Environmental Impact Assessment of a School Building in Iceland Using LCA-Including the Effect of Long Distance Transport of Materials

Abstract

:1. Introduction

2. Research Method

- Goal and scope outlines the envisioned application, the motivations for conducting a study, defines the methodological framework to satisfy the intended goals, outlines the boundary of the system and defines impact assessment methodology [33].

- Inventory analysis captures all inputs and all outputs that cross the selected system boundary.

- The Life Cycle Impact Assessment (LCIA) recognizes and estimates the extent and importance of the environmental impacts. Several methods are available [31], of which the most popular include:

- ○

- ○

- Eco-indicator 99 allows the calculation of single-point eco-indicator score that can support designers in decision-making [36].

- ○

- Interpretation depicts the results of the inventory analysis and/or impact assessment to reach clear, defensible conclusions.

3. Research Design

3.1. Goal and Scope Definition

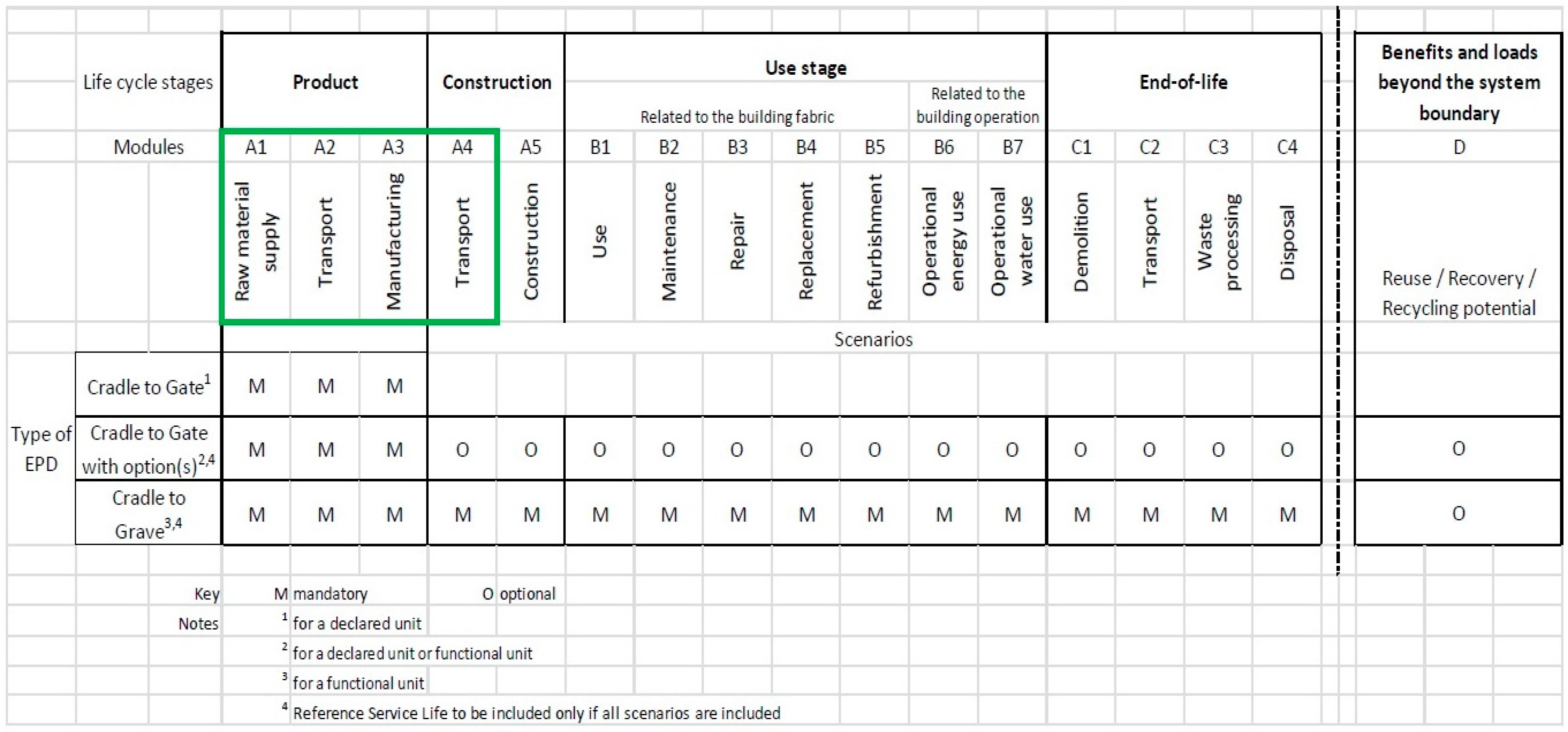

3.2. System Boundaries

3.3. Inventory

3.4. Impact Assessment

4. Results

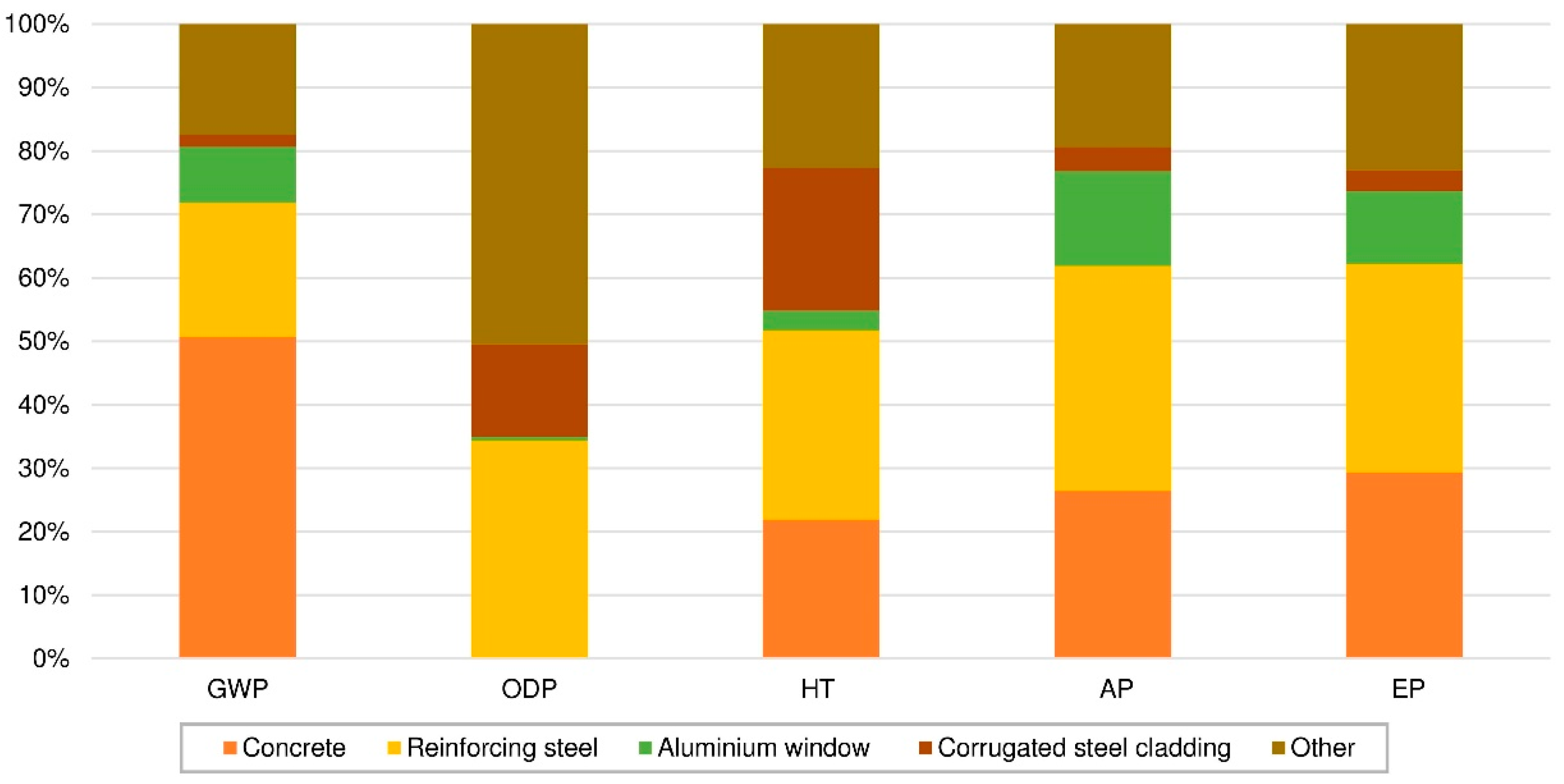

4.1. Overall Environmental Impacts

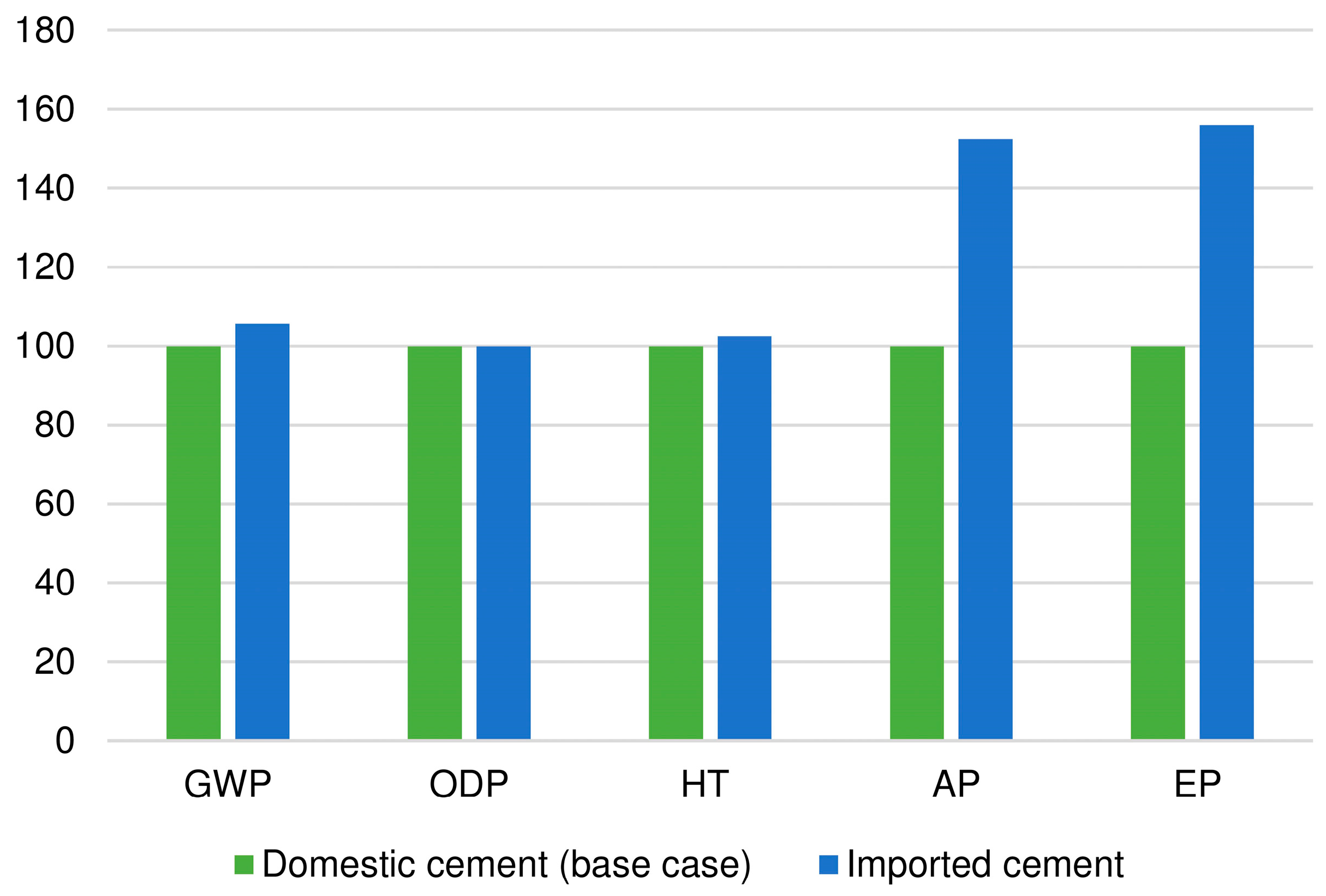

4.2. Transportation

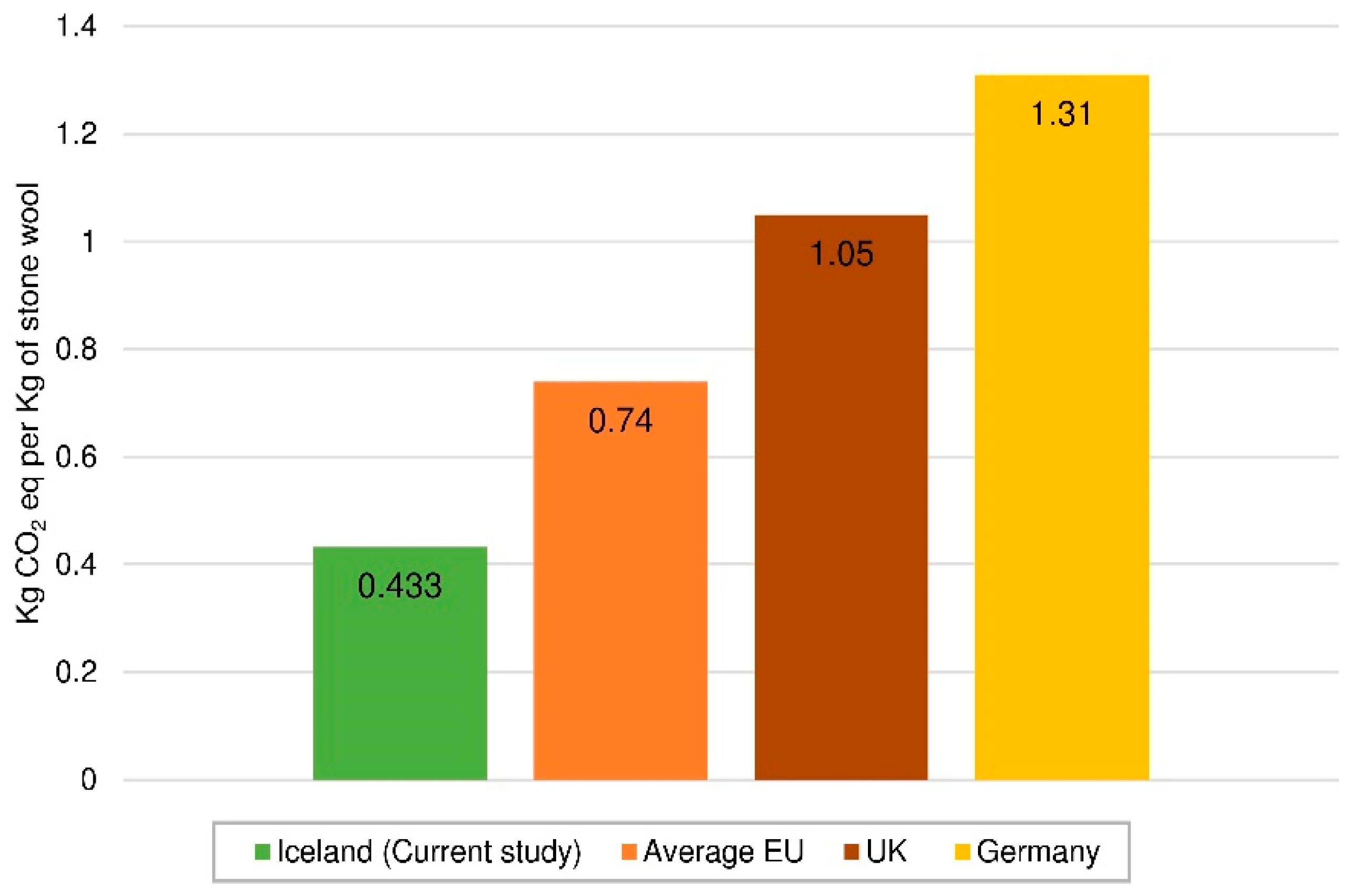

4.3. Inter-Study Comparison of the GWP Impact Assessment

5. Discussion and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- International Energy Agency Publications (IEA). Transition to Sustainable Buildings—Strategies and Oppurtunities to 2050; International Energy Agency Publications: Paris, France, 2013. [Google Scholar]

- Rode, P.; Burdett, R.; Soares, J.C. Buildings: Investing in energy and resource efficiency Book section. In Towards a Green Economy: Pathways to Sustainable Development and Poverty Eradication; United Nations Environment Programme: Washington, DC, USA, 2011; pp. 331–373. [Google Scholar]

- Intergovernmental Panel on Climate Change (IPCC). Managing the Risks of Extreme Events and Disasters to Advance Climate Change Adaptation; Field, C.B., Barros, V., Stocker, T.F., Qin, D., Dokken, D.J., Ebi, K.L., Mastrandrea, M.D., Mach, K.J., Plattner, G.-K., Allen, S.K., et al., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2012. [Google Scholar]

- The European Parliament and the Council of the European Union. Directive 2010/31/EU of the European Parliament and of the Council on the Energy Performance of Buildings (Recast); Official Journal of the European Union: Luxembourg, 2010; Volume 153, pp. 13–35. [Google Scholar]

- The European Parliament and the Council of the European Union. Directive 2012/27/EU of the European Parliament and of the Council of 25 October 2012 on Energy Efficiency, Amending Directives 2009/125/EC and 2010/30/EU and Repealing Directives 2004/8/EC and 2006/32/EC; Official Journal of the European Union: Luxembourg, 2012. [Google Scholar]

- Chastas, P.; Theodosiou, T.; Bikas, D. Embodied energy in residential buildings-towards the nearly zero energy building: A literature review. Build. Environ. 2016, 105, 267–282. [Google Scholar] [CrossRef]

- Säynäjoki, A.; Heinonen, J.; Junnila, S. A scenario analysis of the life cycle greenhouse gas emissions of a new residential area. Environ. Res. Lett. 2012, 7, 034037. [Google Scholar] [CrossRef]

- Isaksson, C.; Karlsson, F. Indoor climate in low-energy houses-an interdisciplinary investigation. Build. Environ. 2006, 41, 1678–1690. [Google Scholar] [CrossRef]

- Karlsson, J.; Roos, A.; Karlsson, B. Building and climate influence on the balance temperature of buildings. Build. Environ. 2003, 38, 75–81. [Google Scholar] [CrossRef]

- Tingley, D.D.; Davison, B. Design for deconstruction and material reuse. Proc. Inst. Civ. Eng. 2011, 164, 195–204. [Google Scholar] [CrossRef]

- Georgiadou, M. Future-Proofed Energy Design Approaches for Achieving Low-Energy Homes: Enhancing the Code for Sustainable Homes. Buildings 2014, 4, 488–519. [Google Scholar] [CrossRef]

- Minx, J.C.; Baiocchi, G.; Peters, G.P.; Weber, C.L.; Guan, D.; Hubacek, K. A “Carbonizing Dragon”: China’s Fast Growing CO2 Emissions Revisited. Environ. Sci. Technol. 2011, 45, 9144–9153. [Google Scholar] [CrossRef] [PubMed]

- Thormark, C. A low energy building in a life cycle—Its embodied energy, energy need for operation and recycling potential. Build. Environ. 2002, 37, 429–435. [Google Scholar] [CrossRef]

- Rawlinson, S.; Weight, D. Sustainability—Embodied carbon. Building 2007, 41, 88–91. [Google Scholar]

- Sturgis, S.; Roberts, G. Redefining Zero: Carbon Profiling as a Solution to Whole Life Carbon Emission Measurement in Buildings; RICS Research: London, UK, 2010. [Google Scholar]

- Rossi, B.; Marique, A.F.; Glaumann, M.; Reiter, S. Life-cycle assessment of residential buildings in three different European locations, basic tool. Build. Environ. 2012, 51, 395–401. [Google Scholar] [CrossRef]

- Salcido, J.C.; Raheem, A.A.; Ravi, S. Comparison of embodied energy and environmental impact of alternative materials used in reticulated dome construction. Build. Environ. 2016, 96, 22–34. [Google Scholar] [CrossRef]

- Morel, J.C.; Mesbah, A.; Oggero, M.; Walker, P. Building houses with local materials: Means to drastically reduce the environmental impact of construction. Build. Environ. 2001, 36, 1119–1126. [Google Scholar] [CrossRef]

- González, M.J.; García Navarro, J. Assessment of the decrease of CO2 emissions in the construction field through the selection of materials: Practical case study of three houses of low environmental impact. Build. Environ. 2006, 41, 902–909. [Google Scholar] [CrossRef]

- Thormark, C. The effect of material choice on the total energy need and recycling potential of a building. Build. Environ. 2006, 41, 1019–1026. [Google Scholar] [CrossRef]

- Utama, N.A.; Mclellan, B.C.; Gheewala, S.H.; Ishihara, K.N. Embodied impacts of traditional clay versus modern concrete houses in a tropical regime. Build. Environ. 2012, 57, 362–369. [Google Scholar] [CrossRef]

- Du, P.; Wood, A.; Stephens, B.; Song, X. Life-Cycle Energy Implications of Downtown High-Rise vs. Suburban Low-Rise Living: An Overview and Quantitative Case Study for Chicago. Buildings 2015, 5, 1003–1024. [Google Scholar] [CrossRef]

- Khasreen, M.M.; Banfill, P.F.G.; Menzies, G.F. Life-Cycle Assessment and the Environmental Impact of Buildings: A Review. Sustainability 2009, 1, 674–701. [Google Scholar] [CrossRef]

- Robertson, A.B.; Lam, F.C.F.; Cole, R.J. A Comparative Cradle-to-Gate Life Cycle Assessment of Mid-Rise Office Building Construction Alternatives: Laminated Timber or Reinforced Concrete. Buildings 2012, 2, 245–270. [Google Scholar] [CrossRef]

- Blengini, G.A.; Di Carlo, T. Energy-saving policies and low-energy residential buildings: An LCA case study to support decision makers in piedmont (Italy). Int. J. Life Cycle Assess. 2010, 15, 652–665. [Google Scholar] [CrossRef]

- Passer, A.; Kreiner, H.; Maydl, P. Assessment of the environmental performance of buildings: A critical evaluation of the influence of technical building equipment on residential buildings. Int. J. Life Cycle Assess. 2012, 17, 1116–1130. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; Garcia-Martinez, A. Simplification in life cycle assessment of single-family houses: A review of recent developments. Build. Environ. 2016, 103, 215–227. [Google Scholar] [CrossRef]

- Kellenberger, D.; Althaus, H.J. Relevance of simplifications in LCA of building components. Build. Environ. 2009, 44, 818–825. [Google Scholar] [CrossRef]

- Heinonen, J.; Säynäjoki, A.; Junnonen, J.-M.; Pöyry, A.; Junnila, S. Pre-use phase LCA of a multi-story residential building: Can greenhouse gas emissions be used as a more general environmental performance indicator? Build. Environ. 2016, 95, 116–125. [Google Scholar] [CrossRef]

- Sand, H.; Hjorth, K.L.; Nittegaard, C.B. Survey of Green Legislation and Standards in the Construction Area in the Nordic Countries; Nordic Council of Ministers: Copenhagen, Denmark, 2012. [Google Scholar]

- Vífilsdóttir, H.; Bjarnadóttir, H.J.; Kadmark, L.; Sigurðardóttir, K.; Jónsdóttir, S.B. Vistvottunarkerfi Fyrir Byggingar-Greining á Hagkvæmni og Aðlögunarhæfni Erlendra Vottunarkerfa Fyrir Íslenskan Byggingarmarkað, (Ecological Certification System for Architectural Analysis of the Efficiency and Adaptability of Foreign Certification System; Vistbyggðarráð: Reykjavik, Iceland, 2013. [Google Scholar]

- IOS 14044 Environmental Management—Life Cycle Assessment: Requirements and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2006.

- IOS 14040 Environmental Management—Life Cycle Assessment: Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006.

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; de Koning, A.; van Oers, L.; Wegener Sleeswijk, A.; Suh, S.; Udo de Haes, H.A.; et al. Handbook on Life cycle Assessment. Operational Guide to the ISO Standards. I: LCA in Perspective. IIa: Guide. IIb: Operational Annex. III: Scientific Background; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002. [Google Scholar]

- Heijungs, R.; Guinée, J.; Huppes, G.; Lankreijer, R.M.; Udo de Haes, H.A.; Wegener Sleeswijk, A.; Ansems, A.M.M.; Eggels, P.G.; van Duin, R.; de Goede, H.P. Environmental Life Cycle Assessment of Products—Guide and Backgrounds; Institute of Environmental Sciences (CML): Leiden, The Netherlands, 1992. [Google Scholar]

- Goedkoop, M.; Spriensma, R. The Eco-indicator 99—A Damage-Oriented Method for Life Cycle Impact Assessment; Methodology Report; Product Ecology Consultants: Amersfoort, The Netherlands, 2000. [Google Scholar]

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; De Schryver, A.; Struijs, J.; ZelmR, V. ReCiPe 2008. A life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level; Rijksinstituut voor Volksgezondheid en Milieu: Bilthoven, The Netherlands, 2009. [Google Scholar]

- De Schryver, A.M.; Brakkee, K.W.; Goedkoop, M.J.; Huijbregts, M.A.J. Characterization factors for global warming in life cycle assessment based on damages to humans and ecosystems. Environ. Sci. Technol. 2009, 43, 1689–1695. [Google Scholar] [CrossRef] [PubMed]

- Curran, M.A. Life Cycle Assessment Handbook: A Guide for Environmentally Sustainable Products; John Wiley & Sons.: New York, NY, USA, 2012. [Google Scholar]

- European Conmmission JRC (EC-JRC). International Reference Life Cycle Data System (ILCD) Handbook—General Guide for Life Cycle Assessment—Detailed Guidance; European Conmmission JRC: Luxembourg, 2010. [Google Scholar]

- EN 15804:2012+A1 Sustainability of Construction Works. Environmental Product Declarations. Core Rules for the Product Category of Construction Products; U.S. Green Building Council: Atlanta, GA, USA, 2012.

- Marteinsson, B. Materials and energy use in buildings. In Proceedings of the 9th International Conference on Durability of Building Materials and Components, Brisbane, Australia, 17–21 March 2002.

- Úlfarsson, S.O. Vistferilsgreining á Timbureiningahúsi frá Vöggu til Grafar (Life Cycle Assessment of a Timber House from Cradle to Grave); University of Iceland: Reykjavík, Iceland, 2011. [Google Scholar]

- Emami, N. Environmental Impact Assessment of a School Building in Iceland Using Life Cycle Analysis; Case Study of the Vættaskóli-Engi Building; University of Iceland: Reykjavík, Iceland, 2016. [Google Scholar]

- Breiðfjörð, K. Byggingarefni á Íslandi. Uppruni, Flutningar til Landsins Ásamt kolefnisspori Timburs (Building Materials in Iceland. Origin, Transportation to the Country Together with the Carbon Footprint of Timber); University of Iceland: Reykjavík, Iceland, 2011. [Google Scholar]

- Hammond, G.P.; Jones, C.I. Embodied energy and carbon in construction materials. Proc. Inst. Civ. Eng. Energy 2008, 161, 87–98. [Google Scholar] [CrossRef] [Green Version]

- Steinull H.F. Available online: http://steinull.is/mineral-fiber-insulation (accessed on 10 June 2016).

- PE-International GaBi: Product Sustainability Software. Version 6.0. Available online: www.gabi-software.com/ (accessed on 15 February 2016).

- Herrmann, I.T.; Moltesen, A. Does it matter which Life Cycle Assessment (LCA) tool you choose?—A comparative assessment of SimaPro and GaBi. J. Clean. Prod. 2015, 86, 163–169. [Google Scholar] [CrossRef]

- Junnila, S.; Horvath, A. Life-Cycle Environmental Effects of an Office Building. J. Infrastruct. Syst. 2003, 9, 157–166. [Google Scholar] [CrossRef]

- Junnila, S.; Horvath, A.; Guggemos, A.A. Life-Cycle Assessment of Office Buildings in Europe and the United States. J. Infrastruct. Syst. 2006, 12, 10–17. [Google Scholar] [CrossRef]

- Biswas, W.K. Carbon footprint and embodied energy assessment of a civil works program in a residential estate of Western Australia. Int. J. Life Cycle Assess. 2014, 19, 732–744. [Google Scholar] [CrossRef]

- BS EN 1994-1-1 Eurocode 4. Design of Composite Steel and Concrete Structures. General Rules and Rules for Buildings; The British Standards Institution (BIS): London, UK, 2004.

- Suh, S.; Lenzen, M.; Treloar, G.J.; Hondo, H.; Horvath, A.; Huppes, G.; Jolliet, O.; Klann, U.; Krewitt, W.; Moriguchi, Y.; et al. System boundary selection in life-cycle inventories using hybrid approaches. Environ. Sci. Technol. 2004, 38, 657–664. [Google Scholar] [CrossRef] [PubMed]

- Matthews, H.S.; Hendrickson, C.T.; Weber, C.L. The importance of carbon footprint estimation boundaries. Environ. Sci. Technol. 2008, 42, 5839–5842. [Google Scholar] [CrossRef] [PubMed]

- Lenzen, M. Errors in Conventional and Input-Output—Based Life-Cycle Inventories. J. Ind. Ecol. 2001, 4, 127–148. [Google Scholar] [CrossRef]

- Fuller, R.J.; Crawford, R.H. Impact of past and future residential housing development patterns on energy demand and related emissions. J. Hous. Built Environ. 2011, 26, 165–183. [Google Scholar] [CrossRef]

- Polasky, S.; Carpenter, S.R.; Folke, C.; Keeler, B. Decision-making under great uncertainty: Environmental management in an era of global change. Trends Ecol. Evol. 2011, 26, 398–404. [Google Scholar] [CrossRef] [PubMed]

- Säynäjoki, A. How Does the Construction of a Residential Area Contribute to Climate Change?—Timing Reveals New Perspectives to Climate Change Mitigation; Aalto University: Espoo, Finland, 2015. [Google Scholar]

| Building Materials | Quantities | Unit | Density (kg/m3) | Export Country |

|---|---|---|---|---|

| Reinforcing steel | 175,000.0 | kg | Lithuania | |

| Reinforcing mat | 17,197.8 | kg | Lithuania | |

| Concrete | 2505.0 | m3 | 2278 | Iceland |

| Glued laminated timber | 15.42 | m3 | 515 | Norway |

| Corrugated steel cladding | 2820 | m2 | 7850 | Finland |

| Insulation, hard pressed stone wool | 12.3 | m3 | 100 | Iceland |

| Insulation, hard pressed stone wool | 306.8 | m3 | 80 | Iceland |

| Insulation lightweight stone wool | 234.4 | m3 | 32 | Iceland |

| Polyethylene, high density | 575 | m2 | 950 | Germany |

| Gypsum plaster board | 8908.0 | m2 | 800 | Denmark |

| Aluminum window | 625 | m2 | Germany | |

| Expanded Polystyrene | 210.0 | m2 | 25 | Germany |

| Extruded polystyrene | 400.5 | m3 | 32 | Germany |

| Underroof membrane | 2670.0 | m2 | Germany | |

| Plywood board | 13.4 | m3 | 575 | Finland |

| Built-up asphalt | 3845.0 | m2 | Denmark | |

| Concrete roofing tile | 131.8 | m3 | 2100 | Iceland |

| Plaster | 148.6 | m3 | 2000 | Iceland |

| Paint | 2.1 | m3 | 1350 | Norway |

| Flow | Amount | Unit | Embodied Energy (MJ/kg) |

|---|---|---|---|

| Cement (CEM I 32.5) | 0.1334 | kg | 3.4 |

| Sand | 0.3781 | kg | 0.0379 |

| Gravel | 0.4092 | kg | 0.0422 |

| Concrete admixtures-plasticizer | 0.0013 | Kg | 30 |

| Water | 0.0780 | Kg | - |

| Electricity (Hydropower) | 8.90 × 10−6 | MJ | 8.90 × 10−6 |

| Flow | Amount | Unit |

|---|---|---|

| Electricity [hydro power] | 7.92 | MJ |

| Gravel (2/32) [Minerals] | 0.82 | kg |

| Sea shell sand | 0.22 | kg |

| Olivine [Non-renewable resources] | 0.10 | kg |

| Aluminum oxide (alumina) [Inorganic intermediate products] | 0.05 | kg |

| Phenol (hydroxyl benzene) [Organic intermediate products] | 0.05 | kg |

| Three-Layer panels [Parts from renewable materials] (Package) | 0.04 | kg |

| Plastic profile [Plastics] (Package) | 0.015 | kg |

| Urea formaldehyde resin in-situ foam [Plastics] | 0.008 | kg |

| Ammonia [Inorganic intermediate products] | 0.007 | kg |

| Impacts Categories | Total Impacts | Total Impacts per One Sqm |

|---|---|---|

| Global warming potential (GWP) | 1275 ton CO2 eq | 255 kgCO2 eq |

| Ozone depletion potential (ODP) | 6.80 × 10−3 kg CFC 11 eq | 1.36 × 10−6 kg CFC 11 eq |

| Human toxicity (HT) | 0.16 CTUh | 3.23 × 10−5 CTUh |

| Acidification (AP) | 4.44 kmol of H+ eq | 0.88 Mole of H+ eq |

| Eutrophication (EP) | 11.44 kmol of N eq | 2.28 Mole of N eq |

| GWP (kg CO2 eq.) | ODP (kg CFC 11 eq.) | HT (Mole of H+ eq.) | AP (CTUh) | EP (Mole of N eq.) | |

|---|---|---|---|---|---|

| 1 kg of Concrete | 1.13 × 10−1 | 1.74 × 10−12 | 6.12 × 10−9 | 2.03 × 10−4 | 5.74 × 10−4 |

| 1 kg of Stone wool | 4.33 × 10−1 | 1.33 × 10−11 | 5.34 × 10−8 | 1.05 × 10−3 | 3.45 × 10−3 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Emami, N.; Marteinsson, B.; Heinonen, J. Environmental Impact Assessment of a School Building in Iceland Using LCA-Including the Effect of Long Distance Transport of Materials. Buildings 2016, 6, 46. https://doi.org/10.3390/buildings6040046

Emami N, Marteinsson B, Heinonen J. Environmental Impact Assessment of a School Building in Iceland Using LCA-Including the Effect of Long Distance Transport of Materials. Buildings. 2016; 6(4):46. https://doi.org/10.3390/buildings6040046

Chicago/Turabian StyleEmami, Nargessadat, Björn Marteinsson, and Jukka Heinonen. 2016. "Environmental Impact Assessment of a School Building in Iceland Using LCA-Including the Effect of Long Distance Transport of Materials" Buildings 6, no. 4: 46. https://doi.org/10.3390/buildings6040046