Numerical Analysis of Bicycle Helmet under Blunt Behavior

Abstract

:1. Introduction

2. Materials and Methods

2.1. Introduction to the Development of Numerical Model

2.1.1. Helmet Model

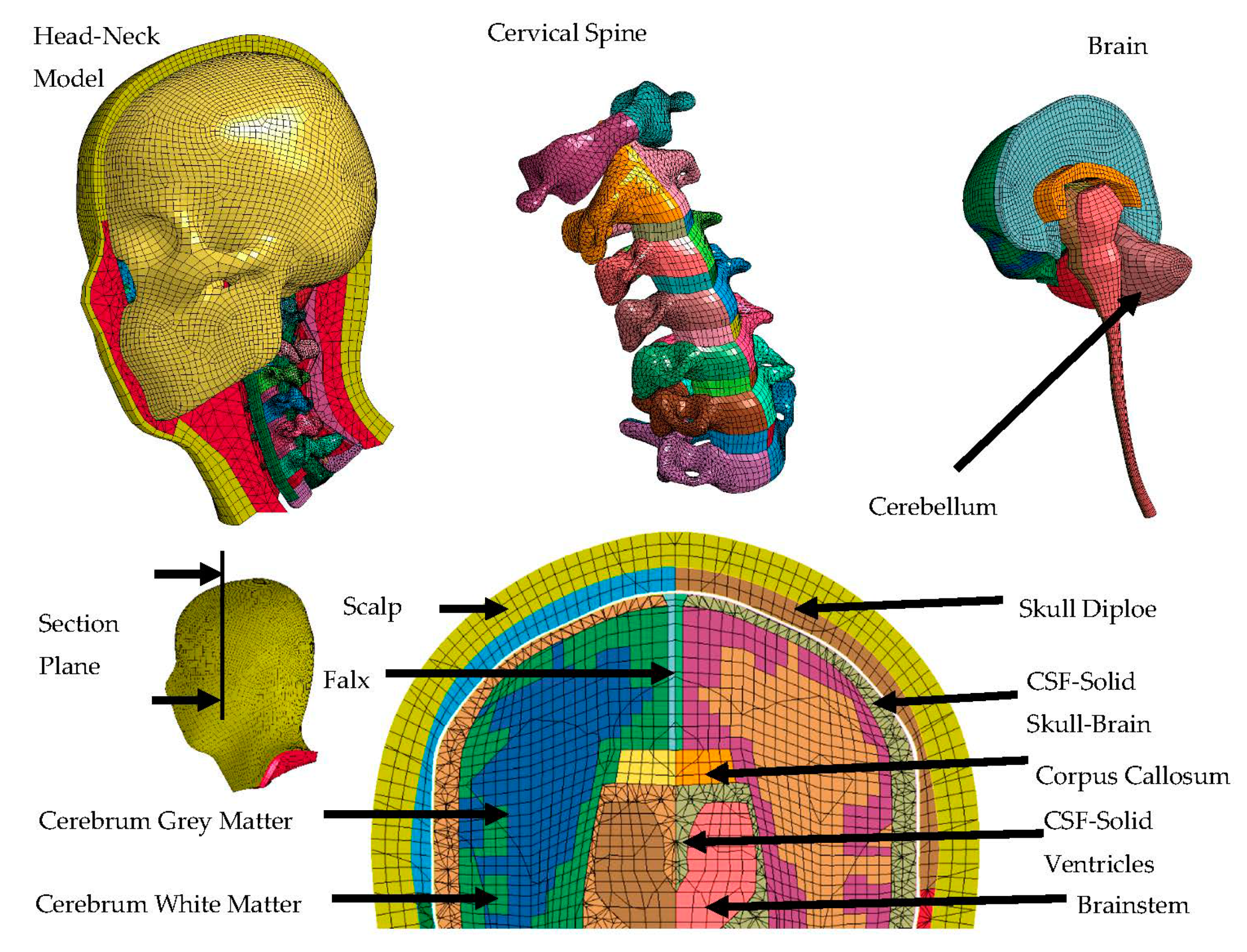

2.1.2. Human Head Model

2.1.3. Boundary Conditions

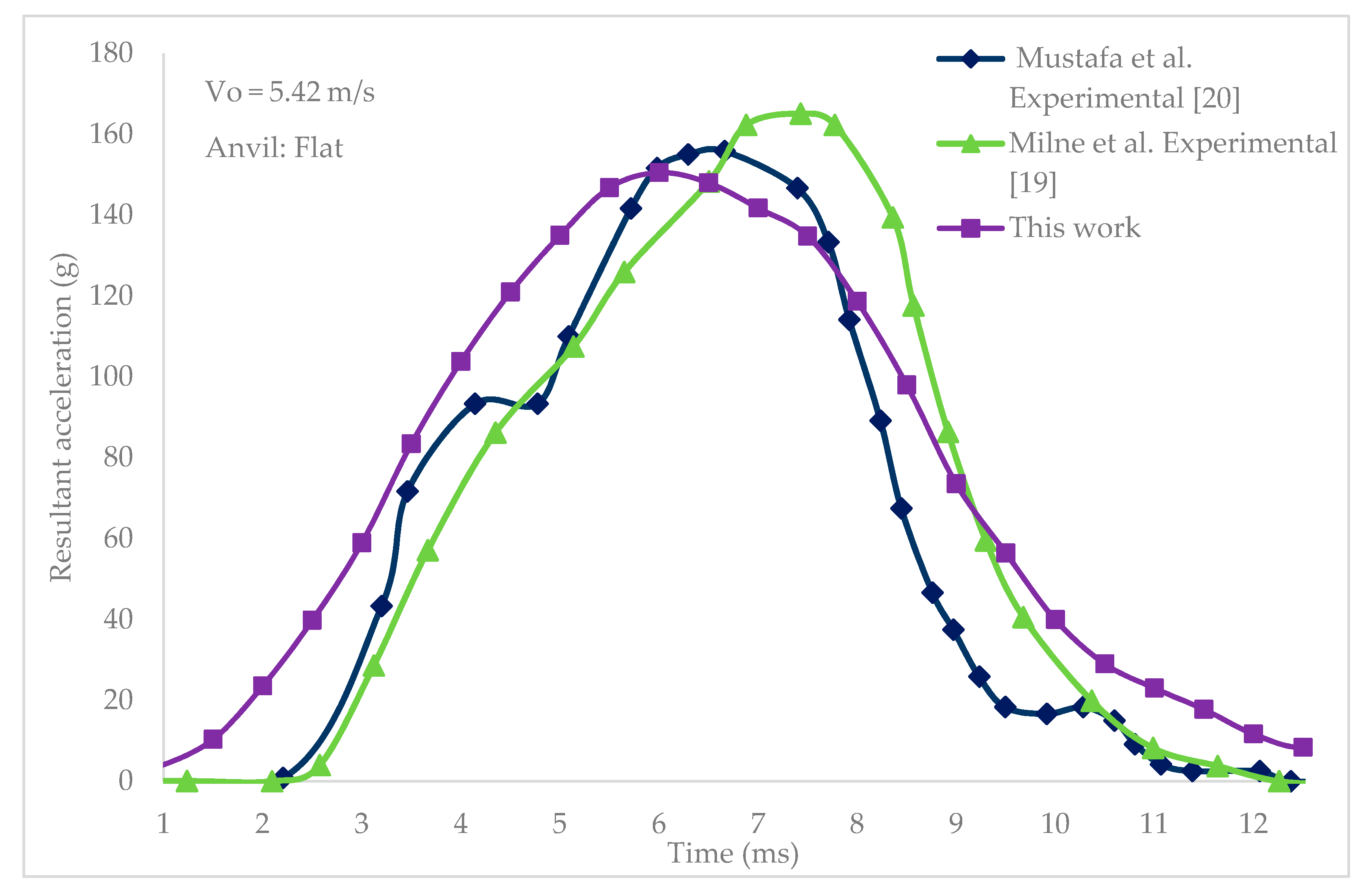

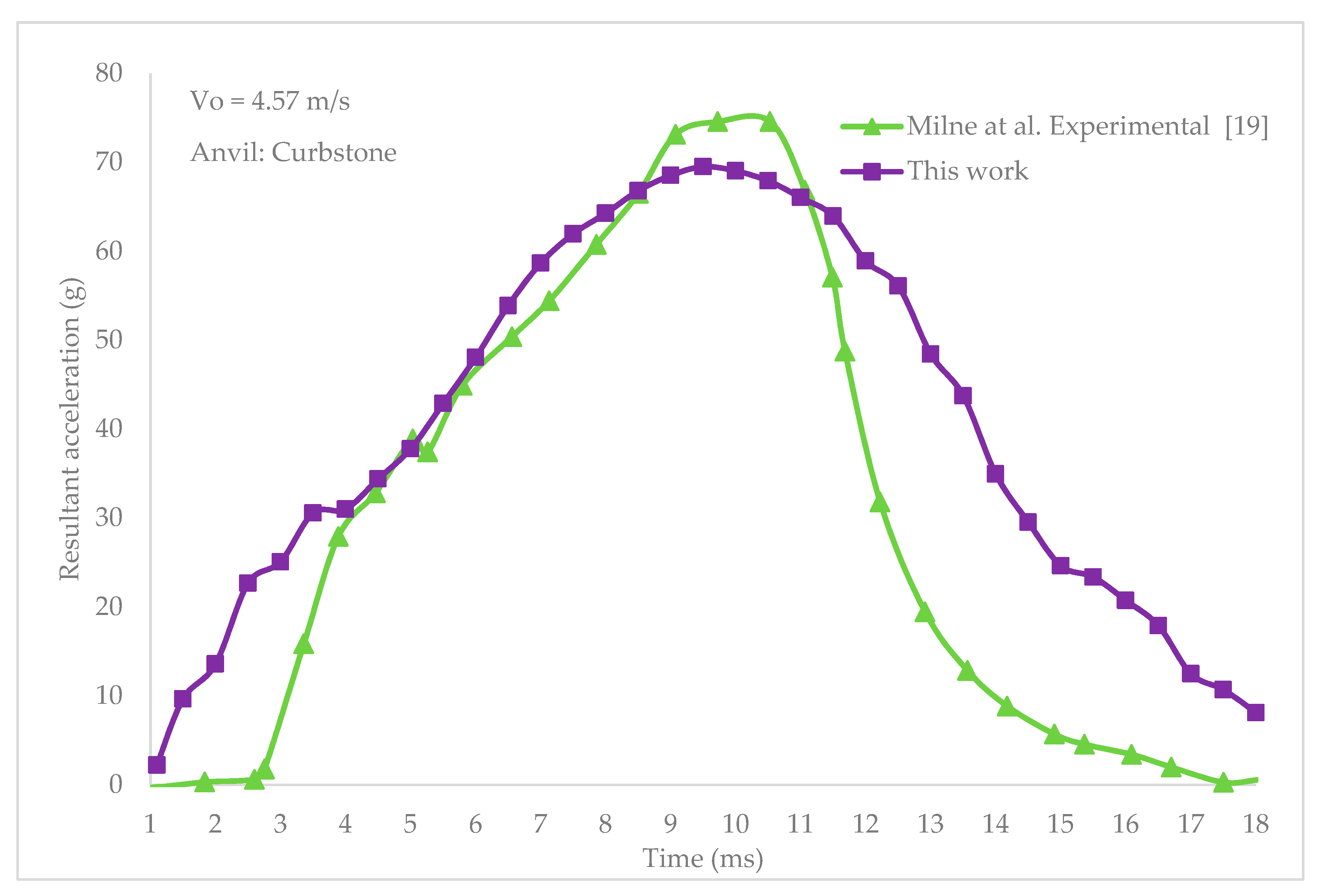

2.2. Head Acceleration Response Validation in Standardized Impacts

2.3. Injury Predictors

2.3.1. Peak Linear Acceleration (PLA)

2.3.2. Gadd Severity Index (GSI)

2.3.3. Generalized Acceleration Model for Brain Injury Threshold (GAMBIT)

2.3.4. Head Injury Criterion (HIC15)

2.3.5. Energy Absorbed by the Helmet during Impact

2.3.6. Parametric Study for the Development of an Injury Risk Curve

3. Results

3.1. Head Acceleration Response Validation in Standardized Impacts Results

3.1.1. EN 1078 Flat Anvil Validation

3.1.2. EN 1078 Curbstone Anvil Validation

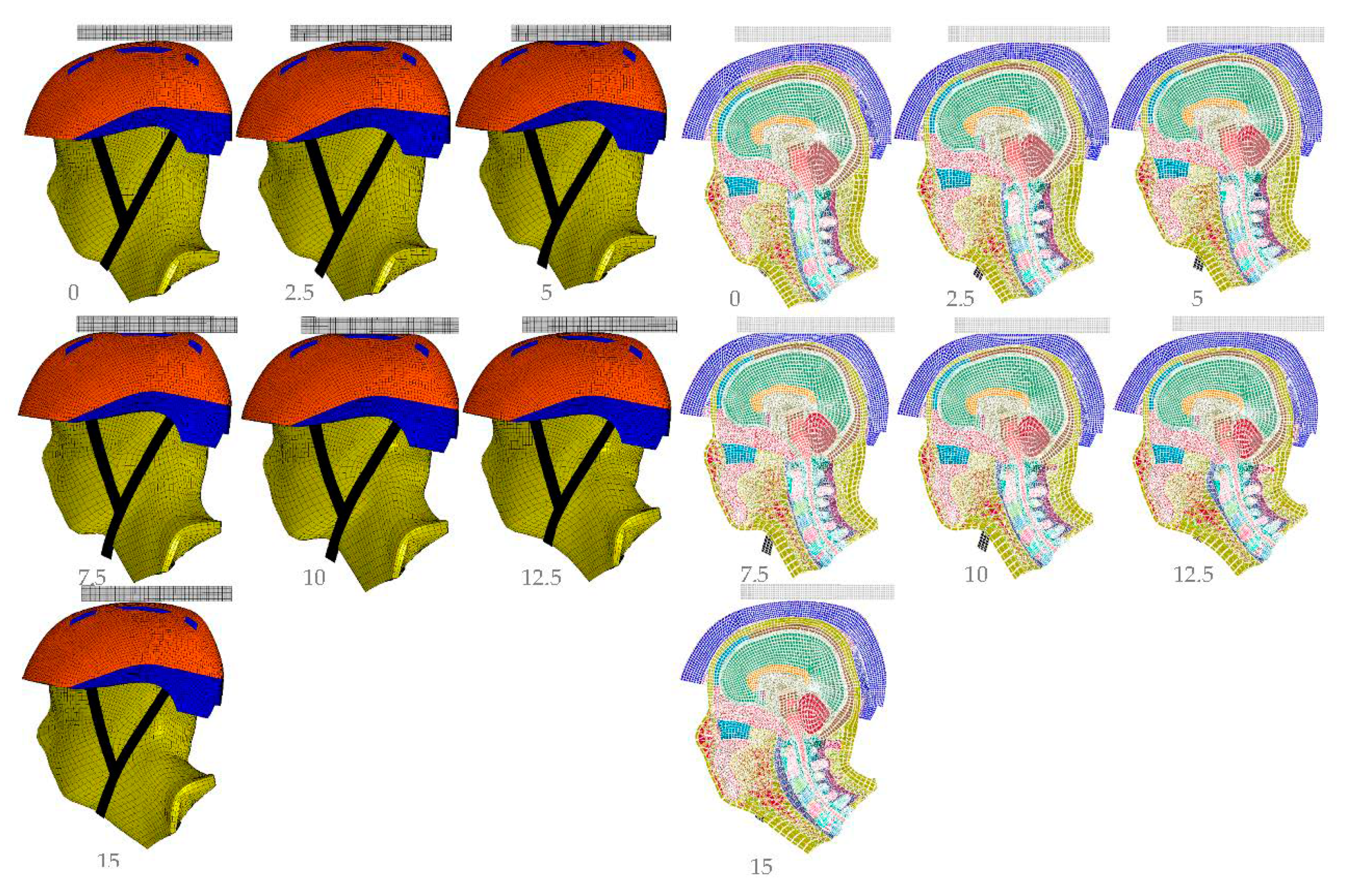

3.1.3. Helmet–Head Numerical Simulation Validation

3.2. Injury Predictors Results

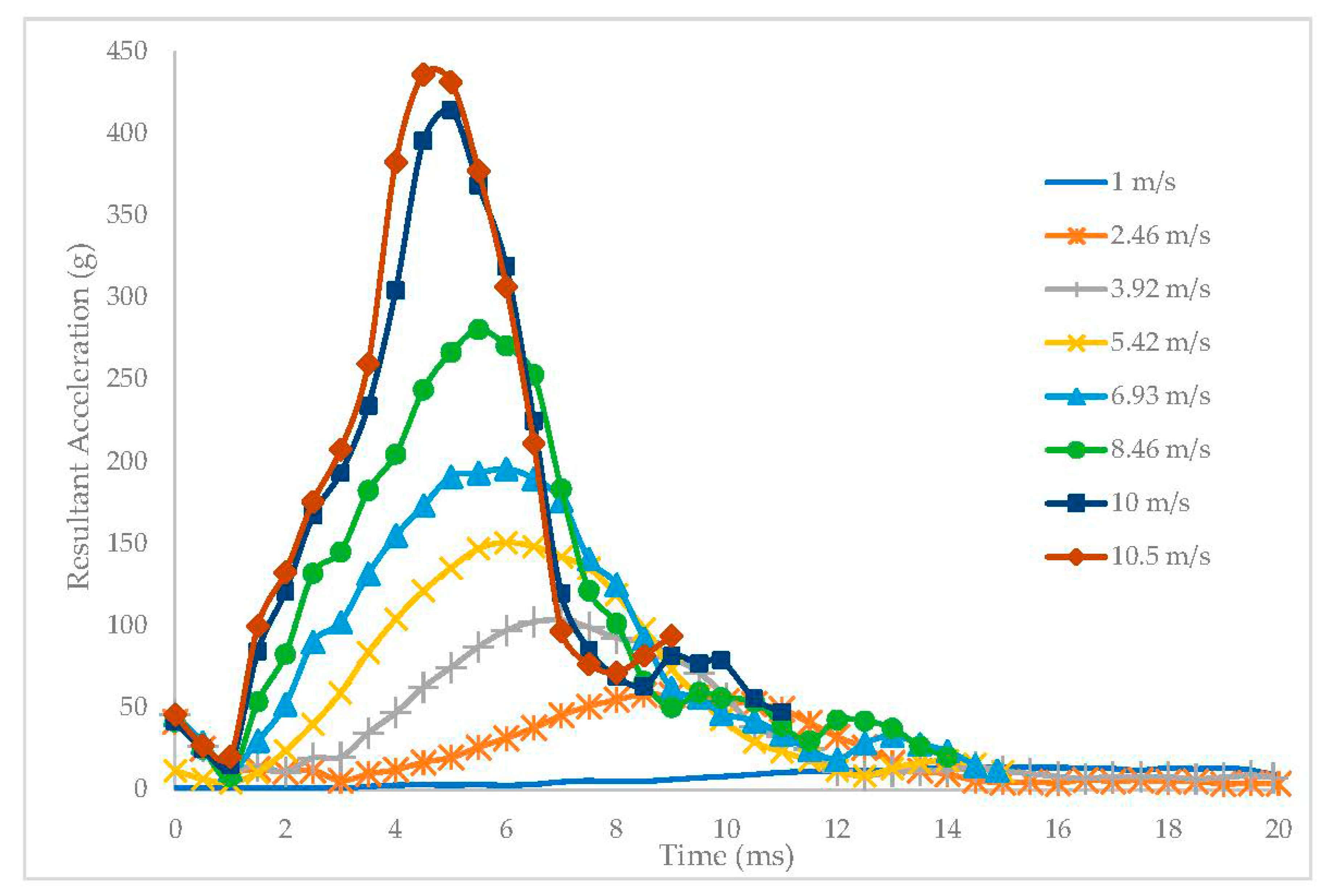

3.2.1. Peak Linear Acceleration (PLA)

3.2.2. Gadd Severity Index (GSI)

3.2.3. Generalized Acceleration Model for Brain Injury Threshold (GAMBIT)

3.2.4. Head Injury Criterion (HIC15)

3.3. Influence of Velocity in Cyclist Safety

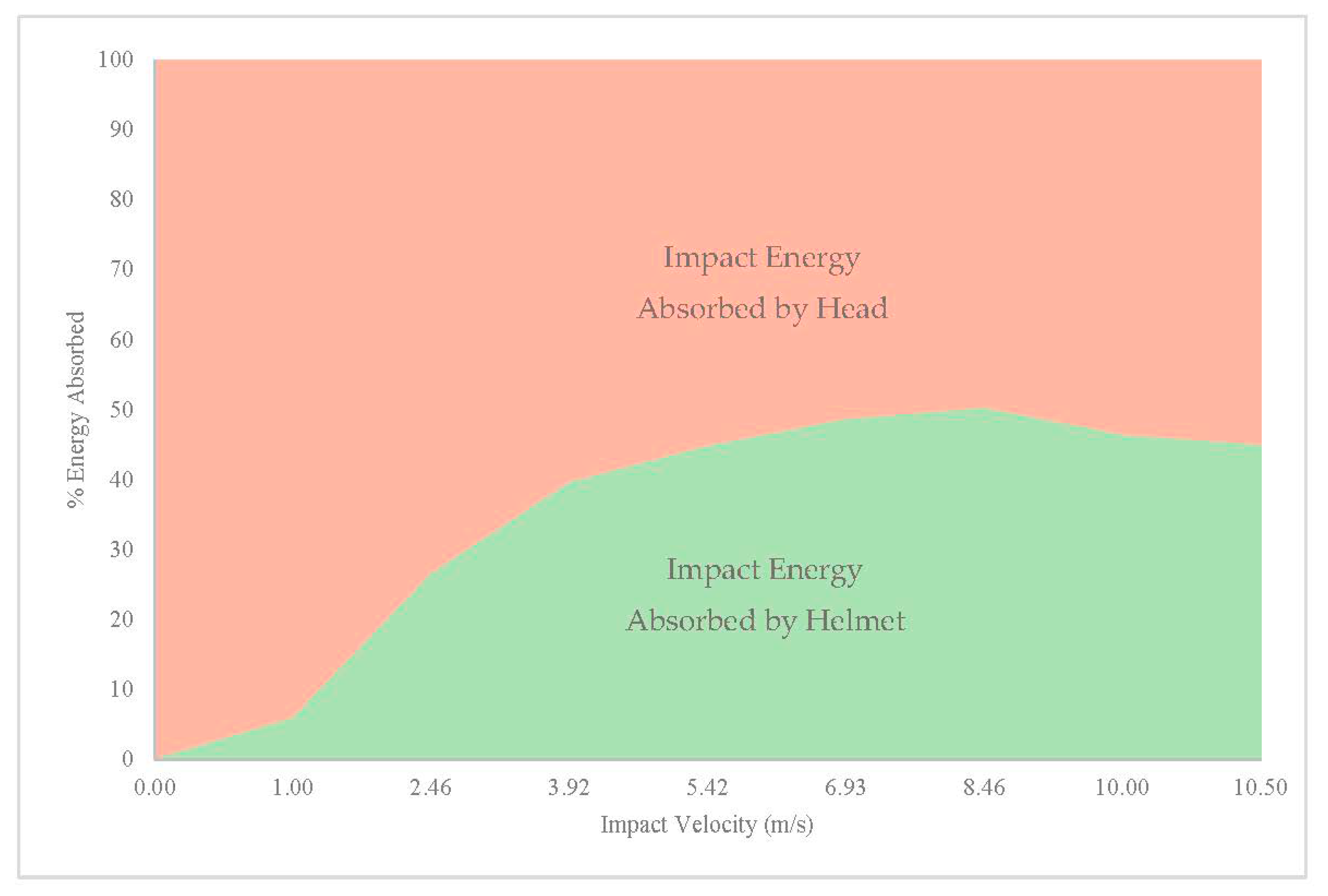

3.3.1. Energy Absorbed by the Helmet during Impacts

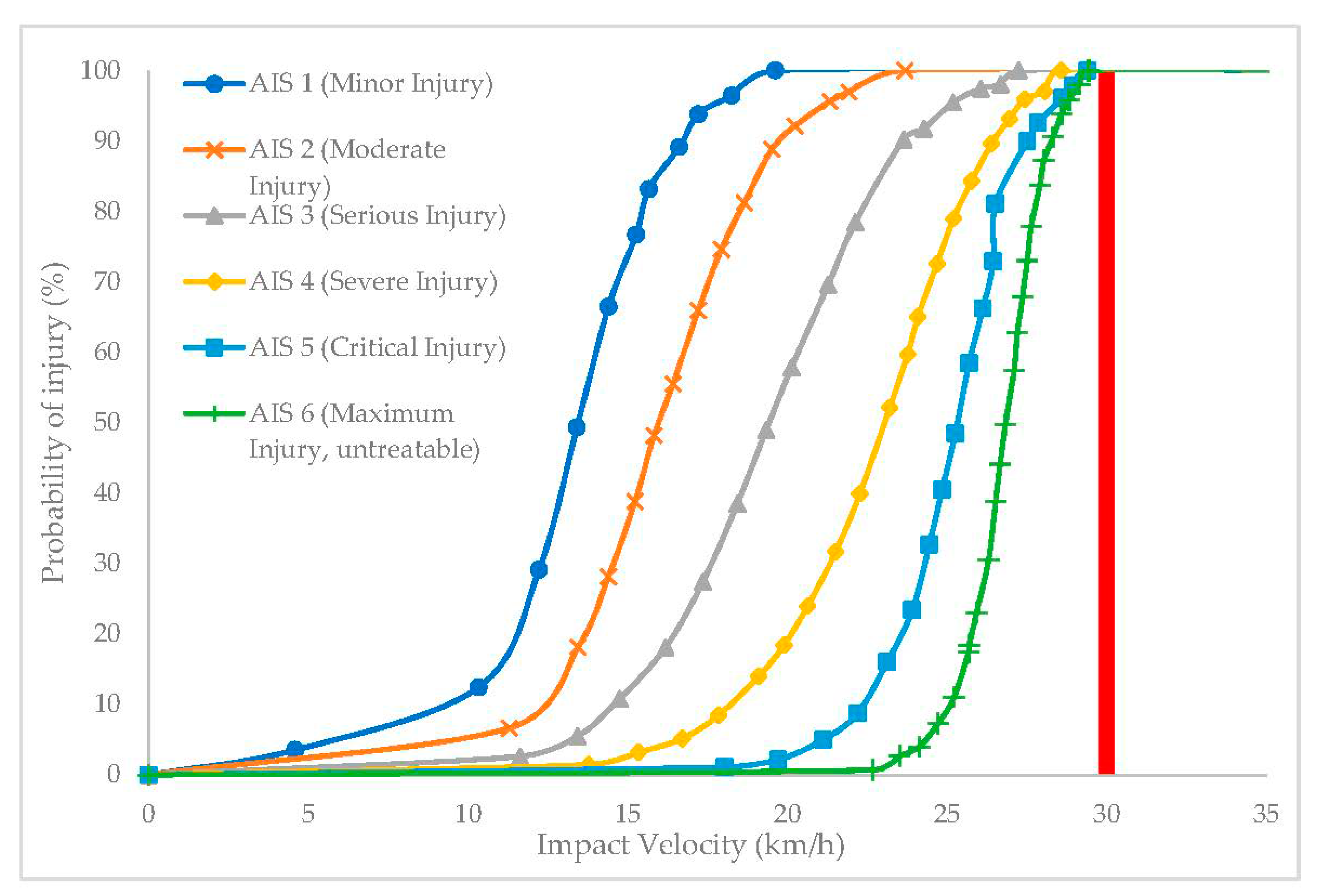

3.3.2. Result of a Parametric Study for the Development of an Injury Risk Curve

4. Discussion

4.1. Effectiveness of Current Standards to Prevent Head Injuries

4.2. Should a Bicycle Helmet Be Worn?

4.3. Relationship between Impact Velocity and Head Injury Probability

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Commision, E. Traffic Safety Basic Facts-Main Figures Cyclists Traffic Safety Basic Facts 2018; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Highway Traffic Safety Administration, N.; Department of Transportation, U. 2016 Data: Bicyclists and Other Cyclists; National Highway Traffic Safety Administration: Washington, DC, USA, 2016.

- Foundation, S.L. Road Statistics Involving Bicycle Users in India; Save Life Foundation: New Delhi, India, 2017. [Google Scholar]

- Olofsson, E.; Bunketorp, O.; Andersson, A.L. Helmet use and injuries in children’s bicycle crashes in the Gothenburg region. Saf. Sci. 2017, 92, 311–317. [Google Scholar] [CrossRef]

- Macpherson, A.; Spinks, A. Cochrane review: Bicycle helmet legislation for the uptake of helmet use and prevention of head injuries. Evid. Based Child Health Cochrane Rev. J. 2008, 3, 16–32. [Google Scholar] [CrossRef]

- Olivier, J.; Creighton, P. Bicycle injuries and helmet use: A systematic review and meta-analysis. Int. J. Epidemiol. 2017, 46, 278–292. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bíl, M.; Dobiáš, M.; Andrášik, R.; Bílová, M.; Hejna, P. Cycling fatalities: When a helmet is useless and when it might save your life. Saf. Sci. 2018, 105, 71–76. [Google Scholar] [CrossRef]

- Ohlin, M.; Strandroth, J.; Tingvall, C. The combined effect of vehicle frontal design, speed reduction, autonomous emergency braking and helmet use in reducing real life bicycle injuries. Saf. Sci. 2017, 92, 338–344. [Google Scholar] [CrossRef]

- Ramage-Morin, P.L. Health Reports Cycling in Canada; Statistics Canada: Ottawa, ON, Canada, 2017.

- Popa, I.; Ferraro, O.E.; Orsi, C.; Morandi, A.; Montomoli, C. Bicycle helmet use patterns in Italy. A description and analysis of survey data from an Italian friends of cycling association. Accid. Anal. Prev. 2017, 108, 268–274. [Google Scholar] [CrossRef]

- Elvik, R. Publication bias and time-trend bias in meta-analysis of bicycle helmet efficacy: A re-analysis of Attewell, Glase and McFadden, 2001. Accid. Anal. Prev. 2011, 43, 1245–1251. [Google Scholar] [CrossRef]

- Swami, H.M.; Puri, S.; Bhatia, V. Road Safety Awareness and Practices among School Children of Chandigarh. Indian J. Commun. Med. 2006, 31, 199. [Google Scholar]

- Schramm, A.; Rakotonirainy, A.; Haworth, N. The role of traffic violations in police-reported bicycle crashes in Queensland. J. Australas. Coll. Road Saf. 2010, 21, 61–67. [Google Scholar]

- Towner, E.; Dowswell, T.; Burkes, M.; Dickinson, H.; Towner, J.; Hayes, M. Bicycle Helmets-A Review of Their Effectiveness: A Critical Review of the Literature; Department for Transport: London, UK, 2002.

- BSEN 1078. Helmets for Pedal Cyclists and for Users of Skateboards and Roller Skates; BSI: London, UK, 1997. [Google Scholar]

- Mills, N.J.; Gilchrist, A. Finite-element analysis of bicycle helmet oblique impacts. Int. J. Impact Eng. 2008, 35, 1087–1101. [Google Scholar] [CrossRef]

- Der Perre, V.G. A Transient finite element study reveals the importance of the bycicle helmet material properties on head protection during an impact. In Proceedings of the IRCOBI Conference, York, UK, 9–11 September 2009. [Google Scholar]

- Teng, T.L.; Liang, C.L.; Nguyen, V.H. Development and validation of finite element model of helmet impact test. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2013, 227, 82–88. [Google Scholar] [CrossRef]

- Milne, G.; Deck, C.; Bourdet, N.; Carreira, R.P.; Allinne, Q.; Gallego, A.; Willinger, R. Bicycle helmet modelling and validation under linear and tangential impacts. Int. J. Crashworthiness 2014, 19, 323–333. [Google Scholar] [CrossRef]

- Mustafa, H.; Pang, T.Y.; Perret-Ellena, T.; Subic, A. Finite Element Bicycle Helmet Models Development. Procedia Technol. 2015, 20, 91–97. [Google Scholar] [CrossRef] [Green Version]

- Fahlstedt, M.; Halldin, P.; Kleiven, S. The protective effect of a helmet in three bicycle accidents—A finite element study. Accid. Anal. Prev. 2016, 91, 135–143. [Google Scholar] [CrossRef] [PubMed]

- Sandberg, M.; Tse, K.M.; Tan, L.B.; Lee, H.P. A computational study of the EN 1078 impact test for bicycle helmets using a realistic subject-specific finite element head model. Comput. Methods Biomech. Biomed. Eng. 2018, 21, 684–692. [Google Scholar] [CrossRef] [Green Version]

- Peng, Y.; Deck, C.; Yang, J.; Otte, D.; Willinger, R. A Study of Adult Pedestrian Head Impact Conditions and Injury Risks in Passenger Car Collisions Based on Real-World Accident Data. Traffic Inj. Prev. 2013, 14, 639–646. [Google Scholar] [CrossRef]

- McIntosh, A.S.; Patton, D.A.; Fréchède, B.; Pierré, P.-A.; Ferry, E.; Barthels, T. The biomechanics of concussion in unhelmeted football players in Australia: A case–control study. BMJ Open 2014, 4, e005078. [Google Scholar] [CrossRef] [Green Version]

- Newman, J.; Barr, C.; Beusenberg, M.; Fournier, E.; Shewchenko, N.; Welbourne, E.; Withnall, C. A new biomechanical assessment of mild traumatic brain injury. Part 2: Results and conclusions. IRCOBI (Int. Res. Counc. Biokinetics Impacts) 2000, 2000, 223–233. [Google Scholar]

- Gadd, C.W. Criteria for injury potential. In Proceedings of the Impact Acceleration Stress: A Symposium; The National Academies Press: Washington, DC, USA, 1961. [Google Scholar]

- Nokes, L.D.M.; Roberts, A.M.; Knight, B.H. Use of the Gadd severity index in forensic medicine: A case study. Forensic Sci. Int. 1995, 76, 85–90. [Google Scholar] [CrossRef]

- A Generalized Acceleration Model for Brain Injury Threshold (GAMBIT). Available online: http://www.ircobi.org/wordpress/downloads/irc1986/pdf_files/1986_9.pdf (accessed on 3 April 2020).

- Hutchinson, J.; Kaiser, M.J.; Lankarani, H.M. The Head Injury Criterion (HIC) functional. Appl. Math. Comput. 1998, 96, 1–16. [Google Scholar] [CrossRef]

- Kimpara, H.; Iwamoto, M. Mild Traumatic Brain Injury Predictors Based on Angular Accelerations During Impacts. Ann. Biomed. Eng. 2012, 40, 114–126. [Google Scholar] [CrossRef] [PubMed]

- Antona-Makoshi, J. Traumatic Brain Injuries: Animal Experiments and Numerical Simulations to Support the Development of a Brain Injury Criterion; Chalmers Tekniska Högskola. Division of Vehicle Safety: Gothenburg, Sweden, 2016; ISBN 9789162898489. [Google Scholar]

- Van den Bosch, H.L.A. Crash helmet testing and design specifications. Eindh. Tech. Univ. Eindh. 2006. [Google Scholar] [CrossRef]

- Brands, D.W.A.; Thunnissen, J.G.M.; Wismans, J.S.H.M. Modelling head injury countermeasures: A 3D helmet model. In Proceedings of the AGARD Conference Proceedings; AGARD: Neuilly sur Seine, France, 1997; pp. 26.1–26.8. [Google Scholar]

- Hardy, W.N.; Foster, C.D.; Mason, M.J.; Yang, K.H.; King, A.I.; Tashman, S. Investigation of Head Injury Mechanisms Using Neutral Density Technology and High-Speed Biplanar X-ray; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2001; Volume 45, pp. 337–368. [Google Scholar]

- Hardy, W.N.; Mason, M.J.; Foster, C.D.; Shah, C.S.; Kopacz, J.M.; Yang, K.H.; King, A.I.; Bishop, J.; Bey, M.; Anderst, W.; et al. A study of the response of the human cadaver head to impact. Stapp Car Crash J. 2007, 51, 17–80. [Google Scholar]

- Snyder, R.G. Occupant Impact Injury Tolerances for Aircraft Crashworthiness Design; SAE Technical Papers; SAE International: Warrendale, PA, USA, 1971. [Google Scholar]

- McElhaney, J.H.; Roberts, V.L.; Hilyard, J.F. Handbook of Human Tolerance (1976 edition); Japan Automobile Research Institute: Tsukuba, Japan, 1976. [Google Scholar]

- Melvin, J.W.; Yoganandan, N. Biomechanics of Brain Injury: A Historical Perspective; Springer: New York, NY, USA, 2015; ISBN 9781493917327. [Google Scholar]

- Jin, X.; Yang, K.H.; King, A.I. Mechanical properties of bovine pia-arachnoid complex in shear. J. Biomech. 2011, 44, 467–474. [Google Scholar] [CrossRef] [PubMed]

- Arbogast, K.B.; Margulies, S.S. Material characterization of the brainstem from oscillatory shear tests. J. Biomech. 1998, 31, 801–807. [Google Scholar] [CrossRef]

- Brolin, K.; Halldin, P. Development of a Finite Element Model of the Upper Cervical Spine and a Parameter Study of Ligament Characteristics. Spine 2004, 29, 376–385. [Google Scholar] [CrossRef]

- Yoganandan, N.; Kumaresan, S.; Pintar, F.A. Geometric and mechanical properties of human cervical spine ligaments. J. Biomech. Eng. 2000, 122, 623–629. [Google Scholar] [CrossRef]

- Antona-Makoshi, J.; Davidsson, J.; Ejima, S.; Ono, K.; Brolin, K.; Anata, K. Correlation of Global Head and Brain Tissue Injury Criteria to Experimental Concussion derived from Monkey Head Trauma Experiments. In Proceedings of the IRCOBI 2013 Conference, Gothenburg, Sweden, 11–13 September 2013; Volume IRC-13-55, pp. 509–522. [Google Scholar]

- Hayes, W.C.; Erickson, M.S.; Power, E.D. Forensic Injury Biomechanics. Annu. Rev. Biomed. Eng. 2007, 9, 55–86. [Google Scholar] [CrossRef]

| Europe | United States | Australia New Zealand | China | |

|---|---|---|---|---|

| Flat Anvil | Velocity: 5.42 m/s | Velocity: 6.2 m/s | Height: 1.5 m | Velocity: 6.2 m/s |

| Max acc: 250 g | Max acc: 300 g | Max acc: 250 g | Max acc: 300 g | |

| Curved Anvil | Velocity: 4.57 m/s | Velocity: 4.8 m/s | Not | Velocity: 4.8 m/s |

| Max acc: 250 g | Max acc: 300 g | Tested | Max acc: 300 g |

| Flat Anvil J/(100 kgm/s2) | Curbstone Anvil J/(100 kgm/s2) | |

|---|---|---|

| Europe | 5.88 | 4.17 |

| America | 6.40 | 3.84 |

| Australia/New Zealand | 5.88 | Not Tested |

| China | 6.40 | 3.84 |

| Material Model in Ls-Dyna | Material Properties | Source | |

|---|---|---|---|

| EPS Foam (86.8 kg/m3) | mat_low_density_foam_57 | ϱ = 86 kg/m3 E = 22.4 MPa | [18,32] |

| Straps (PET) | mat_piece wise_linear_plasticit y_24 | ϱ = 1400 kg/m3 ʋ = 0.44 E = 1000 MPa | [18,32] |

| Shell (Fiberglass & Polyester Resin) | mat_piecewise_linear_plasticity_24 | ϱ = 2080 kg/m3 ʋ = 0.325 E = 8.54 GPa | [32,33] |

| Anvil (Steel) | mat_rigid_20 | ϱ = 7800 kg/m3 ʋ = 0.3 E = 200 GPa | [19] |

| Padding (PU Foam) | mat_low_density_foam_57 | ϱ = 32 kg/m3 E = 0.47 MPa | [18,32] |

| Material Model | Material Properties | Source | |

|---|---|---|---|

| Scalp & Neck Flesh | Fu Chang Foam | Stress–Strain curves at 3 Strain rates | Human cadaver Scalp in Compression, McElhaney [37] |

| Skull Tables | Piece-Wise Linear Plasticity | E = 6.48 GPa | Human Skull Tables in Shear, McElhaney [37] |

| Skull Diploe | Isotropic Elastic Plastic | E = 40 MPa | McElhaney [37] |

| Dura Mater | Elastic | E = 40 MPa | Human Dura in Tension Melvin [38] |

| Pia Mater | Elastic | E = 12.5 MPa | Bovine Pia-Arachnoid in Shear [39] |

| Cerebrospinal Fluid (CSF) | Elastic Fluid | K = 2.1 GPa υ = 0.4999 | McElhaney [37] |

| Brain | Brain Linear Viscoelastic | G0 = 1.6 kPa G1 = 0.9 kPa | Porcine Brain Tissue in Shear Arbogast & Margulies [40] |

| Falx & Tentorium | Elastic | E = 12.5 MPa | Jin et al. [39] |

| Vertebrae | Rigid | - | - |

| Intervertebral Discs & Facet Joints | Elastic | E = 10 MPa | Brolin et al. [41] |

| Neck Ligaments | Elastic | E = 43.8 MPa | Yoganandan [42] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sepulveda-Lopez, D.; Antona-Makoshi, J.; Rubio, I.; Rodríguez-Millán, M. Numerical Analysis of Bicycle Helmet under Blunt Behavior. Appl. Sci. 2020, 10, 3692. https://doi.org/10.3390/app10113692

Sepulveda-Lopez D, Antona-Makoshi J, Rubio I, Rodríguez-Millán M. Numerical Analysis of Bicycle Helmet under Blunt Behavior. Applied Sciences. 2020; 10(11):3692. https://doi.org/10.3390/app10113692

Chicago/Turabian StyleSepulveda-Lopez, David, Jacobo Antona-Makoshi, Ignacio Rubio, and Marcos Rodríguez-Millán. 2020. "Numerical Analysis of Bicycle Helmet under Blunt Behavior" Applied Sciences 10, no. 11: 3692. https://doi.org/10.3390/app10113692