Advancing Motivation Feedforward Control of Permanent Magnetic Linear Oscillating Synchronous Motor for High Tracking Precision

Abstract

:1. Introduction

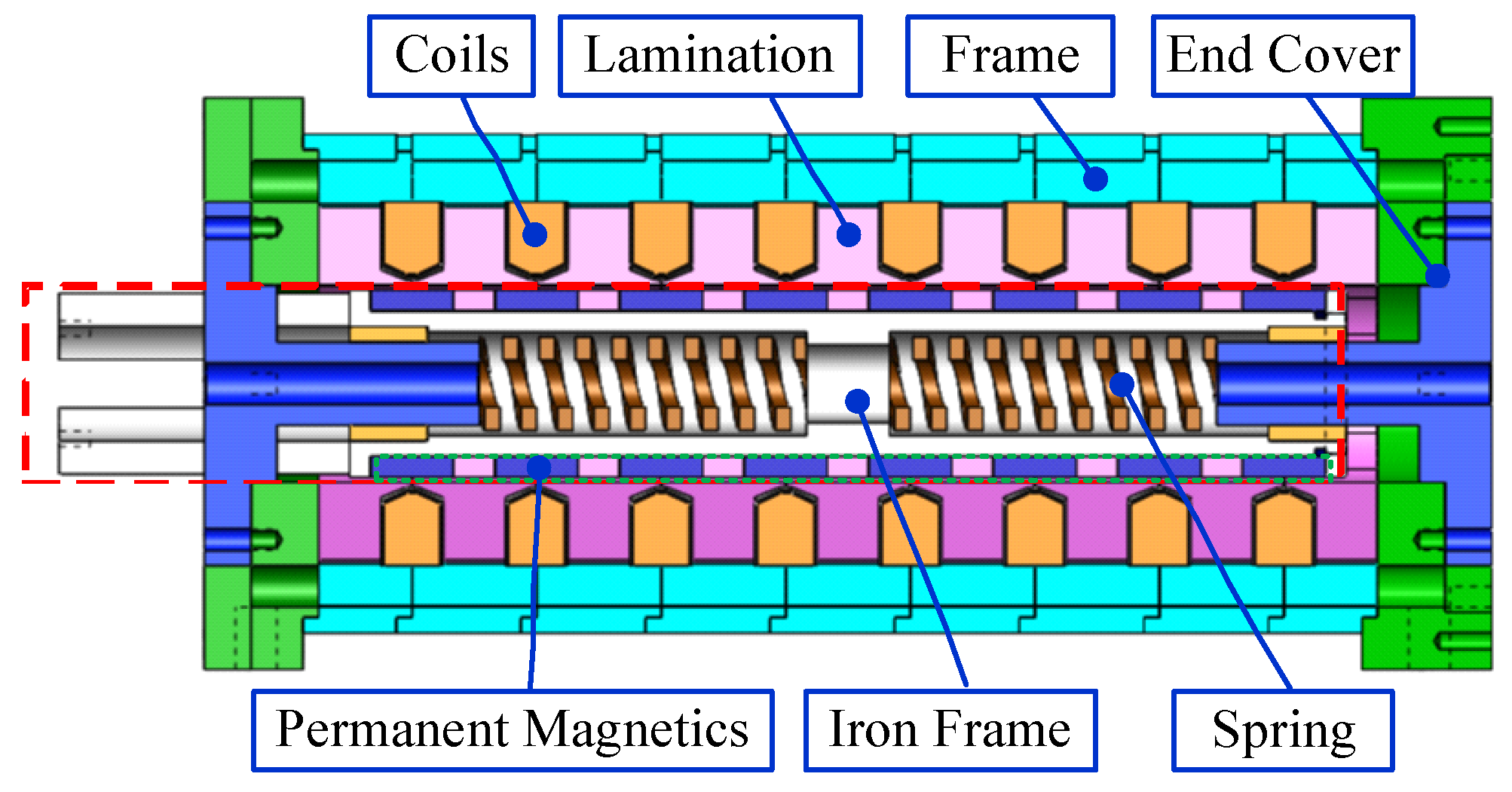

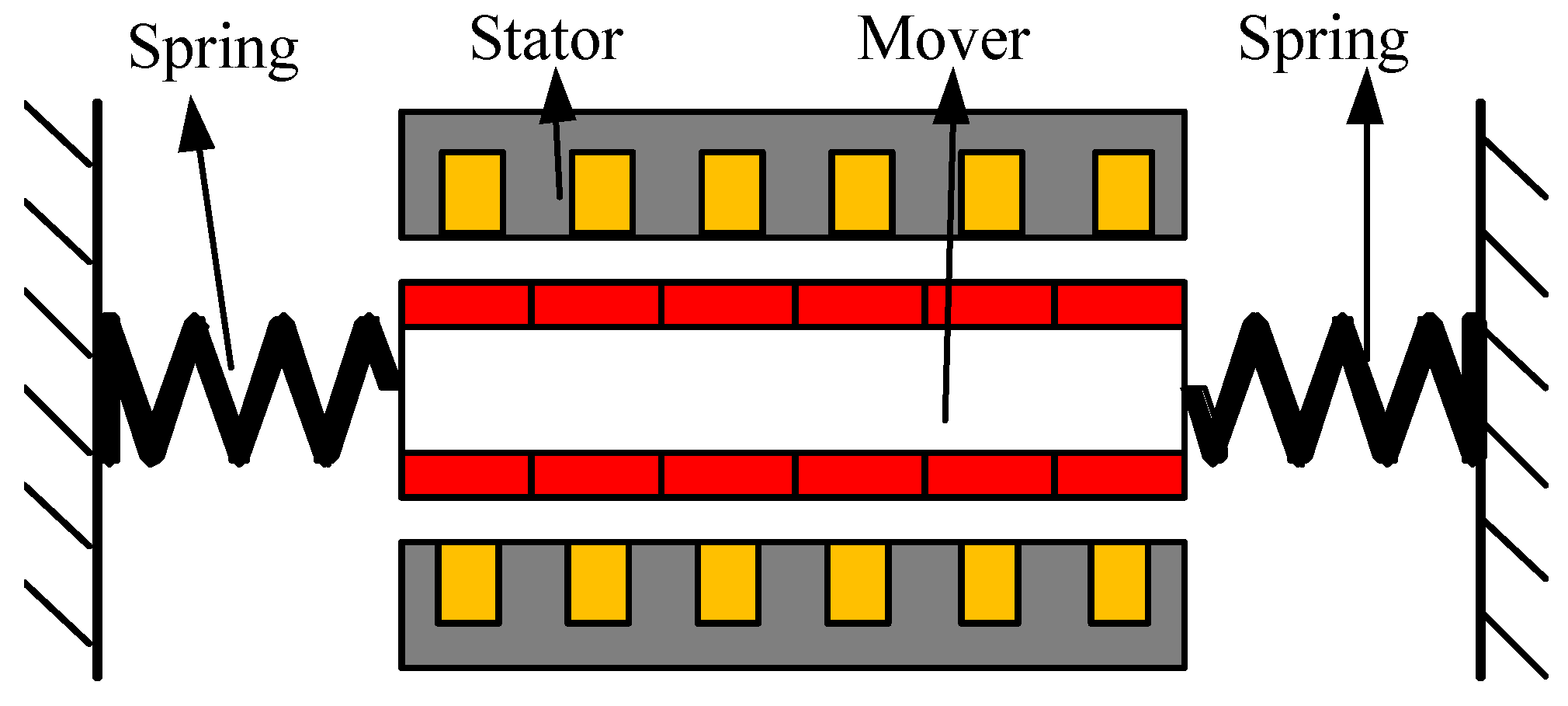

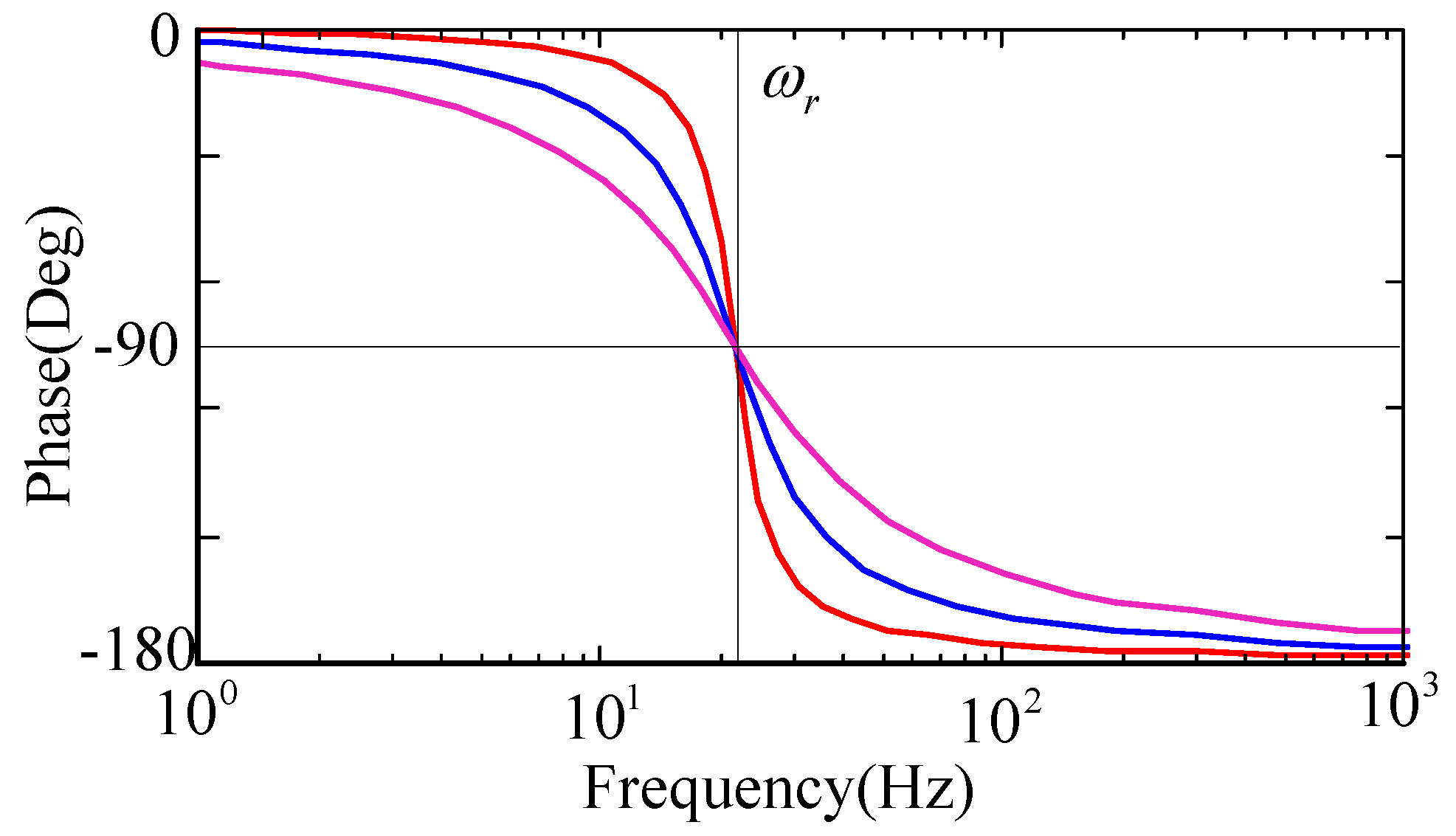

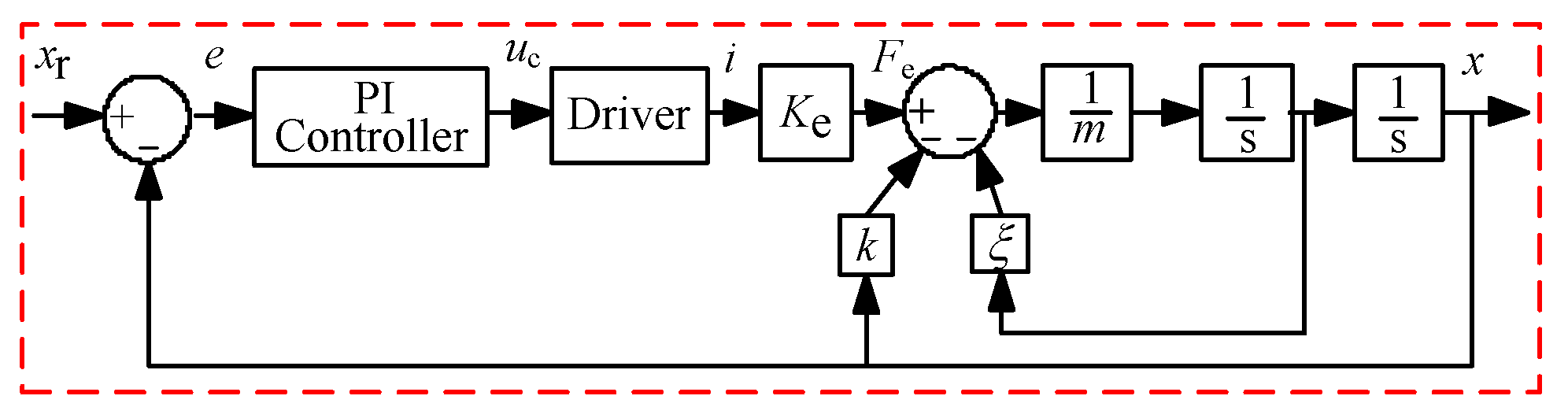

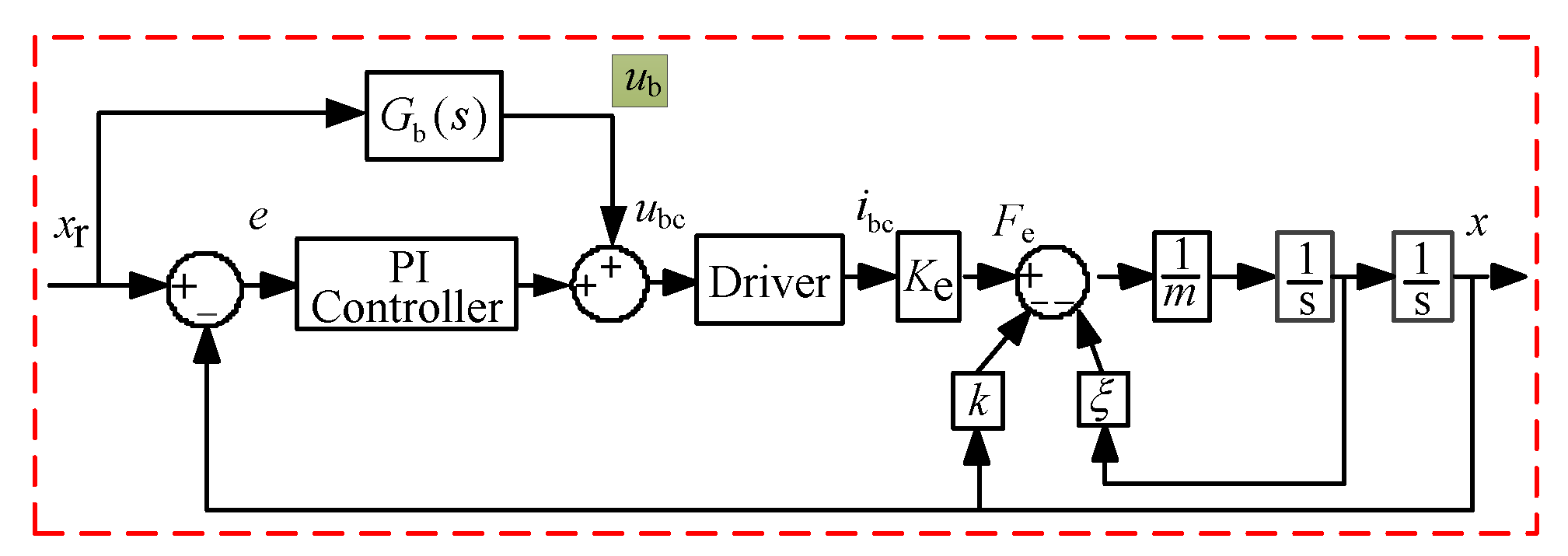

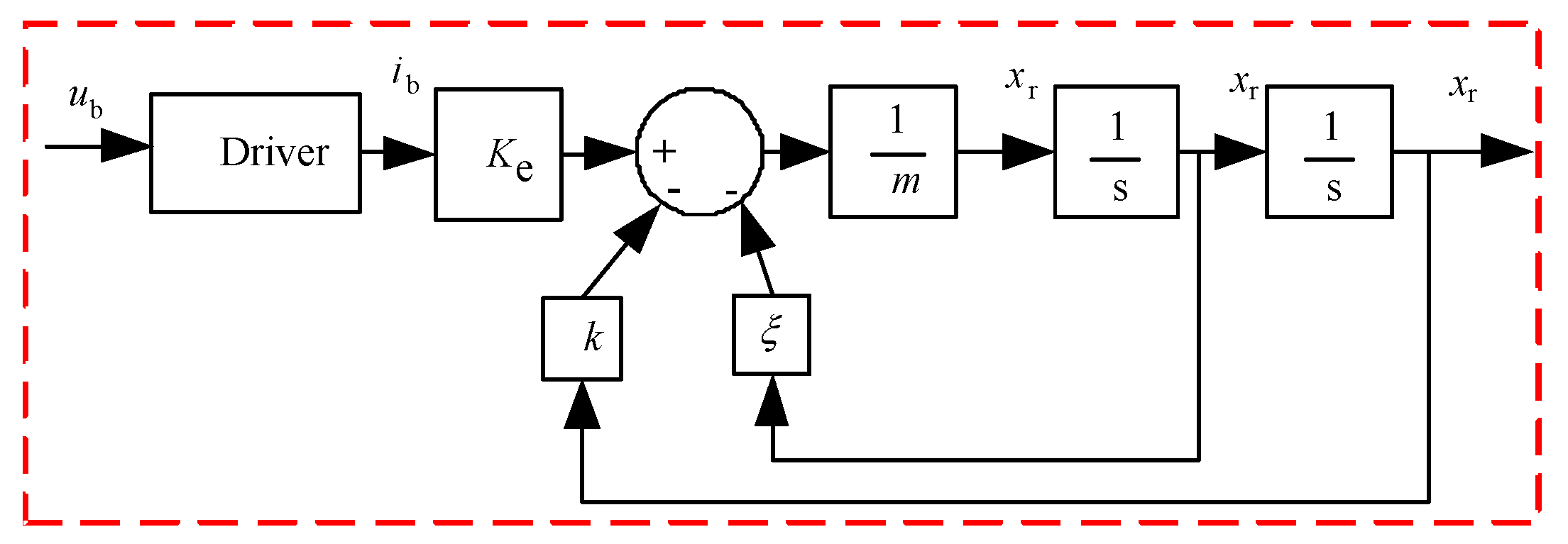

2. Structure and Problem Illustration

3. Mathematical Model and Simulation Analysis

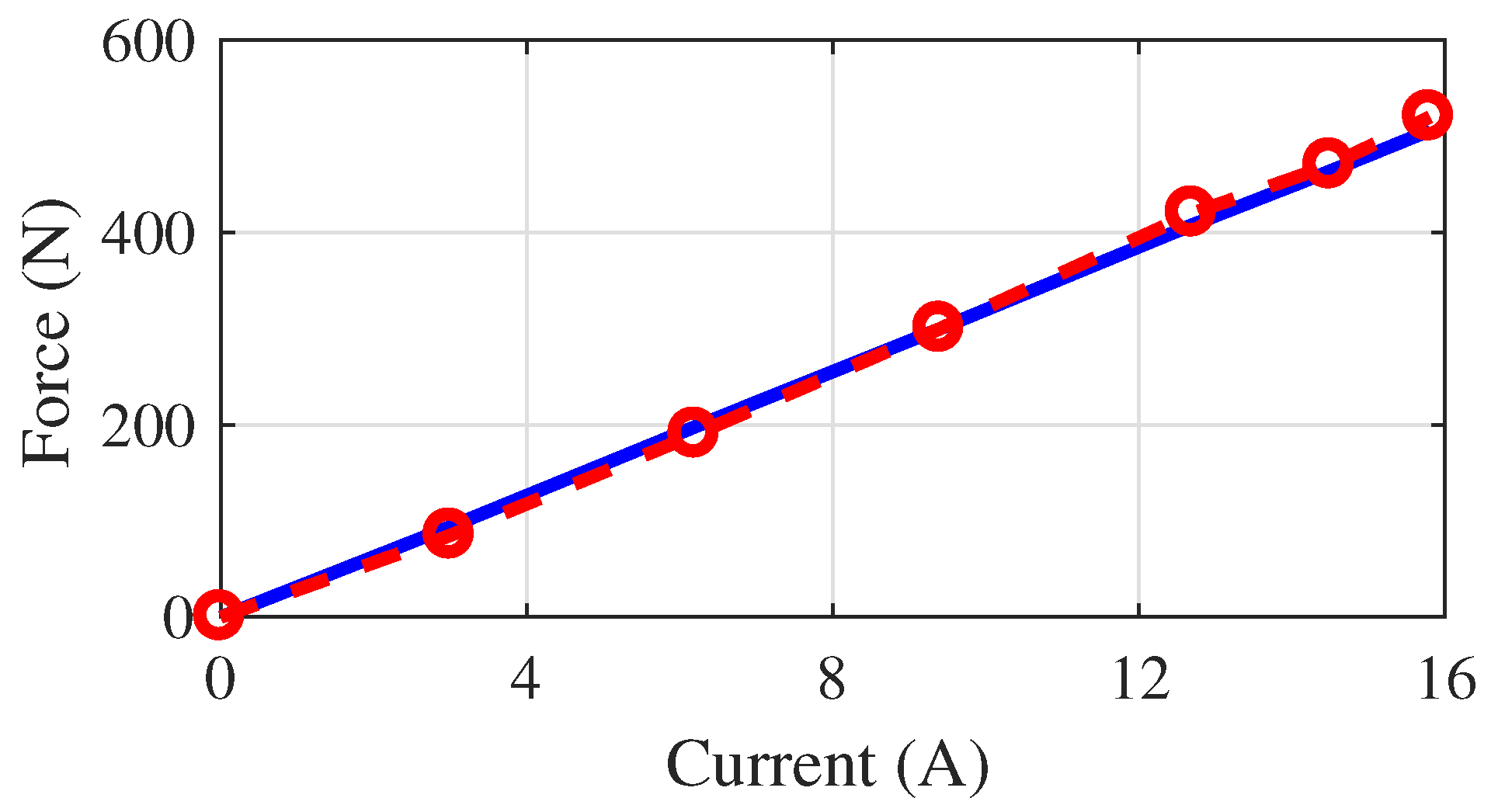

3.1. Mathematical Model

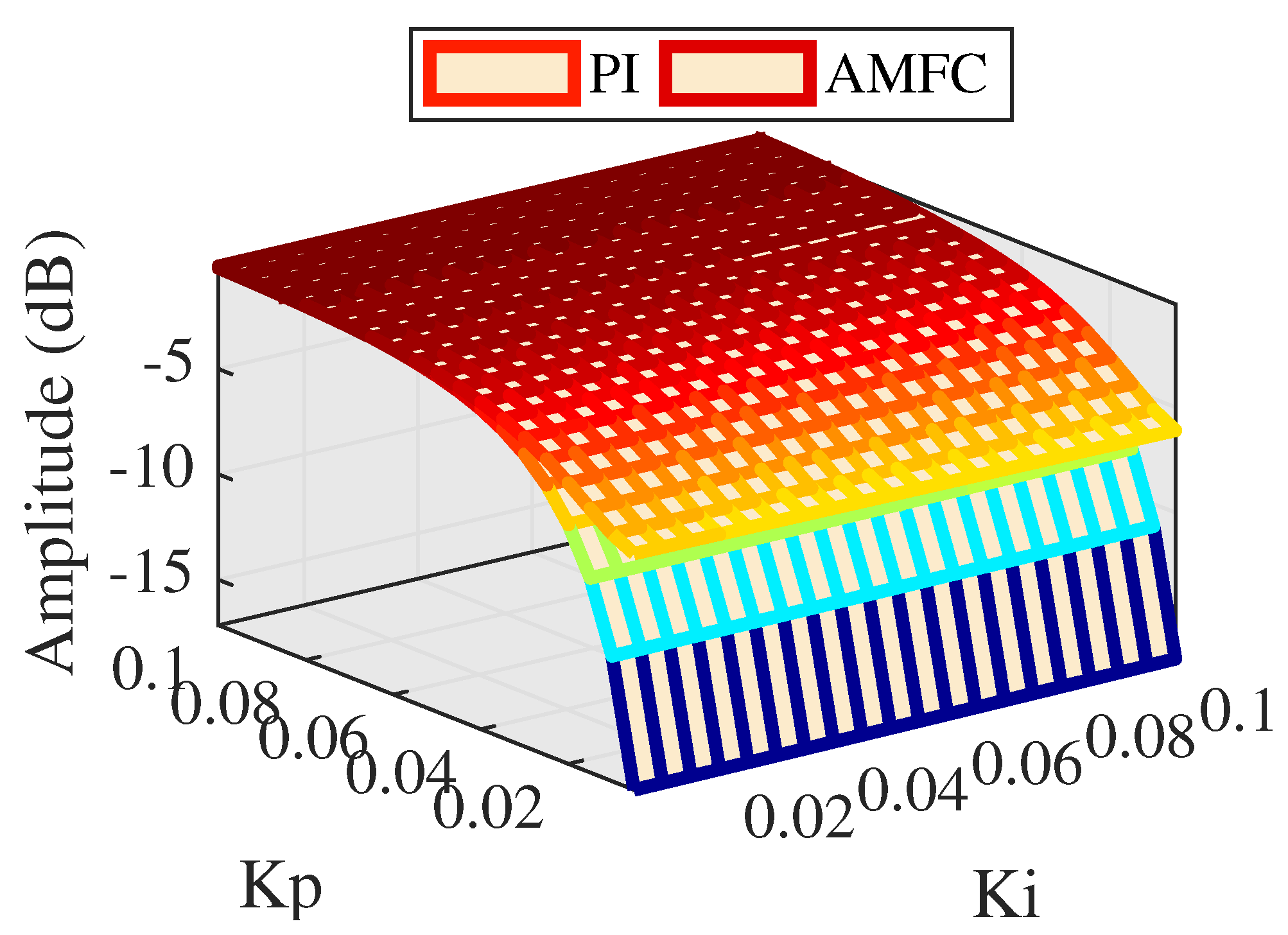

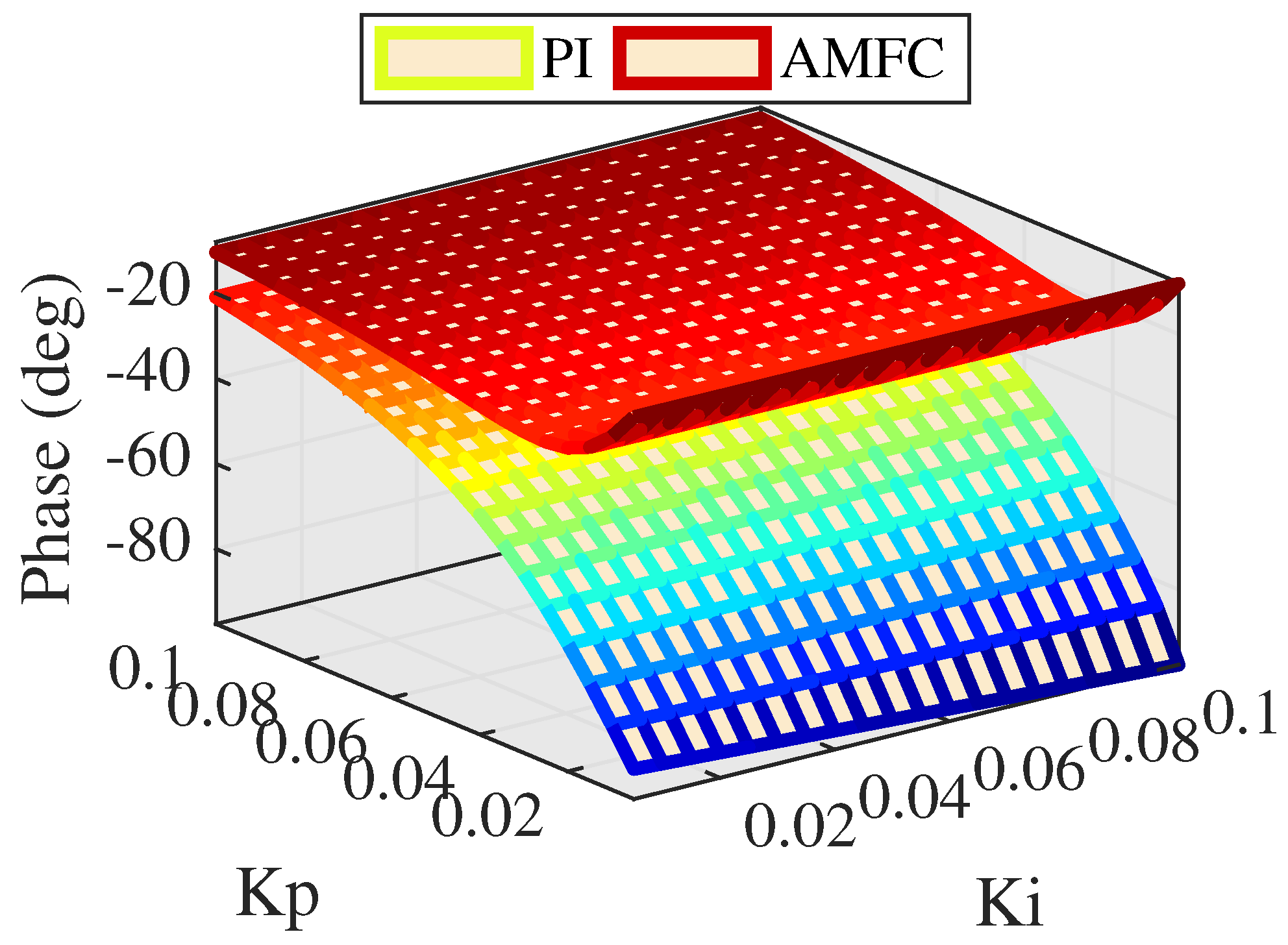

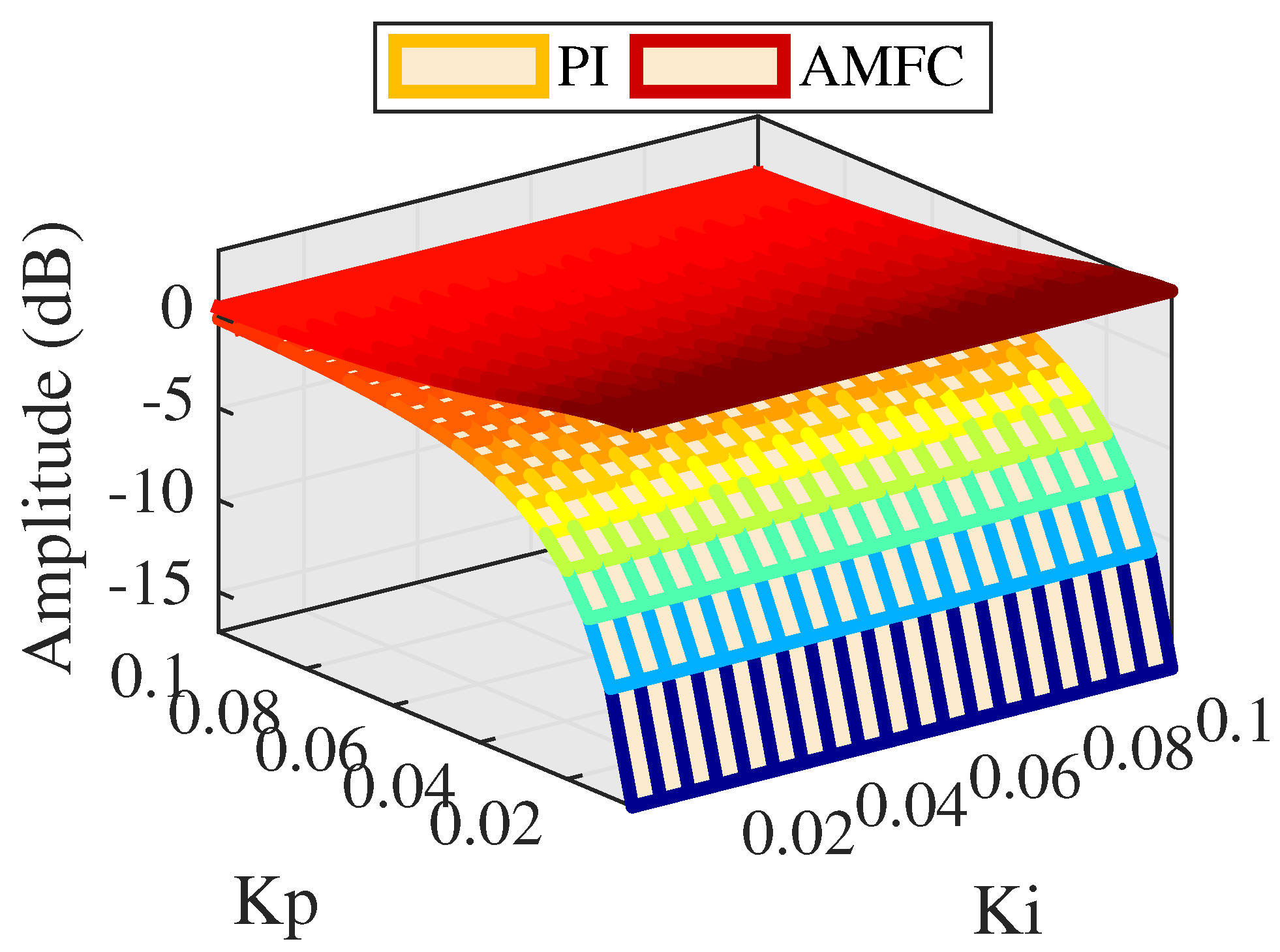

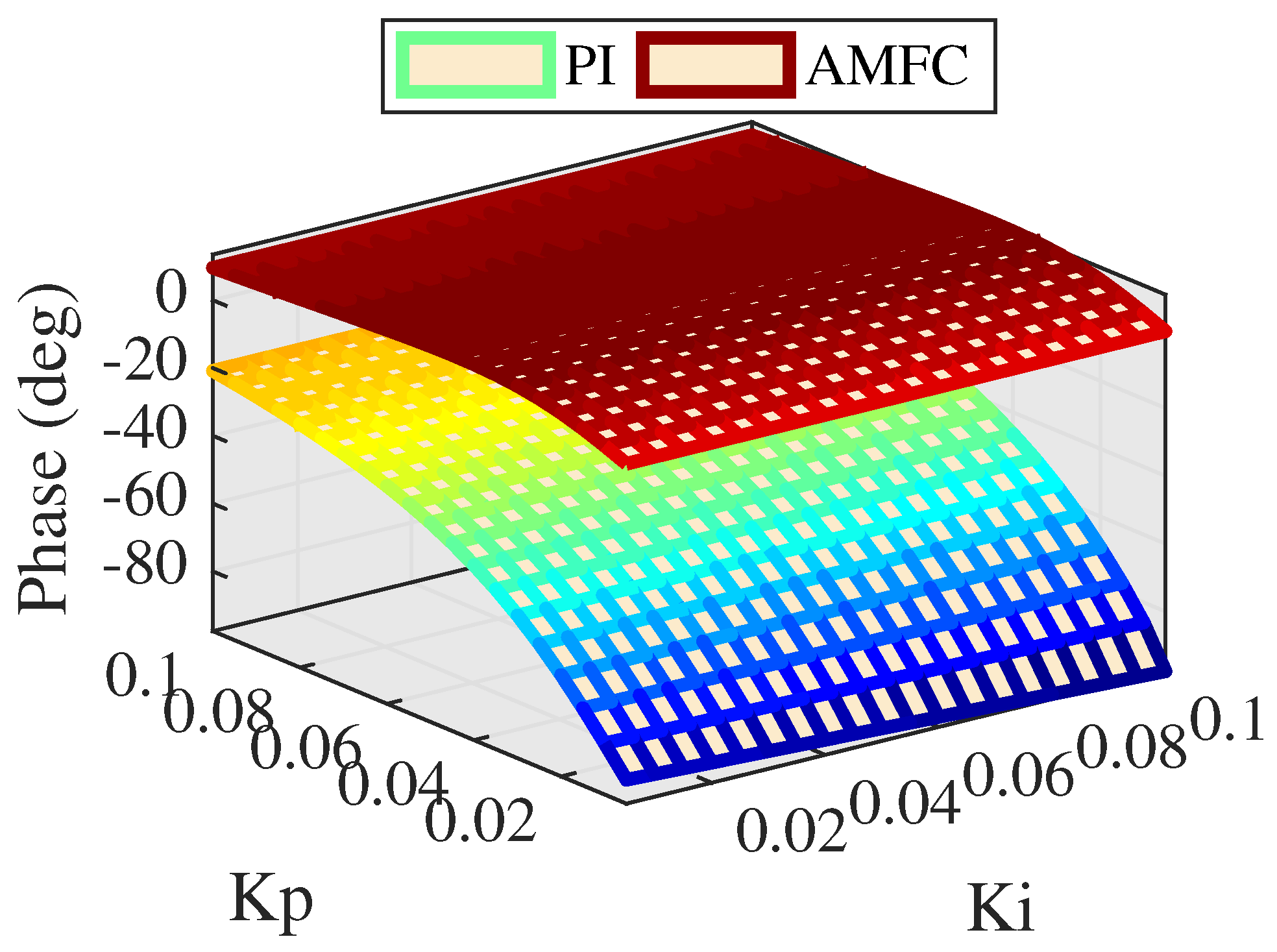

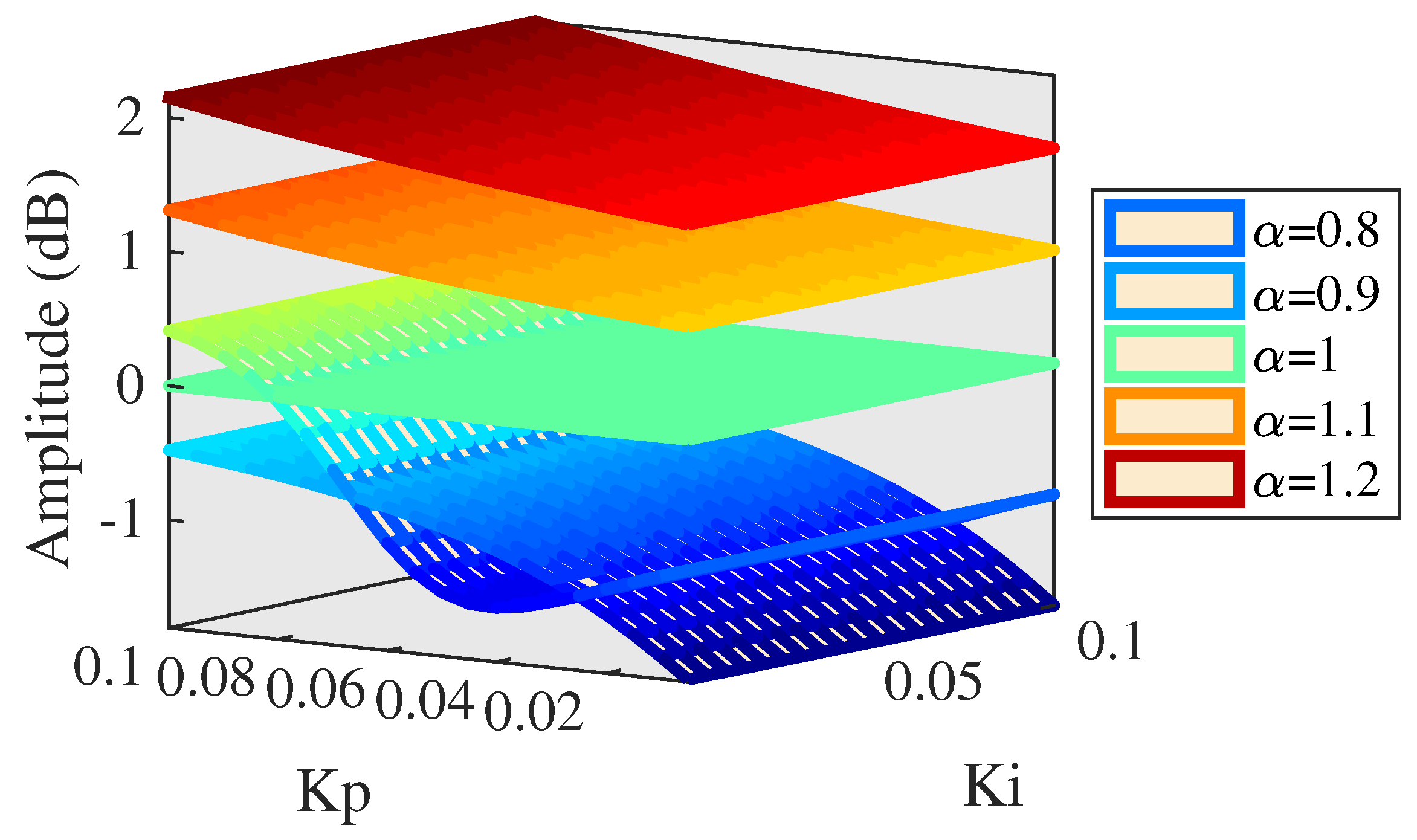

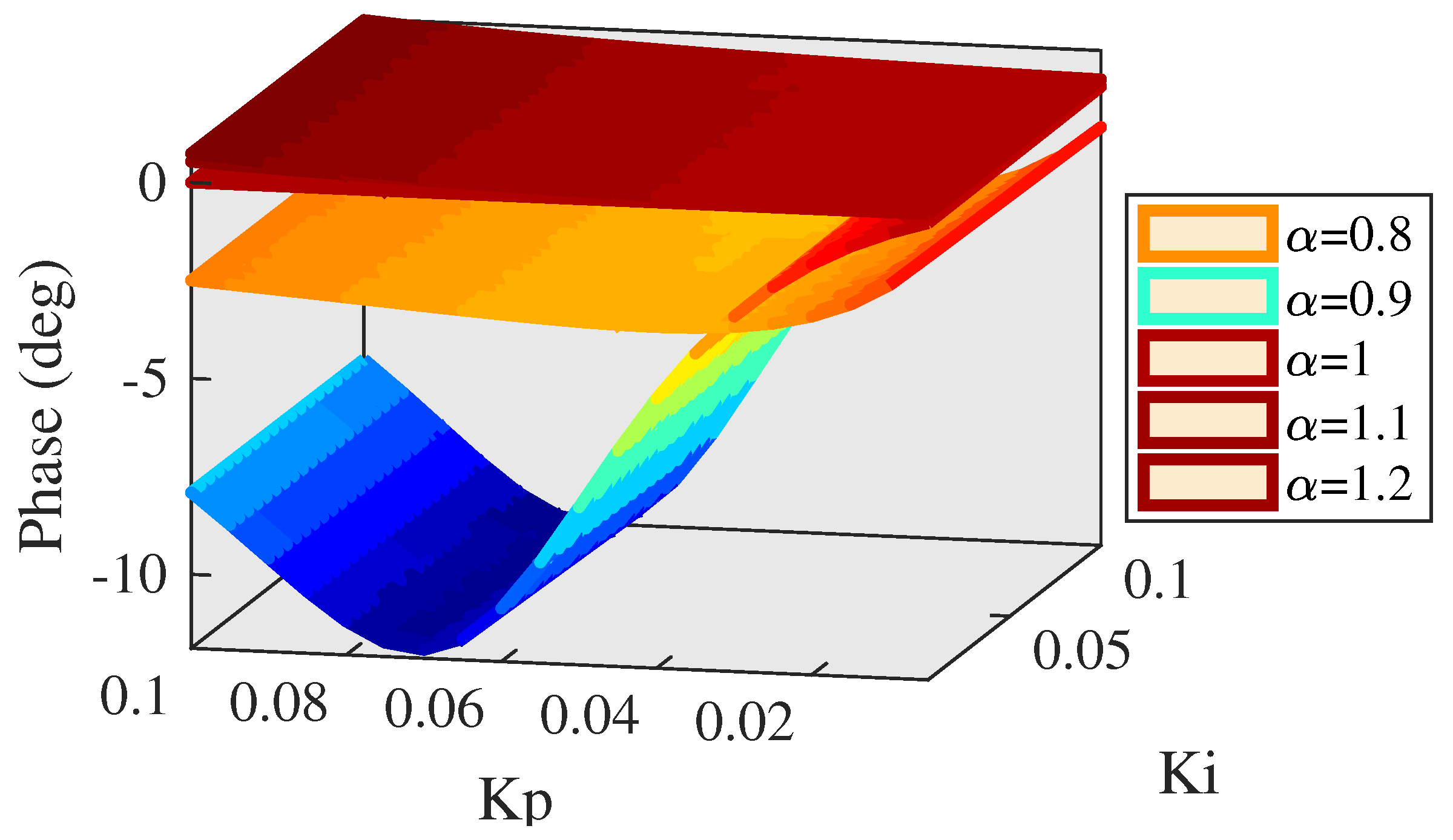

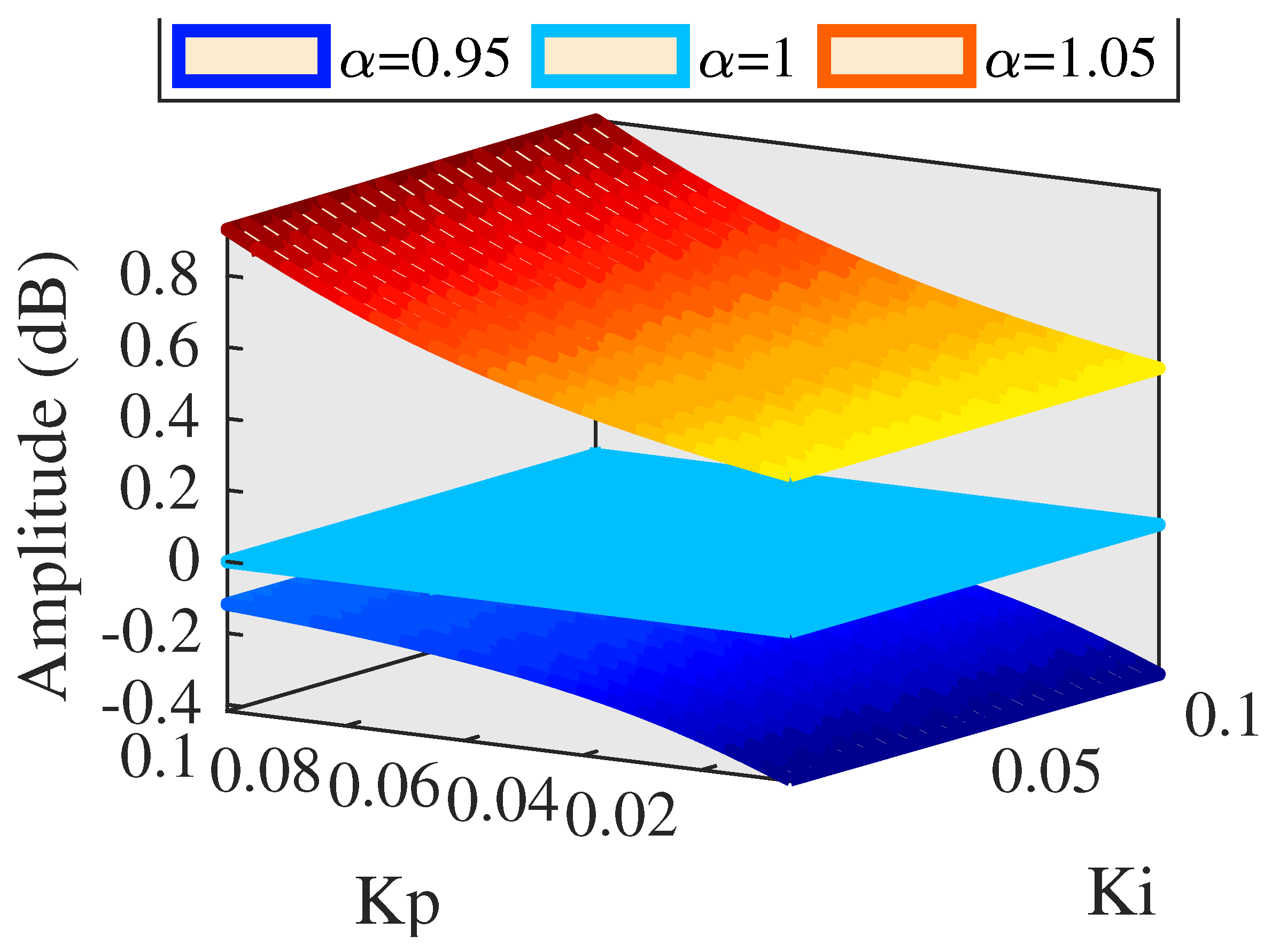

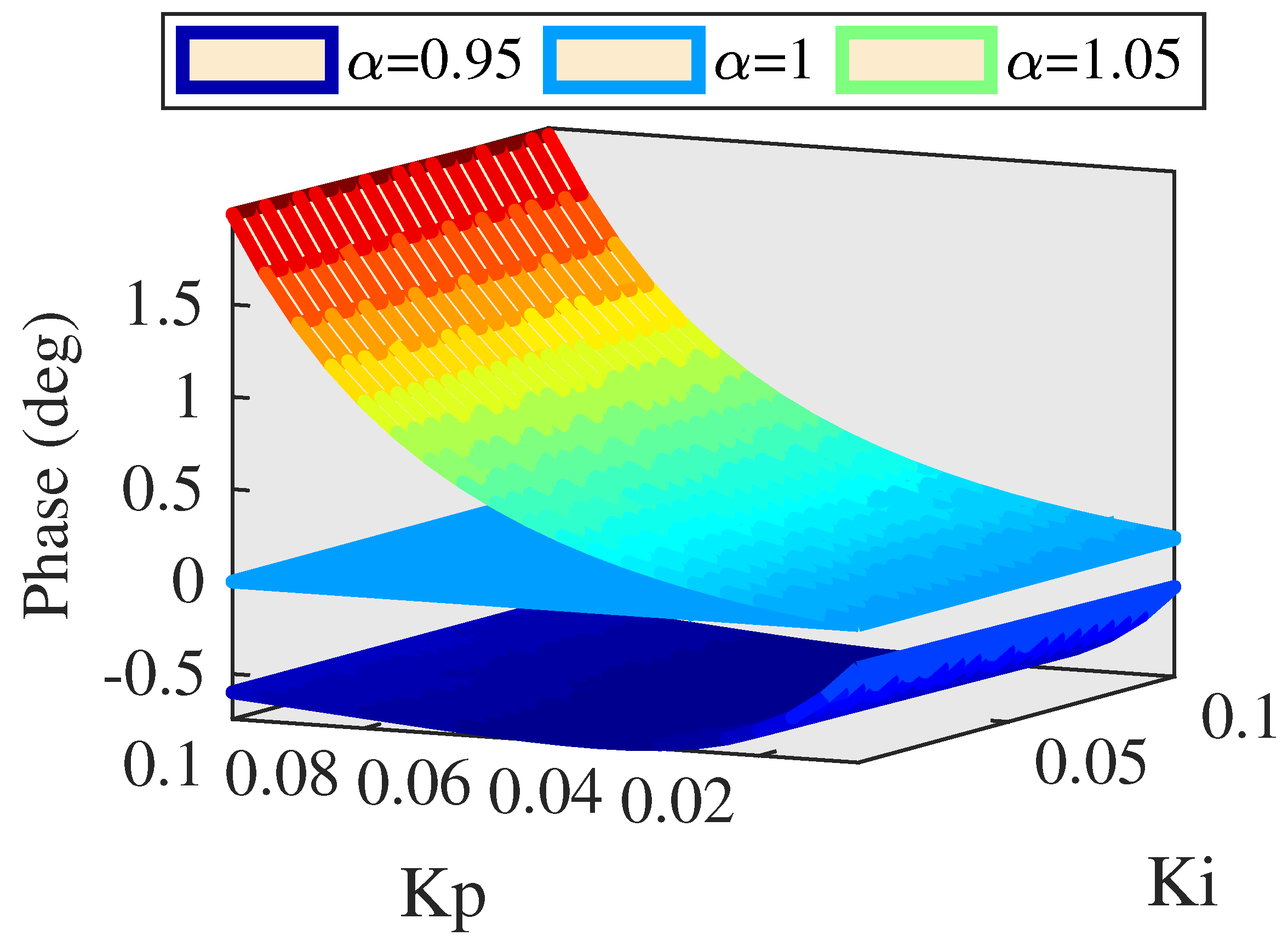

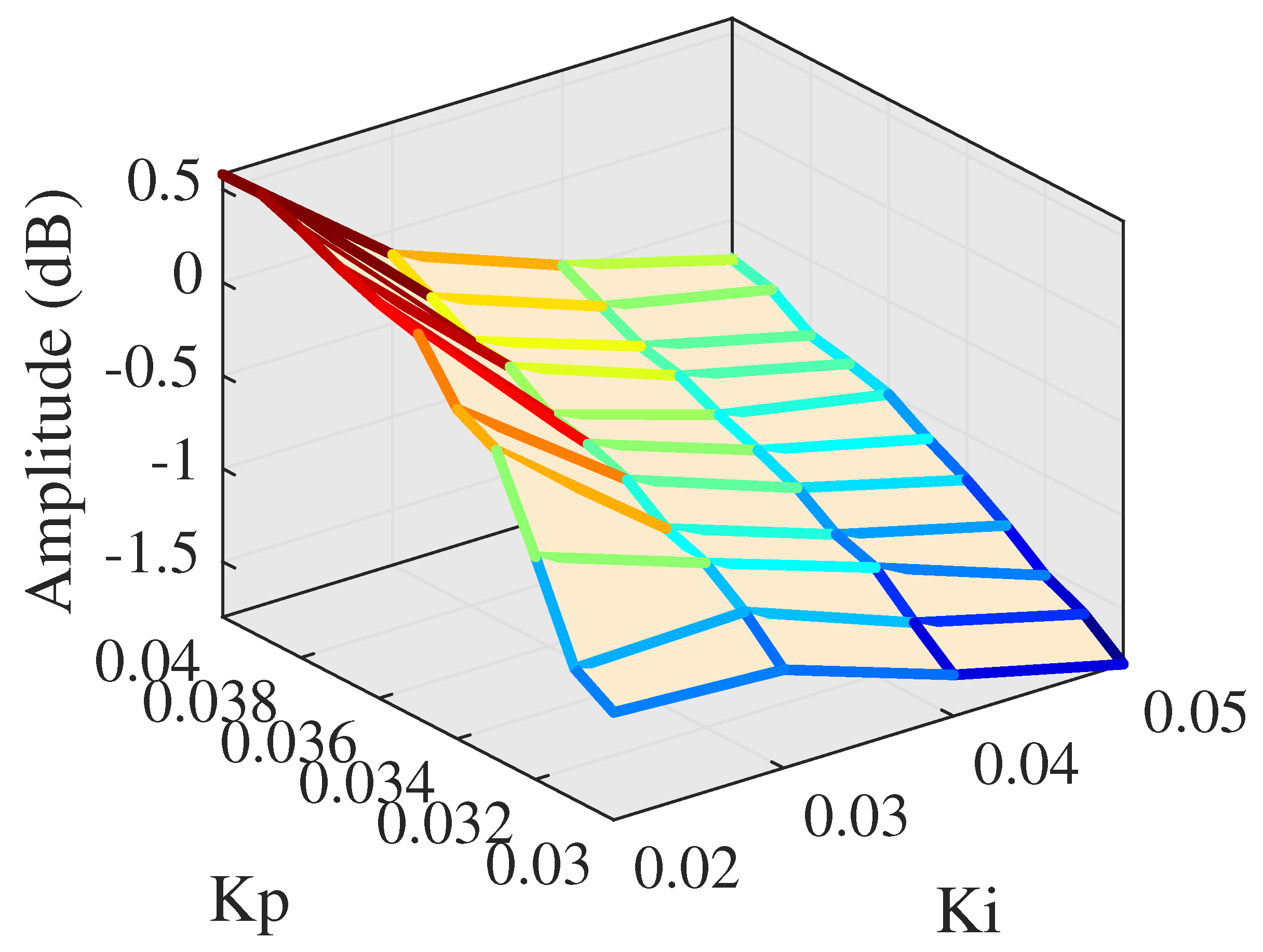

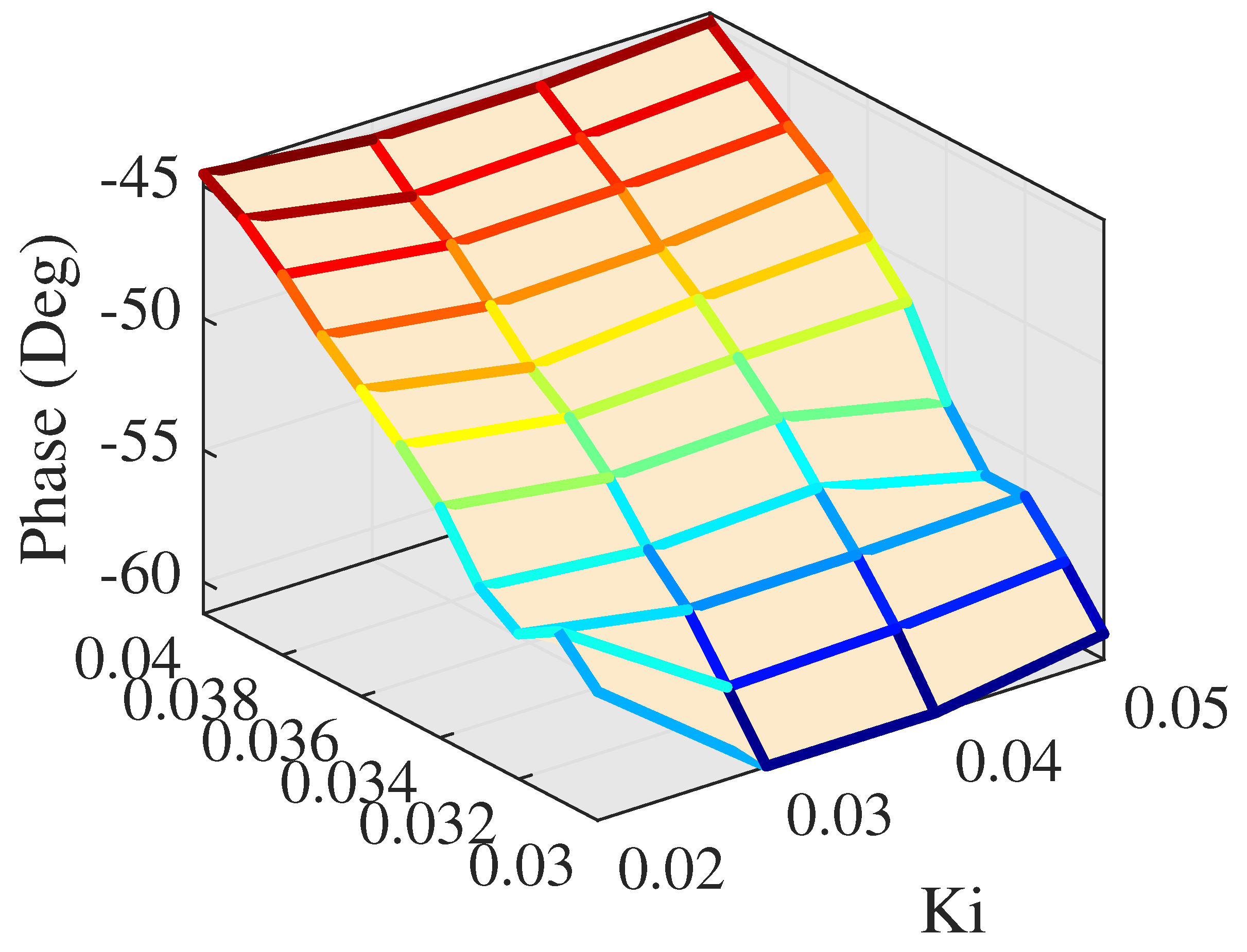

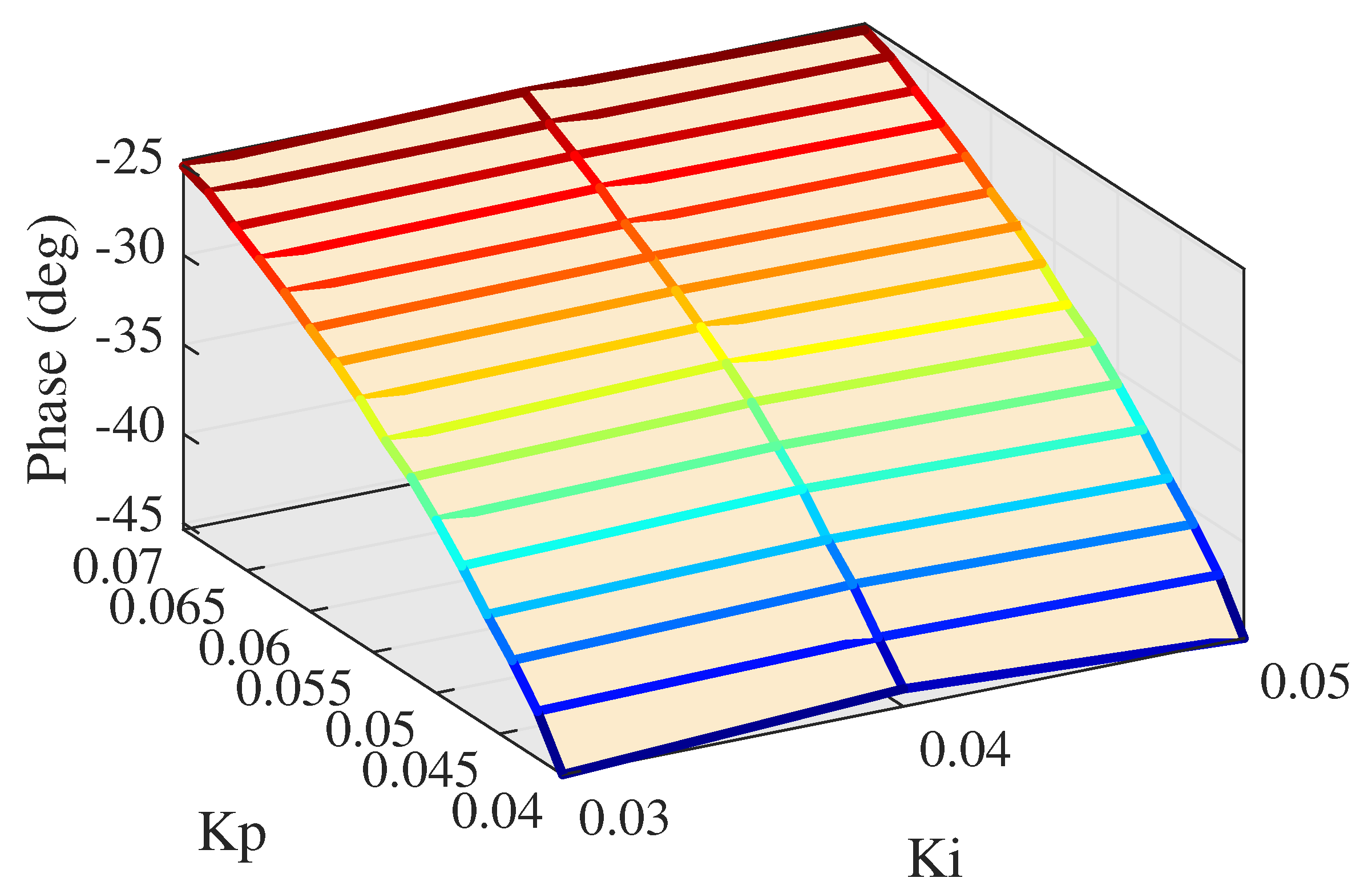

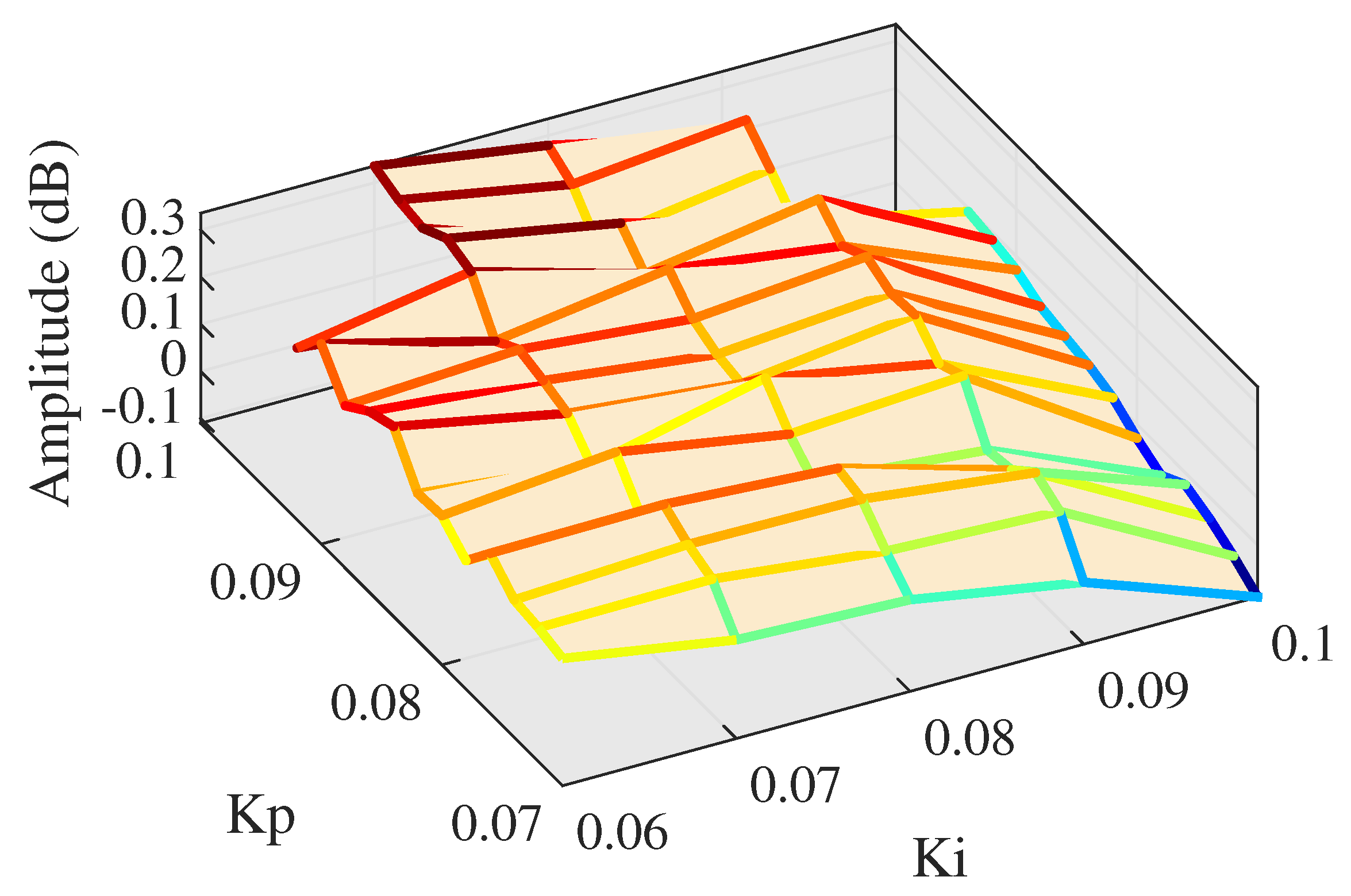

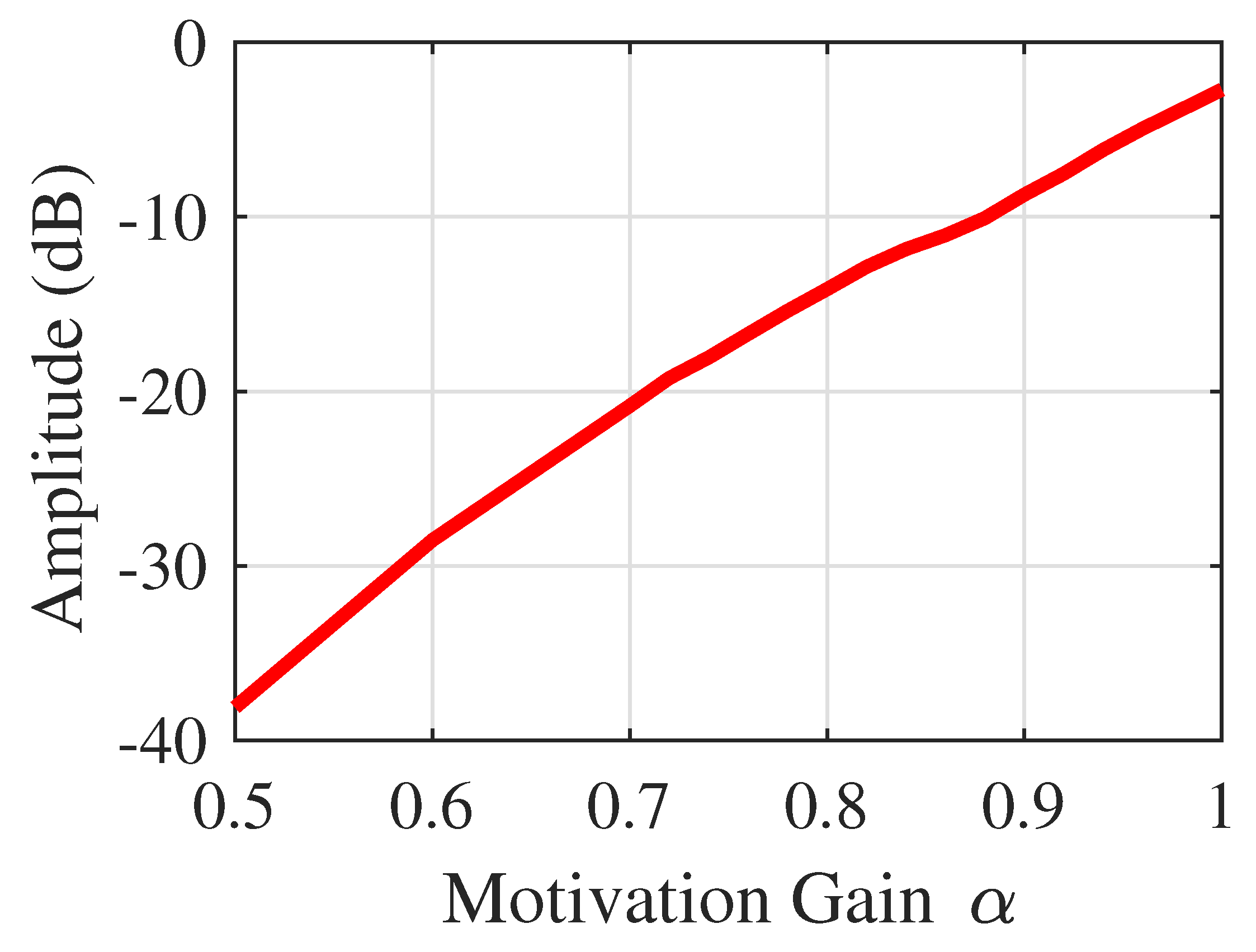

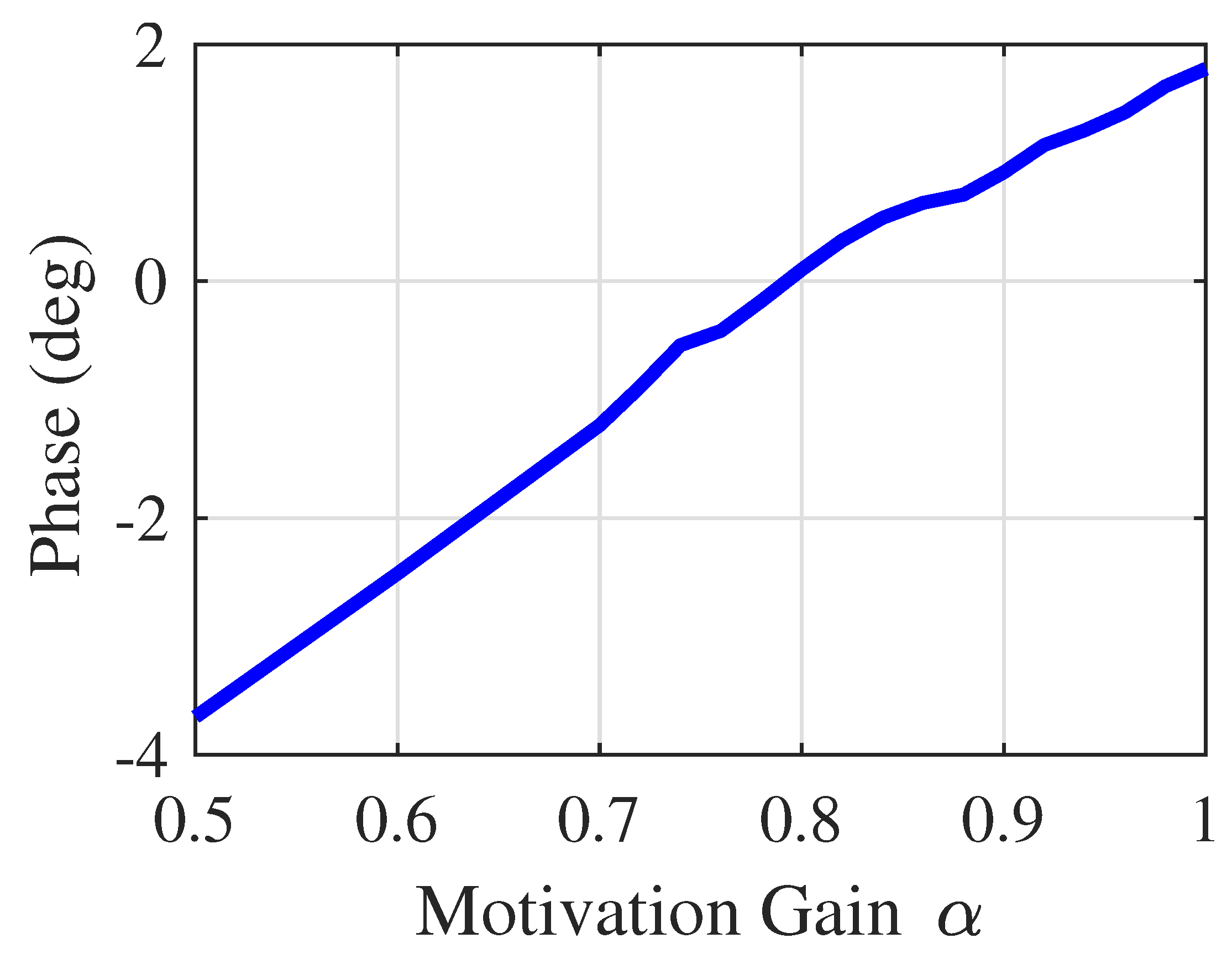

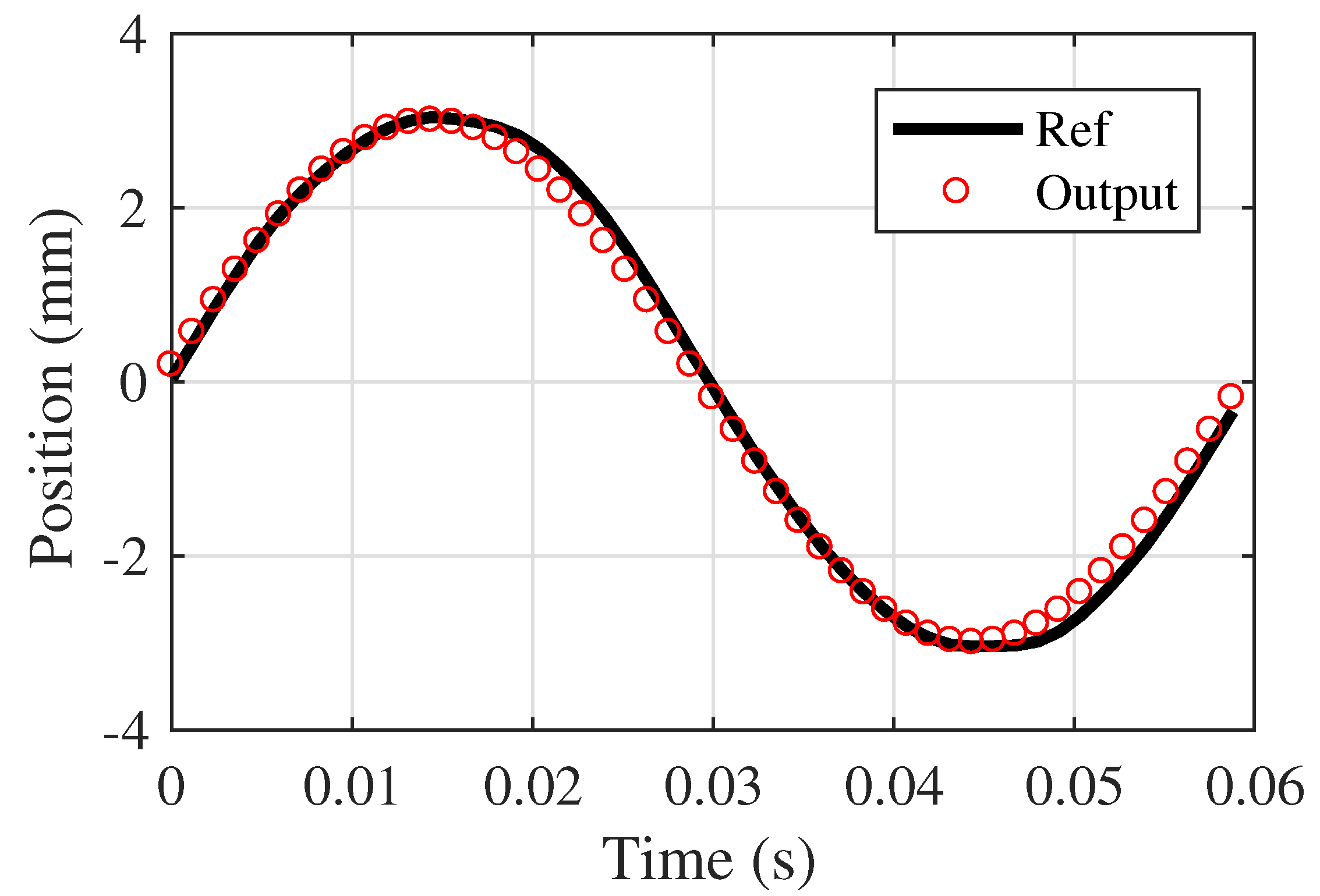

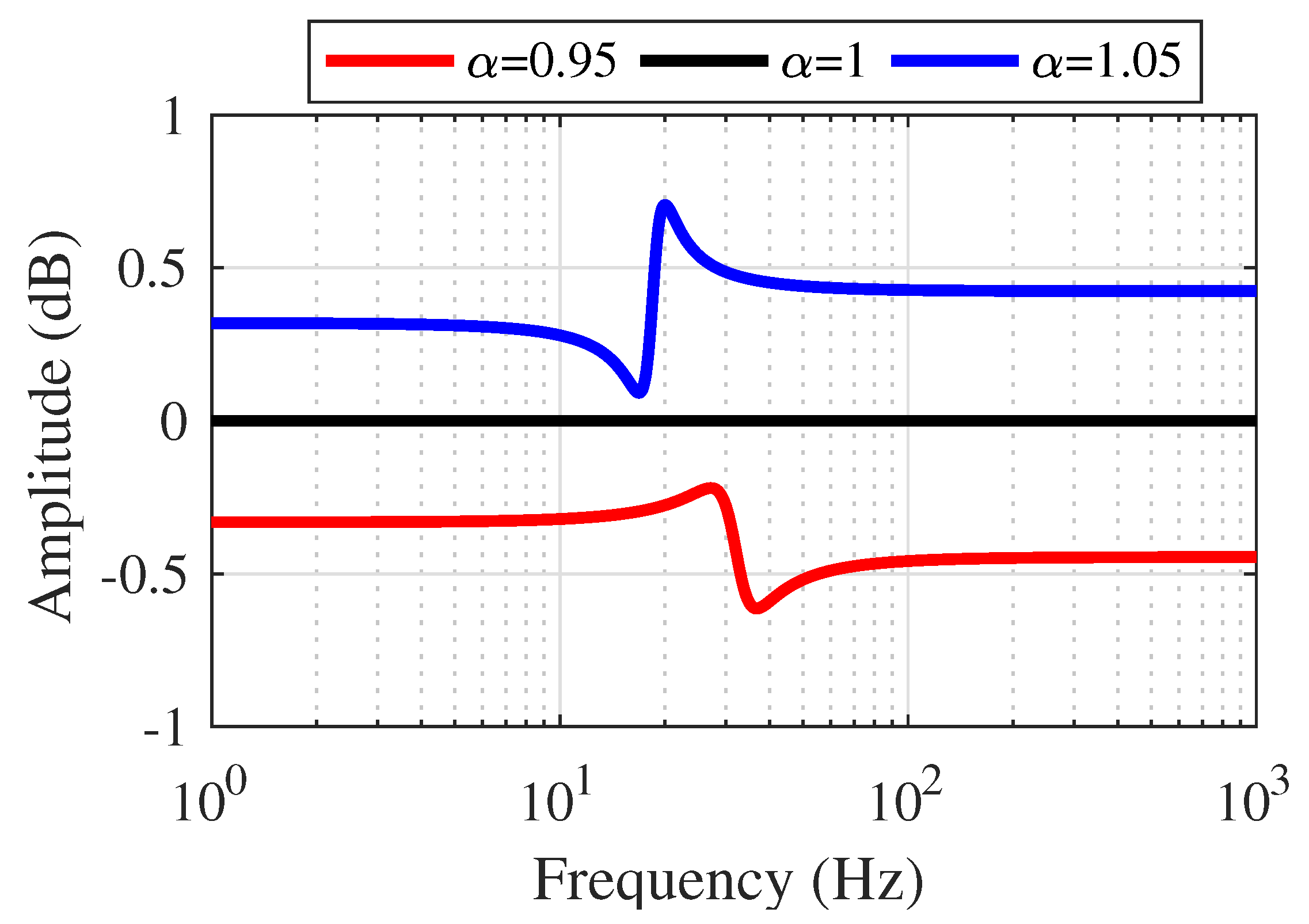

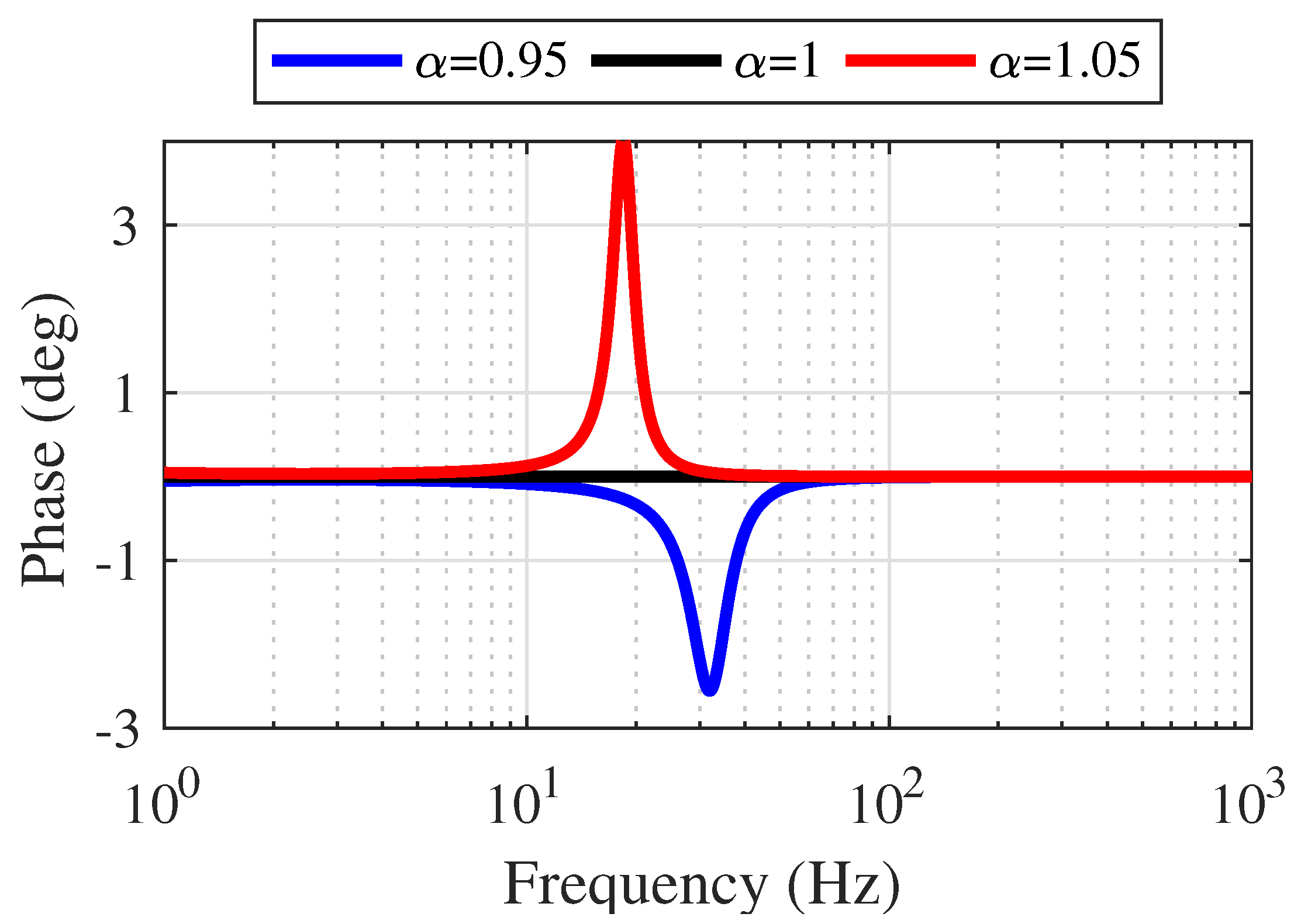

3.2. Simulation Analysis

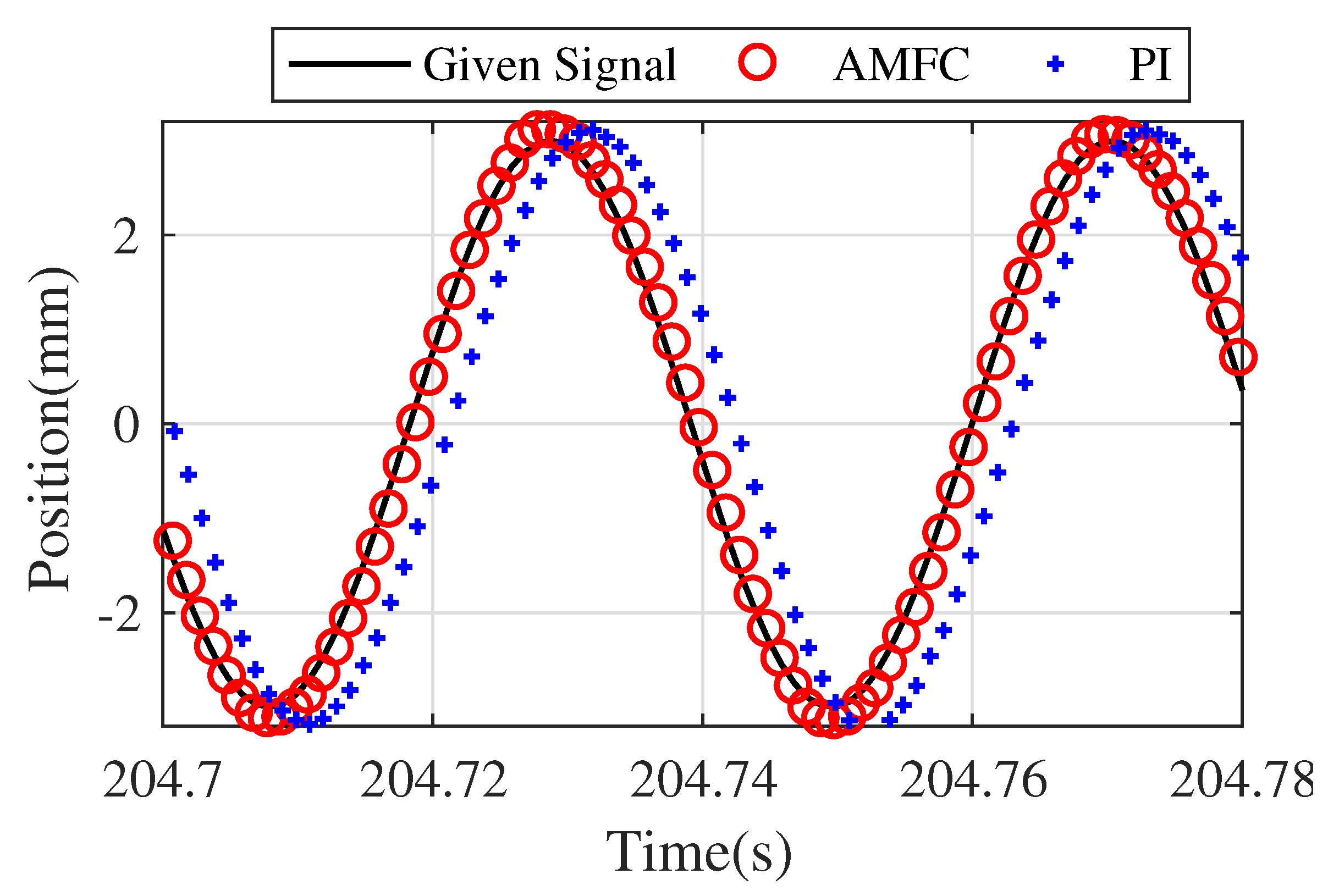

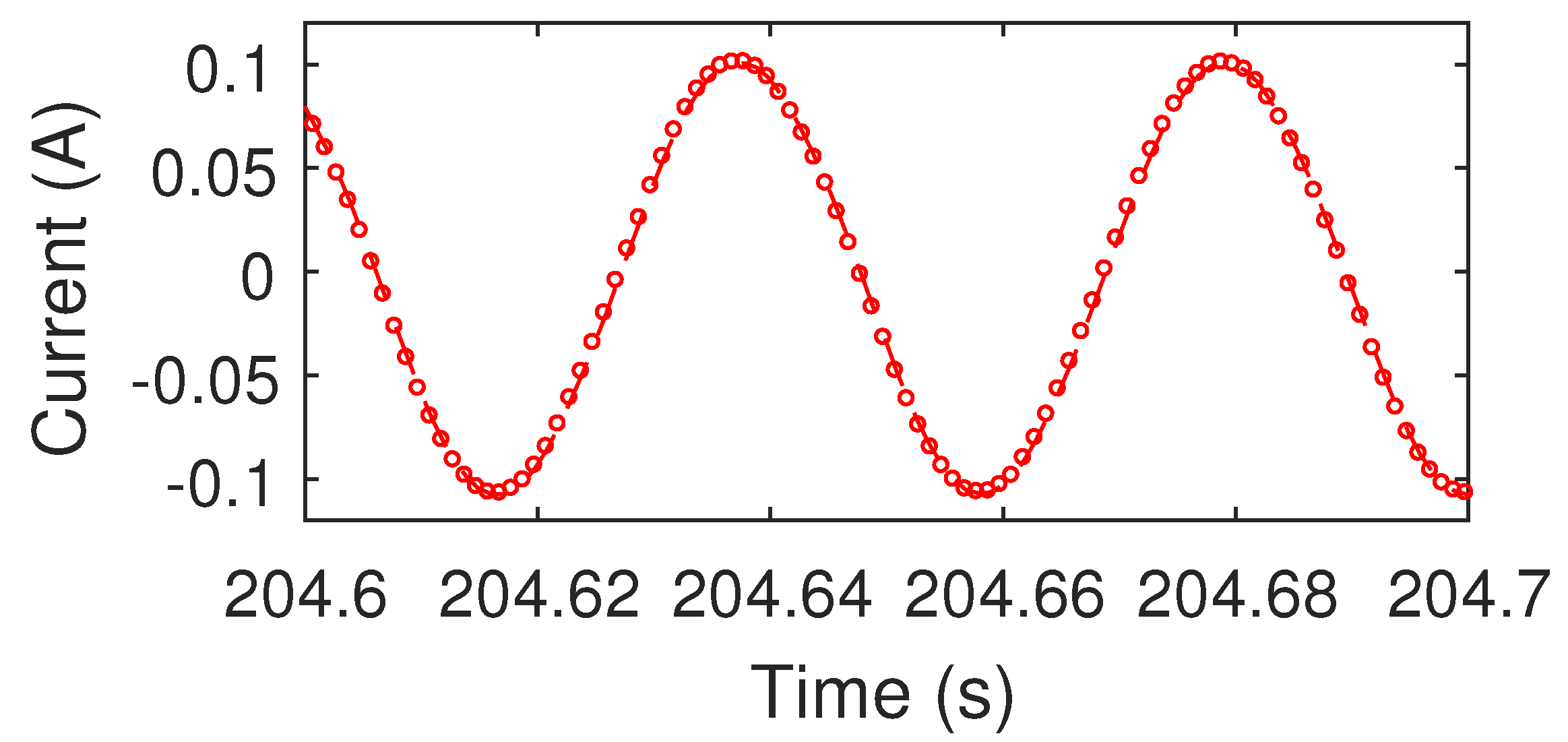

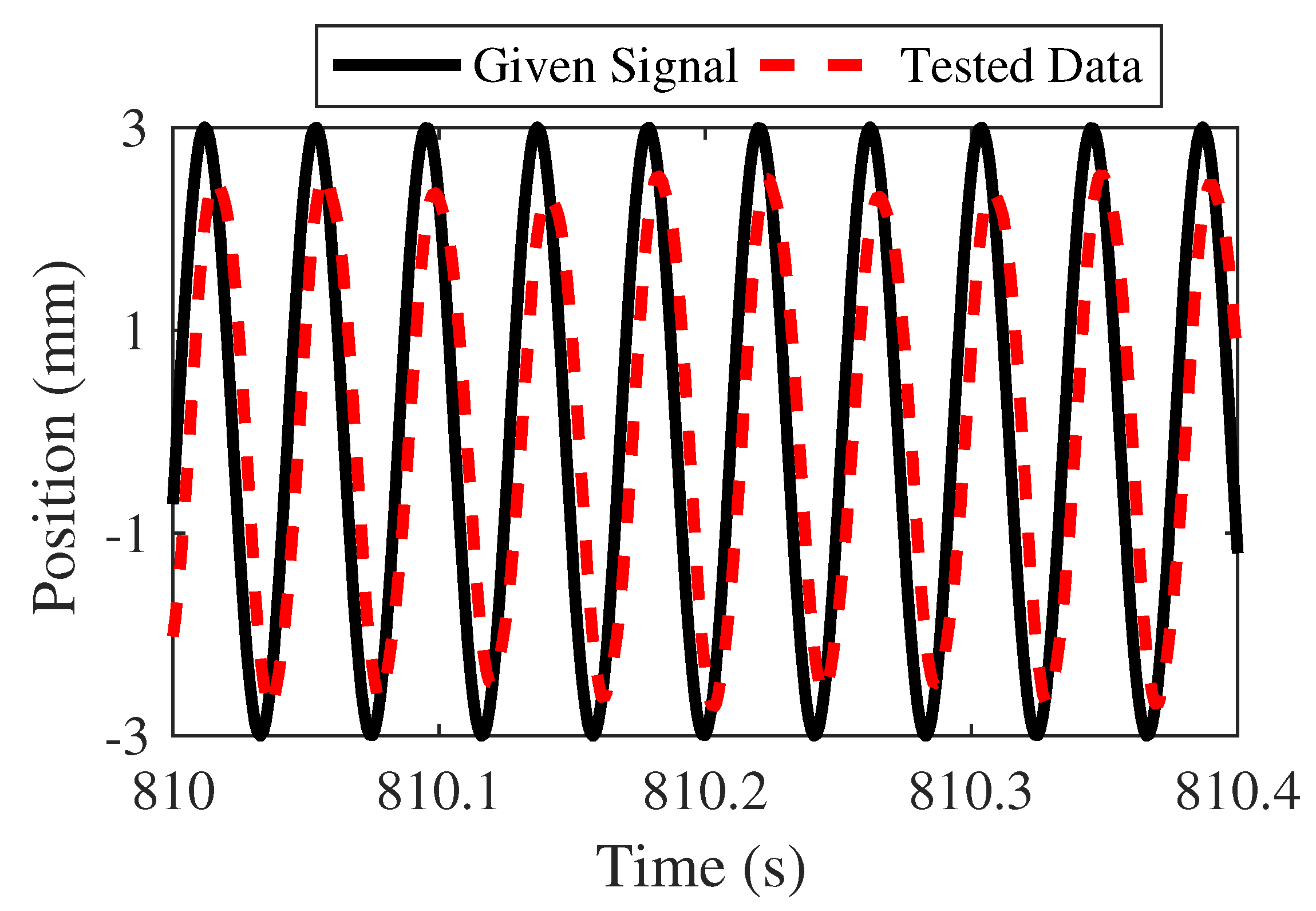

4. Experiment Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, J.Q.; Li, W.L.; Deng, G.Q.; Ming, Z. Continuous-Behavior and Discrete-Time Combined Control for Linear Induction Motor-Based Urban Rail Transit. IEEE Trans. Magn. 2016, 52, 8500104. [Google Scholar] [CrossRef]

- Lu, L.; Chen, Z.; Yao, B.; Wang, Q. A Two-Loop Performance-Oriented Tip-Tracking Control of a Linear-Motor-Driven Flexible Beam System with Experiments. IEEE Trans. Ind. Electron. 2013, 60, 1011–1022. [Google Scholar] [CrossRef]

- Hu, C.; Yao, B.; Wang, Q. Global Task Coordinate Frame-Based Contouring Control of Linear-Motor-Driven Biaxial Systems with Accurate Parameter Estimations. IEEE Trans. Ind. Electron. 2011, 58, 5195–5205. [Google Scholar] [CrossRef]

- Toshimitsu, M.; Kousuke, T.; Noriyuki, K. Control of Traction and Levitation of Linear Induction Motor Driven by Power Source with Frequency Component Synchronous with the Motor Speed. IEEE Trans. Magn. 2011, 47, 4302–4305. [Google Scholar] [CrossRef]

- Chih-Jer, L.; Her-Terng, Y.; Yun, C. Identification and Compensation of Nonlinear Friction Characteristics and Precision Control for a Linear Motor Stage. IEEE-ASME Trans. Mechatron. 2013, 18, 1385–1396. [Google Scholar] [CrossRef]

- Chen, Z.; Li, C.; Yao, B.; Yuan, M.; Yang, C. Integrated Coordinated/Synchronized Contouring Control of a Dual-Linear-Motor-Driven Gantry. IEEE Trans. Ind. Electron. 2020, 67, 3944–3954. [Google Scholar] [CrossRef]

- Hossein, K.; Sadgeh, V.; Farzad, R.S. Combined Vector and Direct Thrust Control of Linear Induction Motors with End Effect Compensation. IEEE Trans. Energy Convers. 2016, 31, 196–205. [Google Scholar] [CrossRef]

- Chen, Z.; Yao, B.; Wang, Q. Synthesis Based Adaptive Robust Control of Linear Motor Driven Stages with High Frequency Dynamics: A Case Study. IEEE-ASME Trans. Mechatron. 2015, 20, 1482–1490. [Google Scholar] [CrossRef]

- Jiao, Z.; Cao, Y.; Yan, L.; Li, X.; Zhang, L. Design and Analysis of Novel Linear Oscillating Loading System. Appl. Sci. 2019, 18, 3771. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Yao, B.; Wang, Q. Adaptive Robust Precision Motion Control of Linear Motors with Integrated Compensation of Nonlinearities and Bearing Flexible Modes. IEEE Trans. Ind. Inform. 2013, 9, 965–973. [Google Scholar] [CrossRef]

- Lin, F.-J.; Chou, P.-H.; Hung, Y.-C.; Wang, W.-M. Field-programmable gate array-based functional link radial basis function network control for permanent magnet linear synchronous motor servo drive system. IET Electr. Power Appl. 2010, 4, 357–372. [Google Scholar] [CrossRef]

- Muhammad, A.M.C.; John, E.F.; Muhammad, F.R.; Dan, X. Optimal, Combined Speed and Direct Thrust Control of Linear Permanent Magnet Synchronous Motors. IEEE Trans. Energy Convers. 2016, 31, 947–958. [Google Scholar] [CrossRef]

- Liu, X.; Zhen, S.; Sun, H.; Zhao, H. A Novel Model-based Robust Control for Position Tracking of Permanent Magnet Linear Motor. IEEE Trans. Ind. Electron. 2020, 67, 7767–7777. [Google Scholar] [CrossRef]

- Yuan, M.; Chen, Z.; Yao, B.; Liu, X. Fast and Accurate Motion Tracking of a Linear Motor System under Kinematic and Dynamic Constraints: An Integrated Planning and Control Approach. IEEE Trans. Control Syst. Technol. 2021, 29, 804–811. [Google Scholar] [CrossRef]

- Yi, S.H.; Cheng, C.S. Function-Based Controller for Linear Motor Control Systems. IEEE Trans. Ind. Electron. 2010, 57, 1096–1105. [Google Scholar] [CrossRef]

- Cheema, M.A.; Fletcher, J.E.; Farshadnia, M.; Xiao, D.; Rahman, M.F. Combined Speed and Direct Thrust Force Control of Linear Permanent-Magnet Synchronous Motors with Sensorless Speed Estimation Using a Sliding Mode Control with Integral Action. IEEE Trans. Ind. Electron. 2017, 64, 3489–3502. [Google Scholar] [CrossRef]

- Hui, Y.; Chi, R.; Huang, B.; Hou, Z. Extended State Observer-Based Data-Driven Iterative Learning Control for Permanent Magnet Linear Motor with Initial Shifts and Disturbances. IEEE Trans. Syst. Man Cybern. Syst. 2021, 51, 1881–1891. [Google Scholar] [CrossRef]

- Chiang, H.H.; Hsu, K.C.; Li, I.H. Optimized Adaptive Motion Control Through an SoPC Implementation for Linear Induction Motor Drives. IEEE-ASME Trans. Mechatron. 2015, 20, 348–360. [Google Scholar] [CrossRef]

- Chaio, S. Supervisory Interval Type-2 TSK Neural Fuzzy Network Control for Linear Microstepping Motor Drives with Uncertainty Observer. IEEE Trans. Power Electron. 2011, 26, 2049–2064. [Google Scholar] [CrossRef]

- Shao, K.; Zheng, J.; Huang, K.; Wang, H.; Man, Z.; Fu, M. Finite-Time Control of a Linear Motor Positioner Using Adaptive Recursive Terminal Sliding Mode. IEEE Trans. Ind. Electron. 2020, 67, 6659–6668. [Google Scholar] [CrossRef]

- Chen, Z.; Yao, B.; Wang, Q. Accurate Motion Control of Linear Motors with Adaptive Robust Compensation of Nonlinear Electromagnetic Field Effect. IEEE-ASME Trans. Mechatron. 2013, 18, 1122–1129. [Google Scholar] [CrossRef]

- Francesco, A.; Maurizio, C.; Filippo, D.I.; Marcello, P.; Antonino, S. Active Disturbance Rejection Control of Linear Induction Motor. IEEE Trans. Ind. Appl. 2017, 53, 4460–4471. [Google Scholar] [CrossRef]

- Bastian, C.; Serge, G.; Luca, R.; Mauro, C. Speed Control of a Multiphase Active Way Linear Motor Based on Back EMF Estimation. IEEE Trans. Ind. Electron. 2015, 62, 7299–7307. [Google Scholar] [CrossRef]

- Ruchao, P.; Nattapon, C.; David, G.T.; Niyom, N.; Seubsuang, K.; Prapon, J.; Pakasit, S.; Kanokvate, T. Adaptive Integral Sliding-Mode Position Control of a Coupled-Phase Linear Variable Reluctance Motor for High-Precision Applications. IEEE Trans. Ind. Appl. 2012, 48, 1353–1363. [Google Scholar] [CrossRef]

- Zheng, J.; Wang, H.; Man, Z.; Jin, J.; Fu, M. Robust Motion Control of a Linear Motor Positioner Using Fast Nonsingular Terminal Sliding Mode. IEEE-ASME Trans. Mechatron. 2015, 20, 1743–1752. [Google Scholar] [CrossRef]

- Huang, Y.-S.; Sung, C.-C. Implementation of sliding mode controller for linear synchronous motors based on direct thrust control theory. IET Contr. Theory Appl. 2010, 4, 326–338. [Google Scholar] [CrossRef]

- Sadighi, A.; Kim, W.J. Sensorless Control of a Novel Linear Magnetostrictive Motor. IEEE Trans. Ind. Appl. 2011, 47, 736–743. [Google Scholar] [CrossRef]

- Cao, R.; Jiang, N.; Lu, M. Sensorless Control of Linear Flux-switching Permanent Magnet Motor Based on Extended Kalman Filter. IEEE Trans. Ind. Electron. 2019, 67, 5971–5979. [Google Scholar] [CrossRef]

- Ting, C.S.; Chang, Y.N.; Shi, B.W.; Lieu, J.F. Adaptive Backstepping Control for Permanent Magnet Linear Synchronous Motor Servo Drive. IET Electr. Power Appl. 2015, 9, 265–279. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, W. Dual stroke and phase control and system identification of linear compressor of a split-stirling cryocooler. Asian J. Control 1999, 1, 116–121. [Google Scholar] [CrossRef]

- Du, Z.; Zhou, Z.; Ai, W.; Chen, Y. A linear drive system for the dynamic focus module of SLS machines. Int. J. Adv. Manuf. Technol. 2007, 32, 1211–1217. [Google Scholar] [CrossRef]

- Pan, J.F.; Zou, Y.; Cao, G.; Cheung, N.C.; Zhang, B. High-Precision Dual-Loop Position Control of an Asymmetric Bilateral Linear Hybrid Switched Reluctance Motor. IEEE Trans. Magn. 2015, 51, 8600405. [Google Scholar] [CrossRef]

- Lin, Z.; Wang, J.; Howe, D. A Hybrid Current Controller for Linear Reciprocating Vapor Compressors. In Proceedings of the 2007 IEEE Industry Applications Annual Meeting, New Orleans, LA, USA, 23–27 September 2007; pp. 274–280. [Google Scholar] [CrossRef]

- Chun, T.W.; Ahn, J.R.; Lee, H.H.; Kim, H.G.; Nho, E.C. A novel strategy of efficiency control for a linear compressor system driven by a PWM inverter. IEEE Trans. Ind. Electron. 2008, 55, 296–301. [Google Scholar] [CrossRef]

- Kim, G.; Jeon, J.; Yim, C. Dynamic performance improvement of oscillating linear motors via efficient parameter identification. J. Power Electron. 2010, 10, 58–64. [Google Scholar] [CrossRef]

- Wang, X.; Chen, F.; Zhu, R.; Huang, X.; Sang, N.; Yang, G.; Zhang, C. A Review on Disturbance Analysis and Suppression for Permanent Magnet Linear Synchronous Motor. Actuator 2021, 10, 77. [Google Scholar] [CrossRef]

- Jean-Franco, L.; Nicolas, M.; Pascal, L.; Bertr, N. Analysis and Modeling of Linear-Switched Reluctance for Medical Application. Actuator 2013, 2, 27–44. [Google Scholar] [CrossRef] [Green Version]

- Mituhiko, A.; Hidefumi, T. Two-Degree-of-Freedom PID Controllers. Int. J. Control Autom. Syst. 2003, 1, 401–411. [Google Scholar]

Short Biography of Authors

| Zongxia Jiao received the B.S. and Ph.D. degrees in mechatronics engineering from Zhejiang University, Hangzhou, China, in 1985 and 1991, respectively. From 1991 to 1993, he was as a Postdoctoral Fellow with Beihang University, where he became a Professor in 1994. He is currently the Dean of the School of Automation Science and Electrical Engineering, Beihang University. His research interests include fluid power and transmission, actuators, and sensors. |

| Yuan Cao received the Master degree from Yanshan University, Qinhuangdao, China in 2016. He is currently working toward his Ph.D. degree in mechanical engineering at Beihang University. His research interests include electro-hydrostatic actuators and linear motors. |

| Liang Yan received the Bachelor degree from North China Institute of Technology, Shanxi, China in 1995, the Master degree from Beijing Institute of Technology (BIT), Beijing, China, in 1998, and the Ph.D. degree from Nanyang Technological University (NTU), Singapore, in 2006. He was with BIT from 1998 to 2002, NTU from 2006 to 2009, and currently is a Professor at Beihang University. His research interests include robotics, actuators and sensors. He served more than ten IEEE/ASME conferences as program and publication chairman. |

| Xinglu Li received the Bachelor degree from Beihang University, Beijing, China in 2014. He is currently working toward his Ph.D. degree in mechanical engineering at Beihang University. His research interests include electro-hydrostatic actuators and electrohydraulic load simulators. |

| Lu Zhang received the master’s degree in electrical engineering from the Hebei University of Science and Technology, Shijiazhuang, China, in 2015, and the Ph.D. degree in mechatronics from Beihang University, Beijing, China, in 2020. She is currently a Postdoc with Beihang University, Beijing. Her research interests include actuators, sensors, robotics and navigation systems. |

| Yang Li is a research associate at Beihang University. He received his bachelor degree and Ph.D. at the School of automation science and electrical engineering in Beihang University. His research focuses on more electric aircraft flight control actuation system, intelligent mechatronic system and aircraft integrated energy management technology. |

| Symbol | Quantity | Value |

|---|---|---|

| Force constant | 32 N/A | |

| k | Spring stiffness | 30,700 N/m |

| Damping coefficient | 60 N s/m | |

| m | Total mass | 1.35 kg |

| Control Method | Phase Lag/deg |

|---|---|

| AMFC | 2.7 |

| PID | 6.4 |

| PI | 18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiao, Z.; Cao, Y.; Yan, L.; Li, X.; Zhang, L.; Li, Y. Advancing Motivation Feedforward Control of Permanent Magnetic Linear Oscillating Synchronous Motor for High Tracking Precision. Actuators 2021, 10, 128. https://doi.org/10.3390/act10060128

Jiao Z, Cao Y, Yan L, Li X, Zhang L, Li Y. Advancing Motivation Feedforward Control of Permanent Magnetic Linear Oscillating Synchronous Motor for High Tracking Precision. Actuators. 2021; 10(6):128. https://doi.org/10.3390/act10060128

Chicago/Turabian StyleJiao, Zongxia, Yuan Cao, Liang Yan, Xinglu Li, Lu Zhang, and Yang Li. 2021. "Advancing Motivation Feedforward Control of Permanent Magnetic Linear Oscillating Synchronous Motor for High Tracking Precision" Actuators 10, no. 6: 128. https://doi.org/10.3390/act10060128