Numerical Study of the Solar Energy-Powered Embedded Pipe Envelope System

Abstract

:1. Introduction

2. System Description and Numerical Model

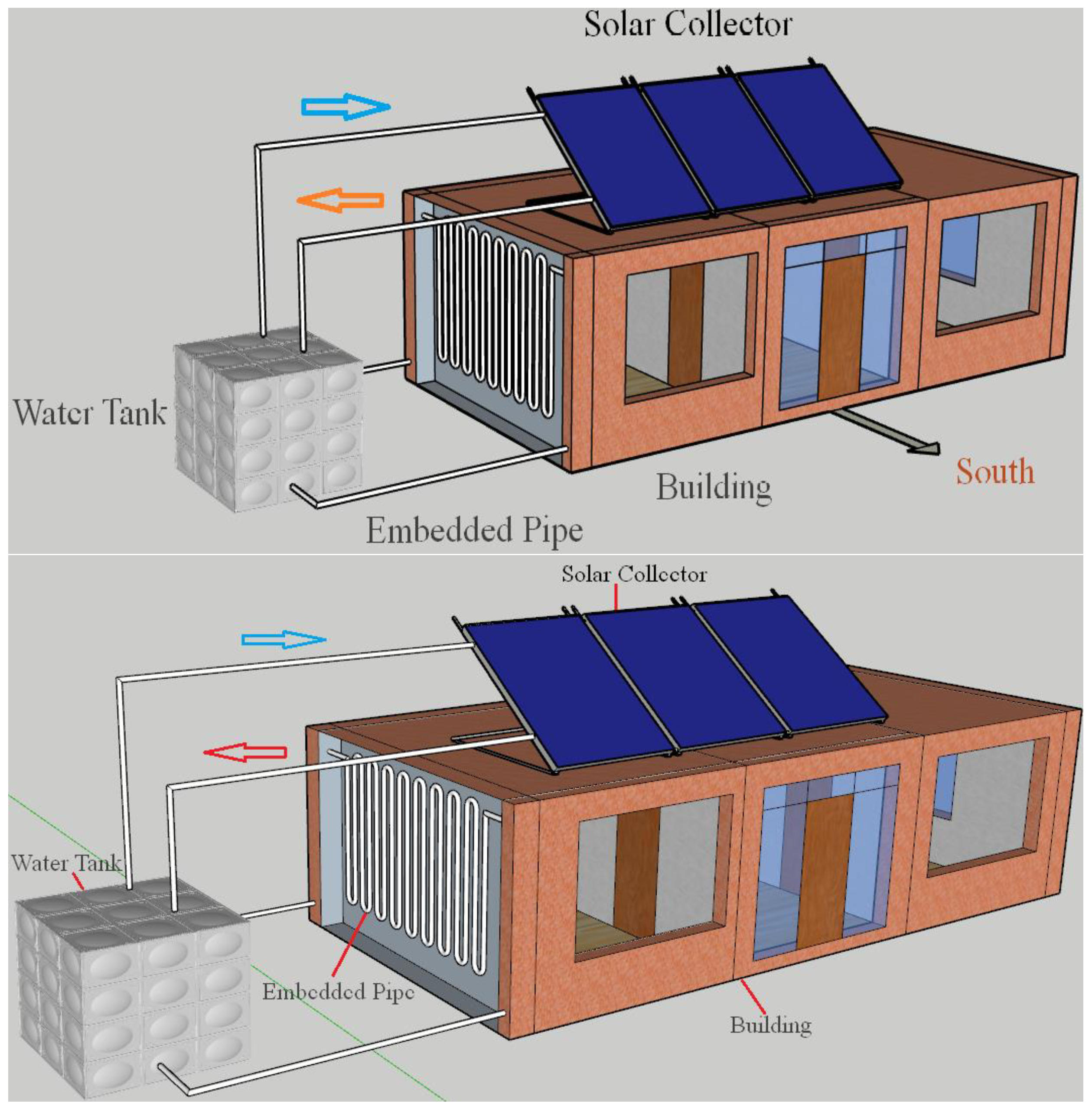

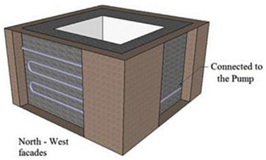

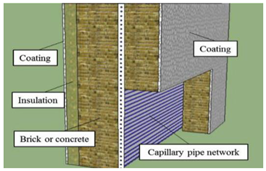

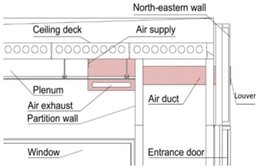

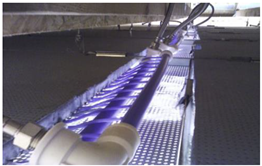

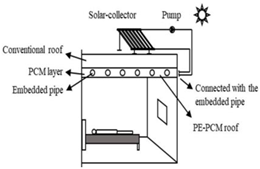

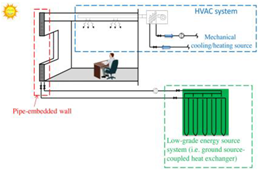

2.1. The Solar Energy-Powered Embedded Pipe Envelope System

2.2. Model Setting

2.3. Evaluated Index

- -

- Annual heating load

- -

- System energy consumption

- -

- Coefficient of performance

3. Results and Discussion

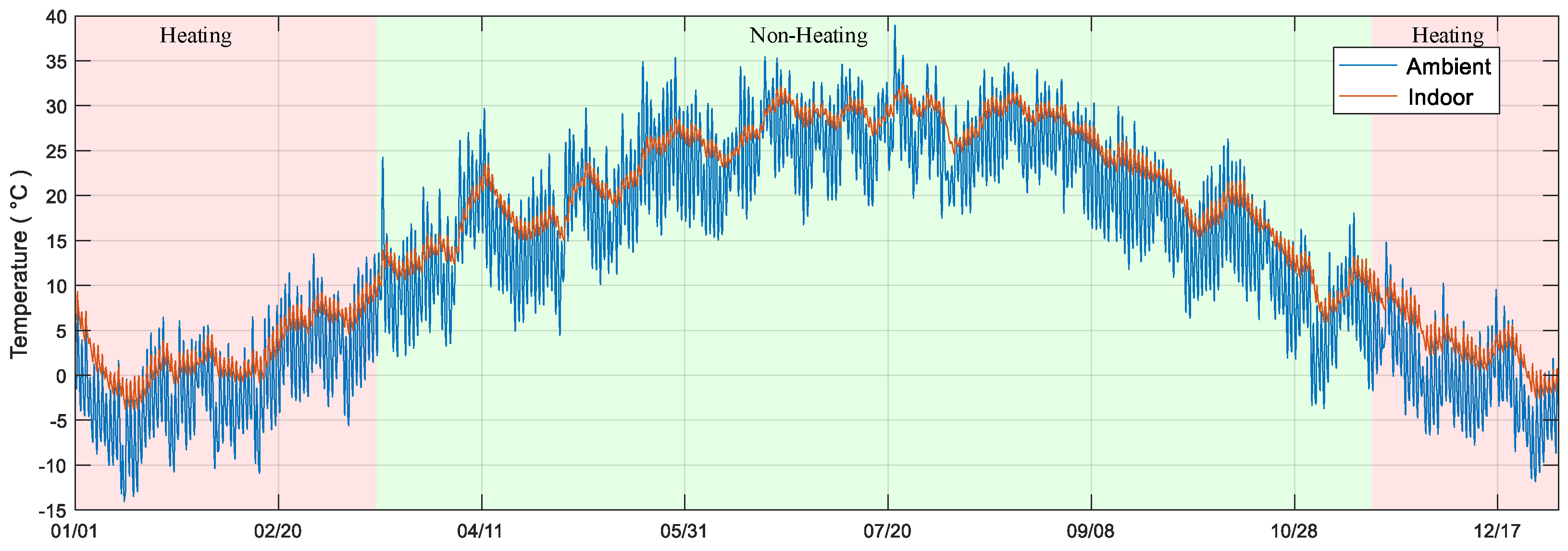

3.1. A Case Study for Rural Buildings in Beijing

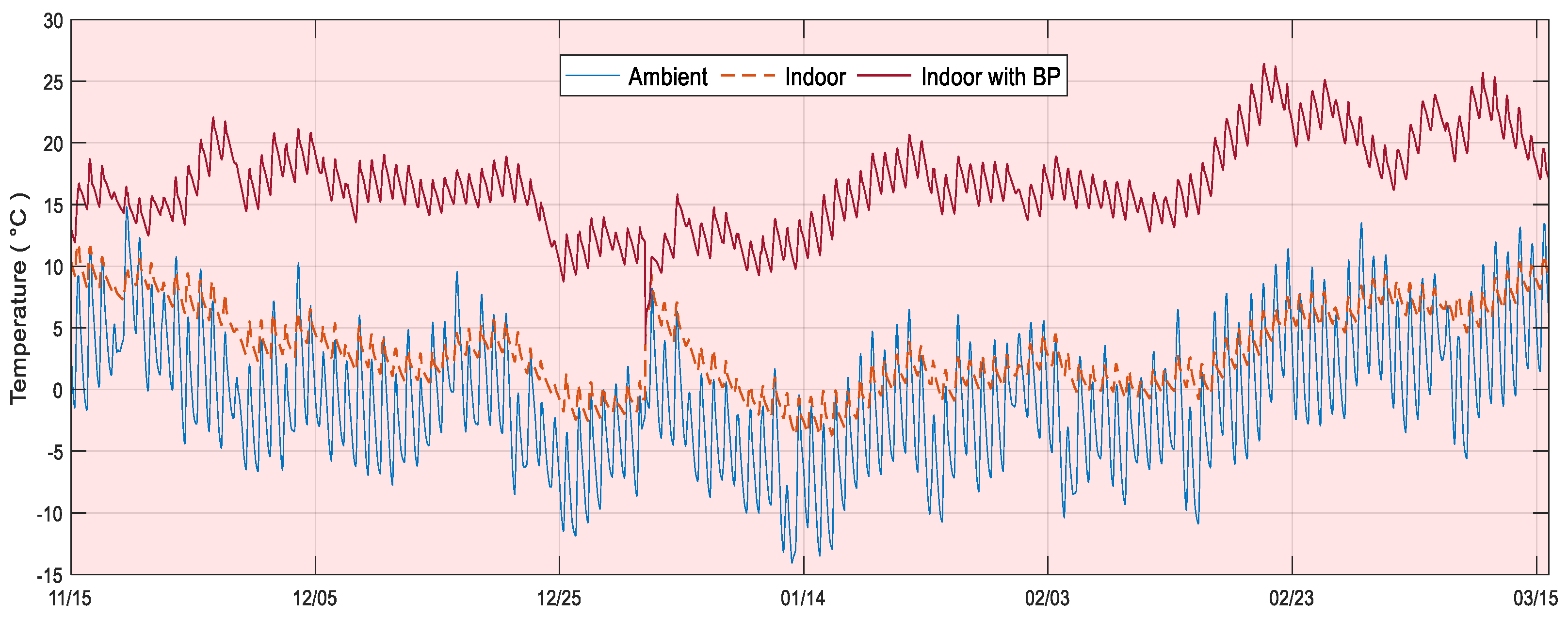

3.1.1. Room Temperature

3.1.2. Heating Energy Consumption

3.2. Parameters Analysis

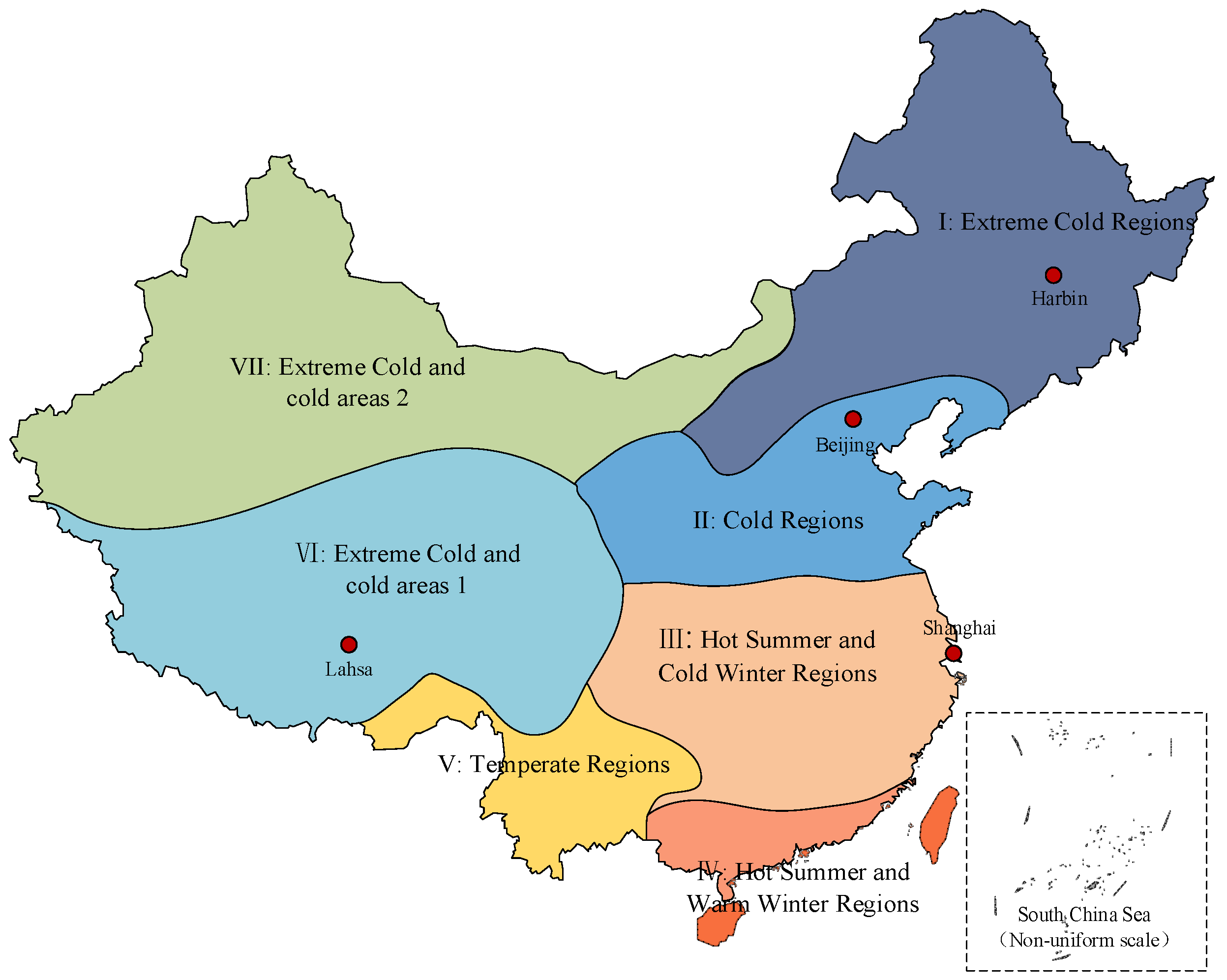

3.3. Regional Adaptation of the SEPES

4. Conclusions

- In the case study in Beijing rural residential building, the SEPES demonstrates a notable enhancement in room natural temperatures and a reduction in heating energy consumption. During the entire heating season, the natural indoor temperature elevation in the building ranges from 13.6 °C to 16.6 °C. Meanwhile, the total heating load decreased from 9305 kWh to 2478 kWh, yielding an energy-saving rate of 73.4%.

- Concerning the design parameters of the SEPES, the area of the SC, the volume of the water tank, and the circulation flow rates for both SC and BP are the three most significant parameters influencing the overall performance during the heating seasons. Importantly, both the water tank volume and circulation flow rates are not advantageous when overly large; rather, they exhibit optimal and reasonable value ranges.

- According to the regional adaptability analysis, the energy-saving rate of the SEPES during the heating season in cold and hot-summer/cold-winter regions of China can reach 43.9% to 66%. The most suitable climate for optimal performance is in areas characterized by both cold temperatures and abundant solar energy, as exemplified by a typical rural building in Lhasa. In this scenario, the annual heating load is reduced by 7205 kWh, achieving an energy-saving rate of 66%.

- Overall, the SEPES presents itself as a potential viable solution for harnessing low-grade solar energy in the regulation of building environments in cold regions. However, in regions characterized by relatively higher winter temperatures and limited solar resources, the performance advantages of the SEPES may be significantly diminished.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Total heating load ) | |

| Set indoor temperature ) | |

| n1 | The start time of heating season (s) |

| n2 | The end time of heating season (s) |

| Energy consumption (kJ) | |

| Temperature ) | |

| COP | coefficient of performance ) |

| Heating capacity ) | |

| Sig | Control signals ) |

| Hourly energy consumption of SC (kJ) | |

| Hourly energy consumption of pumb ) |

References

- Xu, G.; Dong, H.; Xu, Z.; Bhattarai, N. China can reach carbon neutrality before 2050 by improving economic development quality. Energy 2022, 243, 123087. [Google Scholar] [CrossRef]

- Ibrahim, M.; Wurtz, E.; Biwole, P.H.; Achard, P. Transferring the south solar energy to the north facade through embedded water pipes. Energy 2014, 78, 834–845. [Google Scholar] [CrossRef]

- Ding, Y.; Han, S.; Tian, Z.; Yao, J.; Chen, W.; Zhang, Q. Review on occupancy detection and prediction in building simulation. In Building Simulation; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Bucarelli, N.; El-Gohary, N. Sensor deployment configurations for building energy consumption prediction. Energy Build. 2024, 308, 113888. [Google Scholar] [CrossRef]

- Omer, A.M. Energy, environment and sustainable development. Renew. Sustain. Energy Rev. 2008, 12, 2265–2300. [Google Scholar] [CrossRef]

- Cao, X.; Dai, X.; Liu, J. Building energy-consumption status worldwide and the state-of-the-art technologies for zero-energy buildings during the past decade. Energy Build. 2016, 128, 198–213. [Google Scholar] [CrossRef]

- Shamoushaki, M.; Koh, S.C.L. Heat pump supply chain environmental impact reduction to improve the UK energy sustainability, resiliency and security. Sci. Rep. 2023, 13, 20633. [Google Scholar] [CrossRef] [PubMed]

- Li, A.; Simard, B.; Yim, C.H.; Robertson, G.P.; Zborowski, A.; Mercier, P.H.; Kingston, C.T.; Guan, J. Electrospun Green Fibers from Alberta Oilsands Asphaltenes. Energy Fuels 2023, 37, 13645–13657. [Google Scholar] [CrossRef]

- Li, W.-Y.; Li, Y.-C.; Zeng, L.-Y.; Lu, J. Comparative study of vertical and horizontal indirect evaporative cooling heat recovery exchangers. Int. J. Heat Mass Transf. 2018, 124, 1245–1261. [Google Scholar] [CrossRef]

- Li, S.; Lu, J.; Li, W.; Zhang, Y.; Huang, S.; Tian, L.; Lv, Y.; Hu, Y.; Zeng, Y. Thermodynamic analyses of a novel ejector enhanced dual-temperature air source heat pump cycle with self-defrosting. Appl. Therm. Eng. 2022, 215, 118944. [Google Scholar] [CrossRef]

- Li, W.; Wang, J.; Shi, W.; Lu, J. High-efficiency cooling solution for exhaust air heat pump: Modeling and experimental validation. Energy 2022, 254, 124396. [Google Scholar] [CrossRef]

- Xu, X.; Wang, S.; Wang, J.; Xiao, F. Active pipe-embedded structures in buildings for utilizing low-grade energy sources: A review. Energy Build. 2010, 42, 1567–1581. [Google Scholar] [CrossRef]

- Xie, J.-L.; Zhu, Q.-Y.; Xu, X.-H. An active pipe-embedded building envelope for utilizing low-grade energy sources. J. Cent. South Univ. 2012, 19, 1663–1667. [Google Scholar] [CrossRef]

- Gwerder, M.; Tödtli, J.; Lehmann, B.; Dorer, V.; Güntensperger, W.; Renggli, F. Control of thermally activated building systems (TABS) in intermittent operation with pulse width modulation. Appl. Energy 2009, 86, 1606–1616. [Google Scholar] [CrossRef]

- Niu, F.; Yu, Y. Location and optimization analysis of capillary tube network embedded in active tuning building wall. Energy 2016, 97, 36–45. [Google Scholar] [CrossRef]

- Chiam, Z.; Papas, I.; Easwaran, A.; Alonso, C.; Estibals, B. Holistic optimization of the operation of a GCHP system: A case study on the ADREAM building in Toulouse, France. Appl. Energy 2022, 321, 119377. [Google Scholar] [CrossRef]

- Alexander, K.; Phillip, S.; Dirk, M. Development of a Long-Term Operational Optimization Model for a Building Energy System Supplied by a Geothermal Field. J. Therm. Sci. 2022, 31, 1293–1301. [Google Scholar]

- Venko, S.; Pavlovič, E.; Vidrih, B.; Arkar, C.; Medved, S. An experimental study of mixed convection over various thermal activation lengths of vertical TABS. Energy Build. 2015, 98, 151–160. [Google Scholar] [CrossRef]

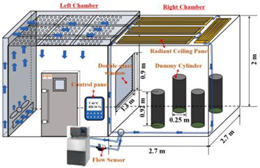

- Mikeska, T.; Fan, J.; Svendsen, S. Full scale measurements and CFD investigations of a wall radiant cooling system integrated in thin concrete walls. Energy Build. 2017, 139, 242–253. [Google Scholar] [CrossRef]

- Popescu, L.; Popescu, R.; Damian, A.; Serban, A. Renewable Energy Sources Used for a Low Energy Building Rehabilitation; IEEE: Piscataway, NJ, USA, 2021. [Google Scholar]

- Yu, Y.; Niu, F.; Guo, H.-A.; Woradechjumroen, D. A thermo-activated wall for load reduction and supplementary cooling with free to low-cost thermal water. Energy 2016, 99, 250–265. [Google Scholar] [CrossRef]

- Monna, S.; Coccolo, S.; Kämpf, J.; Mauree, D.; Scartezzini, J. Energy Demand Analysis for Building Envelope Optimization for Hot Climate. Energy 2016, 4, 2. [Google Scholar]

- Alaidroos, A.; Krarti, M. Optimal design of residential building envelope systems in the Kingdom of Saudi Arabia. Energy Build. 2015, 86, 104–117. [Google Scholar] [CrossRef]

- Mahmoodzadeh, M.; Gretka, V.; Blue, A.; Adams, D.; Mukhopadhyaya, P. Evaluating Thermal Performance of Vertical Building Envelopes: Case Studies in a Canadian University Campus. J. Build. Eng. 2021, 40, 102712. [Google Scholar] [CrossRef]

- Villar-Ramos, M.M.; Hernández-Pérez, I.; Aguilar-Castro, K.M.; Zavala-Guillén, I.; Macias-Melo, E.V.; Hernández-López, I.; Serrano-Arellano, J. A Review of Thermally Activated Building Systems (TABS) as an Alternative for Improving the Indoor Environment of Buildings. Energies 2022, 15, 6179. [Google Scholar] [CrossRef]

- Koschenz, M.; Dorer, V. Interaction of an air system with concrete core conditioning. Energy Build. 1999, 30, 139–145. [Google Scholar] [CrossRef]

- Liu, J.; Qin, F.; Xie, X.; Zhang, L. An Applied Research on the Compound Air Conditioning System of Ground Source Direct Cooling System and Water Storage Tank System. Procedia Eng. 2016, 146, 559–566. [Google Scholar] [CrossRef]

- Soni, S.K.; Pandey, M.; Bartaria, V.N. Ground coupled heat exchangers: A review and applications. Renew. Sustain. Energy Rev. 2015, 47, 83–92. [Google Scholar] [CrossRef]

- Ye, M.; Serageldin, A.A.; Radwan, A.; Sato, H.; Nagano, K. Thermal performance of ceiling radiant cooling panel with a segmented and concave surface: Laboratory analysis. Appl. Therm. Eng. 2021, 196, 117280. [Google Scholar] [CrossRef]

- Rawat, M.; Singh, R.N. A study on the comparative review of cool roof thermal performance in various regions. Energy Built Environ. 2022, 3, 327–347. [Google Scholar] [CrossRef]

- Oravec, J.; Šikula, O.; Krajčík, M.; Arıcı, M.; Mohapl, M. A comparative study on the applicability of six radiant floor, wall, and ceiling heating systems based on thermal performance analysis. J. Build. Eng. 2021, 36, 102133. [Google Scholar] [CrossRef]

- Zhou, L.; Li, C. Study on thermal and energy-saving performances of pipe-embedded wall utilizing low-grade energy. Appl. Therm. Eng. 2020, 176, 115477. [Google Scholar] [CrossRef]

- Xu, K.; Xu, X.; Yan, T. Performance evaluation of a pipe-embedded phase change material (PE-PCM) roof integrated with solar collector. J. Build. Eng. 2023, 71, 106582. [Google Scholar] [CrossRef]

- Li, A.; Xu, X.; Sun, Y. A study on pipe-embedded wall integrated with ground source-coupled heat exchanger for enhanced building energy efficiency in diverse climate regions. Energy Build. 2016, 121, 139–151. [Google Scholar] [CrossRef]

- Shen, C.; Li, X. Energy saving potential of pipe-embedded building envelope utilizing low-temperature hot water in the heating season. Energy Build. 2017, 138, 318–331. [Google Scholar] [CrossRef]

- Vangtook, P.; Chirarattananon, S. Application of radiant cooling as a passive cooling option in hot humid climate. Build. Environ. 2007, 42, 543–556. [Google Scholar] [CrossRef]

- Facão, J.; Oliveira, A.C. Thermal behaviour of closed wet cooling towers for use with chilled ceilings. Appl. Therm. Eng. 2000, 20, 1225–1236. [Google Scholar] [CrossRef]

- Shen, C.; Li, X. Dynamic thermal performance of pipe-embedded building envelope utilizing evaporative cooling water in the cooling season. Appl. Therm. Eng. 2016, 106, 1103–1113. [Google Scholar] [CrossRef]

- Krajčík, M.; Šikula, O. Heat storage efficiency and effective thermal output: Indicators of thermal response and output of radiant heating and cooling systems. Energy Build. 2020, 229, 110524. [Google Scholar] [CrossRef]

- Zhang, Z.; Sun, Z.; Duan, C. A new type of passive solar energy utilization technology—The wall implanted with heat pipes. Energy Build. 2014, 84, 111–116. [Google Scholar] [CrossRef]

- Yu, J.; Yang, Q.; Ye, H.; Huang, J.; Liu, Y.; Tao, J. The optimum phase transition temperature for building roof with outer layer PCM in different climate regions of China. Energy Procedia 2019, 158, 3045–3051. [Google Scholar] [CrossRef]

- Yu, J.; Leng, K.; Ye, H.; Xu, X.; Luo, Y.; Wang, J.; Yang, X.; Yang, Q.; Gang, W. Study on thermal insulation characteristics and optimized design of pipe-embedded ventilation roof with outer-layer shape-stabilized PCM in different climate zones. Renew. Energy 2020, 147, 1609–1622. [Google Scholar] [CrossRef]

- Klein, S. Calculation of flat-plate collector loss coefficients. In Renewable Energy; Routledge: Abingdon-on-Thames, UK, 2018; Volume 2, pp. 382–391. [Google Scholar]

- Deng, M.; Ma, R.; Lu, F.; Nie, Y.; Li, P.; Ding, X.; Yuan, Y.; Shan, M.; Yang, X. Techno-economic performances of clean heating solutions to replace raw coal for heating in Northern rural China. Energy Build. 2021, 240, 110881. [Google Scholar] [CrossRef]

- National Civil Building Engineering Design Technical Measures of China; Ministry of Housing and Urban-Rural Development of China: Beijing, China, 2007.

| Reference | Cooling/Heating | Weather | Model | Results of Research |

|---|---|---|---|---|

| [2] | H | Mediterranean |  | The annual heating load has the potential to be decreased by 15–43%. |

| [15] | H, C | / |  | The power benefit associated with the wall modifications ranges from 2 W to 39 W. |

| [19] | C | / |  | The wall radiant cooling system has the capability to supply energy for cooling in the range of 29–59 W/. |

| [21] | C | / |  | The wall contributed minimal cooling when the MTC inlet water temperature matched the indoor air temperature. |

| [29] | C | / |  | Reducing the inlet water temperature from 24 °C to 15 °C, while maintaining a constant flow rate of 4 L/min, resulted in an average air temperature decrease exceeding 1.5 °C. |

| [33] | H | / |  | The total energy demand for room heating can be decreased by 54% when employing a PE–PCM roof. |

| [34] | H, C | Five typical climate regions of China. |  | In climates characterized by hot summers and mild winters, the reductions in building cooling load are noticeably smaller. |

| Module Name | Calling Components | Function |

|---|---|---|

| Solar collector | Type 73 | Models the thermal performance of a theoretical flat plate collector |

| Single-speed pump | Type 114 | Models a single (constant) speed pump that is able to maintain a constant fluid outlet mass flow rate |

| Cylindrical Storage Tank | Type 158 | Models a fluid-filled, constant volume storage tank |

| Weather data | Weather data | Provides outdoor temperature and humidity and calculates solar radiation |

| Outputs | Type 65d | Analyzes the calculation results of each component |

| Design Parameter | Description Value | Design Parameter | Description Value |

|---|---|---|---|

| Solar collector | Water tank | ||

| Number in series | 1 | Tank volume | 10 |

| Collector area | 80 | Loss coefficient of tank | 3.35 |

| Fluid specific heat in SC | 4.19 | Pump of wall | |

| Absorptance of absorber plate | 0.9 | Number in series | 4 |

| Number of pumps | 1 | Rated power of pump | 180 W |

| Rated power of pump | 100 W |

| Material Layers | Convective Heat Transfer Coefficient () | U-Value () | |||

|---|---|---|---|---|---|

| Name | Thickness (mm) | Interior | Lateral | ||

| External Wall | Plaster | 2.5 | 3.06 | 17.78 | 0.6 (E, W, N) 0.65 (S) |

| Brick | 370 (E, W, N) 240 (S) | ||||

| Insulation | 48 | ||||

| Floor and Interior walls | Insulation | 30 | 3.06 | 3.06 | 1.0 |

| Concrete | 120 | ||||

| Roof | Insulation | 80 | 3.06 | 17.78 | 0.45 |

| Concrete | 240 | ||||

| External window | Glass | 4 | 3.06 | 17.78 | 3.2 |

| Air | 3.2 | ||||

| Glass | 4 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Onn, C.C.; Chew, B.T.; Li, W.; Li, Y. Numerical Study of the Solar Energy-Powered Embedded Pipe Envelope System. Buildings 2024, 14, 613. https://doi.org/10.3390/buildings14030613

Wang L, Onn CC, Chew BT, Li W, Li Y. Numerical Study of the Solar Energy-Powered Embedded Pipe Envelope System. Buildings. 2024; 14(3):613. https://doi.org/10.3390/buildings14030613

Chicago/Turabian StyleWang, Linfeng, Chiu Chuen Onn, Bee Teng Chew, Wuyan Li, and Yongcai Li. 2024. "Numerical Study of the Solar Energy-Powered Embedded Pipe Envelope System" Buildings 14, no. 3: 613. https://doi.org/10.3390/buildings14030613