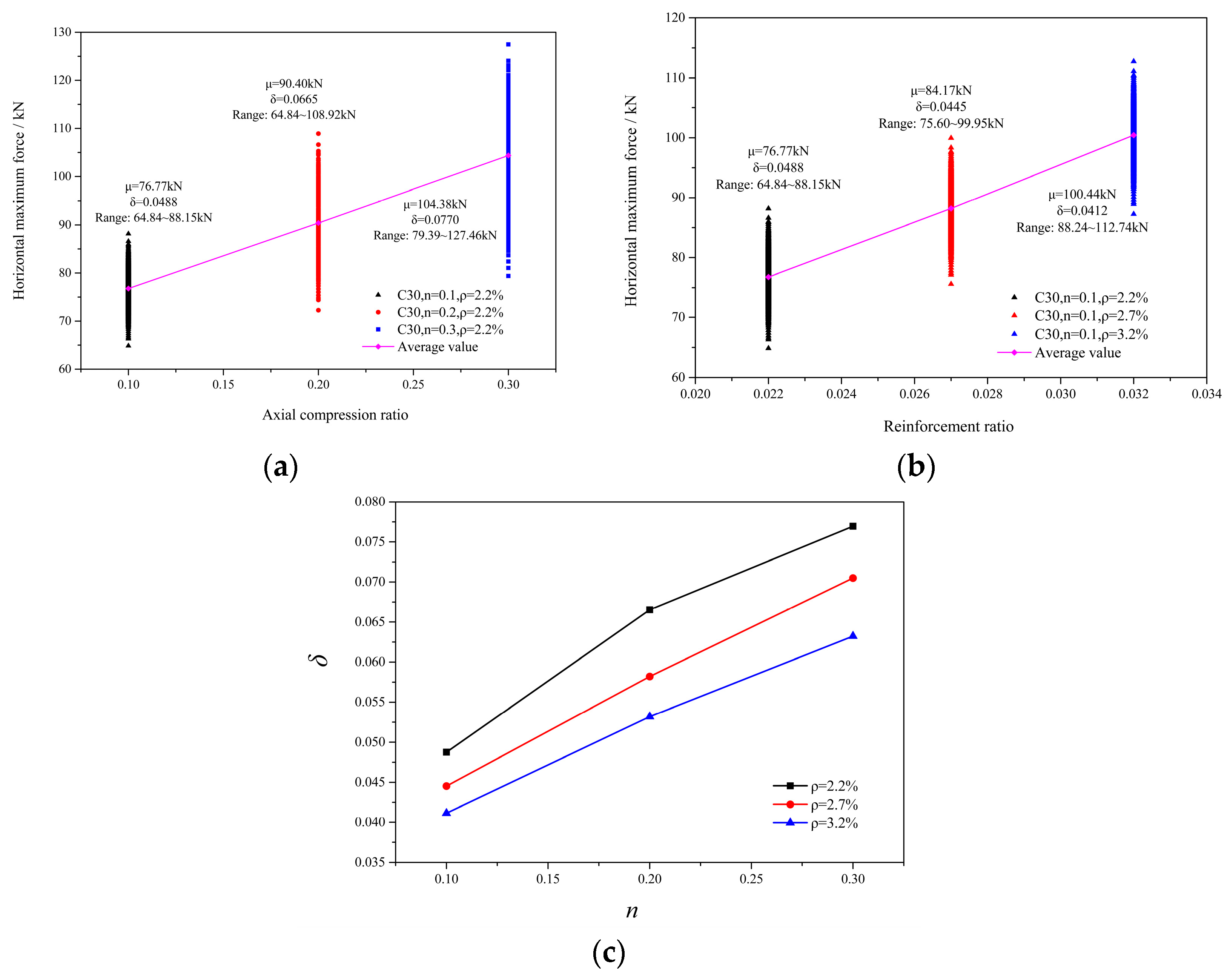

4.3.1. Variability Analysis of the Maximum Horizontal Force of FRP-C RC Columns

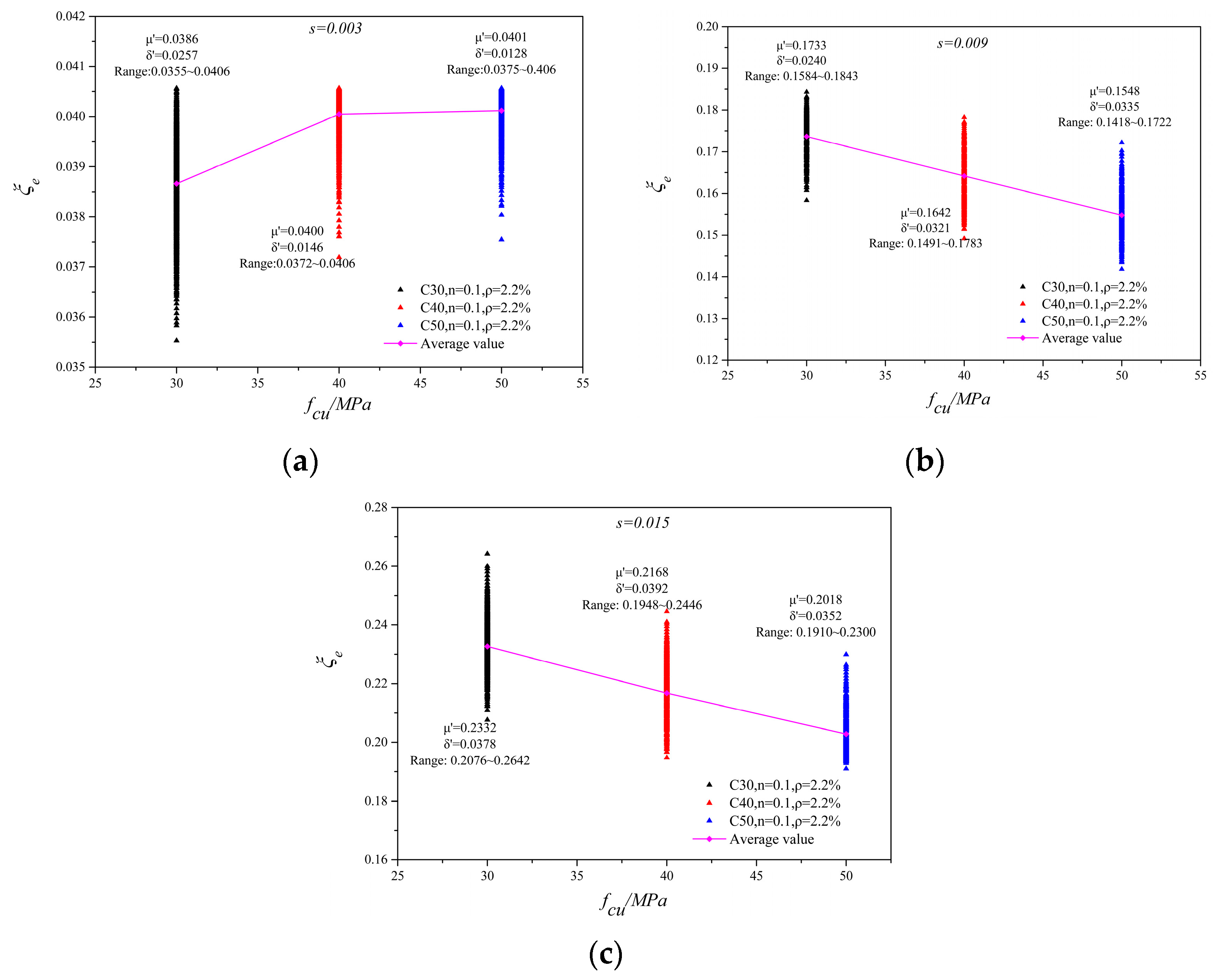

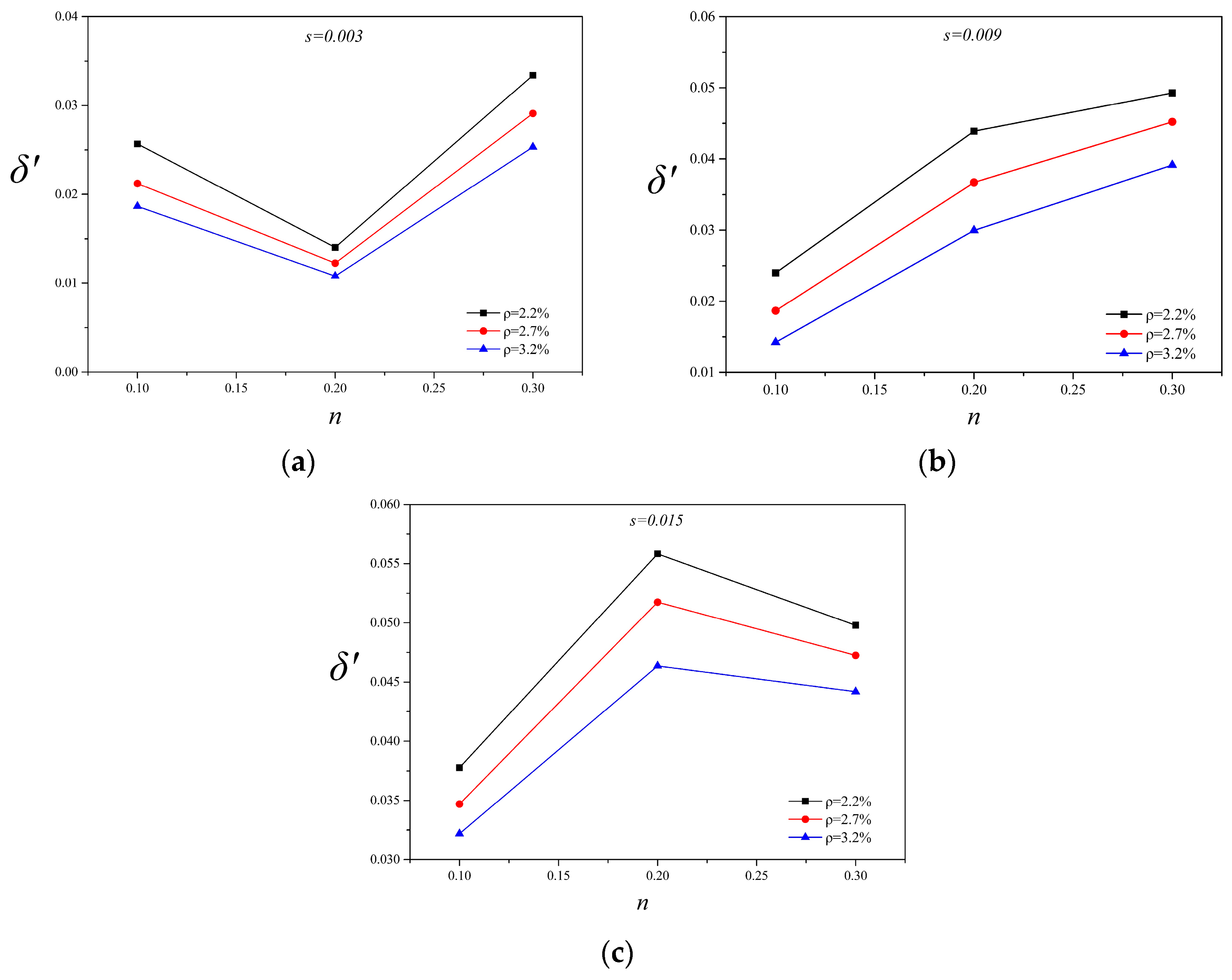

4.3.2. Variability Analysis of the Equivalent Viscous Damping Ratio of FRP-C RC Columns

5. Conclusions

- Based on the Lam–Teng 2003 model, the mechanical tension properties and the stress drop section after the peak stress point of the compressive skeleton curve are considered in FRP-confined concrete materials. The proposed model has been verified by comparing with test data from the literature.

- In this paper, the OpenSees secondary development function and the quasi-Monte Carlo random sampling method are first applied to study the influence of concrete material variations on the hysteretic behavior of FRP-C RC columns.

- By analyzing the variability in hysteretic behavior of FRP-C RC columns, some interesting rules are found, which will be helpful in the optimization of seismic structure designs. For instance, the average value of the maximum horizontal force is positively correlated with the influencing parameters (i.e., the concrete strength grade, reinforcement ratio and axial compression ratio). However, the variation rule of the maximum force is different, and is positively correlated with the axial compression ratio and negatively correlated with the strength grade and reinforcement ratio of concrete. Additionally, for example, the variation coefficient of the equivalent damping ratio is almost constant with the increase in the lateral displacement rate of the specimen under cyclic loading.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Poudel, P.; Belarbi, A.; Dawood, M.; Gencturk, B.; Acun, B. Prestressing bridge girders with carbon fiber-reinforced polymer: State of knowledge and research needs. Adv. Struct. Eng. 2018, 21, 598–612. [Google Scholar] [CrossRef]

- Xie, Q.; Sinaei, H.; Shariati, M.; Khorami, M.; Mohamad, E.T.; Bui, D.T. An experimental study on the effect of CFRP on behavior of reinforce concrete beam column connections. Steel Compos. Struct. 2019, 30, 433–441. [Google Scholar] [CrossRef]

- Liu, X.; Li, Y. Experimental study of seismic behavior of partially corrosion-damaged reinforced concrete columns strengthened with FRP composites with large deformability. Constr. Build. Mater. 2018, 191, 1071–1081. [Google Scholar] [CrossRef]

- Isleem, H.F.; Wang, D.Y.; Wang, Z.Y. Modeling the axial compressive stress-strain behavior of CFRP-confined rectangular RC columns under monotonic and cyclic loading. Compos. Struct. 2018, 185, 229–240. [Google Scholar] [CrossRef]

- Mugahed Amran, Y.H.; Alyousef, R.; Raizal, S.M.R.; Alabduljabbar, H.; Hung, C.C. Properties and applications of FRP in strengthening RC structures: A review. Structures 2018, 16, 208–238. [Google Scholar] [CrossRef]

- Tuhta, S. GFRP retrofitting effect on the dynamic characteristics of model steel structure. Steel Compos. Struct. 2018, 28, 223–231. [Google Scholar] [CrossRef]

- Abbassi, M.; Dabbagh, H. Seismic response of reactive powder concrete columns confined with FRP. Slovak J. Civi. Eng. 2019, 27, 12–20. [Google Scholar] [CrossRef]

- Pavlovic, A.; Donchev, T.; Petkova, D.; Limbachiya, M. Short- and Long-Term Prestress Losses in Basalt FRP Prestressed Concrete Beams under Sustained Loading. J. Compos. Constr. 2022, 26, 04022069. [Google Scholar] [CrossRef]

- Dong, Z.Q.; Wu, G.; Xu, Y.Q. Bond and flexural behavior of sea sand concrete members reinforced with hybrid steel-composite bars presubjected to wet-dry cycles. J. Compos. Constr. 2016, 19, 04016095. [Google Scholar] [CrossRef]

- Xian, G.J.; Guo, R.; Li, C.G. Combined effects of sustained bending loading, water immersion and fiber hybrid mode on the mechanical properties of carbon/glass fiber reinforced polymer composite. Compos. Struct. 2022, 281, 115060. [Google Scholar] [CrossRef]

- Wang, Z.K.; Zhao, X.L.; Xian, G.J.; Wu, G.; Raman, R.K.S.; Al-Saadi, S. Effect of sustained load and seawater and sea sand concrete environment on durability of basalt- and glass-fibre reinforced polymer (B/GFRP) bars. Corros. Sci. 2018, 138, 200–218. [Google Scholar] [CrossRef]

- Wu, J.Y.; Zhu, Y.Q.; Li, C.G. Experimental investigation of fatigue capacity of bending-anchored CFRP cables. Polymers 2023, 15, 2483. [Google Scholar] [CrossRef] [PubMed]

- Park, J.W.; Choi, S.M. Structural behavior of CFRP strengthened concrete-filled steel tubes columns under axial compression loads. Steel Compos. Struct. 2013, 14, 453–472. [Google Scholar] [CrossRef]

- Abbasnia, R.; Holakoo, A. An investigation of stress-strain behavior of FRP-confined concrete under cyclic compressive loading. Int. J. Civ. Eng. 2012, 10, 201–209. [Google Scholar]

- Lam, L.; Teng, J.G. Stress-strain model for FRP-confined concrete under cyclic axial compression. Eng. Struct. 2009, 31, 308–321. [Google Scholar] [CrossRef]

- Lin, G.; Teng, J.G. Advanced stress-strain model for FRP-confined concrete in square columns. Compos. B 2020, 197, 108149. [Google Scholar] [CrossRef]

- Berradia, M.; Kassoul, A. Ultimate strength and strain models proposed for CFRP confined concrete cylinders. Steel Compos. Struct. 2018, 29, 465–481. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Design-oriented stress-strain model for FRP-confined concrete. Constr. Build. Mater. 2003, 17, 471–489. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Strength models for fiber reinforced plastic confined concrete. J. Struct. Eng. 2002, 128, 612–623. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Design-oriented stress-strain model for FRP-confined concrete in rectangular columns. J. Reinf. Plast. Compos. 2003, 22, 1149–1186. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Lim, J.C.; Vincent, T. FRP-confined concrete in circular sections: Review and assessment of stress-strain models. Eng. Struct. 2013, 49, 1068–1088. [Google Scholar] [CrossRef]

- Rousakis, T.C.; Karabinis, A.I. Adequately FRP confined reinforced concrete columns under axial compressive monotonic or cyclic loading. Mater. Struct. 2012, 45, 957–975. [Google Scholar] [CrossRef]

- Ishaqian, M.; Keramati, A. Performance of CFRP-confined pultruded GFRP-concrete composite columns subjected to cyclic and monotonic compressive loading. Sci. Iran. 2020, 27, 1685–1698. [Google Scholar] [CrossRef]

- Su, L.; Li, X.R.; Wang, Y.F. Experimental study and modelling of CFRP-confined damaged and undamaged square RC columns under cyclic loading. Steel Compos. Struct. 2016, 21, 411–427. [Google Scholar] [CrossRef]

- Abbasnia, R.; Hosseinpour, F.; Rostamian, M.; Ziaadiny, H. Cyclic and monotonic behavior of FRP confined concrete rectangular prisms with different aspect ratios. Constr. Build. Mater. 2013, 40, 118–125. [Google Scholar] [CrossRef]

- Abbasnia, R.; Ziaadiny, H. Behavior of concrete prisms confined with FRP composites under axial cyclic compression. Eng. Struct. 2010, 32, 648–655. [Google Scholar] [CrossRef]

- Sharbatar, M.K. Monotonic and cyclic loading of new FRP reinforced concrete cantilever beams. Int. J. Civ. Eng. 2008, 6, 58–71. [Google Scholar]

- Li, B.; Zohrevand, P.; Mirmiran, A. Cyclic behavior of FRP concrete bridge pier frames. J. Bridge. Eng. 2012, 18, 429–438. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Akin, E. Behavior of FRP-confined normal and high-strength concrete under cyclic axial compression. J. Compos. Constr. 2012, 16, 451–463. [Google Scholar] [CrossRef]

- Eshghi, S.; Zanjanizadeh, V. Repair of earthquake-damaged square R/C columns with glass fiber-reinforced polymer. Int. J. Civ. Eng. 2007, 5, 210–223. [Google Scholar]

- Li, S.; Chan, T.M.; Young, B. Cyclic compressive behavior and load-strain model of FRP-concrete double tube composite columns. Thin Wall Struct. 2023, 184, 110515. [Google Scholar] [CrossRef]

- Shao, Y.; Zhu, Z.; Mirmiran, A. Cyclic modeling of FRP-confined concrete with improved ductility. Cem. Concr. Compos. 2006, 28, 959–968. [Google Scholar] [CrossRef]

- Ziaadiny, H.; Abbasnia, R. Unified cyclic stress-strain model for FRP-confined concrete circular, square and rectangular prisms. Struct. Concr. 2016, 17, 220–234. [Google Scholar] [CrossRef]

- Demir, C.; Darilmaz, K.; Llki, A. Cyclic stress-strain relationships of FRP confined concrete members. Arab. J. Sci. Eng. 2015, 40, 363–379. [Google Scholar] [CrossRef]

- Li, P.; Wu, Y.F. Stress-strain model of FRP confined concrete under cyclic loading. Compos. Struct. 2015, 134, 60–71. [Google Scholar] [CrossRef]

- Li, P.; Wu, Y.F.; Zhou, Y.W.; Xing, F. Cyclic stress-strain model for FRP-confined concrete considering post-peak softening. Compos. Struct. 2018, 201, 902–915. [Google Scholar] [CrossRef]

- Bai, Y.L.; Dai, J.G.; Teng, J.G. Cyclic compressive behavior of concrete confined with large rupture strain FRP composites. J. Compos. Constr. 2014, 18, 04013025. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G.; Cheung, C.H.; Xiao, Y. FRP-confined concrete under axial cyclic compression. Cem. Concr. Compos. 2006, 28, 949–958. [Google Scholar] [CrossRef]

- Liu, H.; He, M.H.; Luan, Y.Q.; Guo, J.; Liu, L.L. A modified constitutive model for FRP confined concrete in circular sections and its implementation with OpenSees programming. J. Zhejiang Univ. Sci. A 2013, 14, 856–866. [Google Scholar] [CrossRef]

- He, M.H.; Luan, Y.Q.; Liu, H.; Wang, Z.X. Development of FRP confined concrete constitutive models and analysis of pier/column behavior based on OpenSees. Bridge Constr. 2013, 43, 22–30. (In Chinese) [Google Scholar]

- De Stefano, M.; Tanganelli, M.; Viti, S. Variability in concrete mechanical properties as a source of in-plan irregularity for existing RC framed structures. Eng. Struct. 2014, 59, 161–172. [Google Scholar] [CrossRef]

- Stefano, M.D.; Tanganelli, M.; Viti, S. On the variability of concrete strength as a source of irregularity in elevation for existing RC buildings: A case study. Bull. Earthq. Eng. 2013, 11, 1711–1726. [Google Scholar] [CrossRef]

- Zelaschia, C.; Monteirob, R.; Pinho, R. Parametric characterization of RC bridges for seismic assessment purposes. Structures 2016, 7, 14–24. [Google Scholar] [CrossRef]

- Sengupta, S.; Ghosh, S. Influence of material variability on the seismic response of pile foundation. Civ. Environ. Res. 2012, 2, 12–18. [Google Scholar]

- Lu, X.; Wu, Z.Y.; Pei, L.; He, K.; Chen, J.K.; Li, Z.F.; Yang, Z. Effect of the spatial variability of strength parameters on the dynamic damage characteristics of gravity dams. Eng. Struct. 2019, 183, 281–289. [Google Scholar] [CrossRef]

- Kwon, O.; Elnashai, A. The effect of material and ground motion uncertainty on the seismic vulnerability curves of RC structure. Eng. Struct. 2006, 28, 289–303. [Google Scholar] [CrossRef]

- Karabinis, A.I.; Rousakis, T.C. Concrete confined by FRP material: A plasticity approach. Eng. Struct. 2002, 24, 923–932. [Google Scholar] [CrossRef]

- Mander, J.B.; Priestley, M.J.N.; Park, R. Theoretical stress-strain model for confined concrete. J. Struct. Eng. 1988, 114, 1804–1826. [Google Scholar] [CrossRef]

- Chen, X.W.; Lin, Z. OpenSees Principles and Examples of Structural Elastoplastic Analysis Program; China Building Industry Press: Beijing, China, 2014. [Google Scholar]

- Scott, B.D.; Park, R.; Priestley, M.J.N. Stress-strain behavior of concrete confined by overlapping hoops at low and high strain rates. ACI J. Proc. 1982, 79, 13–27. [Google Scholar] [CrossRef]

- Mohd-Yassin, M.H.; Filippou, F.C. Nonlinear analysis of prestressed concrete structures. In Structures Congress XII; ASCE: Reston, VA, USA, 1994. [Google Scholar]

- Wang, D.Y. Experimental and Analytical Inverstigation of Seismic Performance of Nonductile RC Frames Retrofitted with FRP. Ph.D. Dissertation, Harbin Institute of Technology, Harbin, China, 2012. (In Chinese). [Google Scholar]

- Li, Z.X.; Xu, C.X.; Jing, M.; Cai, W.D.; Hao, Y.C. Experimental research on seismic behavior of reinforced concrete short columns strengthened with carbon firber sheets. China J. Build. Struct. 2002, 23, 41–48. (In Chinese) [Google Scholar]

- Ye, L.P.; Zhang, K.; Zhao, S.H.; Feng, P. Experimental study on seismic strengthening of RC columns with wrapped CFRP sheets. Constr. Build. Struct. 2001, 17, 499–506. [Google Scholar] [CrossRef]

- Gu, D.S.; Wu, G.; Wu, Z.S.; Jiang, J.B.; Wei, Y. Experimental study on seismic performance of RC short circular columns strengthened with CFRP composites under high-level compression. Earthq. Resist. Engin. Retrofit. 2006, 28, 71–77. (In Chinese) [Google Scholar]

- Tang, X.L.; Cai, J.; Chen, Q.J.; Liu, X.P.; He, A. Seismic behaviour of through-beam connection between square CFST columns and RC beams. J. Constr. Steel. Res. 2016, 122, 151–166. [Google Scholar] [CrossRef]

- GB50010-2010; Code for Design of Concrete Structure. China Building Industry Press: Beijing, China, 2010.

- Metropolis, N.C.; Ulam, S.M. The Monte Carlo method. J. Am. Stat. Assoc. 1949, 44, 335–341. [Google Scholar] [CrossRef] [PubMed]

- Hastings, W.K. Monte Carlo sampling methods using Markov Chains and their applications. Biometrika 1970, 57, 97–109. [Google Scholar] [CrossRef]

- Zhu, P. The Studies and Applications of Quasi-Monte Carlo Methods. Ph.D. Dissertation, Zhejiang University, Hangzhou, China, 2010. (In Chinese). [Google Scholar]

- Weitao, N. Development and Variability Analysis of Hysteretic Constitutive Model of FRP-Confined Concrete Based on OpenSees; Beijing Jiaotong University: Beijing, China, 2018. [Google Scholar]

| Specimen | FRP Type | Sectional Type | S-D/mm | H/mm | γ |

|---|---|---|---|---|---|

| CVH3 (Li et al., 2002 [53]) | CFRP | Square | 300 × 300 | 480 | 0.52 |

| CF30-4-48 (Ye et al., 2001 [54]) | CFRP | Square | 200 × 200 | 600 | 0.48 |

| C1H1C3N2 (Wang, 2012 [52]) | GFRP | Cylinder | 400 | 1200 | 0.45 |

| CL1 (Gu et al., 2006 [55]) | CFRP | Cylinder | 360 | 600 | 0.35 |

| CL2 (Gu et al., 2006 [55]) | CFRP | Cylinder | 360 | 600 | 0.35 |

| Specimen | fc/MPa | fy/MPa | Φ/mm | fy,FRP/MPa | εcu,FRP | tFRP/mm | nFRP |

|---|---|---|---|---|---|---|---|

| CVH3 (Li et al., 2002 [53]) | 32.1 | 359.64 | 20 | 3200 | 0.0144 | 0.086 | 1 |

| CF30-4-48 (Ye et al., 2001 [54]) | 34 | 360 | 16 | 3500 | 0.0149 | 0.111 | 1 |

| C1H1C3N2 (Wang, 2012 [52]) | 34 | 335 | 20 | 4340 | 0.0178 | 0.167 | 3 |

| CL1 (Gu et al., 2006 [55]) | 44.3 | 382.4 | 25 | 3950 | 0.0158 | 0.167 | 1 |

| CL2 (Gu et al., 2006 [55]) | 44.3 | 382.4 | 25 | 3950 | 0.0158 | 0.167 | 2.5 |

| Specimen | Fmax+/kN | Fmax−/kN | Error Mean | ||||

|---|---|---|---|---|---|---|---|

| Test | Simulation | Re+ | Test | Simulation | Re− | ||

| CVH3 [53] | 451.45 | 465.92 | 3.20% | −485.19 | −463.83 | 4.40% | 3.8% |

| CF30-4-48 [54] | 97.34 | 106.54 | 9.46% | −98.98 | −100.45 | 1.48% | 5.47% |

| C1H1C3N2 [52] | 223.77 | 221.64 | 0.95% | −224.36 | −220.90 | 1.54% | 1.25% |

| CL1 [55] | 556.68 | 564.97 | 1.49% | −597.14 | −563.39 | 5.65% | 3.57% |

| CL2 [55] | 618.35 | 654.26 | 5.81% | −649.09 | −645.38 | 0.57% | 3.19% |

| Specimen | fcu,m/MPa | fy/MPa | Φ/mm | ρ/% | H/mm | D/mm | n | fy,FRP/MPa | εcu,FRP | tFRP/mm | nFRP |

|---|---|---|---|---|---|---|---|---|---|---|---|

| C30-series | 38.98 | 360 | 18 | 2.2/2.7/3.2 | 1000 | 300 | 0.1/0.2/0.3 | 3500 | 0.0149 | 0.111 | 3 |

| C40-series | 49.84 | 360 | 18 | 2.2/2.7/3.2 | 1000 | 300 | 0.1/0.2/0.3 | 3500 | 0.0149 | 0.111 | 3 |

| C50-series | 61.05 | 360 | 18 | 2.2/2.7/3.2 | 1000 | 300 | 0.1/0.2/0.3 | 3500 | 0.0149 | 0.111 | 3 |

| ρ | Average Values (kN) | Variation Coefficient | |||||

|---|---|---|---|---|---|---|---|

| n | 2.2% | 2.7% | 3.2% | 2.2% | 2.7% | 3.2% | |

| 0.1 | 76.77 | 88.17 | 100.44 | 0.0488 | 0.0445 | 0.0412 | |

| 0.2 | 90.40 | 101.30 | 113.24 | 0.0665 | 0.0582 | 0.0532 | |

| 0.3 | 104.38 | 114.40 | 125.55 | 0.0770 | 0.0705 | 0.0632 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Pan, L.; Niu, W.; Li, K.; Guo, K. Variability Analysis of the Hysteretic Behavior of Fiber-Reinforced Polymer (FRP)-Confined Concrete Columns Based on a Secondary Development Model. Buildings 2023, 13, 2396. https://doi.org/10.3390/buildings13092396

Wang Y, Pan L, Niu W, Li K, Guo K. Variability Analysis of the Hysteretic Behavior of Fiber-Reinforced Polymer (FRP)-Confined Concrete Columns Based on a Secondary Development Model. Buildings. 2023; 13(9):2396. https://doi.org/10.3390/buildings13092396

Chicago/Turabian StyleWang, Yuanfeng, Lei Pan, Weitao Niu, Kai Li, and Kun Guo. 2023. "Variability Analysis of the Hysteretic Behavior of Fiber-Reinforced Polymer (FRP)-Confined Concrete Columns Based on a Secondary Development Model" Buildings 13, no. 9: 2396. https://doi.org/10.3390/buildings13092396