Examination of High-Torque Sandwich-Type Spherical Ultrasonic Motor Using with High-Power Multimode Annular Vibrating Stator

Abstract

:1. Introduction

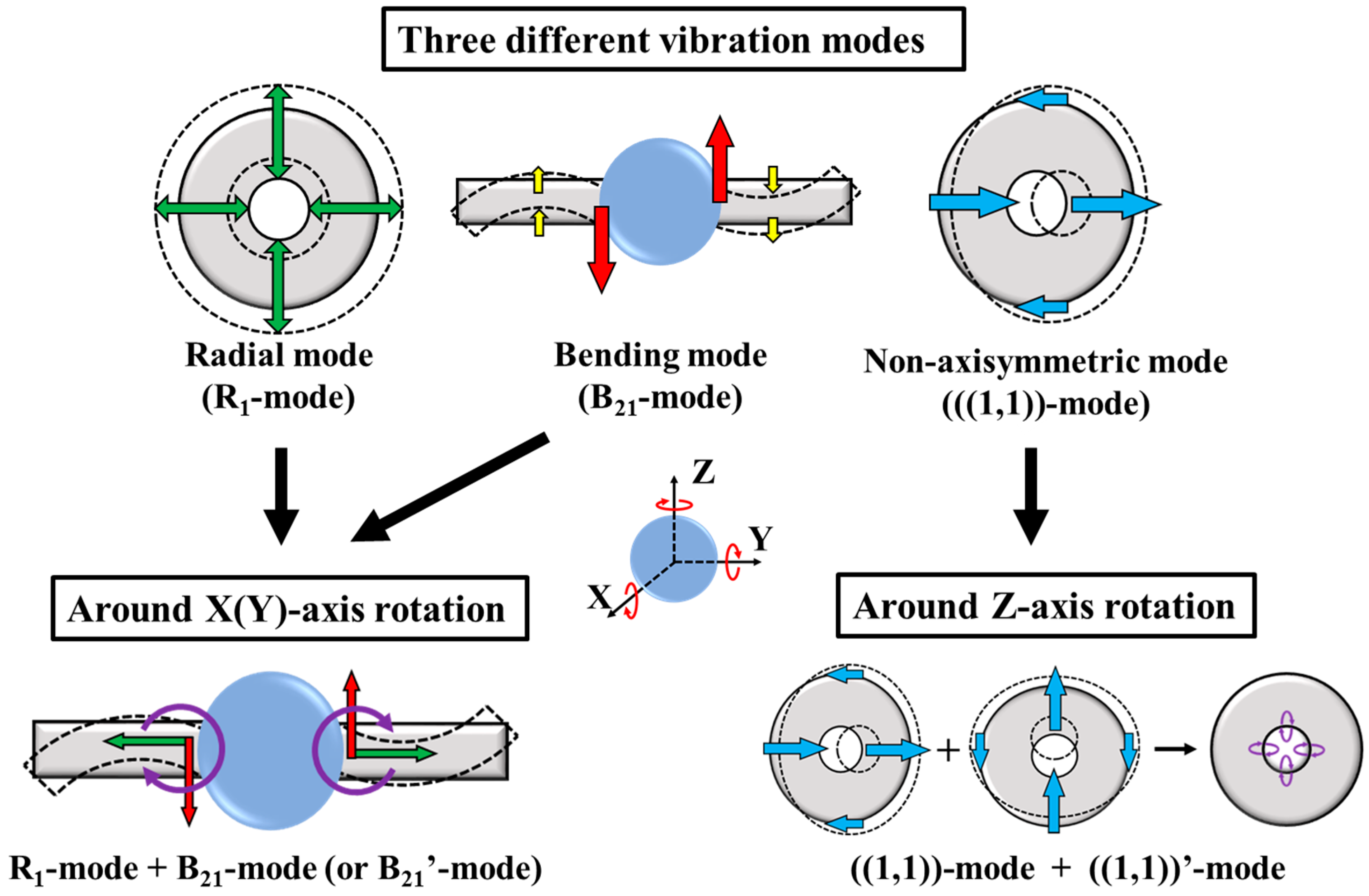

2. Operating Principle

2.1. Rotation around X(Y)-Axis

2.2. Rotation around Z-Axis

3. Construction Design and Driving Method

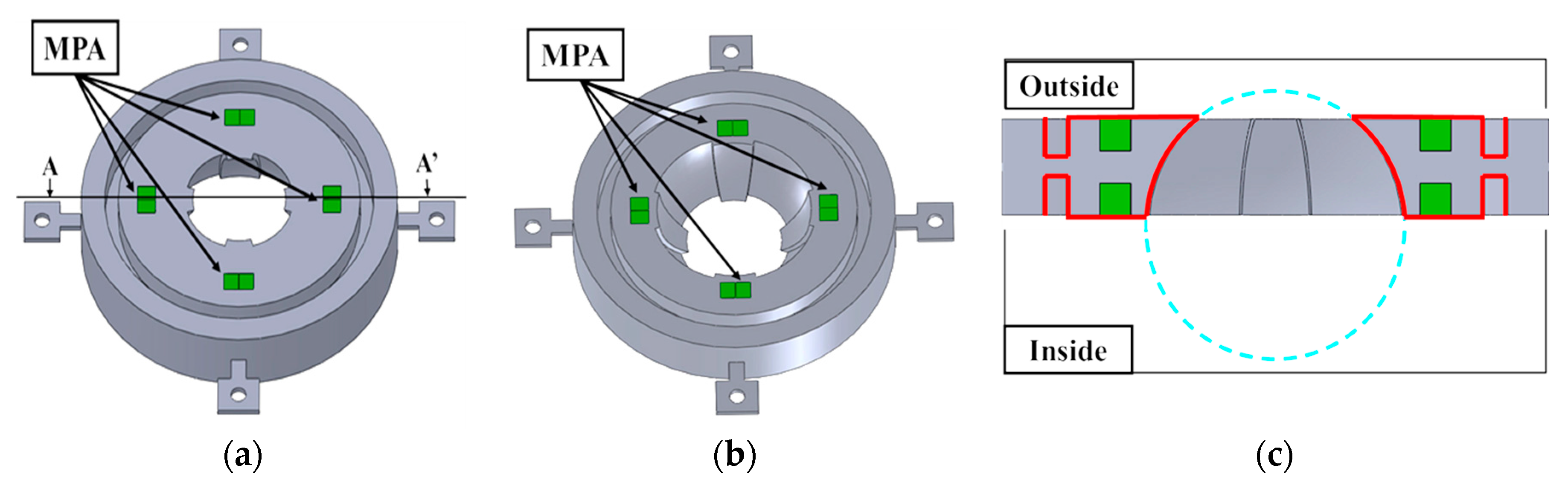

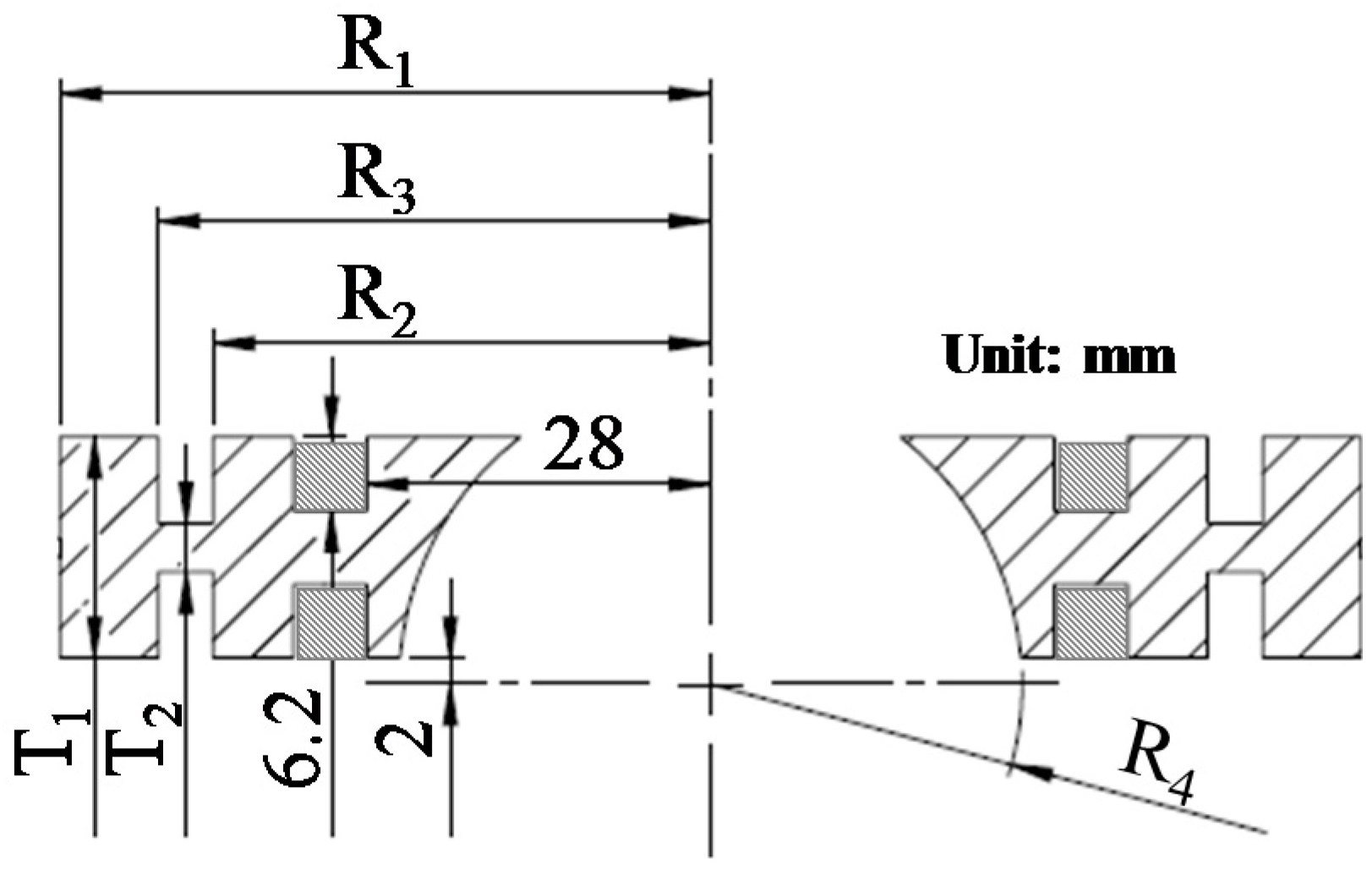

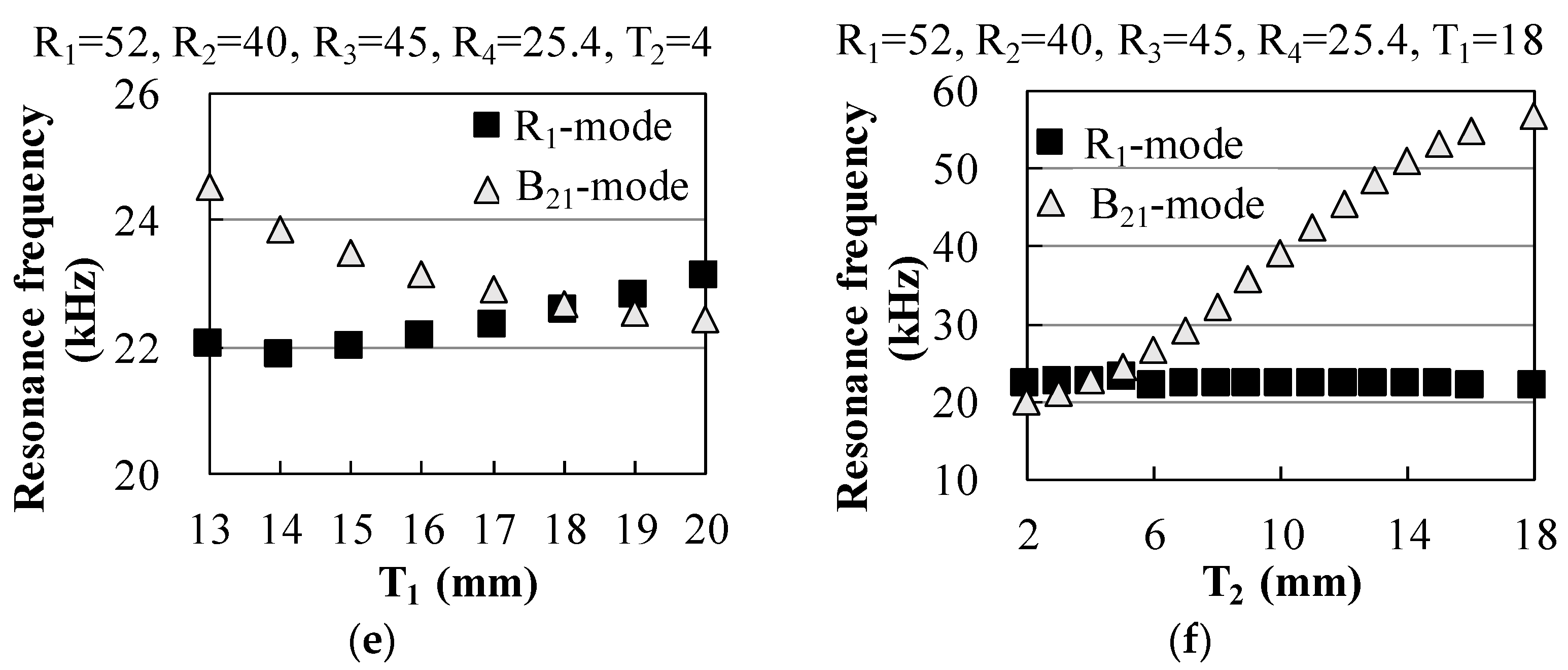

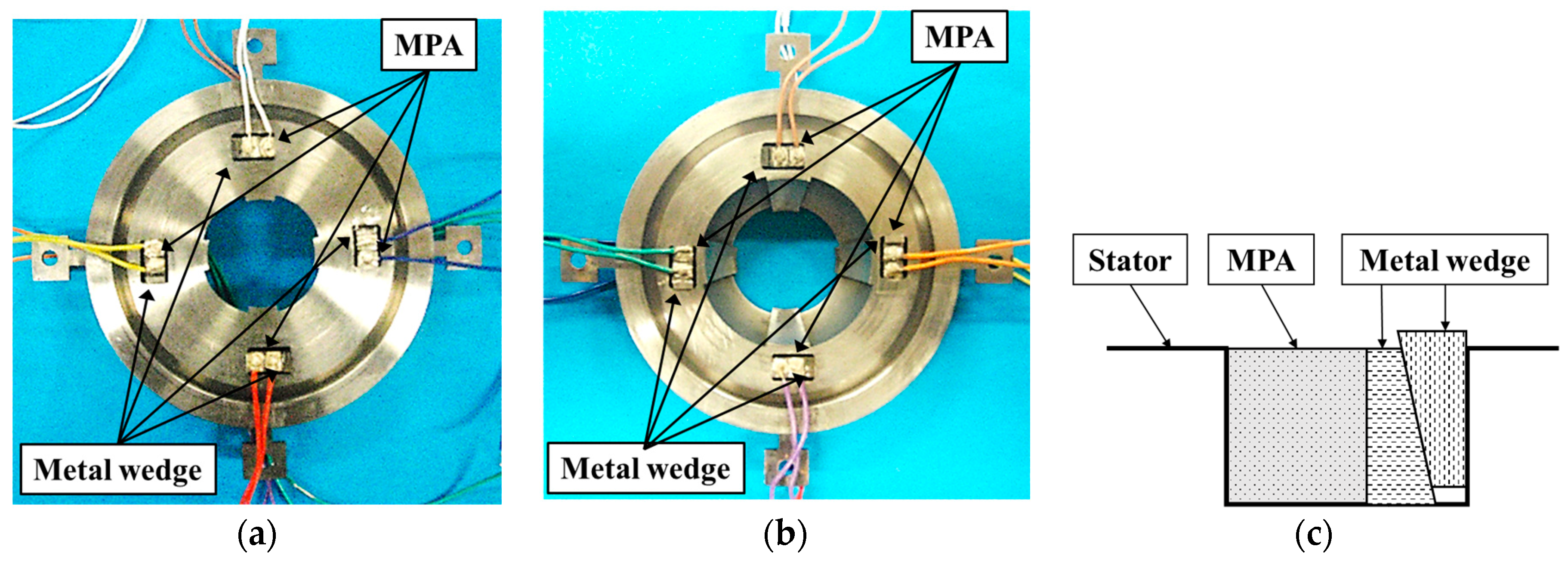

3.1. Vibrating Stator Construction

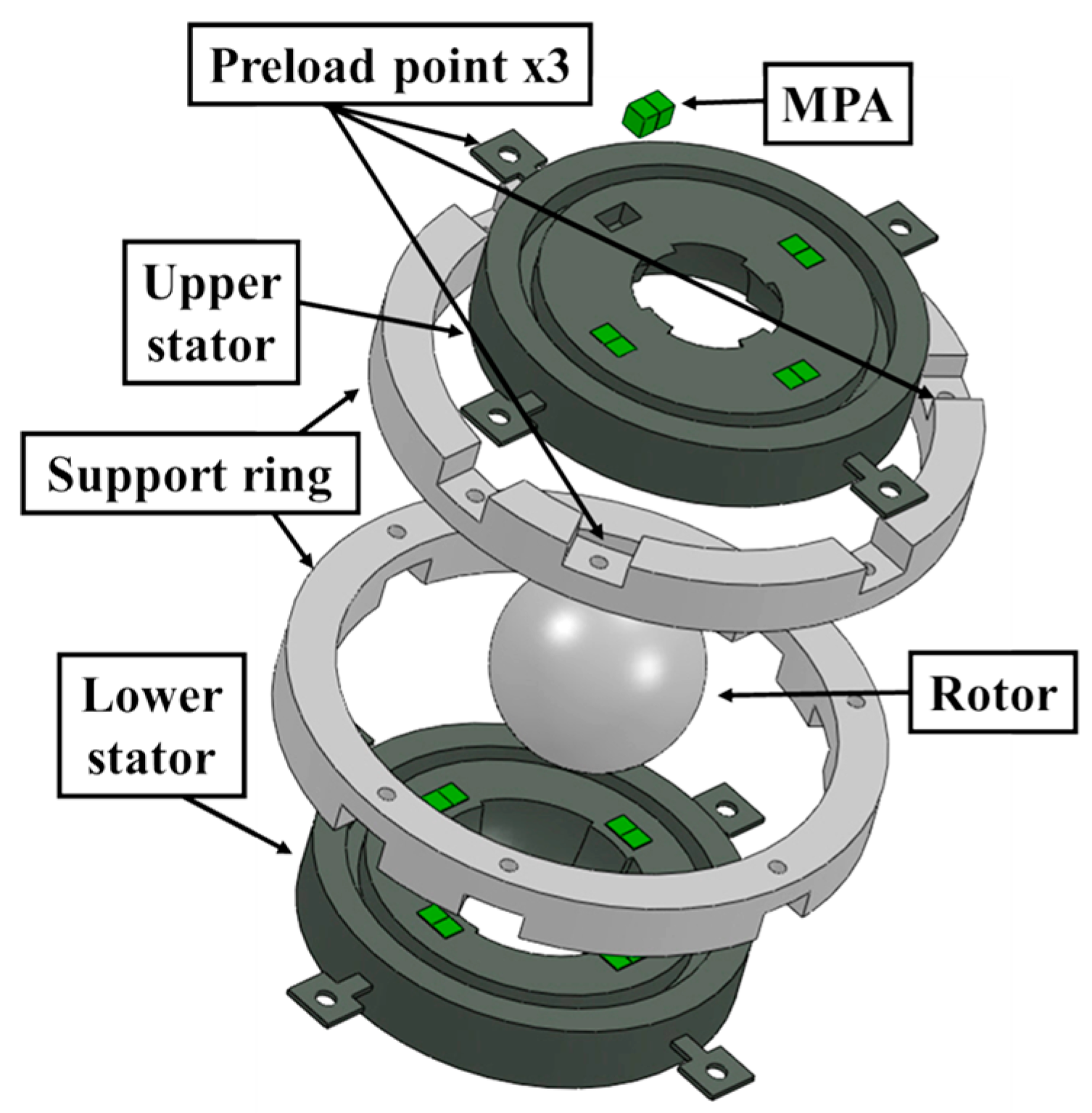

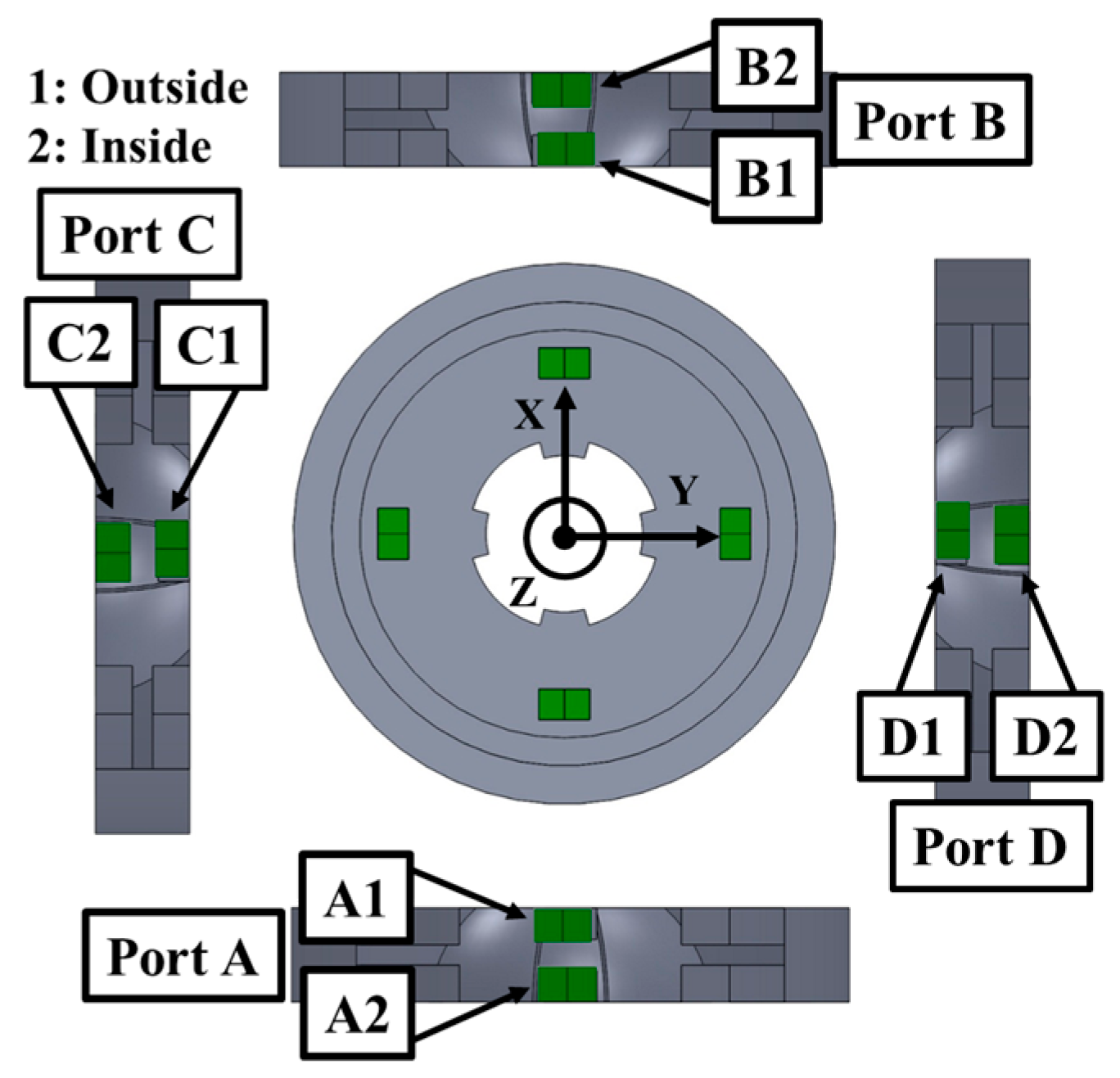

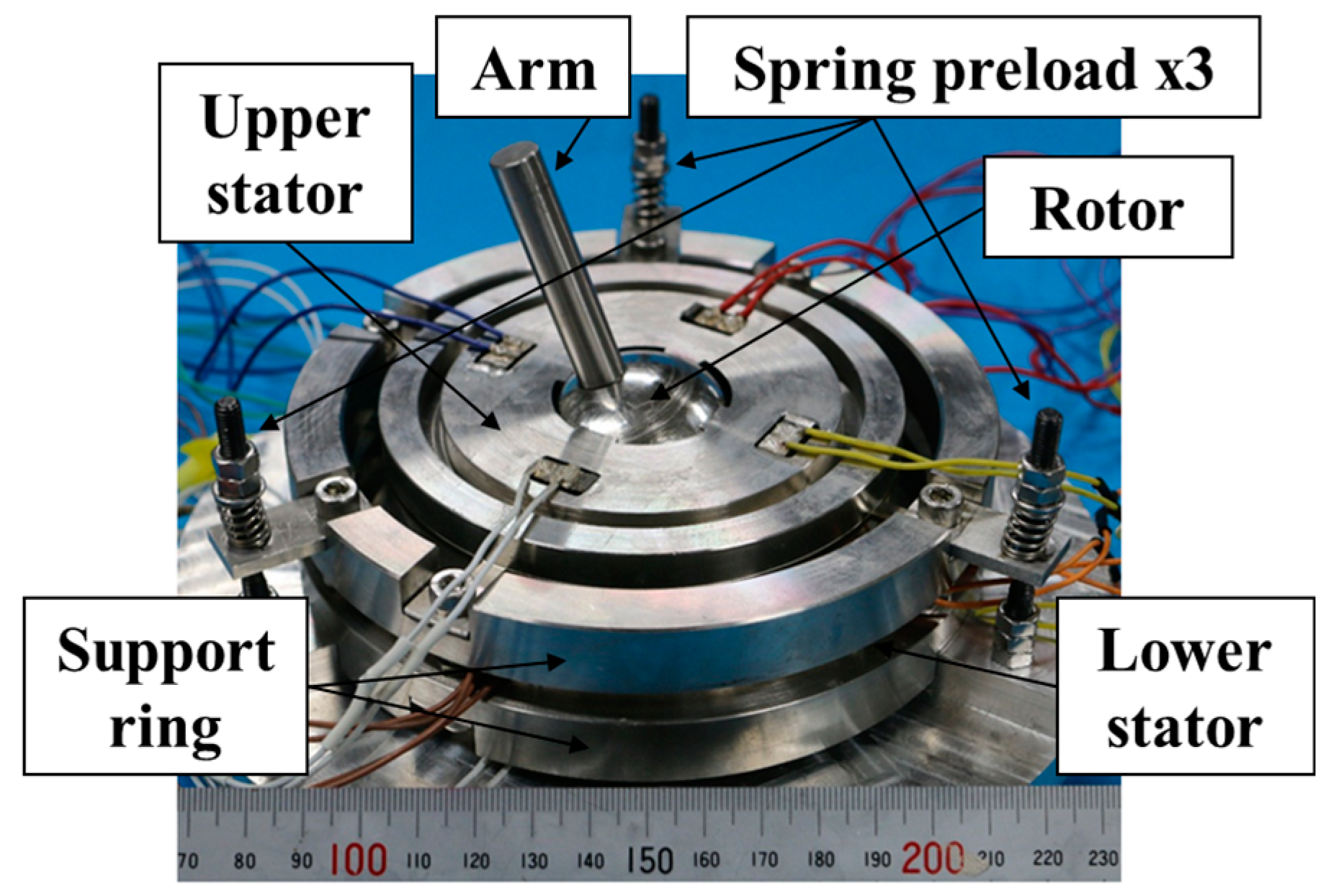

3.2. Motor Structure

3.3. Driving Method

4. Structure and Measured Characteristics

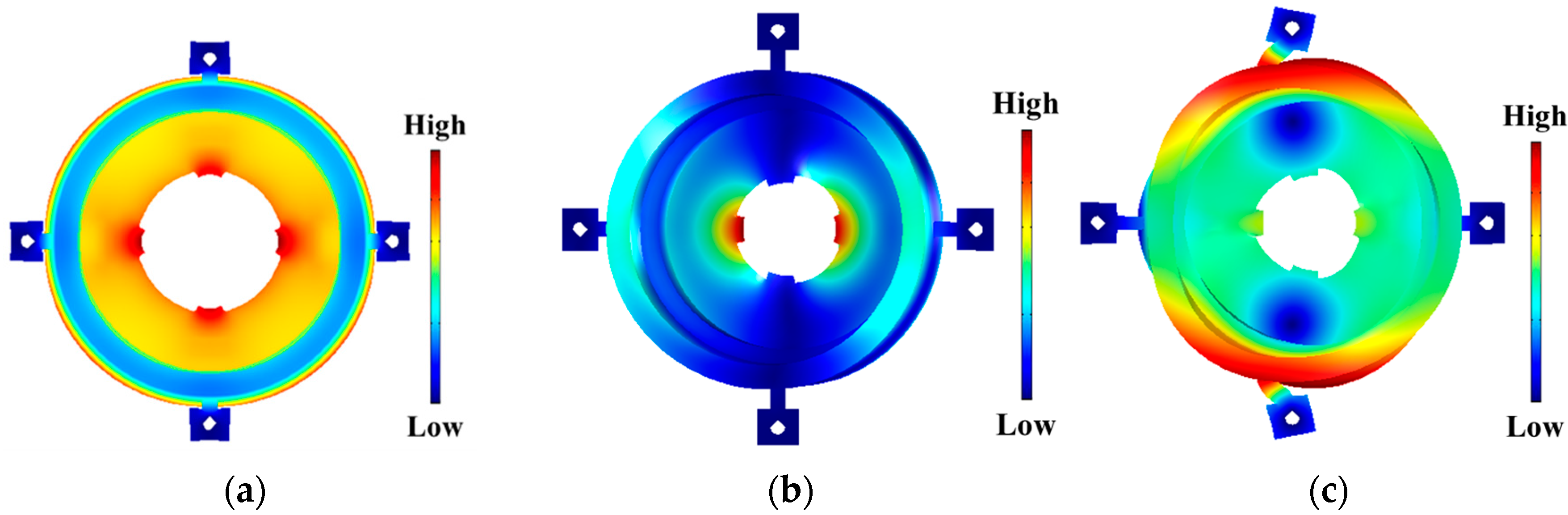

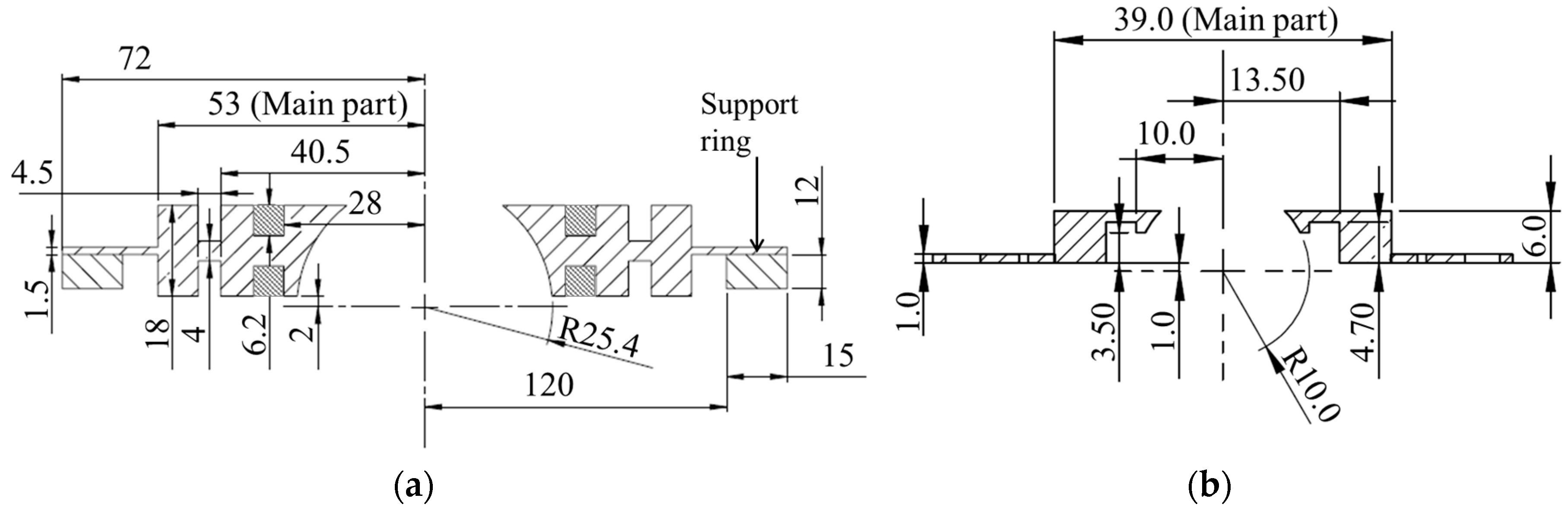

4.1. Stator Dimensions

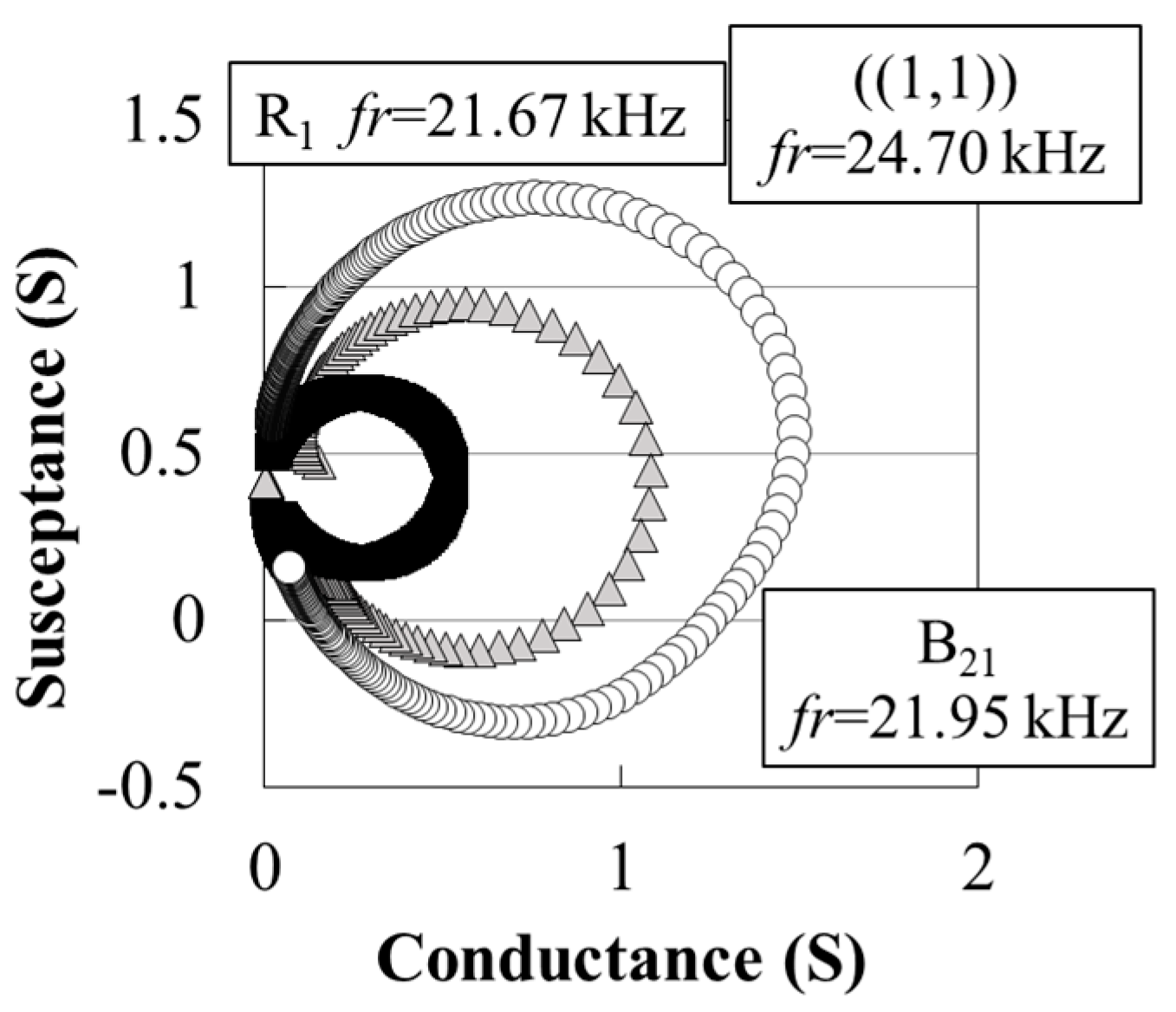

4.2. Admittance Characteristics

4.3. Vibration Displacement

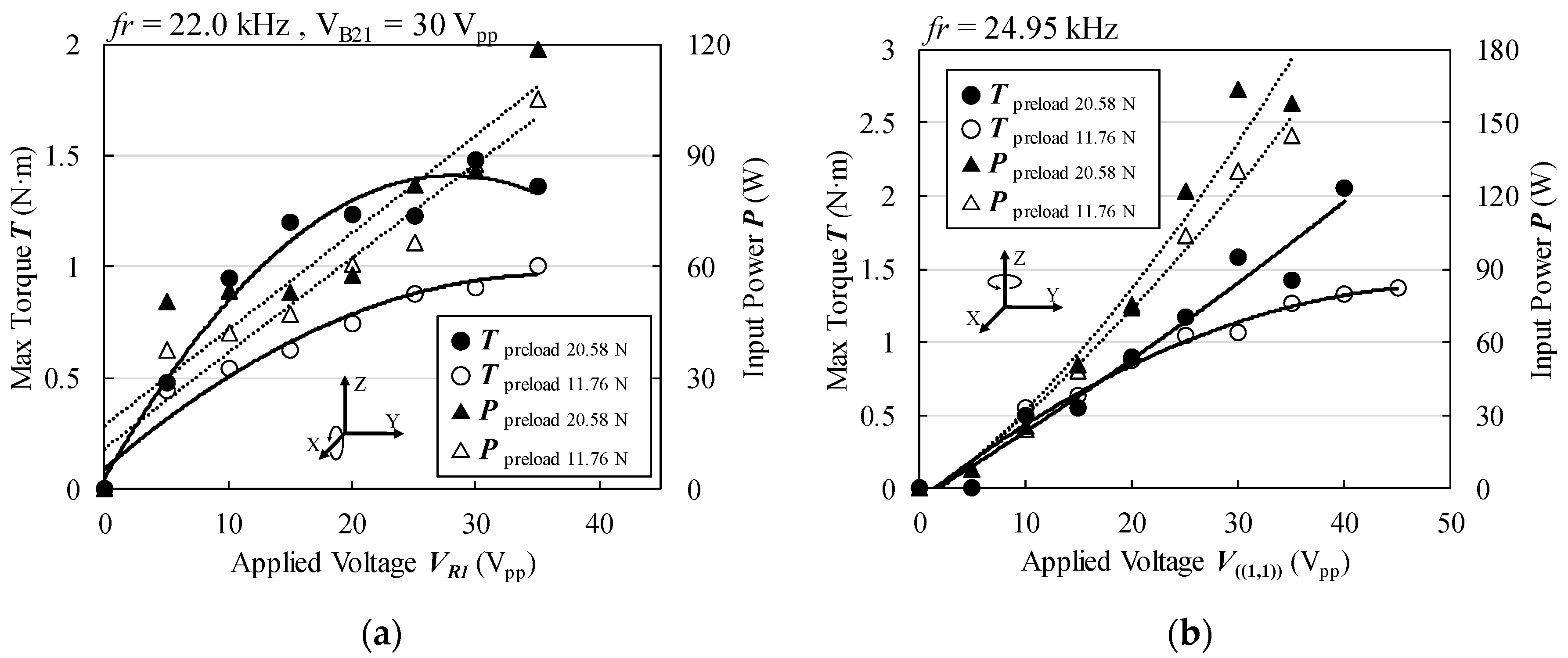

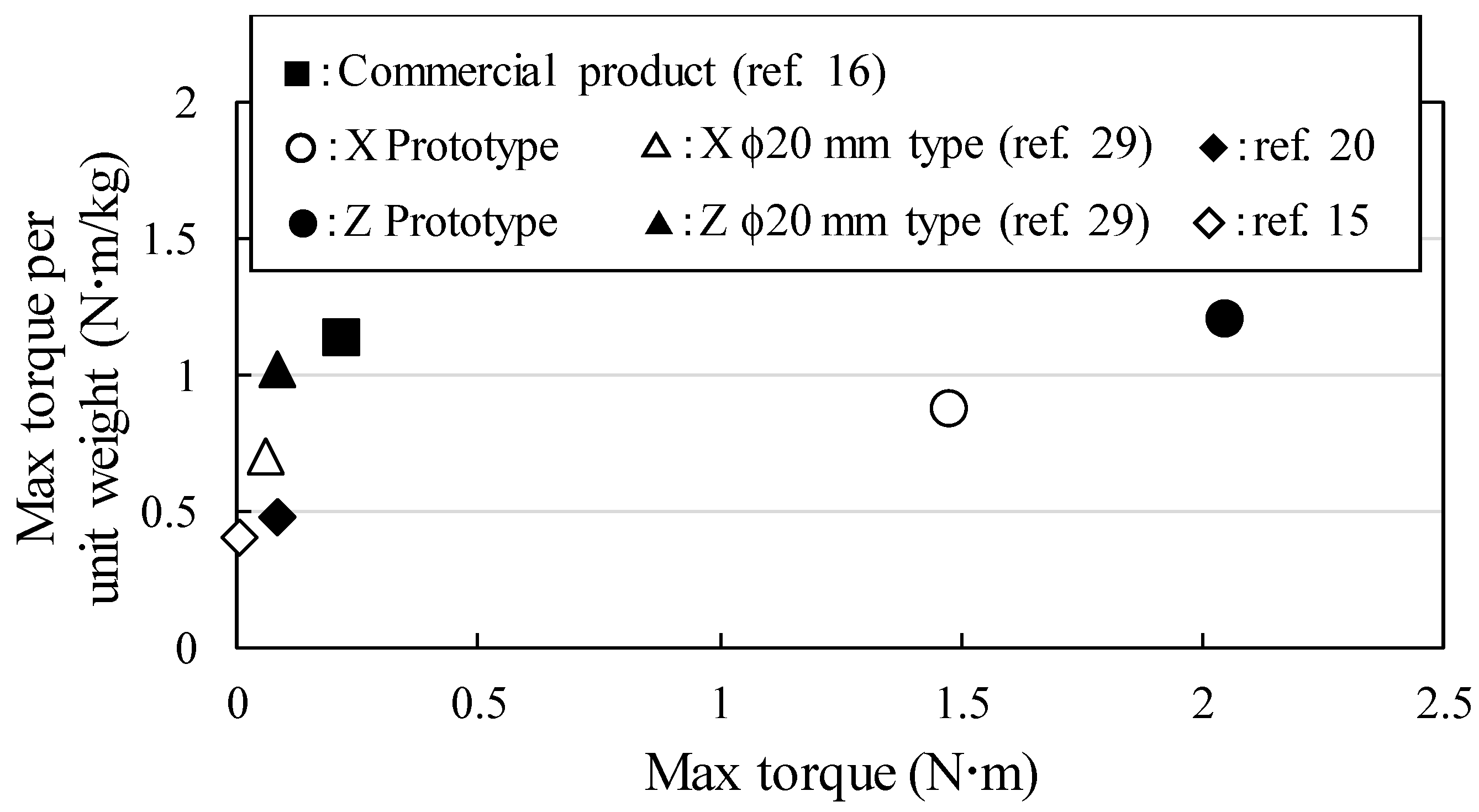

4.4. Maximum Torque

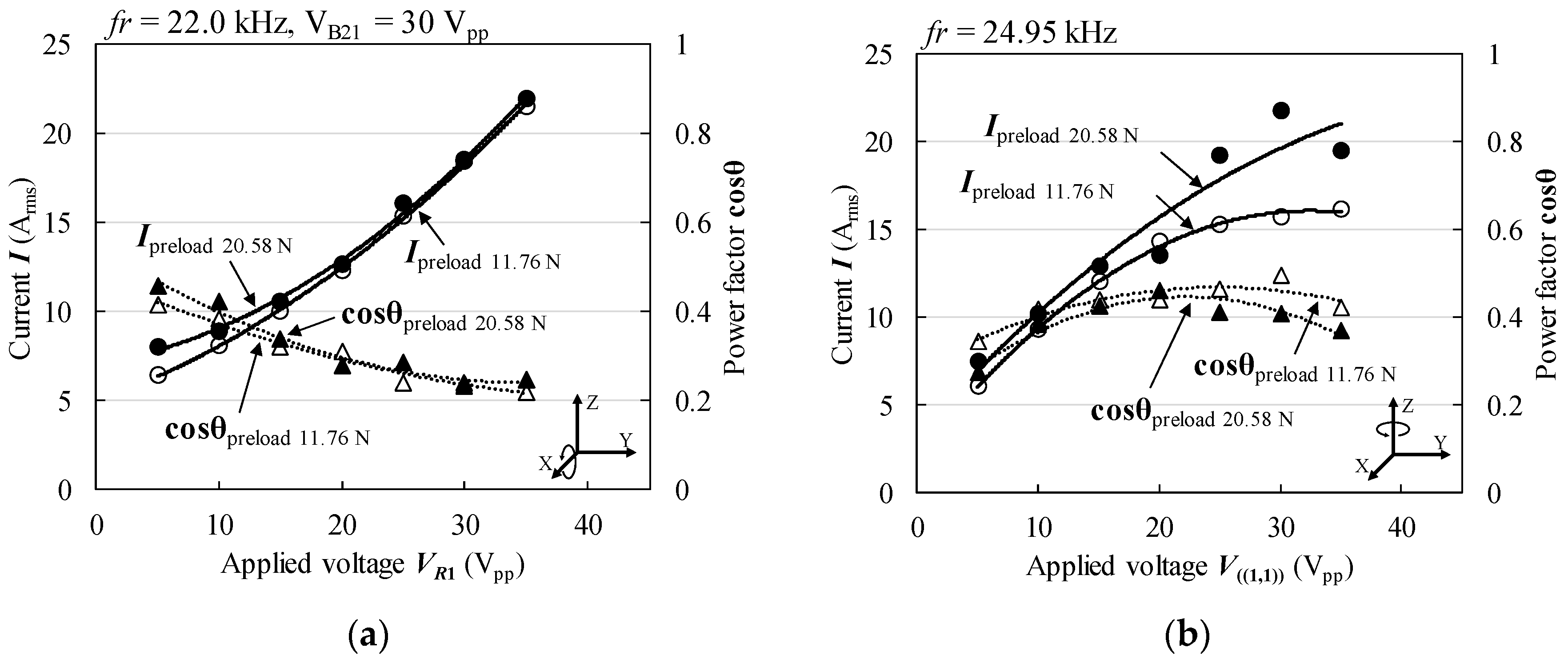

4.5. Current and Power Factor

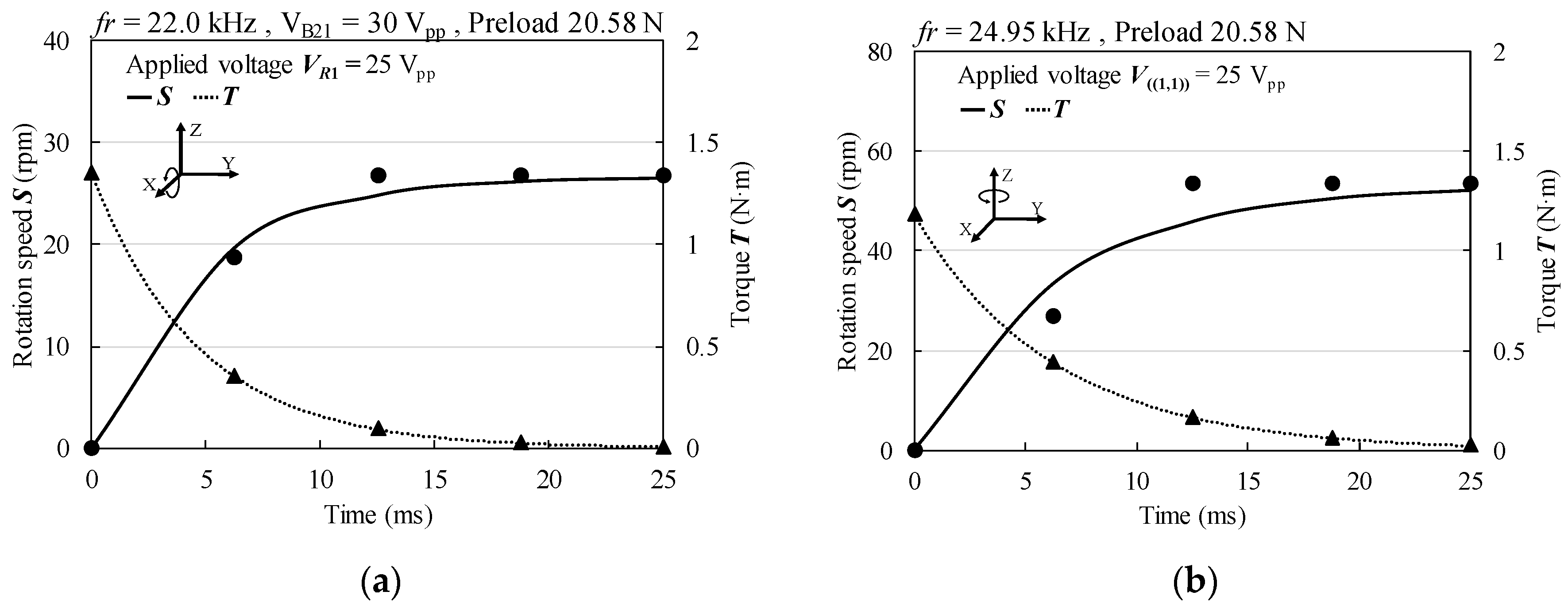

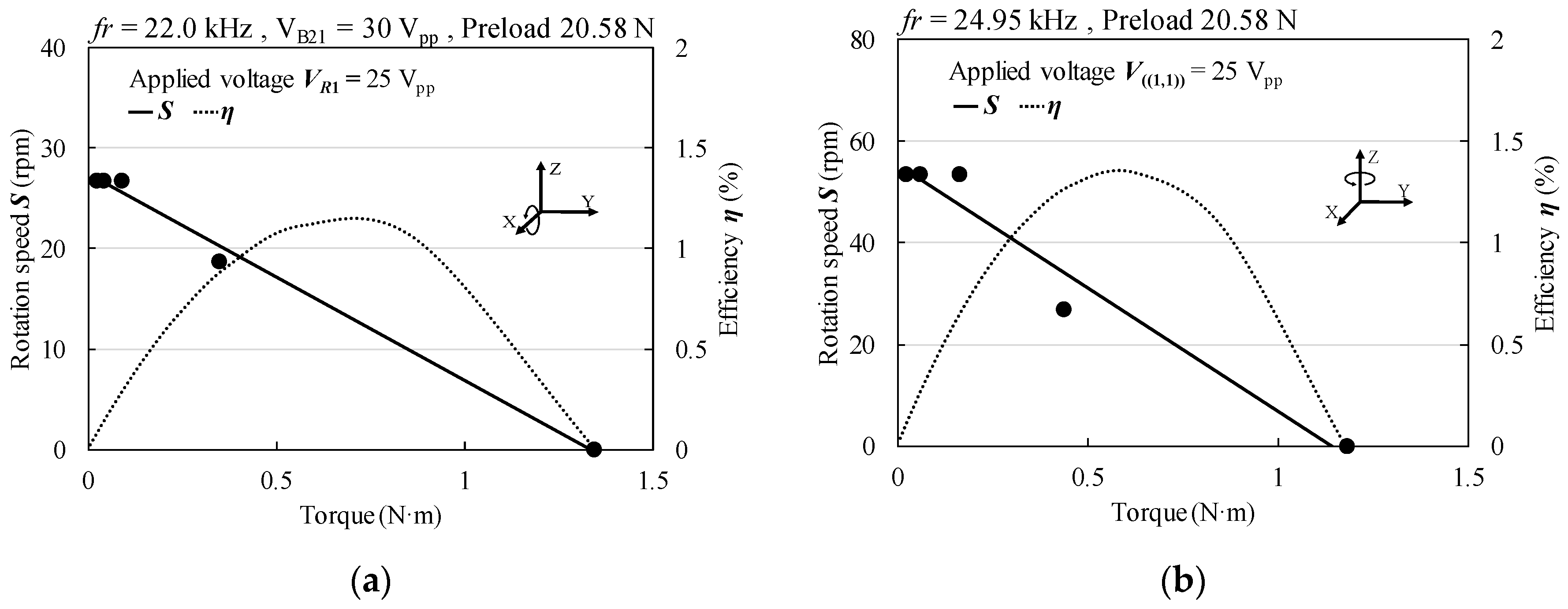

4.6. Transient Response and Load Characteristics

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

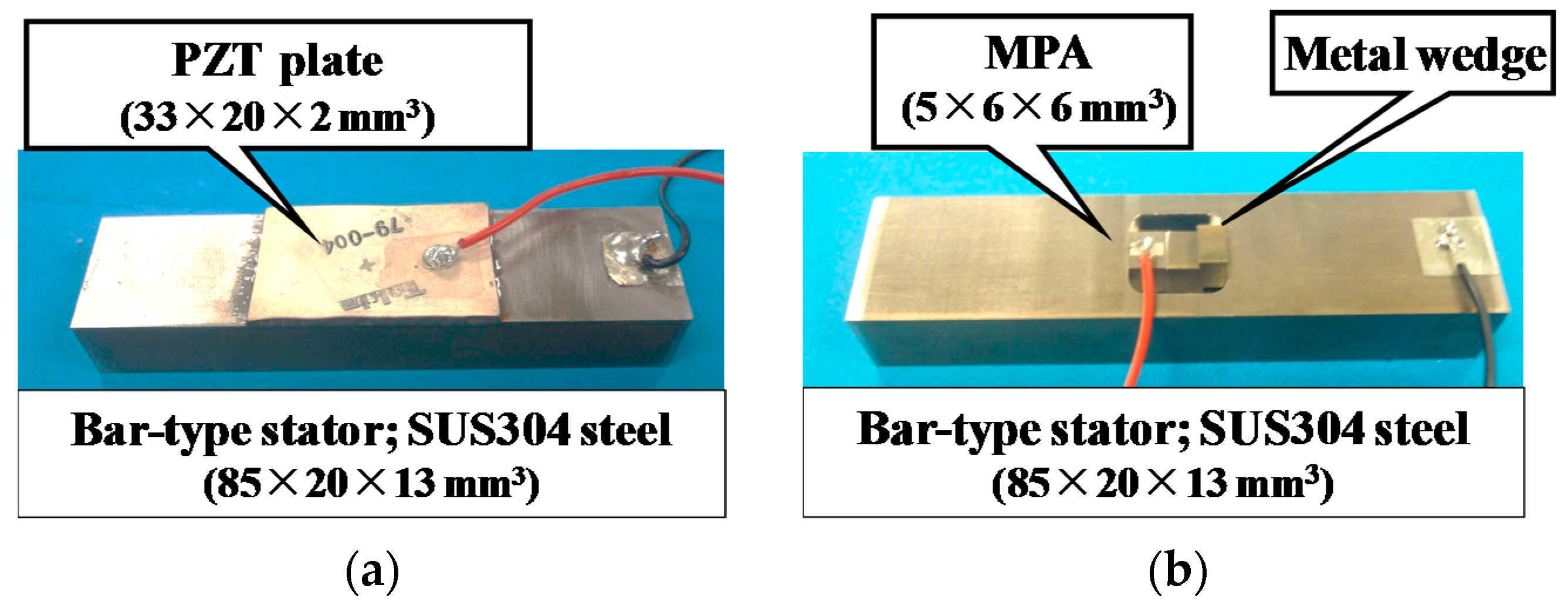

Appendix A. Comparison of Excitation Methods by MPAs and PZT Plate

| Item | Unit | PZT | MPA | |

|---|---|---|---|---|

| Dielectric properties | ε33T/ε0 | 1400 | 1460 | |

| Curie temperature | °C | 315 | 310 | |

| Dielectric loss | tanδ | % | 0.3 | 0.4 |

| Piezoelectric strain constant | d31 | ×10−12 m/V | −132 | −120 |

| d33 | ×10−12 m/V | 296 | 315 | |

| Density | ρ | ×103 kg/m3 | 7.76 | 7.6 |

| Poison’s ratio | 0.31 | 0.31 | ||

| Young’s modulus | Y11 | ×1010 Pa | 7.6 | 8.2 |

| Mechanical quality factor | Qm | 1800 | 2000 |

| Mode | Resonance Frequency (kHz) | Vibration Velocity (mm/s rms) | Motional Current (mA rms) | Force Factor (N/V) | ||||

|---|---|---|---|---|---|---|---|---|

| PZT | MPA | PZT | MPA | PZT | MPA | PZT | MPA | |

| B1-mode | 8.98 | 8.10 | 21.2 | 290 | 2.84 | 144 | 0.134 | 0.497 |

| L1-mode | 29.7 | 27.7 | 6.85 | 492 | 2.31 | 863 | 0.337 | 1.75 |

References

- Kaneko, K.; Yamada, I.; Itao, K. A Spherical DC Servo Motor with Three Degrees of Freedom. Trans. ASME Dyn. Syst. Meas. Control 1989, 111, 398–402. [Google Scholar] [CrossRef]

- Lee, K.M.; Kwan, C.K. Design Concept: Development of a Spherical Stepper for Robotic Applications. IEEE Trans. Robot. Autom. 1991, 7, 175–181. [Google Scholar] [CrossRef]

- Hollis, R.L.; Salcudean, S.E.; Allan, A.P. A Six-Degree-of-Freedom Magnetically Levitate Variable Compliance Fine-Motion Wrist: Design, Modeling, and Control. IEEE Trans. Robot. Autom. 1991, 7, 320–332. [Google Scholar] [CrossRef]

- Tsuda, M.; Higuchi, T.; Fujiwara, S. Magnetic Levitation Servo for Flexible Assembly Automation. J. Robot. Res. 1992, 11, 329–345. [Google Scholar] [CrossRef]

- Gosselin, C.M.; Hamel, J.F. The agile eye: A high-performance three degrees of freedom camera-orienting device. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), San Diego, CA, USA, 8–13 May 1994; pp. 781–786. [Google Scholar]

- Chirikjian, G.S.; Stein, D. Kinematic Design and Commutation of a Spherical Stepper Motor. IEEE/ASME Trans. Mechatron. 1999, 4, 342–353. [Google Scholar] [CrossRef]

- Kahlen, K.; Doncker, R.W. Current regulators for multiple-phase permanent magnet spherical machines. In Proceedings of the IEEE Industrial Application, Rome, Italy, 8–12 October 2000; pp. 2011–2015. [Google Scholar]

- Wang, J.; Mitchell, K.; Jewell, G.W.; Howe, D. Multi-degree-of-freedom spherical permanent magnet motors. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA 2001), Seoul, Korea, 21–26 May 2001; pp. 1798–1805. [Google Scholar]

- Dehez, B.; Grenier, D.; Raucent, B. Two Degree of Freedom Spherical Actuator for Omnimobile ROBOT. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Washington, DC, USA, 11–15 May 2002; pp. 2381–2386. [Google Scholar]

- Yano, T.; Suzuki, T. Basic Characteristics of the Small Spherical Stepping Motor. In Proceedings of the IEEE IROS, Lausanne, Switzerland, 30 September–4 October 2002; pp. 1980–1985. [Google Scholar]

- Lee, K.M.; Joni, J. Concept Development and Design of a Spherical Wheel Motor (SWM). In Proceedings of the 2005 IEEE International Conference on Robotics and Automation (ICRA), Barcelona, Spain, 18–22 April 2005; pp. 3652–3657. [Google Scholar]

- Anders, M.; Binder, A.; Suess, M. A Spherical Linear Motor as Direct Drive of an Airborne Optical Infrared Telescope. In Proceedings of the IEEJ Transactions on Industry Applications, Kobe-Awaji, Japan, 25–28 September 2005; Volume 1, pp. 528–531. [Google Scholar]

- Kumagai, M.; Hollis, R.L. Development and Control of a Three DOF Spherical Induction Motor. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Karlsruhe, Germany, 6–10 May 2013; pp. 1520–1525. [Google Scholar]

- Toyama, S.; Sugitani, S.; Zhang, G.; Miyatani, Y.; Nakamura, K.N. Multi degree of freedom spherical ultrasonic motor. In Proceedings of the International Conference on Robotics and Automation, Nagoya, Japan, 21–27 May 1995; pp. 2935–2940. [Google Scholar]

- Hukaya, N.; Wada, H.; Kikuchi, Y.; Furuya, N.; Toyama, S. An artificial arm using an ultrasonic motor. Soc. Life Support Eng. 2000, 12, 131–136. (In Japanese) [Google Scholar]

- DOUBLE R and D Co., HP. Available online: http://www.j-d.co.jp/ (accessed on 15 April 2014).

- Morita, T.; Kurosuwa, M.; Higuchi, T. Design of a Cylindrical Ultrasonic Micromotor to Obtain Mechanical Output. Jpn. J. Appl. Phys. 1996, 35, 3251–3254. [Google Scholar] [CrossRef]

- Hata, H.; Tomikawa, Y.; Hirose, S.; Takano, T. Ring-Form Two-Dimensional (X–Y) Moving Piezoelectric Actuator. Jpn. J. Appl. Phys. 1996, 35, 5023–5026. [Google Scholar] [CrossRef]

- Amano, T.; Ishii, T.; Nakamura, K.; Ueha, S. An ultrasonic actuator with multi-degree of freedom using bending and longitudinal vibrations of a single stator. In Proceedings of the IEEE Ultrasonics Symposium, Sendai, Japan, 5–8 October 1998; pp. 667–670. [Google Scholar]

- Takemura, K.; Kojima, N.; Maeno, T. Development of a Bar-shaped Ultrasonic Motor for Multi-degrees of freedom Motion. In Proceedings of the 4th International Conference on Motion and Vibration Control, Zurich, Switzerland, 25–28 August 1998; pp. 195–200. [Google Scholar]

- Takemura, K.; Maeno, T. Design and control of an ultrasonic motor capable of generating multi-DOF motion. IEEE/ASME Trans. Mechatron. 2001, 6, 499–506. [Google Scholar] [CrossRef]

- Yun, C.-H.; Niwano, S.; Friend, J.R.; Nakamura, K.; Ueha, S. Support Mechanism for the Ball Rotor in the Three-Degree-of-Freedom Ultrasonic Motor. Jpn. J. Appl. Phys. 2003, 42, 3000–3001. [Google Scholar] [CrossRef]

- Takahashi, H.; Nishimura, O.; Akiba, T.; Tamura, H. Development of a 2DOF Control Type spherical Piezoelectric Motor with Wide Dynamic Range. In Proceedings of the Japan Society Precision Engineering Autumn Meet, Asahikawa, Japan, 12–14 September 2007; pp. 751–752. (In Japanese). [Google Scholar]

- Goda, Y.; Koyama, D.; Nakamura, K. Design of Multi-Degree-of-Freedom Ultrasonic Micromotors. Jpn. J. Appl. Phys. 2009, 48, 07GM06. [Google Scholar] [CrossRef]

- Khoo, T.F.; Dang, D.H.; Friend, J.; Oetomo, D.; Yeo, L. Triple degree-of-freedom piezoelectric ultrasonic micromotor via flexural-axial coupled vibration. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2009, 56, 1716–1724. [Google Scholar] [CrossRef] [PubMed]

- Mashimo, T.; Toyama, S.; Ishida, H. Design and Implementation of a Spherical Ultrasonic Motor. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2009, 56, 2514–2521. [Google Scholar] [CrossRef] [PubMed]

- Watson, B.; Friend, J.; Yeo, L.; Sitti, M. Piezoelectric ultrasonic resonant motor with stator diameter less than 250 μm: The Proteus motor. J. Micromech. Microeng. 2009, 19, 022001. [Google Scholar] [CrossRef]

- Aoyagi, M.; Nakajima, T.; Tomikawa, Y.; Takano, T. Examination of Disk-Type Multidegree-of-Freedom Ultrasonic Motor. Jpn. J. Appl. Phys. 2004, 43, 2884–2890. [Google Scholar] [CrossRef]

- Lu, B.; Aoyagi, M.; Takano, T.; Tamura, H. Examination of Sandwich-Type Multidegree-of-Freedom Spherical Ultrasonic Motor. Jpn. J. Appl. Phys. 2010, 49, 07HE24-1. [Google Scholar] [CrossRef]

- Lu, B.; Aoyagi, M.; Tamura, H.; Takano, T. Development of a Novel Rotor-Embedded-Type Multidegree-of-Freedom Spherical Ultrasonic Motor. J. Robot. Mechatron. 2012, 24, 876–883. [Google Scholar] [CrossRef]

- Lu, B.; Aoyagi, M. Examination of an Outer-Rotor-Type Multidegree-of-Freedom Spherical Ultrasonic Motor. In Proceedings of the 15th International Conference on Electrical Machines and Systems (ICEMS2012), Sapporo, Japan, 21–24 October 2012. [Google Scholar]

- Nakamura, K.; Kurosawa, M.K.; Kurebayashi, H.; Ueha, S. An estimation of load characteristics of an ultrasonic motor by measuring transient responses. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1991, 38, 482–485. [Google Scholar] [CrossRef] [PubMed]

| Phase Difference (deg) | Vibration Mode | |

|---|---|---|

| ① | ② | |

| 0 | 0 | R1-mode |

| 180 | 180 | B21-mode |

| 180 | 0 | ((1,1))-mode |

| Vibration Mode | Rotation Direction | |

|---|---|---|

| Ports A–B | Ports C–D | |

| R1-mode | B21-mode | Around X-axis |

| B21’-mode | R1-mode | Around Y-axis |

| ((1,1))-mode | ((1,1))’-mode | Around Z-axis |

| Basic Characteristics of Stator | R1-Mode | B21-Mode | ((1,1))-Mode | |

|---|---|---|---|---|

| Upper stator | Resonance frequency (kHz) | 22.15 | 21.88 | 24.98 |

| Admittance (S) | 0.45 | 1.38 | 2.17 | |

| Lower stator | Resonance frequency (kHz) | 22.09 | 21.87 | 24.94 |

| Admittance (S) | 0.44 | 1.25 | 1.86 | |

| Performance Characteristic | Rotation | Prototype | ϕ20 mm Type [29] |

|---|---|---|---|

| Max torque (N∙m at Vpp) | Around X(Y)-axis | 1.48 at 30 | 0.058 at 80 |

| Around Z-axis | 2.05 at 40 | 0.084 at 140 | |

| Torque/weight (N∙m/kg) | Around X(Y)-axis | 0.87 | 0.70 |

| Around Z-axis | 1.20 | 1.02 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mizuno, A.; Oikawa, K.; Aoyagi, M.; Kajiwara, H.; Tamura, H.; Takano, T. Examination of High-Torque Sandwich-Type Spherical Ultrasonic Motor Using with High-Power Multimode Annular Vibrating Stator. Actuators 2018, 7, 8. https://doi.org/10.3390/act7010008

Mizuno A, Oikawa K, Aoyagi M, Kajiwara H, Tamura H, Takano T. Examination of High-Torque Sandwich-Type Spherical Ultrasonic Motor Using with High-Power Multimode Annular Vibrating Stator. Actuators. 2018; 7(1):8. https://doi.org/10.3390/act7010008

Chicago/Turabian StyleMizuno, Ai, Koki Oikawa, Manabu Aoyagi, Hidekazu Kajiwara, Hideki Tamura, and Takehiro Takano. 2018. "Examination of High-Torque Sandwich-Type Spherical Ultrasonic Motor Using with High-Power Multimode Annular Vibrating Stator" Actuators 7, no. 1: 8. https://doi.org/10.3390/act7010008