Supporting the Development and Adoption of Automatic Lameness Detection Systems in Dairy Cattle: Effect of System Cost and Performance on Potential Market Shares

Abstract

:Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Approach

2.2. Effect of System Performance on the Potential Market Share

2.3. Effect of System Cost on the Potential Market Share

2.4. Willingness to Pay for Improved System Characteristics

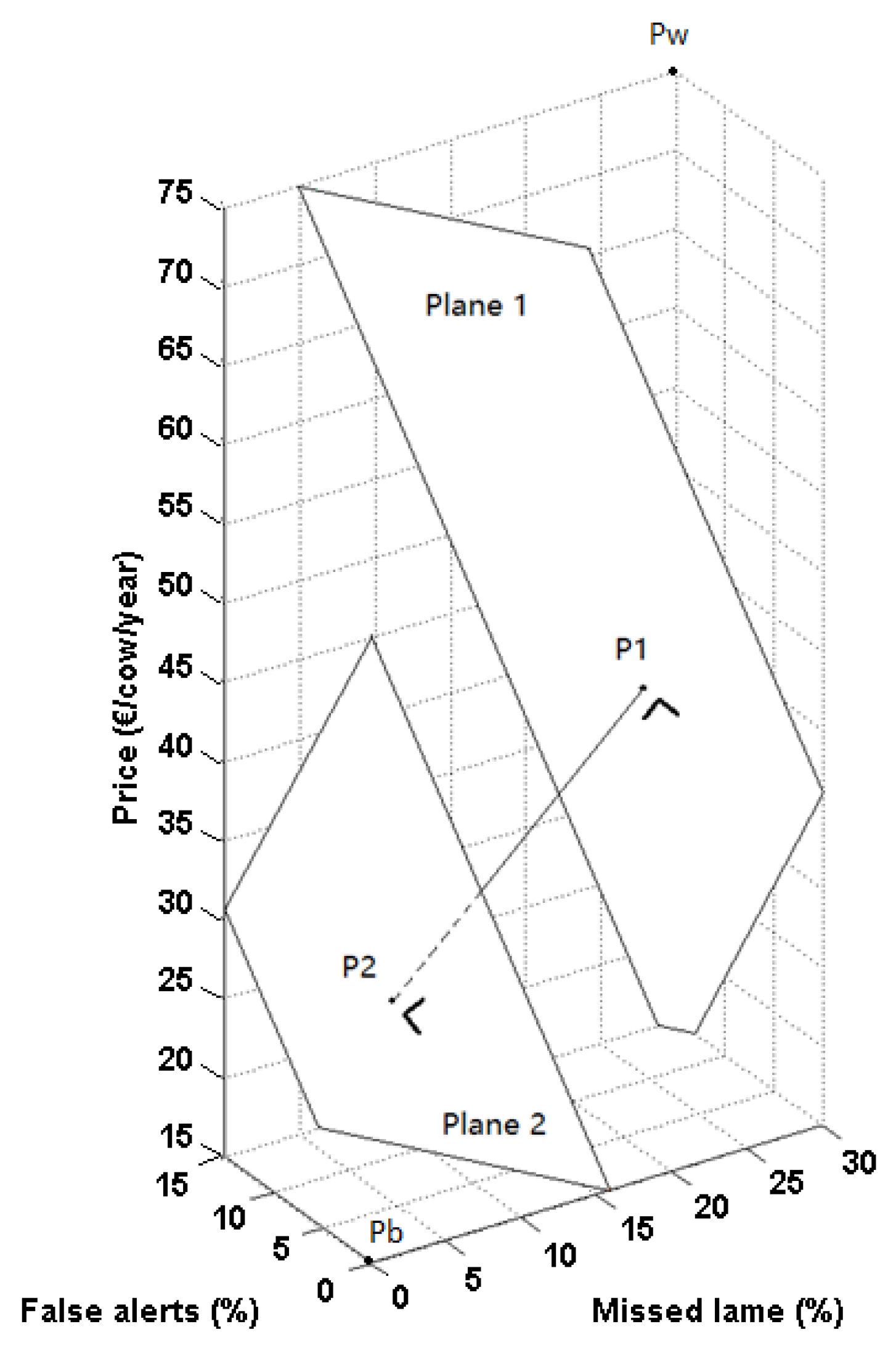

2.5. Usefulness of the Discrete Choice Experiment for Further Technology Development

3. Results

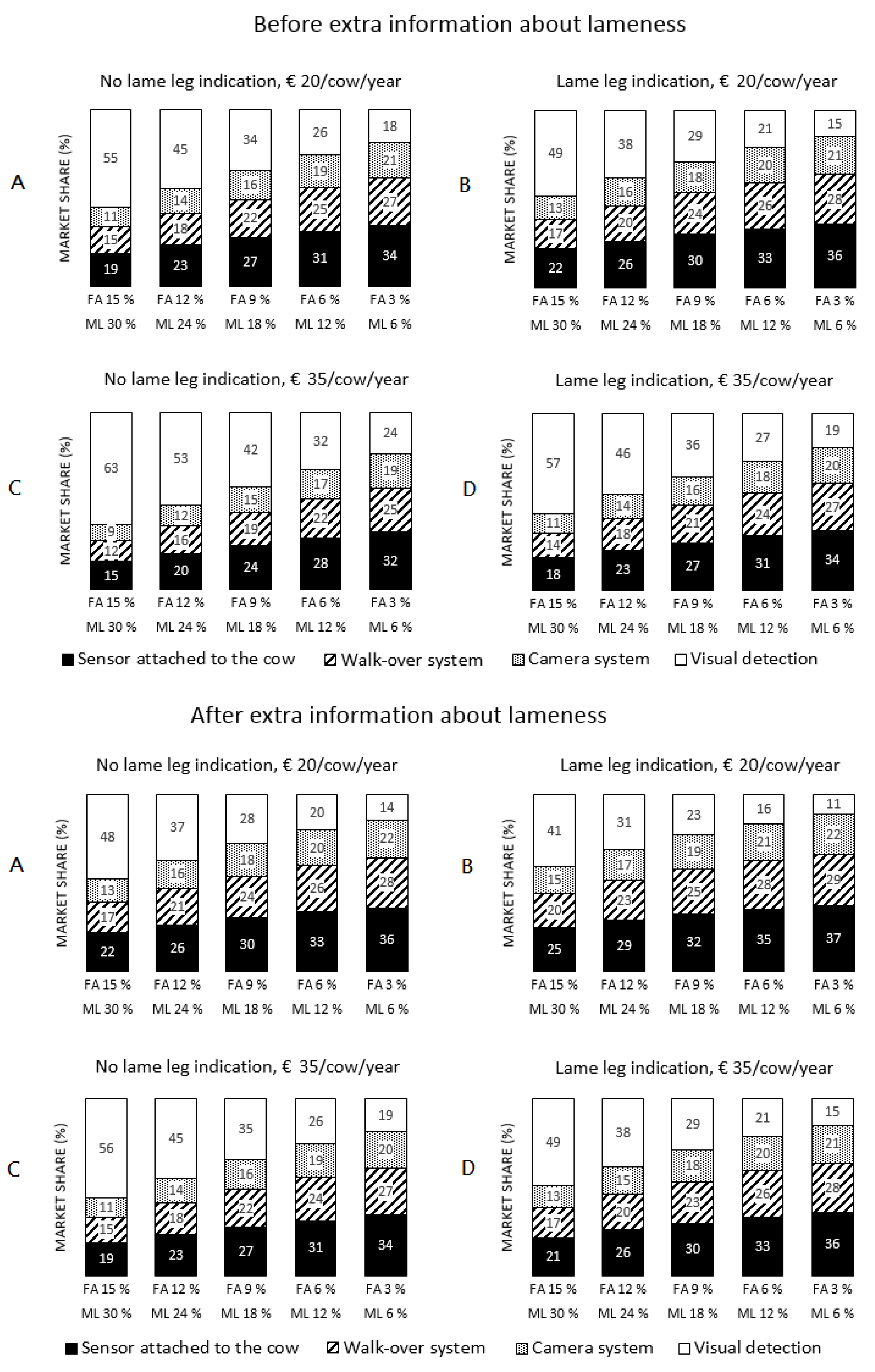

3.1. Effect of Detection Performance on Potential Market Share

3.2. Effect of System Cost on Potential Market Share

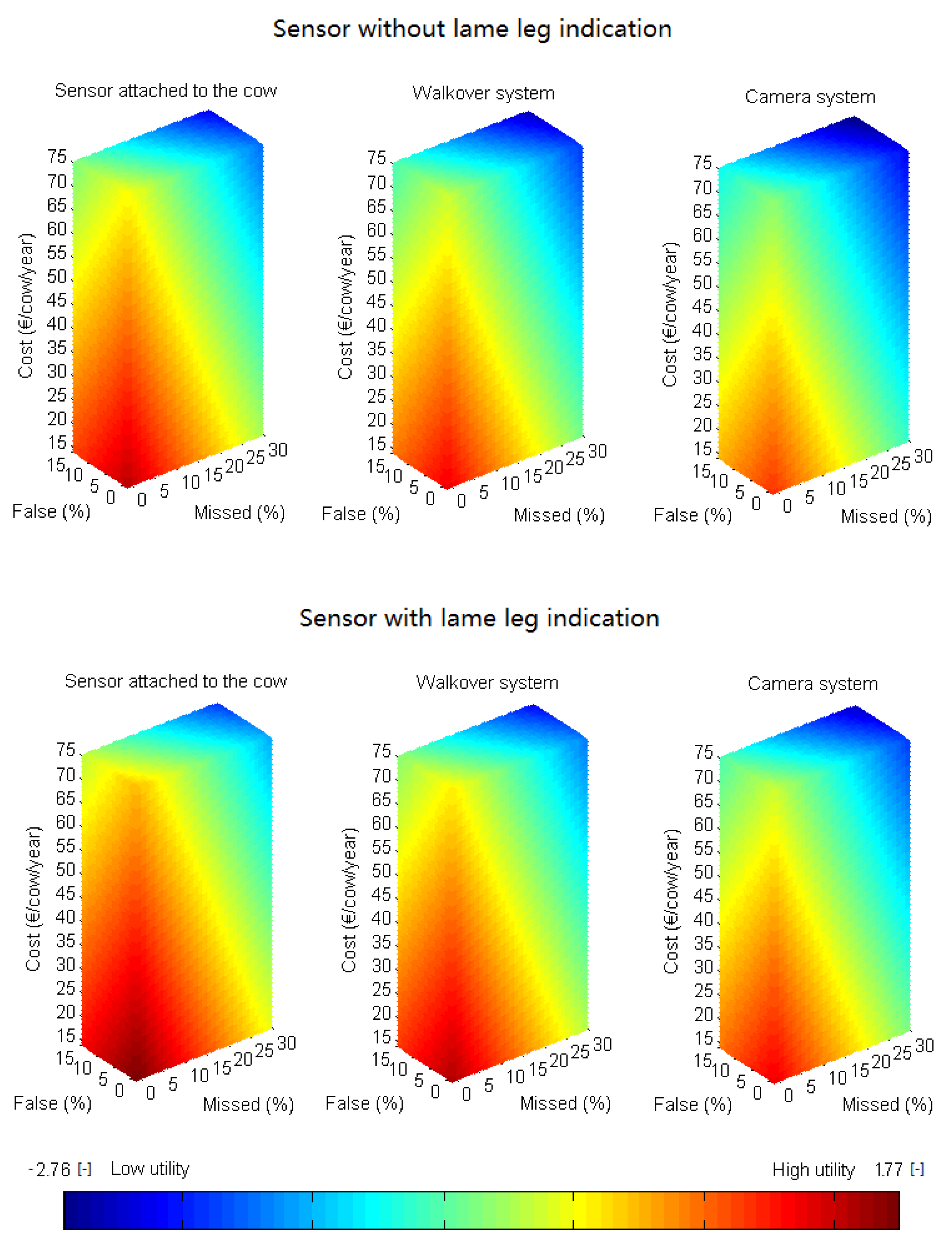

3.3. Willingness to Pay for Improved System Characteristics

3.4. Defining Development Goals for Detection Performance

4. Discussion

4.1. Automatic Systems Have to Become Cheaper and More Performant to Be Preferred over Visual Detection

4.2. Farmers Are Willing to Pay for Improved Lameness Detection and Indication Which Leg Is Lame

4.3. Discrete Choice Experiments Provide Valuable Input for System Development

4.4. More Research on the Effect of Early Detection, Farm Scale and Economic Value of Automatic Detection Is Needed to Support Further Development and Allow More Accurate Market Share Estimations

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rutten, C.J.; Velthuis, A.G.J.; Steeneveld, W.; Hogeveen, H. Invited review: Sensors to support health management on dairy farms. J. Dairy Sci. 2013, 96, 1928–1952. [Google Scholar] [CrossRef] [PubMed]

- Wathes, C.M.; Kristensen, H.H.; Aerts, J.M.; Berckmans, D. Is precision livestock farming an engineer’s daydream or nightmare, an animal’s friend or foe, and a farmer’s panacea or pitfall? Comput. Electron. Agric. 2008, 64, 2–10. [Google Scholar] [CrossRef]

- Bruijnis, M.R.N.; Hogeveen, H.; Stassen, E.N. Assessing economic consequences of foot disorders in dairy cattle using a dynamic stochastic simulation model. J. Dairy Sci. 2010, 93, 2419–2432. [Google Scholar] [CrossRef] [PubMed]

- Warnick, L.D.; Janssen, D.; Guard, C.L.; Grohn, Y.T. The effect of lameness on milk production in dairy cows. J. Dairy Sci. 2001, 84, 1988–1997. [Google Scholar] [CrossRef]

- Viazzi, S.; Bahr, C.; Van Hertem, T.; Schlageter-Tello, A.; Romanini, C.E.B.; Halachmi, I.; Lokhorst, C.; Berckmans, D. Comparison of a three-dimensional and two-dimensional camera system for automated measurement of back posture in dairy cows. Comput. Electron. Agric. 2014, 100, 139–147. [Google Scholar] [CrossRef]

- Van Hertem, T.; Viazzi, S.; Steensels, M.; Maltz, E.; Antler, A.; Alchanatis, V.; Schlageter-Tello, A.A.; Lokhorst, K.; Romanini, E.C.B.; Bahr, C. Automatic lameness detection based on consecutive 3D-video recordings. Biosyst. Eng. 2014, 119, 108–116. [Google Scholar] [CrossRef]

- Bicalho, R.C.; Cheong, S.H.; Cramer, G.; Guard, C.L. Association between a visual and an automated locomotion score in lactating holstein cows. J. Dairy Sci. 2007, 90, 3294–3300. [Google Scholar] [CrossRef] [PubMed]

- Maertens, W.; Vangeyte, J.; Baert, J.; Jantuan, A.; Mertens, K.C.; De Campeneere, S.; Pluk, A.; Opsomer, G.; Van Weyenberg, S.; Van Nuffel, A. Development of a real time cow gait tracking and analysing tool to assess lameness using a pressure sensitive walkway: The gaitwise system. Biosyst. Eng. 2011, 110, 29–39. [Google Scholar] [CrossRef]

- Chapinal, N.; de Passille, A.M.; Pastell, M.; Hanninen, L.; Munksgaard, L.; Rushen, J. Measurement of acceleration while walking as an automated method for gait assessment in dairy cattle. J. Dairy Sci. 2011, 94, 2895–2901. [Google Scholar] [CrossRef] [PubMed]

- Thorup, V.M.; Munksgaard, L.; Robert, P.E.; Erhard, H.W.; Thomsen, P.T.; Friggens, N.C. Lameness detection via leg-mounted accelerometers on dairy cows on four commercial farms. Animal 2015, 9, 1704–1712. [Google Scholar] [CrossRef] [PubMed]

- Van De Gucht, T.; Saeys, W.; Van Meensel, J.; Van Nuffel, A.; Vangeyte, J.; Lauwers, L. Farm-specific economic value of automatic lameness detection systems in dairy cattle: From concepts to operational simulations. J. Dairy Sci. 2017. In press. [Google Scholar] [CrossRef] [PubMed]

- Van De Gucht, T.; Saeys, W.; Van Nuffel, A.; Pluym, L.; Piccart, K.; Lauwers, L.; Vangeyte, J.; Van Weyenberg, S. Farmers’ preferences for automatic lameness detection systems in dairy cattle. J. Dairy Sci. 2017, 100, 5746–5757. [Google Scholar] [CrossRef] [PubMed]

- Bruijnis, M. Foot disorders in dairy cattle: A socio-economic approach to improve dairy cow welfare. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 2012. [Google Scholar]

- Beer, G.; Alsaaod, M.; Starke, A.; Schuepbach-Regula, G.; Müller, H.; Kohler, P.; Steiner, A. Use of extended characteristics of locomotion and feeding behavior for automated identification of lame dairy cows. PLoS ONE 2016, 11, 1–18. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Van Nuffel, A.; Saeys, W.; Sonck, B.; Vangeyte, J.; Mertens, K.C.; De Ketelaere, B.; Van Weyenberg, S. Variables of gait inconsistency outperform basic gait variables in detecting mildly lame cows. Livest. Sci. 2015, 177, 125–131. [Google Scholar] [CrossRef]

- Van De Gucht, T.; Saeys, W.; Van Weyenberg, S.; Lauwers, L.; Mertens, K.; Vandaele, L.; Vangeyte, J.; Van Nuffel, A. Automatically measured variables related to tenderness of hoof placement and weight distribution are valuable indicators for lameness in dairy cows. Appl. Anim. Behav. Sci. 2017, 189, 13–22. [Google Scholar] [CrossRef]

- Van De Gucht, T.; Saeys, W.; Van Weyenberg, S.; Lauwers, L.; Mertens, K.; Vandaele, L.; Vangeyte, J.; Van Nuffel, A. Automatic cow lameness detection with a pressure mat: Effects of mat length and sensor resolution. Comput. Electron. Agr. 2017, 134, 172–180. [Google Scholar] [CrossRef]

- Hensher, D.A.; Rose, J.M.; Greene, W.H. Applied Choice Analysis: A Primer; Cambridge University Press: Cambridge, UK, 2005; Volume 3. [Google Scholar]

- Barkema, H.W.; Westrik, J.D.; Vankeulen, K.A.S.; Schukken, Y.H.; Brand, A. The effects of lameness on reproductive performance, milk production and culling in dutch dairy farms. Prev. Vet. Med. 1994, 20, 249–259. [Google Scholar] [CrossRef]

- Clarkson, M.J.; Downham, D.Y.; Faull, W.B.; Hughes, J.W.; Manson, F.J.; Merritt, J.B.; Murray, R.D.; Russell, W.B.; Sutherst, J.E.; Ward, W.R. Incidence and prevalence of lameness in dairy cattle. Vet. Rec. 1996, 138, 563–567. [Google Scholar] [CrossRef] [PubMed]

- Manske, T.; Hultgren, J.; Bergsten, C. The effect of claw trimming on the hoof health of swedish dairy cattle. Prev. Vet. Med. 2002, 54, 113–129. [Google Scholar] [CrossRef]

- O’Callaghan, K. Lamneness and associated pain in cattle—Challenging traditional perceptions. In Pract. 2002, 24, 212–219. [Google Scholar] [CrossRef]

- Mollenhorst, H.; Rijkaart, L.J.; Hogeveen, H. Mastitis alert preferences of farmers milking with automatic milking systems. J. Dairy Sci. 2012, 95, 2523–2530. [Google Scholar] [CrossRef] [PubMed]

- Alawneh, J.I.; Laven, R.A.; Stevenson, M.A. Interval between detection of lameness by locomotion scoring and treatment for lameness: A survival analysis. Vet. J. 2012, 193, 622–625. [Google Scholar] [CrossRef] [PubMed]

- Leach, K.A.; Whay, H.R.; Maggs, C.M.; Barker, Z.E.; Paul, E.S.; Bell, A.K.; Main, D.C.J. Working towards a reduction in cattle lameness: 1. Understanding barriers to lameness control on dairy farms. Res. Vet. Sci. 2010, 89, 311–317. [Google Scholar] [CrossRef] [PubMed]

- Whay, H. Locomotion scoring and lameness detection in dairy cattle. In Pract. 2002, 24, 444–449. [Google Scholar] [CrossRef]

| System Characteristics | Possible Characteristic Levels |

|---|---|

| Percentage missed lame cows | 0%, 10%, 20%, 30% |

| Percentage false alarms | 0%, 5%, 10%, 15% |

| Cost per cow per year | €15, €35, €55, €75 |

| Indication lame leg | yes, no |

| Characteristics | Option 1 | Option 2 | Option 3 | Option 4 |

|---|---|---|---|---|

| System Attached to the Cow | Walkover System | Camera System | Opt out | |

| Percentage missed lame | 10% | 10% | 30% | I will detect the lame cows myself using visual inspection |

| Percentage false alarms | 15% | 15% | 0% | |

| Cost/cow/year | €55 | €35 | €15 | |

| Indication lame leg | yes | no | yes |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Van De Gucht, T.; Van Weyenberg, S.; Van Nuffel, A.; Lauwers, L.; Vangeyte, J.; Saeys, W. Supporting the Development and Adoption of Automatic Lameness Detection Systems in Dairy Cattle: Effect of System Cost and Performance on Potential Market Shares. Animals 2017, 7, 77. https://doi.org/10.3390/ani7100077

Van De Gucht T, Van Weyenberg S, Van Nuffel A, Lauwers L, Vangeyte J, Saeys W. Supporting the Development and Adoption of Automatic Lameness Detection Systems in Dairy Cattle: Effect of System Cost and Performance on Potential Market Shares. Animals. 2017; 7(10):77. https://doi.org/10.3390/ani7100077

Chicago/Turabian StyleVan De Gucht, Tim, Stephanie Van Weyenberg, Annelies Van Nuffel, Ludwig Lauwers, Jürgen Vangeyte, and Wouter Saeys. 2017. "Supporting the Development and Adoption of Automatic Lameness Detection Systems in Dairy Cattle: Effect of System Cost and Performance on Potential Market Shares" Animals 7, no. 10: 77. https://doi.org/10.3390/ani7100077