Stabilization of Magnetic Suspension System by Using Only a First-Order Reset Element without a Derivative Element

Abstract

:1. Introduction

2. First-Order Reset Element

2.1. Original FORE

2.2. Modified FORE

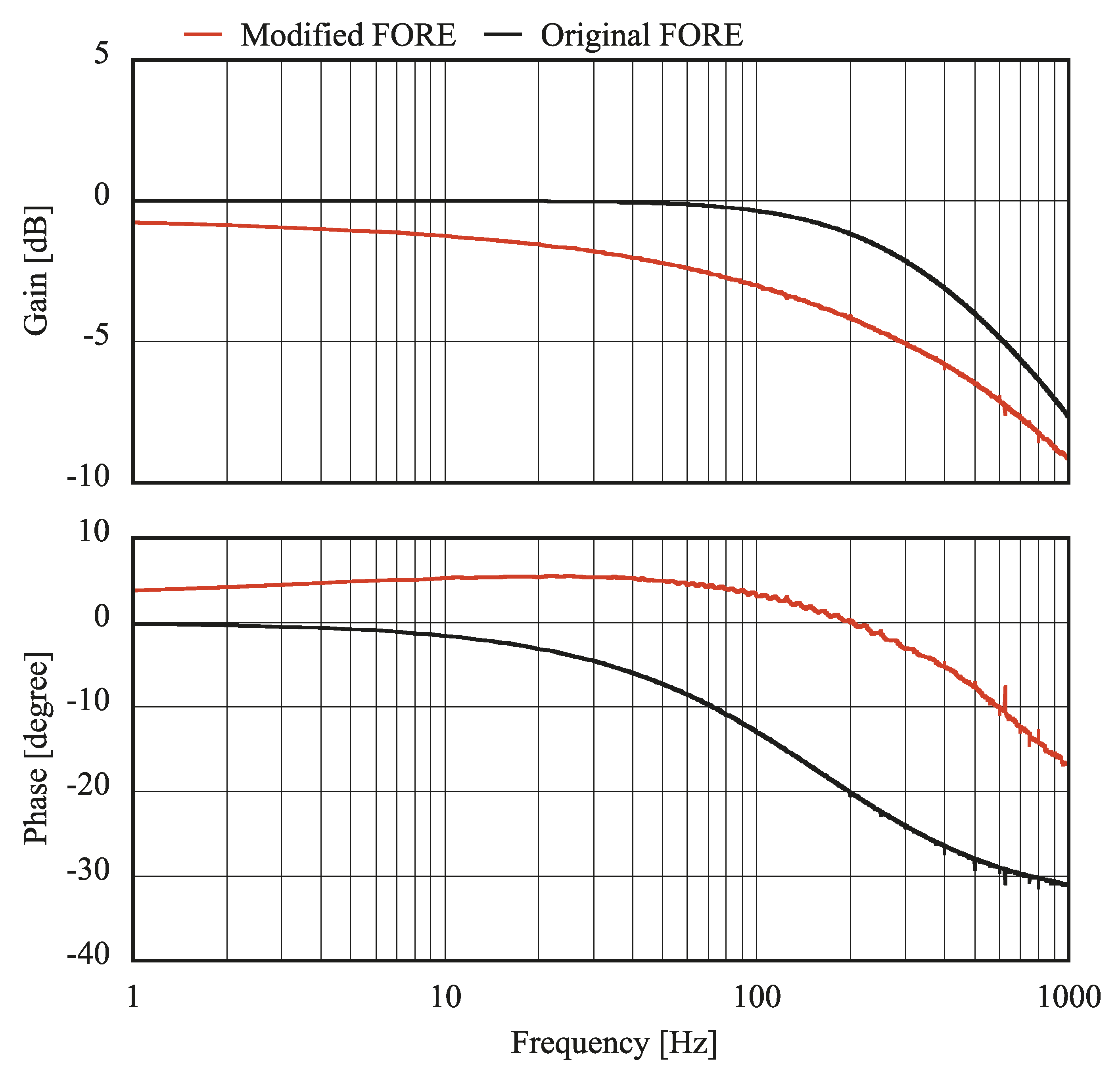

2.3. Comparison between Original and Modified FOREs through Simulations

3. Magnetic Suspension System

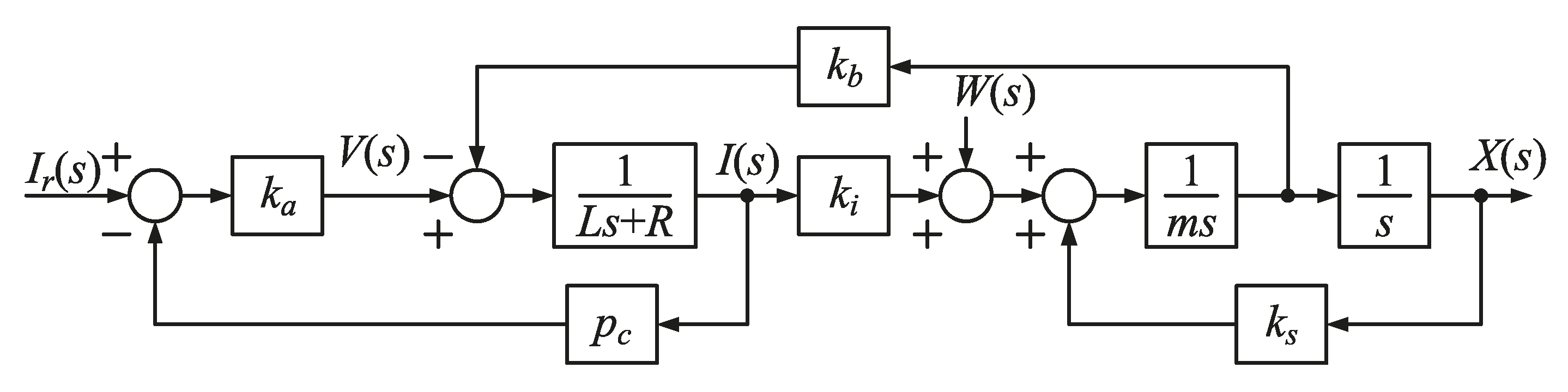

3.1. Model of Magnetic Suspension System

3.2. Experimental Setup

4. Simulation Results

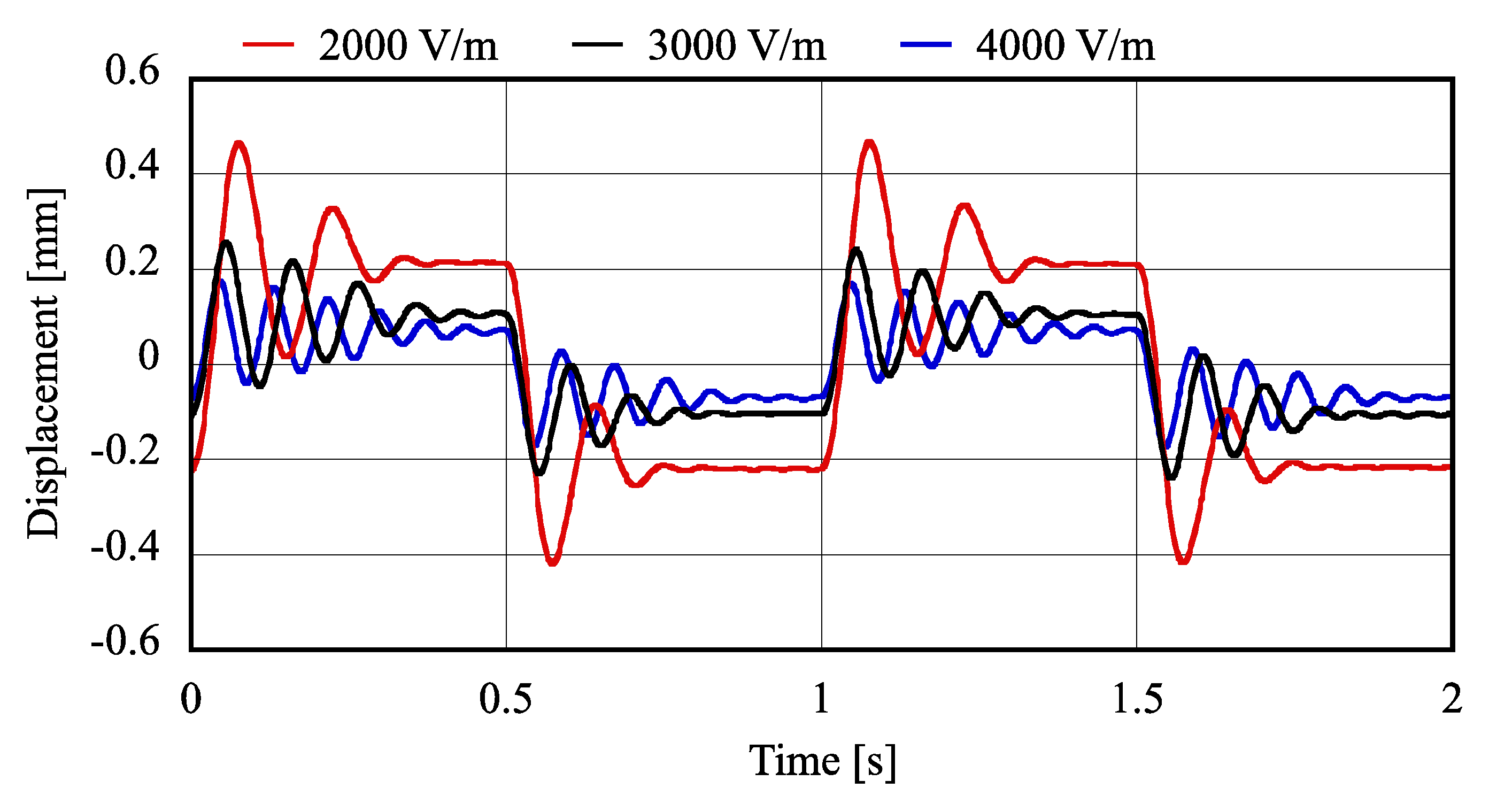

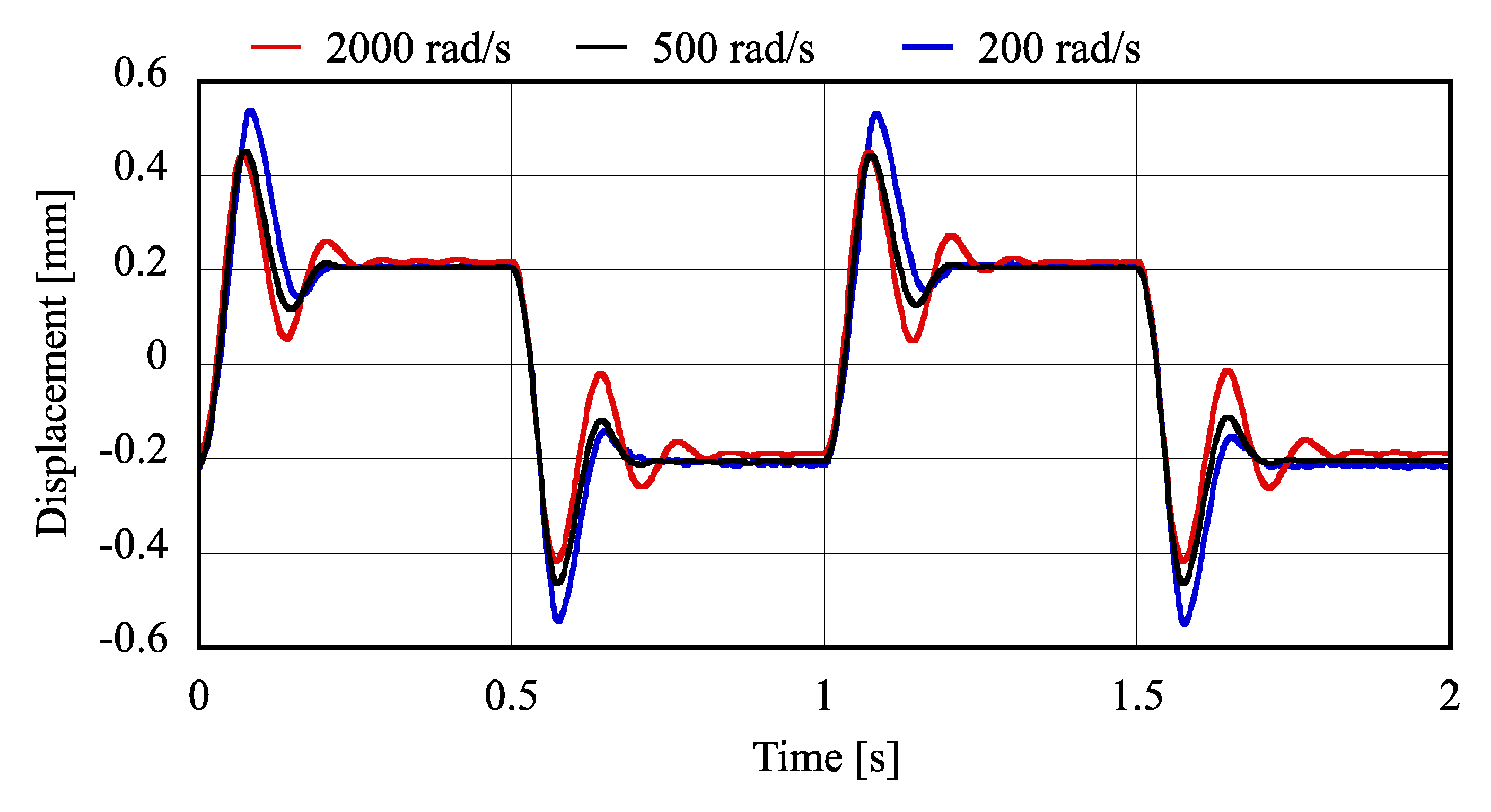

4.1. Responses to Rectangular Disturbance

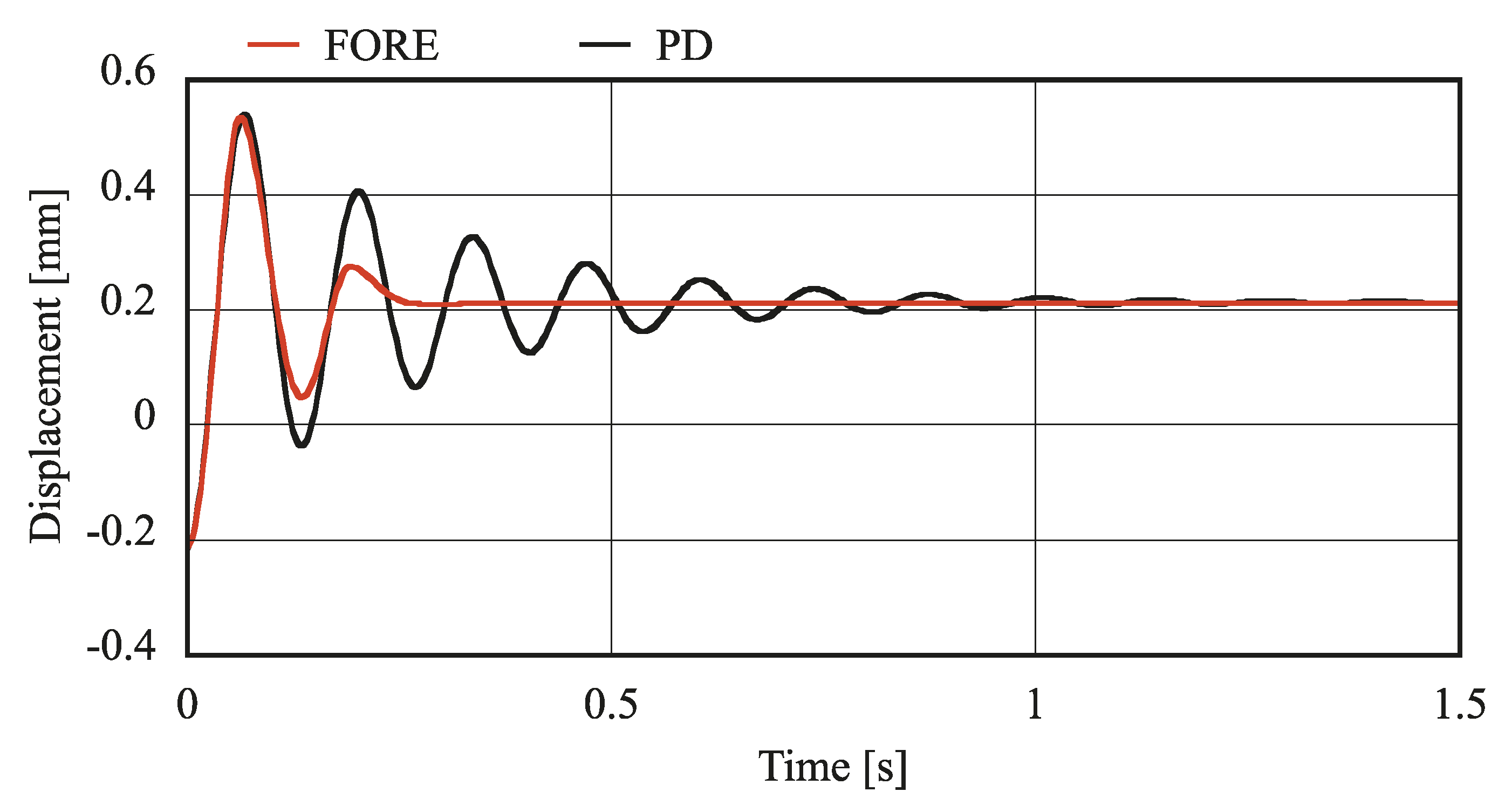

4.2. Comparison of the FORE and PD Control

4.3. Lissajous Figures at Various Frequencies

5. Experimental Results

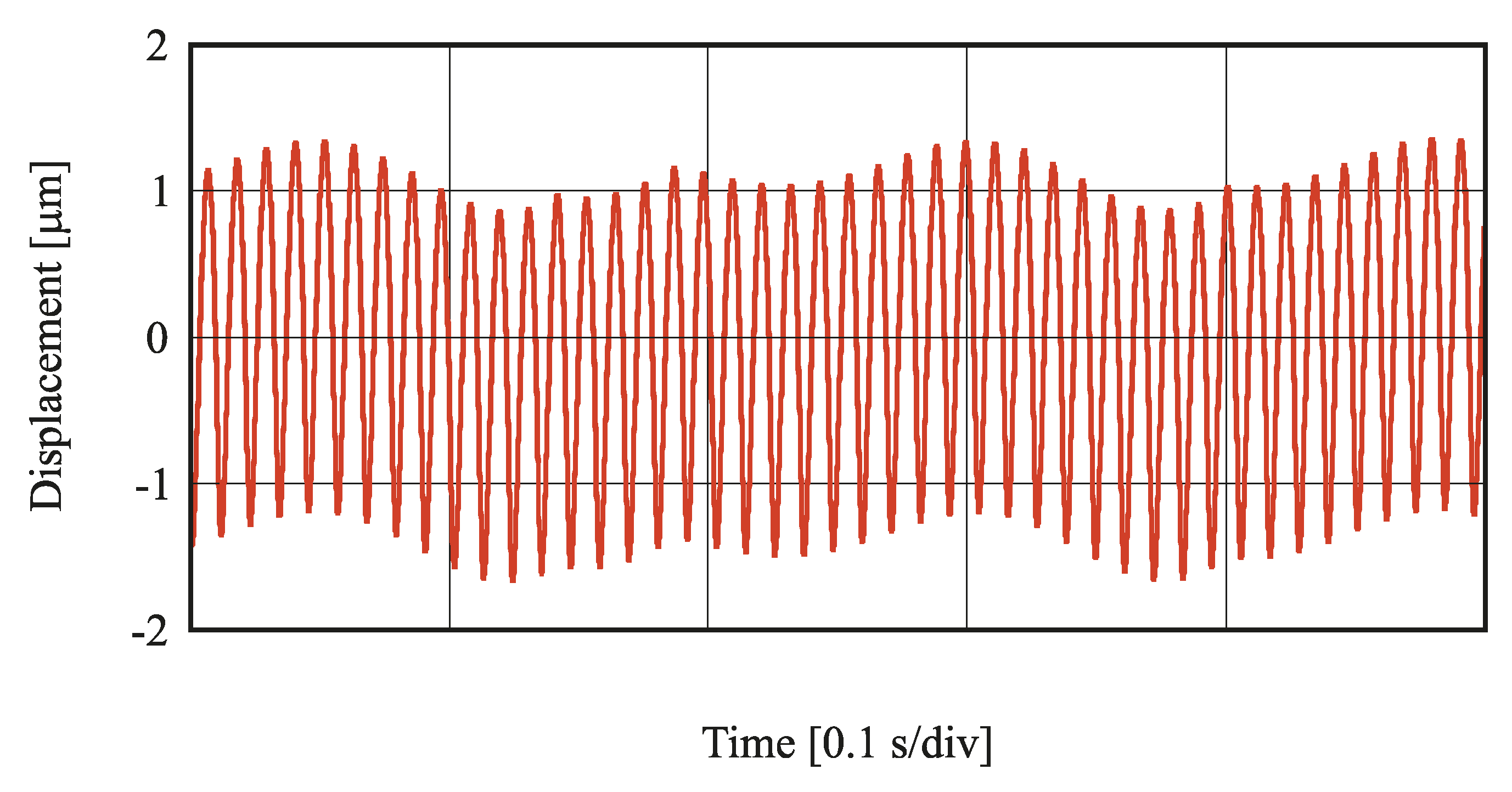

5.1. Confirmation of Stable Suspension

5.2. Responses to Rectangular Disturbance

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Symbol | Description | Unit |

| C | Transfer function of controller | V/m |

| CPD | Transfer function of PD-controller | V/m |

| e | Input signal of FORE | m |

| F | Attractive force between electromagnet and floator | N |

| g | Acceleration due to gravity | m/s2 |

| Ir | Current command | V |

| Ie | Coil current with equivalent current produced by permanent magnet | A |

| i | Current of electromagnet | A |

| ka | Gain of amplifier | V/V |

| kb | Coefficient of back electromotive force | Vs/m |

| ki | Coefficient of force to current | N/A |

| ks | Coefficient of negative stiffness by hybrid magnet | N/m |

| kx | Gain of sensor | V/m |

| L | Inductance of electromagnet | H |

| m | Mass of floator | kg |

| mb | Equivalent mass of counter balancer | kg |

| p | Gain of integral feedback used only in the experiment | V/ms |

| pc | Gain of current sensor | V/A |

| pd | Gain of proportional feedback | V/m |

| pf | Gain of FORE | V/m |

| pv | Gain of derivative feedback | Vs/m |

| R | Resistance of electromagnet | Ω |

| ts | Sampling period of controller | s |

| u | Output signal of FORE | V |

| û | Output signal of CI | V |

| v | Output voltage of amplifier | V |

| w | Disturbance force | N |

| ŵ | Equivalent disturbance force | N(V) |

| x | Displacement of floator | m |

| α | Cutoff angular frequency of FORE in linear operation | rad/s |

| αPD | Cutoff angular frequency of PD controller | rad/s |

References

- Baños, A.; Barreiro, A. Reset Control Systems; Springer: London, UK, 2012. [Google Scholar]

- Clegg, J.C. A nonlinear integrator for servomechanism. Trans. AIEE 1958, 77, 41–42. [Google Scholar] [CrossRef]

- Baños, A.; Vidal, A. Design of PC+CI reset compensators for second order plants. In Proceedings of the IEEE International Symposium on Industrial Electronics, Vigo, Spain, 4–7 June 2007. [Google Scholar]

- Baños, A.; Vidal, A. Design of Reset Control Systems: The PI plus CI Compensator. J. Dyn. Syst. Meas. Control 2012, 134, 051003. [Google Scholar] [CrossRef]

- Horowitz, I.; Rosenbaum, P. Nonlinear design for cost of feedback reduction in systems with large parameter uncertainty. Int. J. Control 1975, 21, 977–1001. [Google Scholar] [CrossRef]

- Chait, Y.; Hollot, C.V. On Horowitz’s contributions to reset control. Int. J. Robust Nonlinear Control 2002, 12, 335–355. [Google Scholar] [CrossRef]

- Zaccarian, L.; Nesic, D.; Nesic, D.; Teel, A.R. First order reset elements and the Clegg integrator revisited. In Proceedings of the 2005 American Control Conference, Portland, OR, USA, 8–10 June 2005; pp. 563–568. [Google Scholar]

- Van Loon, S.J.L.M.; Gruntjens, K.G.J.; Heertjes, M.F.; van de Wouw, N.; Heemels, W.P.M.H. Frequency-domain tools for stability analysis of reset control systems. Automatica 2017, 82, 101–108. [Google Scholar] [CrossRef]

- Iwaki, M. Reset Control of Combustion Oscillation in Lean Premixed Combustor. In Proceedings of the 18th International Conference on Control, Automation and Systems (ICCAS), Pyeongchang, Korea, 17–20 October 2018; pp. 207–211. [Google Scholar]

- Panni, F.S.; Waschl, H.; Alberer, D.; Zaccarian, L. Position Regulation of an EGR Valve Using Reset Control with Adaptive Feedforward. IEEE Trans. Control Syst. Technol. 2014, 22, 2424–2431. [Google Scholar] [CrossRef]

- Acho, L. Nonlinear reset integrator control design: Application to the active suspension control of vehicles. In Proceedings of the IASTED International Conference Modelling, Identification and Control (MIC 2014), Innsbruck, Austria, 17–19 February 2014; pp. 226–228. [Google Scholar]

- Sato, M.; Muraoka, K. Flight Test Verification of Flight Controller for Quad Tilt Wing Unmanned Aerial Vehicle. In Proceedings of the AIAA Guidance, Navigation, and Control (GNC) Conference, Boston, MA, USA, 19–22 August 2013. [Google Scholar]

- Zheng, J.; Guo, Y.; Fu, M.; Wang, Y.; Xie, L. Improved reset control design for a PZT positioning stage. In Proceedings of the 16th IEEE International Conference on Control Applications, Singapore, 1–3 October 2007. [Google Scholar]

- Mizuno, T.; Takemori, Y. A transfer-function approach to the analysis and design of zero-power controllers for magnetic suspension systems. Electr. Eng. Jpn. 2002, 141, 67–75. [Google Scholar] [CrossRef]

- Liu, X. Analysis of Pneumatic Control Systems with Bond Graph: Development of a Simulation Software for Pneumatics. Ph.D. Thesis, Saitama University, Saitama, Japan, 1993. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ishino, Y.; Mizuno, T.; Takasaki, M.; Yamaguchi, D. Stabilization of Magnetic Suspension System by Using Only a First-Order Reset Element without a Derivative Element. Actuators 2019, 8, 24. https://doi.org/10.3390/act8010024

Ishino Y, Mizuno T, Takasaki M, Yamaguchi D. Stabilization of Magnetic Suspension System by Using Only a First-Order Reset Element without a Derivative Element. Actuators. 2019; 8(1):24. https://doi.org/10.3390/act8010024

Chicago/Turabian StyleIshino, Yuji, Takeshi Mizuno, Masaya Takasaki, and Daisuke Yamaguchi. 2019. "Stabilization of Magnetic Suspension System by Using Only a First-Order Reset Element without a Derivative Element" Actuators 8, no. 1: 24. https://doi.org/10.3390/act8010024

APA StyleIshino, Y., Mizuno, T., Takasaki, M., & Yamaguchi, D. (2019). Stabilization of Magnetic Suspension System by Using Only a First-Order Reset Element without a Derivative Element. Actuators, 8(1), 24. https://doi.org/10.3390/act8010024