A Hybrid MADM Approach for the Evaluation of Different Material Handling Issues in Flexible Manufacturing Systems

Abstract

:1. Introduction

2. Material Handling System and Equipment

3. Literature Review

3.1. Review of Literature Regarding ISM

3.2. Review of Literature Regarding TOPSIS

4. Methodology

4.1. Interpretive Structural Modelling

- Step 1:

- First of all different attributes related to any issue are identified either by a survey or any group problem solving technique.

- Step 2:

- Further, these different attributes are related by contextual relationship. For this a Structural self-interaction matrix (SSIM) is developed, which indicates the pair-wise relationship between the different attributes.

- Step 3:

- Reachability Matrix (RM) is developed from the SSIM. The transitivity of this matrix is also checked and Final Reachability Matrix containing all the transitive links is developed.

- Step 4:

- Different level partitioning is done of RM. The reachability set and antecedent set for each issue are found from the final reachability matrix. Then the intersection set is found and the levels are decided based on all the issues which can reach the issue from bottom.

- Step 5:

- Conical matrix is developed with zero elements in the upper diagonal and the unitary elements in the lower half.

- Step 6:

- Based on the conical matrix relationships, a directed graph (digraph) without the transitive links is drawn.

- Step 7:

- The nodes of the digraph are replaced with statements to convert it into an ISM model.

4.2. TOPSIS

- Step 1:

- Determine the related attributes for the given objective.

- Step 2:

- All the information related to the attributes is expressed in matrix form. This information may be collected from a survey or group discussion. Each row of this matrix is allocated to one attribute and each column to one criterion. Raw measurements are standardized by using Equation (1), where, raw measure Xij is standardized into Sij,

- Step 3:

- Importance weights wk is developed for each of the criteria. The relative importance of these criteria is reflected by these weights. In this work the weightage of rating is calculated by using following criteria:

- Step 4:

- The weighted normalized matrix Wij is obtained by multiplying each element of the column of the matrix Sij with its associated weight wk. So, the elements of this are expressed as:Wij = wkSij

- Step 5:

- Identify the ideal attribute on each criterion, S+.

- Step 6:

- Identify the nadir attribute on each criterion, S−.

- Step 7:

- A distance measure is developed over each criterion to both ideal (D+) and nadir (D−).

- Step 8:

- The relative closeness of a particular attribute to the ideal solution, Ri, is calculated as shown in Equation (6)

- Step 9:

- Finally, all the alternatives are arranged in the descending order according to the value of Ri indicating the most preferred and least preferred attribute.

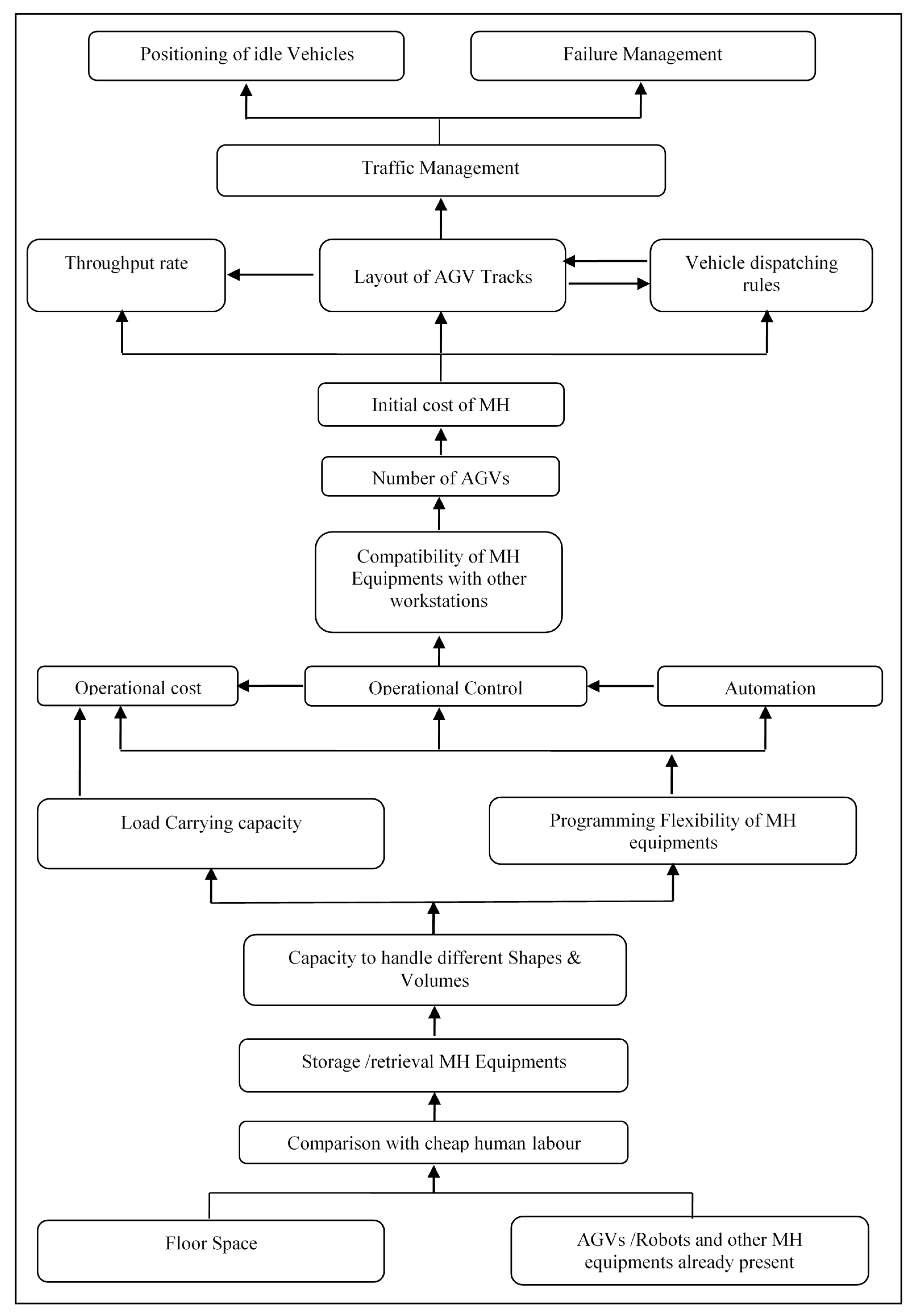

5. ISM Model for the Evaluation of Material Handling Issues

5.1. Development of SSIM

5.2. Development of the Reachability Matrix

5.3. Partitioning the Reachability Matrix

5.4. Development of the Conical Matrix

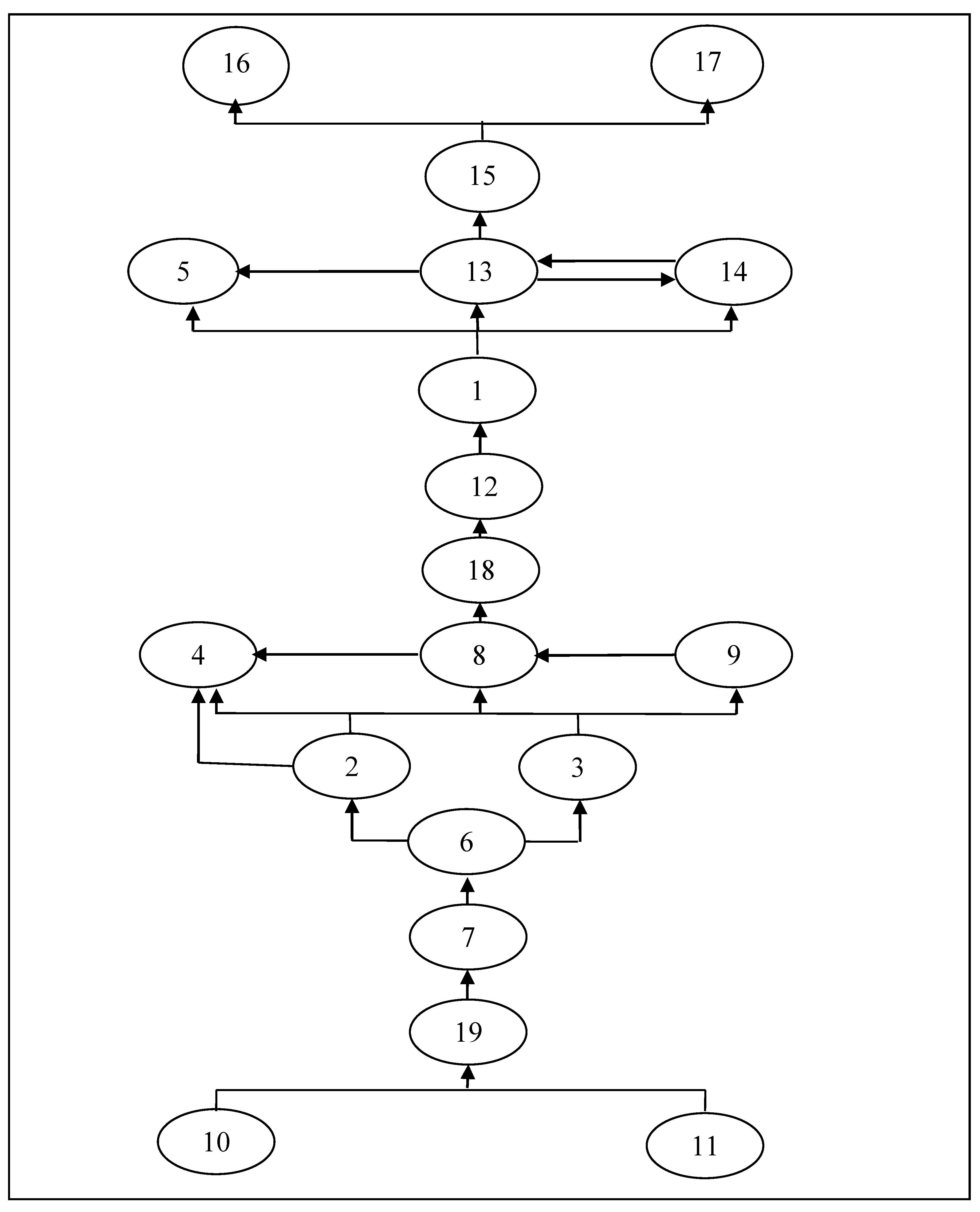

5.5. Development of the Digraph and the ISM Model

6. TOPSIS Model for the Evaluation of Material Handling Issues

- Step 1:

- Objective is to find the significance hierarchy of different material handling issues. For this 19 issues were identified as given in Table 1.

- Step 2:

- The next step is to represent all the information available for the issues in the form of a decision matrix. For this step, the data is collected from a survey and 19 issues of material handling in FMS were rated on a scale of 5 in which responses from 63 respondents were collected. Thus, number of attributes is, n = 19 and criteria, k = 5. This raw data in the form of frequency table is shown in Table 18.

- Step 3:

- Table 20 shows these criteria weights developed for each criteria using Equation (2).

- Step 4:

- Now the weighted matrix is developed by multiplying each value of a rating column by its respective weight. The same is shown in Table 21.

- Step 5:

- Step 6:

- Step 7:

- By using the Equations (4) and (5), a distance measure over each criterion to both ideal (D+) and nadir (D−) is developed. The same is shown in Table 24.

- Step 8:

- A ratio R is determined for each issue which is equal to the distance to the nadir divided by the sum of the distance to the nadir and the distance to the ideal, as shown in Equation (6) and calculated in Table 25.

- Step 9:

- Rank the issues by maximizing the ratio in Step 8 as shown in Table 26.

7. Discussion

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Agrawal, V. P., Anandi Lal Verma, and S. Agarwal. 1992. Computer-aided evaluation and selection of optimum grippers. International Journal of Production Research 30: 2713–32. [Google Scholar] [CrossRef]

- Asef-Vaziri, Ardavan, and Gilbert Laporte. 2005. Loop based facility planning and material handling. European Journal of Operational Research 164: 1–11. [Google Scholar] [CrossRef]

- Attri, Rajesh, Sandeep Grover, Nikhil Dev, and Deepak Kumar. 2012. Analysis of barriers of total productive maintenance (TPM). International Journal System Assurance Engineering and Management 4: 365–77. [Google Scholar] [CrossRef]

- Attri, Rajesh, Nikhil Dev, and Vivek Sharma. 2013. Interpretive structural modelling (ISM) approach: An overview. Research Journal of Management Sciences 2: 3–8. [Google Scholar]

- Beamon, Benita, M. 1998. Performance, reliability and performability of material handling systems. International Journal of Production Research 36: 377–93. [Google Scholar] [CrossRef]

- Chen, C. T., P. F. Pai, and Wei-Zhan Hung. 2011. Combined utility function with TOPSIS for personnel selection based on multi-type information environment. Paper presented at International conference on Business and Information, Business and Information, Bangkok, Thailand, 4–6 July 2011; Volume 8, pp. 1–13. [Google Scholar]

- Dai, James B., and Neville Ka-shek Lee. 2012. Economic feasibility analysis of flexible material handling systems: A case study in the apparel industry. International Journal of Production Economics 136: 28–36. [Google Scholar] [CrossRef]

- Deng, Hepu, Chung-Hsing Yeh, and Robert J. Willis. 2000. Inter-company comparison using modified TOPSIS with objective weights. Computers and Operations Research 27: 963–74. [Google Scholar] [CrossRef]

- Dixit, Sandhya, and Tilak Raj. 2016. Identification and modelling of the various factors affecting the productivity of FMS. International Journal of Productivity and Quality Management 17: 353–79. [Google Scholar] [CrossRef]

- Dixit, Sandhya, and Tilak Raj. 2018. Feasibility analysis of FMS in small and medium scale Indian industries with a hybrid approach using ISM and TOPSIS. International Journal of Advanced Operations Management 10: 252–80. [Google Scholar] [CrossRef]

- Faisal, Mohd Nishat. 2010. Analysing the barriers to corporate social responsibility in supply chains: An interpretive structural modelling approach. Internal Journal of Logistics: Research and Applications 13: 179–95. [Google Scholar] [CrossRef]

- Govindan, Kannan, M. Palaniappan, Qinghua Zhu, and Deevika Kannan. 2012. Analysis of third party reverse logistics provider using interpretive structural modeling. Internationl Journal of Production Economics 140: 179–95. [Google Scholar] [CrossRef]

- Groover, Mikell P. 2001. Automation, Production Systems and Computer-Integrated Manufacturing, 2nd ed. Upper Saddle River: Prentice-Hall. [Google Scholar]

- Hao, Li, and Qing-Sheng Xie. 2006. Application of TOPSIS in the bidding evaluation of manufacturing enterprises. Paper presented at e-ENGDET 2006, 5th International Conference on e-Engineering & Digital Enterprise Technology, Guiyang, China, 16–18 August 2006; pp. 184–88. [Google Scholar]

- Hwang, Ching-Lai, and Kwangsun Yoon. 1981. Multiple Attribute Decision Making: Methods and Applications. New York: Springer. [Google Scholar]

- Ioannou, George. 2007. An integrated model and a decomposition-based approach for concurrent layout and material handling system design. Computers & Industrial Engineering 52: 459–85. [Google Scholar]

- Jahan, Ali, Marjan Baharaminasab, and Kevin L. Edwards. 2012. A target based normalization technique for materials selection. Journal of Materials and Design 35: 647–54. [Google Scholar] [CrossRef]

- Jain, Vineet, and Tilak Raj. 2015. A hybrid approach using ISM and modified TOPSIS for the evaluation of flexibility in FMS. International Journal of Industrial and Systems Engineering 19: 389–406. [Google Scholar] [CrossRef]

- Jharkharia, Sanjay, and Ravi Shankar. 2005. IT-enablement of supply chain: Modeling the enablers. Journal of Enterprise Information Management 18: 11–27. [Google Scholar] [CrossRef]

- Kannan, Govindan, Shaligram Pokharel, and P. Sasi Kumar. 2009. A hybrid approach using ISM and fuzzy TOPSIS for the selection of reverse logistics provider. Conservation and Recycling Resources 54: 28–36. [Google Scholar] [CrossRef]

- Karande, Prasad, and Shankar Chakraborty. 2013. Material Handling Equipment Selection Using Weighted Utility Additive Theory. Journal of Industrial Engineering 2013: 268708. [Google Scholar] [CrossRef] [PubMed]

- Kim, Gyutai, Chan Park, and K. Paul Yoon. 1997. Identifying investment opportunities for advanced manufacturing system with comparative-integrated performance measurement. International Journal of Production Economics 50: 23–33. [Google Scholar] [CrossRef]

- Kulak, Osman, Sule Itir Satoglu, and Mehmet Bulent Durmusoglu. 2004. Multi-attribute material handling equipment selection using information axiom. Paper presented at ICAD2004, The Third International Conference on Axiomatic Design, Seoul, Korea, June 21–24. [Google Scholar]

- Lai, Young-Jou, Ting-Yun Liu, and Ching-Lai Hwang. 1994. TOPSIS for MODM. European Journal of Operational Research 76: 486–500. [Google Scholar] [CrossRef]

- Latpate, Raosaheb V. 2015. Fuzzy modified TOPSIS for supplier selection problem in supply chain management. International Journal of Innovative Research in Computer Science & Technology 3: 22–28. [Google Scholar]

- Luthra, Sunil, Vinod Kumar, Sanjay Kumar, and Abid Haleem. 2011. Barriers to implement green supply chain management in automobile industry using interpretive structural modeling technique: An Indian perspective. Journal of Industrial Engineering and Management 4: 231–57. [Google Scholar] [CrossRef]

- Mishra, Swagatika, Saurav Datta, and S. S. Mahapatra. 2012. Interrelationship of drivers for agile manufacturing: An Indian experience. International. Journal. Services and Operations Management 11: 35–48. [Google Scholar] [CrossRef]

- Nagar, Bhaskar, and Tilak Raj. 2012. Analysis of critical success factors for implementation of humanised flexible manufacturing system in industries. International Journal of Logistics Economicsand Globalisation 4: 309–29. [Google Scholar] [CrossRef]

- Oberoi, J. S., Jaimal Singh Khamba, and Kiran Kiran. 2008. An empirical examination of advanced manufacturing technology and sourcing practices in developing manufacturing flexibilities. International Journal of Services and Operations Management 4: 652–71. [Google Scholar] [CrossRef]

- Ojha, Vimlesh, Sandhya Dixit, and Sanjeev Goyal. 2018. Comparision of automated material handling system with human labour in FMS environment: Identification of core attributes. International Journal of Management Technology and Engineering 8: 209–14. [Google Scholar]

- Parkan, Celik, and Ming-Lu Wu. 1999. Decision-making and performance measurement models with applications to robot selection. Computers and Industrial Engineering 36: 503–23. [Google Scholar] [CrossRef]

- Poduval, Prasanth Sankar, V. R. Pramod, and V. P. Jagathy Raj. 2015. Interpretive Structural Modeling (ISM) and its application in analyzing factors inhibiting implementation of Total Productive Maintenance (TPM). International Journal of Quality & Reliability Management 32: 308–31. [Google Scholar]

- Raj, Tilak, Rajesh Attri, and Vineet Jain. 2012. Modelling the factors affecting flexibility in FMS. International Journal of Industrial and Systems Engineering 11: 350–74. [Google Scholar] [CrossRef]

- Raj, Tilak, Ravi Shankar, and Muhammad Suhaib. 2008. An ISM approach for modeling the enablers of flexible manufacturing system: The case for India. International Journal of Production Research 46: 6883–912. [Google Scholar] [CrossRef]

- Raj, Tilak, Ravi Shankar, and Muhammad Suhaib. 2009. An ISM approach to analyse interaction between barriers of transition to flexible manufacturing system. International Journal of Manufacturing Technology and Management 16: 417–38. [Google Scholar] [CrossRef]

- Rao, Ravipudi Venkata. 2007. Decision Making in Manufacturing Environment: Using Graph Theory and Fuzzy Multiple Attribute Decision Making Methods. London: Springer. [Google Scholar]

- Rao, Ravipudi Venkata, and Manukid Parnichkun. 2009. Flexible manufacturing system selection using a combinatorial mathematics-based decision-making method. International Journal of Production Research 47: 6981–98. [Google Scholar]

- Ravi, V., and Ravi Shankar. 2005. Analysis of interactions among the barriers of reverse logistics. Journal of Technical Forecast & Social Change 72: 1011–29. [Google Scholar]

- Sage, A. P. 1977. Interpretive Structural Modeling: Methodology for Large-Scale Systems. New York: McGraw-Hill, pp. 91–164. [Google Scholar]

- Sharma, Satyendra Kumar, and Anil Bhat. 2014. Modelling supply chain agility enablers using ISM. Journal of Modelling in Management 9: 200–14. [Google Scholar] [CrossRef]

- Singh, M.D., Ravi Shankar, Rakesh Narain, and Ashish Agarwal. 2003. An interpretive structural modelling of knowledge management in engineering industries. Journal of Advances in Management Research 1: 28–40. [Google Scholar] [CrossRef]

- Sujono, Sienny, and R. S. Lashkari. 2007. A multi-objective model of operation allocation and material handling system selection in FMS design. International Journal of Production Economics 105: 116–33. [Google Scholar] [CrossRef]

- Sule, Dileep R. 1994. Manufacturing Facilities: Location, Planning and Design. Boston: PWS Publishing Company. [Google Scholar]

- Telek, Peter. 2013. Equipment preselection for integrated design of materials handling systems. Advanced Logistic Systems 7: 57–66. [Google Scholar]

- Thirupathi, R. M., and S. Vinodh. 2016. Application of interpretive structural modelling and structural equation modelling for analysis of sustainable manufacturing factors in Indian automotive component sector. International Journal of Production Research 54: 6661–82. [Google Scholar] [CrossRef]

- Tompkins, James A. 2010. Facilities Planning. New York: John Wiley and Sons. [Google Scholar]

- Tuzkaya, Gulfem, Bahadir Gulsun, Cengiz Kahraman, and Dogan Ozgen. 2010. An integrated fuzzy multi-criteria decision making methodology for material handling equipment selection problem and an application. Expert Systems with Applications 37: 2853–63. [Google Scholar] [CrossRef]

- Upadhye, Nitin, Devendra Singh Awana, and Sandeep Mathur. 2014. Interpretive structural modeling of implementation enablers for just in time in ICPI. International Journal of Lean Thinking 5: 61–76. [Google Scholar]

- Vieira, Guilherme Bergmann Borges, Giovana Savitri Pasa, Maria Beatriz Nunes Oliveira Borsa, Gabriel Sperandio Milan, and Alberto Pandolfo. 2011. Materials Handling Management: A Case Study. Journal of Operations and Supply Chain Management 4: 19–30. [Google Scholar] [CrossRef]

- Wang, Tien Chin, and Tsung Han Chang. 2007. Application of TOPSIS in evaluating initial training aircraft under a fuzzy environment. Expert Systems with Applications 33: 870–80. [Google Scholar] [CrossRef]

- Warfield, John N. 1974. An interim look at uses of interpretive structural modeling. In Research Futures. Columbus: Battelle Memorial Institute, Third Quarter. [Google Scholar]

- Yang, G., and Lu Sun. 2010. A new personalized recommendation technique based on the modified TOPSIS method. International Journal of Advanced Computer Science and Applications 1: 8–13. [Google Scholar] [CrossRef]

- Yoon, Paul K., and Ching-Lai Hwang. 1995. Multiple Attribute Decision Making: An Introduction. Thousand Oaks: Sage. [Google Scholar]

- Ziaei, Mehdi, Seyed Mojtava Sajadi, and Moghad M. Tavakoli. 2016. The performance improvement of water pump manufacturing system via multi-criteria decision-making and simulation (a case study: Iran Godakht Company). International Journal of Productivity and Quality Management 17: 1–15. [Google Scholar] [CrossRef]

| S. No. | Issue |

|---|---|

| 1. | Initial cost of the MH equipment |

| 2. | Load carrying capacity |

| 3. | Programming flexibility of MH equipment |

| 4. | Operational cost |

| 5. | Throughput rate |

| 6. | Capacity to handle different shapes and volumes |

| 7. | Storage/Retrieval MH equipment |

| 8. | Operational control |

| 9. | Automation |

| 10 | Floor space |

| 11. | AGVs/Robots and other advanced MH equipment already present |

| 12. | Number of AGVs required |

| 13. | Layout of AGV tracks |

| 14. | Vehicle dispatching rules |

| 15. | Traffic management |

| 16. | Positioning of idle vehicles |

| 17. | Failure management |

| 18. | Compatibility of MH equipment with other workstations |

| 19. | Comparison with cheap human labour |

| Issue | 19 | 18 | 17 | 16 | 15 | 14 | 13 | 12 | 11 | 10 | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | X | O | O | O | O | O | O | A | O | O | A | O | O | A | O | O | A | A |

| 2 | V | O | O | O | V | V | V | V | A | O | O | O | O | A | V | V | O | |

| 3 | O | O | O | O | V | O | O | V | O | O | V | V | O | A | V | V | ||

| 4 | V | O | O | O | O | O | O | O | O | O | O | A | O | A | O | |||

| 5 | O | O | O | O | V | V | A | O | O | O | O | O | O | O | ||||

| 6 | O | V | O | O | O | V | O | V | O | O | O | O | A | |||||

| 7 | A | V | O | V | O | O | V | O | O | O | V | O | ||||||

| 8 | O | V | V | O | V | V | O | O | O | O | A | |||||||

| 9 | A | V | V | O | O | O | O | O | O | O | ||||||||

| 10 | O | O | O | V | V | O | V | V | O | |||||||||

| 11 | O | O | V | O | O | V | V | V | ||||||||||

| 12 | O | A | O | O | V | V | V | |||||||||||

| 13 | O | A | O | O | V | X | ||||||||||||

| 14 | O | A | O | O | V | |||||||||||||

| 15 | O | O | O | V | ||||||||||||||

| 16 | O | O | O | |||||||||||||||

| 17 | O | O | ||||||||||||||||

| 18 | O |

| Issue | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| 2 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 |

| 3 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 |

| 4 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| 5 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 |

| 6 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 0 |

| 7 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 0 |

| 8 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 1 | 0 |

| 9 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 |

| 10 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 0 |

| 11 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 |

| 12 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 |

| 13 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 0 |

| 14 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 0 |

| 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 |

| 16 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 |

| 17 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 |

| 18 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 0 |

| 19 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| Issue | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 0 | 0 | 0 | 0 | 1 * | 1 * | 1 * | 1 * | 0 | 0 | 0 | 1 * | 0 | 0 | 1 * | 1 * | 1 * | 1 |

| 2 | 1 | 1 | 0 | 1 | 1 | 1 * | 1 * | 1 * | 1 * | 0 | 0 | 1 | 1 | 1 | 1 | 1 * | 1 * | 1 * | 1 |

| 3 | 1 | 0 | 1 | 1 | 1 | 0 | 1 * | 1 | 1 | 0 | 0 | 1 | 1 * | 1 * | 1 | 1 * | 1 * | 1 * | 1 * |

| 4 | 1 * | 0 | 0 | 1 | 0 | 1 * | 1 * | 1 * | 1 * | 0 | 0 | 0 | 1 * | 0 | 0 | 1 * | 1 * | 1 * | 1 |

| 5 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 * | 1 | 1 | 1 * | 0 | 0 | 0 |

| 6 | 1 | 1 | 1 | 1 | 1 * | 1 | 0 | 1 * | 1 * | 0 | 0 | 1 | 1 * | 1 | 1 * | 0 | 1 * | 1 | 1 * |

| 7 | 1 * | 1 * | 1 * | 1 * | 1 * | 1 | 1 | 1 * | 1 | 0 | 0 | 1 * | 1 | 1 * | 1 * | 1 | 1 * | 1 | 0 |

| 8 | 1 * | 0 | 0 | 1 | 1 * | 0 | 1 * | 1 | 1 * | 0 | 0 | 1 * | 1 * | 1 | 1 | 1 * | 1 | 1 | 1 * |

| 9 | 1 | 0 | 0 | 1 * | 1 * | 0 | 1 * | 1 | 1 | 0 | 0 | 1 * | 1 * | 1 * | 1 * | 1 * | 1 | 1 | 1 * |

| 10 | 1 * | 0 | 0 | 0 | 1 * | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 1 * | 1 | 1 | 0 | 0 | 1 * |

| 11 | 1 * | 1 | 0 | 1 * | 1 * | 0 | 1 * | 0 | 1 * | 0 | 1 | 1 | 1 | 1 | 1 * | 1 * | 1 | 0 | 1 * |

| 12 | 1 | 0 | 0 | 0 | 1 * | 0 | 1 * | 0 | 1 * | 0 | 0 | 1 | 1 | 1 | 1 | 1 * | 0 | 0 | 1 * |

| 13 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 * | 0 | 0 | 0 |

| 14 | 0 | 0 | 0 | 0 | 1 * | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 * | 0 | 0 | 0 |

| 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 |

| 16 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 |

| 17 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 |

| 18 | 1 * | 0 | 0 | 0 | 1 * | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 * | 0 | 0 | 1 | 1 * |

| 19 | 1 | 1 * | 1 * | 1 * | 0 | 1 * | 1 | 1 * | 1 | 0 | 0 | 1 * | 1 * | 1 * | 1 * | 1 * | 1 * | 1 * | 1 |

| Issue | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| 1 | 1,6,7,8,9,13,16,17,18,19 | 1,2,3,4,6,7,8,9,10,11,12,18,19 | 1,6,7,8,9,18,19 | |

| 2 | 1,2,4,5,6,7,8,9,12,13,14,15,16,17,18,19 | 2,6,7,11,19 | 2,6,7,19 | |

| 3 | 1,3,4,5,7,8,9,12,13,14,15,16,17,18,19 | 3,6,7,19 | 3,7,19 | |

| 4 | 1,4,6,7,8,9,13,16,17,18,19 | 2,3,4,6,7,8,9,11,19 | 4,6,7,8,9,19 | |

| 5 | 5, 13,14,15,16 | 1,2,5,6,7,8,9,10,11,12,13,14,18 | 5,13,14 | |

| 6 | 1,2,3,4,5,6,8,9,12,13,14,15,17,18,19 | 1,2,4,6,7,19 | 1,2,4,6,19 | |

| 7 | 1,2,3,4,5,6,7,8,9,12,13,14,15,16,17,18 | 1,2,3,4,7,8,9,11,12,19 | 1,2,3,4,7,8,9,12 | |

| 8 | 1,4,5,7,8,9,12,13,14,15,16,17,18,19 | 1,2,3,4,6,7,8,9,19 | 1,4,7,8,9,19 | |

| 9 | 1,4,5,7,8,9,12,13,14,15,16,17,18,19 | 1,2,3,4,6,7,8,9,11,12,19 | 1,4,7,8,9,12,19 | |

| 10 | 1,5,10,12,13,14,15,16,19 | 10 | 10 | |

| 11 | 1,2,4,5,7,9,11,12,13,14,15,16,17,19 | 11 | 11 | |

| 12 | 1,5,7,9,12,13,14,15,16,19 | 2,3,6,7,8,9,10,11,12,18,19 | 7,9,12,19 | |

| 13 | 5,13,14,15,16 | 1,2,3,4,5,6,7,8,9,10,11,12,13,14,18,19 | 5,13,14 | |

| 14 | 5,13,14,15,16 | 2,3,5,6,7,8,9,10,11,12,13,14,18,19 | 5,13,14 | |

| 15 | 15,16 | 2,3,5,6,7,8,9,10,11,12,13,14,15,18,19 | 15 | |

| 16 | 16 | 1,2,3,4,5,7,8,9,10,11,12,13,14,15,16,19 | 16 | I |

| 17 | 17 | 1,2,3,4,6,7,8,9,11,17,19 | 17 | I |

| 18 | 1,5,12,13,14,15,18,19 | 1,2,3,4,6,7,8,9,18,19 | 1,18,19 | |

| 19 | 1,2,3,4,6,7,8,9,12,13,14,15,16,17,18,19 | 1,2,3,4,6,8,9,10,11,12,18,19 | 1,2,3,4,6,8,9,12,18,19 |

| Issue | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| 1 | 1,6,7,8,9,13,18,19 | 1,2,3,4,6,7,8,9,10,11,12,18,19 | 1,6,7,8,9,18,19 | |

| 2 | 1,2,4,5,6,7,8,9,12,13,14,15,18,19 | 2,6,7,11,19 | 2,6,7,19 | |

| 3 | 1,3,4,5,7,8,9,12,13,14,15,18,19 | 3,6,7,19 | 3,7,19 | |

| 4 | 1,4,6,7,8,9,13,18,19 | 2,3,4,6,7,8,9,11,19 | 4,6,7,8,9,19 | |

| 5 | 5, 13,14,15 | 1,2,5,6,7,8,9,10,11,12,13,14,18 | 5,13,14 | |

| 6 | 1,2,3,4,5,6,8,9,12,13,14,15,18,19 | 1,2,4,6,7,19 | 1,2,4,6,19 | |

| 7 | 1,2,3,4,5,6,7,8,9,12,13,14,15,18 | 1,2,3,4,7,8,9,11,12,19 | 1,2,3,4,7,8,9,12 | |

| 8 | 1,4,5,7,8,9,12,13,14,15,18,19 | 1,2,3,4,6,7,8,9,19 | 1,4,7,8,9,19 | |

| 9 | 1,4,5,7,8,9,12,13,14,15,18,19 | 1,2,3,4,6,7,8,9,11,12,19 | 1,4,7,8,9,12,19 | |

| 10 | 1,5,10,12,13,14,15,19 | 10 | 10 | |

| 11 | 1,2,4,5,7,9,11,12,13,14,15,19 | 11 | 11 | |

| 12 | 1,5,7,9,12,13,14,15,19 | 2,3,6,7,8,9,10,11,12,18,19 | 7,9,12,19 | |

| 13 | 5,13,14,15 | 1,2,3,4,5,6,7,8,9,10,11,12,13,14,18,19 | 5,13,14 | |

| 14 | 5,13,14,15 | 2,3,5,6,7,8,9,10,11,12,13,14,18,19 | 5,13,14 | |

| 15 | 15 | 2,3,5,6,7,8,9,10,11,12,13,14,15,18,19 | 15 | II |

| 18 | 1,5,12,13,14,15,18,19 | 1,2,3,4,6,7,8,9,18,19 | 1,18,19 | |

| 19 | 1,2,3,4,6,7,8,9,12,13,14,15,18,19 | 1,2,3,4,6,8,9,10,11,12,18,19 | 1,2,3,4,6,8,9,12,18,19 |

| Issue | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| 1 | 1,6,7,8,9,13,18,19 | 1,2,3,4,6,7,8,9,10,11,12,18,19 | 1,6,7,8,9,18,19 | |

| 2 | 1,2,4,5,6,7,8,9,12,13,14,18,19 | 2,6,7,11,19 | 2,6,7,19 | |

| 3 | 1,3,4,5,7,8,9,12,13,14,18,19 | 3,6,7,19 | 3,7,19 | |

| 4 | 1,4,6,7,8,9,13,18,19 | 2,3,4,6,7,8,9,11,19 | 4,6,7,8,9,19 | |

| 5 | 5, 13,14 | 1,2,5,6,7,8,9,10,11,12,13,14,18 | 5,13,14 | III |

| 6 | 1,2,3,4,5,6,8,9,12,13,14,18,19 | 1,2,4,6,7,19 | 1,2,4,6,19 | |

| 7 | 1,2,3,4,5,6,7,8,9,12,13,14,18 | 1,2,3,4,7,8,9,11,12,19 | 1,2,3,4,7,8,9,12 | |

| 8 | 1,4,5,7,8,9,12,13,14,18,19 | 1,2,3,4,6,7,8,9,19 | 1,4,7,8,9,19 | |

| 9 | 1,4,5,7,8,9,12,13,14,18,19 | 1,2,3,4,6,7,8,9,11,12,19 | 1,4,7,8,9,12,19 | |

| 10 | 1,5,10,12,13,14,19 | 10 | 10 | |

| 11 | 1,2,4,5,7,9,11,12,13,14,19 | 11 | 11 | |

| 12 | 1,5,7,9,12,13,14,19 | 2,3,6,7,8,9,10,11,12,18,19 | 7,9,12,19 | |

| 13 | 5,13,14 | 1,2,3,4,5,6,7,8,9,10,11,12,13,14,18,19 | 5,13,14 | III |

| 14 | 5,13,14 | 2,3,5,6,7,8,9,10,11,12,13,14,18,19 | 5,13,14 | III |

| 18 | 1,5,12,13,14,18,19 | 1,2,3,4,6,7,8,9,18,19 | 1,18,19 | |

| 19 | 1,2,3,4,6,7,8,9,12,13,14,18,19 | 1,2,3,4,6,8,9,10,11,12,18,19 | 1,2,3,4,6,8,9,12,18,19 |

| Issue | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| 1 | 1,6,7,8,9,18,19 | 1,2,3,4,6,7,8,9,10,11,12,18,19 | 1,6,7,8,9,18,19 | IV |

| 2 | 1,2,4,6,7,8,9,12,18,19 | 2,6,7,11,19 | 2,6,7,19 | |

| 3 | 1,3,4,7,8,9,12,18,19 | 3,6,7,19 | 3,7,19 | |

| 4 | 1,4,6,7,8,9,18,19 | 2,3,4,6,7,8,9,11,19 | 4,6,7,8,9,19 | |

| 6 | 1,2,3,4,6,8,9,12,18,19 | 1,2,4,6,7,19 | 1,2,4,6,19 | |

| 7 | 1,2,3,4,6,7,8,9,12,18 | 1,2,3,4,7,8,9,11,12,19 | 1,2,3,4,7,8,9,12 | |

| 8 | 1,4,7,8,9,12,18,19 | 1,2,3,4,6,7,8,9,19 | 1,4,7,8,9,19 | |

| 9 | 1,4,7,8,9,12,18,19 | 1,2,3,4,6,7,8,9,11,12,19 | 1,4,7,8,9,12,19 | |

| 10 | 1,10,12,19 | 10 | 10 | |

| 11 | 1,2,4,7,9,11,12,19 | 11 | 11 | |

| 12 | 1,7,9,12,19 | 2,3,6,7,8,9,10,11,12,18,19 | 7,9,12,19 | |

| 18 | 1,12,18,19 | 1,2,3,4,6,7,8,9,18,19 | 1,18,19 | |

| 19 | 1,2,3,4,6,7,8,9,12,18,19 | 1,2,3,4,6,8,9,10,11,12,18,19 | 1,2,3,4,6,8,9,12,18,19 |

| Issue | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| 2 | 2,4,6,7,8,9,12,18,19 | 2,6,7,11,19 | 2,6,7,19 | |

| 3 | 3,4,7,8,9,12,18,19 | 3,6,7,19 | 3,7,19 | |

| 4 | 4,6,7,8,9,18,19 | 2,3,4,6,7,8,9,11,19 | 4,6,7,8,9,19 | |

| 6 | 2,3,4,6,8,9,12,18,19 | 2,4,6,7,19 | 2,4,6,19 | |

| 7 | 2,3,4,6,7,8,9,12,18 | 2,3,4,7,8,9,11,12,19 | 2,3,4,7,8,9,12 | |

| 8 | 4,7,8,9,12,18,19 | 2,3,4,6,7,8,9,19 | 4,7,8,9,19 | |

| 9 | 4,7,8,9,12,18,19 | 2,3,4,6,7,8,9,11,12,19 | 4,7,8,9,12,19 | |

| 10 | 10,12,19 | 10 | 10 | |

| 11 | 2,4,7,9,11,12,19 | 11 | 11 | |

| 12 | 7,9,12,19 | 2,3,6,7,8,9,10,11,12,18,19 | 7,9,12,19 | V |

| 18 | 12,18,19 | 2,3,4,6,7,8,9,18,19 | 18,19 | |

| 19 | 2,3,4,6,7,8,9,12,18,19 | 2,3,4,6,8,9,10,11,12,18,19 | 2,3,4,6,8,9,12,18,19 |

| Issue | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| 2 | 2,4,6,7,8,9,18,19 | 2,6,7,11,19 | 2,6,7,19 | |

| 3 | 3,4,7,8,9,18,19 | 3,6,7,19 | 3,7,19 | |

| 4 | 4,6,7,8,9,18,19 | 2,3,4,6,7,8,9,11,19 | 4,6,7,8,9,19 | |

| 6 | 2,3,4,6,8,9,18,19 | 2,4,6,7,19 | 2,4,6,19 | |

| 7 | 2,3,4,6,7,8,9,18 | 2,3,4,7,8,9,11,19 | 2,3,4,7,8,9 | |

| 8 | 4,7,8,9,18,19 | 2,3,4,6,7,8,9,19 | 4,7,8,9,19 | |

| 9 | 4,7,8,9,18,19 | 2,3,4,6,7,8,9,11,19 | 4,7,8,9,19 | |

| 10 | 10,19 | 10 | 10 | |

| 11 | 2,4,7,9,11,19 | 11 | 11 | |

| 18 | 18,19 | 2,3,4,6,7,8,9,18,19 | 18,19 | VI |

| 19 | 2,3,4,6,7,8,9,18,19 | 2,3,4,6,8,9,10,11,18,19 | 2,3,4,6,8,9,18,19 |

| Issue | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| 2 | 2,4,6,7,8,9,19 | 2,6,7,11,19 | 2,6,7,19 | |

| 3 | 3,4,7,8,9,19 | 3,6,7,19 | 3,7,19 | |

| 4 | 4,6,7,8,9,19 | 2,3,4,6,7,8,9,11,19 | 4,6,7,8,9,19 | VII |

| 6 | 2,3,4,6,8,9,19 | 2,4,6,7,19 | 2,4,6,19 | |

| 7 | 2,3,4,6,7,8,9 | 2,3,4,7,8,9,11,19 | 2,3,4,7,8,9 | |

| 8 | 4,7,8,9,19 | 2,3,4,6,7,8,9,19 | 4,7,8,9,19 | VII |

| 9 | 4,7,8,9,19 | 2,3,4,6,7,8,9,11,19 | 4,7,8,9,19 | VII |

| 10 | 10,19 | 10 | 10 | |

| 11 | 2,4,7,9,11,19 | 11 | 11 | |

| 19 | 2,3,4,6,7,8,9,19 | 2,3,4,6,8,9,10,11,19 | 2,3,4,6,8,9,19 |

| Issue | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| 2 | 2,6,7,19 | 2,6,7,11,19 | 2,6,7,19 | VIII |

| 3 | 3,7,19 | 3,6,7,19 | 3,7,19 | VIII |

| 6 | 2,3,6,19 | 2,6,7,19 | 2,6,19 | |

| 7 | 2,3,6,7 | 2,3,7,11,19 | 2,3,7 | |

| 10 | 10,19 | 10 | 10 | |

| 11 | 2,7,11,19 | 11 | 11 | |

| 19 | 2,3,6,7,19 | 2,3,6,10,11,19 | 2,3,6,19 |

| Issue | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| 6 | 6,19 | 6,7,19 | 6,19 | IX |

| 7 | 6,7 | 7,11,19 | 7 | |

| 10 | 10,19 | 10 | 10 | |

| 11 | 7,11,19 | 11 | 11 | |

| 19 | 6,7,19 | 6,10,11,19 | 6,19 |

| Issue | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| 7 | 7 | 7,11,19 | 7 | X |

| 10 | 10,19 | 10 | 10 | |

| 11 | 7,11,19 | 11 | 11 | |

| 19 | 7,19 | 10,11,19 | 19 |

| Issue | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| 10 | 10,19 | 10 | 10 | |

| 11 | 11,19 | 11 | 11 | |

| 19 | 19 | 10,11,19 | 19 | XI |

| Issue | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| 10 | 10 | 10 | 10 | XII |

| 11 | 11 | 11 | 11 | XII |

| Issue | 16 | 17 | 15 | 5 | 13 | 14 | 1 | 12 | 18 | 4 | 8 | 9 | 2 | 3 | 6 | 7 | 19 | 10 | 11 | Driving Power |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| 17 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| 15 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 |

| 5 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 5 |

| 13 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 5 |

| 14 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 5 |

| 1 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 10 |

| 12 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 10 |

| 18 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 8 |

| 4 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 11 |

| 8 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 14 |

| 9 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 14 |

| 2 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 16 |

| 3 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 15 |

| 6 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 15 |

| 7 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 16 |

| 19 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 16 |

| 10 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 9 |

| 11 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 1 | 14 |

| Dependence Power | 16 | 11 | 15 | 13 | 16 | 14 | 13 | 11 | 10 | 9 | 9 | 11 | 5 | 4 | 6 | 10 | 12 | 1 | 1 |

| Rating | 5 | 4 | 3 | 2 | 1 |

|---|---|---|---|---|---|

| Issue | Most Important | Above Average | Average | Below Average | Least Important |

| 1 | 2 | 5 | 24 | 28 | 4 |

| 2 | 1 | 10 | 33 | 15 | 4 |

| 3 | 0 | 10 | 34 | 16 | 3 |

| 4 | 0 | 23 | 28 | 12 | 0 |

| 5 | 5 | 4 | 29 | 20 | 5 |

| 6 | 12 | 9 | 34 | 8 | 0 |

| 7 | 6 | 18 | 34 | 2 | 3 |

| 8 | 2 | 28 | 15 | 18 | 0 |

| 9 | 0 | 21 | 30 | 12 | 0 |

| 10 | 4 | 9 | 50 | 0 | 0 |

| 11 | 5 | 34 | 22 | 2 | 0 |

| 12 | 0 | 11 | 30 | 22 | 0 |

| 13 | 6 | 8 | 22 | 27 | 0 |

| 14 | 7 | 14 | 30 | 12 | 0 |

| 15 | 17 | 17 | 18 | 10 | 1 |

| 16 | 2 | 18 | 13 | 24 | 6 |

| 17 | 4 | 2 | 18 | 28 | 11 |

| 18 | 11 | 25 | 25 | 2 | 0 |

| 19 | 3 | 4 | 50 | 6 | 0 |

| Rating | 5 | 4 | 3 | 2 | 1 |

|---|---|---|---|---|---|

| Issue | Most Important | Above Average | Average | Below Average | Least Important |

| 1 | 0.1433 | 0.3442 | 4.4057 | 10.8659 | 1.0482 |

| 2 | 0.0358 | 1.3767 | 8.3295 | 3.1184 | 1.0482 |

| 3 | 0.0000 | 1.3767 | 8.8420 | 3.5480 | 0.5896 |

| 4 | 0.0000 | 7.2829 | 5.9966 | 1.9958 | 0.0000 |

| 5 | 0.8957 | 0.2203 | 6.4326 | 5.5438 | 1.6378 |

| 6 | 5.1593 | 1.1151 | 8.8420 | 0.8870 | 0.0000 |

| 7 | 1.2898 | 4.4606 | 8.8420 | 0.0554 | 0.5896 |

| 8 | 0.1433 | 10.7935 | 1.7210 | 4.4905 | 0.0000 |

| 9 | 0.0000 | 6.0714 | 6.8839 | 1.9958 | 0.0000 |

| 10 | 0.5733 | 1.1151 | 19.1219 | 0.0000 | 0.0000 |

| 11 | 0.8957 | 15.9150 | 3.7020 | 0.0554 | 0.0000 |

| 12 | 0.0000 | 1.6658 | 6.8839 | 6.7080 | 0.0000 |

| 13 | 1.2898 | 0.8811 | 3.7020 | 10.1036 | 0.0000 |

| 14 | 1.7556 | 2.6984 | 6.8839 | 1.9958 | 0.0000 |

| 15 | 10.3545 | 3.9787 | 2.4782 | 1.3860 | 0.0655 |

| 16 | 0.1433 | 4.4606 | 1.2926 | 7.9831 | 2.3584 |

| 17 | 0.5733 | 0.0551 | 2.4782 | 10.8659 | 7.9270 |

| 18 | 4.3353 | 8.6045 | 4.7805 | 0.0554 | 0.0000 |

| 19 | 0.3225 | 0.2203 | 19.1219 | 0.4989 | 0.0000 |

| Rating | Most Important | Above Average | Average | Below Average | Least Important |

|---|---|---|---|---|---|

| Instance of each importance | 87 | 270 | 539 | 264 | 37 |

| Total of each importance | 435 | 1080 | 1617 | 528 | 37 |

| Normalized weight of each importance | 0.1177 | 0.2921 | 0.4374 | 0.1428 | 0.0100 |

| Rating | 5 | 4 | 3 | 2 | 1 |

|---|---|---|---|---|---|

| Issue | Most Important | Above Average | Average | Below Average | Least Important |

| 1 | 0.0252 | 0.1360 | 1.3506 | 1.1561 | 0.0160 |

| 2 | 0.0063 | 0.5441 | 2.5576 | 0.3318 | 0.0160 |

| 3 | 0.0000 | 0.5441 | 2.7152 | 0.3775 | 0.0090 |

| 4 | 0.0000 | 2.8782 | 1.8400 | 0.2123 | 0.0000 |

| 5 | 0.1572 | 0.0871 | 1.9741 | 0.5899 | 0.0251 |

| 6 | 0.9055 | 0.4407 | 2.7152 | 0.0944 | 0.0000 |

| 7 | 0.2264 | 1.7628 | 2.7152 | 0.0059 | 0.0090 |

| 8 | 0.0252 | 4.2656 | 0.5248 | 0.4778 | 0.0000 |

| 9 | 0.0000 | 2.3994 | 2.1129 | 0.2123 | 0.0000 |

| 10 | 0.1006 | 0.4407 | 5.8773 | 0.0000 | 0.0000 |

| 11 | 0.1572 | 6.2896 | 1.1341 | 0.0059 | 0.0000 |

| 12 | 0.0000 | 0.6583 | 2.1129 | 0.7137 | 0.0000 |

| 13 | 0.2264 | 0.3482 | 1.1341 | 1.0750 | 0.0000 |

| 14 | 0.3081 | 1.0664 | 2.1129 | 0.2123 | 0.0000 |

| 15 | 1.8172 | 1.5724 | 0.7577 | 0.1475 | 0.0010 |

| 16 | 0.0252 | 1.7628 | 0.3930 | 0.8494 | 0.0361 |

| 17 | 0.1006 | 0.0218 | 0.7577 | 1.1561 | 0.1213 |

| 18 | 0.7608 | 3.4005 | 1.4659 | 0.0059 | 0.0000 |

| 19 | 0.0566 | 0.0871 | 5.8773 | 0.0531 | 0.0000 |

| max Wi1 | max Wi2 | max Wi3 | max Wi4 | max Wi5 | |

|---|---|---|---|---|---|

| S+ | 1.8172 | 6.2896 | 5.8819 | 1.1561 | 0.1213 |

| min Wi1 | min Wi2 | min Wi3 | min Wi4 | min Wi5 | |

|---|---|---|---|---|---|

| S− | 0.0000 | 0.0218 | 0.3976 | 0.0000 | 0.0000 |

| Issue | ||

|---|---|---|

| Initial cost of the MH equipment | 10.9437 | 1.7833 |

| Load carrying capacity | 10.4622 | 2.6358 |

| Programming flexibility of MH equipment | 10.3733 | 2.7948 |

| Operational cost | 9.5797 | 3.4227 |

| Throughput rate | 10.8597 | 2.0683 |

| Capacity to handle different shapes and volumes | 10.3192 | 2.8975 |

| Storage/Retrieval MH equipment | 9.7465 | 3.2452 |

| Operational control | 9.7077 | 4.3243 |

| Automation | 9.6648 | 3.2041 |

| Floor space | 9.6956 | 5.8947 |

| AGVs/Robots and other advanced MH equipment already present | 9.0706 | 6.3930 |

| Number of AGVs required | 10.4161 | 2.3253 |

| Layout of AGV tracks | 10.8966 | 1.6169 |

| Vehicle dispatching rules | 10.3076 | 2.3961 |

| Traffic management | 10.4425 | 2.5240 |

| Positioning of idle vehicles | 10.6712 | 1.9964 |

| Failure management | 11.3093 | 1.3914 |

| Compatibility of MH equipment with other workstations | 9.4341 | 3.7804 |

| Comparison with cheap human labour | 9.9357 | 5.8785 |

| Issue | Ri |

|---|---|

| Initial cost of the MH equipment | 0.1401 |

| Load carrying capacity | 0.2012 |

| Programming flexibility of MH equipment | 0.2122 |

| Operational cost | 0.2632 |

| Throughput rate | 0.1600 |

| Capacity to handle different shapes and volumes | 0.2192 |

| Storage/Retrieval MH equipment | 0.2498 |

| Operational control | 0.3082 |

| Automation | 0.2490 |

| Floor space | 0.3781 |

| AGVs/Robots and other advanced MH equipment already present | 0.4134 |

| Number of AGVs required | 0.1825 |

| Layout of AGV tracks | 0.1292 |

| Vehicle dispatching rules | 0.1886 |

| Traffic management | 0.1947 |

| Positioning of idle vehicles | 0.1576 |

| Failure management | 0.1096 |

| Compatibility of MH equipment with other workstations | 0.2861 |

| Comparison with cheap human labour | 0.3717 |

| Issue | Ri |

|---|---|

| AGVs/Robots and other advanced MH equipment already present | 0.4134 |

| Floor space | 0.3781 |

| Comparison with cheap human labour | 0.3717 |

| Operational control | 0.3082 |

| Compatibility of MH equipment with other workstations | 0.2861 |

| Operational cost | 0.2632 |

| Storage/Retrieval MH equipment | 0.2498 |

| Automation | 0.2490 |

| Capacity to handle different shapes and volumes | 0.2192 |

| Programming flexibility of MH equipment | 0.2122 |

| Load carrying capacity | 0.2012 |

| Traffic management | 0.1947 |

| Vehicle dispatching rules | 0.1886 |

| Number of AGVs required | 0.1825 |

| Throughput rate | 0.1600 |

| Positioning of idle vehicles | 0.1576 |

| Initial cost of the MH equipment | 0.1401 |

| Layout of AGV tracks | 0.1292 |

| Failure management | 0.1096 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dixit, S.; Raj, T. A Hybrid MADM Approach for the Evaluation of Different Material Handling Issues in Flexible Manufacturing Systems. Adm. Sci. 2018, 8, 69. https://doi.org/10.3390/admsci8040069

Dixit S, Raj T. A Hybrid MADM Approach for the Evaluation of Different Material Handling Issues in Flexible Manufacturing Systems. Administrative Sciences. 2018; 8(4):69. https://doi.org/10.3390/admsci8040069

Chicago/Turabian StyleDixit, Sandhya, and Tilak Raj. 2018. "A Hybrid MADM Approach for the Evaluation of Different Material Handling Issues in Flexible Manufacturing Systems" Administrative Sciences 8, no. 4: 69. https://doi.org/10.3390/admsci8040069