The Performance Analysis of a Novel Sterilizable Trombe Wall Based on the Combined Effect of Heat and UV Light

Abstract

:1. Introduction

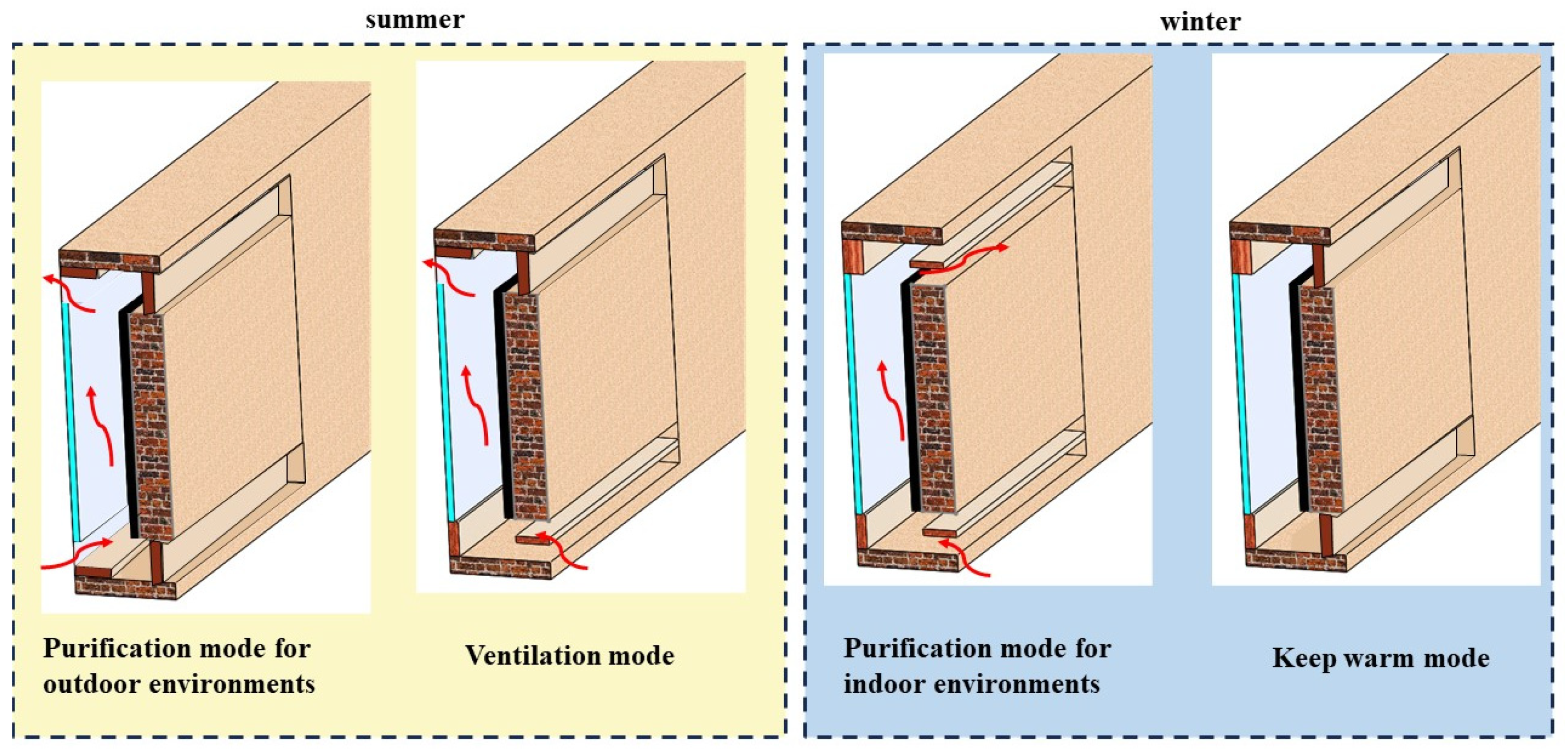

2. System Descriptions

3. System Model and Performance Evaluation

- (1)

- The heat transfer process of the glass cover plate could be considered to involve one-dimensional heat transfer, that is, only the heat transfer in the y direction was considered;

- (2)

- The convective heat transfer coefficient in the air flow channel was assumed to have a uniform distribution;

- (3)

- The thermophysical parameters used in the model were assumed to be constant;

- (4)

- There was no transmission loss of bacteria in the process.

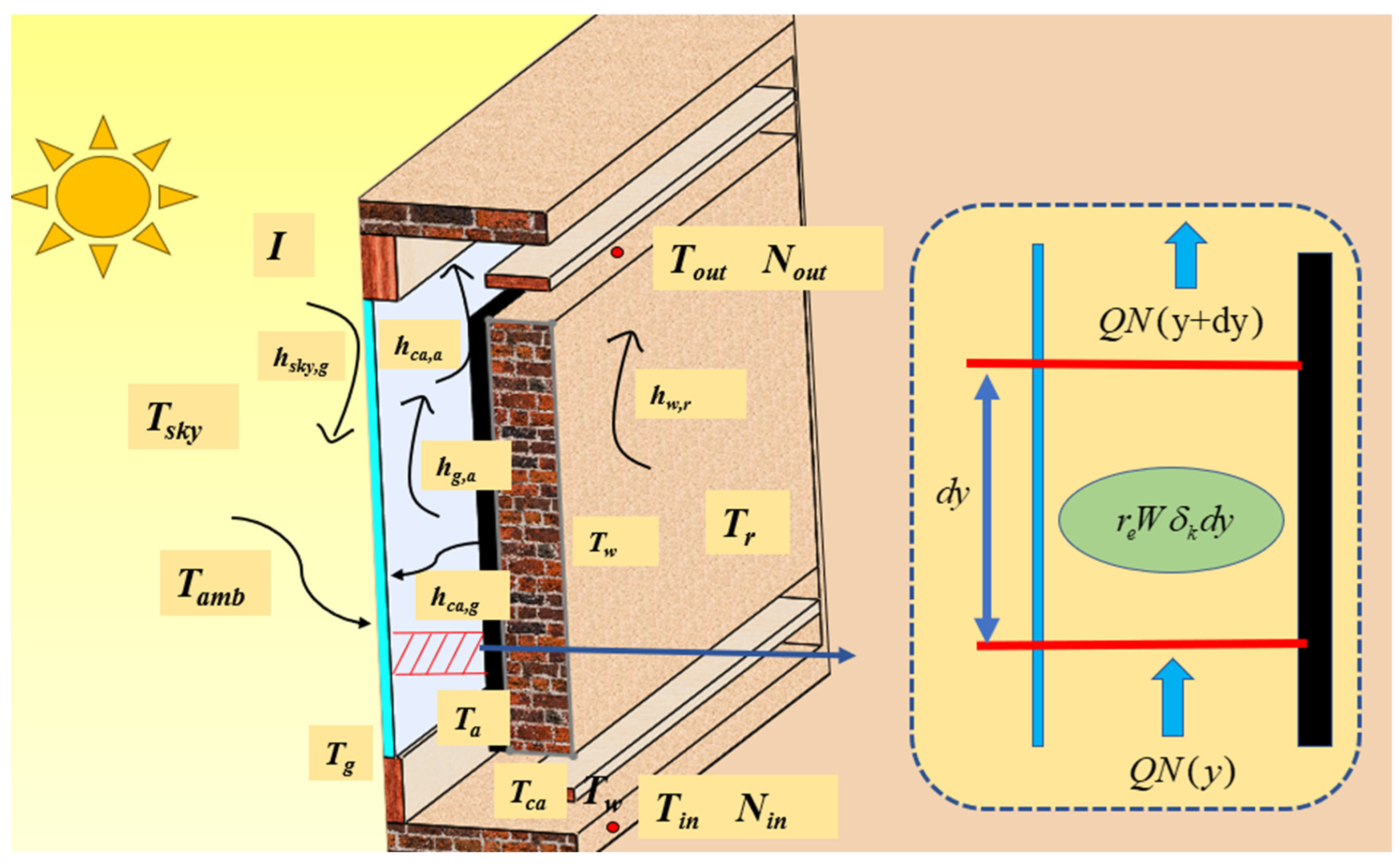

3.1. Heat Transfer Model

3.2. Mass Transfer Model

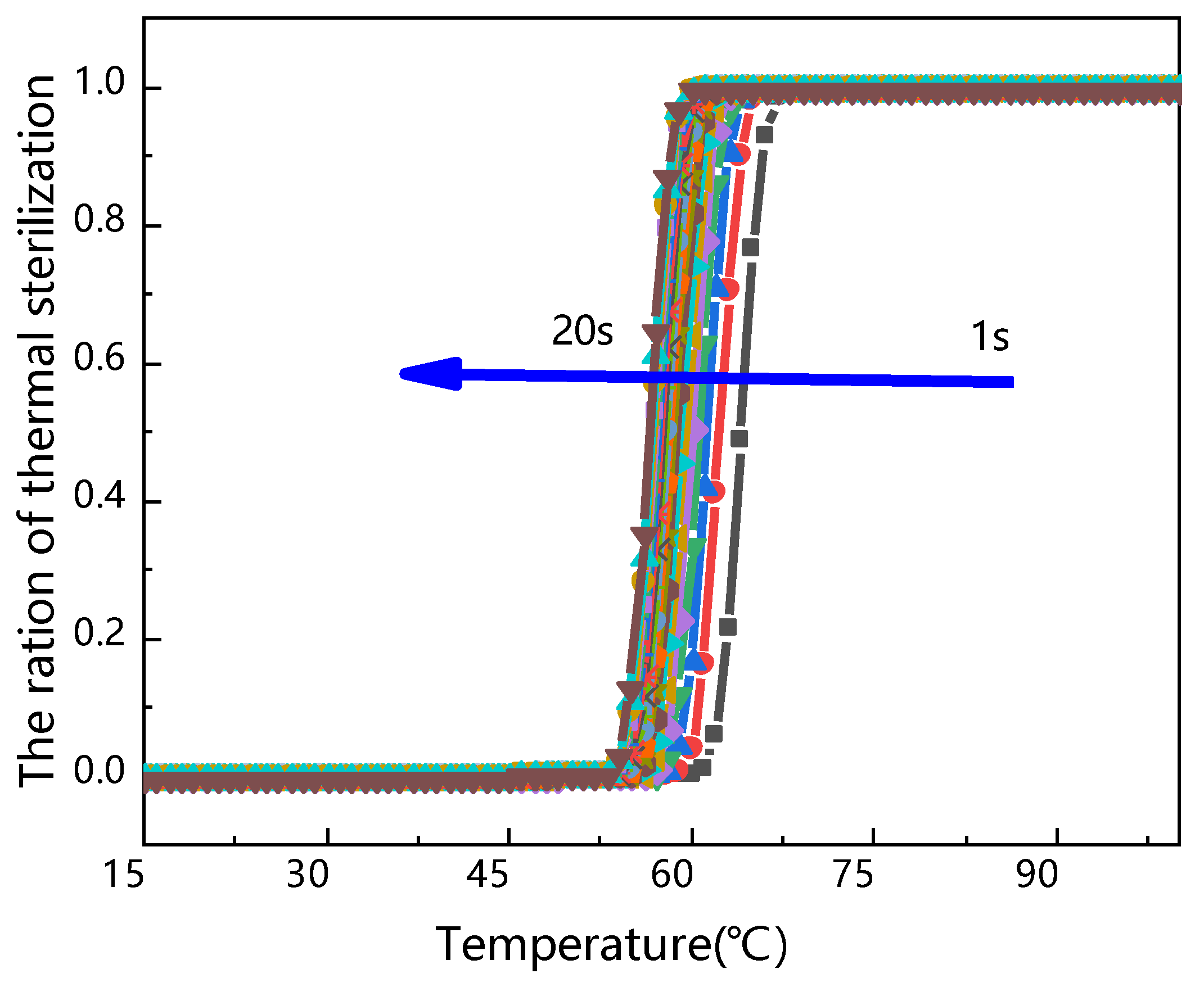

3.2.1. Thermal Sterilization Kinetic Model

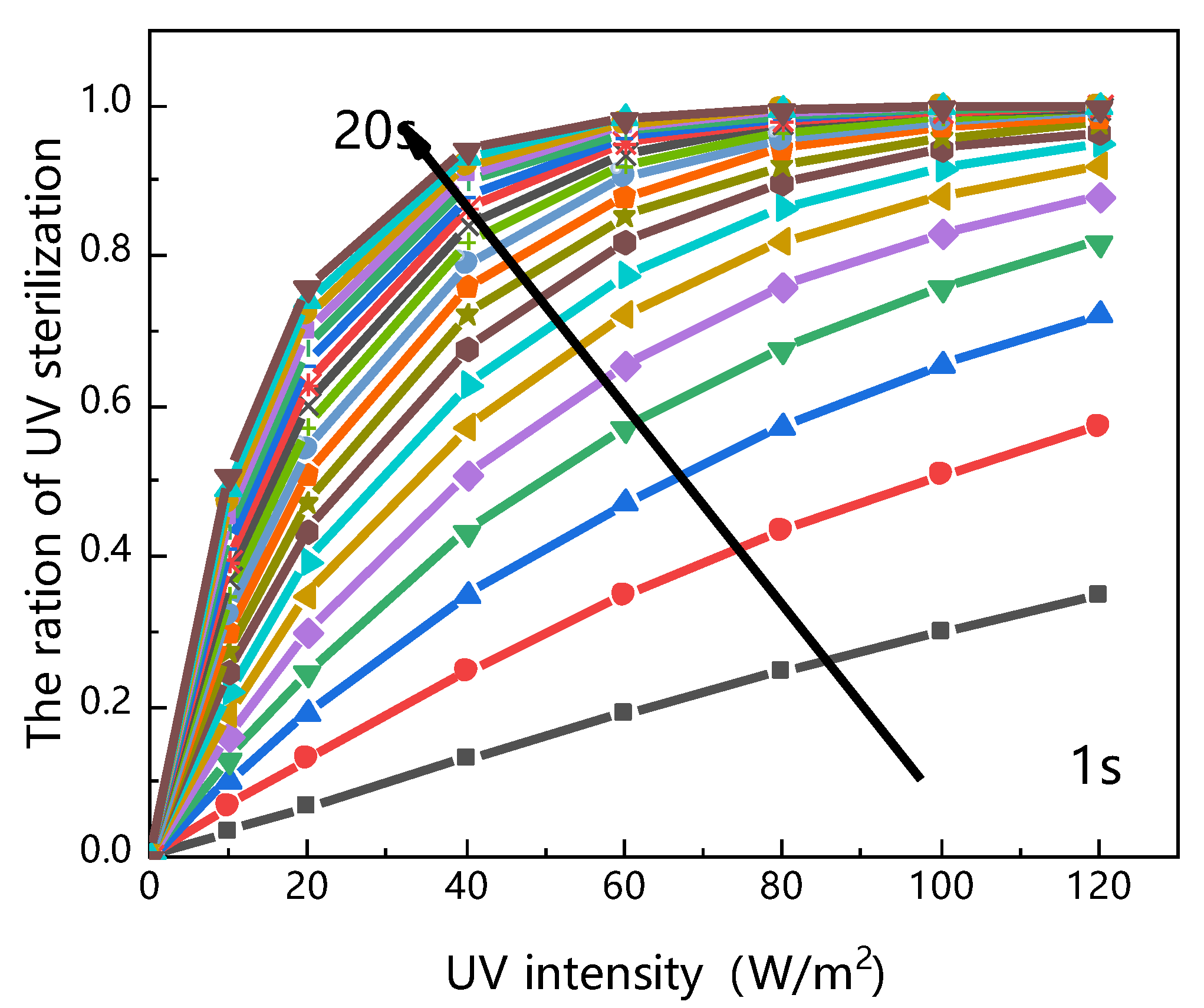

3.2.2. UV Sterilization Kinetic Model

3.3. Performance Evaluation

3.4. Model Verification

4. Results and Discussions

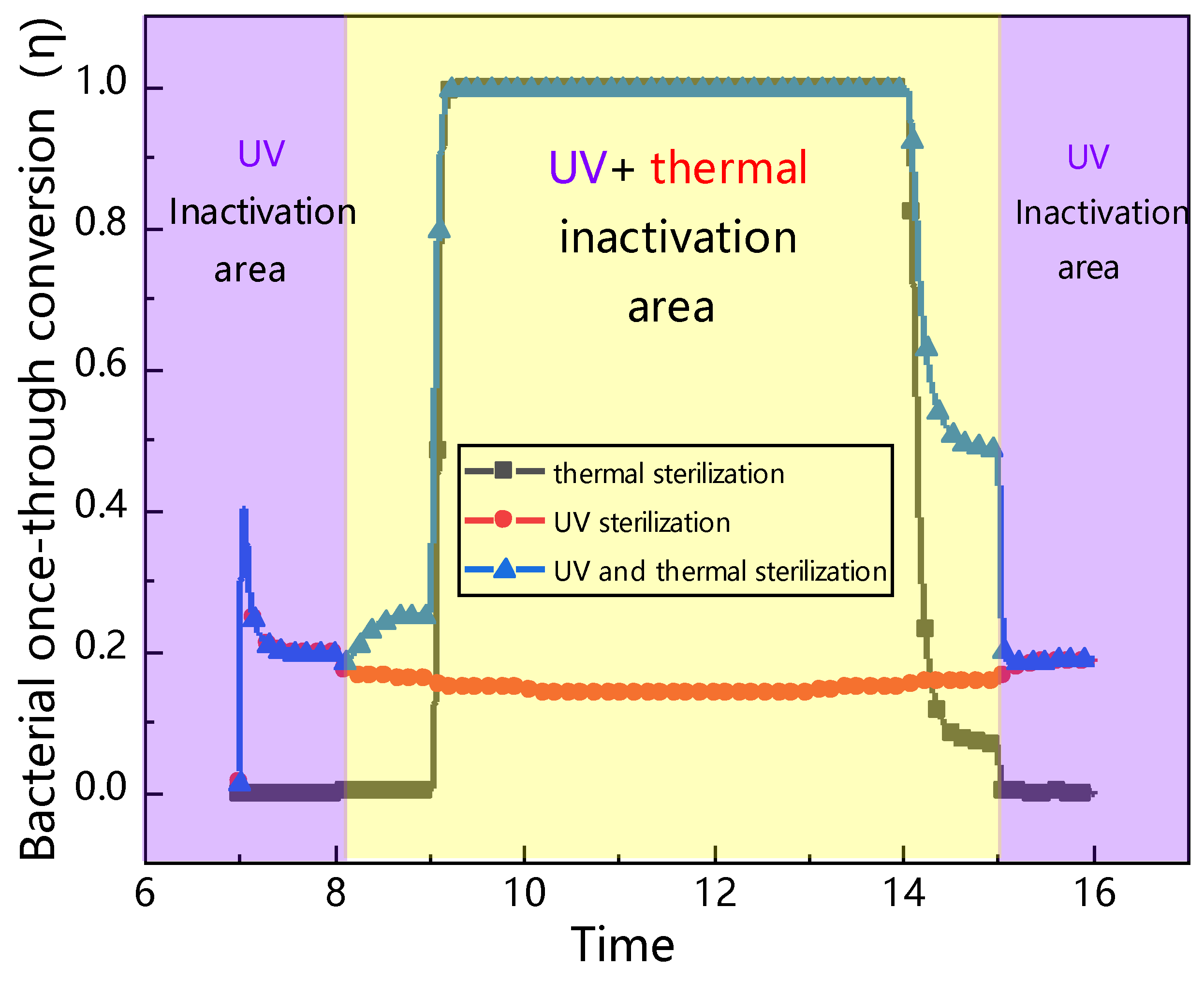

4.1. Mechanism of UV and Thermal Sterilization in a Trombe Wall

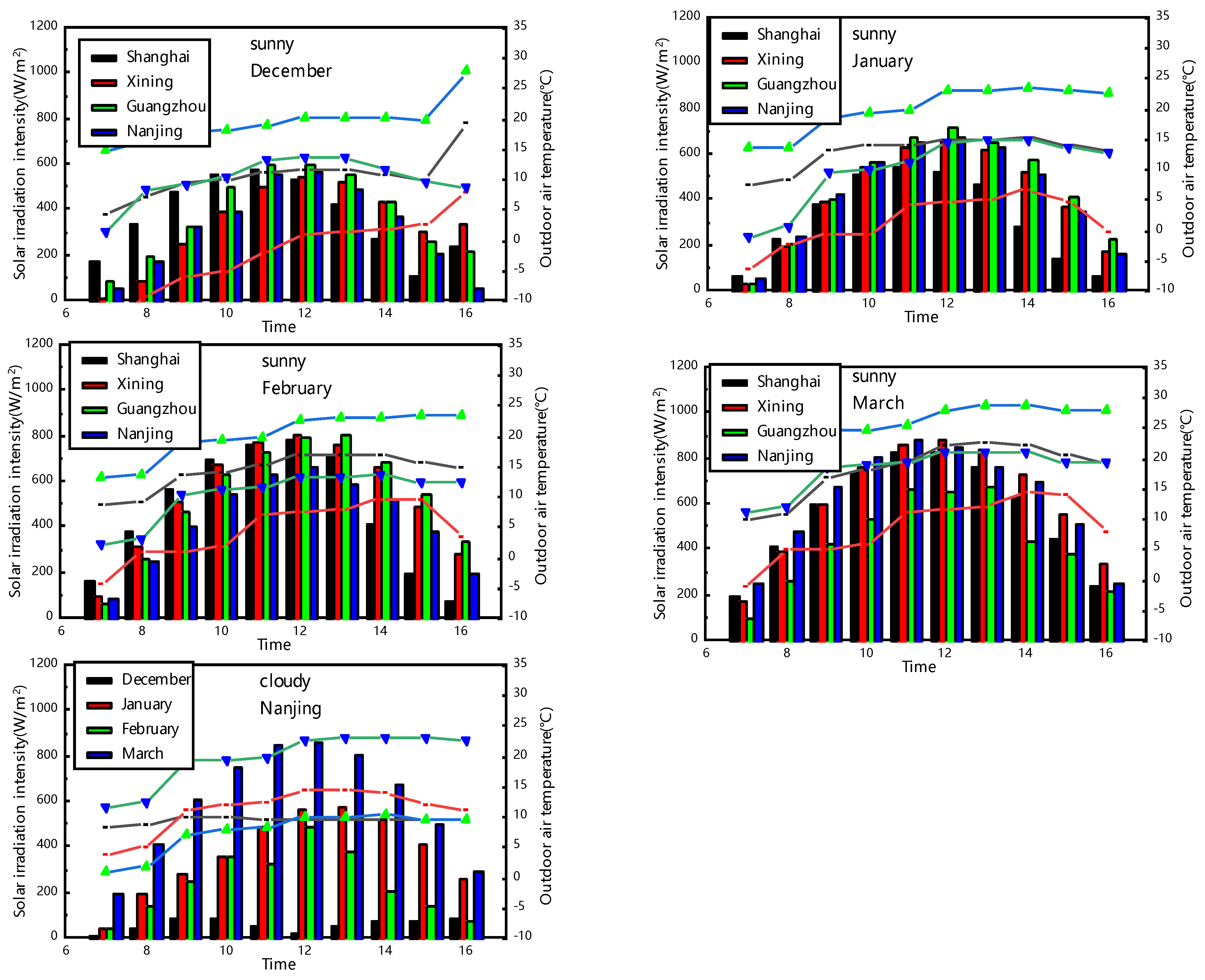

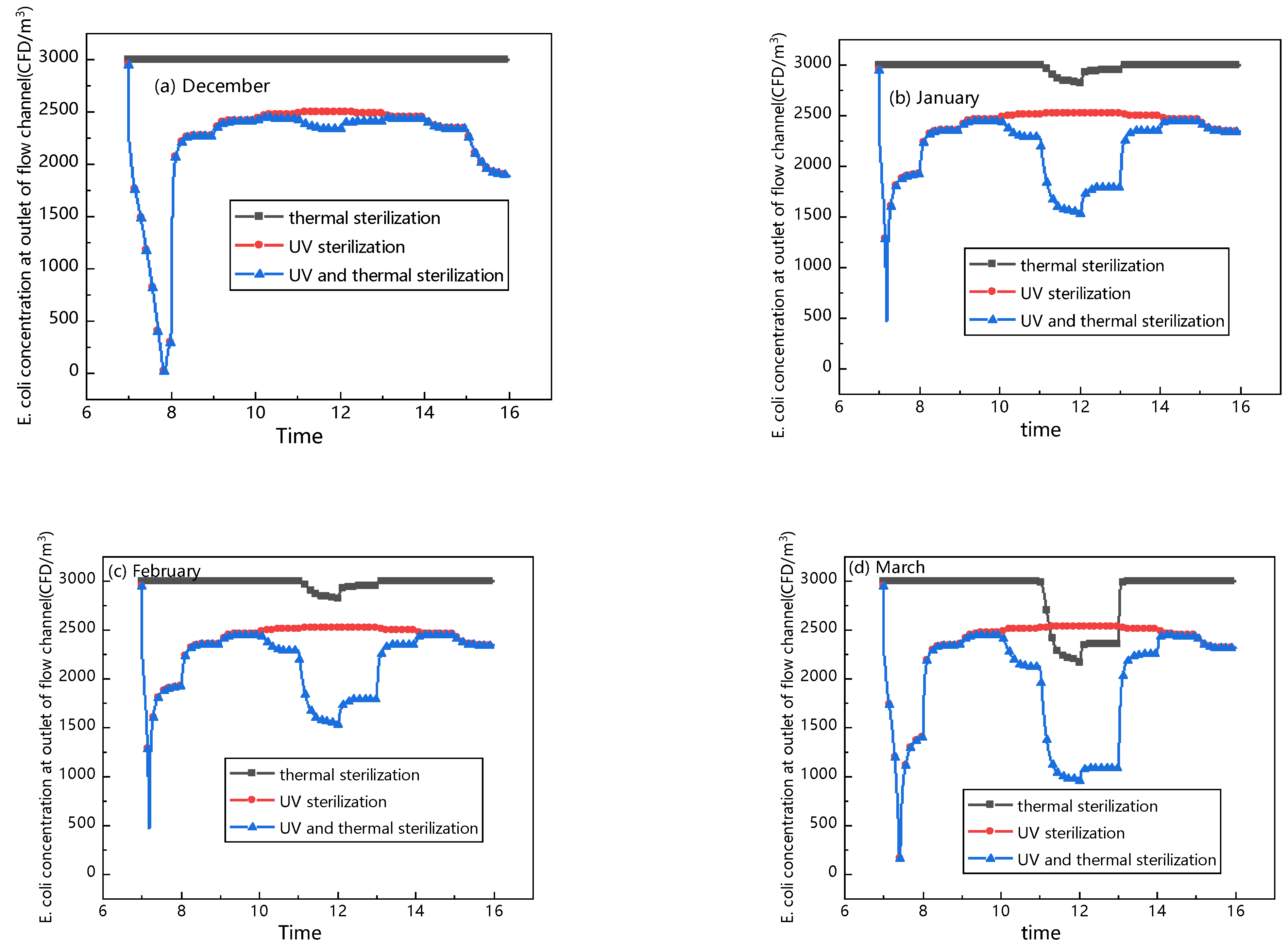

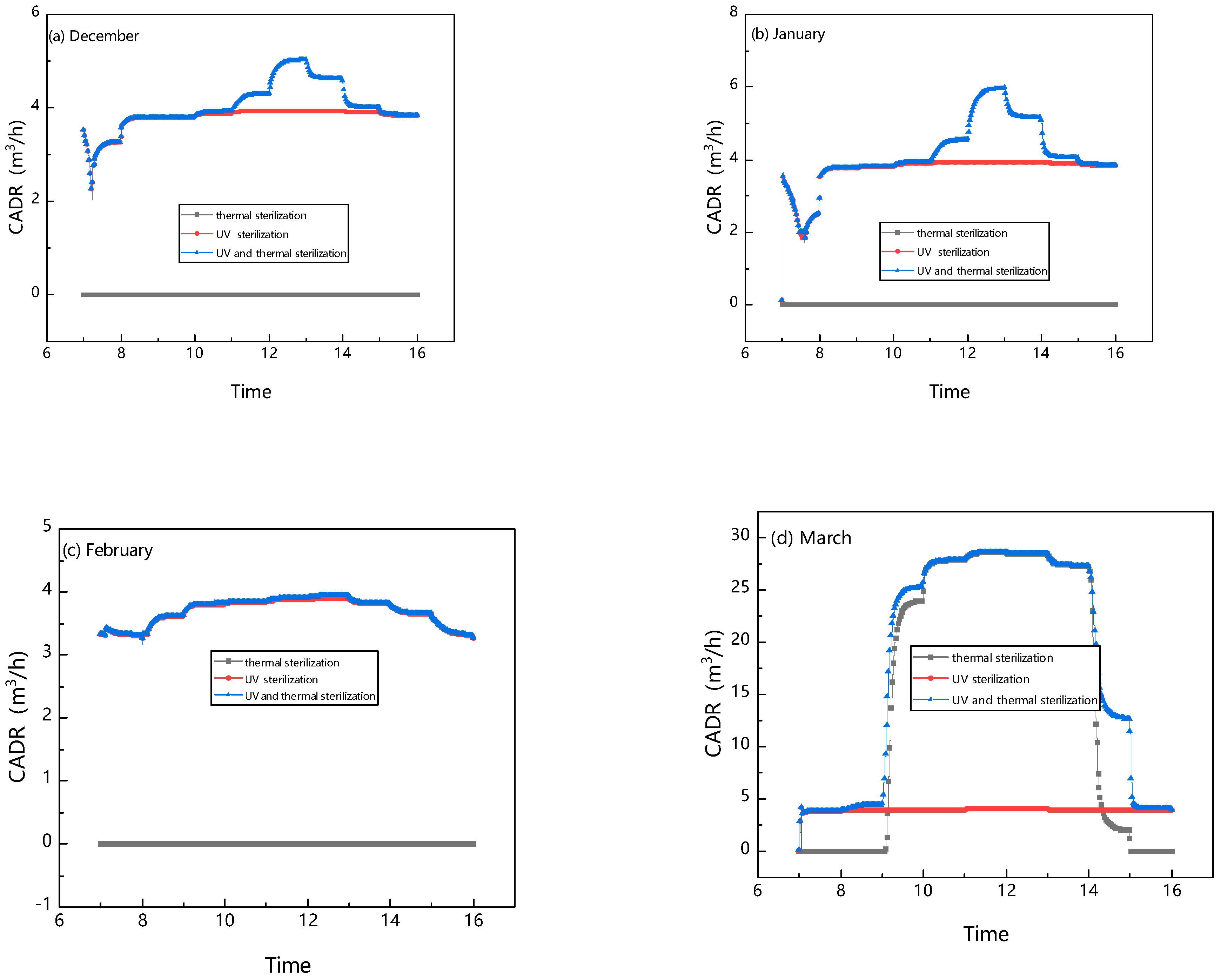

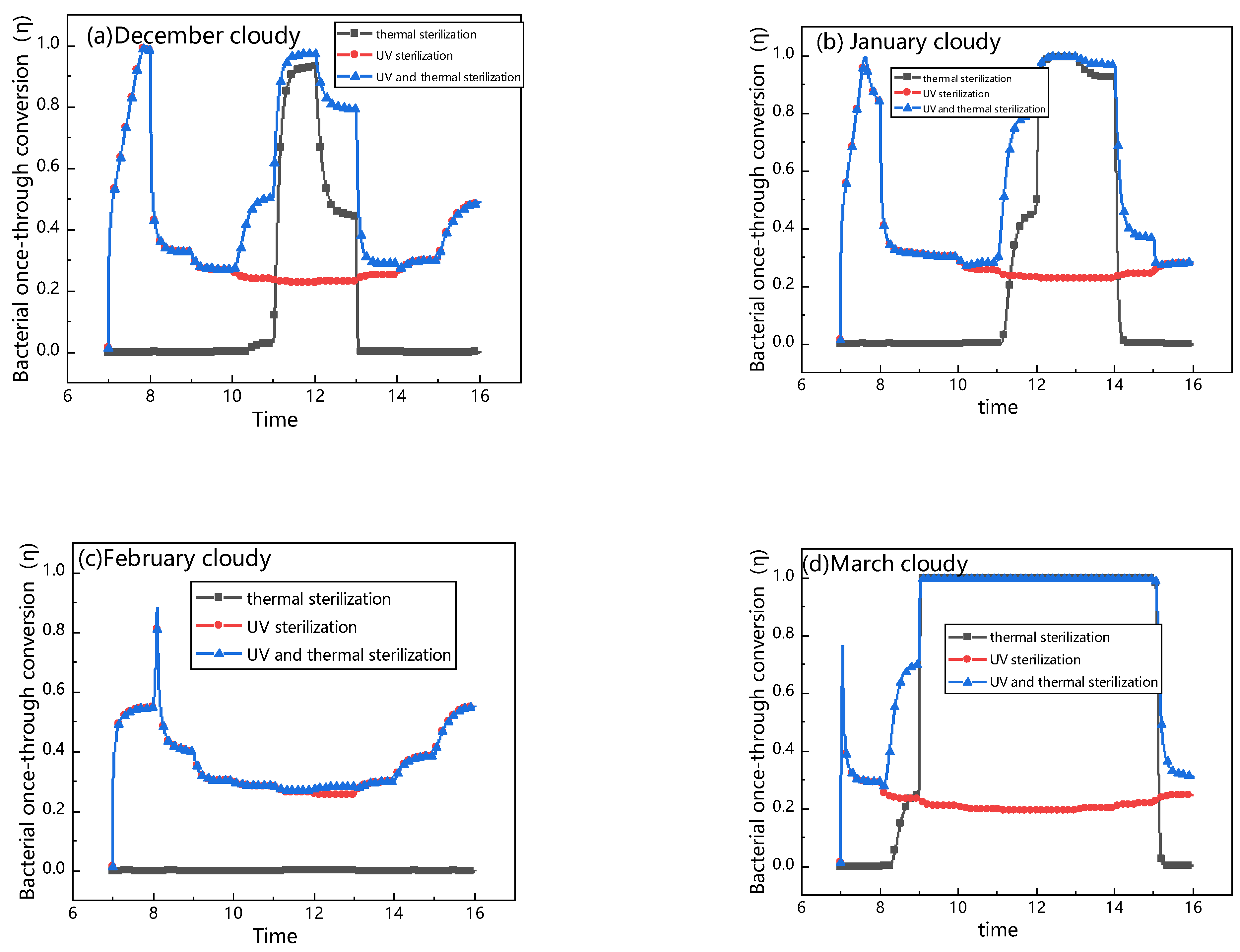

4.2. Sterilization Performances in Different Weather Conditions

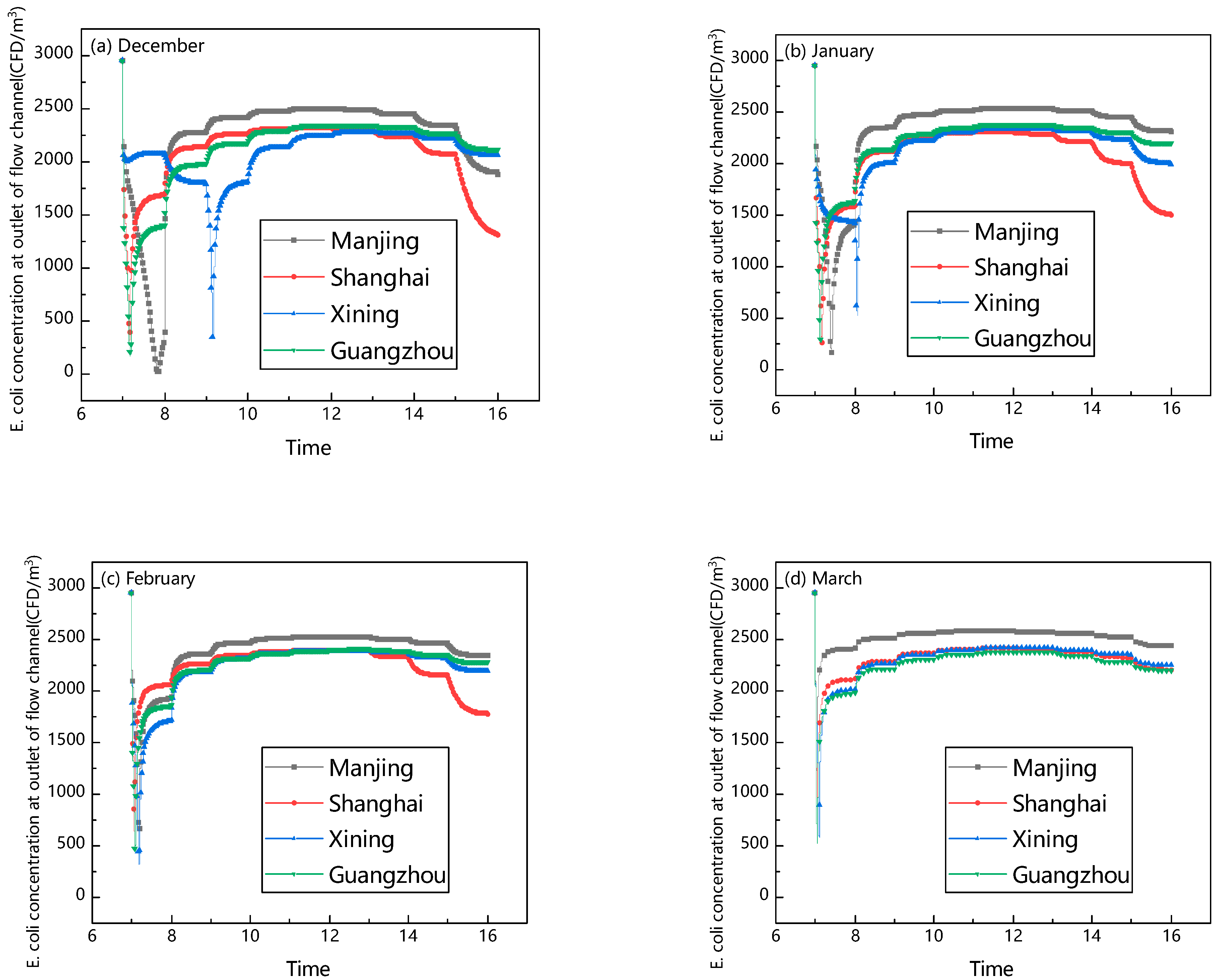

4.3. Sterilization Performances in Different Cities

4.4. Effect of Wall Height on System Performance

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | area, m2 |

| c | specific heat capacity, J/(kg·K) |

| f | resistance factor |

| I | solar irradiance, W/m2 |

| H | height, m |

| h | heat transfer coefficient, W/(m2·K) |

| N | bacterial concentration, CFD/m3 |

| Nu | nusslet number |

| Q | volume flow rate, m3/s |

| Ra | Rayleigh number |

| r | sterilization ratio CFD/m3 |

| T | temperature, K |

| t | time, s |

| residence time, s | |

| u | air velocity, m/s |

| V | volume, m3 |

| E | UV radiation dose, J/m3 |

| Greeks | |

| ρ | density, kg/m3 |

| λ | thermal conductivity, W/(m·K) |

| σ | Stefan–Boltzmann constant, W/(m2·K4) |

| α | absorptivity |

| τ | residence time, s |

| η | bacterial once-through conversion |

| β | expansion coefficient, 1/K |

| Subscripts | |

| amb | ambient |

| g | glass cover |

| ab | absorber layer |

| sky | sky |

| a | air |

| w | thermal storage wall |

| r | room |

| in | inlet |

| out | outlet |

| UV | ultraviolet light |

| Abbreviation | |

| CADR | clean air delivery rate |

References

- Pei, J.; Qu, M.; Sun, L.; Wang, X.; Yin, Y. The relationship between indoor air quality (IAQ) and perceived air quality (PAQ)—A review and case analysis of Chinese residential environment. Energy Built Environ. 2022, 5, 230–243. [Google Scholar] [CrossRef]

- Zheng, H.; Long, E.; Cheng, Z.; Yang, Z.; Jia, Y. Experimental exploration on airtightness performance of residential buildings in the hot summer and cold winter zone in China. Build. Environ. 2022, 214, 108848. [Google Scholar] [CrossRef]

- Abdullatif, Y.M.; Sodiq, A.; Al-Ansari, T.; Nassar, N.N.; Amhamed, A.I. Optimizing chemisorption based direct air capture unit efficiency in HVAC systems: A study on the impact of DAC location and adsorption conditions as a response to the climate crisis and indoor air quality. Energy Convers. Manag. 2023, 291, 117280. [Google Scholar] [CrossRef]

- Liu, Z.; Ma, S.; Cao, G.; Meng, C.; He, B.-J. Distribution characteristics, growth, reproduction and transmission modes and control strategies for microbial contamination in HVAC systems: A literature review. Energy Build. 2018, 177, 77–95. [Google Scholar] [CrossRef]

- Paleologos, K.E.; Selim, M.Y.E.; Mohamed, A.-M.O. Chapter 8—Indoor air quality: Pollutants, health effects, and regulations. In Pollution Assessment for Sustainable Practices in Applied Sciences and Engineering; Mohamed, A.-M.O., Paleologos, E.K., Howari, F.M., Eds.; Butterworth-Heinemann: Oxford, UK, 2021; pp. 405–489. [Google Scholar] [CrossRef]

- Wei, G.; Yu, X.; Fang, L.; Wang, Q.; Tanaka, T.; Amano, K.; Yang, X. A review and comparison of the indoor air quality requirements in selected building standards and certifications. Build. Environ. 2022, 226, 109709. [Google Scholar] [CrossRef]

- Liu, Y.; Huo, C.; Wang, X.; Liu, D.; Liu, Y.; Wang, X.; Xu, C.; Li, M.; Lu, D.; Ren, R.; et al. Effects of high hydrostatic pressure sterilisation and thermal sterilisation combined with glutamine transaminase treatment on the properties of yoghurt. Int. Dairy J. 2024, 149, 105808. [Google Scholar] [CrossRef]

- Lewis, M. Chapter 22—Thermal processing: Pasteurisation and sterilisation. In Food Process Engineering Principles and Data; Lewis, M., Ed.; Woodhead Publishing: Sawston, UK, 2023; pp. 197–205. [Google Scholar] [CrossRef]

- Bharti, B.; Li, H.; Ren, Z.; Zhu, R.; Zhu, Z. Recent advances in sterilization and disinfection technology: A review. Chemosphere 2022, 308, 136404. [Google Scholar] [CrossRef] [PubMed]

- McGuigan, K.; Joyce, T.M.; Conroy, R.M.; Gillespie, J.; Elmore-Meegan, M. Solar disinfection of drinking water contained in transparent plastic bottles: Characterizing the bacterial inactivation process. J. Appl. Microbiol. 1998, 84, 1138–1148. [Google Scholar] [CrossRef] [PubMed]

- Jin, Y.; Wang, Y.; Huang, Q.; Zhu, L.; Cui, Y.; Cui, L. The performance and applicability study of a fixed photovoltaic-solar water disinfection system. Energy Convers. Manag. 2016, 123, 549–558. [Google Scholar] [CrossRef]

- Jung, J.H.; Lee, J.E.; Kim, S.S. Thermal effects on bacterial bioaerosols in continuous air flow. Sci. Total Environ. 2009, 407, 4723–4730. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Zhao, X.; Shen, J.; Hu, X.; Liu, X.; Xu, J. Design, fabrication and experimental study of a solar photovoltaic/loop-heat-pipe based heat pump system. Sol. Energy 2013, 97, 551–568. [Google Scholar] [CrossRef]

- Damit, B.; Wu, C.-Y.; Yao, M. Ultra-high temperature infrared disinfection of bioaerosols and relevant mechanisms. J. Aerosol Sci. 2013, 65, 88–100. [Google Scholar] [CrossRef]

- Li, X.; Cai, M.; Wang, L.; Niu, F.; Yang, D.; Zhang, G. Evaluation survey of microbial disinfection methods in UV-LED water treatment systems. Sci. Total Environ. 2019, 659, 1415–1427. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.-P.; Liao, J.-Y. Effect of UV-C LED arrangement on the sterilization of Escherichia coli in planar water disinfection reactors. J. Water Process Eng. 2023, 56, 104399. [Google Scholar] [CrossRef]

- Hwang, G.B.; Jung, J.H.; Jeong, T.G.; Lee, B.U. Effect of hybrid UV-thermal energy stimuli on inactivation of S. epidermidis andB. subtilis bacterial bioaerosols. Sci. Total Environ. 2010, 408, 5903–5909. [Google Scholar] [CrossRef] [PubMed]

- Balamurugan, S.; Zaidi, M.; Arvaj, L.; Pendyala, B.; Gabriel, M.; Farber, J.M.; Sasges, M.; Patras, A. Modeling the UV-C Inactivation Kinetics and Determination of Fluence Required for Incremental Inactivation of Cronobacter spp. J. Food Prot. 2022, 85, 1625–1634. [Google Scholar] [CrossRef] [PubMed]

- Ye, S.; Li, Y.; Huang, H.; Xu, Y.; Du, S.; Wan, F.; Xie, R.; Huang, P.; Liu, B.; Dong, T.; et al. Fast and deep disinfection for face masks recycle using vacuum ultraviolet irradiation. J. Clean. Prod. 2022, 368, 133221. [Google Scholar] [CrossRef]

- Kanaan, M. CFD optimization of return air ratio and use of upper room UVGI in combined HVAC and heat recovery system. Case Stud. Therm. Eng. 2019, 15, 100535. [Google Scholar] [CrossRef]

- Keklik, N.M.; Demirci, A.; Puri, V.M.; Heinemann, P.H. Modeling the Inactivation of Salmonella Typhimurium, Listeria monocytogenes, and Salmonella Enteritidis on Poultry Products Exposed to Pulsed UV Light. J. Food Prot. 2012, 75, 281–288. [Google Scholar] [CrossRef] [PubMed]

- Gayán, E.; Serrano, M.J.; Álvarez, I.; Condón, S. Modeling optimal process conditions for UV-heat inactivation of foodborne pathogens in liquid foods. Food Microbiol. 2016, 60, 13–20. [Google Scholar] [CrossRef] [PubMed]

- Shen, J.; Lassue, S.; Zalewski, L.; Huang, D. Numerical study of classical and composite solar walls by TRNSYS. J. Therm. Sci. 2007, 16, 46–55. [Google Scholar] [CrossRef]

- Omrany, H.; Ghaffarianhoseini, A.; Ghaffarianhoseini, A.; Raahemifar, K.; Tookey, J. Application of passive wall systems for improving the energy efficiency in buildings: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 62, 1252–1269. [Google Scholar] [CrossRef]

- Sun, W.; Ji, J.; Luo, C.; He, W. Performance of PV-Trombe wall in winter correlated with south façade design. Appl. Energy 2011, 88, 224–231. [Google Scholar] [CrossRef]

- Shen, J.; Lassue, S.; Zalewski, L.; Huang, D. Numerical study on thermal behavior of classical or composite Trombe solar walls. Energy Build. 2007, 39, 962–974. [Google Scholar] [CrossRef]

- Saadatian, O.; Sopian, K.; Lim, C.H.; Asim, N.; Sulaiman, M.Y. Trombe walls: A review of opportunities and challenges in research and development. Renew. Sustain. Energy Rev. 2012, 16, 6340–6351. [Google Scholar] [CrossRef]

- Tunç, M.; Uysal, M. Passive solar heating of buildings using a fluidized bed plus Trombe wall system. Appl. Energy 1991, 38, 199–213. [Google Scholar] [CrossRef]

- Yu, B.; Jiang, Q.; He, W.; Hu, Z.; Chen, H.; Ji, J.; Xu, G. The performance analysis of a novel TC-Trombe wall system in heating seasons. Energy Convers. Manag. 2018, 164, 242–261. [Google Scholar] [CrossRef]

- Guo, S.-R.; Jiang, X.-C.; Jia, Y.-H.; Xiang, M.-L.; Liao, Y.-X.; Zhang, W.-T.; Huang, R.-Y.; Long, E.-S. Experimental and numerical study on indoor thermal environment of solar Trombe walls with different air-channel thicknesses in plateau. Int. J. Therm. Sci. 2023, 193, 108469. [Google Scholar] [CrossRef]

- Yu, B.; He, W.; Li, N.; Wang, L.; Cai, J.; Chen, H.; Ji, J.; Xu, G. Experimental and numerical performance analysis of a TC-Trombe wall. Appl. Energy 2017, 206, 70–82. [Google Scholar] [CrossRef]

- Gu, W.; Li, G.; Xiermaimaiti, A.; Ma, T. A review of recent techniques in performance augmentation and evaluation metrics of Trombe walls. Energy Build. 2023, 301, 113693. [Google Scholar] [CrossRef]

- Yu, B.; Li, N.; Xie, H.; Ji, J. The performance analysis on a novel purification-cleaning trombe wall based on solar thermal sterilization and thermal catalytic principles. Energy 2021, 225, 120275. [Google Scholar] [CrossRef]

- Yu, B.; Li, N.; Yan, C.; Liu, X.; Liu, H.; Ji, J.; Xu, X. The comprehensive performance analysis on a novel high-performance air-purification-sterilization type PV-Trombe wall. Renew. Energy 2022, 182, 1201–1218. [Google Scholar] [CrossRef]

- Swinbank, W.C. Long-wave radiation from clear skies. Q. J. R. Meteorol. Soc. 1963, 89, 339–348. [Google Scholar] [CrossRef]

- Pakowski, Z. Fundamentals of Heat and Mass Transfer, Frank P Incropera, David P DeWitt, Theodore L Bergman, Adrienne S Lavine, J. Wiley & Sons, Hoboken NJ (2007), 997 pp. Chem. Eng. Res. Des. 2007, 85, 1683–1684. [Google Scholar] [CrossRef]

- Khalifa, A.J.N.; Marshall, R.H. Validation of heat transfer coefficients on interior building surfaces using a real-sized indoor test cell. Int. J. Heat Mass Transf. 1990, 33, 2219–2236. [Google Scholar] [CrossRef]

- Mastwijk, H.C.; Timmermans, R.A.H.; Van Boekel, M.A.J.S. The Gauss-Eyring model: A new thermodynamic model for biochemical and microbial inactivation kinetics. Food Chem. 2017, 237, 331–341. [Google Scholar] [CrossRef] [PubMed]

- Timmermans, R.A.H.; Mastwijk, H.C.; Nierop Groot, M.N.; Van Boekel, M.A.J.S. Evaluation of the Gauss-Eyring model to predict thermal inactivation of micro-organisms at short holding times. Int. J. Food Microbiol. 2017, 263, 47–60. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Lu, S.; Zhang, Z. Inactivation of airborne bacteria using different UV sources: Performance modeling, energy utilization, and endotoxin degradation. Sci. Total Environ. 2019, 655, 787–795. [Google Scholar] [CrossRef] [PubMed]

- Pousty, D.; Hofmann, R.; Gerchman, Y.; Mamane, H. Wavelength-dependent time–dose reciprocity and stress mechanism for UV-LED disinfection of Escherichia coli. J. Photochem. Photobiol. B Biol. 2021, 217, 112129. [Google Scholar] [CrossRef] [PubMed]

| Part | Symbol | Item | Unit | Value |

|---|---|---|---|---|

| Glass cove | ρg | Density | kg/m3 | 2500 |

| cg | Specific heat capacity | J/(kg·K) | 840 | |

| ag | Emissivity | - | 0.1 | |

| τg | Refractive index | - | 0.9 | |

| εg | Extinction coefficient | - | 0.9 | |

| absorber layer | ρal | Emissivity | kg/m3 | 1287 |

| cal | Refractive index | J/(kg·K) | 900 | |

| λal | Extinction coefficient | W/(m·K) | 112 | |

| αab | Emissivity | - | 0.94 | |

| εab | Refractive index | - | 0.94 | |

| Air flow channel | ρa | Density | kg/m3 | 1.18 |

| ca | Specific heat capacity | J/(kg·K) | 1100 | |

| λa | Thickness | m | 0.04 | |

| νa | Thermal conductivity | W/(m·K) | 0.026 | |

| Massive wall | Density | kg/m3 | 1800 | Massive wall |

| Specific heat capacity | J/(kg·K) | 840 | 9.0 | |

| Thickness | m | 0.3 | 8 |

| Apparatus | Accuracy |

|---|---|

| Hot-wire anemometer KANOMAX | ±0.01 m/s |

| Copper–constantan thermocouple thermometer | ±0.5 °C |

| Solar pyranometer TBQ-2 | ±11.04 μv/(W m2) |

| Data acquisition 34970A | – |

| Air flow meter LZB-3W | ±2.4 mL/min |

| Sterilizing Methods | Month | Maximum Daily Once-Through Conversion η (%) | Volume of Clean Air Content Produced by Day (m3/Day) | Volume of Clean Air Content Produced by Month (m3) | ||

|---|---|---|---|---|---|---|

| Sunny | Cloudy | Sunny | Cloudy | |||

| thermal sterilization | December | 0.02 | 0 | 0.002 | 0 | 38.5 |

| January | 28.5 | 0 | 10.8 | 0 | 86.4135 | |

| February | 6.5 | 0 | 1.5 | 0.0 | 66 | |

| March | 100.0 | 100.0 | 142.0 | 136.6 | 1808.2 | |

| UV sterilization | December | 16.5 | 16.60 | 34.0 | 34.0 | 782 |

| January | 15.5 | 16.3 | 34.0 | 33.5 | 774.5 | |

| February | 15.7 | 18.5 | 34.5 | 33.1 | 667.6 | |

| March | 14.3 | 14.2 | 35.5 | 35.4 | 460.8 | |

| UV and thermal sterilization | December | 21.8 | 21.2 | 35.1 | 36.2 | 820.5 |

| January | 68.4 | 24.7 | 63.5 | 37.3 | 1067.5 | |

| February | 49.4 | 18.7 | 50.8 | 33.2 | 734.4 | |

| March | 100.0 | 100.0 | 165.8 | 161.6 | 2126 | |

| Sterilizing Methods | Month | Maximum Daily Once-Through Conversion η (%) | Volume of Clean Air Content Produced by Day (m3/Day) | Volume of Clean Air Content Produced by Month (m3) | ||

|---|---|---|---|---|---|---|

| Sunny | Cloudy | Sunny | Cloudy | |||

| thermal sterilization | December | 93.1 | 88.3 | 33.4 | 36.3 | 803 |

| January | 100.0 | 99.6 | 103.4 | 56.3 | 1671.7 | |

| February | 100.0 | 0.0 | 97.1 | 0.0 | 388.4 | |

| March | 100.0 | 100.0 | 193.7 | 177.0 | 2401.2 | |

| UV sterilization | December | 22.8 | 22.7 | 46.6 | 48.3 | 1092.2 |

| January | 21.5 | 22.5 | 48.4 | 47.4 | 1098.2 | |

| February | 21.7 | 25.4 | 49.2 | 41.4 | 859.2 | |

| March | 21.5 | 21.5 | 51.3 | 51.1 | 665.5 | |

| UV and thermal sterilization | December | 97.4 | 95.7 | 84.8 | 91.0 | 2024.8 |

| January | 100.0 | 99.8 | 134.2 | 101.6 | 2597.6 | |

| February | 100.0 | 28.3 | 130.7 | 47.2 | 1278 | |

| March | 100.0 | 100.0 | 207.9 | 199.9 | 2646.7 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, M.; Li, N.; Yu, B. The Performance Analysis of a Novel Sterilizable Trombe Wall Based on the Combined Effect of Heat and UV Light. Buildings 2024, 14, 1210. https://doi.org/10.3390/buildings14051210

Fan M, Li N, Yu B. The Performance Analysis of a Novel Sterilizable Trombe Wall Based on the Combined Effect of Heat and UV Light. Buildings. 2024; 14(5):1210. https://doi.org/10.3390/buildings14051210

Chicago/Turabian StyleFan, Miaomiao, Niansi Li, and Bendong Yu. 2024. "The Performance Analysis of a Novel Sterilizable Trombe Wall Based on the Combined Effect of Heat and UV Light" Buildings 14, no. 5: 1210. https://doi.org/10.3390/buildings14051210