Technical and Economic Feasibility of a Stable Yellow Natural Colorant Production from Waste Lemon Peel

Abstract

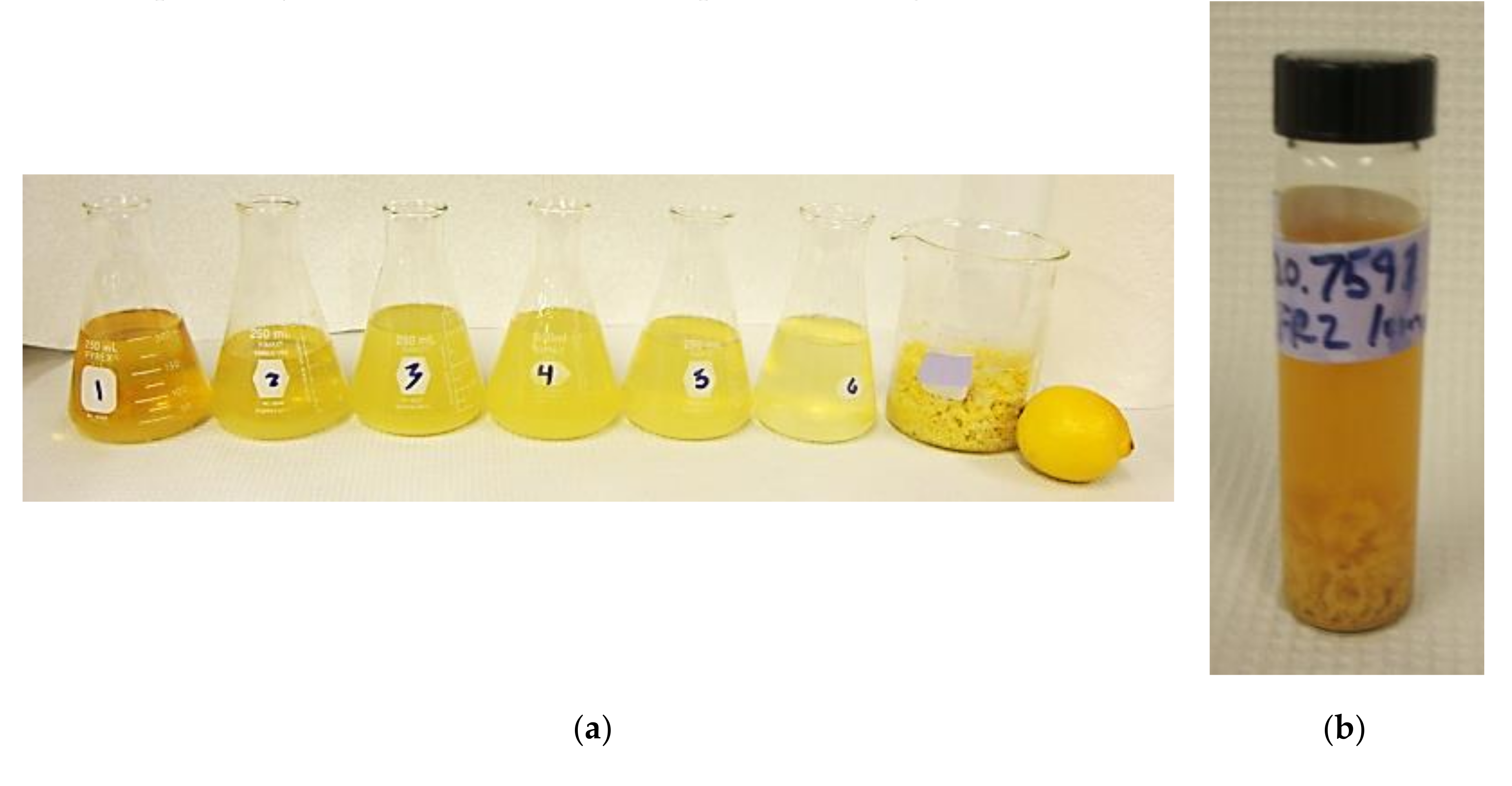

:1. Introduction

2. Technical and Economic Aspects

3. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- McCann, D.; Barrett, A.; Cooper, A.; Crumpler, D.; Dalen, L.; Grimshaw, K.; Kitchin, E.; Lok, K.; Porteous, L.; Prince, E.; et al. Food additives and hyperactive behaviour in 3-year-old and 8/9-year-old children in the community: A randomised, double-blinded, placebo-controlled trial. Lancet 2007, 370, 1560–1567. [Google Scholar] [CrossRef]

- Galaffu, N.; Bortlik, K.; MichelIn, M. An industry perspective on natural food colour stability. In Colour Additives for Foods and Beverages; Scotter, M.J., Ed.; Elsevier: New York, NY, USA, 2015; pp. 91–130. [Google Scholar]

- Chapman, S. Guidelines on Approaches to the Replacement of Tartrazine, Allura Red, Ponceau 4R, Quinoline Yellow, Sunset Yellow and Carmoisine in Food and Beverages; Report No: FMT/21810/1; Guidelines Commissioned by Food Standards Agency in Scotland; Food Standards Agency: Aberdeen, UK, 2011. [Google Scholar]

- Kobylewski, S.; Jacobson, M. Food Dyes. A Rainbow of Risks; Center for Science in the Public Interest: Washington, DC, USA, 2010. [Google Scholar]

- Prival, M.J.; Peiperl, M.D.; Bell, S.J. Determination of combined benzidine in FD&C yellow no. 5 (Tartrazine), using a highly sensitive analytical method. Food Chem. Toxicol. 1993, 10, 751–758. [Google Scholar]

- Ciriminna, R.; Fidalgo, A.; Meneguzzo, F.; Ilharco, L.M.; Pagliaro, M. Lycopene: Emerging Production Methods and Applications of a Valued Carotenoid. ACS Sustain. Chem. Eng. 2016, 4, 643–650. [Google Scholar] [CrossRef]

- Ciriminna, R.; Fidalgo, A.M.; Avellone, G.; Danzì, C.; Timpanaro, G.; Locatelli, M.; Carnaroglio, D.; Meneguzzo, F.; Ilharco, L.M.; Pagliaro, M. Integral Extraction of Opuntia ficus-indica Peel Bioproducts via Microwave-Assisted Hydrodiffusion and Hydrodistillation. ACS Sustain. Chem. Eng. 2019, 7, 7884–7891. [Google Scholar] [CrossRef]

- Chen, X.; Ding, Y.; Forrest, B.; Oh, J.; Boussert, S.M.; Hamann, M.T. Lemon yellow #15 a new highly stable, water soluble food colorant from the peel of Citrus limon. Food Chem. 2019, 270, 251–256. [Google Scholar] [PubMed]

- Ciriminna, R.; Fidalgo, A.; Delisi, R.; Ilharco, L.M.; Pagliaro, M. Pectin Production and Global Market. Agro Food Ind. Hi-Tech. 2016, 27, 17–20. [Google Scholar]

- Ciriminna, R.; Fidalgo, A.; Scurria, A.; Sciortino, M.; Lino, C.; Meneguzzo, F.; Ilharco, L.M.; Pagliaro, M. The case for lemon bioeconomy. Adv. Sustain. Syst. 2020, 4, 2000006. [Google Scholar] [CrossRef]

- Gentili, B.; Horowitz, R.M. Flavonoids of citrus—VII: Limocitrol and isolimocitrol. Tetrahedron 1964, 20, 2313–2318. [Google Scholar] [CrossRef]

- Ciriminna, R.; Scurria, A.; Danzì, C.; Timpanaro, G.; Di Stefano, V.; Avellone, G.; Pagliaro, M. Fragrant bioethanol: A valued bioproduct from orange juice and essential oil extraction. Sustain. Chem. Pharm. 2018, 9, 42–45. [Google Scholar] [CrossRef]

- Chemat, F.; Vian, M.; Cravotto, G. Green extraction of natural products: Concept and principles. Int. J. Mol. Sci. 2012, 13, 8615–8627. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Girones-Vilaplana, A.; Moreno, D.A.; García-Viguera, C. Phytochemistry and biological activity of Spanish Citrus fruits. Food Funct. 2014, 5, 764–772. [Google Scholar] [CrossRef] [PubMed]

- Nuzzo, D.; Cristaldi, L.; Sciortino, M.; Albanese, L.; Scurria, A.; Zabini, F.; Lino, C.; Pagliaro, M.; Meneguzzo, F.; Di Carlo, M.; et al. Exceptional antioxidant, non-cytotoxic activity of integral lemon pectin from hydrodynamic cavitation. ChemistrySelect 2020, 5, 5066–5071. [Google Scholar] [CrossRef]

- Albanese, L.; Ciriminna, R.; Meneguzzo, F.; Pagliaro, M. Energy efficient inactivation of Saccharomyces cerevisiae via advanced hydrodynamic cavitation. Energy Sci. Eng. 2015, 3, 221–238. [Google Scholar] [CrossRef]

- Olas, B.; Urbańska, K.; Bryś, M. Selected food colourants with antiplatelet activity as promising compounds for the prophylaxis and treatment of thrombosis. Food Chem. Toxicol. 2020, 141, 111437. [Google Scholar] [CrossRef] [PubMed]

- Pagliaro, M.; Meneguzzo, F. Distributed Generation from Renewable Energy Sources: Ending Energy Poverty across the World. Energy Technol. 2020, 8, 2000126. [Google Scholar] [CrossRef]

- Binard, P. Global Citrus Outlook. In Proceedings of the CGA Citrus Summit, Port Elizabeth, South Africa, 12–14 March 2019. [Google Scholar]

- Wrolstad, R.E.; Culver, C.A. Alternatives to Those Artificial FD&C Food Colorants. Ann. Rev. Food Sci. Technol. 2012, 3, 59–77. [Google Scholar]

- Dutch Company PeelPioneers. Producing Orange Oil from Waste Orange Peels. Available online: https://peelpioneers.nl (accessed on 26 September 2020).

- He, J.-Z.; Shao, P.; Liu, J.-H.; Ru, Q.-M. Supercritical Carbon Dioxide Extraction of Flavonoids from Pomelo (Citrus grandis (L.) Osbeck) Peel and Their Antioxidant Activity. Int. J. Mol. Sci. 2012, 13, 13065–13078. [Google Scholar] [CrossRef] [PubMed]

- Hwang, S.-L.; Shih, P.-H.; Yen, G.-C. Neuroprotective Effects of Citrus Flavonoids. J. Agric. Food Chem. 2012, 60, 877–885. [Google Scholar] [CrossRef] [PubMed]

- López, J.; Ángel, S.; Li, Q.; Thompson, I.P. Biorefinery of waste orange peel. Crit. Rev. Biotechnol. 2010, 30, 63–69. [Google Scholar] [CrossRef] [PubMed]

| Year | Amount (Million Tonnes) | Share of Citrus Production |

|---|---|---|

| 1980 | 5.2 | 8% |

| 2016 | 17.5 | 13% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciriminna, R.; Forest, B.; Meneguzzo, F.; Pagliaro, M.; Hamann, M.T. Technical and Economic Feasibility of a Stable Yellow Natural Colorant Production from Waste Lemon Peel. Appl. Sci. 2020, 10, 6812. https://doi.org/10.3390/app10196812

Ciriminna R, Forest B, Meneguzzo F, Pagliaro M, Hamann MT. Technical and Economic Feasibility of a Stable Yellow Natural Colorant Production from Waste Lemon Peel. Applied Sciences. 2020; 10(19):6812. https://doi.org/10.3390/app10196812

Chicago/Turabian StyleCiriminna, Rosaria, Billy Forest, Francesco Meneguzzo, Mario Pagliaro, and Mark T. Hamann. 2020. "Technical and Economic Feasibility of a Stable Yellow Natural Colorant Production from Waste Lemon Peel" Applied Sciences 10, no. 19: 6812. https://doi.org/10.3390/app10196812