Stabilization of a Magnetic Repulsive Levitation Flywheel System Using a High-Efficiency Superconducting Magnetic Bearing

Abstract

:1. Introduction

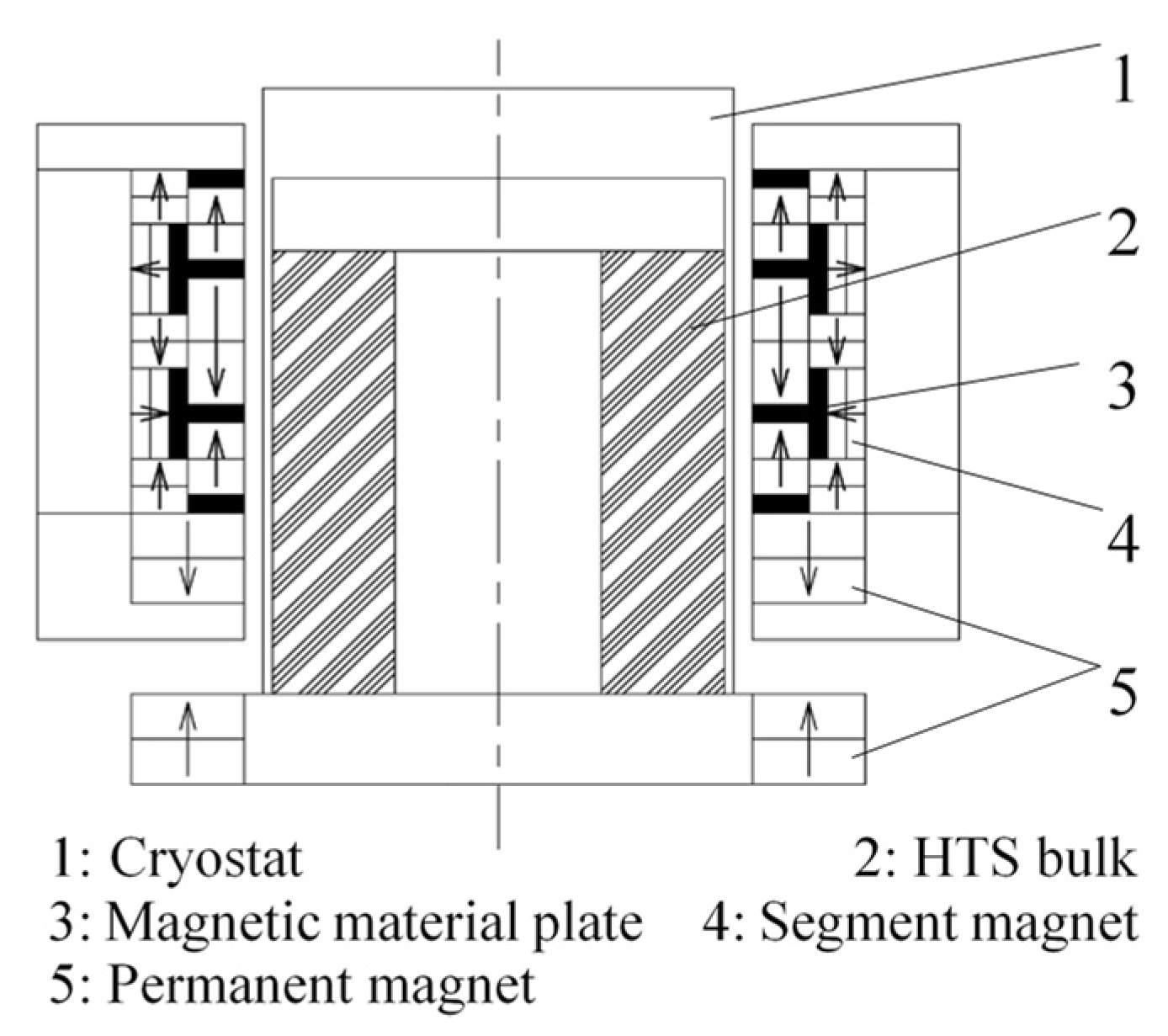

2. Development of Superconducting Magnetic Bearing (SMB)

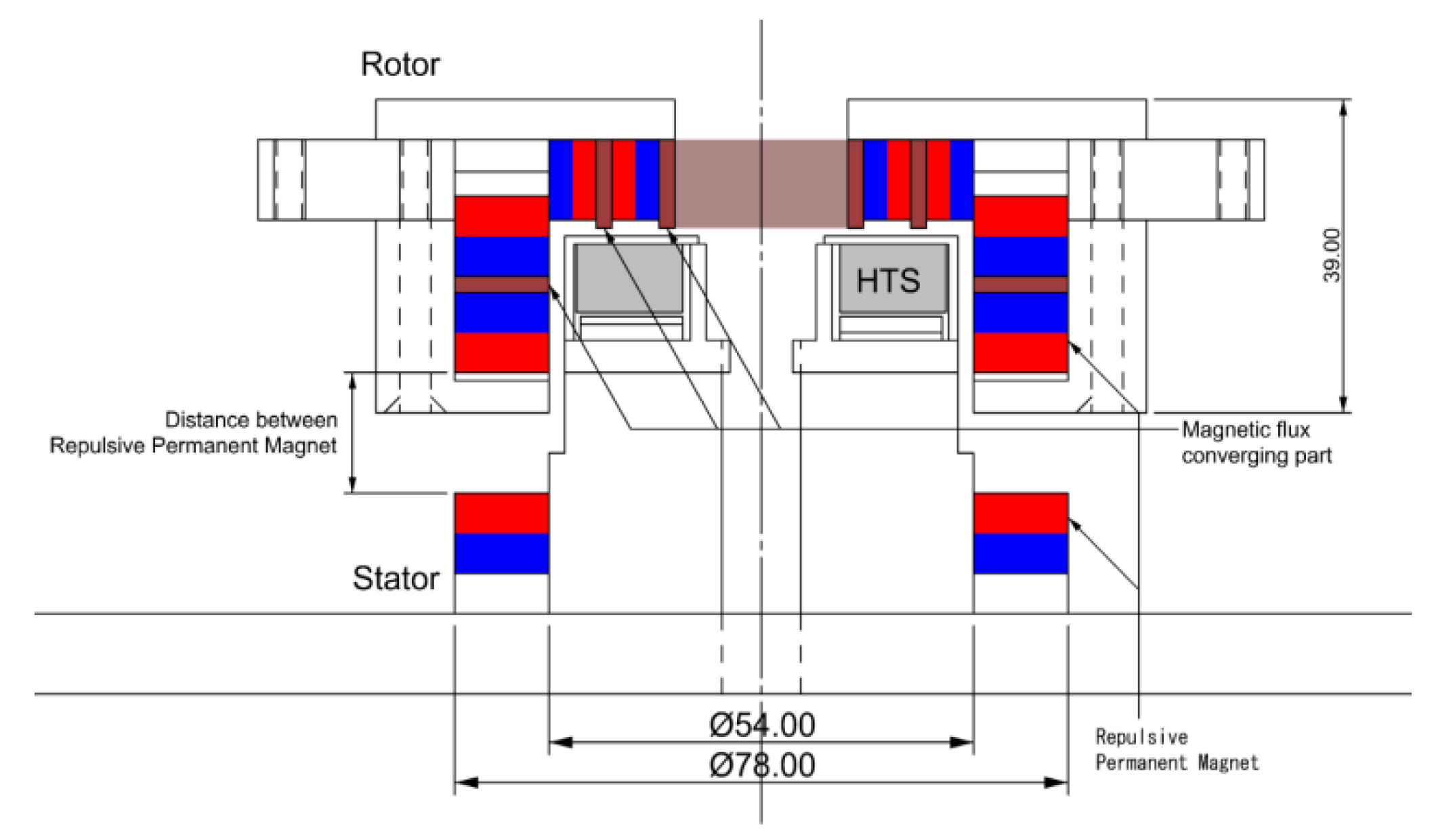

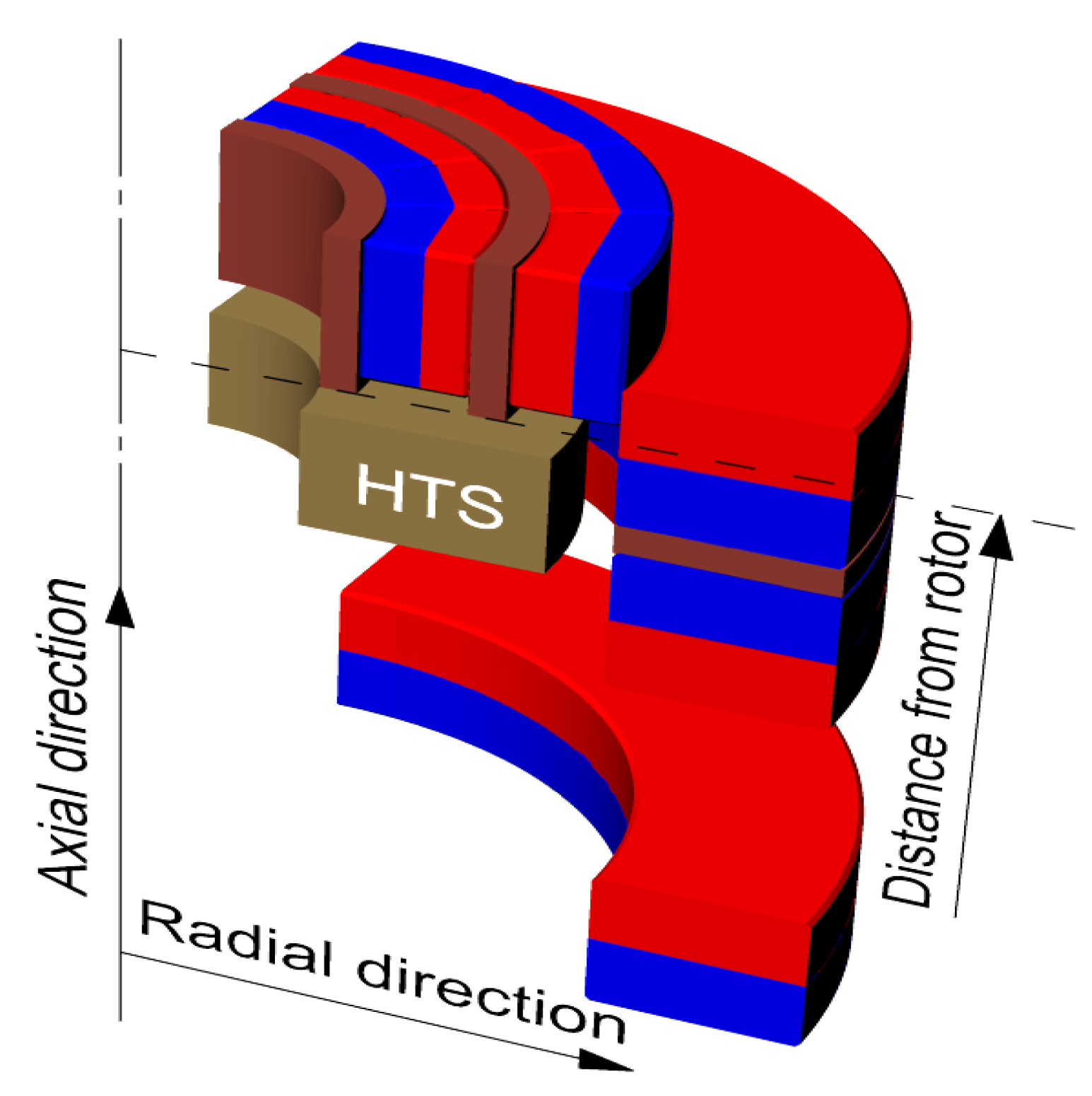

2.1. Configuration of SMB

2.2. Specifications of Superconductor

3. Development of Superconducting Magnetic Bearing (SMB)

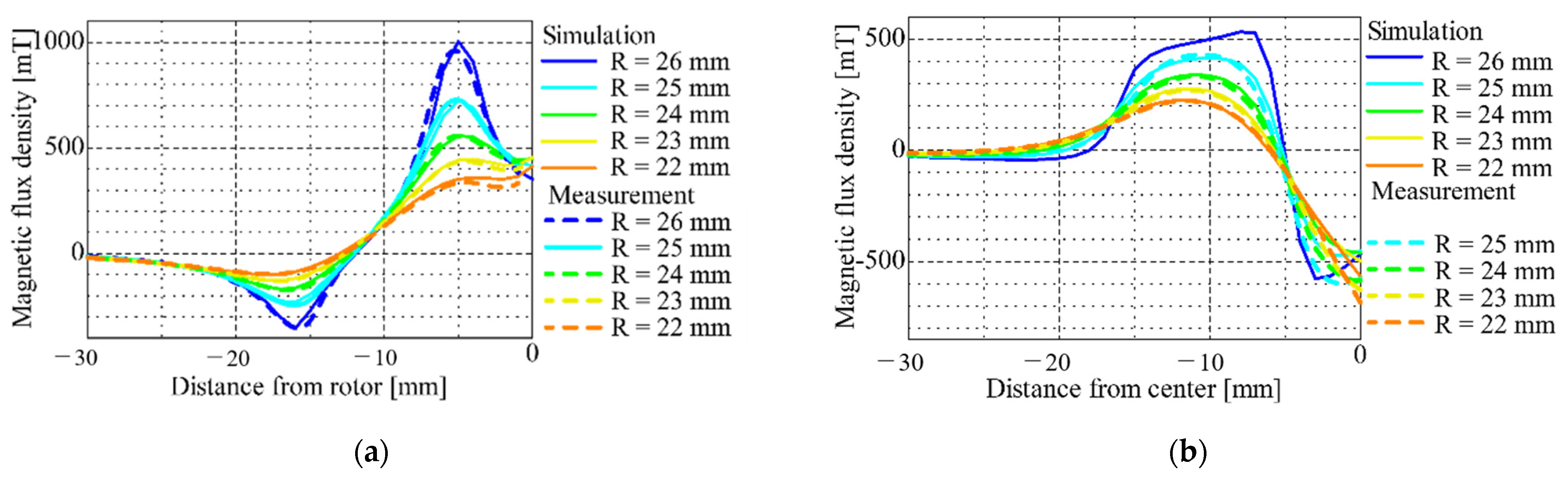

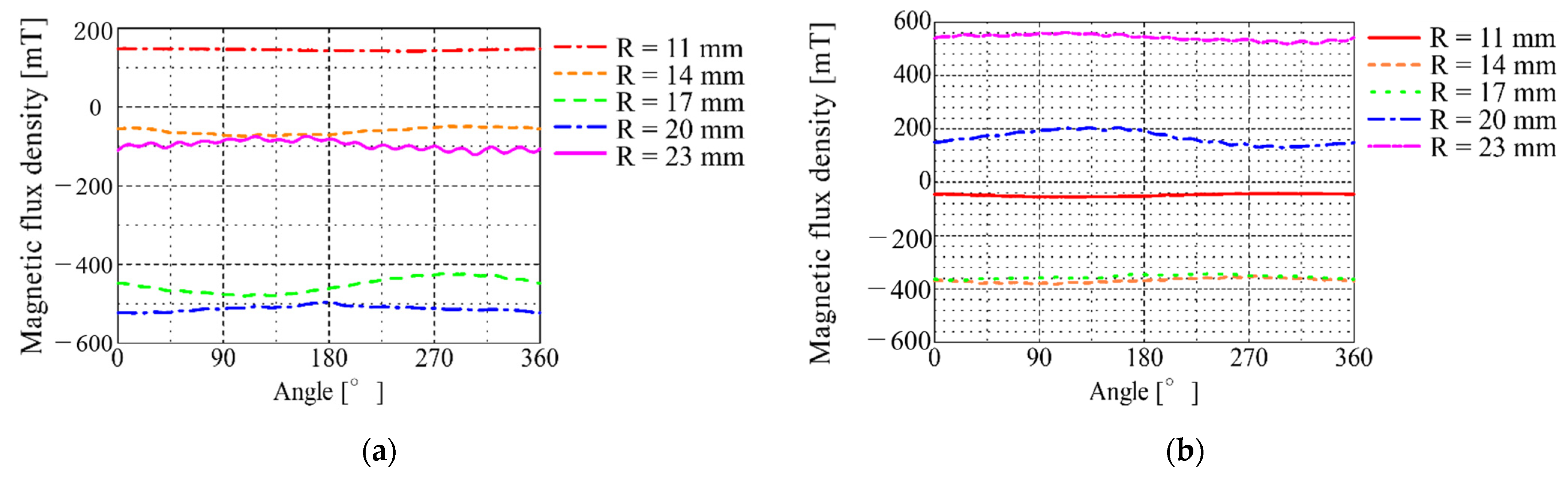

3.1. Magnetic Flux Density Distribution Generated by the SMB Rotor Section

3.1.1. Simulation of the Magnetic Flux Density

3.1.2. Measurement of Magnetic Flux Density

3.2. Restoring Force Generated by SMB

3.3. Comparison with Previous Research of the Restoring Force along Each Axis

4. Driving Experiment

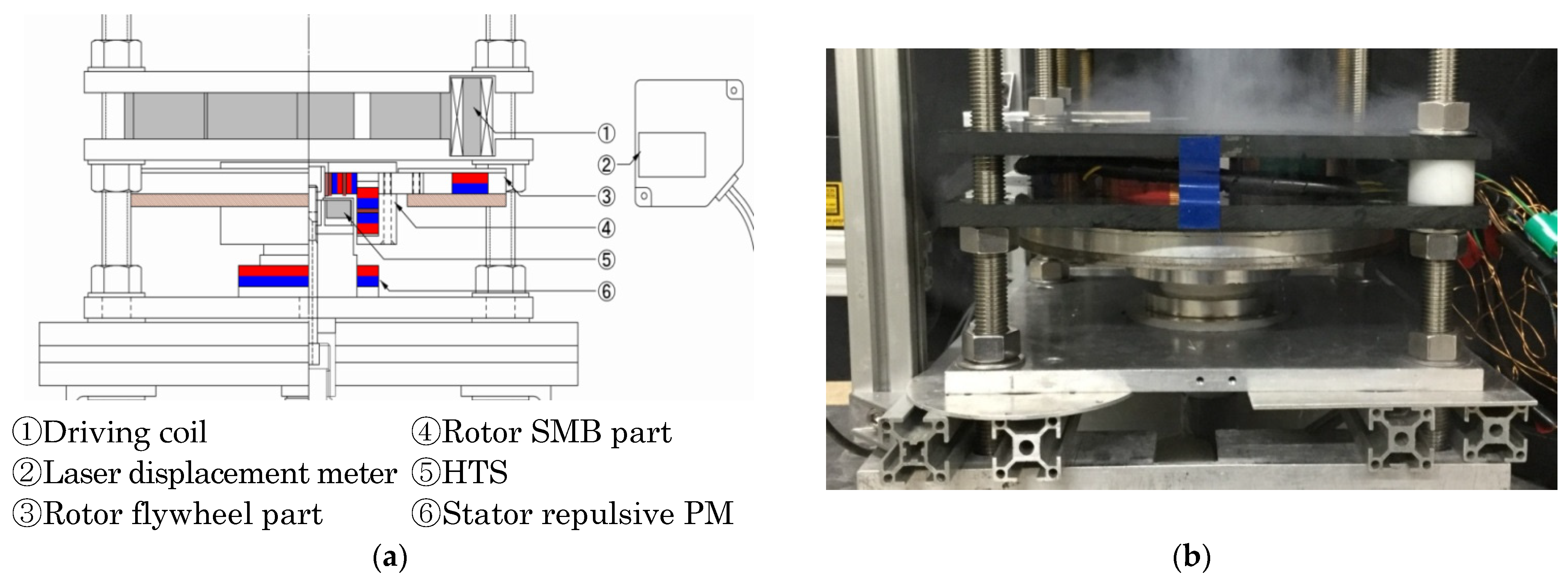

4.1. Experimental Device Specifications

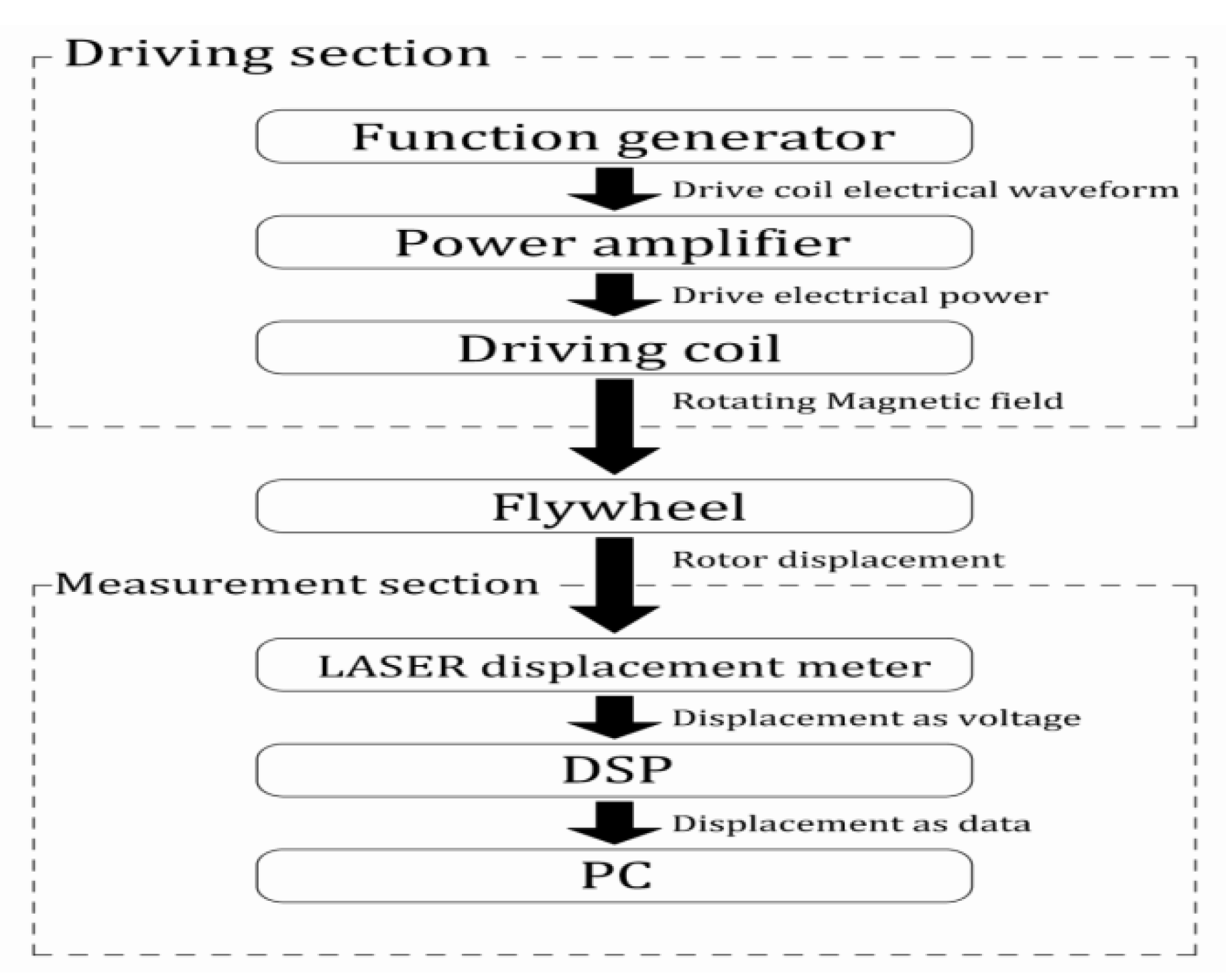

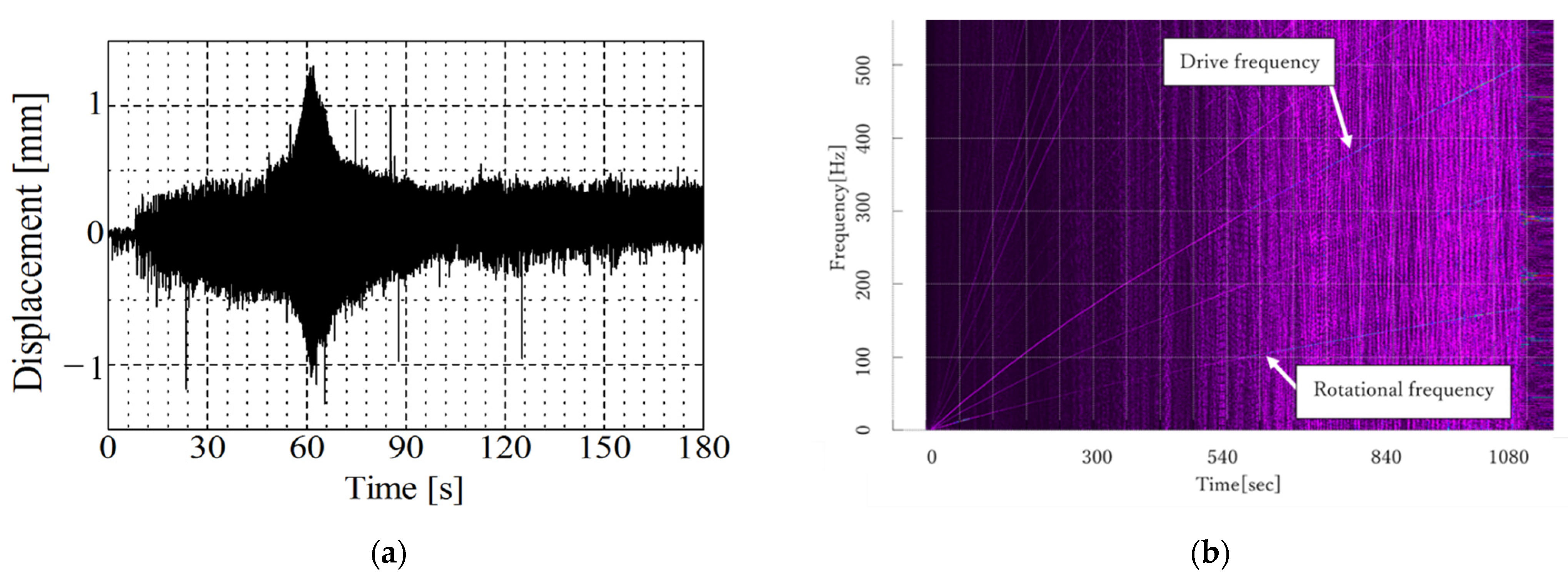

4.2. Method and Results of the Experiment

5. Conclusions

- We devised and manufactured an SMB with a magnetic field that utilized the top and sides of a ring-shaped HTS.

- It was confirmed that the unstable force owing to repulsive magnetic levitation can be stabilized by the developed SMB.

- Compared with previous research, the restoring force characteristics per unit volume of HTS were significantly increased by 4.2 to 4.9 times.

- It was confirmed that the flywheel using the proposed SMB could rotate beyond the swinging resonance speed without a requirement for control and could be stably driven up to the high-speed rotation range.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Arai, U. Chodendo jiki jikuuke ni yoru furaihoiru chikuden sochi no Kaihatsu (Development of flywheel power storage device using superconducting magnetic bearings). Appl. Phys. 2015, 84, 150–153. [Google Scholar]

- Yamashita, T.; Ogata, M.; Magashima, K. The Superconducting Flywheel Storage Systems using the Superconducting Magnetic Bearing. J. JSAEM 2016, 24, 293–298. [Google Scholar]

- Miyazaki, Y.; Mizuno, K.; Yamashita, T.; Ogata, M.; Hasegawa, H.; Nagashima, K.; Mukoyama, S.; Matsuoka, T.; Nakao, K.; Horiuch, S.; et al. Development of superconducting magnetic bearing for flywheel energy storage system. Cryogenics 2016, 80, 234–237. [Google Scholar] [CrossRef]

- Nagashima, K. Development Overview of a Superconducting Flywheel Energy Storage System for Demonstration Tests. Low Temp. Eng. 2019, 54, 351–358. [Google Scholar] [CrossRef] [Green Version]

- Miyazaki, Y.; Mizuno, K.; Ogata, M.; Yamashita, Y.; Nagashima, K. Development of a Superconducting Magnetic Bearing Capable of Supporting Large Loads in a Flywheel Energy Storage for Railway Application. Q. Rep. RTRI 2020, 61, 54–59. [Google Scholar] [CrossRef] [Green Version]

- Ai, L.; Zhang, G.; Li, W.; Liu, G.; Liu, Q. Optimization of radial-type superconducting magnetic bearing using the Taguchi method. Phys. C Supercond. 2018, 550, 57–64. [Google Scholar] [CrossRef]

- Zou, Y.; Shang, J.; Guan, X.; Bian, X.; Wu, J.; Li, Q. Design and experimental research of superconducting magnetic bearing for helium cold compressor. Cryogenics 2020, 106, 103047. [Google Scholar] [CrossRef]

- Murakami, I.; Shimada, T.; Kobayashi, Y.; Mori, H.; Ando, Y. Stabilization of repulsive-type magnetic levitation system using superconducting magnetic bearing. Int. J. Appl. Electromagn. Mech. 2016, 52, 1607–1613. [Google Scholar] [CrossRef]

| Items | Detailed Specifications |

|---|---|

| Material composition | Gd-Ba-Cu-O type |

| Maker | Nippon Steel |

| Outside diameter | 47 mm |

| Inside diameter | 20 mm |

| Height | 8 mm |

| Items | Detailed Specifications |

|---|---|

| Analysis type | Three-dimensional static magnetic field analysis |

| Number of elements | 541,884 |

| Number of nodes | 100,480 |

| Boundary conditions | vector potential |

| PM material | NEOMAX 41H, NEOMAX 35H |

| Ferromagnetic material | 50JN1300 |

| Items | Previous Model with Repulsive PM Gap 10 mm | Present Model with Repulsive PM Gap 10 mm |

|---|---|---|

| Radial restoring force [N/m] | ||

| Axial restoring force [N/m] | ||

| 13.55 × 10−5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murakami, I.; Zhao, Y.; Tashiro, T. Stabilization of a Magnetic Repulsive Levitation Flywheel System Using a High-Efficiency Superconducting Magnetic Bearing. Actuators 2022, 11, 180. https://doi.org/10.3390/act11070180

Murakami I, Zhao Y, Tashiro T. Stabilization of a Magnetic Repulsive Levitation Flywheel System Using a High-Efficiency Superconducting Magnetic Bearing. Actuators. 2022; 11(7):180. https://doi.org/10.3390/act11070180

Chicago/Turabian StyleMurakami, Iwanori, Yiming Zhao, and Tatuhiro Tashiro. 2022. "Stabilization of a Magnetic Repulsive Levitation Flywheel System Using a High-Efficiency Superconducting Magnetic Bearing" Actuators 11, no. 7: 180. https://doi.org/10.3390/act11070180