Cold Ironing and the Study of RES Utilization for Maritime Electrification on Lesvos Island Port

Abstract

:1. Introduction

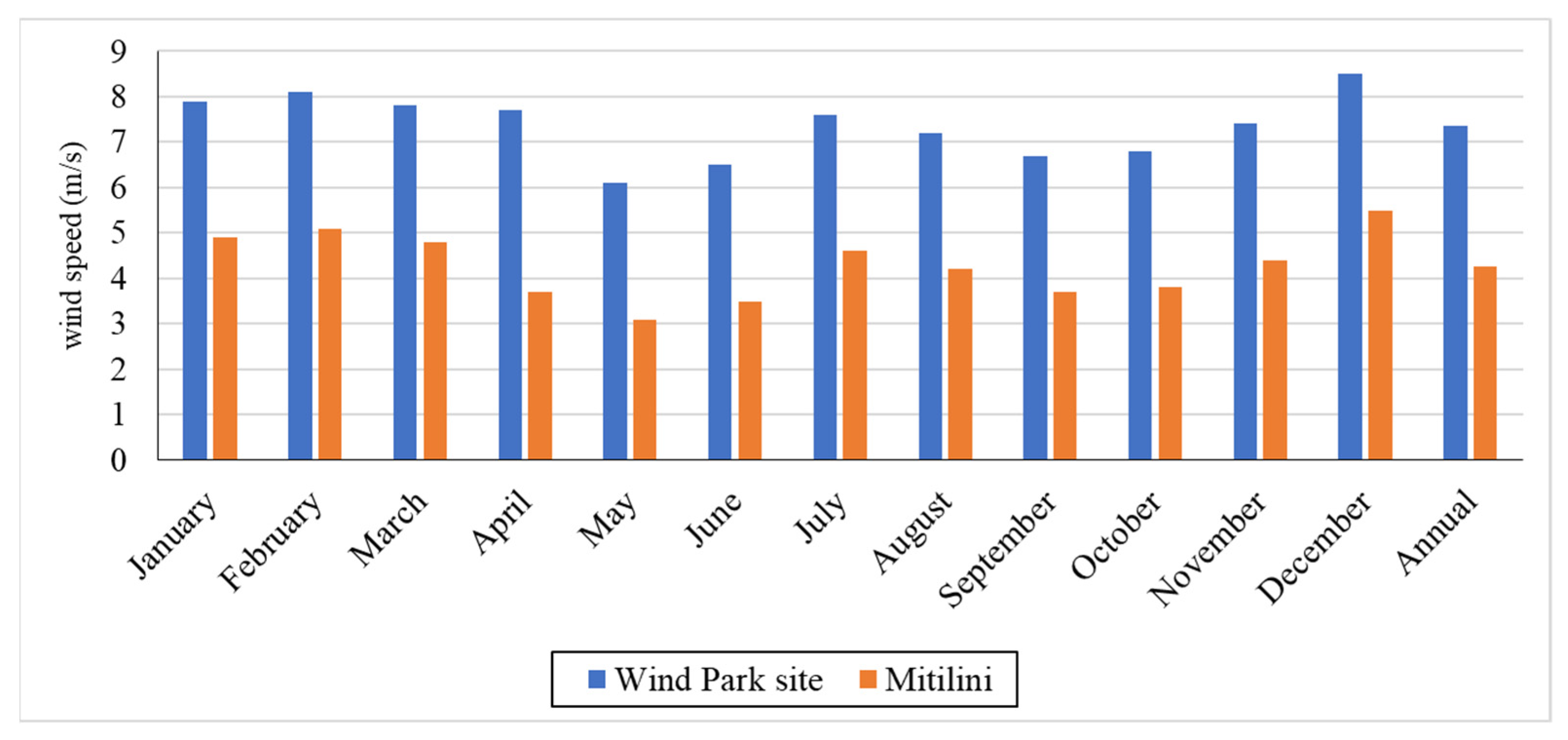

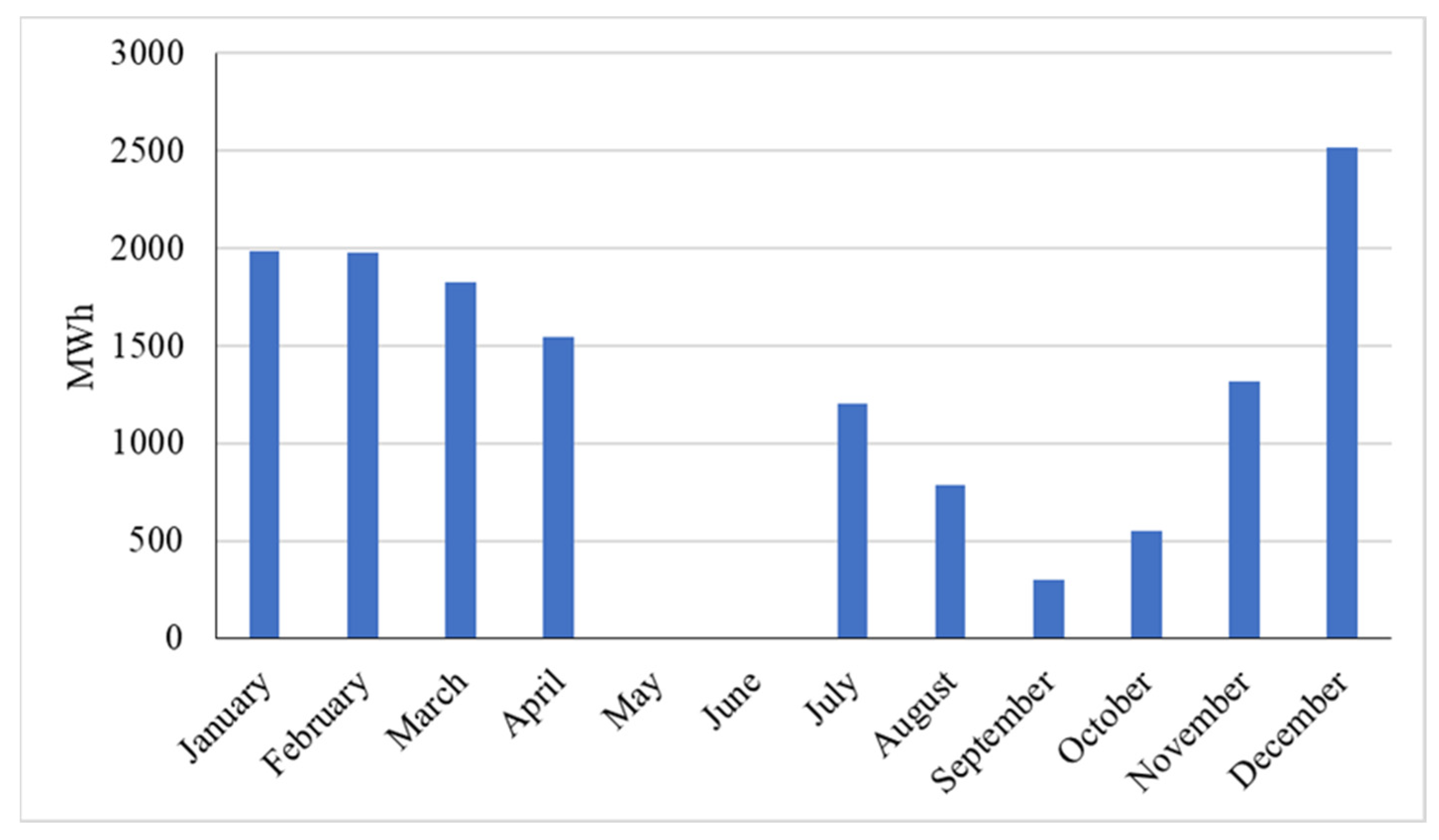

2. Materials and Methods

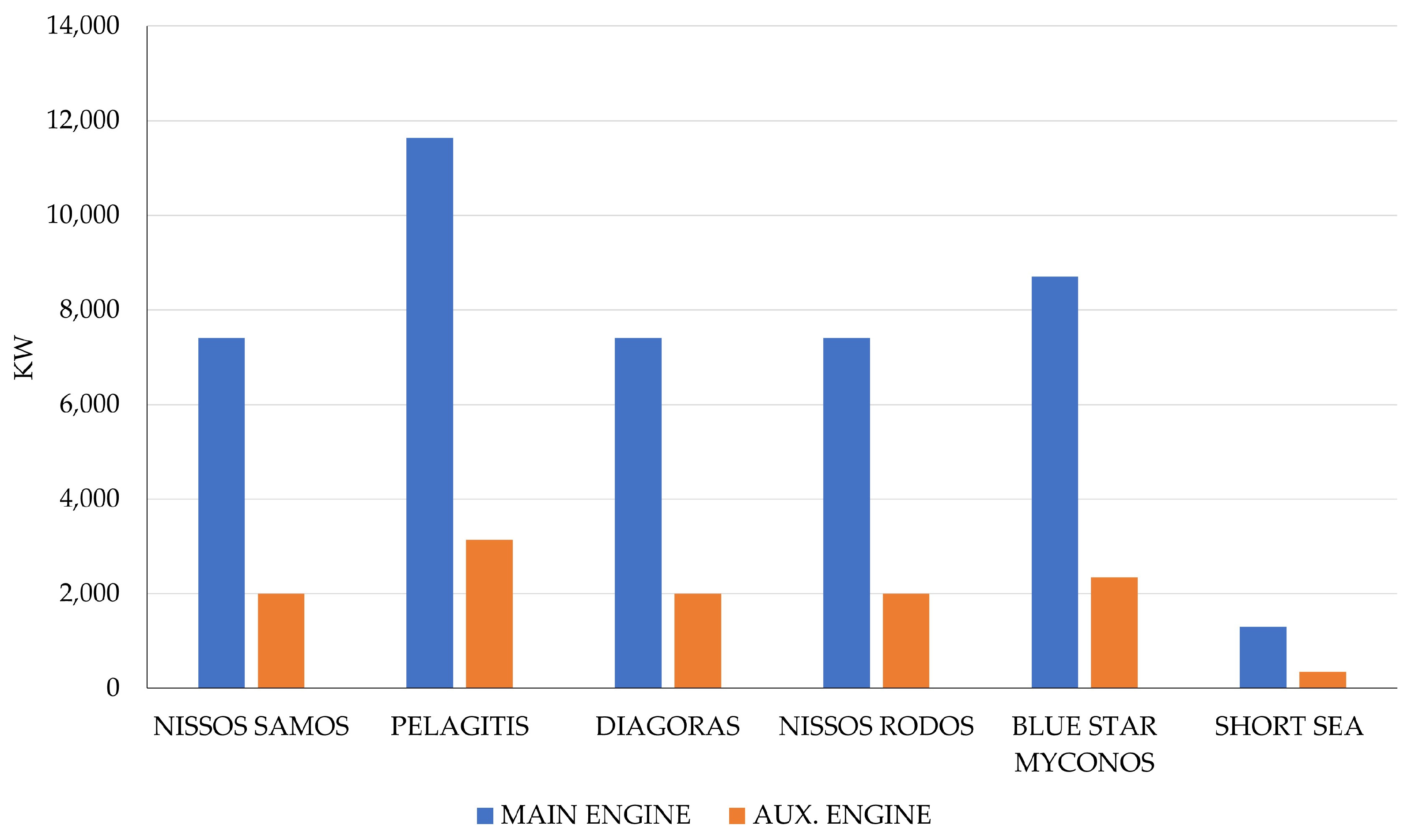

2.1. Available Data from Shipping Routes

2.2. Methodology and Software for the In-Port Energy Demand Analysis

- Uanem: wind speed at anemometer height,

- Zhub: height of the wind turbine,

- Zanem: height of the anemometer,

- Z0: surface roughness length.

- ρ: actual air density,

- ρo: air density at standard air density,

- PSTP: wind power output at standard air density.

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- International Maritime Organization. IMO: Fuel Oil Consumption Data Collection System Enters into Force. 2022. Available online: https://www.imo.org/en/MediaCentre/PressBriefings/Pages/33-GHG-data-collection.aspx (accessed on 14 November 2023).

- European Maritime Safety Agency. Cold Ironing—Alternative Maritime Power (AMP). 2022. Available online: https://www.emsa.europa.eu/operations/maritime-security/cold-ironing-alternative-maritime-power.html (accessed on 14 November 2023).

- European Maritime Safety Agency. Use of Cold Ironing and Electrical Connection for Ships at Berth. 2022. Available online: https://www.emsa.europa.eu/operations/maritime-safety/use-of-cold-ironing.html (accessed on 14 November 2023).

- Kotrikla, A.M.; Lilas, T.; Nikitakos, N. Abatement of air pollution at an Aegean island port utilizing shore side electricity and renewable energy. Mar. Policy 2017, 75, 238–248. [Google Scholar] [CrossRef]

- Martínez-López, A.; Romero, A.; Orosa, J.A. Assessment of Cold Ironing and LNG as Mitigation Tools of Short Sea Shipping Emissions in Port: A Spanish Case Study. Appl. Sci. 2021, 11, 2050. [Google Scholar] [CrossRef]

- Ballini, F.; Bozzo, R. Air pollution from ships in ports: The socio-economic benefit of cold-ironing technology. Res. Transp. Bus. Manag. 2015, 17, 92–98. [Google Scholar] [CrossRef]

- The European Environment Agency. Cleaner Fuels and Energy Sources for Ships Can Lower Environmental Risks. 2022. Available online: https://www.eea.europa.eu/signals/signals-2017-content-list/cleaner-fuels-and-energy-sources (accessed on 14 November 2023).

- Katsaprakakis, D.A.; Proka, A.; Zafirakis, D.; Damasiotis, M.; Kotsampopoulos, P.; Hatziargyriou, N.; Dakanali, E.; Arnaoutakis, G.; Xevgenos, D. Greek Islands’ Energy Transition: From Lighthouse Projects to the Emergence of Energy Communities. Energies 2022, 15, 5996. [Google Scholar] [CrossRef]

- Colarossi, D.; Principi, P. Optimal sizing of a photovoltaic/energy storage/cold ironing system: Life Cycle cost approach and environmental analysis. Energy Convers. Manag. 2023, 291, 117255. [Google Scholar] [CrossRef]

- Genave, A.; Blancard, S.; Garabedian, S. An Assessment of Energy Vulnerability in Small Island Developing States. Ecol. Econ. 2020, 171, 106595. [Google Scholar] [CrossRef]

- Dimou, A.; Vakalis, S. Technoeconomic Analysis of Green Energy Transitions in Isolated Grids: The Case of Ai Stratis—Green Island. Renew. Energy 2022, 195, 66–75. [Google Scholar] [CrossRef]

- Carrasco, J.M.; Franquelo, L.G.; Bialasiewicz, J.T.; Galvan, E.; PortilloGuisado, R.C.; Prats, M.A.M.; Leon, J.I.; Moreno-Alfonso, N. Power-Electronic Systems for the Grid Integration of Renewable Energy Sources: A Survey. IEEE Trans. Ind. Electron. 2006, 53, 1002–1016. [Google Scholar] [CrossRef]

- Katsoulakos, N. An Overview of the Greek Islands’ Autonomous Electrical Systems: Proposals for a Sustainable Energy Future. Smart Grid Renew. Energy 2019, 10, 55–82. [Google Scholar] [CrossRef]

- Barney, A.; Polatidis, H.; Jelić, M.; Tomašević, N.; Pillai, G.; Haralambopoulos, D. Transition towards decarbonisation for islands: Development of an integrated energy planning platform and application. Sustain. Energy Technol. Assess. 2021, 47, 101501. [Google Scholar] [CrossRef]

- Altiparmaki, G.; Vasileiadou, M.A.; Vakalis, S. The effect of excess water on the hydrothermal carbonization of anise waste from ouzo production on Lesvos island. Sustain. Chem. Pharm. 2022, 29, 100831. [Google Scholar] [CrossRef]

- Vasileiadou, M.A.; Altiparmaki, G.; Moustakas, K.; Vakalis, S. Quality of Hydrochar from Wine Sludge under Variable Conditions of Hydrothermal Carbonization: The Case of Lesvos Island. Energies 2022, 15, 3574. [Google Scholar] [CrossRef]

- Barney, A.; Polatidis, H.; Vakalis, S.; Grondin, D.; Benne, M.; Salces, F.S.; Haralambopoulos, D. Energy transition awareness: Can it guide local transition planning on islands? Heliyon 2023, 9, e19960. [Google Scholar] [CrossRef] [PubMed]

- Dimou, A.; Moustakas, K.; Vakalis, S. The Role of Hydrogen and H2 Mobility on the Green Transition of Islands: The Case of Anafi (Greece). Energies 2023, 16, 3542. [Google Scholar] [CrossRef]

- EMEP/EEA. Air Pollutant Emission Inventory Guidebook; Technical report No 21/2016; EEA: Copenhagen, Denmark, 2016. [Google Scholar]

- Tzannatos, E. Ship emissions and their externalities for the port of Piraeus—Greece. Atmos. Environ. 2010, 44, 400–407. [Google Scholar] [CrossRef]

- Kelmalis, A.; Lekkas, D.F.; Moustakas, K.; Vakalis, S. Assessing the Emissions of Short Sea International Shipping: A Case Study of the Mytilini–Ayvalik Route. Environ. Sci. Pollut. Res. 2023, 30, 115496–115505. [Google Scholar] [CrossRef] [PubMed]

- Moya, D.; Paredes, J.; Kaparaju, P. Technical, financial, economic and environmental pre-feasibility study of geothermal power plants by RETScreen—Ecuador’s case study. Renew. Sustain. Energy Rev. 2018, 92, 628–637. [Google Scholar] [CrossRef]

- HEDNO. Report: Issuance of Power Generation Informative Report for the Non-Interconnected Islands. 2023. Available online: https://deddie.gr/en/kentro-enhmerwsis/nea-anakoinwseis/miniaia-deltia-ape-december-2022/ (accessed on 25 October 2023).

- Orfanou, A.; Vakalis, S. Wind Based Hybrid Systems for Increased RES Penetration in Isolated Grids: The Case Study of Anafi (Greece). AIMS Energy 2022, 10, 1046–1058. [Google Scholar] [CrossRef]

- Bakar, N.N.A.; Guerrero, J.M.; Vasquez, J.C.; Bazmohammadi, N.; Othman, M.; Rasmussen, B.D.; Al-Turki, Y.A. Optimal Configuration and Sizing of Seaport Microgrids including Renewable Energy and Cold Ironing—The Port of Aalborg Case Study. Energies 2022, 15, 431. [Google Scholar] [CrossRef]

- Karapidakis, E.; Nikolaidis, E.; Moraitakis, G.; Georgakis, F.; Papadakis, M. Cold ironing feasibility study at the Heraklion Port. J. Phys. Conf. Ser. 2022, 2339, 012016. [Google Scholar] [CrossRef]

- Piccoli, T.; Fermeglia, M.; Bosich, D.; Bevilacqua, P.; Sulligoi, G. Environmental Assessment and Regulatory Aspects of Cold Ironing Planning for a Maritime Route in the Adriatic Sea. Energies 2021, 14, 5836. [Google Scholar] [CrossRef]

- Glavinović, R.; Krčum, M.; Vukić, L.; Karin, I. Cold Ironing Implementation Overview in European Ports—Case Study—Croatian Ports. Sustainability 2023, 15, 8472. [Google Scholar] [CrossRef]

- Zis, T.P.V. Prospects of Cold Ironing as an Emissions Reduction Option. Transp. Res. Part A Policy Pract. 2019, 119, 82–95. [Google Scholar] [CrossRef]

- Arduino, G.; Murillo, D.; Ferrari, C. Key Factors and Barriers to the Adoption of Cold Ironing in Europe. In Proceedings of the Società Italiana di Economia dei Trasporti e della Logistica—XIII Riunione Scientifica, Messina, Italy, 16–17 June 2011. [Google Scholar]

- Martínez-López, A.; Romero-Filgueira, A.; Chica, M. Specific Environmental Charges to Boost Cold Ironing Use in the European Short Sea Shipping. Transp. Res. Part D Transp. Environ. 2021, 94, 102775. [Google Scholar] [CrossRef]

- Iris, Ç.; Lam, J.S.L. Optimal Energy Management and Operations Planning in Seaports with Smart Grid While Harnessing Renewable Energy Under Uncertainty. Omega 2021, 103, 102445. [Google Scholar] [CrossRef]

| % Load ME | % Time ME | % Load AE | |

|---|---|---|---|

| Cruise | 80 | 100 | 30 |

| Maneuvering | 20 | 100 | 50 |

| Hoteling | 20 | 5 | 40 |

| Ship Type | Cruise (km/h) | Maneuvering (h) | Hoteling (h) |

|---|---|---|---|

| Ro-ro cargo | 27 | 1 | 6 |

| Passenger | 39 | 0.8 | 6 |

| Passenger (short sea) | 25 | 0.6 | 2 |

| Model | ENERCON—48–76 m | |

|---|---|---|

| Parameter | Unit | Value |

| Power capacity per turbine | kW | 800 |

| Number of turbines | 25 | |

| Total power capacity | kW | 20,000 |

| Hub height | m | 76 |

| Rotor diameter per turbine | m | 48 |

| Swept area per turbine | m2 | 1809.6 |

| Air temperature—annual | °C | 17.1 |

| Atmospheric pressure—annual | kPa | 99.6 |

| Wind shear exponent | 0.14 | |

| Shape factor | 2 |

| Wind Speed (m/s) | Power Curve Data (kW) | Energy Curve Data (MWh) |

|---|---|---|

| 0 | 0 | - |

| 1 | 0 | - |

| 2 | 2 | - |

| 3 | 12 | 234.07 |

| 4 | 32 | 575.20 |

| 5 | 66 | 1084.68 |

| 6 | 120 | 1697.24 |

| 7 | 191 | 2330.31 |

| 8 | 284 | 2926.60 |

| 9 | 405 | 3458.51 |

| 10 | 555 | 3916.83 |

| 11 | 671 | 4299.86 |

| 12 | 750 | 4608.18 |

| 13 | 790 | 4843.49 |

| 14 | 810 | 5009.13 |

| 15 | 810 | 5110.46 |

| 15 | 0 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kelmalis, A.; Dimou, A.; Lekkas, D.F.; Vakalis, S. Cold Ironing and the Study of RES Utilization for Maritime Electrification on Lesvos Island Port. Environments 2024, 11, 84. https://doi.org/10.3390/environments11040084

Kelmalis A, Dimou A, Lekkas DF, Vakalis S. Cold Ironing and the Study of RES Utilization for Maritime Electrification on Lesvos Island Port. Environments. 2024; 11(4):84. https://doi.org/10.3390/environments11040084

Chicago/Turabian StyleKelmalis, Alexandros, Andreas Dimou, Demetris Francis Lekkas, and Stergios Vakalis. 2024. "Cold Ironing and the Study of RES Utilization for Maritime Electrification on Lesvos Island Port" Environments 11, no. 4: 84. https://doi.org/10.3390/environments11040084