Regeneration of Impregnated Activated Carbon after Aging

Abstract

:1. Introduction

2. Experimental

2.1. Chemicals

2.2. Preparation of IAC Beds

2.3. IAC Pretreatments

2.3.1. Humidification of the Carbon Beds

2.3.2. Accelerated Aging

2.3.3. Drying of the IAC Beds

2.4. CK dynamic Adsorption

2.5. Toluene Dynamic Adsorption

2.6. TEDA Evaporation

2.7. Regeneration of the Aged IAC (Impregnation Reactivation)

2.7.1. Dry Thermal Regeneration

2.7.2. Wet Regeneration

2.8. TEDA Impregnation

2.9. IAC Characterization

- The Brunauer–Emmett–Teller (BET) surface area and micropore volume of the IACs were calculated from N2 adsorption–desorption isotherms at a temperature of 77 K using a NOVA 1200e (Quantachrome, Graz, Austria) system. Before the measurement, all the IAC samples were subjected to outgassing under vacuum at 80 °C. The surface area of the IAC micropores was determined using t-plot analysis of the sorption isotherm. Outgassing was carried out at a temperature of 80 °C, since significant TEDA sublimation may occur at higher temperatures. Moreover, the sublimation rate may vary for different types of carbons.

- Energy dispersive X-ray spectroscopy (EDS) was used to analyze changes in the surface element composition of the IACs with scanning electron microscopy (SEM) using a PhenomX instrument (Phenom-Word B.V., Eindhoven, The Netherlands), at a 15 keV electron acceleration voltage. Since the distribution of the impregnated metals on the external surface of the IAC is non-uniform even on a given carbon particle, the element concentrations were determined as the average of 10 different areas obtained from different carbon particles, and the area analyzed in each measurement was large, at 316 μm × 316 μm (magnification of X850).

- A second surface element composition analysis was performed ESCALAB X+ apparatus (Thermo Fisher Scientific, Waltham, MA USA) with a basic pressure of 5 × 10−10. For X-ray photoelectron spectroscopy (XPS) measurements, the carbon samples were irradiated with monochromatic Al Kα X-rays at 1486.6 eV. The X-ray beam size was 500 μm. Survey spectra were recorded with a pass energy (PE) of 150 eV, and high-energy resolution spectra were recorded with a PE of 20 eV. AVANTAGE, software (version 6.6.0) was used for data acquisition and analysis. The atomic concentrations were calculated using elemental sensitivity factors without applying any standardization procedure.

2.10. Determination of the Copper Oxide Dissolving Capacity of the Regeneration Solutions

3. Results and Discussion

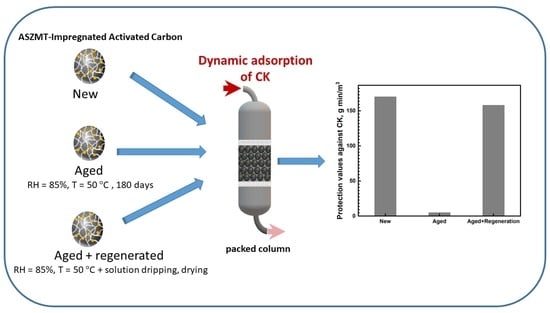

3.1. CK Protection Values of Aged IAC

3.2. Thermal Regeneration Efficiency

3.3. Wet Regeneration Efficiency

3.4. The Effect of the Regeneration Process on Toluene Adsorption

3.5. IAC Characterization

Effect of the Regeneration Process on the Textural Properties of IAC

4. Elemental Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wilson, R.E.; Whetzwl, J.C. Imtrgmated Carbon and Process of Making Same. U.S. Patent 1,519,470A, 16 December 1924. [Google Scholar]

- Noyes, W.A.J. Military Problems with Aerosols and Non-Persistent Gases; Summary Technical Report of the National Defence Research Committee (NDRC), Division 10; National Defense Research Committee: Washington, DC, USA, 1946.

- Lodewyckx, P.; Lodewyckx, P. Chapter 10 Adsorption of Chemical Warfare Agents. In Activated Carbon Surfaces in Environmental Remediation; Elsevier: Amsterdam, The Netherlands, 2006; Volume 7, pp. 475–528. ISBN 9780123705365. [Google Scholar]

- Kiani, S.S.; Farooq, A.; Ahmad, M.; Irfan, N.; Nawaz, M.; Irshad, M.A. Impregnation on Activated Carbon for Removal of Chemical Warfare Agents (CWAs) and Radioactive Content. Environ. Sci. Pollut. Res. 2021, 28, 60477–60494. [Google Scholar] [CrossRef] [PubMed]

- Doughty, D.T.; Knebel, W.J.; Cobes, J.W. Chromium-Free Impregnated Activated Universal Respirator Carbon for Adsorption of Toxic Gases and/or Vapors. EP. Patent 0 405 404 B1, 1993. [Google Scholar]

- Wang, S.; Nam, H.; Lee, D.; Nam, H. H2S Gas Adsorption Study Using Copper Impregnated on KOH Activated Carbon from Coffee Residue for Indoor Air Purification. J. Environ. Chem. Eng. 2022, 10, 108797. [Google Scholar] [CrossRef]

- Zulkefli, N.N.; Mathuray Veeran, L.S.; Noor Azam, A.M.I.; Masdar, M.S.; Wan Isahak, W.N.R. Effect of Bimetallic-Activated Carbon Impregnation on Adsorption–Desorption Performance for Hydrogen Sulfide (H2S) Capture. Materials 2022, 15, 5409. [Google Scholar] [CrossRef]

- Wang, X.; Jing, X.; Wang, F.; Ma, Y.; Cheng, J.; Wang, L.; Xu, K.; Cheng, C.; Ning, P. Coupling Catalytic Hydrolysis and Oxidation on Metal-Modified Activated Carbon for HCN Removal. RSC Adv. 2016, 6, 57108–57116. [Google Scholar] [CrossRef]

- Smith, J.W.H.; Romero, J.V.; Dahn, T.R.; Dunphy, K.; Croll, L.M.; Dahn, J.R. The Effect of Co-Impregnated Acids on the Performance of Zn-Based Broad Spectrum Respirator Carbons. J. Hazard. Mater. 2012, 235–236, 279–285. [Google Scholar] [CrossRef] [PubMed]

- Ehrburger, P. Aging of Cupric Oxide Supported on Activated Carbon. J. Catal. 1986, 100, 429–436. [Google Scholar] [CrossRef]

- Brown, P.N.; Jayson, G.G.; Thompson, G.; Wilkinson, M.C. Effect of Ageing and Moisture on the Retention of Hydrogen Cyanide by Impregnated Activated Charcoals. Carbon 1989, 27, 821–833. [Google Scholar] [CrossRef]

- Rossin, J.A.; Morrison, R.W. The Effects of Molybdenum on Stabilizing the Performance of an Experimental Copper/Zinc Impregnated, Activated Carbon. Carbon 1993, 31, 657–659. [Google Scholar] [CrossRef]

- Rossin, J.A.; Morrison, R.W. Spectroscopic Analysis and Performance of an Experimental Copper/Zinc Impregnated, Activated Carbon. Carbon 1991, 29, 887–892. [Google Scholar] [CrossRef]

- Rossin, J.; Petersen, E.; Tevault, D. Effects of Environnental Weathering on the Properties of ASC-Whetlerite. Carbon 1991, 29, 197–205. [Google Scholar] [CrossRef]

- Nir, I.; Shepelev, V.; Pevzner, A.; Marciano, D.; Rosh, L.; Amitay-Rosen, T.; Rotter, H. Phosphate Additives for Aging Inhibition of Impregnated Activated Carbon against Hazardous Gases. Int. J. Mol. Sci. 2023, 24, 13000. [Google Scholar] [CrossRef] [PubMed]

- Afandizadeh, S.; Foumeny, E.A. Design of Packed Bed Reactors: Guides to Catalyst Shape, Size, and Loading Selection. Appl. Therm. Eng. 2001, 21, 669–682. [Google Scholar] [CrossRef]

- Smith, J.W.H.; Westreich, P.; Croll, L.M.; Reynolds, J.H.; Dahn, J.R. Understanding the Role of Each Ingredient in a Basic Copper Carbonate Based Impregnation Recipe for Respirator Carbons. J. Colloid Interface Sci. 2009, 337, 313–321. [Google Scholar] [CrossRef] [PubMed]

- Smith, J.W.H.; Romero, J.V.; Dahn, T.R.; Dunphy, K.; Sullivan, B.; Mallay, M.; Croll, L.M.; Reynolds, J.H.; Andress, C.; Dahn, J.R. The Effect of Heating Temperature and Nitric Acid Treatments on the Performance of Cu- and Zn-Based Broad Spectrum Respirator Carbons. J. Colloid Interface Sci. 2011, 364, 178–194. [Google Scholar] [CrossRef] [PubMed]

- Deitz, V.R.; Karwacki, C.J. Chemisorption of Cyano-Containing Vapors by Metal-Ligand Structures Adsorbed by Activated Carbon. Carbon 1994, 32, 703–707. [Google Scholar] [CrossRef]

- Morrow, J.R.; Trogler, W.C. Hydrolysis of Phosphate Triesters with Copper(II) Catalysts. Inorg. Chem. 1989, 28, 2330–2333. [Google Scholar] [CrossRef]

- Choma, J.; Jaroniec, M.; Jaroniec, M. Chapter 3 Characterization of Nanoporous Carbons by Using Gas Adsorption Isotherms. In Activated Carbon Surfaces in Environmental Remediation; Elsevier: Amsterdam, The Netherlands, 2006; Volume 7, pp. 107–158. ISBN 9780123705365. [Google Scholar]

- Park, S.H.; McClain, S.; Tian, Z.R.; Suib, S.L.; Karwacki, C. Surface and Bulk Measurements of Metals Deposited on Activated Carbon. Chem. Mater. 1997, 9, 176–183. [Google Scholar] [CrossRef]

| R0 | R1 | R2 | |

|---|---|---|---|

| Ammonium carbonate | 14.3 | 24.2 | 28.6 |

| Ammonium hydroxide solution (25 wt.%) | 35.7 | 60.6 | 71.4 |

| Water | 50.0 | 15.2 | 0 |

| New IAC | IAC after 6 Months Accelerated Aging | IAC after 6 Months Accelerated Aging + Regeneration | |

|---|---|---|---|

| Surface area (m2/g) (BET) | 686 | 760 | 677 |

| % microporosity | 80.8 | 82.4 | 83.0 |

| Micropore volume (cm3/g) | 0.281 | 0.316 | 0.286 |

| SEM-EDS | XPS | |||||||

|---|---|---|---|---|---|---|---|---|

| Zn/C | Cu/C | Mo/C | O/C | Zn/C | Cu/C | Mo/C | O/C | |

| New | 0.428 | 0.152 | 0.068 | 0.306 | 0.075 | 0.037 | 0.020 | 0.131 |

| Aging for six months | 4.944 | 3.619 | 0.450 | 3.605 | 3.101 | 1.025 | 0.328 | 2.958 |

| Aging for six months + regeneration | 0.198 | 0.168 | 0.093 | 0.375 | 1.094 | 0.376 | 0.521 | 0.244 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nir, I.; Shepelev, V.; Rosh, L.; Lybman, A.; Aviram, L.; Amitay-Rosen, T.; Rotter, H. Regeneration of Impregnated Activated Carbon after Aging. Environments 2023, 10, 214. https://doi.org/10.3390/environments10120214

Nir I, Shepelev V, Rosh L, Lybman A, Aviram L, Amitay-Rosen T, Rotter H. Regeneration of Impregnated Activated Carbon after Aging. Environments. 2023; 10(12):214. https://doi.org/10.3390/environments10120214

Chicago/Turabian StyleNir, Ido, Vladislav Shepelev, Lilach Rosh, Amir Lybman, Liat Aviram, Tal Amitay-Rosen, and Hadar Rotter. 2023. "Regeneration of Impregnated Activated Carbon after Aging" Environments 10, no. 12: 214. https://doi.org/10.3390/environments10120214